Slitting dual-pressure roll and winding method thereof

A technology of double pressure rollers and pressure rollers, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of winding wrinkles and achieve the effect of reducing the amount of involvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

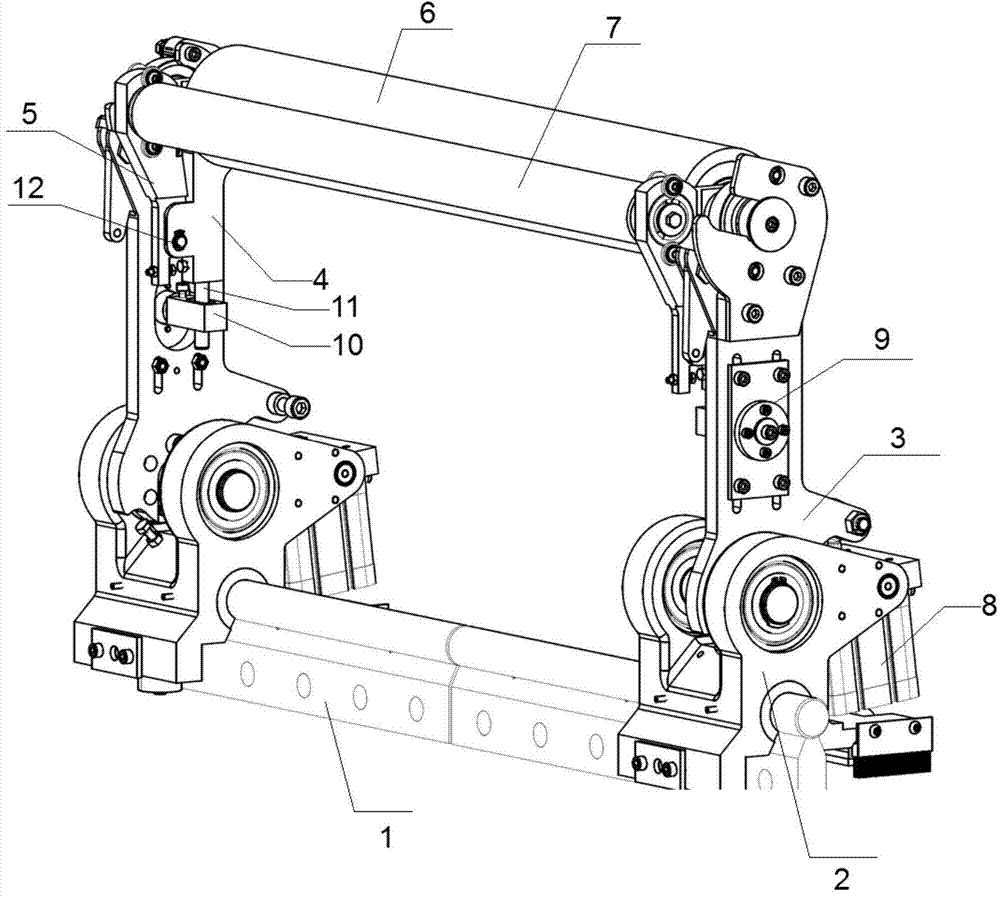

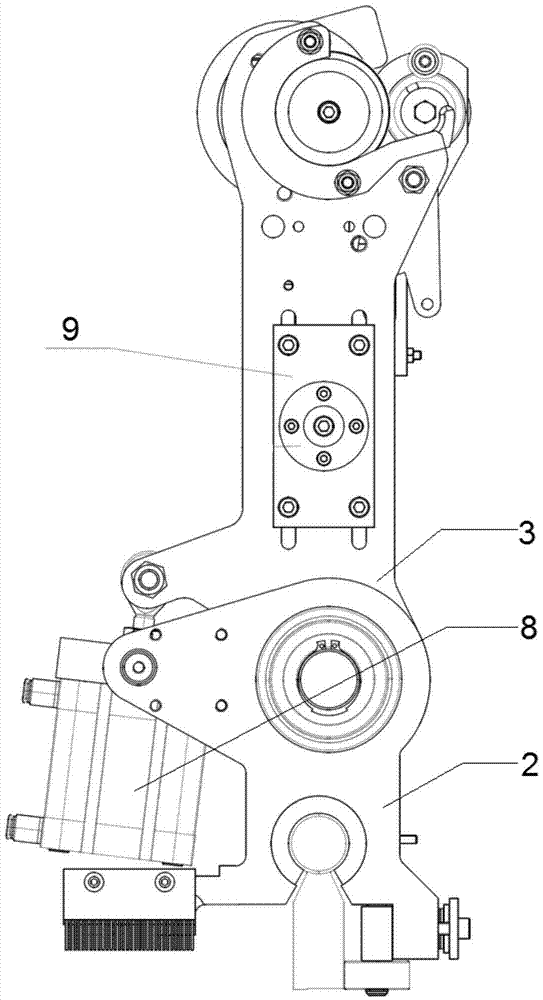

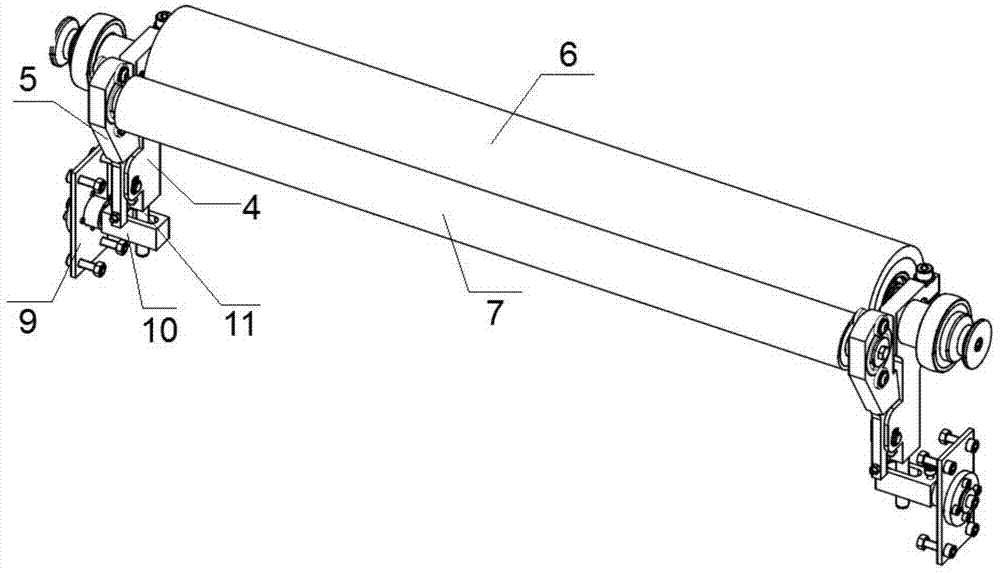

[0026] see figure 1 , a slitting double pressure roller, including a base 1, a support 2, a swing arm 3, a clamping arm 4, a rotating arm 5, a first pressure roller 6 and a second pressure roller 7, and the support 2 is fixedly installed on the base 1 Above, one end of the swing arm 3 is hinged on the support 2, the clamping arm 4 is connected with the swing arm 3, the rotating arm 5 is connected with the clamping arm 4, the first pressure roller 6 is rotatably installed on the clamping arm 4, the second Two pressing rollers 7 are rotatably mounted on the rotating arm 5 , and the diameter of the second pressing roller 7 is smaller than that of the first pressing roller 6 .

[0027] It also includes a drive mechanism that drives the swing arm 3 to rotate around the support 2. The drive mechanism is a cylinder 8, the cylinder seat of the cylinder 8 is fixed on the support 2, and the piston rod of the cylinder 8 is hinged to the swing arm 3. The swing arm 3 is driven to swing by...

Embodiment 2

[0032] A kind of winding method of above-mentioned slitting double pressure roller, comprises the steps:

[0033] 1) The film is drawn out from the lower end of the slitting traction roll 13, and wound from the lower end to the bottom of the first pressure roll 6 with a larger diameter;

[0034] 2) The film wound to the bottom of the first press roller 6 is drawn out from the upper end of the first press roller 6, and wound from the upper end to the upper part of the second press roller 7 with a smaller diameter;

[0035] The film wound on the upper part of the second pressing roller 7 is drawn out from the lower end of the second pressing roller 7 and wound onto the finished film roll 14 from the lower end.

[0036] After adopting the above scheme,

[0037] 1. Increase the path between film traction transition and winding, and shorten the gap between rollers;

[0038] 2. In terms of structure, the wrap angle between the film and the transition roller is increased;

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com