Preparation method and device of semi-solid slurry

A technology of semi-solid slurry and preparation device, which is applied in the field of semi-solid slurry preparation, aluminum alloy and magnesium alloy semi-solid slurry preparation, and can solve the difficulty of controlling the consistency and stability of slurry quality, the difficulty of precise temperature control, It is easy to be involved in problems such as oxidation inclusions and gas defects, so as to reduce the involvement of oxide scale and air, good protection effect, and easy industrial-scale production control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The semi-solid slurry of A356 alloy (liquidus line 615° C., solidus line 555° C.) is prepared by the present invention. The melt temperature was maintained at 670°C. Choose the mold steel to prepare the crucible, and the wall thickness of the crucible is 1mm. The inner wall of the crucible is coated with 0.05mm corundum coating. Place multiple crucibles in a constant temperature furnace at 100°C to keep warm. Take a crucible out of the constant temperature furnace, place it on a mechanical vibration platform and fix it, and seal the bottom. Nitrogen was blown over the top of the crucible for protection. Slowly pour the A356 alloy melt at 670°C into the crucible. After reaching the specified height, the pouring process ends. Turn on the vibration device, and apply weak horizontal circular vibration to the crucible and the melt in the crucible. During the vibration process, the top of the melt has laminar flow along the horizontal direction, but there is no vertical ...

Embodiment 2

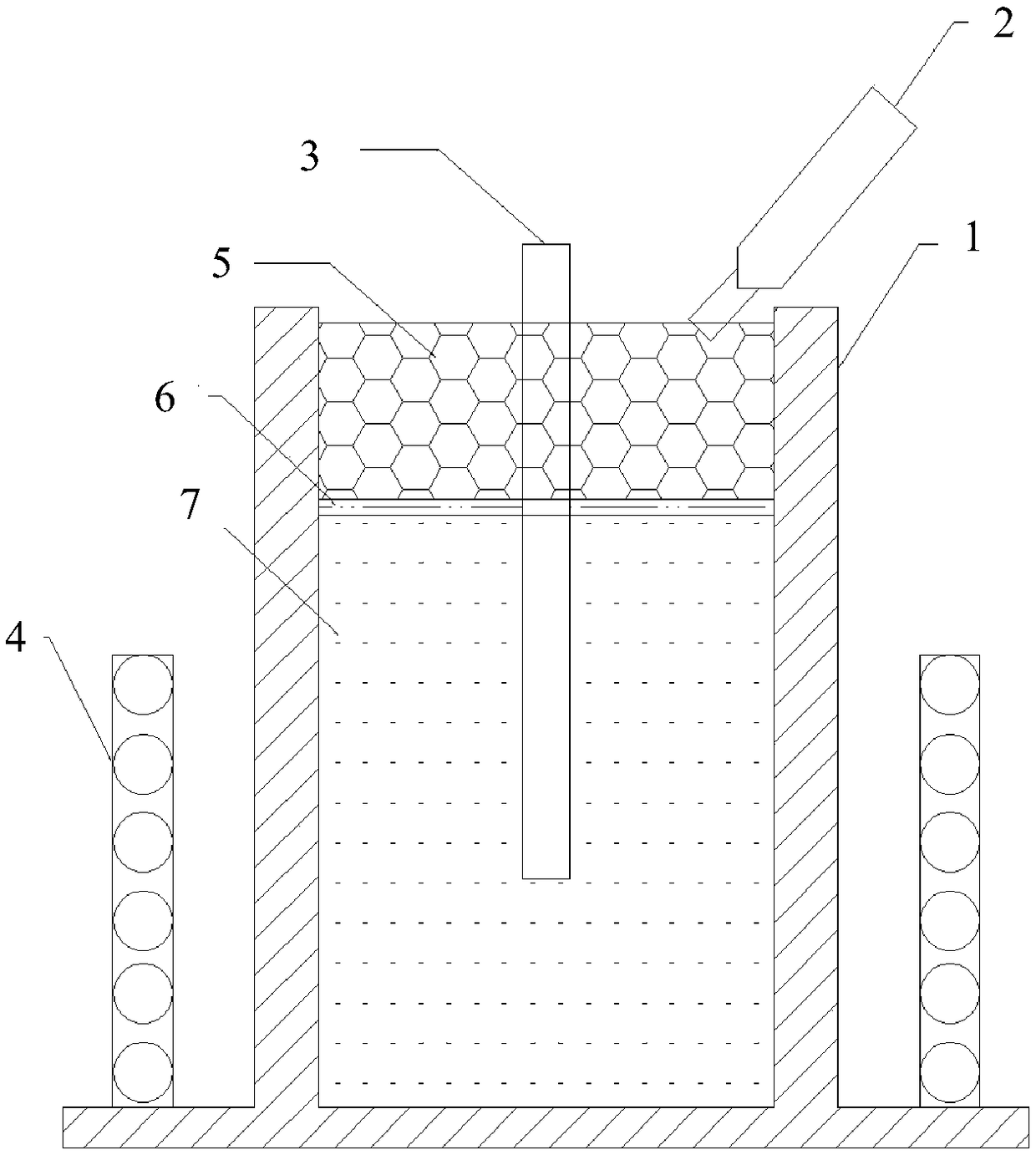

[0031] The invention prepares AZ91 magnesium alloy semi-solid slurry. The melt temperature was maintained at 700°C. A titanium alloy is selected to prepare a crucible, and the wall thickness of the crucible is 10mm. The outer wall of the crucible is coated with 0.1mm silicon carbide coating. Place multiple crucibles in a constant temperature furnace at 400°C to keep warm. Take a crucible out of the constant temperature furnace, place it on the pulping platform and fix it, and seal the bottom. Argon was blown over the top of the crucible for protection. Slowly pour the AZ91 alloy melt at 700°C into the crucible. After reaching the specified height, the pouring process ends. Extend another flow-controllable argon tube vertically into the middle and lower part of the melt, such as figure 1As shown, the melt was subjected to gas disturbance treatment with argon gas. During the aeration process, fine air bubbles are generated on the upper surface of the melt, but there is no ...

Embodiment 3

[0033] The invention prepares semi-solid slurry of 15% SiC particles reinforced A357 alloy composite material. The melt temperature was maintained at 700°C. Choose graphite to prepare the crucible, and the wall thickness of the crucible is 50mm. Multiple crucibles were placed in a constant temperature furnace at 0°C to keep warm. Take a crucible out of the constant temperature furnace, place it in the electromagnetic induction coil and fix it, and seal the bottom, such as figure 1 shown. The composite material melt at 700°C is slowly poured into the crucible, and the pouring process ends when the specified height is reached. Install a vacuum device on the top of the crucible and evacuate it. Start the electromagnetic induction coil to apply stirring to the melt in the lower part of the crucible, and keep the top in a static state. After the electromagnetic stirring was continued for 50 seconds, the temperature of the semi-solid slurry reached 565° C., and the solid fracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com