Steel rib and steel frame beam connecting node

A technology for connecting nodes and steel bar connectors, which is applied in the directions of buildings and building structures, can solve the problems of affecting the smoothness of the concrete surface, low engineering construction efficiency, and hindering the travel of the sliding form, and achieves high construction efficiency, simple design and implementation, and structural stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The connection node between the steel frame and the steel frame beam in this embodiment includes a steel frame located in the concrete and a steel frame beam located outside the concrete, and the connection node between the steel frame and the steel frame beam also includes a set on the steel frame 1. An end plate whose front is exposed outside the concrete and does not protrude from the concrete; the steel frame beam is connected to the front of the end plate.

[0041] The steel frame is divided into a steel frame column and a steel frame beam. An end plate is provided at the joint between the steel frame beam or the steel frame column and the steel frame beam, and the front of the end plate is placed on the concrete when pouring concrete. and the end plate is flush with or slightly below the concrete so that the steel frame beam is no longer attached to an embed fully anchored in the concrete or to a corbel protruding in the concrete It has the characteristics of conv...

Embodiment 2

[0043] In this embodiment, on the basis of any of the above-mentioned embodiments, in the connection node between the steel frame and the steel frame beam in this embodiment, the steel frame is provided with reinforcing ribs or reinforcing ribs at the connection with the steel frame beam . The steel frames include Wang-shaped steel frames, cross-shaped steel frames, and H-shaped steel frames.

[0044] Such as Figure 4-Figure 5 As shown, the steel column 12 is provided with a reinforcement rib 20 at the joint with the corbel 15;

[0045] Such as Figure 7-Figure 8 As shown, the steel column 120 is provided with a reinforcement rib 200 at the joint with the corbel 150;

[0046] Such as Figure 12 As shown, the king-shaped steel frame is provided with a reinforcing rib 202 at the joint with the steel frame beam;

[0047] Such as Figure 13 As shown, the cross-shaped steel frame is provided with a reinforcing rib 203 at the connection with the steel frame beam;

[0048] Su...

Embodiment 3

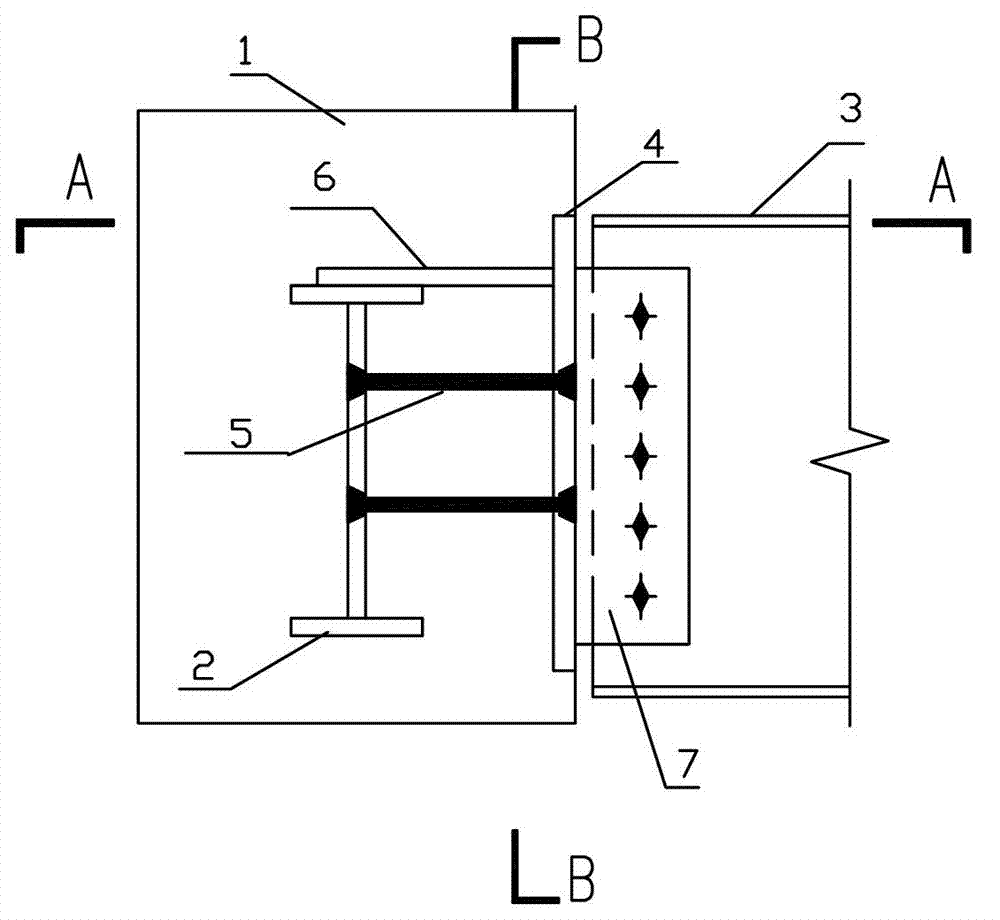

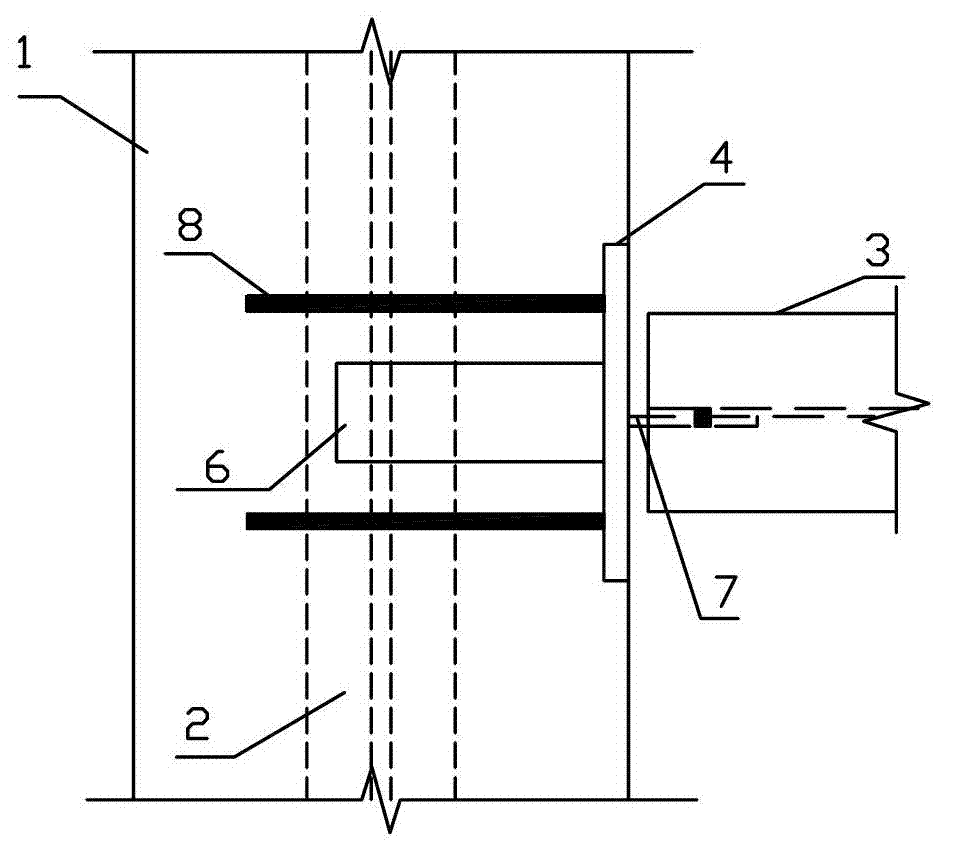

[0051] Such as Figure 1-Figure 3 As shown, the connection node between the steel frame and the steel frame beam in this embodiment includes the steel frame beam 2 and the steel frame beam 3 located in the concrete, and the connection node between the steel frame and the steel frame beam also includes a An end plate 4 flush with the outer surface of the concrete 1; the steel frame beam 3 is connected to the front of the end plate 4.

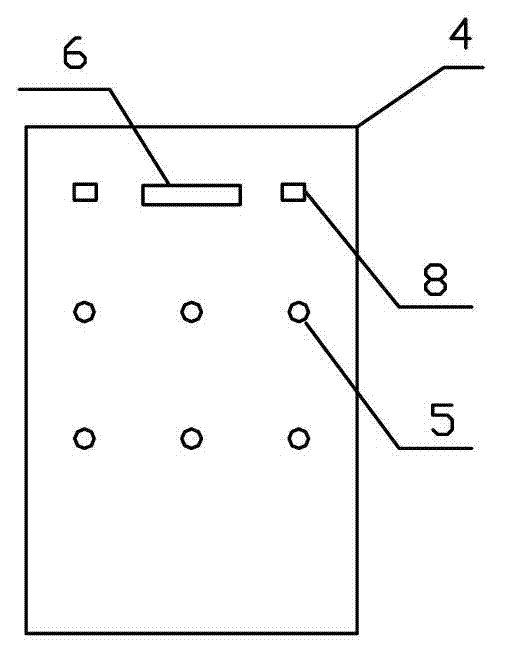

[0052] The steel frame beam 2 is arranged horizontally, and several steel bars 5 are arranged between the steel frame beam 3; Wherein, the symbol 9 in the end plate 4 is the plug welding hole for the welding of the steel bar 5 .

[0053] In this embodiment, one end of the end plate 4 used to connect the steel frame beam 2 and the steel frame beam 3 is connected to the steel frame beam 2 before pouring the concrete 1 to form a whole, and when the concrete 1 is poured, the end plate 4 The front of the concrete 1 is flush with the outer surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com