Programmable logic controller (PLC) control-based full-automatic sample cutting machine and cutting method thereof

A cutting machine, fully automatic technology, applied in the field of mechanical processing, can solve the problems of difficult to guarantee the cutting accuracy and quality of the sample, and consume a lot of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

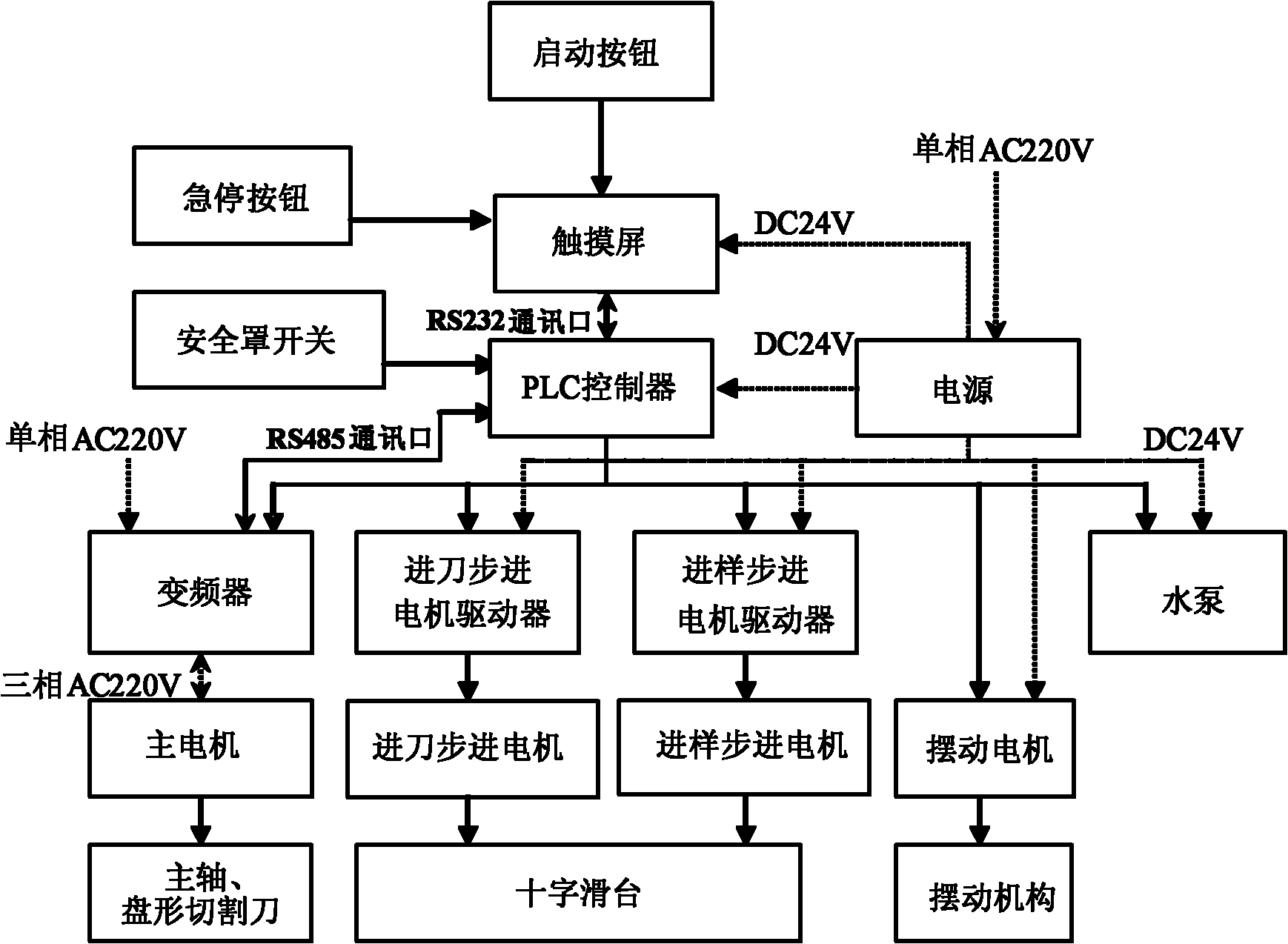

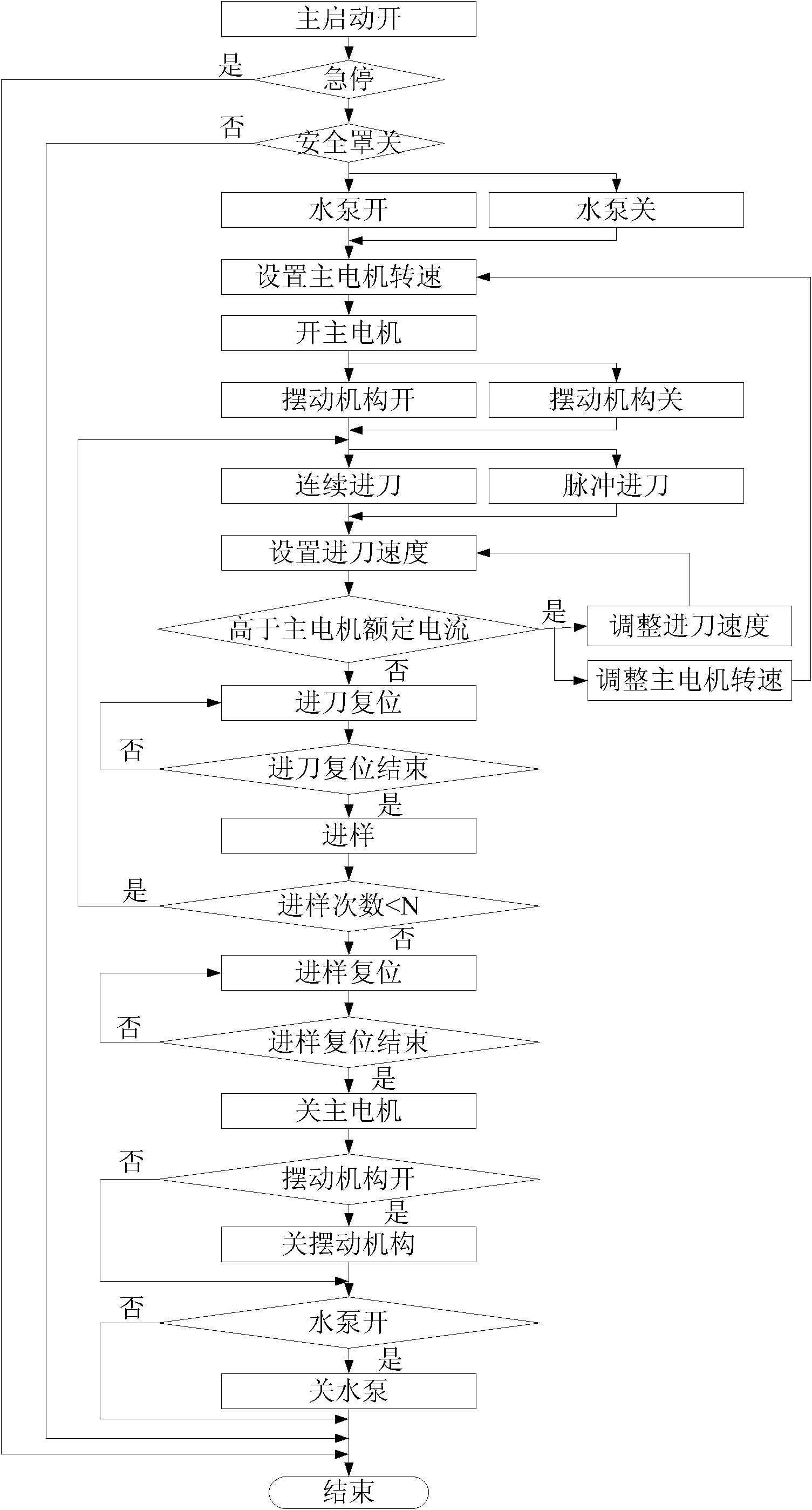

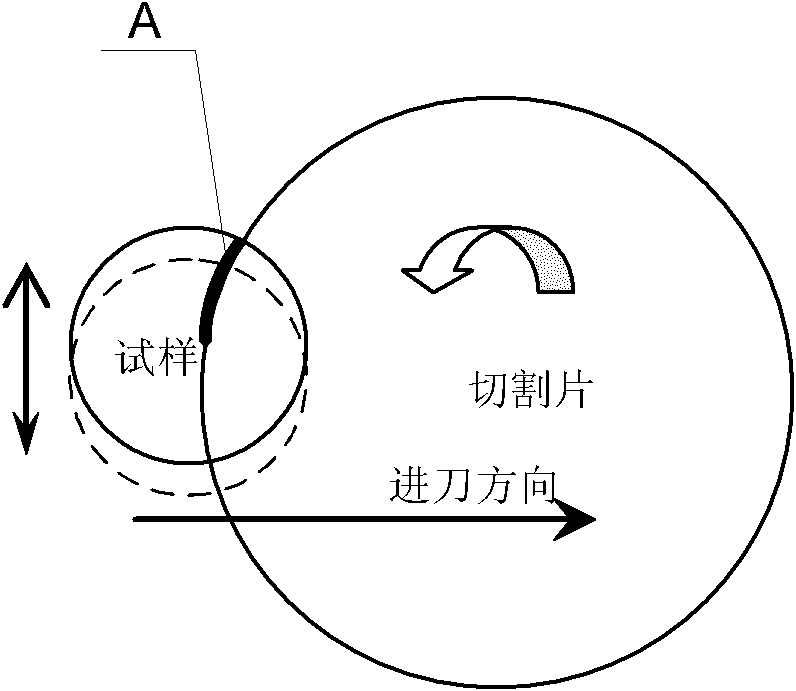

[0038] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, a kind of automatic sample cutting machine based on PLC control of this embodiment, it comprises main shaft, disc cutting knife, sample holder, cross slide table, feeding mechanism and sampling mechanism, on the main shaft A disc-shaped cutting knife is installed, a sample holder is set on the cross slide, and a swing mechanism is arranged on the sample holder, and the swing mechanism can drive the sample to swing up and down.

[0039] The feeding mechanism includes a feeding stepping motor driver and a feeding stepping motor. The feeding stepping motor driver drives the feeding stepping motor to move, and then drives the cross slide to slide longitudinally to realize the feeding or retracting operation;

[0040] The sampling mechanism includes a sampling stepping motor driver and a sampling stepping motor, and the sampling stepping motor driver drives the samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com