Automatically controlled high-precision crystal wire electrode cutting machine

A wire cutting machine, high-precision technology, applied in the field of mechanical equipment, can solve the problems of large driving power, large frictional resistance, poor overall rigidity, etc., and achieve the effect of improving dynamic and static rigidity, reducing driving power and improving cutting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Content of the present invention is further elaborated below by embodiment:

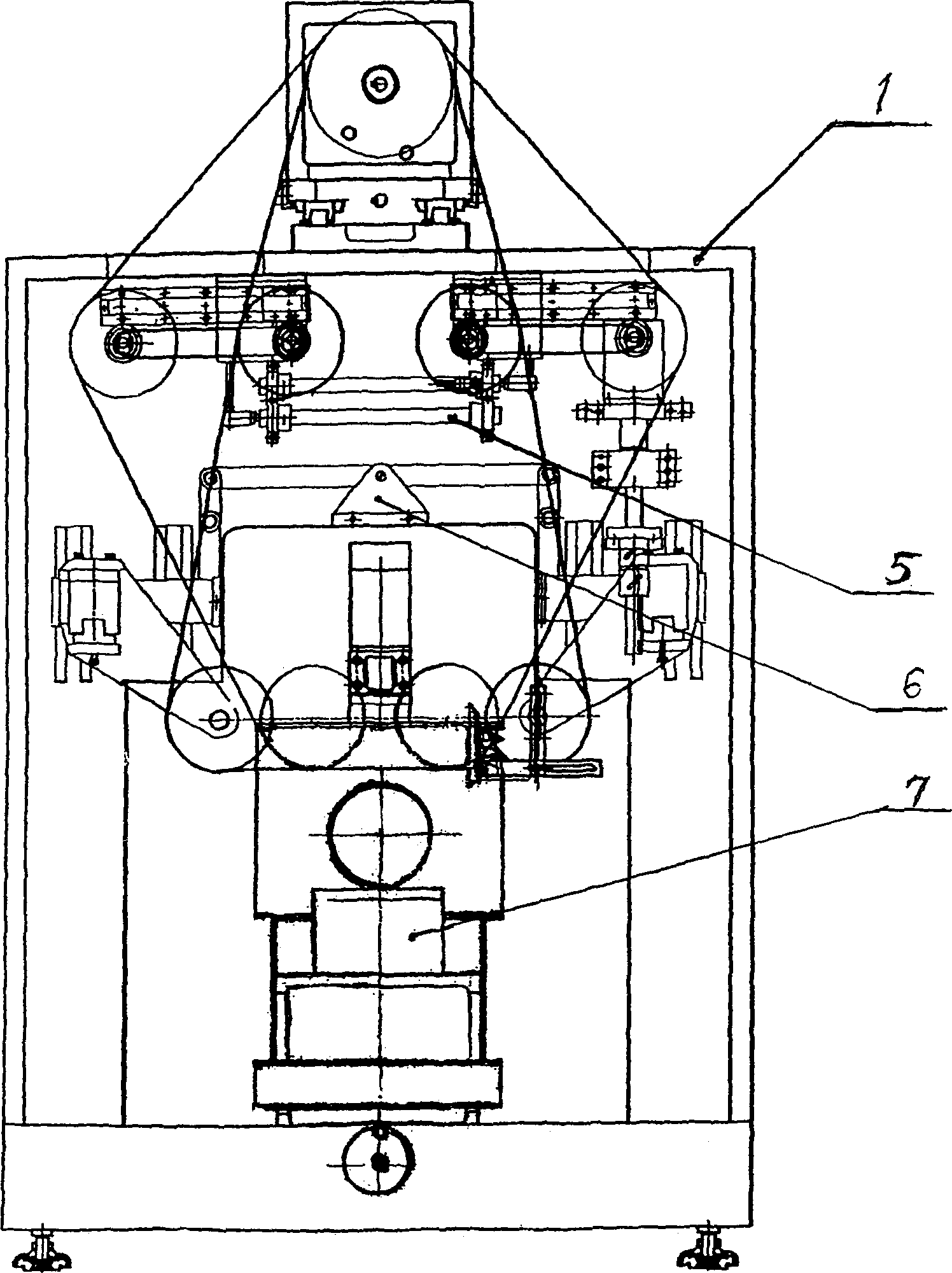

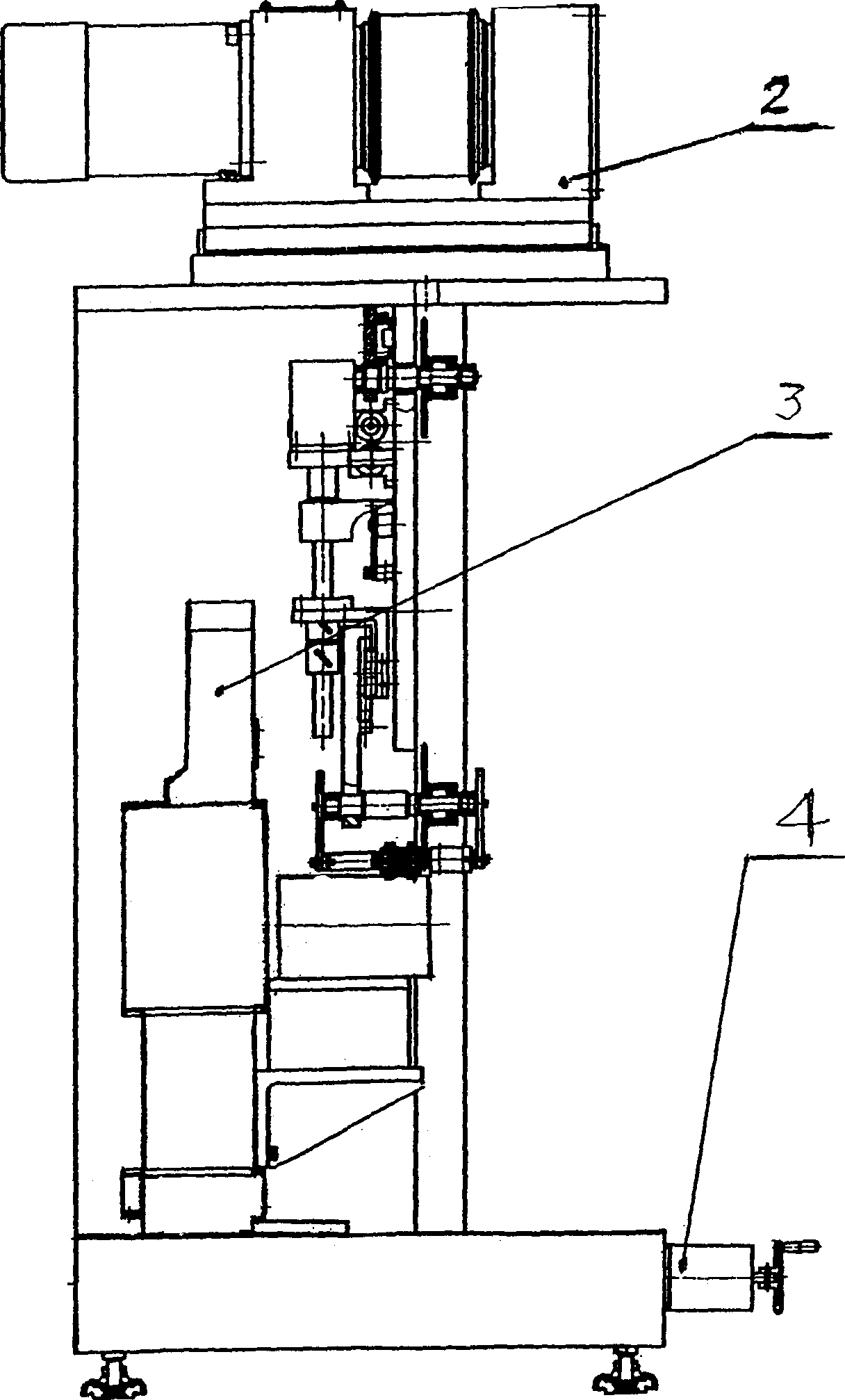

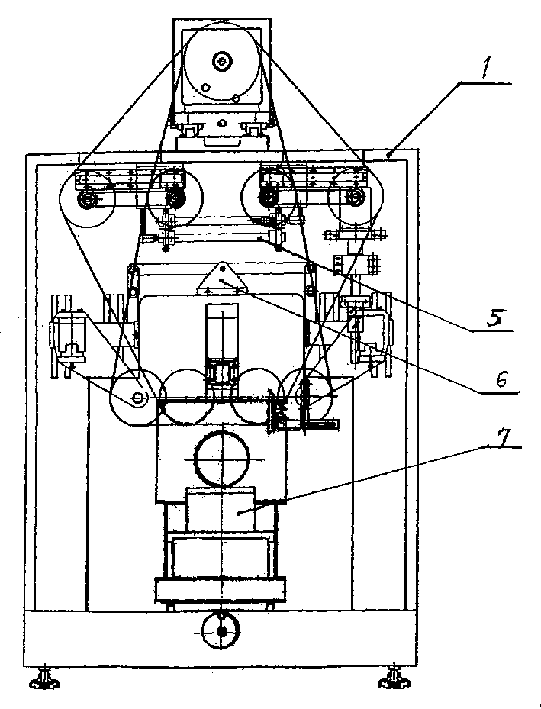

[0032] The machine tool is controlled by a single-chip microcomputer to coordinate three stepping motors and one DC speed regulating motor. A wire winding drum (2) is installed on the frame (1). The wire winding drum (2) is composed of a speed-regulating motor and a three-stage gear pair. The speed-adjustable DC motor drives the wire winding drum (2) to rotate counterclockwise. It is used for the winding and reciprocating motion of the metal cutting wire. When the cylinder applies a certain tension to the wire through the tensioning device (5), it cuts the crystal together with the abrasive slurry. Since the cutting tension is controlled by a pair of tension wheels that elastically support the cutting wire with a pair of miniature cylinders, and at the same time, the swing of the cutting wire is realized by another pair of supporting guide wheels that can swing up and down relative to each oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com