Machine-room-free elevator arrangement structure

A machine room-less elevator and layout structure technology, which is applied to elevators, lifts, transportation and packaging in buildings, can solve problems such as unfavorable maintenance, long traction wire ropes, and complex structures, and achieve simple and tidy layout structures. The effect of shortening the length of the wire rope and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

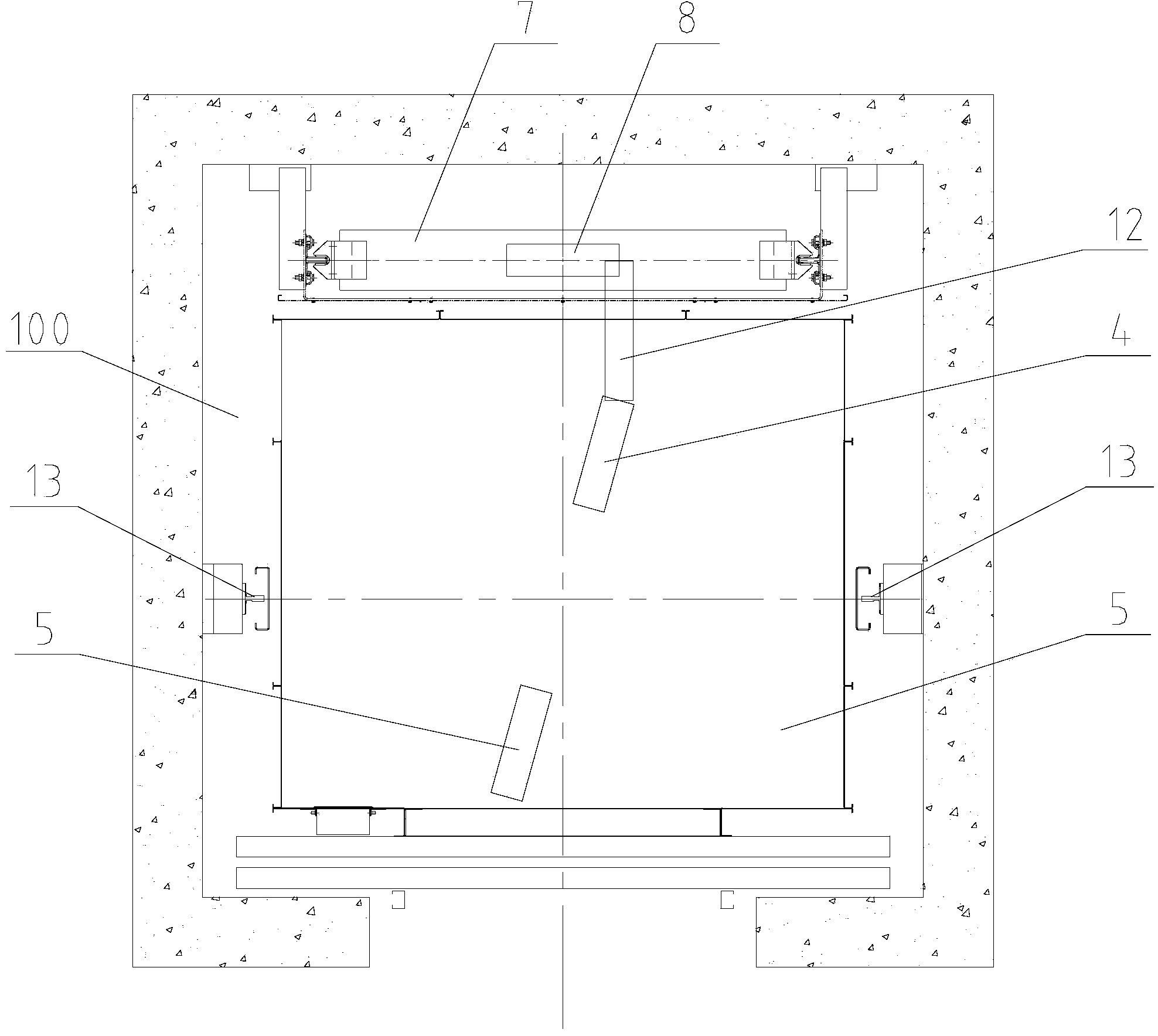

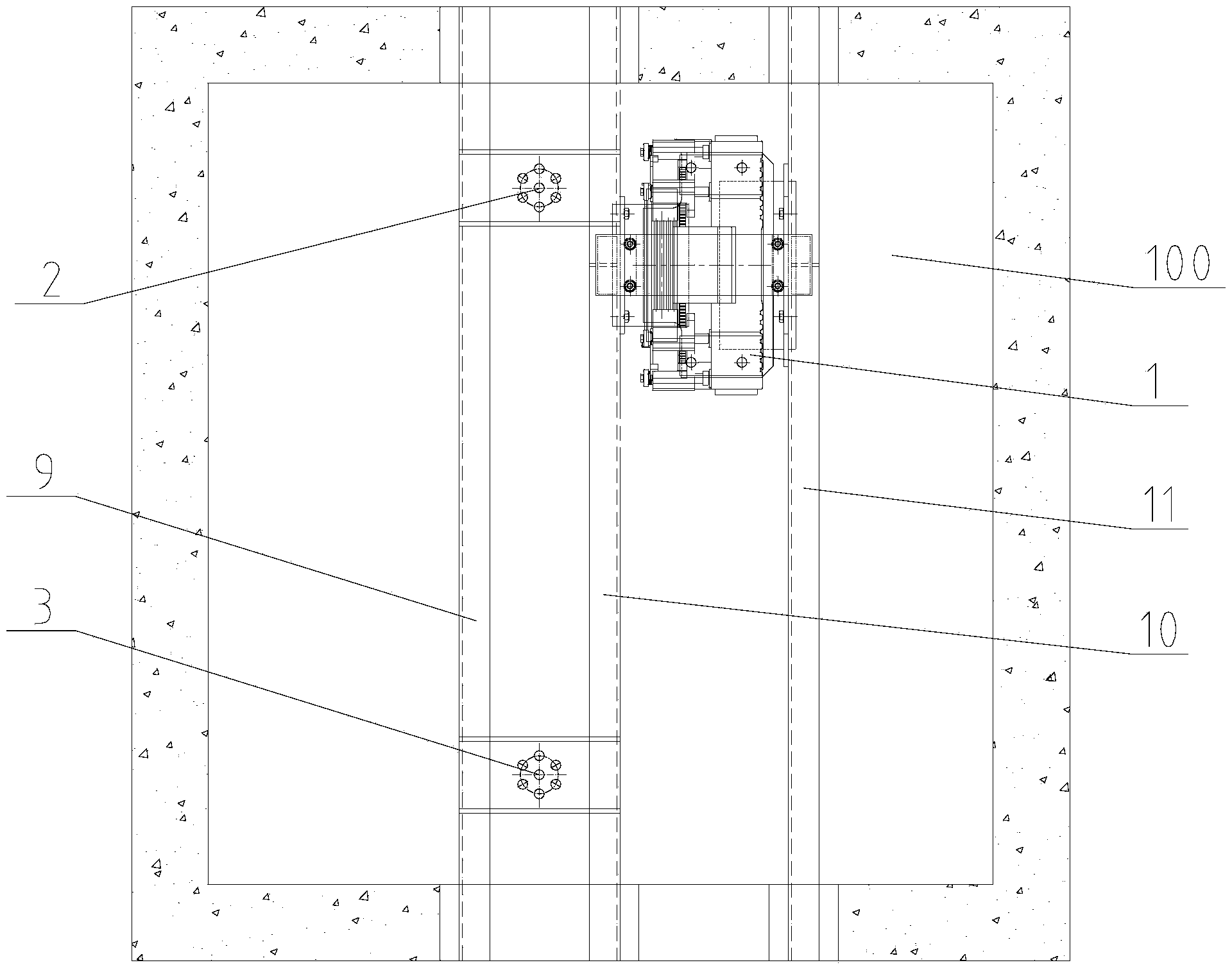

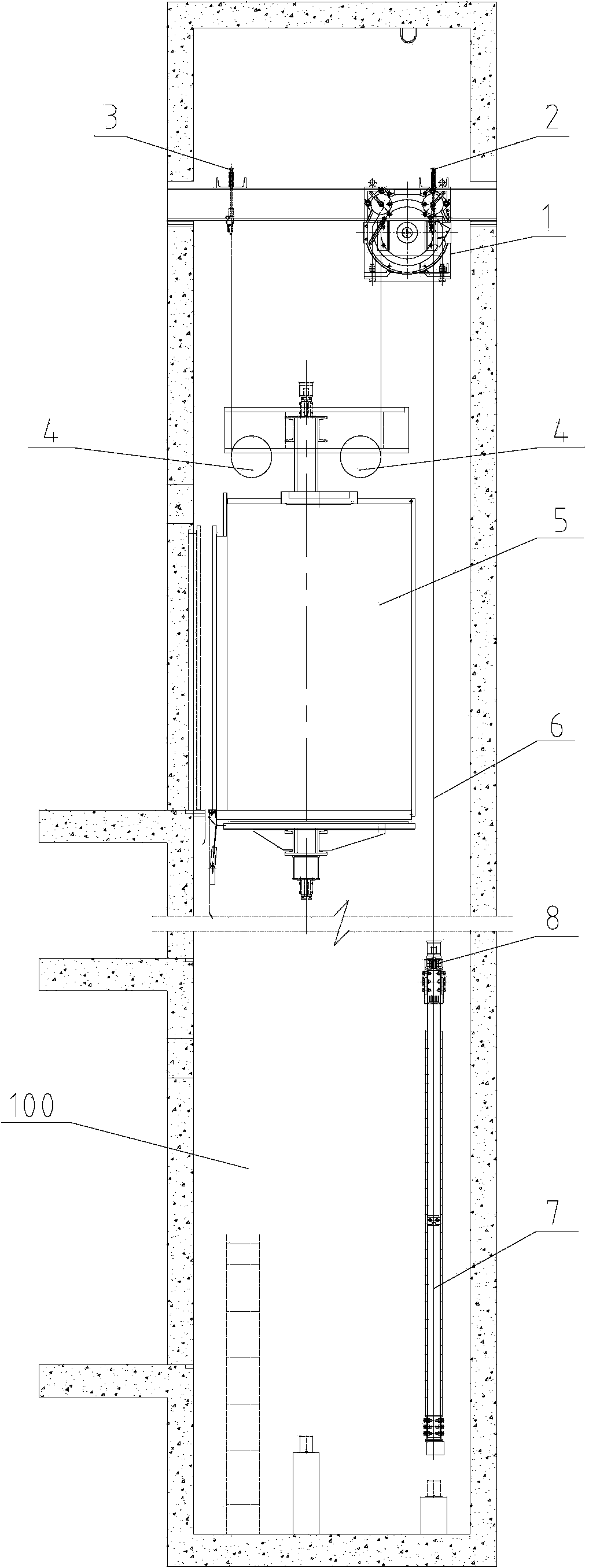

[0015] see Figures 1 to 3 , a machine-room-less elevator arrangement structure, including a car 5 , a counterweight device 7 , a traction machine 1 and a wire rope 6 arranged in a hoistway 100 .

[0016] see figure 1 The counterweight device 7 is positioned at the rear side of the car 5, and the counterweight device 7 is provided with a counterweight reversing sheave 8 parallel to the transverse center line of the hoistway 100. The top of the car 5 is provided with two car reversing sheaves 4 along the longitudinal direction of the hoistway 100 from front to back. Wherein, the two car anti-sheave pulleys 4 are respectively located on both sides of the longitudinal center line of the car 5, and both deflect the same angle to the right side of the car 5, and after the deflection, the two car anti-sheave pulleys 4 are located on the same strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com