Method and apparatus for continuous casting of metals

A continuous casting and metal technology, applied in the field of continuous casting of metals and its devices, can solve problems such as segregation of molten metal, large molten metal, increased flow rate of molten metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

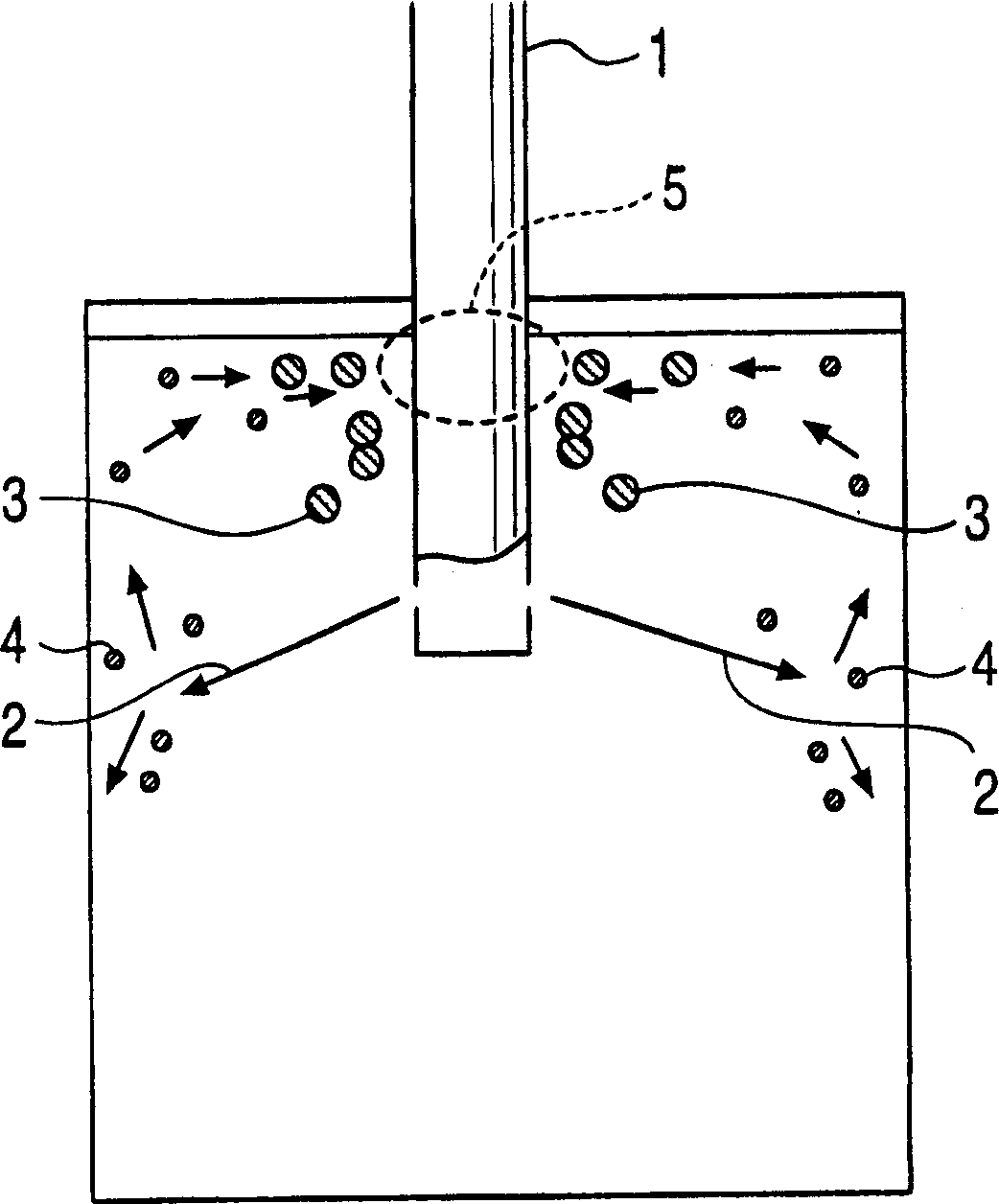

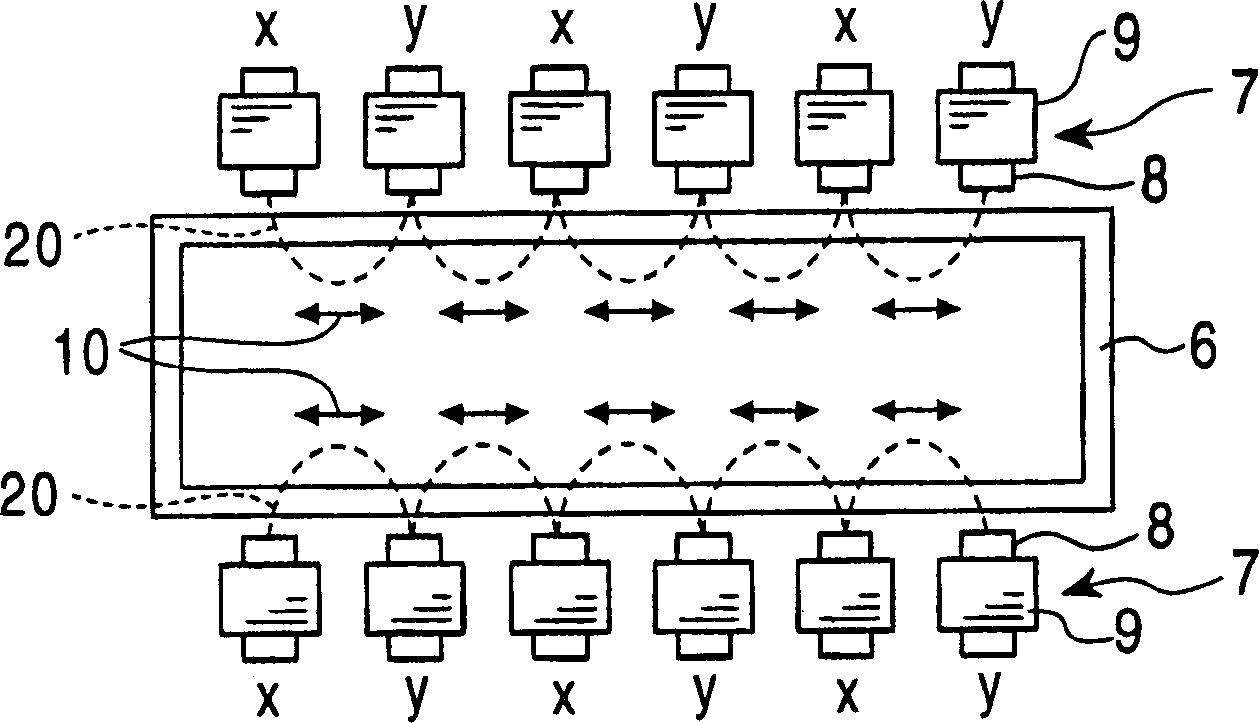

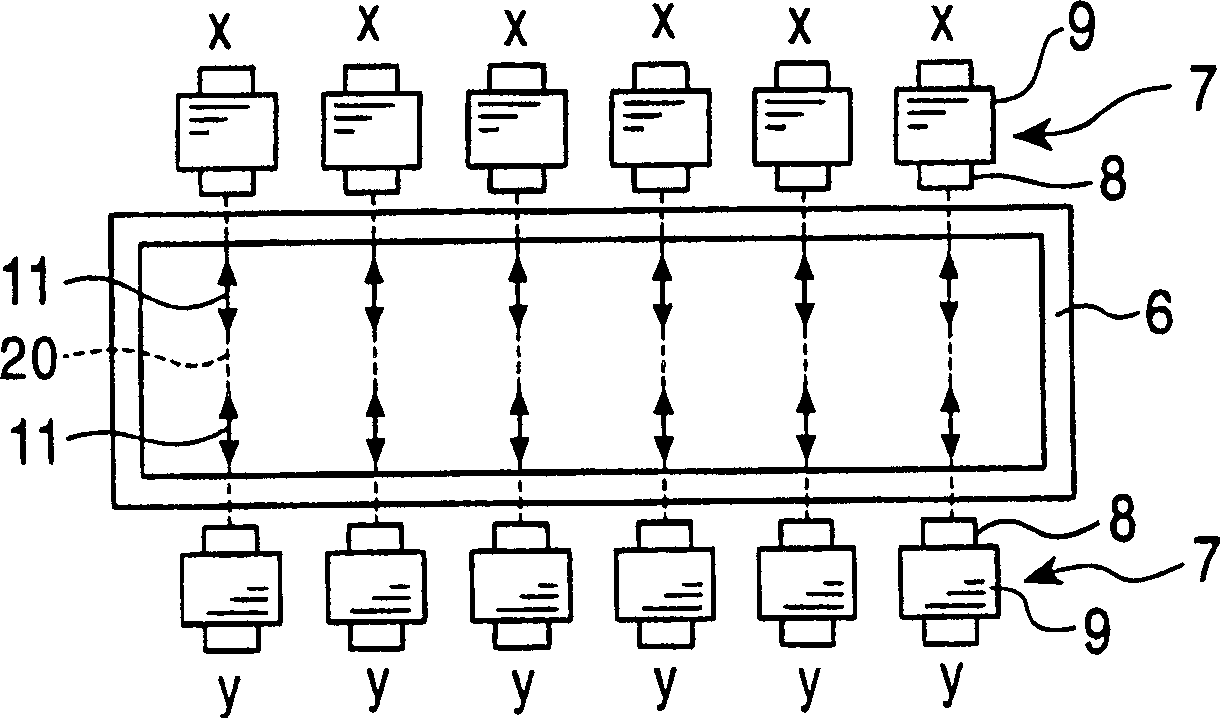

[0056] Through the continuous casting machine, using the dipping nozzle, at the pouring speed of 4-5t / min, about 300t of ultra-low carbon aluminum-killed steel smelted by the converter-RH treatment process (the representative chemical composition is shown in Table 1) is poured into the mold When pouring, when casting a continuous casting slab with a width of 1500-1700mm and a thickness of 220mm, the figure 2 , image 3 , Figure 4 In any of the forms, the electromagnet is arranged on the position including the position corresponding to the surface of the molten metal in the mold, and the coils of the electromagnet are passed with three-phase alternating current or single-phase alternating current of various frequencies. Continuous casting experiments were carried out with a moving magnetic field with a maximum flux density of 0.1T, or three-phase, or a non-moving vibrating magnetic field, or no external magnetic field.

[0057] In this experiment, three items of surface seg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com