3D (three-dimensional) mechanical probe and rope transmission device

A rope transmission and rope technology, which is applied in the field of 3D mechanical probes and rope transmission devices, achieves the effect of large selection range and avoiding mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

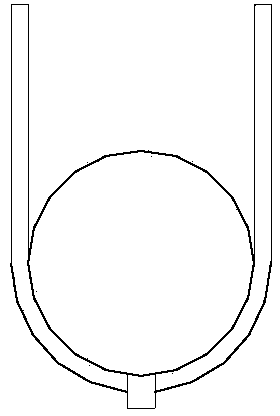

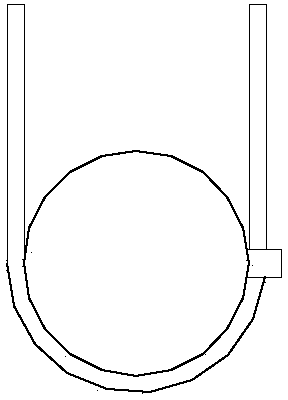

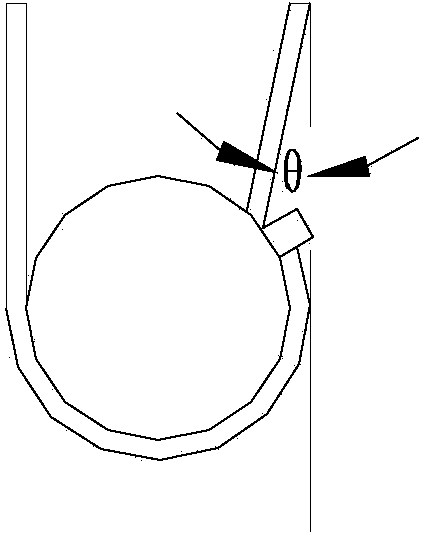

[0052] In the traditional 3D mechanical probe rope transmission device, the two ropes are on the same plane and the ropes are fixed on the same fixed point of the driving shaft, such as Figure 1a and Figure 1b As shown, the driving shaft can maintain linear transmission within the rotation angle of ±90° (clockwise rotation is counted as +, and counterclockwise rotation is counted as -). Taking 90° counterclockwise rotation as an example, it is obvious that the Within the range of rotation angle, the transmission of the driving shaft and the driven shaft is linear transmission. When the rotation angle exceeds 90°, such as Figure 1c As shown, due to the existence of a fixed point, the rope will form an angle θ with the vertical direction, and as the driving shaft continues to rotate, the value of θ will become larger and larger, so the transmission of the driving shaft and the driven shaft is a nonlinear transmission , increasing the difficulty of controlling the rotation ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com