Paper tube cutting equipment with self cooling function

A cutting equipment and self-cooling technology, applied in metal processing and other directions, can solve the problems of different lengths of paper tubes, no cooling of cutting equipment, low cutting efficiency, etc., and achieve the effect of high cutting efficiency, high cutting accuracy and consistent length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

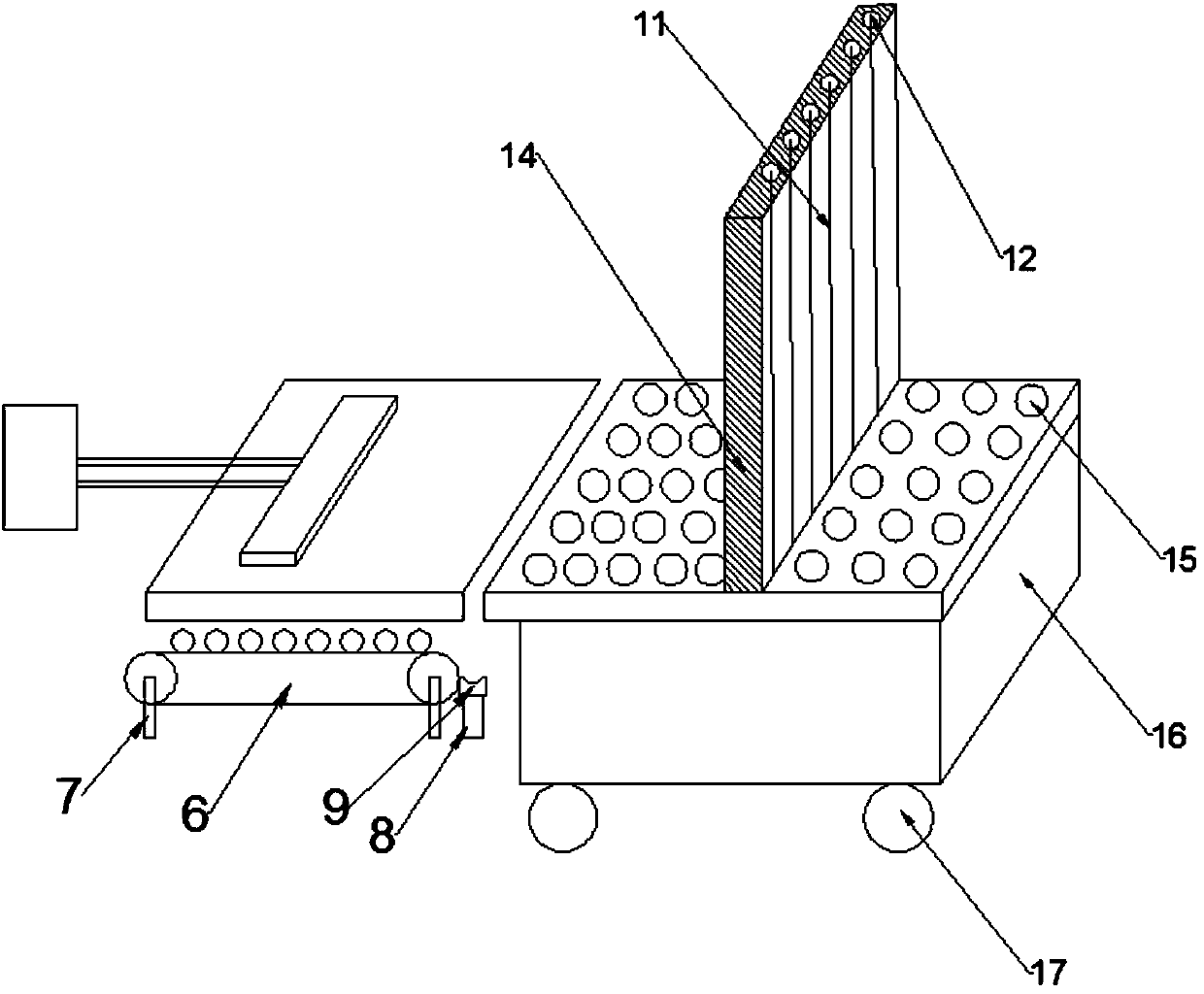

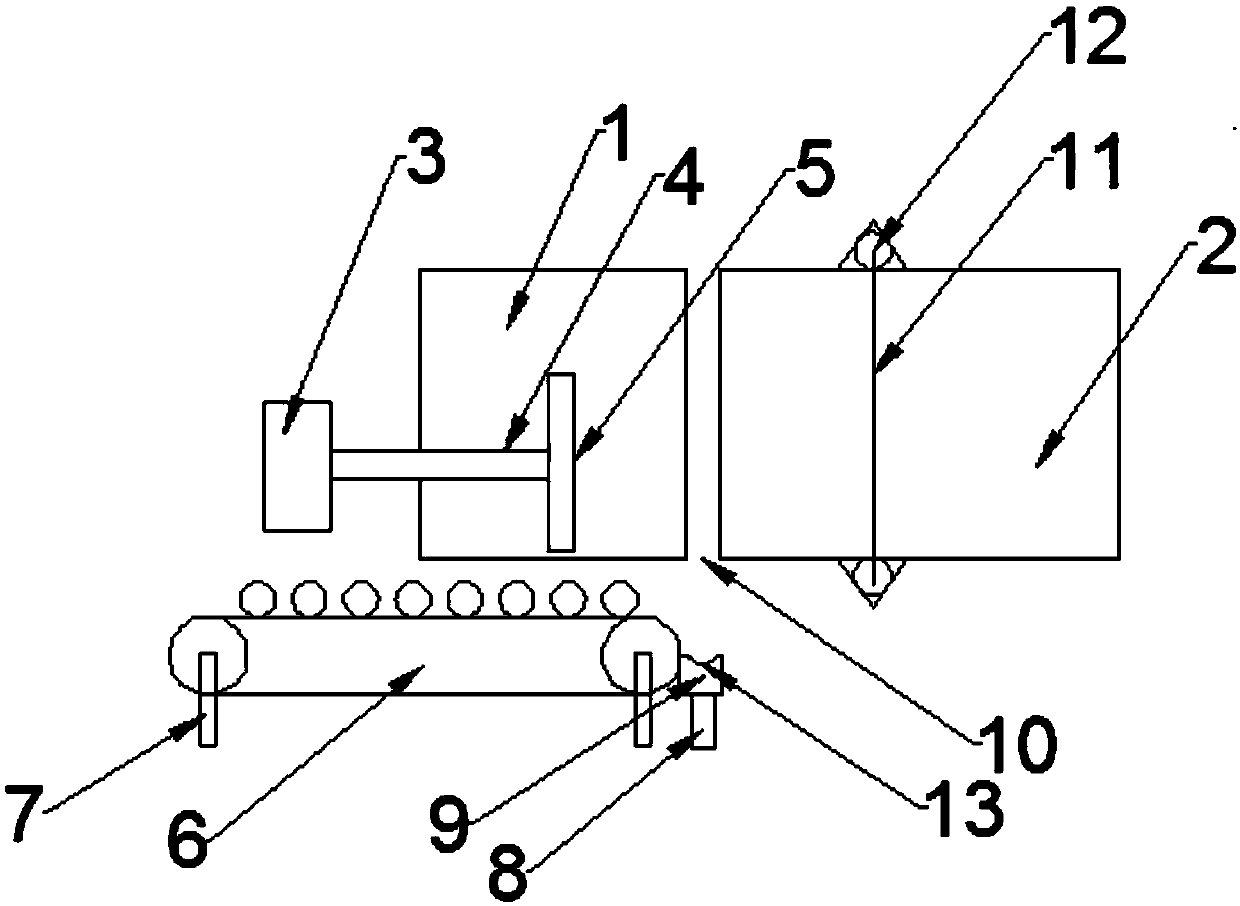

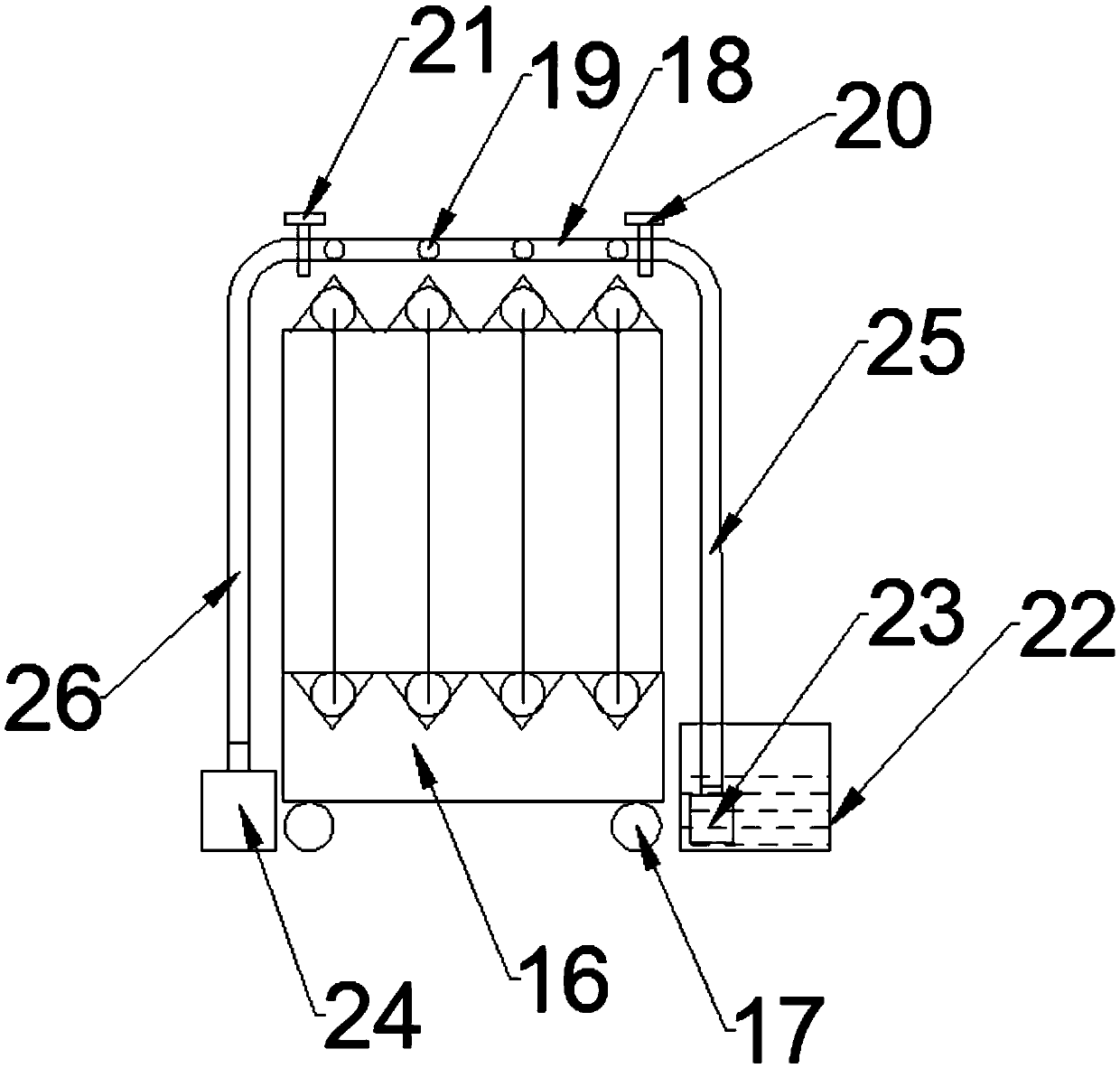

[0023] like Figure 1-3 As shown, a kind of paper tube cutting equipment with self-cooling function, including pushing bottom plate 1 and cutting bottom plate 2,

[0024] A gap 10 is left between the opposite sides of the pushing bottom plate 1 and the cutting bottom plate 2. A pneumatic cylinder 3 is provided on the side of the pushing bottom plate 1. The pneumatic cylinder 3 is connected with a first telescopic rod 4, and the other end of the first telescopic rod 4 is fixedly connected There is a push plate 5, the push plate 5 is located on the surface of the push bottom plate 1, and the push plate 5 can move back and forth along the length direction of the push bottom plate 1; a conveyor belt 6 is provided below the push bottom plate 1, and the conveyor belt 6 is fixed on the ground by a fixing rod 7, and the conveyor belt 6. The right side is provided with a second telescopic rod 8, the top of the second telescopic rod 8 is fixedly connected with a fixed plate 9, the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com