Patents

Literature

31results about How to "Guaranteed cutting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

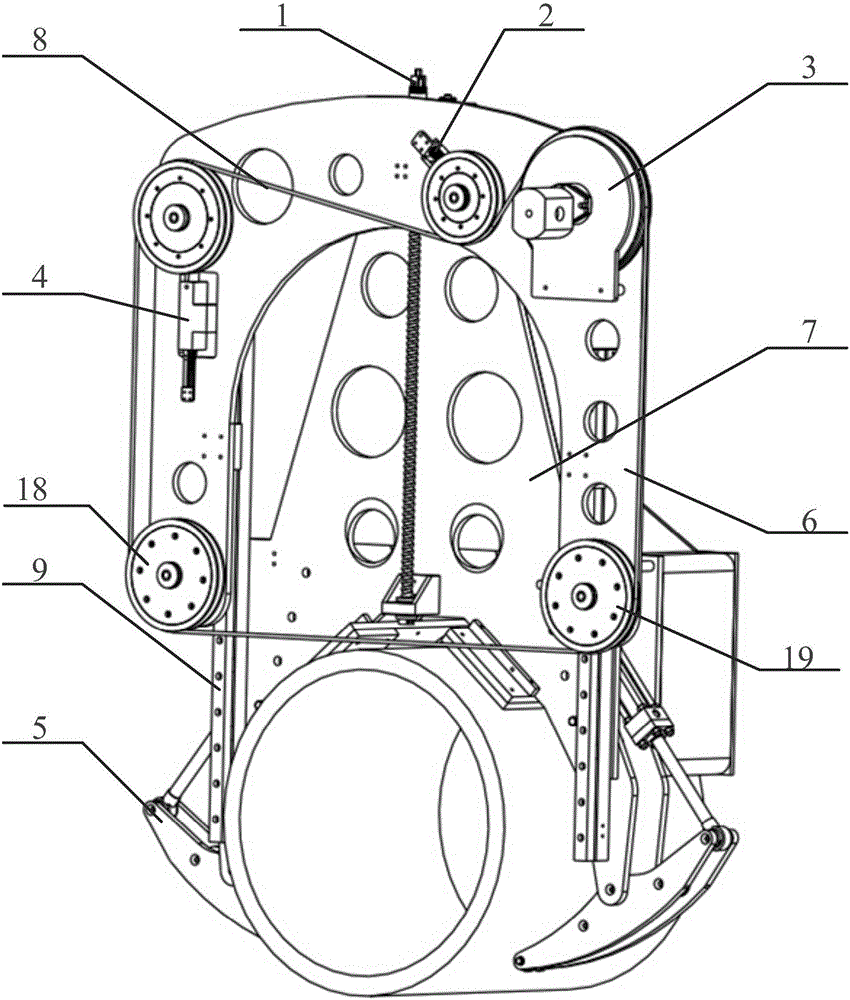

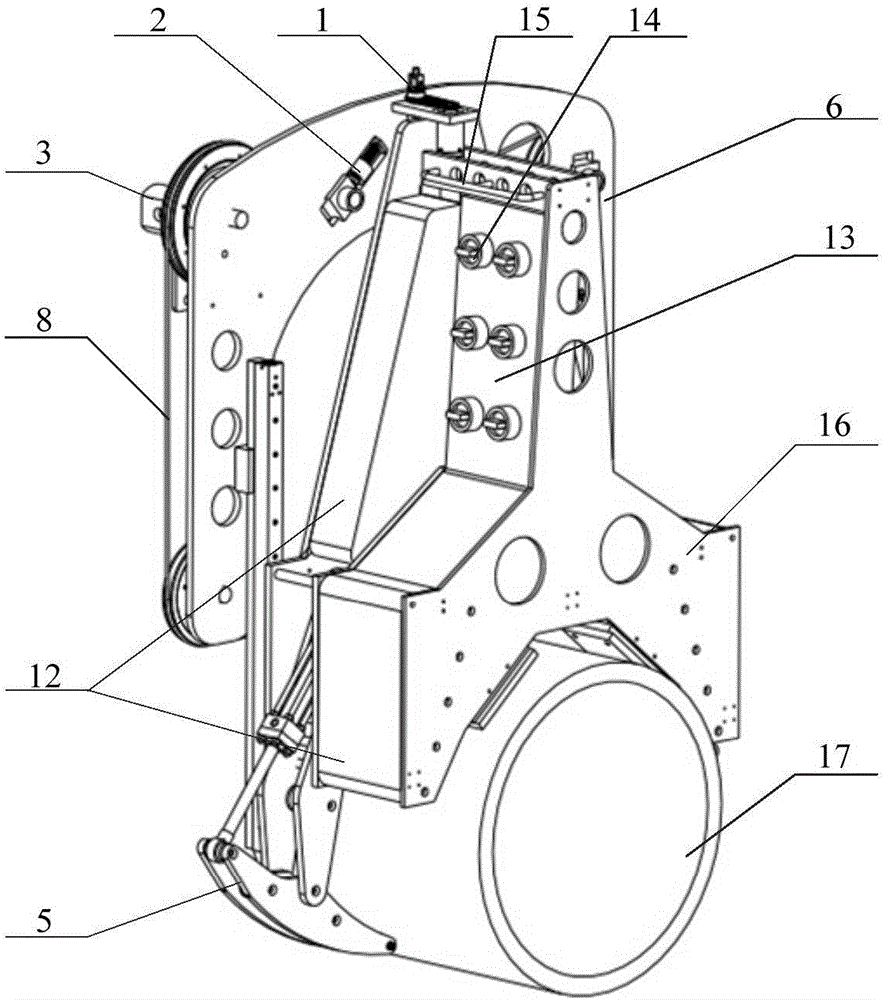

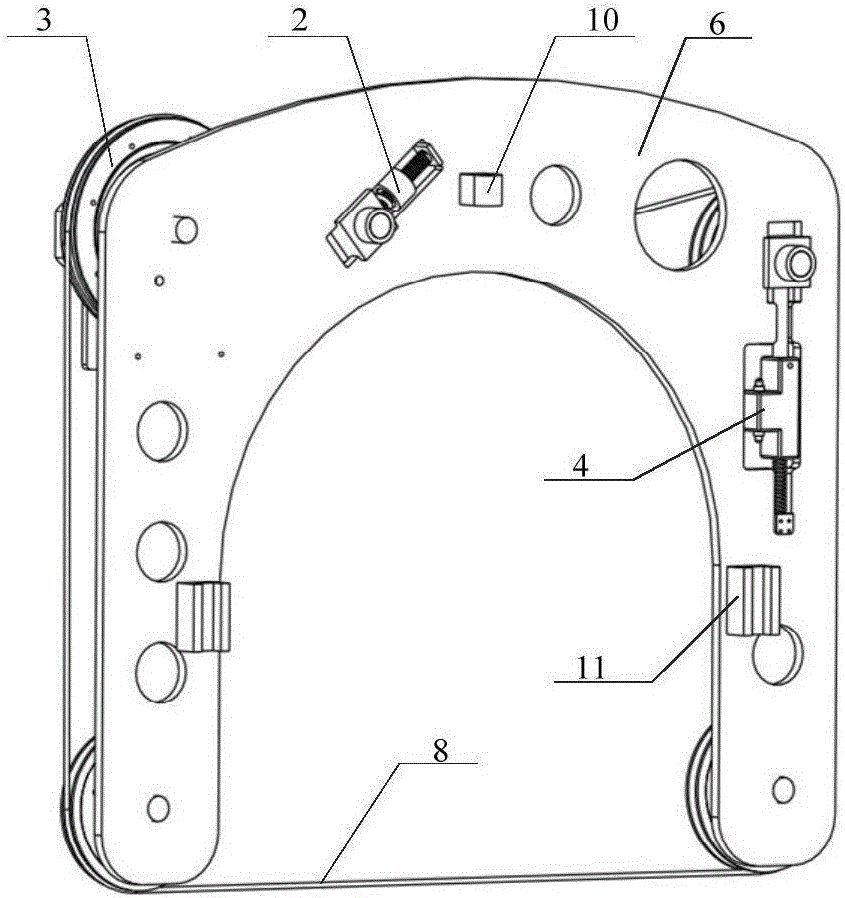

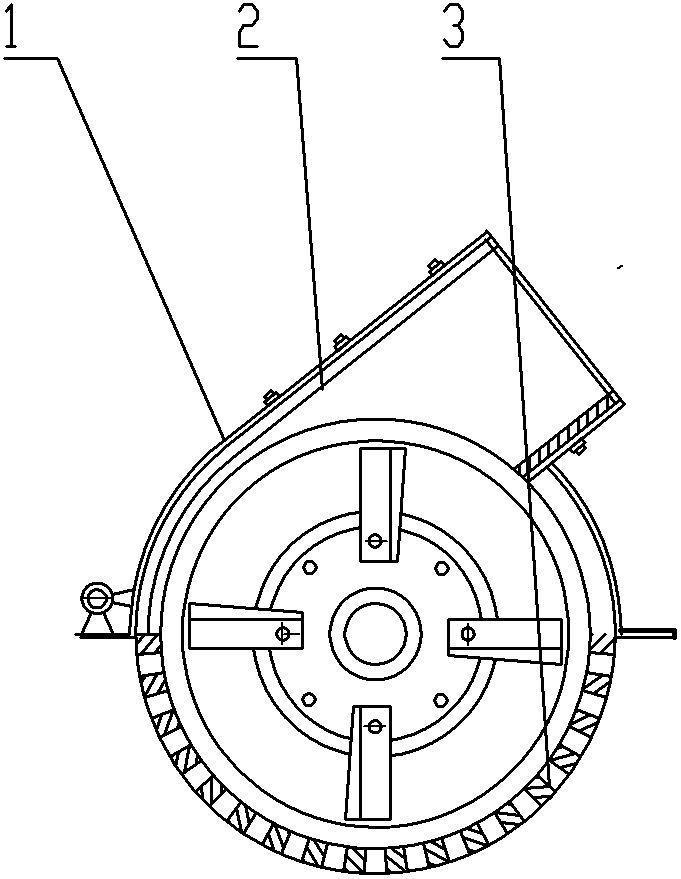

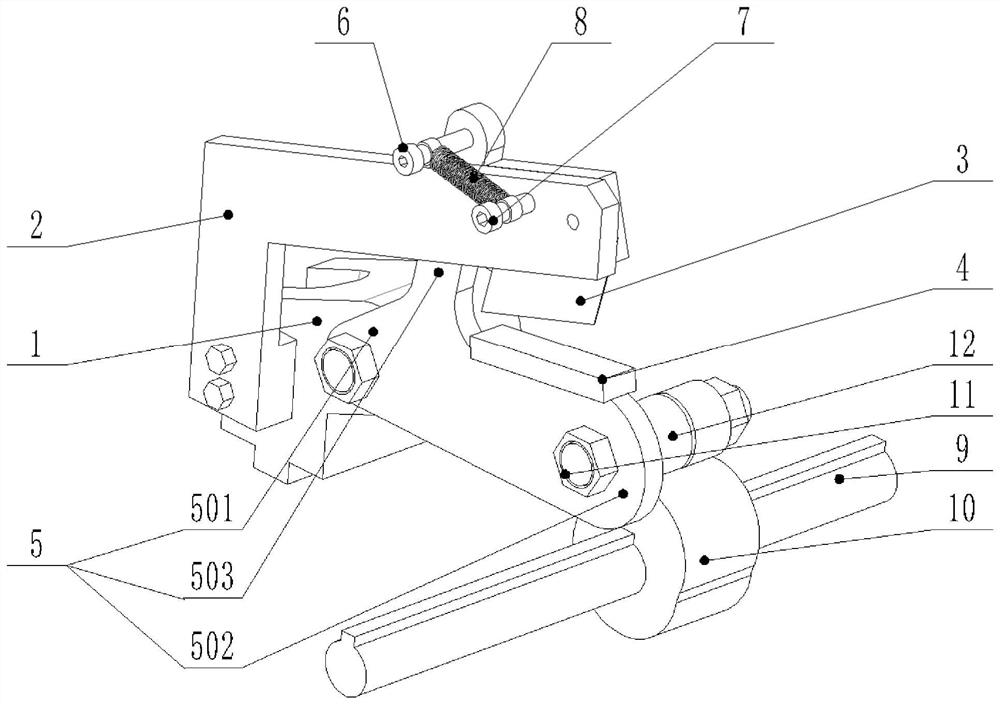

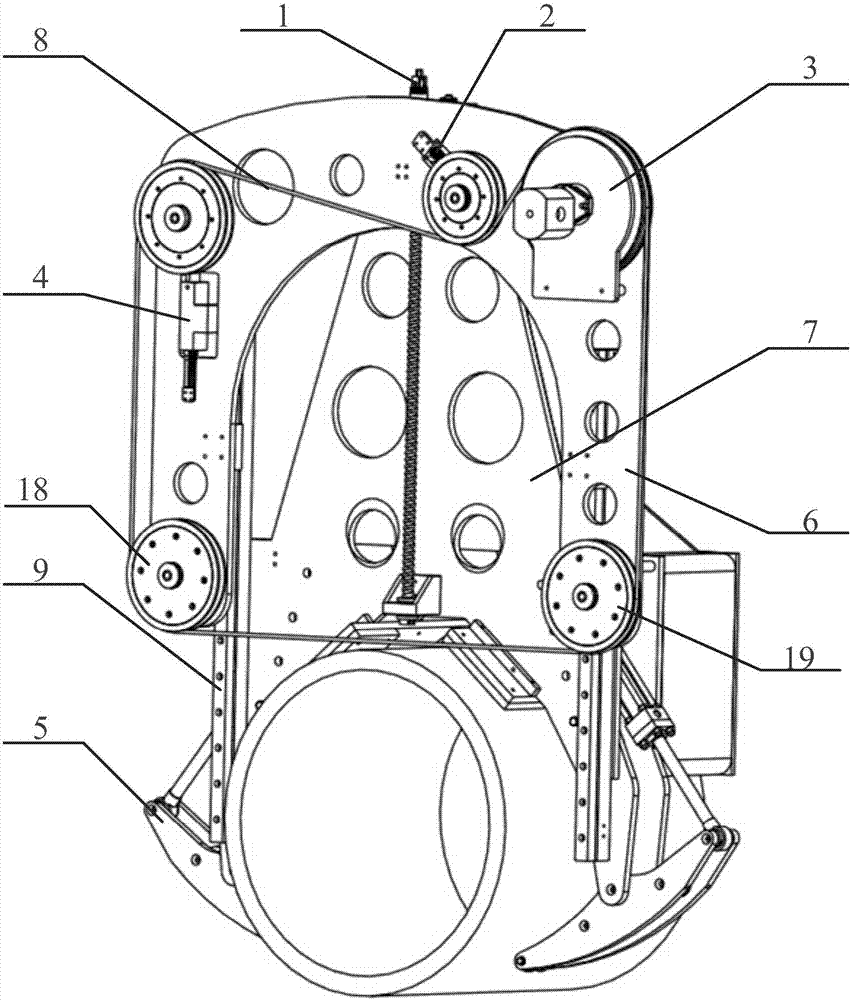

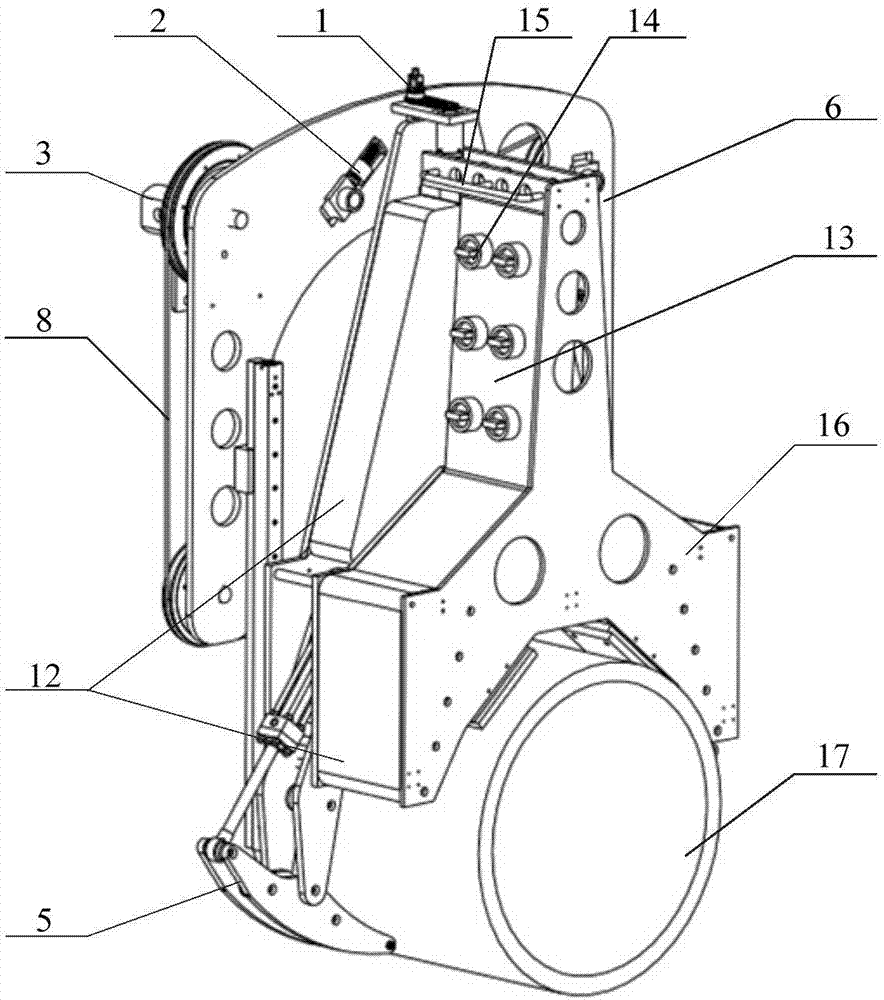

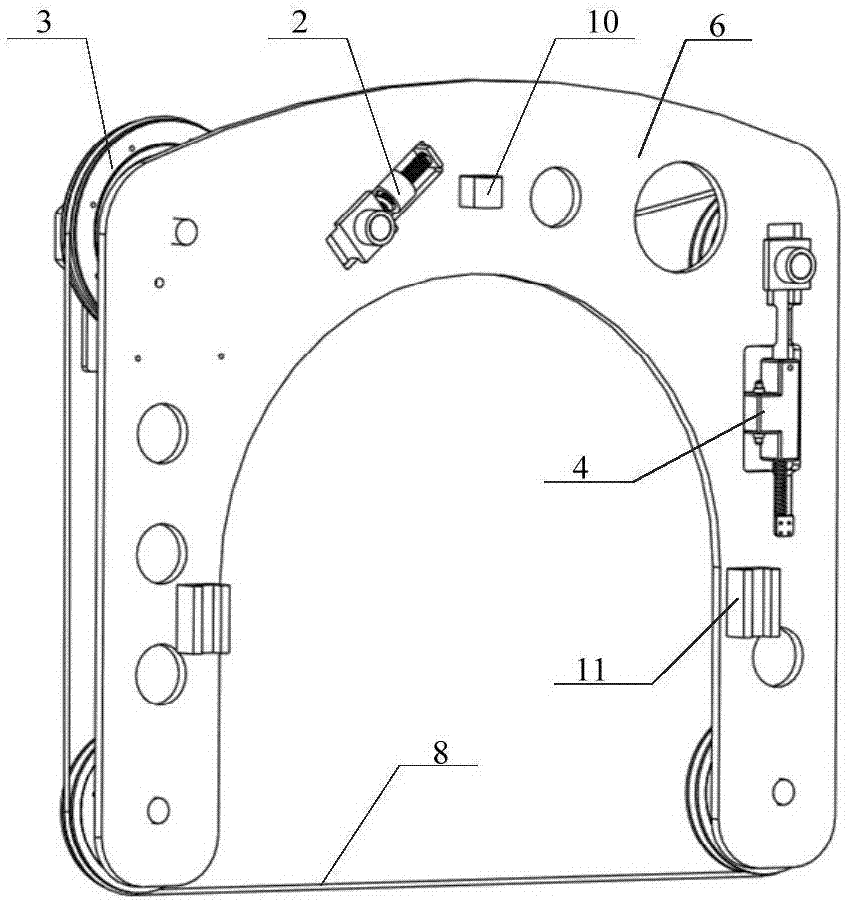

Deepwater diamond wire sawing machine

ActiveCN106141304AConvenient for underwater workGuaranteed lifeMetal sawing devicesMetal sawing accessoriesDiamond wire sawEngineering

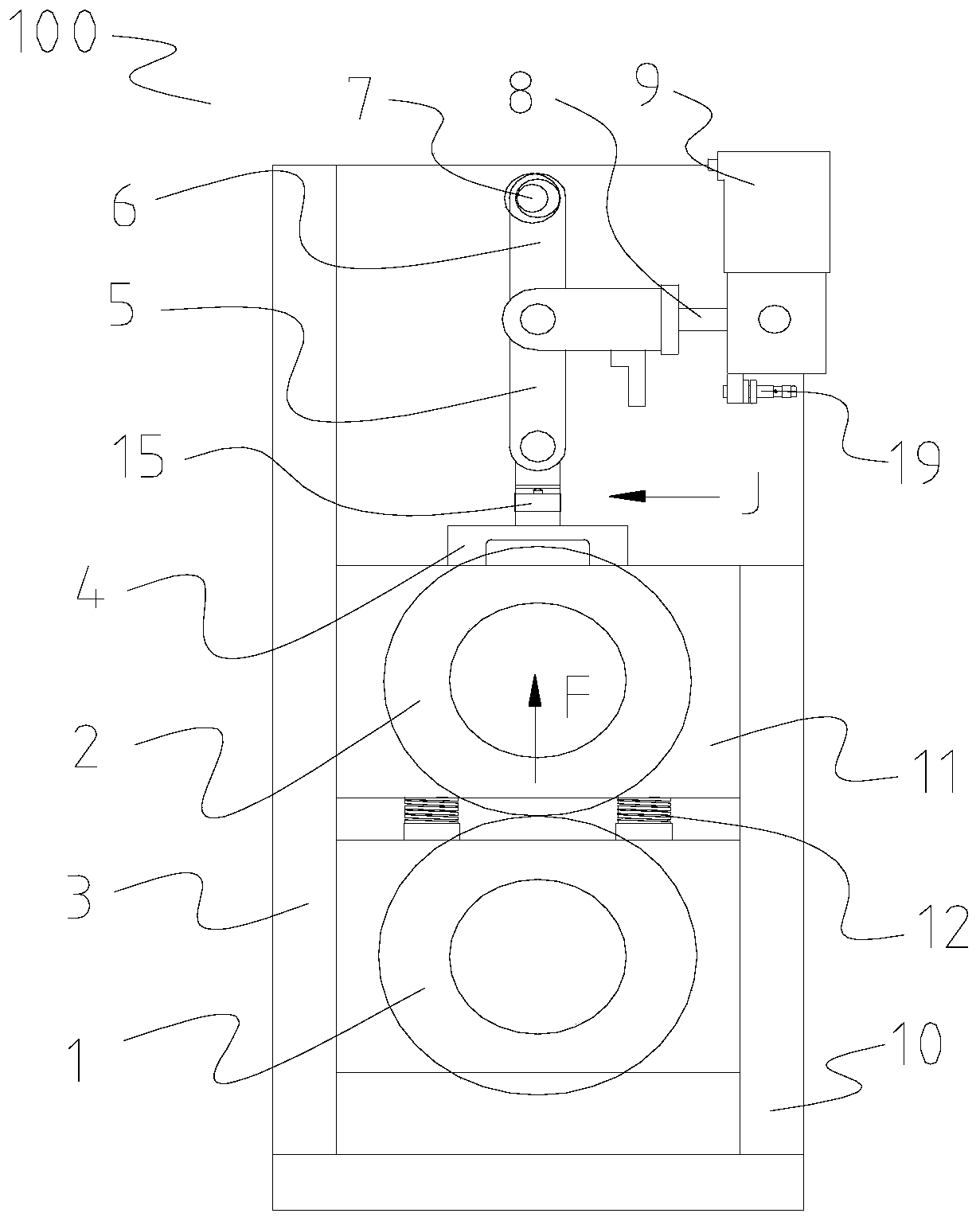

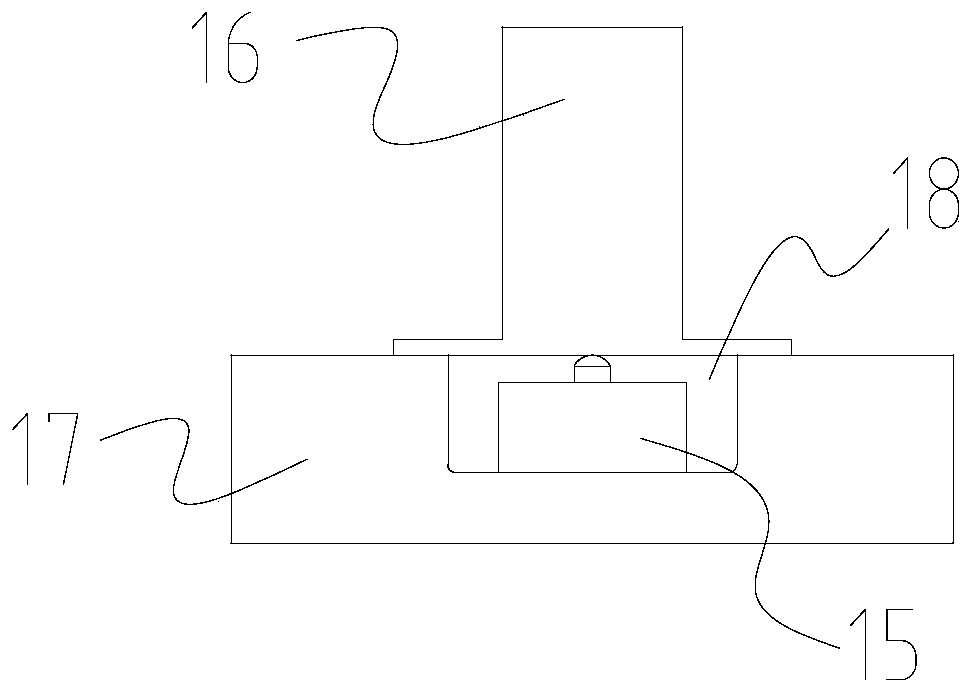

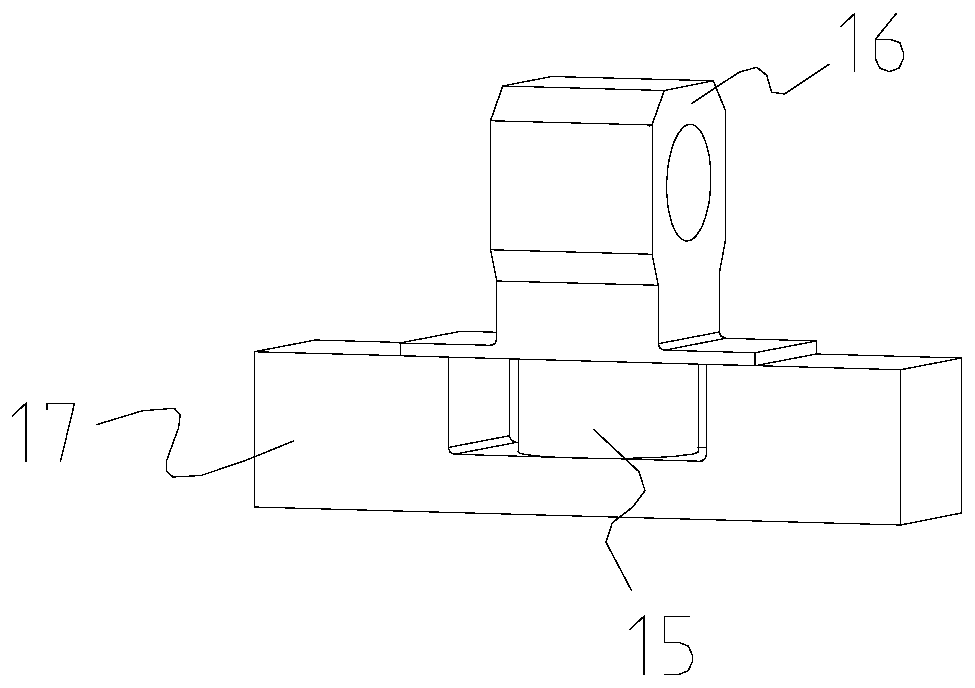

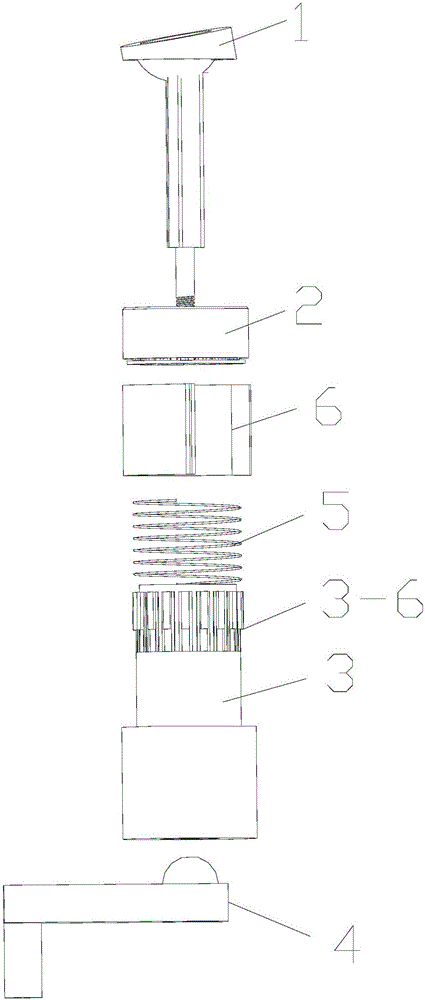

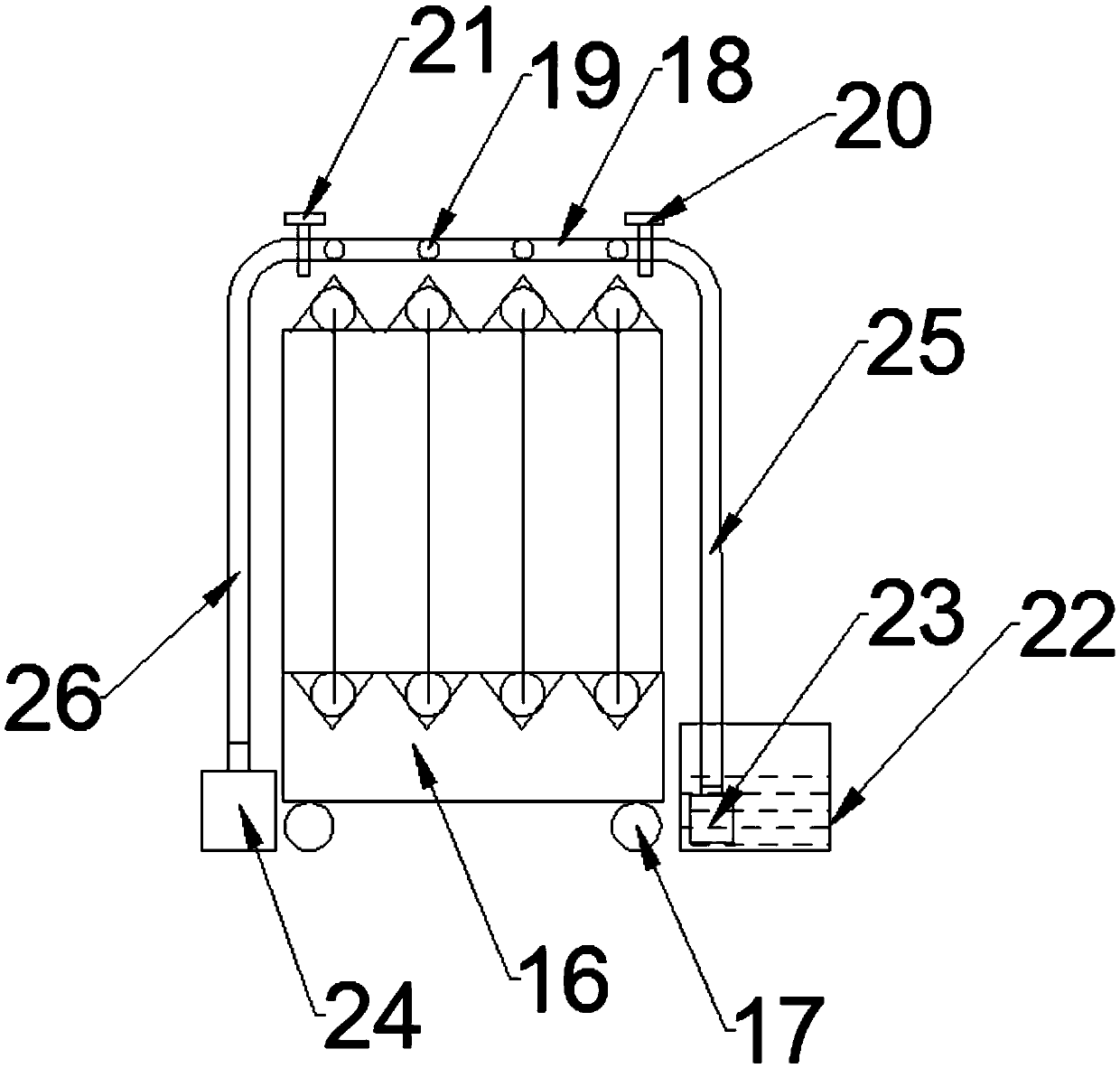

The invention provides a deepwater diamond wire sawing machine which is majorly composed of a cutting drive mechanism, a feeding drive mechanism, a feeding speed regulating mechanism, a string bead wire tensioning mechanism and clamping mechanisms, and used for completing cutting repair of underwater structures. The feeding speed regulating mechanism is adopted for the deepwater diamond wire sawing machine, the feeding speed can be regulated along with the change of tension of a string bead wire in the operating process, and the service life of the string bead wire, the cutting efficiency of the machine and the reliability of cutting operation are effectively guaranteed. The feeding drive mechanism can promote transmission separation of a feeding motor and a lead screw, so that overload protection for the feeding drive mechanism is achieved; and meanwhile, under the condition that the machine does not have power, a handle can be rotated for feeding, and integrally automatic and manual drive feeding is achieved. A strong spring, a nut and a screw are adopted for tensioning of the string bead wire tensioning mechanism, and vibration of the string bead wire in the cutting process can be effectively reduced accordingly. The deepwater diamond wire sawing machine is provided with buoyancy materials and a deepwater valve box and suitable for deepwater environment operation.

Owner:HARBIN ENG UNIV

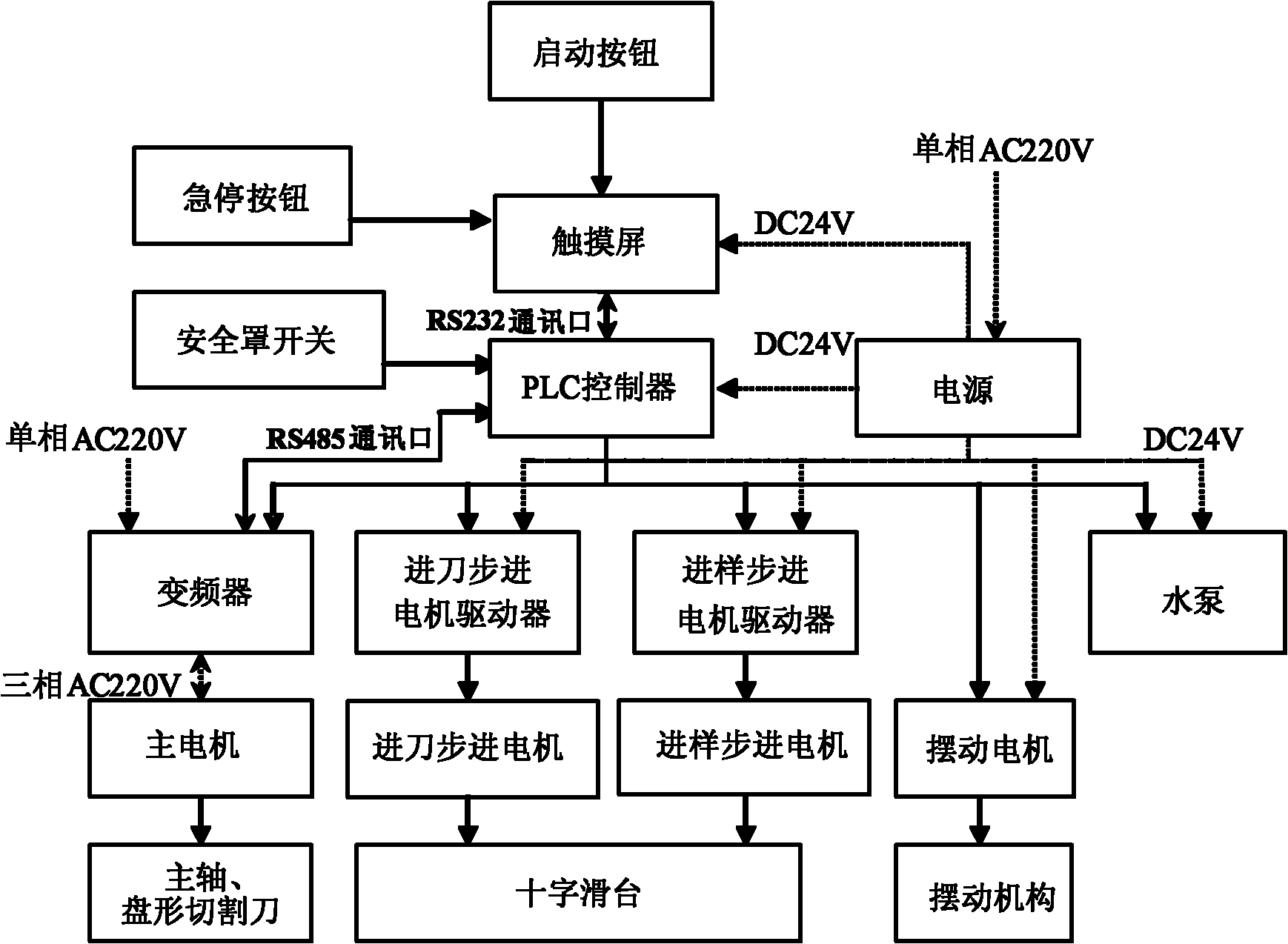

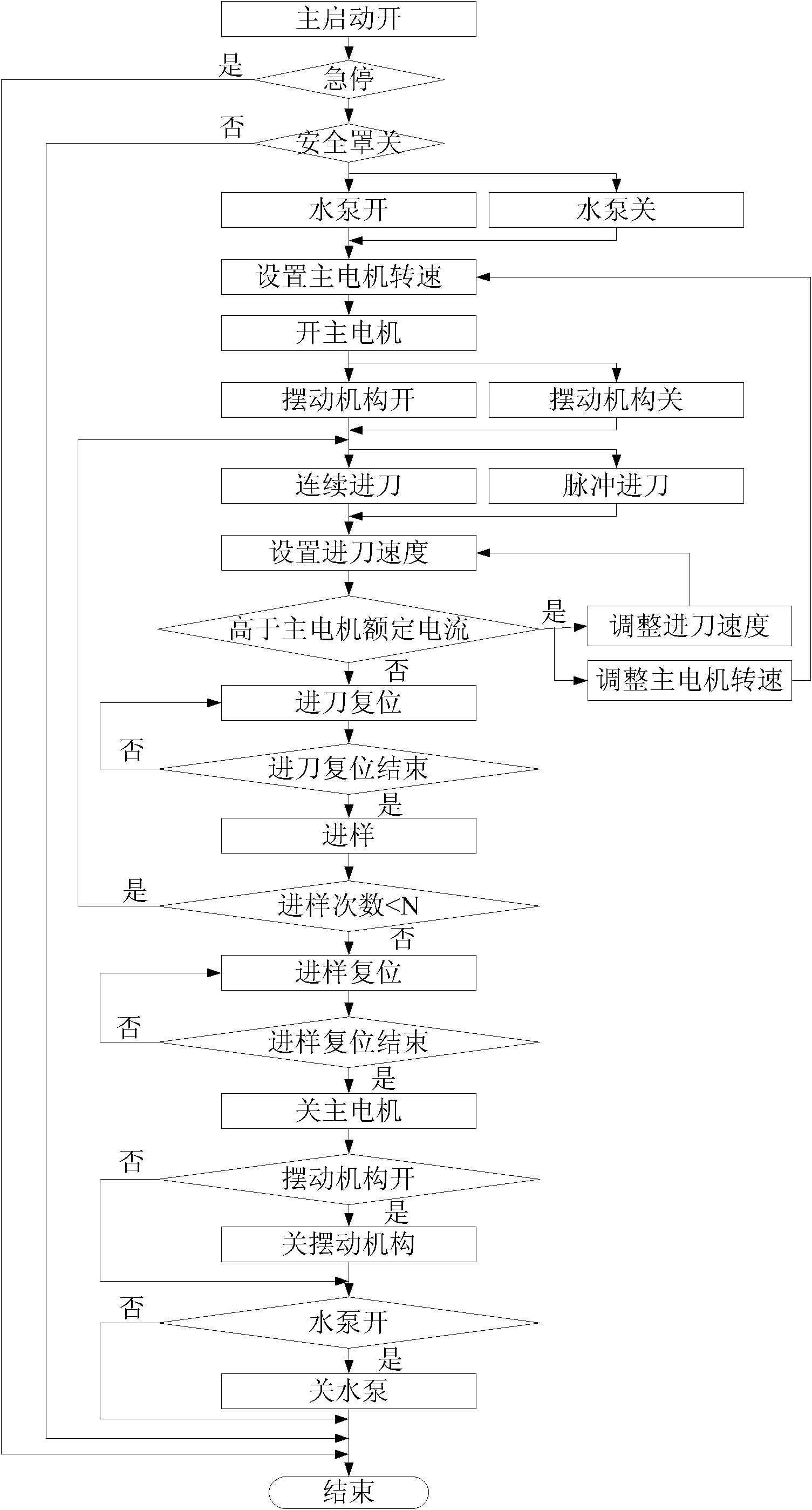

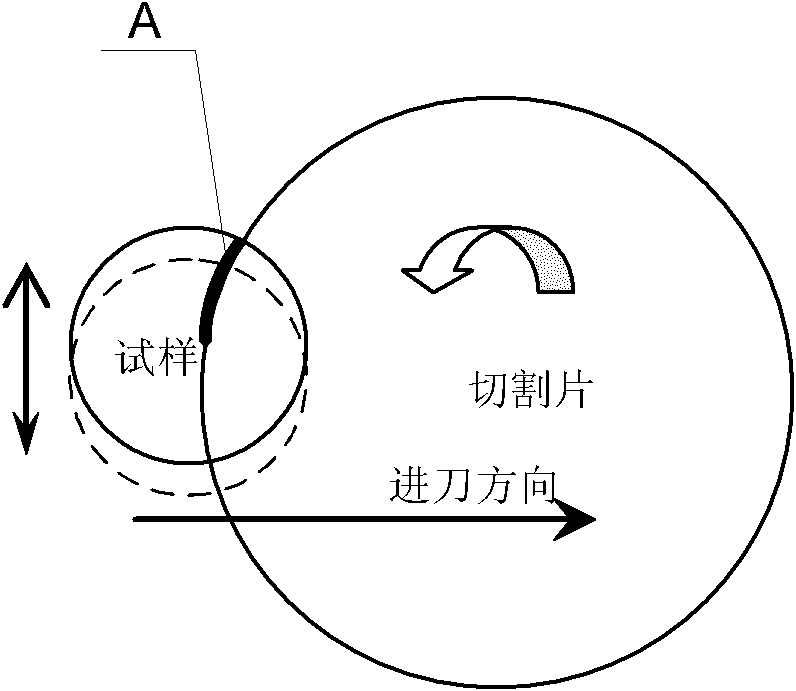

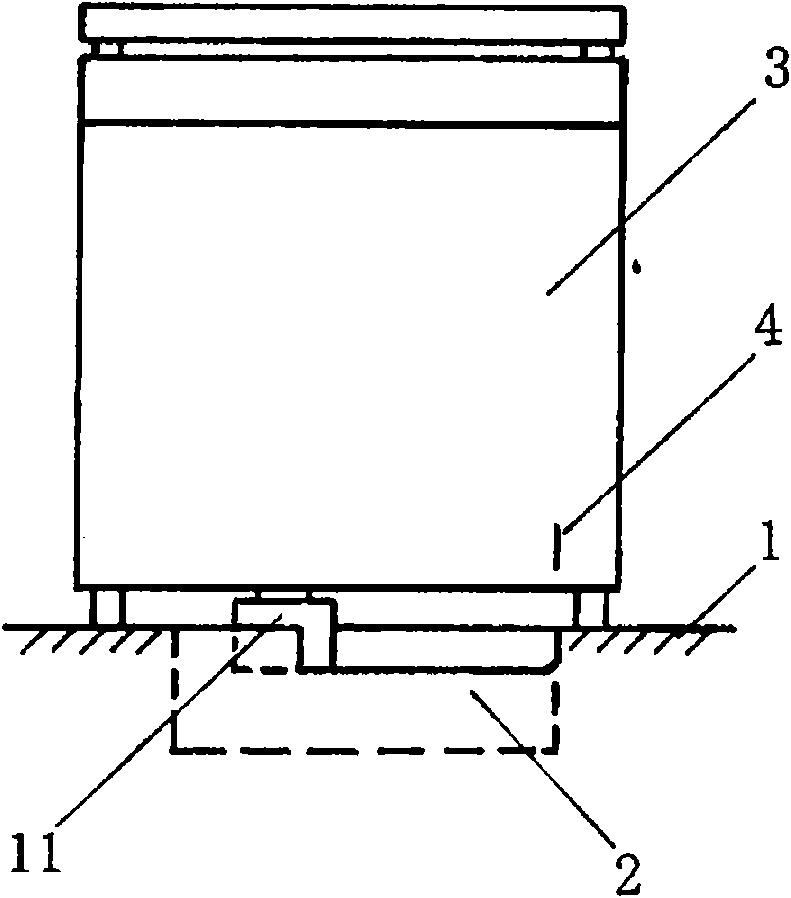

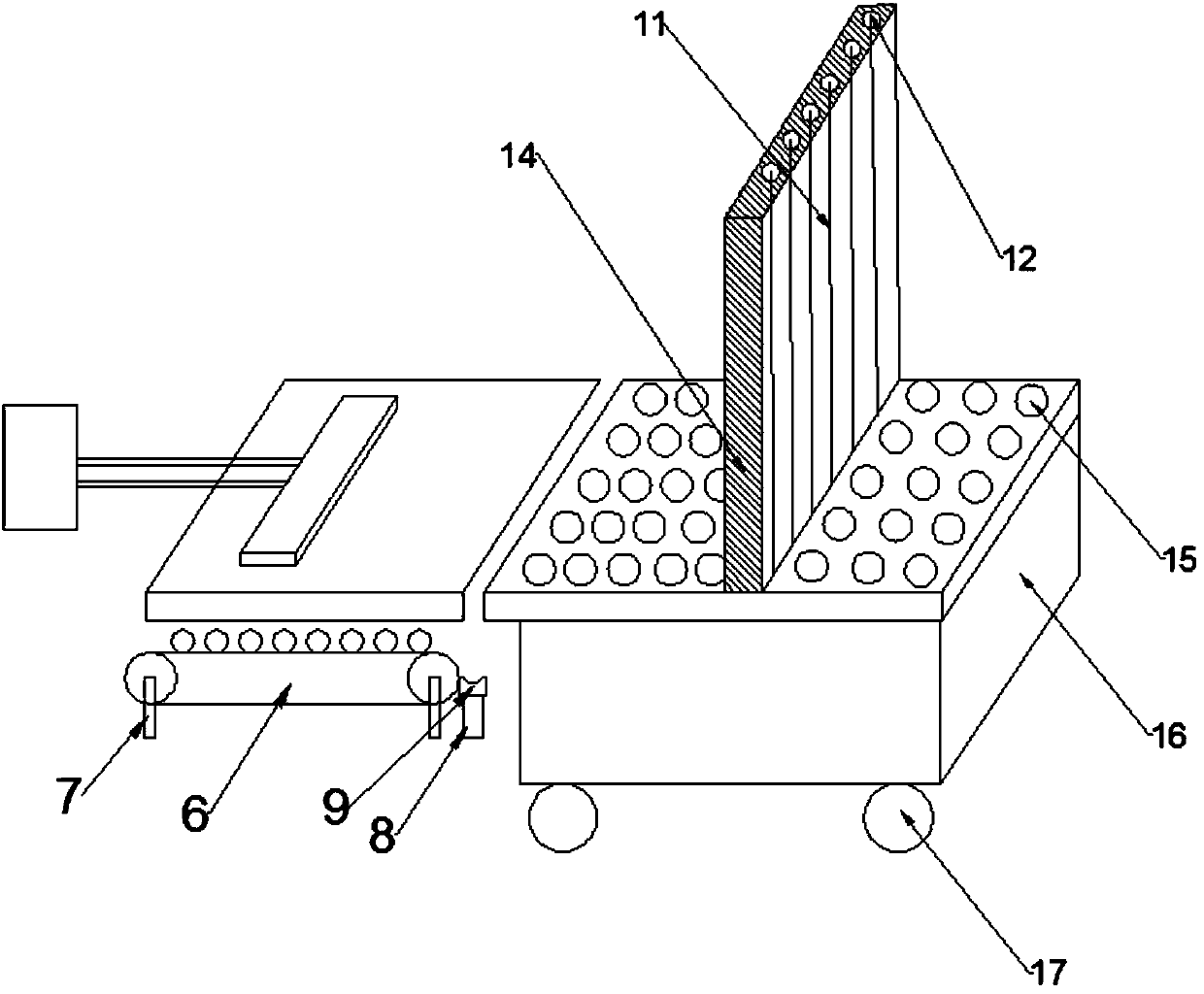

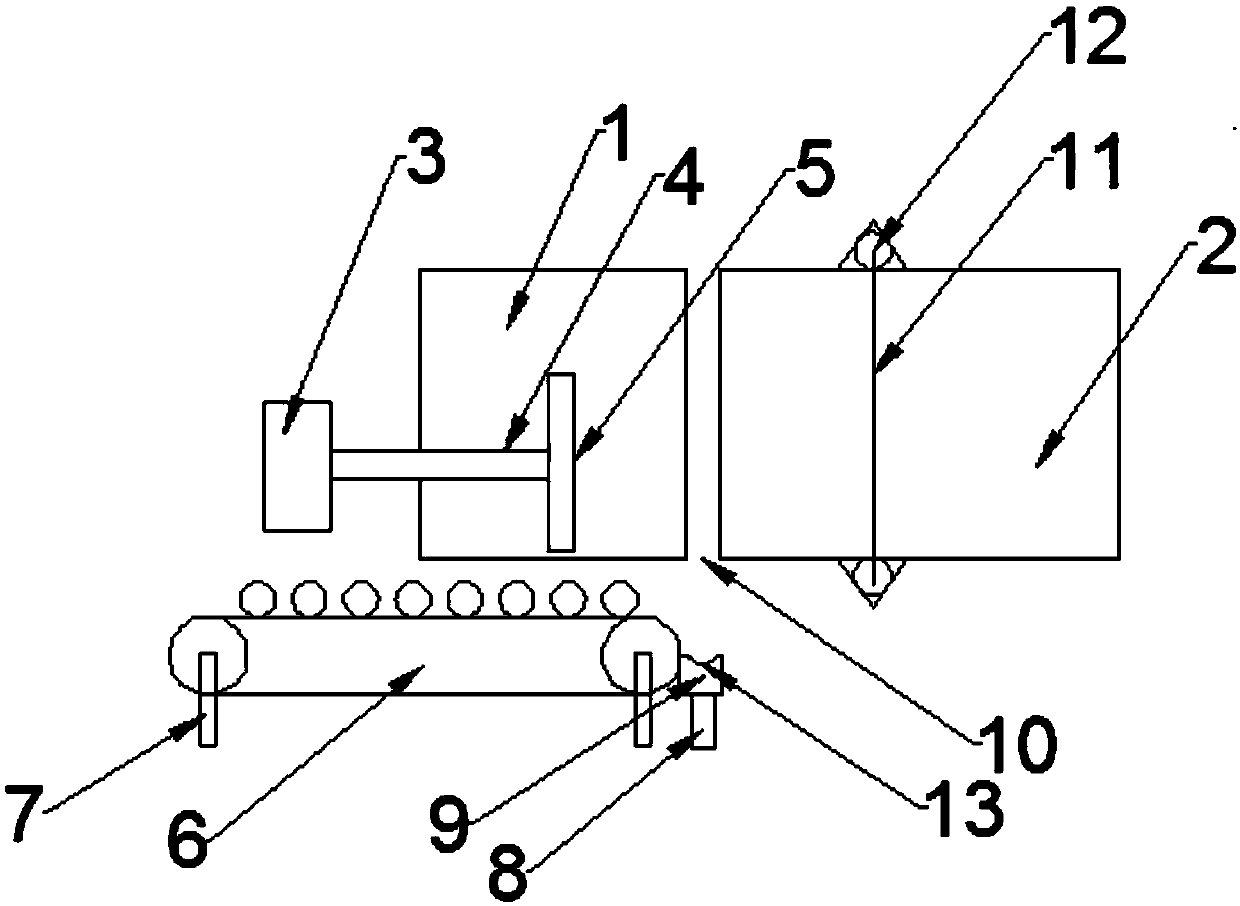

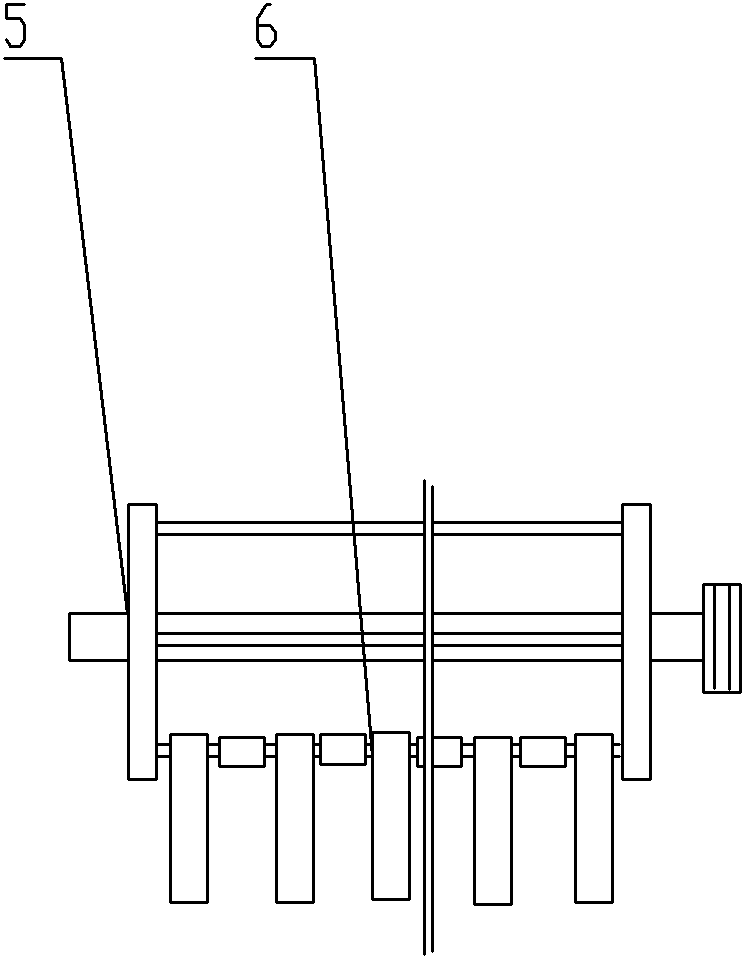

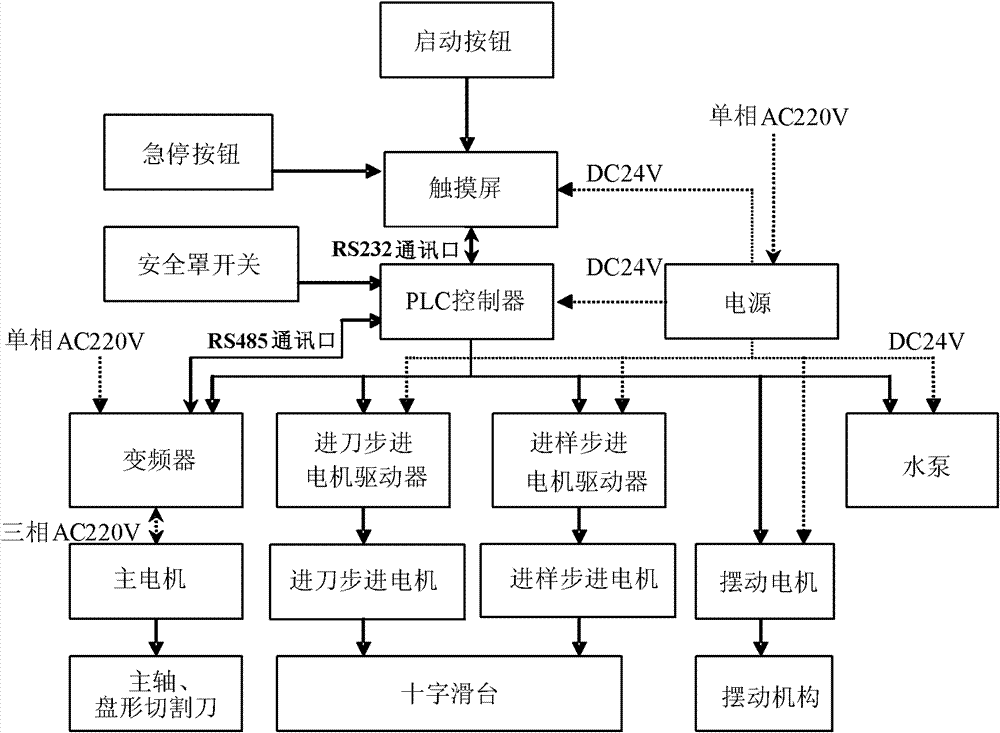

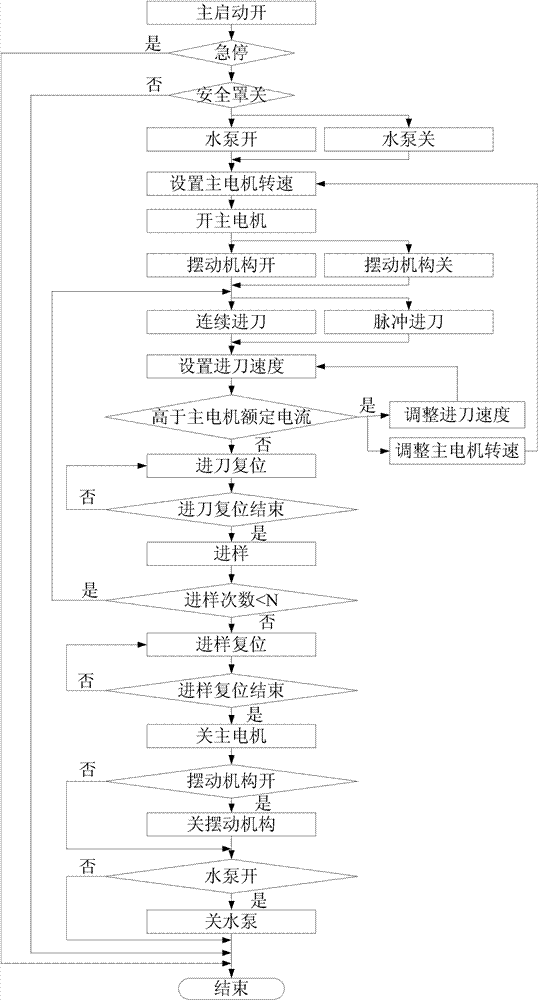

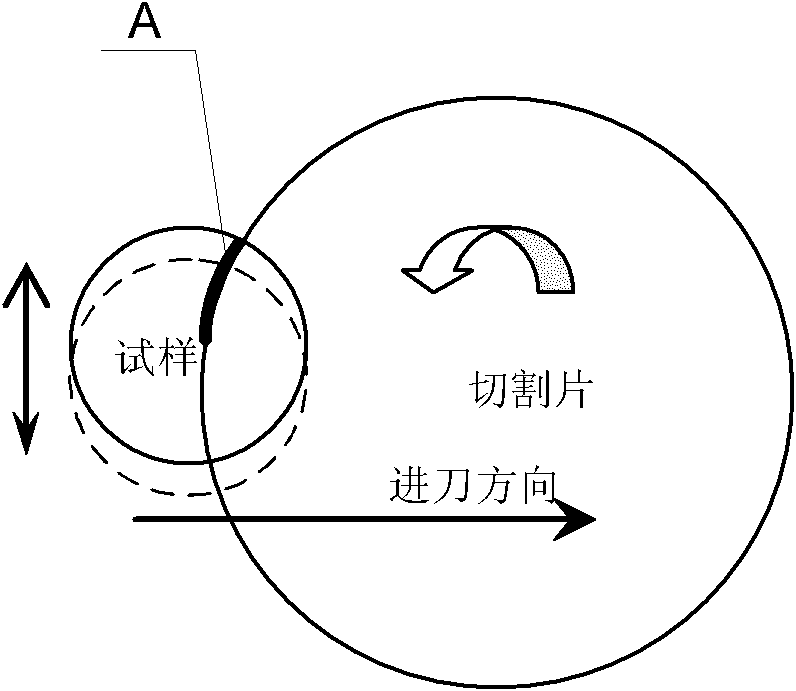

Programmable logic controller (PLC) control-based full-automatic sample cutting machine and cutting method thereof

InactiveCN101961874AReduce wear rateShorten the lengthWithdrawing sample devicesMetal working apparatusElectric machineProgrammable logic controller

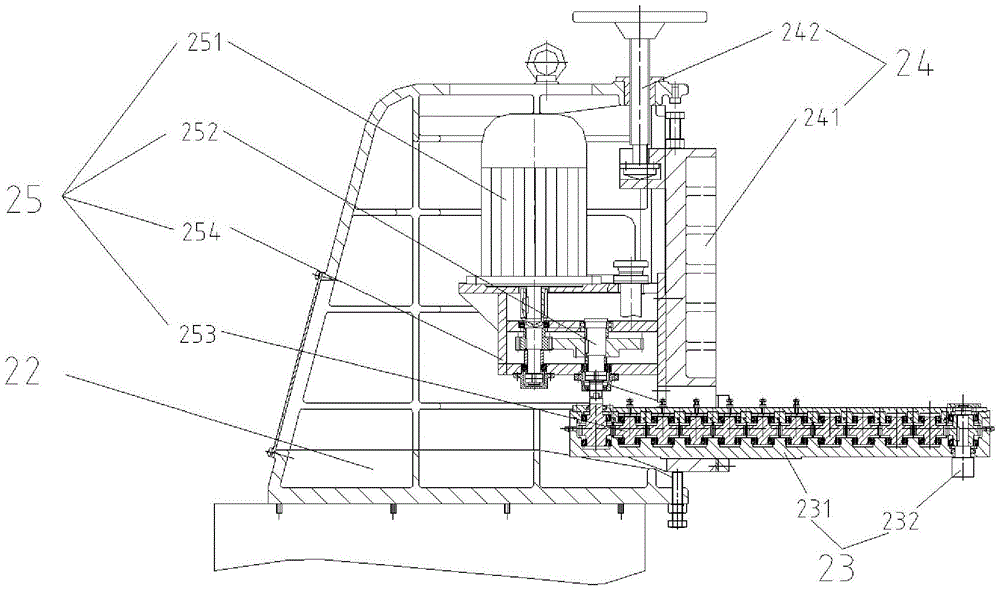

The invention relates to a programmable logic controller (PLC) control-based full-automatic sample cutting machine and a cutting method thereof, and belongs to the field of machining, which solves the problems of large labor consumption and difficult guarantee of precise cutting and quality of samples in the conventional cutting technology. The PLC control-based full-automatic sample cutting machine comprises a main shaft, a disc cutter, a sample clamping table, a cross-shaped sliding table, a feed mechanism, a sample introduction mechanism and a swinging mechanism, wherein the disc cutter isarranged on the main shaft; the sample clamping table is arranged on the cross-shaped sliding table; and the swing mechanism is arranged on the sample clamping table and can drive samples to swing upand down. In the PLC control-based full-automatic sample cutting machine, on the basis of PLC control, a touch screen is used as a man-machine interaction interface to perform parameter setting, so that the PLC control-based full-automatic sample cutting machine can complete actions such as feed / retracting, sample introduction / sample return, restoration, swinging and the like automatically according to preset advance parameters, and can regulate the rotational speed and feed speed and feed mode of blades automatically according to the change of blade speed or the change of main motor loads which are generated by the complexity of sample cutting.

Owner:HARBIN INST OF TECH

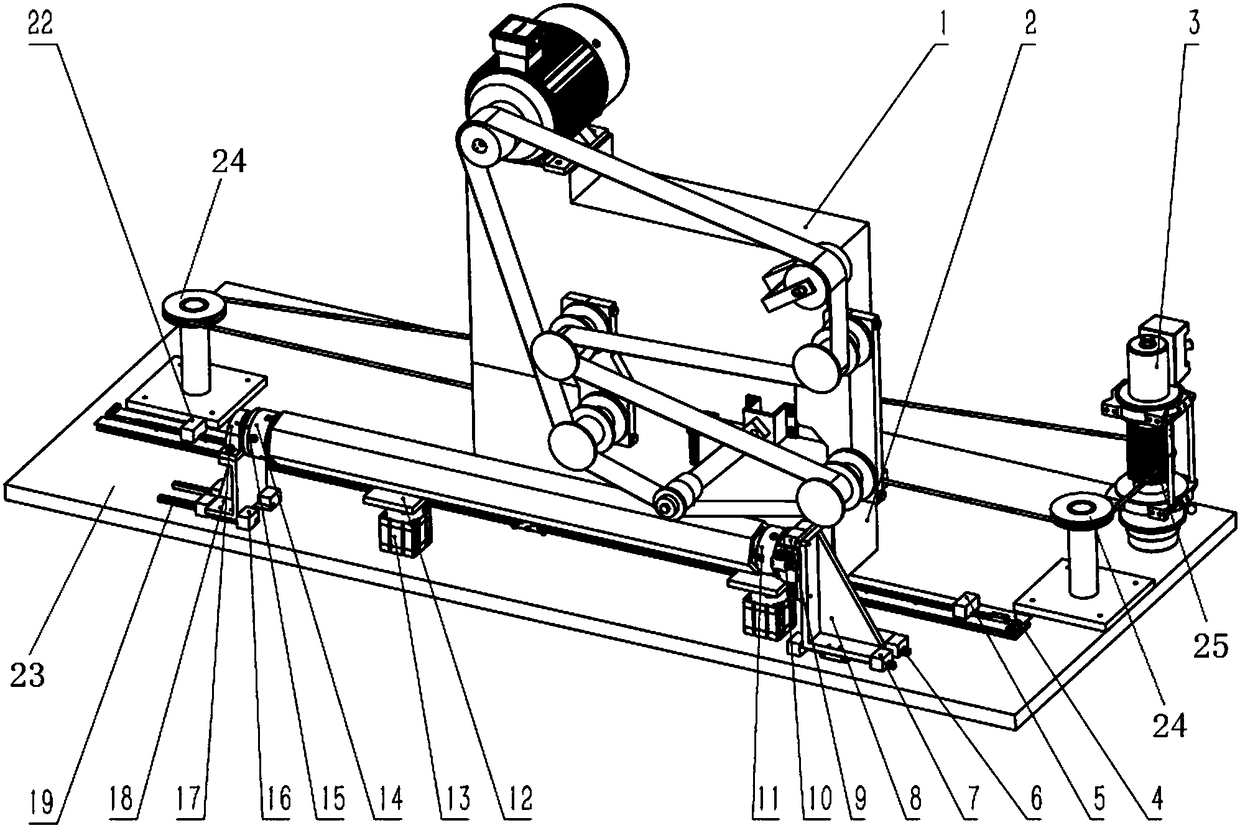

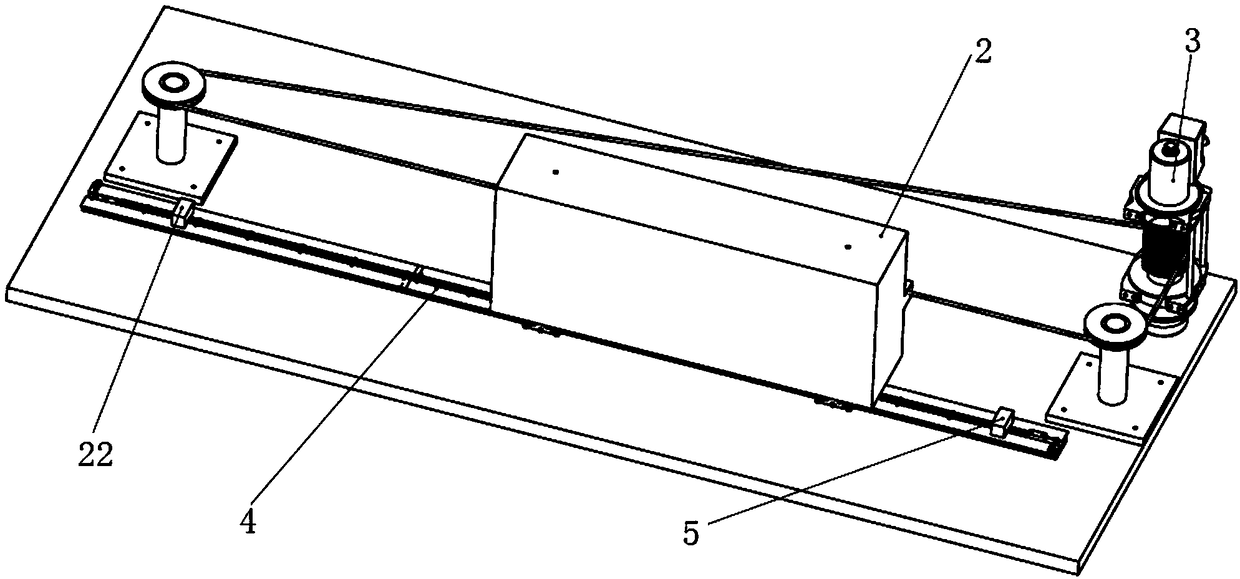

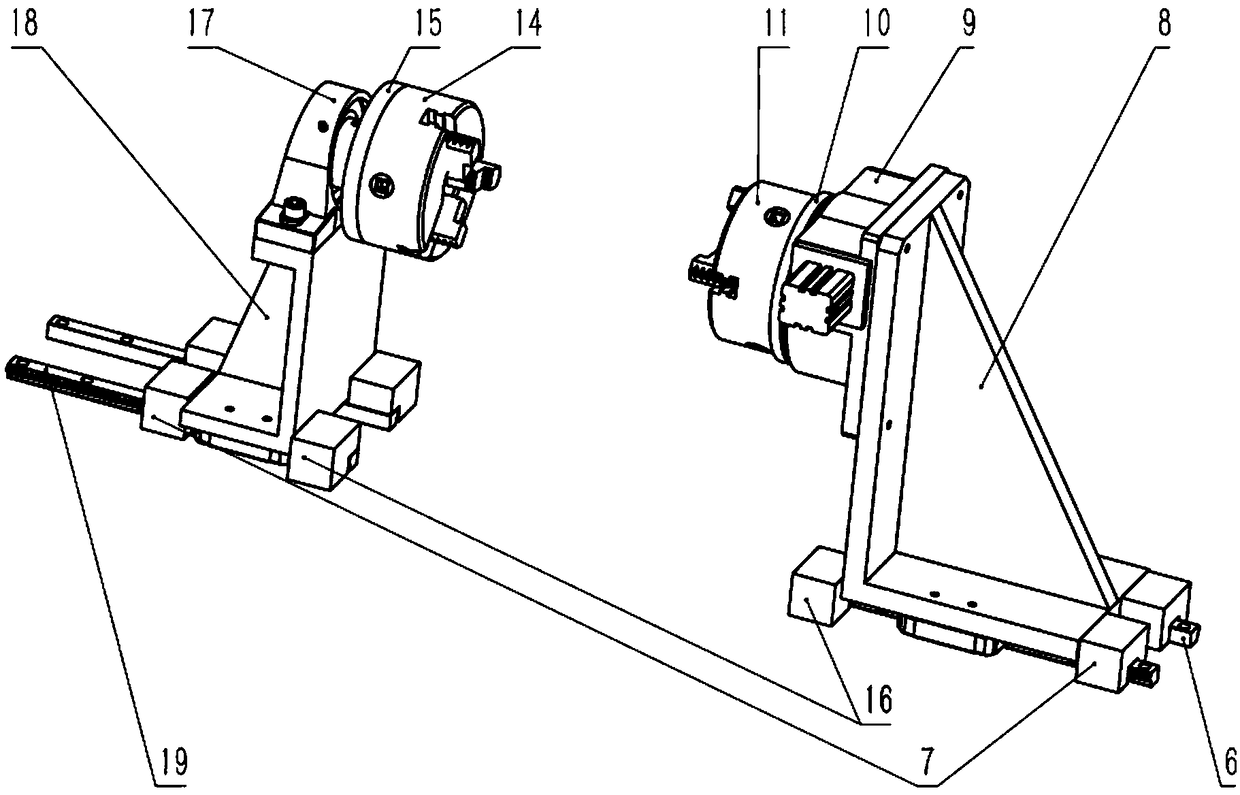

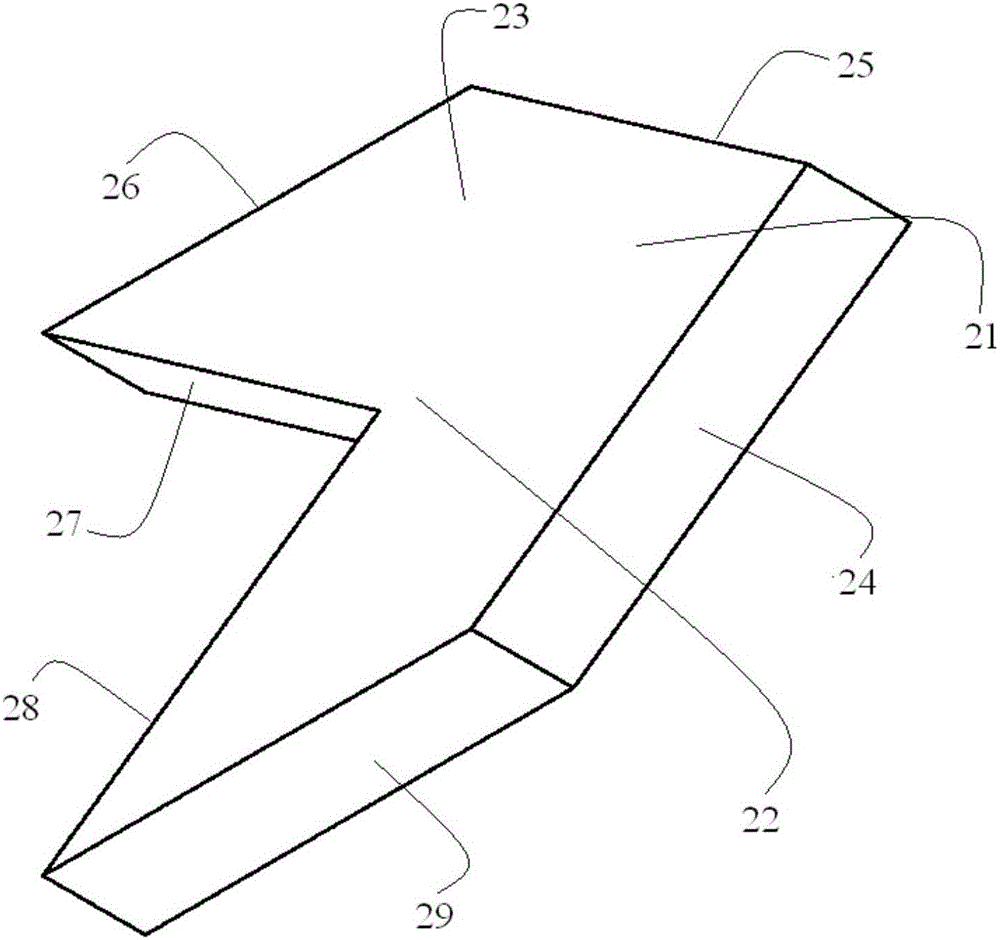

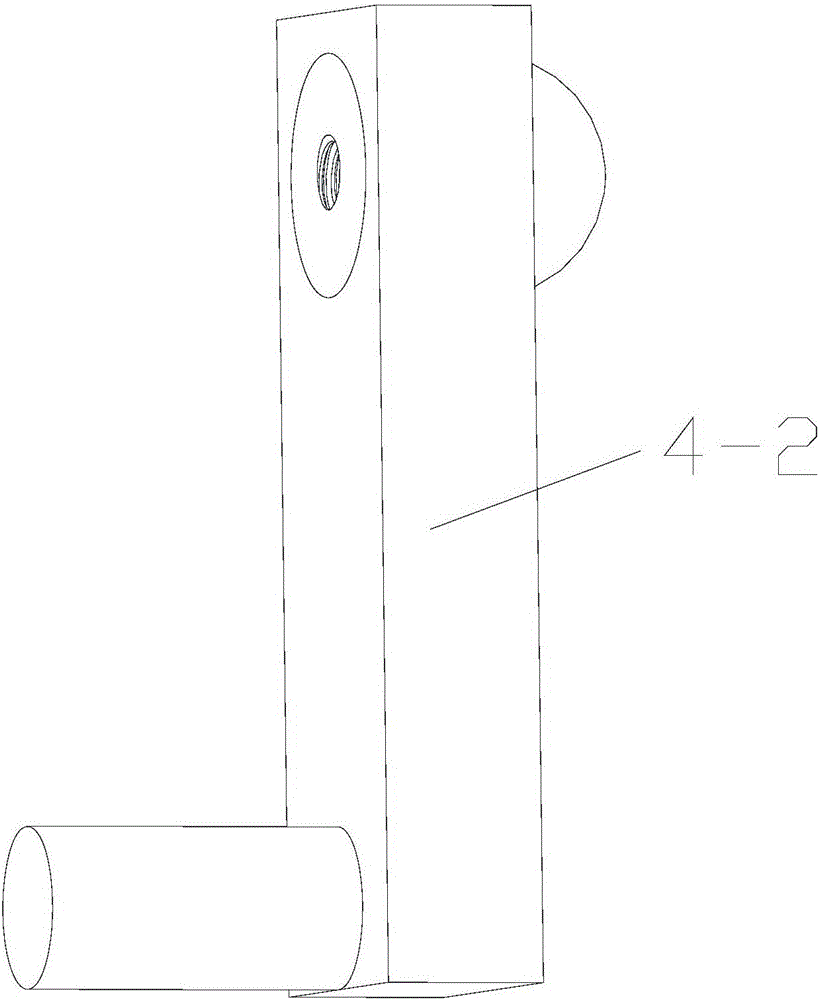

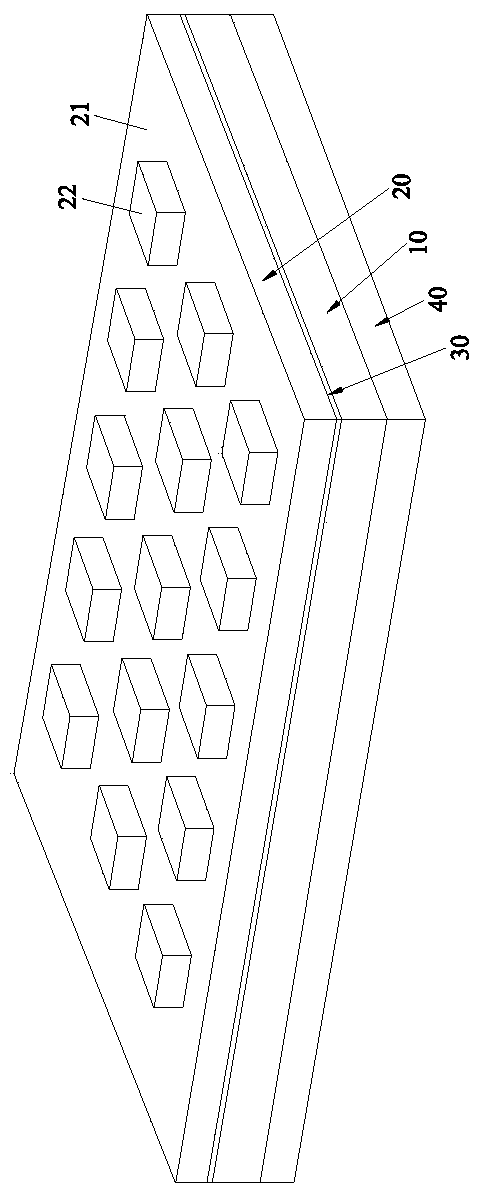

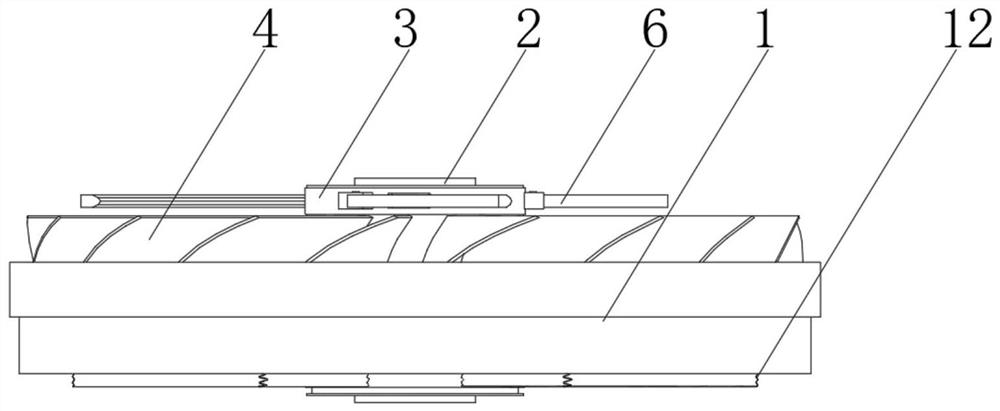

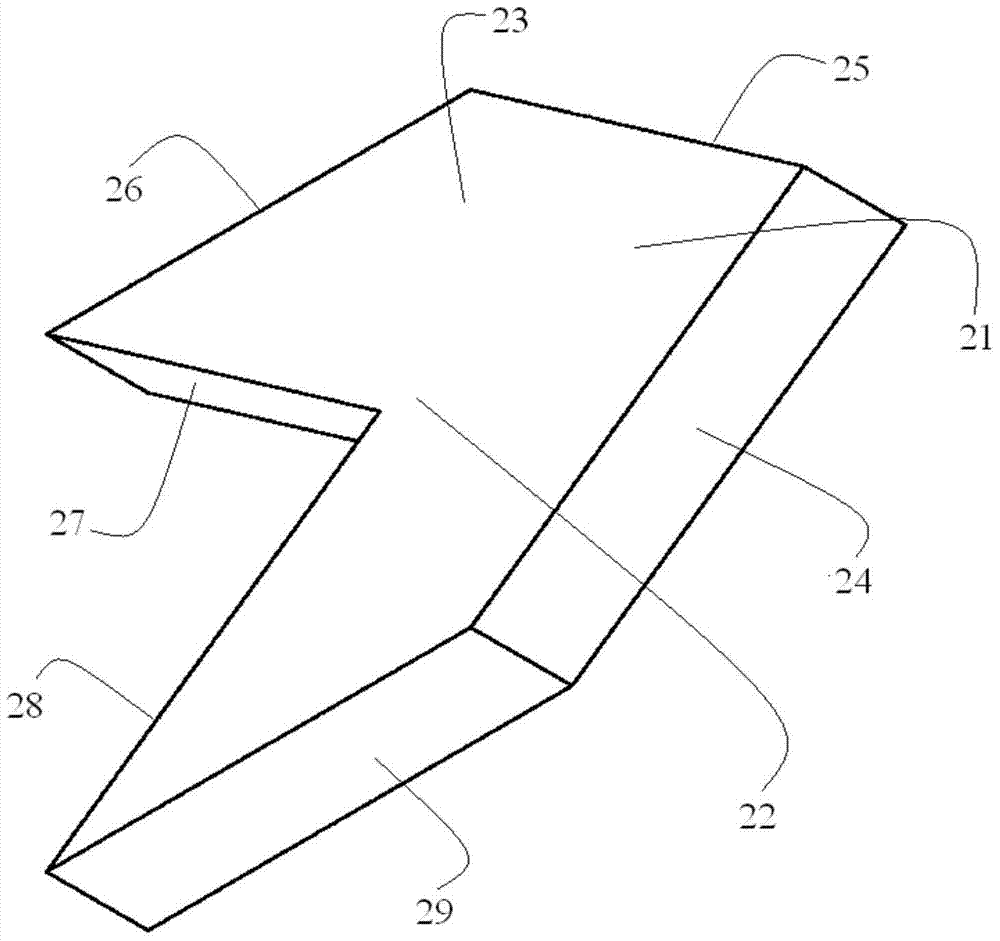

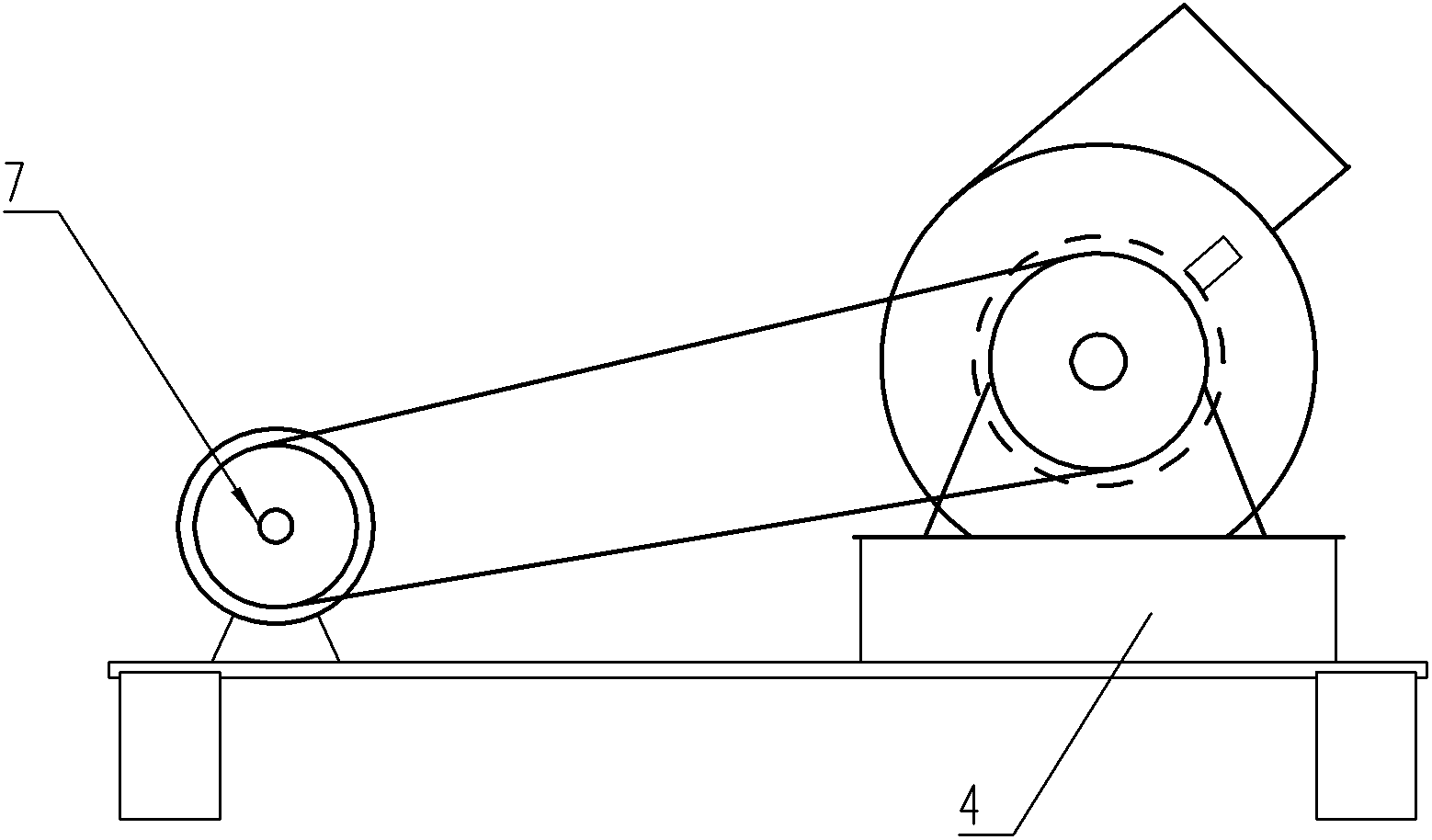

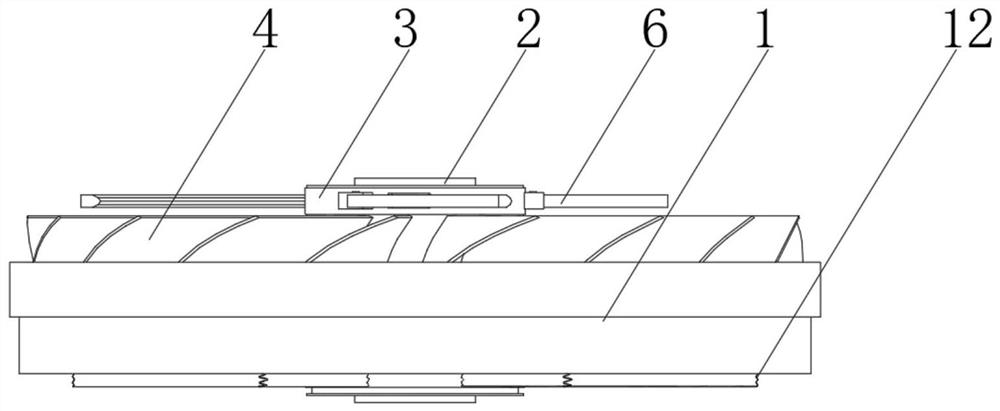

Surface polishing and grinding process and equipment used for long rod part with specially-shaped section

ActiveCN108500792AImprove polishing qualityGuaranteed cutting forceBelt grinding machinesGrinding work supportsLinear motionGrinding process

The invention discloses a surface polishing and grinding process and equipment used for a long rod part with a specially-shaped section. The equipment comprises a belt grinder, a travelling mechanismand a clamping mechanism with a turnover function, wherein the travelling mechanism comprises a slide rail and a slide base mounted on the slide rail; the slide base is driven by a linear motion drivedevice to move back and forth along the slide rail; the belt grinder is fixedly mounted on the slide base; a belt grinder contact wheel presses an abrasive belt to a to-be-polished and to-be-grindedsurface or edge of a workpiece for polishing and grinding the to-be-polished and to-be-grinded surface or edge of the workpiece; a supporting mechanism is arranged between a drive rotary mechanism anda driven rotary mechanism; the workpiece is firstly placed onto the clamping mechanism, and the travelling mechanism drives the belt grinder to move back and forth for polishing and grinding the workpiece; after one surface is polished and grinded, turnover can be performed through a turnover mechanism; and after polishing and grinding are completed, the clamping mechanism is loosened and the supporting mechanism is withdrawn, so that the workpiece can be taken out. The surface polishing and grinding equipment is consistent in polishing and grinding effect of each part of the workpiece, is good in polishing and grinding quality of the workpiece, is stable in performance, and can be suitable for various long rod parts with specially-shaped sections.

Owner:WUHAN UNIV OF TECH

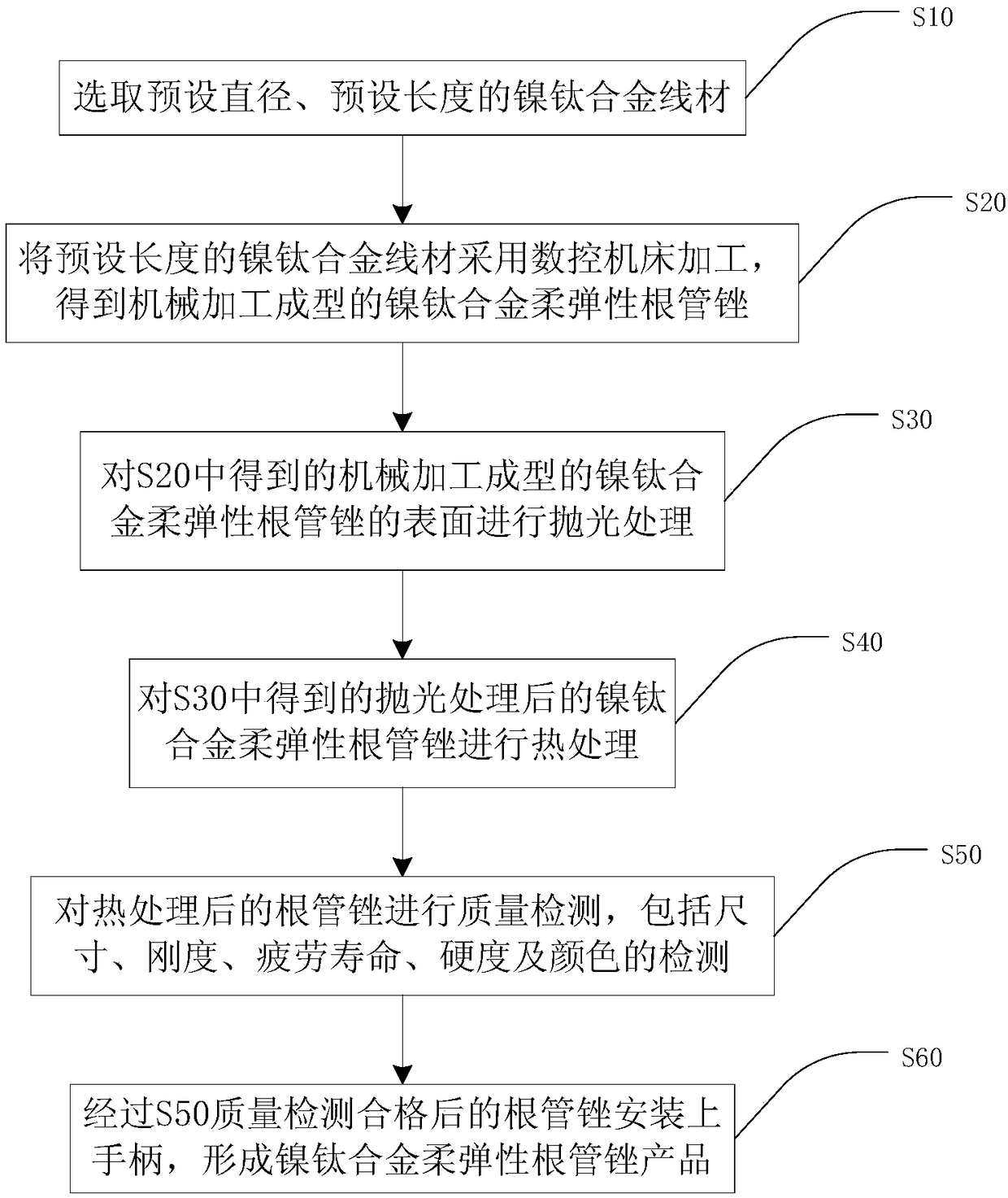

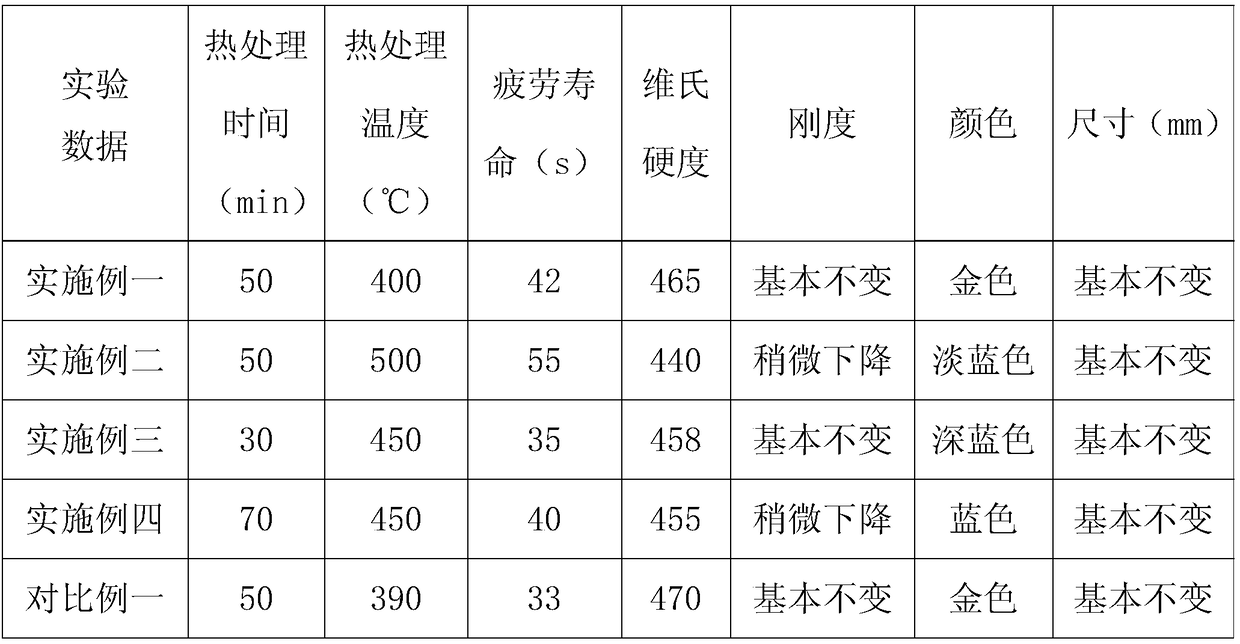

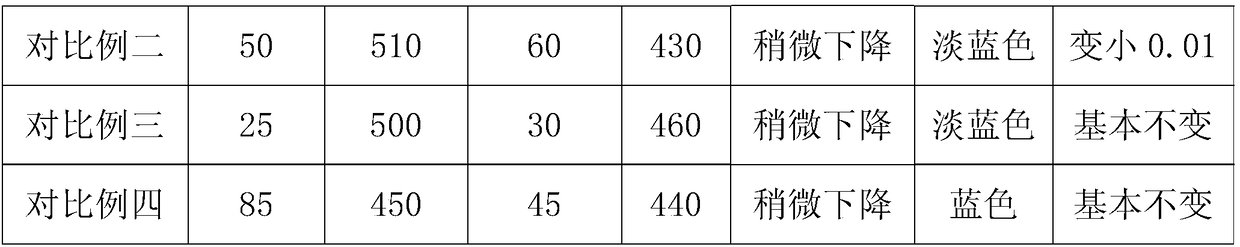

Preparation method of nickel-titanium alloy flexible and elastic root canal file

PendingCN108788644AStable stiffnessHardness and fatigue life meetTeeth fillingFurnace typesNickel titaniumTitanium nickelide

The invention relates to the field of medical apparatuses and in particular discloses a preparation method of a nickel-titanium alloy flexible and elastic root canal file. The preparation method comprises the following steps: machining a nickel-titanium alloy wire rod at a preset length to obtain a machined and formed nickel-titanium alloy flexible and elastic root canal file; polishing the surface of the machined and formed nickel-titanium alloy flexible and elastic root canal file; and thermally processing the polished nickel-titanium alloy flexible and elastic root canal file. By adopting the preparation method of the nickel-titanium alloy flexible and elastic root canal file, the rigidity of the root canal file is stable, the hardness and the fatigue life meet the using demands, the side penetrating and straightening frequency on a bent root canal by using the nickel-titanium alloy flexible and elastic file is reduced greatly, the fatigue resistance is improved on the premise of guaranteeing the cutting ability, and the treatment time is shortened; moreover, the temperature and time of thermal treatment can be adjusted properly according to color demands of root canal file products.

Owner:深圳市葆丰医疗器械有限公司

Method and milling cutter for repairing surface defect of cement concrete construction member

InactiveCN101876208AGuaranteed cutting forceGuaranteed StrengthBuilding repairsCeramic shaping apparatusMilling cutterArchitectural engineering

The invention discloses a method and a milling cutter for repairing surface defect of a cement concrete construction member, which is used for repairing the surface defects of the building construction members, such as cement concrete wall, piers, girders, plates and the like. For defects of cracks, local damage, voids and pits and the like on the surface of the building construction member, the method and the special milling cutter of the invention firstly remove defects, form a repairing groove and pour concrete again to repair. The method and the milling cutter of the invention can process the surface of the construction member into geometry, such as a plane, a cambered surface, a groove and the like, and especially processes the boundary surface of the repairing groove into regular, smooth, rough and circular-arc corner, which is favourable for construction stress and combination of new and old concrete, improves appearance quality and solves the difficulty problem that the surface of the cement concrete construction member is difficult to repair.

Owner:HEFEI UNIV OF TECH

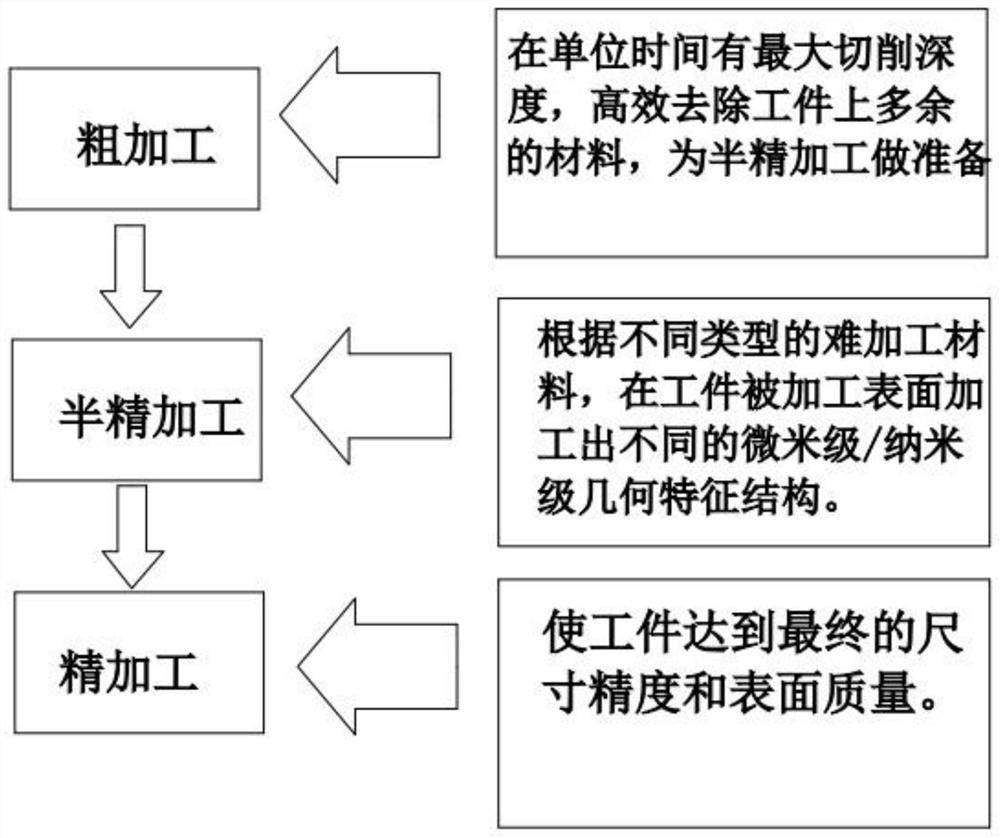

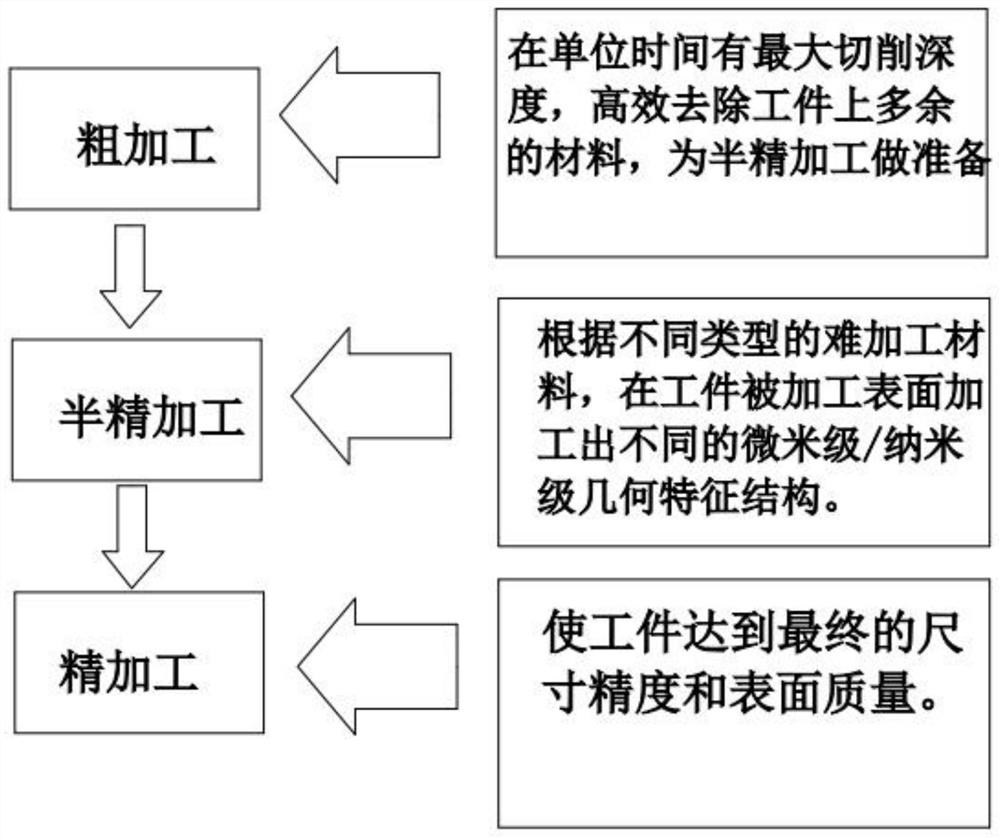

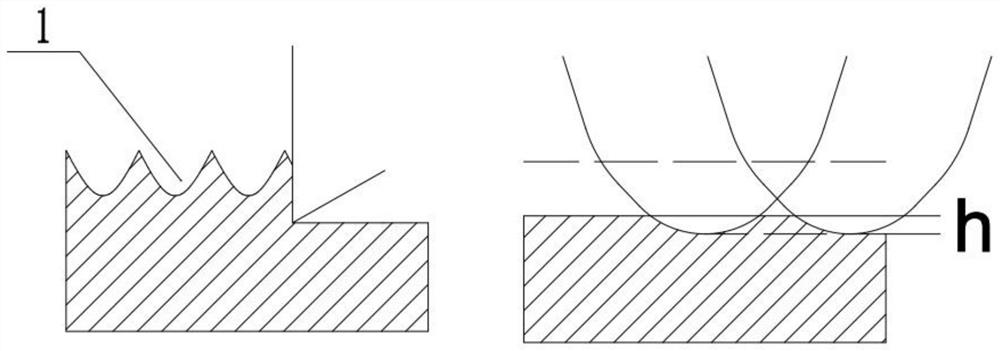

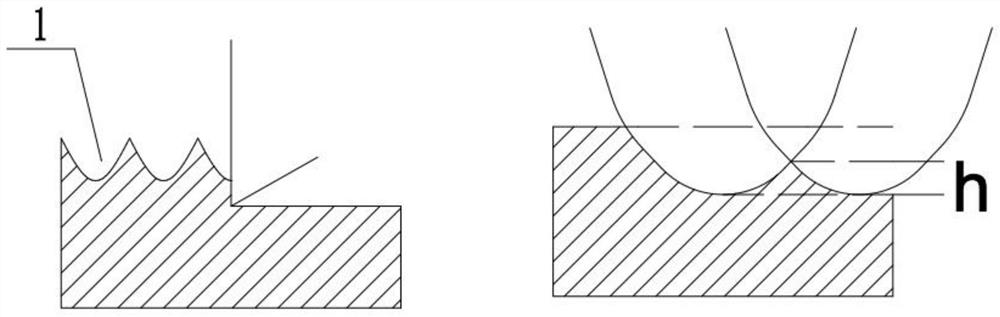

Ultra-precision cutting method based on surface microstructure design

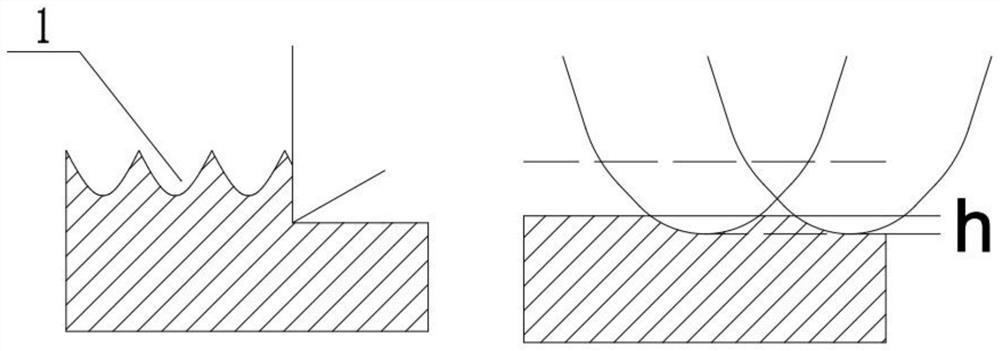

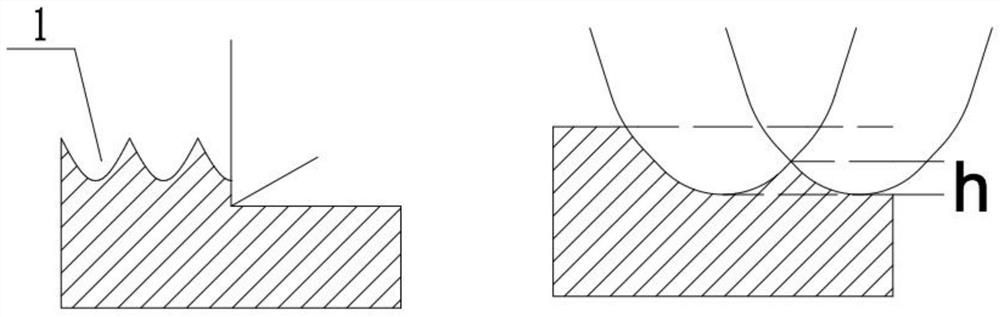

The invention provides an ultra-precision cutting method based on surface microstructure design. The method comprises the following steps that rough machining is conducted, redundant materials on a workpiece are removed by utilizing a machine tool, the geometric contour of the workpiece can be prepared for semi-finish machining, and the machining allowance is left on the to-be-machined surface of the workpiece, and the thickness of the machining allowance is micron-sized; semi-finish machining is conducted, a plurality of densely-arranged defect structures are machined on the to-be-machined surface of the workpiece subjected to rough machining through the machine tool, namely, micro structures with the geometric dimensions being micron-scaled or nano-scaled are machined, and the depth of each micro / nano structure is smaller than the machining allowance; and finish machining is conducted, the micro / nano structure machined in the semi-finish machining process and the remaining machining allowance are removed through the machine tool, the cutting depth is equal to the thickness of the machining allowance reserved in the rough machining process, and the designed micro / nano structure is obtained on the to-be-machined face of the workpiece by comprehensively controlling the finish machining process and the semi-finish machining process. Therefore, the ultra-precision machining purposes of controlling the cutting force borne by a cutter in finish machining, reducing heat generated in the cutting process, prolonging the service life of the cutter and obtaining ultra-precision machining with nanoscale surface roughness on materials difficult to machine are achieved.

Owner:GUANGDONG UNIV OF TECH

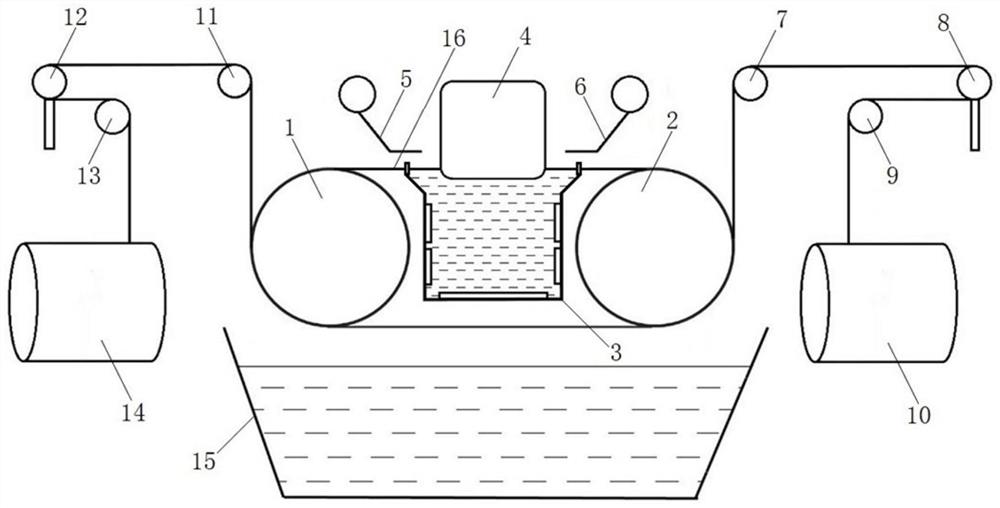

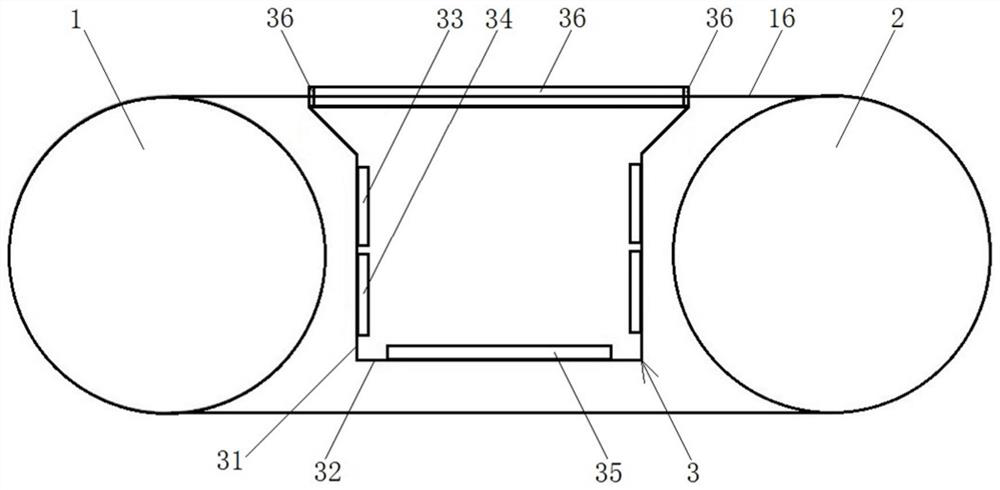

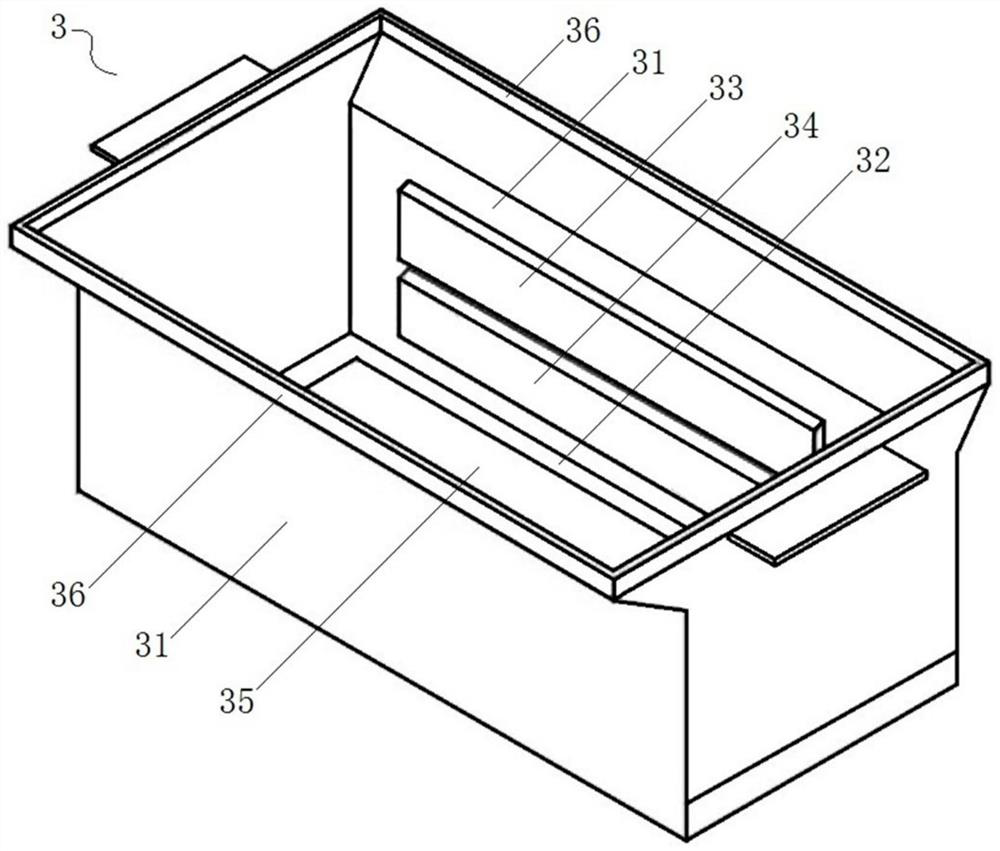

Splicing groove, diamond wire slicing machine and cutting method of large-size silicon rod

PendingCN114851413AImprove permeabilityRemove in timeFinal product manufactureWorking accessoriesStructural engineeringUltrasonic vibration

The invention relates to the technical field of diamond wire slicing machines, in particular to a piece receiving groove, a diamond wire slicing machine and a cutting method of a large-size silicon rod.The diamond wire slicing machine comprises a left cutting main roller, a right cutting main roller and the piece receiving groove, and the piece receiving groove comprises a groove body used for containing cooling liquid and arranged between the two cutting main rollers; the groove body comprises two groove side walls arranged left and right and a groove bottom wall connected between the two groove side walls, side wall ultrasonic vibration plates are fixed on the two groove side walls in the groove body respectively, and a bottom wall ultrasonic vibration plate is fixed on the groove bottom wall in the groove body. According to the diamond wire slicing machine and the cutting method of the large-size silicon rod, the cutting force is higher, and the abnormity of TTV, line marks and the like of a silicon wafer is obviously lower than that of a conventional method; in the cutting process, the wire breaking rate is also remarkably reduced, the cutting efficiency is improved, the wire consumption is reduced, and the silicon wafer cutting machining cost is reduced; when the method is used for processing the large-size silicon rod, the cutting yield is remarkably improved, and a solution is provided for processing the large-size silicon rod.

Owner:HENAN UNIV OF SCI & TECH

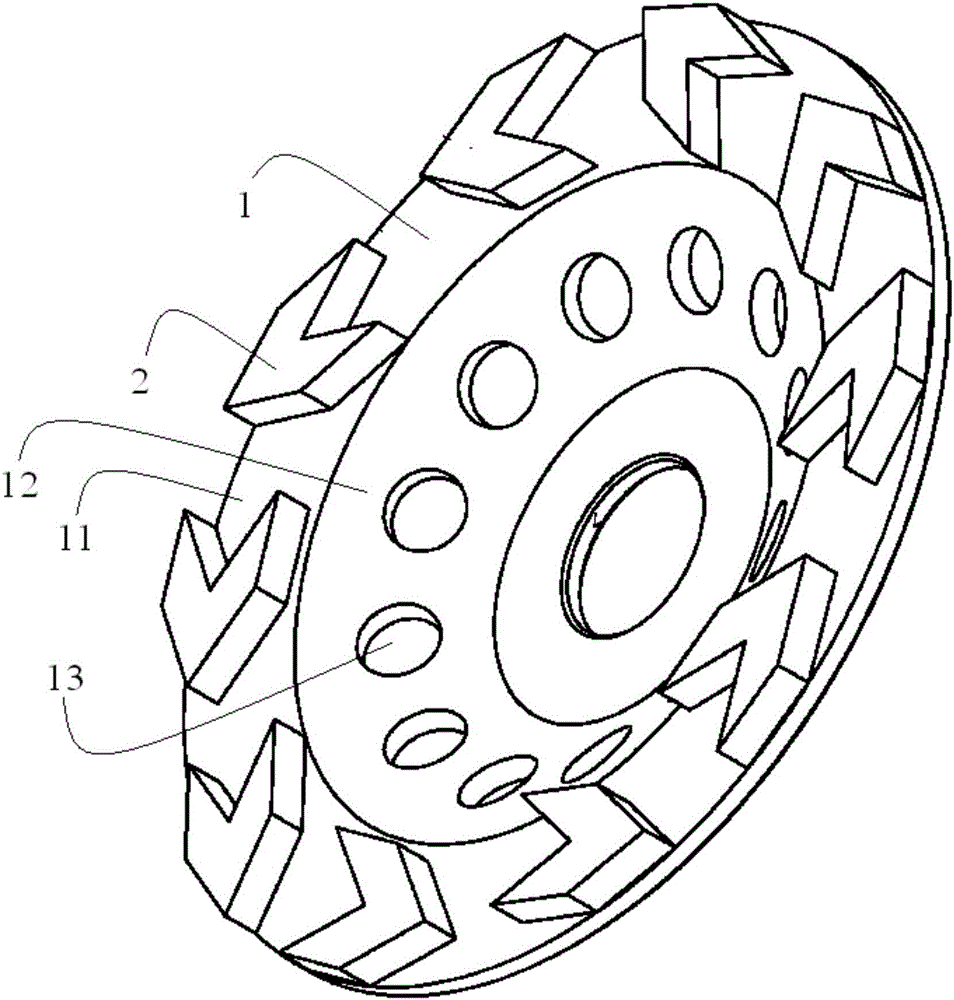

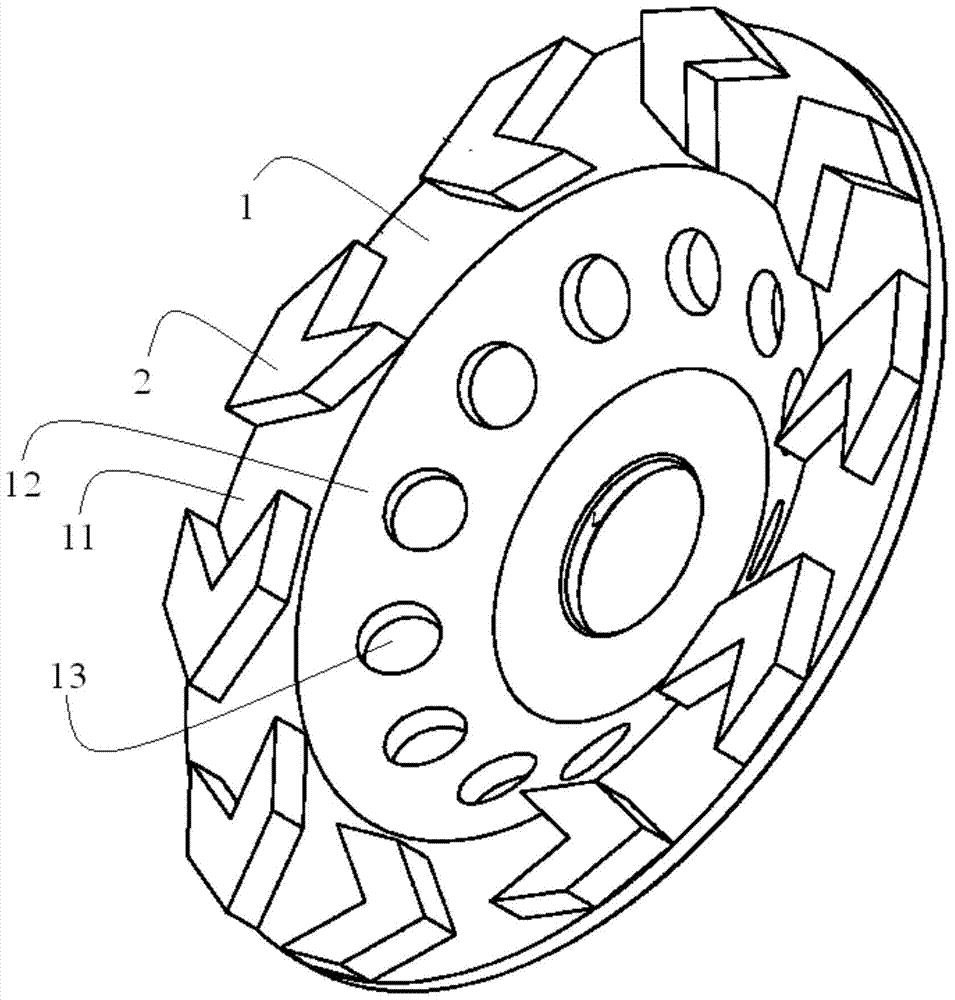

Terrace grinding wheel and manufacturing method thereof

ActiveCN105081994AGuaranteed connection strengthGuaranteed cutting forceBonded abrasive wheelsEngineeringGrinding wheel

The invention discloses a terrace grinding wheel and a manufacturing method thereof. The terrace grinding wheel comprises a base body and a plurality of tool bits sintered to the outer circle surfaceof the base body. Each tool bit comprises a front part and a rear part, wherein the top end of the front part is a sharp corner, and a groove is formed in the bottom end of the rear part. The tool bits are fixed to the base body through a hot press sintering method. According to the technical scheme, rapid cutting and smooth cutting removing are achieved, and the purpose of removing a terrace coating is achieved.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Sheet-shaped object cutting-off method

ActiveCN110980388AExtended service lifeGuaranteed cutting forceFunction indicatorsArticle deliveryControl systemStructural engineering

The invention discloses a sheet-shaped object cutting-off method, which feeds a sheet-shaped object between a knife roller and an anvil roller while enabling the knife roller to rotate. The knife roller rotating process comprises a cutting-off procedure, a detection procedure, a comparison procedure and an adjustment procedure. In the cutting-off procedure, the knife roller and the anvil roller relatively rotate to cut off the sheet-shaped object, and the sheet-shaped object can generate a counter-acting force on the knife roller in the cutting-off process; in the detection procedure, a pressure sensor senses the magnitude of the cutting force and transmits the sensed value to a control system; in the comparison procedure, the control system compares the received value with a set value andsends out different responses according to a comparison result; and in the adjustment procedure, the position of the knife roller is adjusted in real time according to the response sent by the control system. According to the invention, the pressure sensor is used for detecting the cutting-off force of the knife roller for cutting off the sheet-shaped object, the cutting-off force is fed back tothe control system, the control system carries out comparison and analysis, and the gap between the knife roller and the anvil roller is adjusted through a servo motor so as to keep the cutting-off quality of the sheet-shaped object be consistent.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

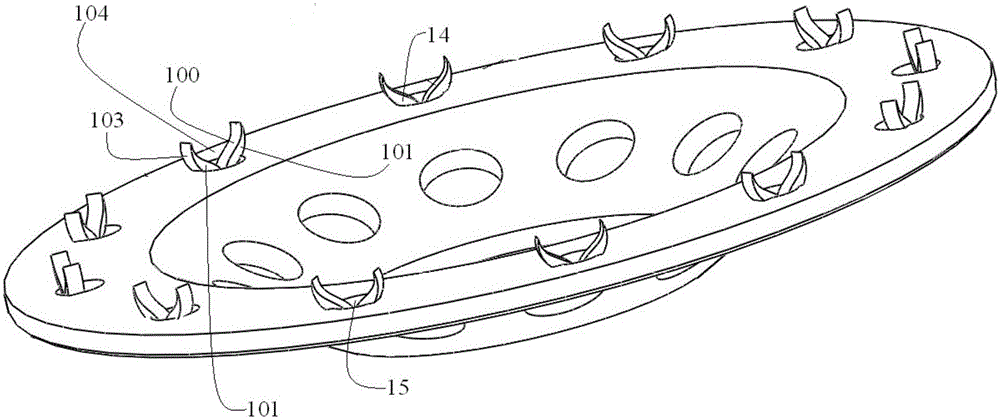

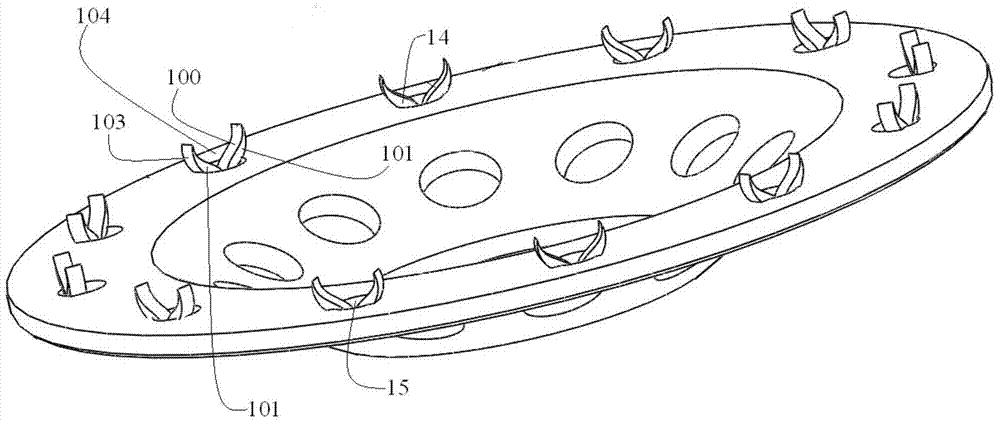

Prepuce anastomat

ActiveCN106725753AAvoid displacementQuality improvementSurgical staplesEngineeringSurgical instrument

The invention belongs to the technical field of surgical instruments and relates to a prepuce anastomat. The prepuce anastomat comprises a glans holder, a slide staple chamber, a body, a knife closing mechanism and a buffering compression mechanism. The body comprises a staple ejector and a circumcision knife, the staple ejector is positioned on the outer side of the front end of the body, and the circumcision knife is positioned on the inner side of the staple ejector and extends to the front of the staple ejector. The slide staple chamber with anastomosis staples mounted at the front end sleeves the staple ejector, and the buffering compression mechanism which pushes the slide staple chamber forwards is mounted between the slide staple chamber and the body. The glans holder for fixing tissues is provided with a knife abutting ring matched with the circumcision knife and staple anvils matched with the anastomosis staples in the slide staple chamber. By backward movement of the knife closing mechanism, the glans holder clings to the slide staple chamber, pushes the slide staple chamber to move backwards to get close to the circumcision knife, and finally pushes the slide staple chamber to make the staple ejector eject the anastomosis staples. The prepuce anastomat has advantages of simple structure and improvement of surgical quantity and surgical comfort.

Owner:吴健强

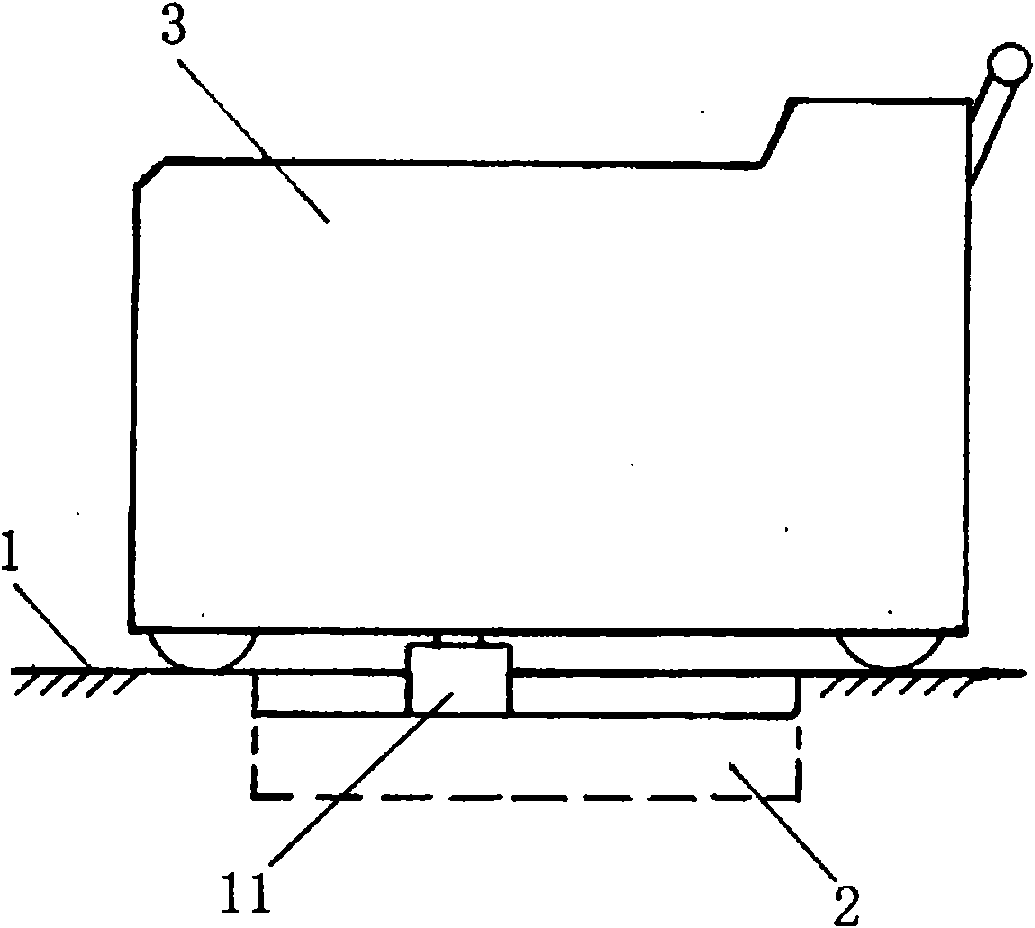

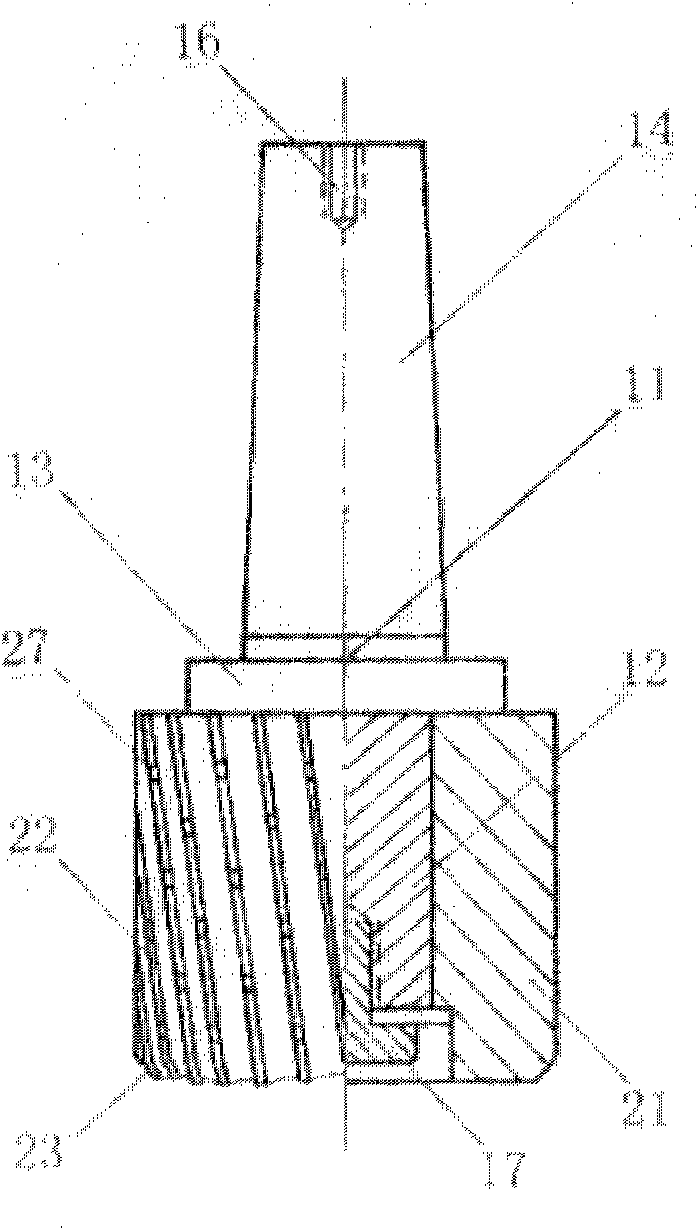

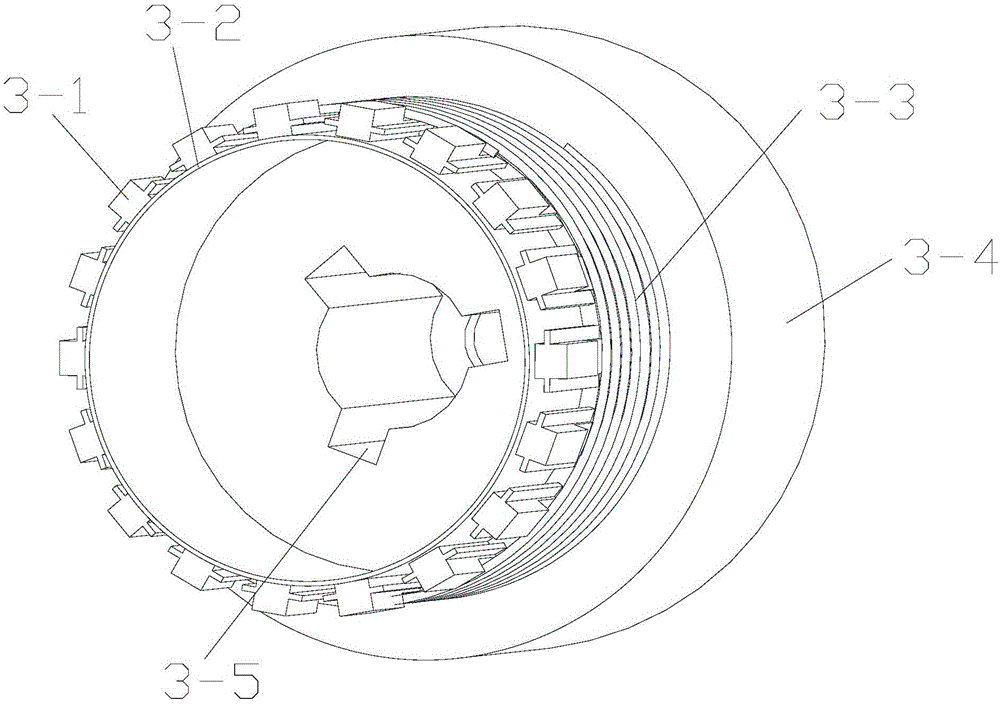

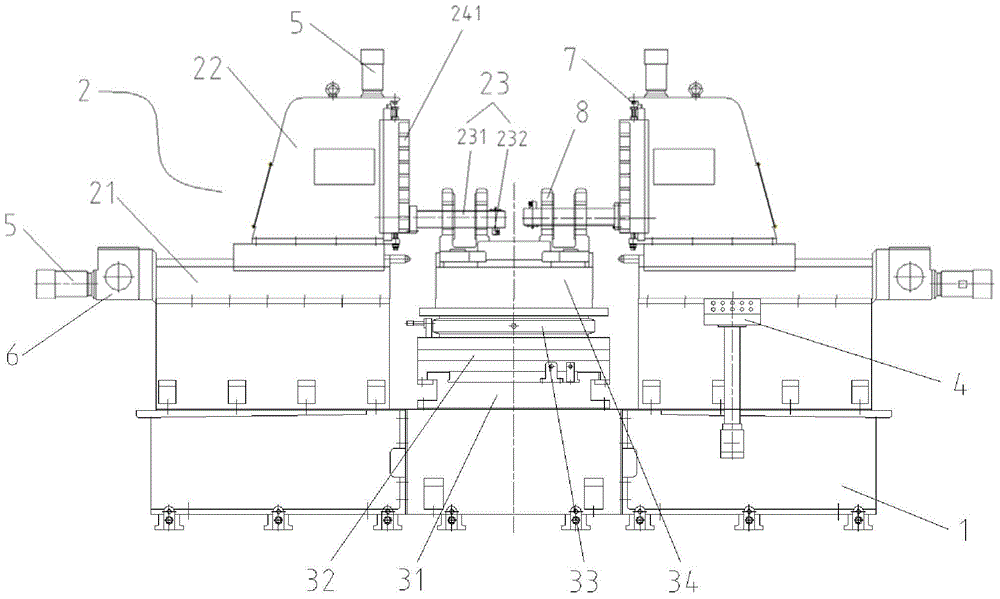

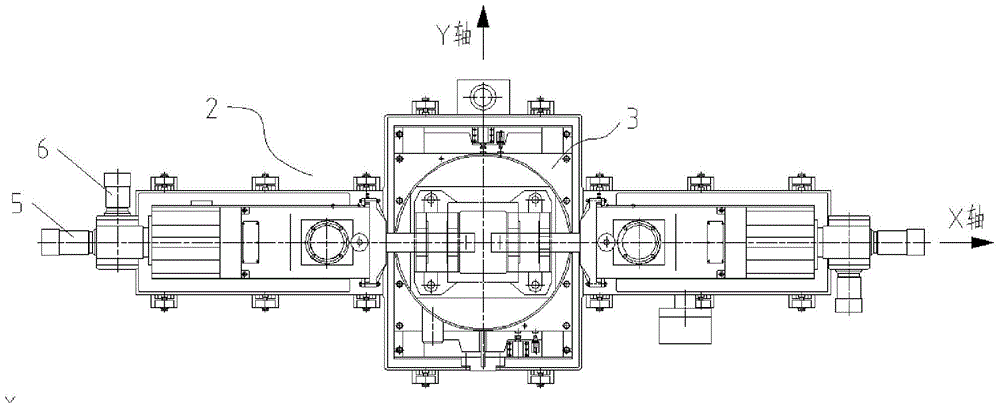

Light rail support keyway processing equipment and processing method

ActiveCN103978254BReduce labor intensityReduce the number of equipmentMilling equipment detailsMilling cutterLight rail

The invention discloses light rail support keyway processing equipment and a processing method thereof. The equipment is mainly composed of a pedestal, a horizontal sliding table assembly, which is arranged on the pedestal and moves along the X-axis in a straight line, a longitudinal sliding table assembly, which is arranged on the pedestal and moves along the Y-axis in a straight line, and a PLC control table arranged on the pedestal; wherein the horizontal sliding table assembly comprises a horizontal slide rail, a power head member, and a transmission mechanism I, the power head member comprises a power head body, a milling cutter, a transmission mechanism II, and a transmission mechanism III, and the longitudinal slide table assembly comprises a longitudinal slide rail, a sliding table, a transmission mechanism IV, a revolving workbench, and a work tool clamp. The processing method mainly comprises the steps of clamping, tool setting, milling, steering, position changing, milling, and detection. Compared to the prior art, the equipment has the advantages of small size, little occupied space, and high automation degree; moreover, the work strength for workers and the required operators are both reduced, thus the light rail support keyway processing efficiency is improved, the cost is saved, and the equipment is suitable for massive production on a plurality of machines at the same time.

Owner:CMCU ENG

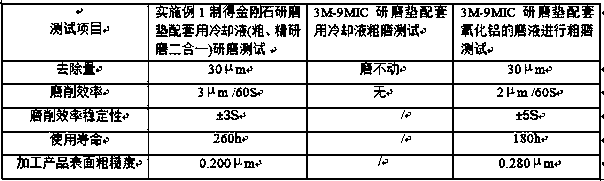

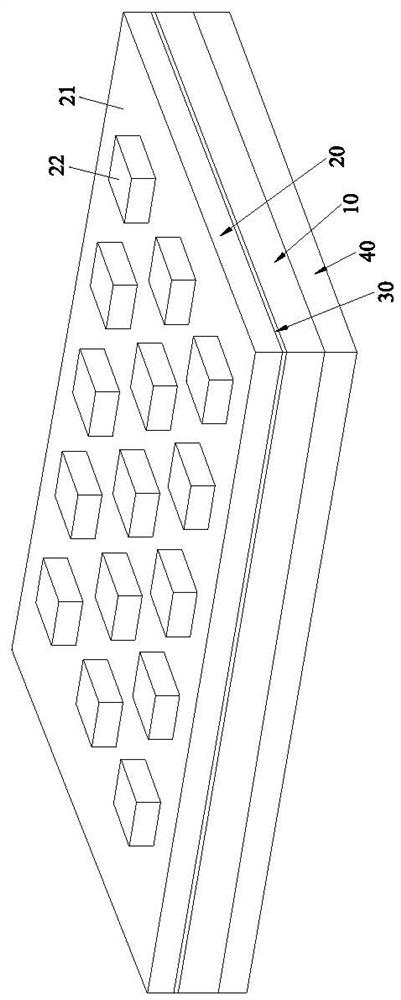

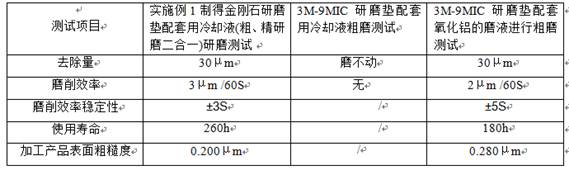

Diamond polishing pad and preparation process thereof

The invention discloses a diamond polishing pad and a preparation process thereof. The diamond polishing pad comprises a substrate and an abrasive layer arranged on the surface of the substrate. The abrasive layer comprises the following raw materials of, by mass, 5-10% of diamond cluster abrasive, 70-75% of adhesive and the balance filler, wherein the diamond cluster abrasive is composed of single-grain diamond clusters. The diamond polishing pad prepared through the formula and the process, is high in removal amount, the cutting force is ensured, the grinding efficiency is effectively improved, the grinding efficiency and stability are better, the service life is greatly prolonged, meanwhile, the surface roughness of machined products is lower, the surface quality of the machined products is greatly improved, and the diamond polishing pad is worthy of application and popularization.

Owner:黄文魁

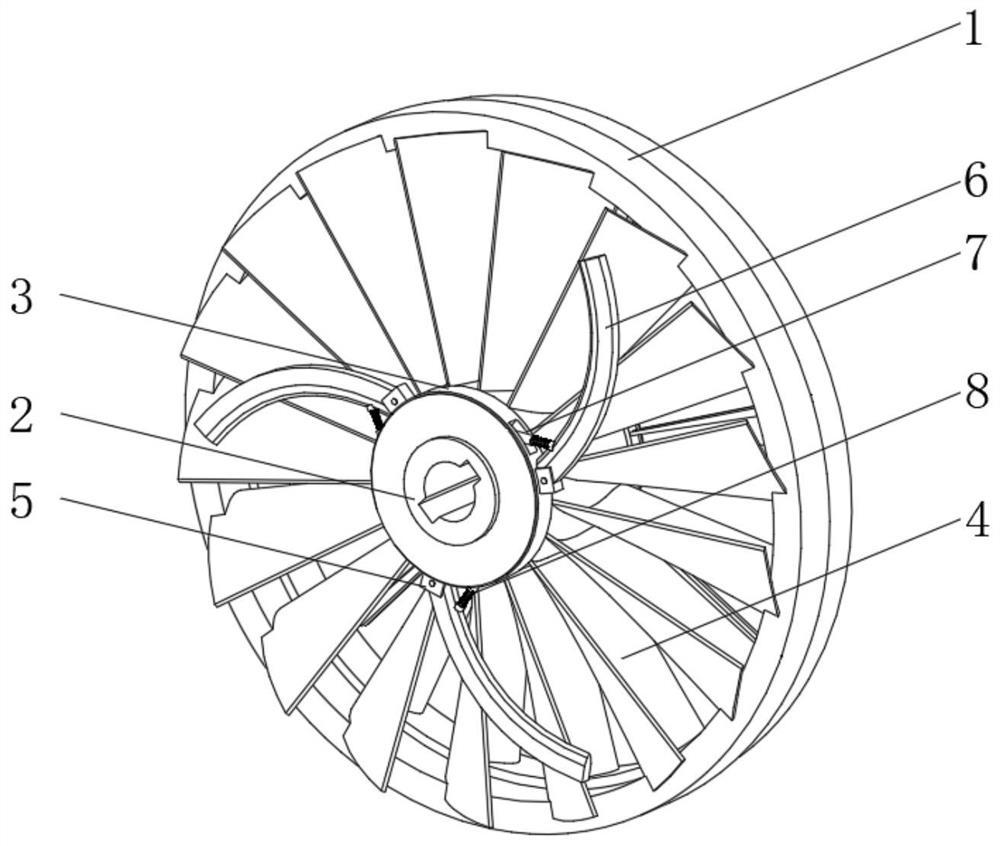

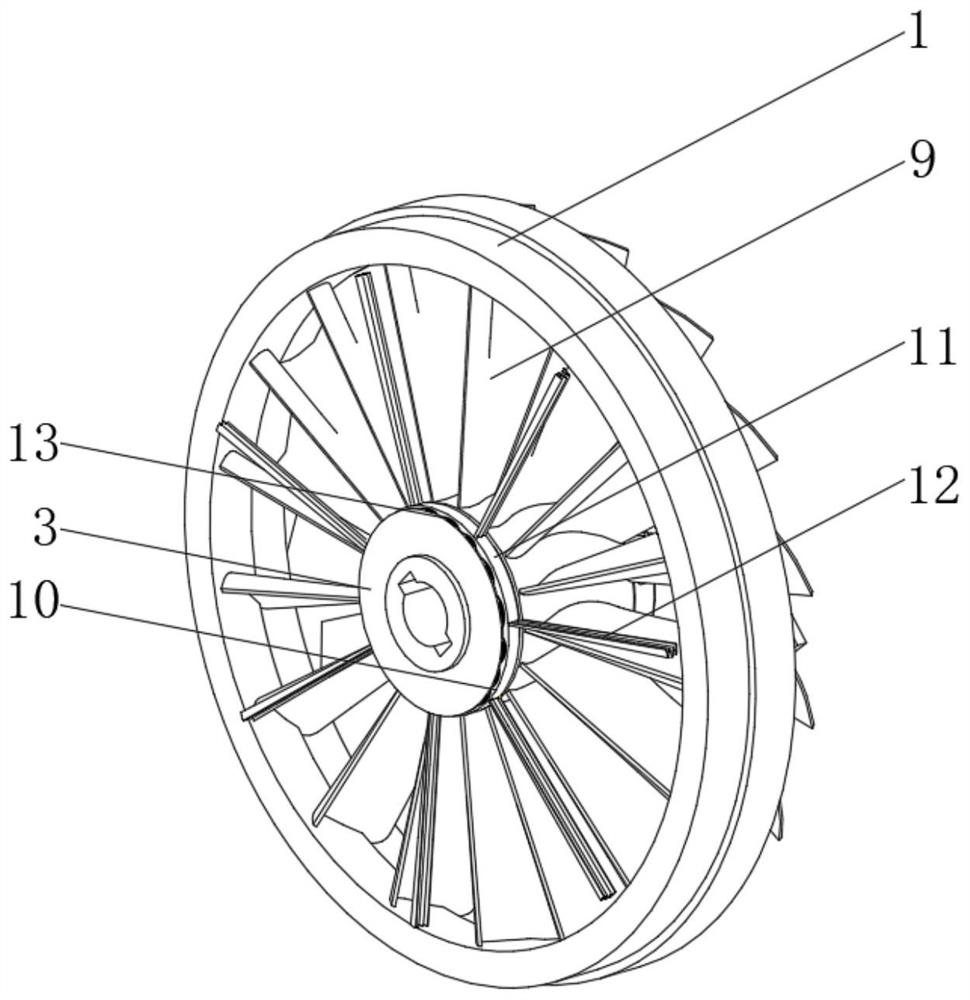

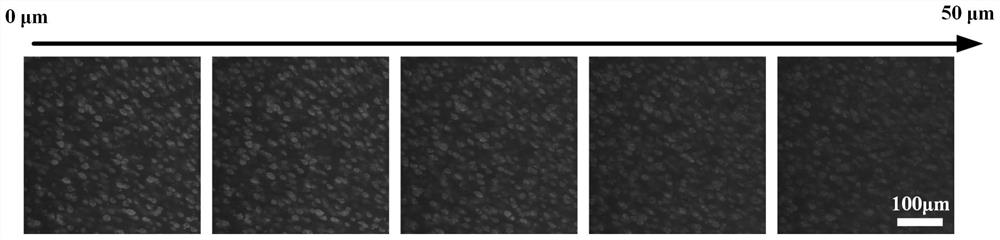

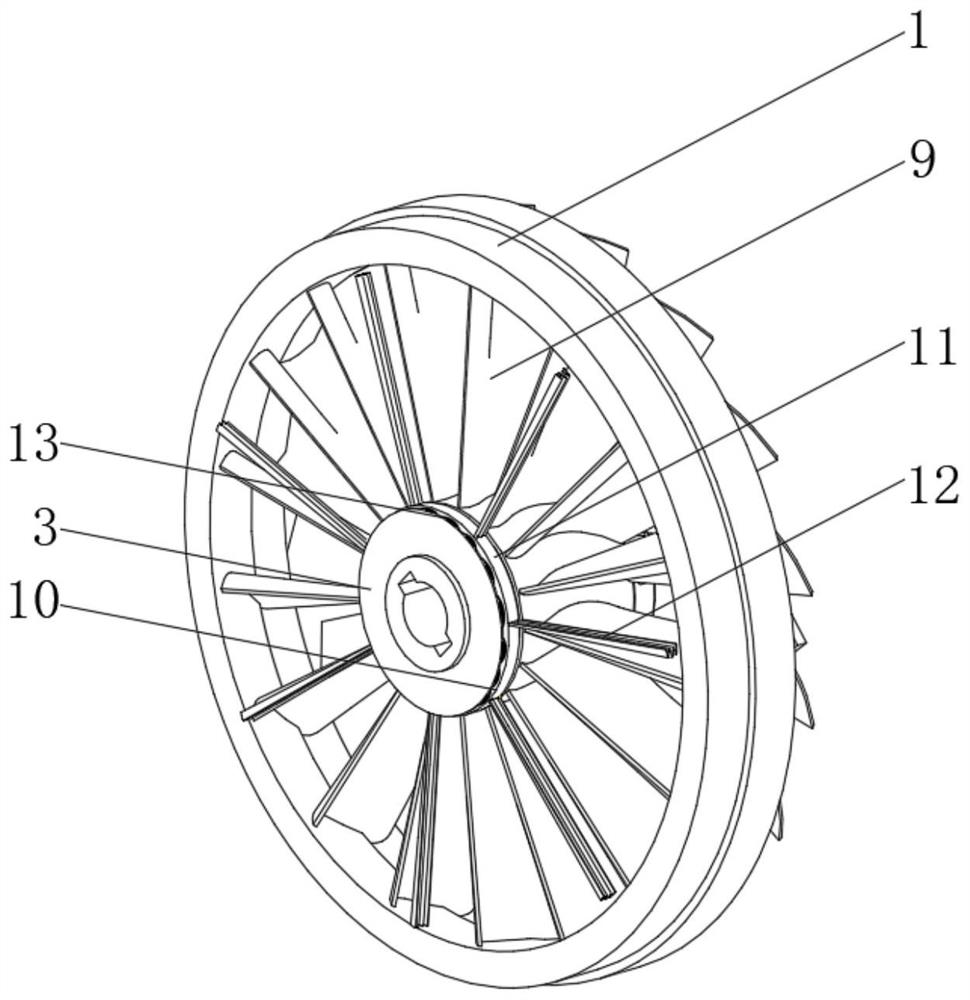

Hydraulic engineering impeller based on high-speed centrifugal magnetic pole cutters

ActiveCN112081773AUse efficientlyExtended service lifePump componentsHydro energy generationPhysicsImpeller

The invention discloses a hydraulic engineering impeller based on high-speed centrifugal magnetic pole cutters and relates to the technical field of hydraulic engineering. The hydraulic engineering impeller based on the high-speed centrifugal magnetic pole cutters comprises a wheel body, a center shaft body, an outer ring sleeve shaft and an impeller body, wherein the outer ring sleeve shaft is installed on the outer side of the center shaft body, and the center shaft body and the outer ring sleeve shaft are rotationally connected with the wheel body through a connecting frame. The outer sideof the outer ring sleeve shaft is fixedly connected with a rotating base, the outer side of the rotating base is rotationally connected with retracting and extending internal cutting smashing cutters,containing inner grooves are formed at the positions, located on the inner sides of the retracting and extending internal cutting smashing cutters, of the outer portion of the outer ring sleeve shaft, and retracting and resetting devices are installed in the containing inner grooves. According to the hydraulic engineering impeller based on the high-speed centrifugal magnetic pole cutter, different components are arranged at the two ends of an impeller assembly correspondingly, water energy can be more effectively utilized, the service life of the impeller can be effectively prolonged, and therepair and maintenance frequency is reduced. The cutting stress is ensured during working of the device, and the working efficiency of the impeller is also ensured.

Owner:安徽禹溪水利工程有限公司

Paper tube cutting equipment with self cooling function

InactiveCN107856096AImprove cutting accuracySame lengthMetal working apparatusEngineeringPneumatic cylinder

The invention relates to paper tube cutting equipment with a self cooling function. The equipment comprises a push bottom plate and a cutting bottom plate. The side face of the pushing bottom plate isprovided with a pneumatic cylinder, the pneumatic cylinder is connected with a push plate through a first telescopic rod, a conveying belt is arranged below the push bottom plate, the right side of the conveying belt is provided with a second telescopic rod with a fixing plate, and the upper surface of the fixing plate is provided with a groove. The cutting bottom plate is provided with water outlet holes and provided with a support, and a steel wire rope is connected to the support. A cooling and cleaning device is arranged above the support and comprises a first pipeline, the two sides of the first pipeline are connected with a second pipeline and a third pipeline correspondingly, multiple spray heads are arranged in the first pipeline, the second pipeline is connected with air outlet equipment, and the third pipeline is connected with a water pump in a water groove. By means of the paper tube cutting equipment with the self cooling function, the paper tube cutting efficiency is high, cutting precision is high, paper tube finished products are uniform in length and flat in edge, the steel wire rope in the cutting process can be cooled, and the cut steel wire rope can be cleaned.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

Floor grinding wheel and manufacturing method thereof

ActiveCN105081994BGuaranteed connection strengthGuaranteed cutting forceBonded abrasive wheelsGrinding wheelMechanical engineering

The invention discloses a floor grinding wheel and a manufacturing method thereof. The floor grinding wheel comprises: a base body, and a plurality of cutter heads sintered on the surface of the outer ring of the base body, and the cutter heads have: a front part and a rear part, The top of the front part has a sharp angle; the bottom of the rear part has a groove. The invention adopts hot pressing sintering method to fix the cutter head on the substrate. The present invention realizes rapid cutting and ensures the smooth removal of chips through the above technical scheme, and solves the problem of floor coating removal.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

An ultra-precision cutting method based on surface microstructure design

The invention provides an ultra-precision cutting method based on surface microstructure design, comprising the following steps: Rough machining: using a machine tool to remove excess material on the workpiece, preparing the geometric profile of the workpiece for semi-finishing, and leaving Machining allowance, the thickness of the machining allowance is micron level; semi-finishing: on the surface of the workpiece to be processed after rough machining, use the machine tool to process several densely arranged defect structures, that is, the geometric size is micron level or nanometer level The depth of various micro / nano structures is less than the machining allowance; finishing: use machine tools to remove the micro / nano structures and remaining machining allowances processed in semi-finishing, and the cutting depth is equal to that in rough machining The thickness of the reserved machining allowance, through comprehensive control of the finishing process and semi-finishing process, the designed micro / nano structure is obtained on the surface of the workpiece to be processed, so as to control the cutting force on the tool during finishing and reduce the cutting process In order to achieve the purpose of improving the life of the tool and obtaining nano-scale surface roughness on difficult-to-machine materials, the generation of medium heat is achieved.

Owner:GUANGDONG UNIV OF TECH

Preparation method of diamond wire and prepared diamond wire

ActiveCN102352503BGood flexibilityImproved resistance to twistingMetallic material coating processesWire cuttingAlloy

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

Preparation method of composite abrasive material

ActiveCN102417810BRaise the flash point temperatureReduce breakageOther chemical processesWorking environmentCrusher

The invention provides a preparation method of a composite abrasive material, belonging to the technical field of manufacture of abrasive materials. The novel composite abrasive material is characterized by comprising (by weight) 4 to 6 parts of a hard abrasive material, 0.95 to 1 part of a polyurethane elastomeric material and 0.01 to 0.05 part of a fire retardant. The hard abrasive material is uniformly distributed among foams formed by the polyurethane elastomeric material and the fire retardant. The abrasive material provided in the invention can be repeatedly used 8 to 12 times and has working environment dust absorptivity of more than 90% and an abrasive flash point at a temperature of 200 to 300 DEG C. According to the invention, the preparation method comprises the steps of split charging, stirring, maintenance, fragmentation and screening; in the step of fragmentation, a novel horizontal hammerhead crusher or a novel vertical hammerhead crusher installed with a knife type hammerhead is used for fragmentation, which enables the problem that it is difficult to carry out uniform and rapid fragmentation after compounding of the hard abrasive material and soft abrasive materials to be overcome and actual production of the composite abrasive material to be realized.

Owner:淄博大亚金属科技股份有限公司

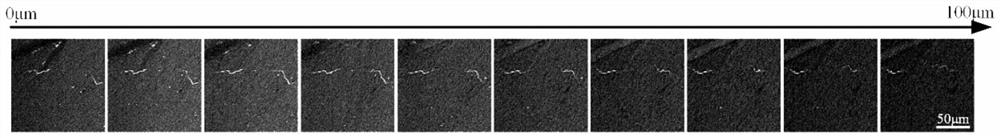

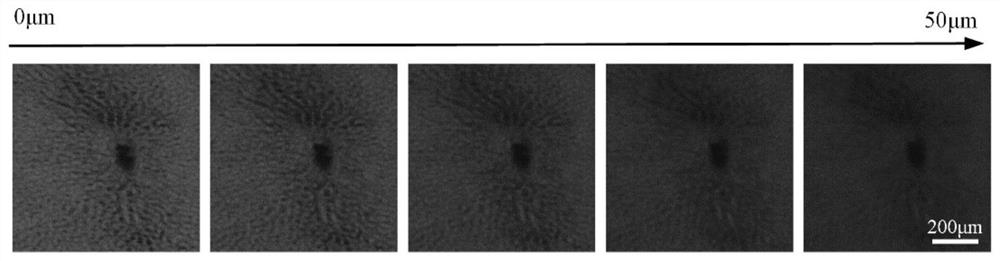

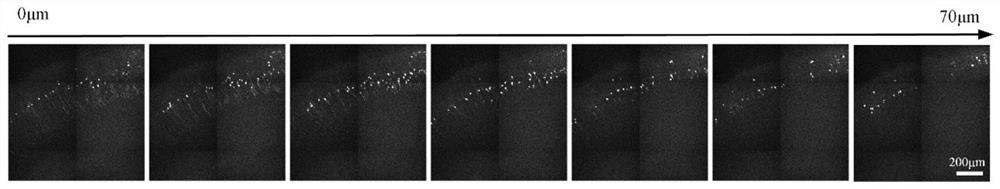

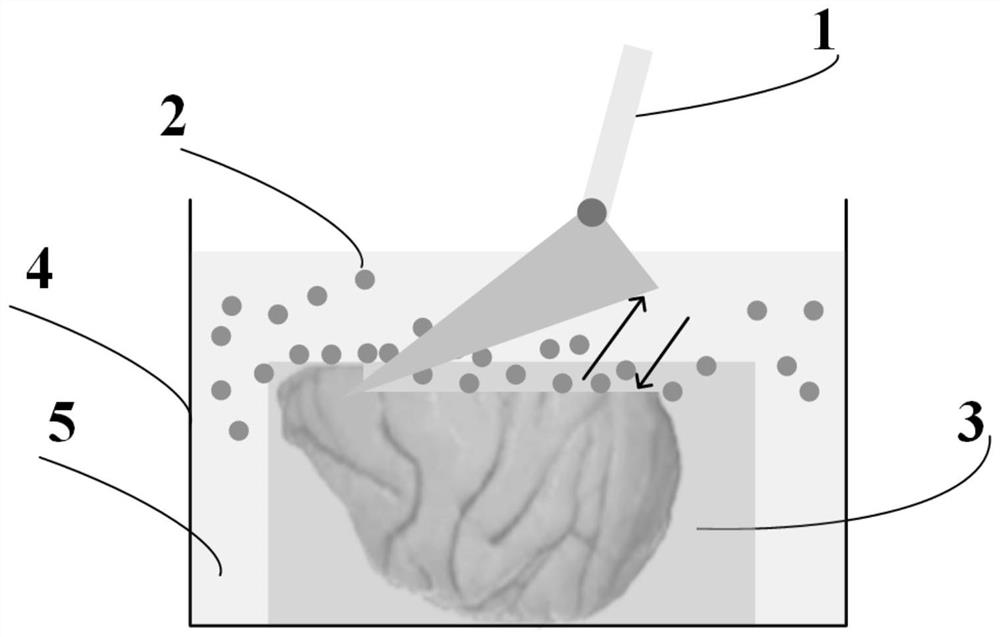

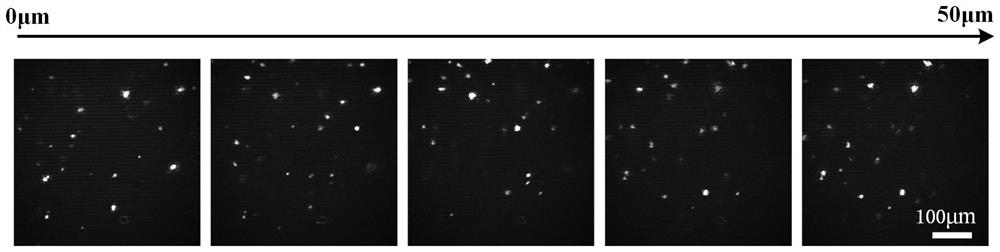

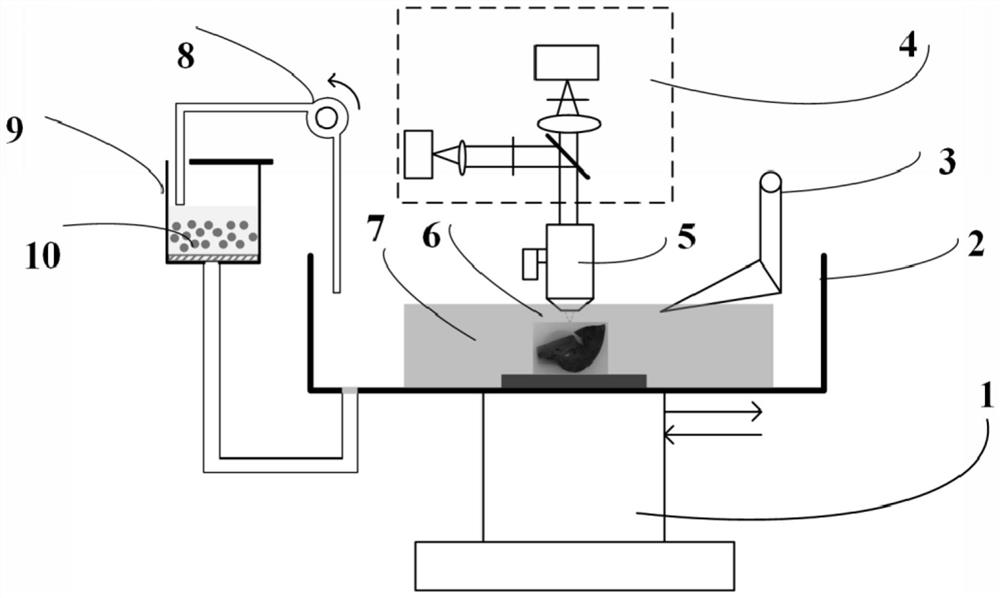

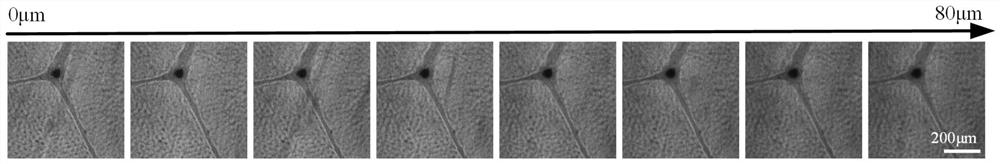

Optical transparency method for quickly acquiring three-dimensional data of large-volume sample

PendingCN113324820AAdd depthEnsure continuous access toPreparing sample for investigationMaterial analysis by optical meansTomographyChemical compound

The invention discloses a method for rapidly acquiring three-dimensional data of a large-volume biological sample. The method comprises the following steps: S1, a first immersion step; s2, an embedding step; s3, a second immersion step; s4, a sample installation step; s5, an optical imaging step; and s6, a slicing step; wherein the S5 and S6 are circularly and alternately carried out until a three-dimensional image of the biological sample tissue is obtained; the light transparent solution comprises the following raw materials in percentage by mass: 20-40% of sugar or alcohol or sugar-alcohol compound, 10 to 30% of urea, 0-30% of a penetration enhancer and the balance of water. According to the invention, the optical transparent solution and the microsection tomography technology are combined for use; optical imaging and microsection are alternately carried out, and meanwhile, the optical transparent solution is used for replacing liquid between tissues of a biological sample in real time; therefore, the refractive index of the biological sample tissue is quickly balanced, the depth of single imaging is expanded, and the slicing frequency of the whole sample is remarkably reduced. Therefore, the applicable sample range of light transparency and the continuous acquisition efficiency of three-dimensional data are greatly improved.

Owner:HUST SUZHOU INST FOR BRAINMATICS

Programmable logic controller (PLC) control-based full-automatic sample cutting machine and cutting method thereof

InactiveCN101961874BReduce wear rateShorten the lengthWithdrawing sample devicesMetal working apparatusElectric machineProgrammable logic controller

The invention relates to a programmable logic controller (PLC) control-based full-automatic sample cutting machine and a cutting method thereof, and belongs to the field of machining, which solves the problems of large labor consumption and difficult guarantee of precise cutting and quality of samples in the conventional cutting technology. The PLC control-based full-automatic sample cutting machine comprises a main shaft, a disc cutter, a sample clamping table, a cross-shaped sliding table, a feed mechanism, a sample introduction mechanism and a swinging mechanism, wherein the disc cutter isarranged on the main shaft; the sample clamping table is arranged on the cross-shaped sliding table; and the swing mechanism is arranged on the sample clamping table and can drive samples to swing upand down. In the PLC control-based full-automatic sample cutting machine, on the basis of PLC control, a touch screen is used as a man-machine interaction interface to perform parameter setting, so that the PLC control-based full-automatic sample cutting machine can complete actions such as feed / retracting, sample introduction / sample return, restoration, swinging and the like automatically according to preset advance parameters, and can regulate the rotational speed and feed speed and feed mode of blades automatically according to the change of blade speed or the change of main motor loads which are generated by the complexity of sample cutting.

Owner:HARBIN INST OF TECH

Width division cutter for glass fiber production

InactiveCN112813670AAvoid quality problemsGuaranteed cutting forceSevering textilesGlass fiberCutting force

The invention belongs to the technical field of glass fiber weaving production, and provides a width division cutter for glass fiber production. The width division cutter comprises a base, a cutter rest, a blade, a cushion block, a fixed seat and a cushion block driving mechanism; the cutter rest is fixedly arranged on the base; the blade is fixedly arranged on the cutter rest; the cushion block is fixedly arranged on the fixed seat; the cushion block is matched with the blade; the fixed seat is hinged to the base; and the cushion block driving mechanism is arranged below the fixed seat and used for driving the cushion block on the fixed seat to make intermittent contact with the blade. Compared with the prior art, the width division cutter has the advantages that the cushion block can be driven to make intermittent contact with the blade by the cushion block driving mechanism arranged below the fixed seat, so that cutting and width division are completed, and the quality problem caused by cloth cover pollution is avoided. The cushion block driving mechanism and the cushion block are arranged at the same end, so that the cutting force is ensured, the torque is reduced, and the service life is prolonged.

Owner:TAISHAN FIBERGLASS INC

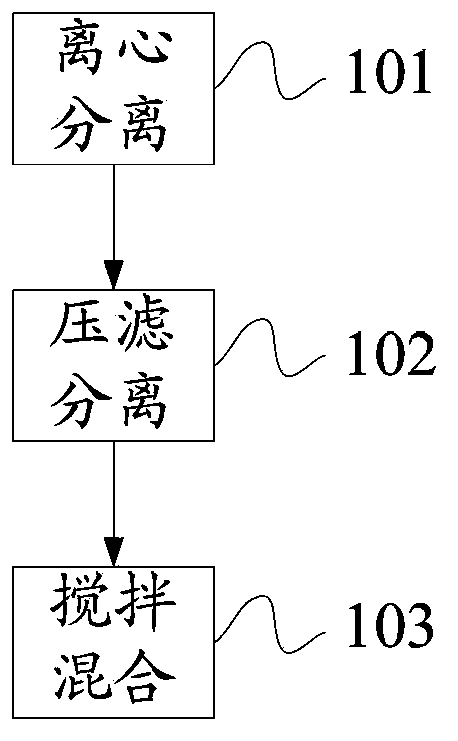

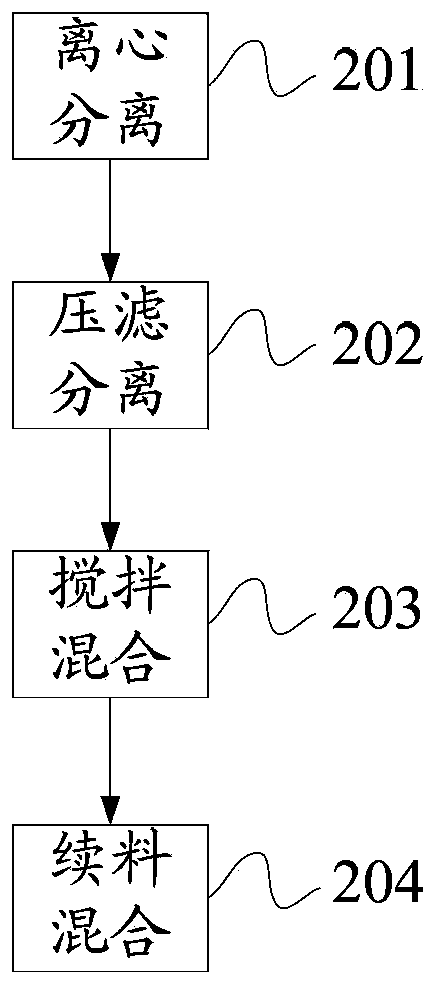

Mortar recycling process

InactiveCN104232287AEnable recyclingSimple recyclingLubricant compositionSolid substanceFilter press

The invention discloses a mortar recycling process. The mortar recycling process comprises process steps of centrifugal separating, filter-pressing separation and stirring and mixing. The mortar recycling process comprises the following steps: firstly, separating effective solid substances such as silicon carbide in mortar; then, separating and removing impurities, silicon powder and the like in the mortar by virtue of filter-pressing; and finally, re-mixing the impurity-removed mortar with the separated effective solid substances such as silicon carbide to realize recycling of the mortar. The whole mortar recycling process is simple and easy to implement, and high in treating efficiency.

Owner:JINKO SOLAR CO LTD

Diamond grinding pad and its preparation process

ActiveCN108857867BLarge amount of removalGuaranteed cutting forceLapping toolsAdhesive cementSurface roughness

The invention discloses a diamond polishing pad and a preparation process thereof. The diamond polishing pad comprises a substrate and an abrasive layer arranged on the surface of the substrate. The abrasive layer comprises the following raw materials of, by mass, 5-10% of diamond cluster abrasive, 70-75% of adhesive and the balance filler, wherein the diamond cluster abrasive is composed of single-grain diamond clusters. The diamond polishing pad prepared through the formula and the process, is high in removal amount, the cutting force is ensured, the grinding efficiency is effectively improved, the grinding efficiency and stability are better, the service life is greatly prolonged, meanwhile, the surface roughness of machined products is lower, the surface quality of the machined products is greatly improved, and the diamond polishing pad is worthy of application and popularization.

Owner:黄文魁

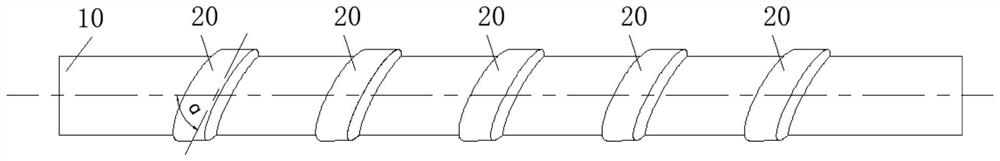

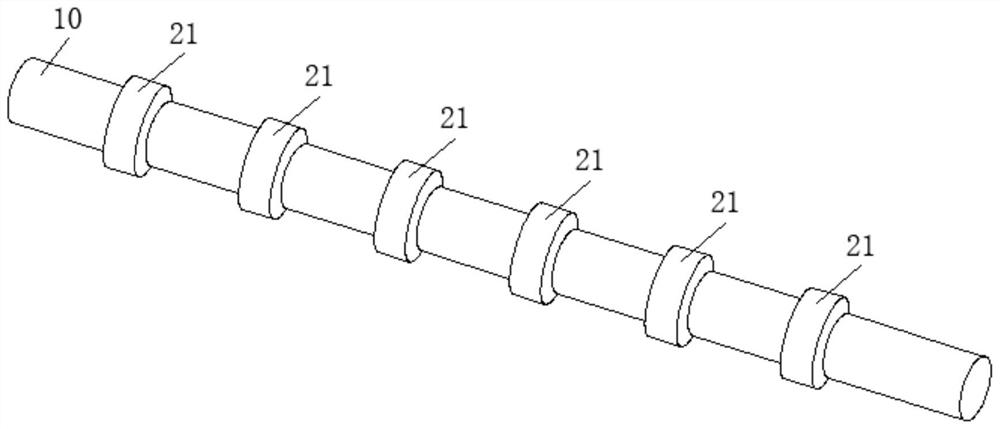

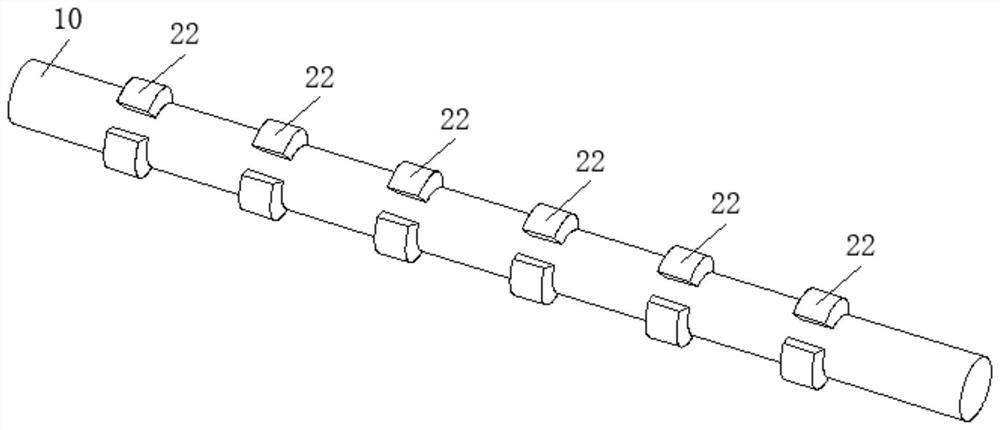

Diamond wire and preparation method thereof

The invention discloses a diamond wire and a preparation method thereof, relates to the technical field of silicon wafer cutting, and is used for guaranteeing the cutting force of the diamond wire under the condition that the diameter of the diamond wire is reduced. The diamond wire comprises a bus, a conductive part arranged on the periphery of the bus and an electroplated layer at least formed on the bus. And a preset included angle is formed between the projection of the conductive part on the bus and the extension direction of the bus. And the conductive part is used for enhancing the conductivity of the bus in the process of forming the electroplated layer. The preparation method of the diamond wire comprises the following steps that the conductive part is arranged on the periphery of the bus; and electroplating the bus to obtain the diamond wire.

Owner:LONGI GREEN ENERGY TECH CO LTD

Method for rapidly dyeing biological sample and acquiring three-dimensional data

ActiveCN113324821AImprove dyeing efficiencyImprove acquisition efficiencyPreparing sample for investigationMaterial analysis by optical meansStaining3d image

The invention discloses a method for rapidly dyeing a biological sample and obtaining three-dimensional data, which comprises the following steps: S1, a first immersion step, S2, an embedding step, S3, a second immersion step, S4, a sample installation step, S5, an optical imaging step, S6, a slicing step; wherein the S5 and S6 are circulated until a three-dimensional image of a biological sample tissue is obtained, and wherein the imaging solution comprises the following raw materials in percentage by mass: 20-40% of sugar or alcohol or sugar alcohol compound; 10-30% of urea; 0-30% of a penetration enhancer aqueous solution; and the balance is the coloring agent. The imaging solution composed of the fructose, the urea, the penetration enhancer and the coloring agent is used for rapidly replacing interstitial fluid in the biological tissue sample, so that the newly exposed surface of the sample is rapidly transparent and dyed; the dyeing efficiency is greatly improved; by matching the microscopic cutting and optical imaging, the three-dimensional data of the dyed biological samples with different volumes can be quickly obtained.

Owner:HUST SUZHOU INST FOR BRAINMATICS

A hydraulic engineering impeller based on high-speed centrifugal pole cutter

ActiveCN112081773BExtended service lifeEfficient use ofPump componentsHydro energy generationImpellerMagnetic poles

The invention discloses a water conservancy engineering impeller based on a high-speed centrifugal magnetic pole cutter, which includes a wheel body, a central shaft body, an outer ring sleeve shaft and an impeller body, the outer ring sleeve shaft is installed outside the central shaft body, the central shaft body and the impeller body The shafts of the outer ring are rotatably connected to the wheel body through a connecting frame; the outside of the shaft of the outer ring is fixedly connected with a rotating seat, and the outer side of the rotating seat is rotatably connected with a retractable internal cutting cutter. An inner groove is provided at the inner side of the incision crushing knife, and the inner groove is equipped with a recovery and reset device. The present invention relates to the technical field of water conservancy engineering. The water conservancy project impeller based on the high-speed centrifugal magnetic pole cutter has different components at both ends of the impeller assembly, which can make more effective use of water energy, and can effectively improve the service life of the impeller and reduce the number of repairs and maintenance. It ensures that the cutting force of the device during work also ensures the working efficiency of the impeller.

Owner:安徽禹溪水利工程有限公司

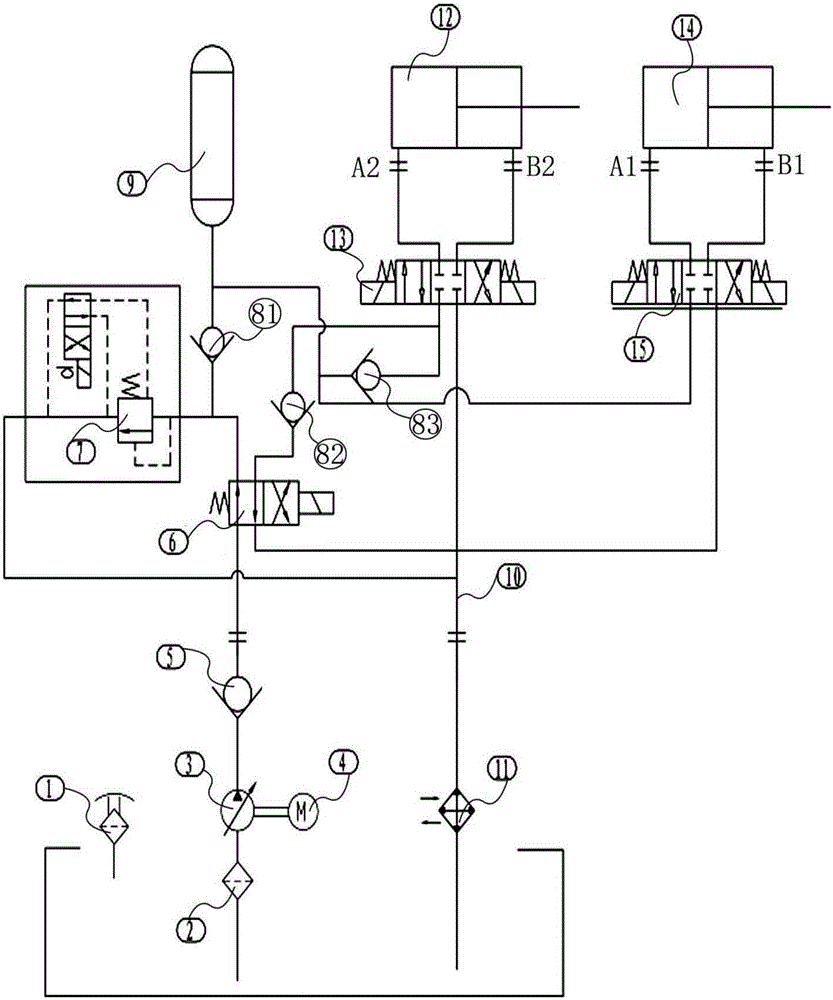

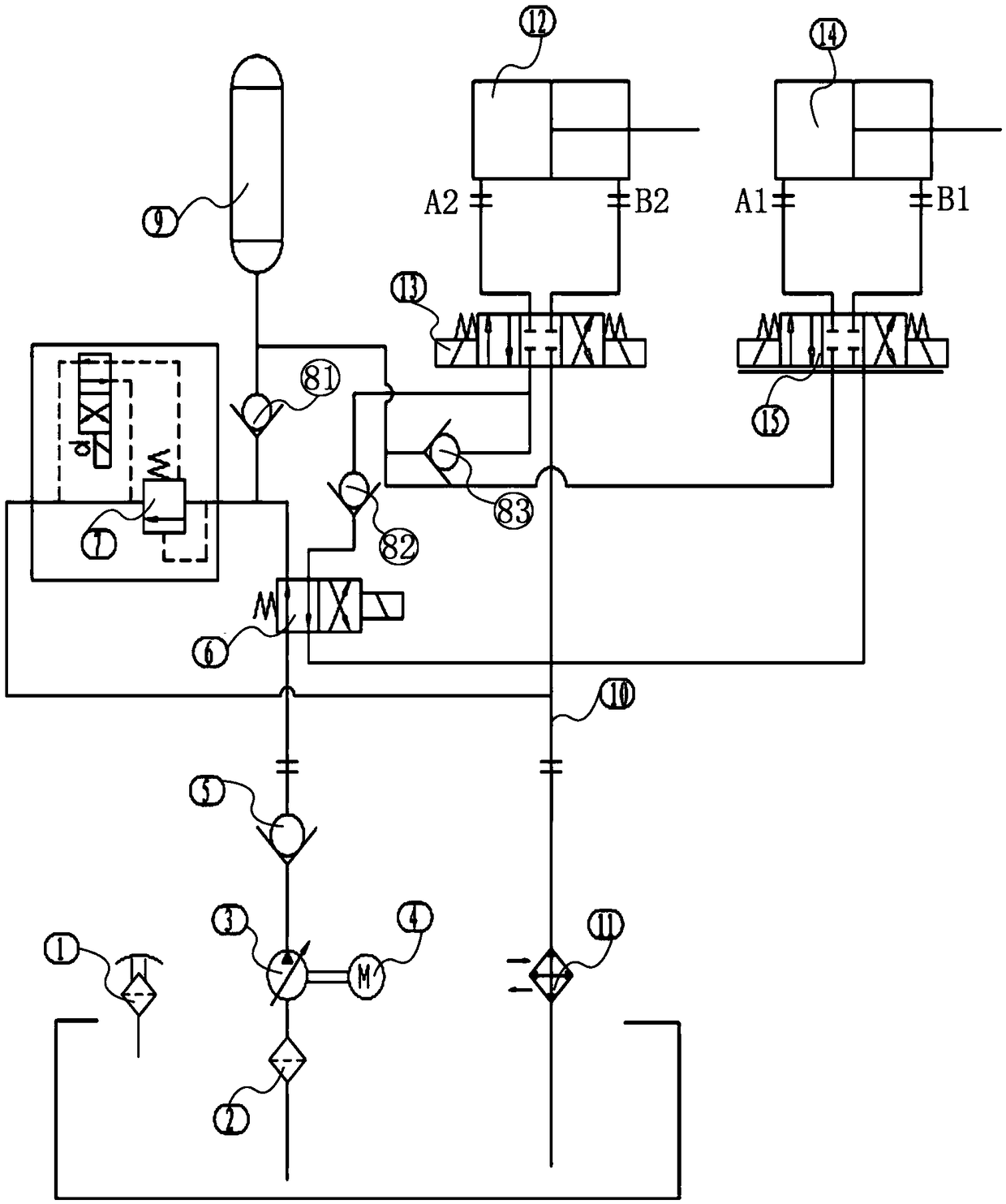

Hydraulic system applied to hydraulic full-automatic unloading iron cutting machine

The invention relates to a hydraulic system applied to a hydraulic full-automatic unloading iron cutting machine. A motor is connected to an oil pump and controls the oil pump to operate, hydraulic oil is sucked from an oil tank through an oil absorption net filter, the oil pump conveys the hydraulic oil to an electromagnetic reversing valve through a one-way check valve I, the electromagnetic reversing valve then conveys the hydraulic oil to an energy accumulator through a one-way valve II, and a pressure is regulated through an electromagnetic overflow valve; after the electromagnetic reversing valve is electrified, the hydraulic oil is then conveyed to an electro-hydraulic reversing valve through a one-way valve III, and the electro-hydraulic reversing valve then conveys the hydraulic oil to a cut-off oil cylinder; the hydraulic oil of a feeding oil cylinder is provided to a proportional flow reversing valve through the energy accumulator and is conveyed to the feeding oil cylinder. The system provided by the invention has the characteristics of being novel in structure, high in degree of automation, fast to unload, and high in percent of pass of finished products, and personnel can be reduced by using the system.

Owner:福建省捷佳液压科技有限公司

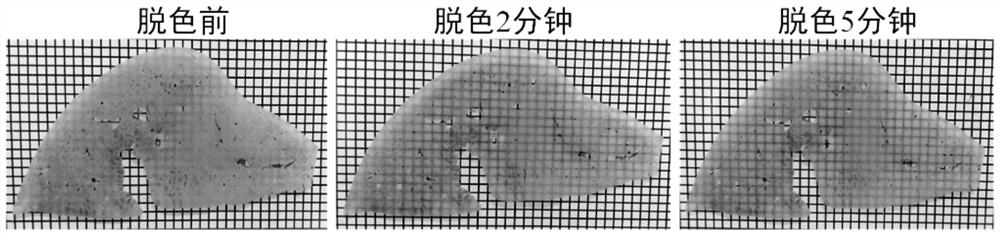

Method for decolorizing transparent large-volume sample and acquiring three-dimensional data online

PendingCN113390695AReduce the number of timesUniform refractive indexWithdrawing sample devicesPreparing sample for investigationOptical transparencyAlcohol sugars

The invention discloses a method for decolorizing a transparent large-volume sample and acquiring three-dimensional data online, which comprises an embedding step, two immersion steps before and after the embedding step, and a cyclic optical imaging and slicing step, wherein an imaging solution in the immersion steps at least comprises sugar or alcohol or a sugar alcohol compound, urea, and an amino alcohol compound. The optical transparency and microsection tomography technologies are combined and alternately used, and the imaging solution performs real-time optical transparency operation on the sample, balances the refractive index of the tissue sample, eluates the heme in the sample to remove the influence of the heme on optical imaging, improves the depth of single imaging, reduces the number of microsection times of the sample, and improves the acquisition efficiency of the three-dimensional data.

Owner:HUST SUZHOU INST FOR BRAINMATICS

A hydraulic system applied to hydraulic automatic cutting iron cutting machine

ActiveCN106640800BHigh speedHigh precisionServomotorsServometer circuitsElectricityElectro hydraulic

The invention relates to a hydraulic system applied to a hydraulic full-automatic unloading iron cutting machine. A motor is connected to an oil pump and controls the oil pump to operate, hydraulic oil is sucked from an oil tank through an oil absorption net filter, the oil pump conveys the hydraulic oil to an electromagnetic reversing valve through a one-way check valve I, the electromagnetic reversing valve then conveys the hydraulic oil to an energy accumulator through a one-way valve II, and a pressure is regulated through an electromagnetic overflow valve; after the electromagnetic reversing valve is electrified, the hydraulic oil is then conveyed to an electro-hydraulic reversing valve through a one-way valve III, and the electro-hydraulic reversing valve then conveys the hydraulic oil to a cut-off oil cylinder; the hydraulic oil of a feeding oil cylinder is provided to a proportional flow reversing valve through the energy accumulator and is conveyed to the feeding oil cylinder. The system provided by the invention has the characteristics of being novel in structure, high in degree of automation, fast to unload, and high in percent of pass of finished products, and personnel can be reduced by using the system.

Owner:福建省捷佳液压科技有限公司

A deep water diamond wire saw machine

ActiveCN106141304BConvenient for underwater workGuaranteed lifeMetal sawing devicesMetal sawing accessoriesDiamond wire sawEngineering

The invention provides a deepwater diamond wire sawing machine which is majorly composed of a cutting drive mechanism, a feeding drive mechanism, a feeding speed regulating mechanism, a string bead wire tensioning mechanism and clamping mechanisms, and used for completing cutting repair of underwater structures. The feeding speed regulating mechanism is adopted for the deepwater diamond wire sawing machine, the feeding speed can be regulated along with the change of tension of a string bead wire in the operating process, and the service life of the string bead wire, the cutting efficiency of the machine and the reliability of cutting operation are effectively guaranteed. The feeding drive mechanism can promote transmission separation of a feeding motor and a lead screw, so that overload protection for the feeding drive mechanism is achieved; and meanwhile, under the condition that the machine does not have power, a handle can be rotated for feeding, and integrally automatic and manual drive feeding is achieved. A strong spring, a nut and a screw are adopted for tensioning of the string bead wire tensioning mechanism, and vibration of the string bead wire in the cutting process can be effectively reduced accordingly. The deepwater diamond wire sawing machine is provided with buoyancy materials and a deepwater valve box and suitable for deepwater environment operation.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com