Preparation method of nickel-titanium alloy flexible and elastic root canal file

A nickel-titanium alloy and root canal file technology, applied in the field of medical devices, can solve the problems of prolonged cutting time, side penetration of curved root canals, straightening, etc., to meet hardness and fatigue life, improve fatigue resistance, and ensure cutting ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

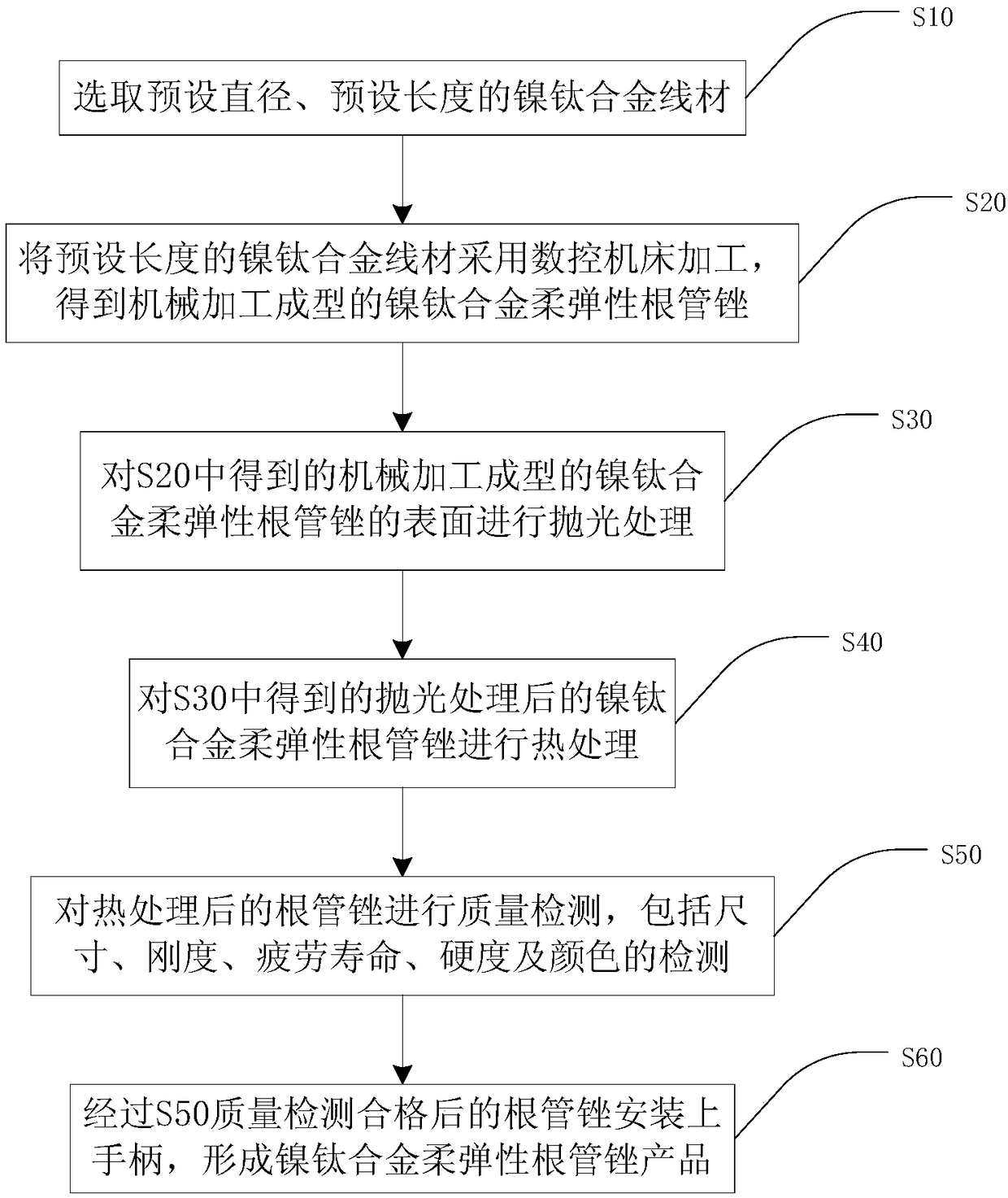

[0022] The invention provides a method for preparing a nickel-titanium alloy flexible and elastic root canal file. figure 1 It is the flow chart of the preparation method of nickel-titanium alloy flexible and elastic root canal file of the present invention, combined below figure 1 The method is described in detail, specifically including the following steps:

[0023] S10. Selecting a nickel-titanium alloy wire with a preset diameter and a preset length.

[0024] Wherein, the preset diameter and the preset length are respectively determined according to the external dimensions of the root canal file to be processed and formed, such as the length and the maximum diameter, and the corresponding preset length and preset diameter of the root canal files of different lengths and different maximum diameters are different, Usually, a preset diameter of 1.2mm, 1.0mm or 0.8mm is used; the preset length is at least greater than the length of the root canal file.

[0025] The atomic pe...

Embodiment 1

[0036] S110. Select a nickel-titanium alloy wire with a diameter of 1.2 mm, a length of 2.5 m, a titanium atomic percentage of 5%-15% and a nickel atomic percentage of 50%-60%.

[0037] S120, processing the nickel-titanium alloy wires selected in S110 with a numerical control machine tool to obtain several mechanically processed nickel-titanium alloy flexible and elastic root canal files.

[0038] When the nickel-titanium alloy wires selected by S110 are processed by CNC machine tools, several mechanically processed nickel-titanium alloy flexible and elastic root canal files can be obtained. The number of processed root canal files is determined according to the length of the processed and formed root canal files.

[0039] S130 , polishing the surface of the mechanically formed nickel-titanium alloy flexible and elastic root canal file obtained in S120 .

[0040] S140. The polished nickel-titanium alloy flexible and elastic root canal file obtained in S130 is kept warm in a ho...

Embodiment 2

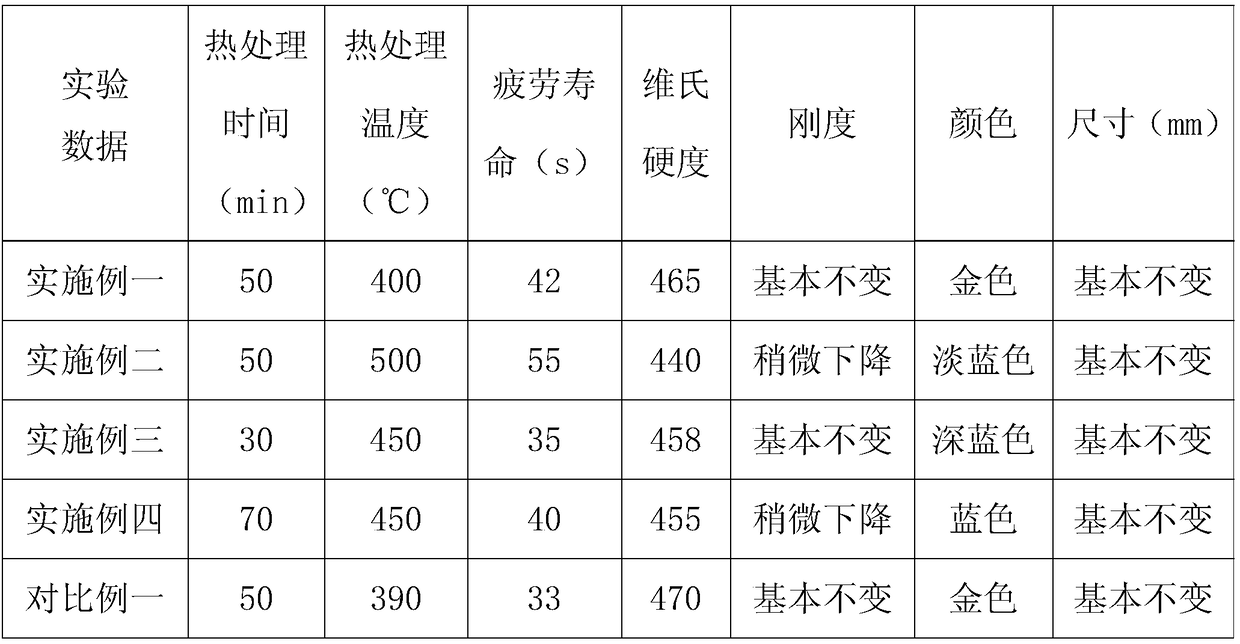

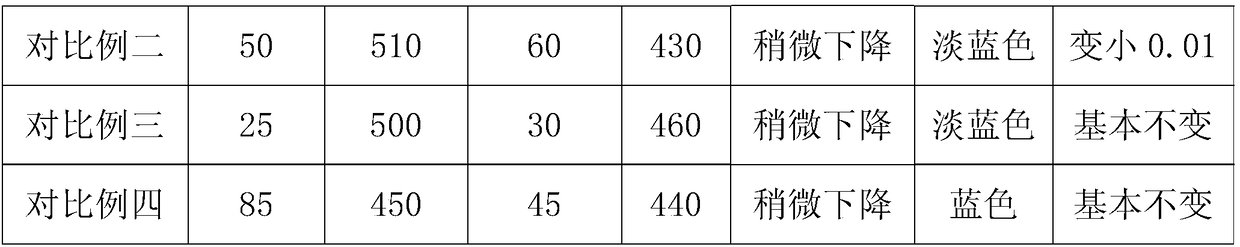

[0045] The differences between this embodiment and the heat treatment conditions of the first embodiment are: the heat treatment temperature is 500° C., the holding time is 50 minutes, and other test conditions are the same as the first embodiment.

[0046] The hardness of the nickel-titanium alloy flexible and elastic root canal file obtained by the above heat treatment conditions is HV440, the fatigue life when the fatigue resistance is tested by a rotary testing machine is 55 seconds, and the color is light blue, the nickel-titanium alloy flexible and elastic root canal file Compared with the size before heat treatment, the size is basically unchanged, and the stiffness of the nitinol flexible root canal file is slightly reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com