Patents

Literature

292results about How to "Guaranteed transmission accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic resonance multichannel digital transmission system and magnetic resonance data transmission method

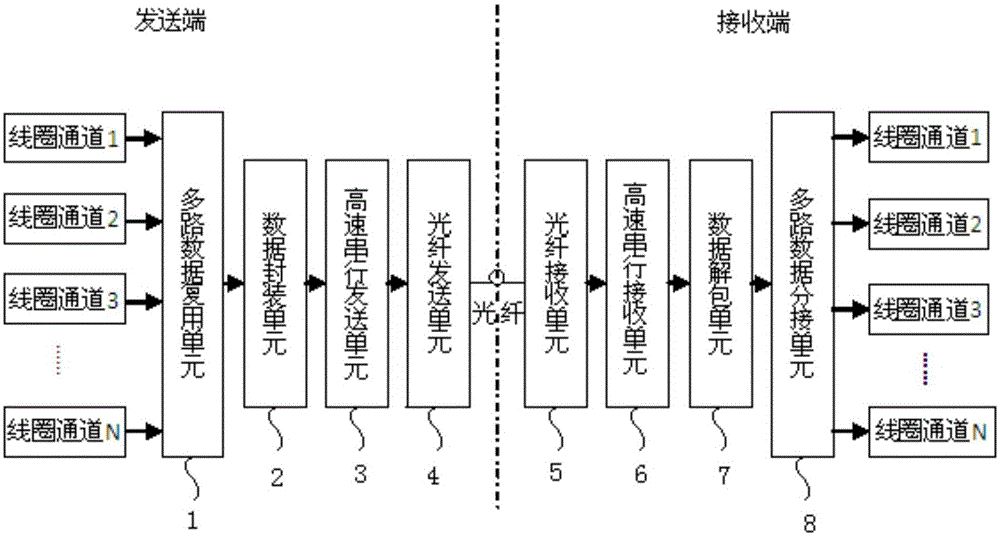

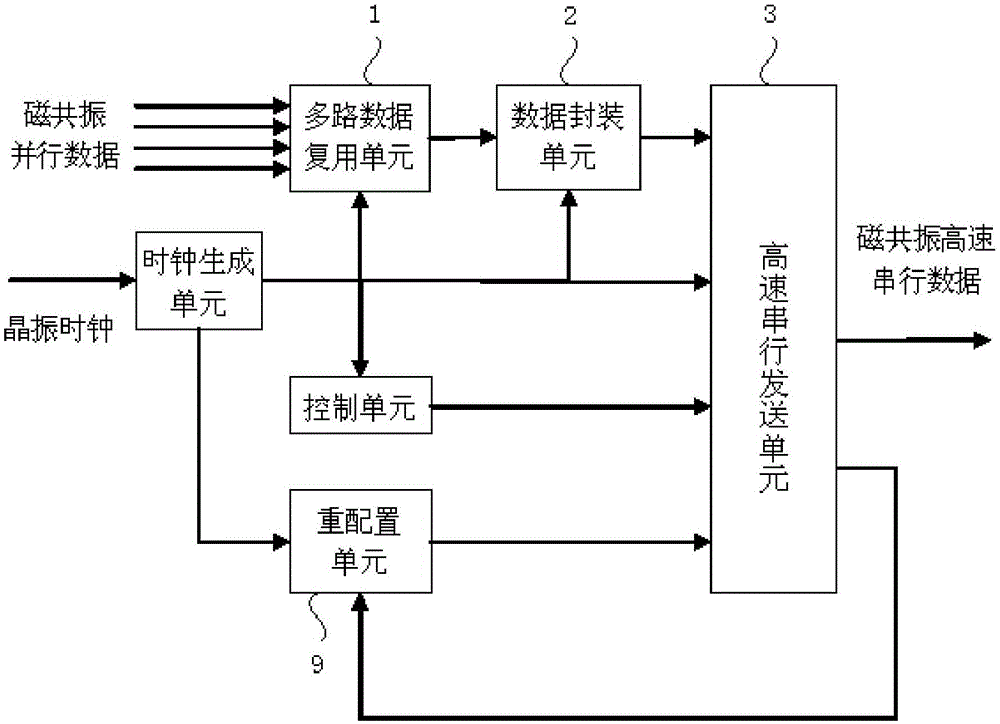

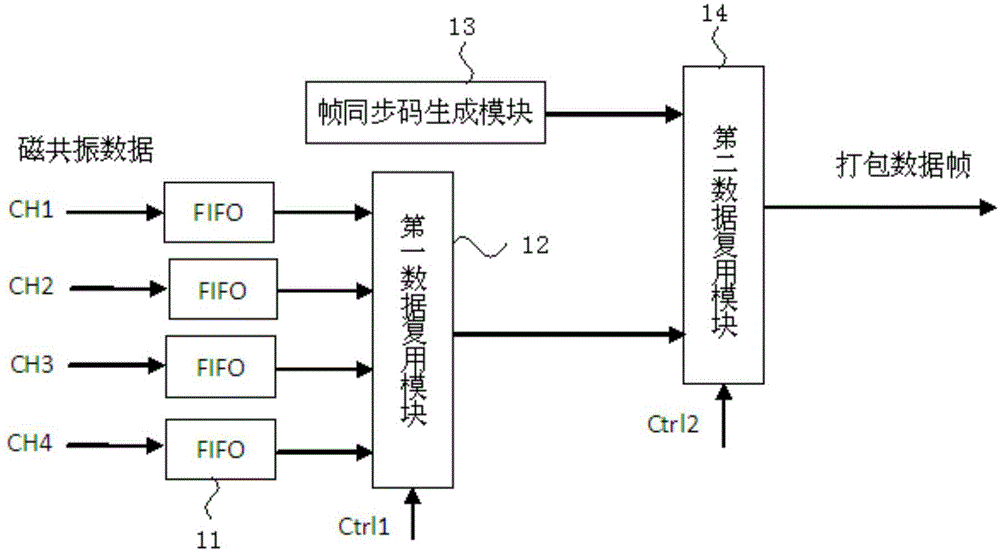

The invention discloses a magnetic resonance multichannel digital transmission system, including a multipath data multiplexing unit, a data encapsulation unit, a high speed serial transmission unit, a fiber transmission unit, a fiber reception unit, a high speed serial reception unit, a data unpacking unit and a multipath data demultiplexing unit. Multichannel magnetic resonance digital signals after sampling and front-end processing are subjected to multiplexing according to magnetic resonance data word lengths, obtained data of all channels are polled as a frame, and frame synchronization codes required in demultiplexing are inserted at a frame header, and thus the real-time property and the integrity of magnetic resonance data are ensured. Synchronous clock information is inserted in line coding, and thus transmission of magnetic resonance data and clock can be completed using a single channel, and system equipment is simplified. FPGA chip programming realization is used to improve the system integration degree. The invention also provides a magnetic resonance multichannel data transmission method.

Owner:EAST CHINA NORMAL UNIV

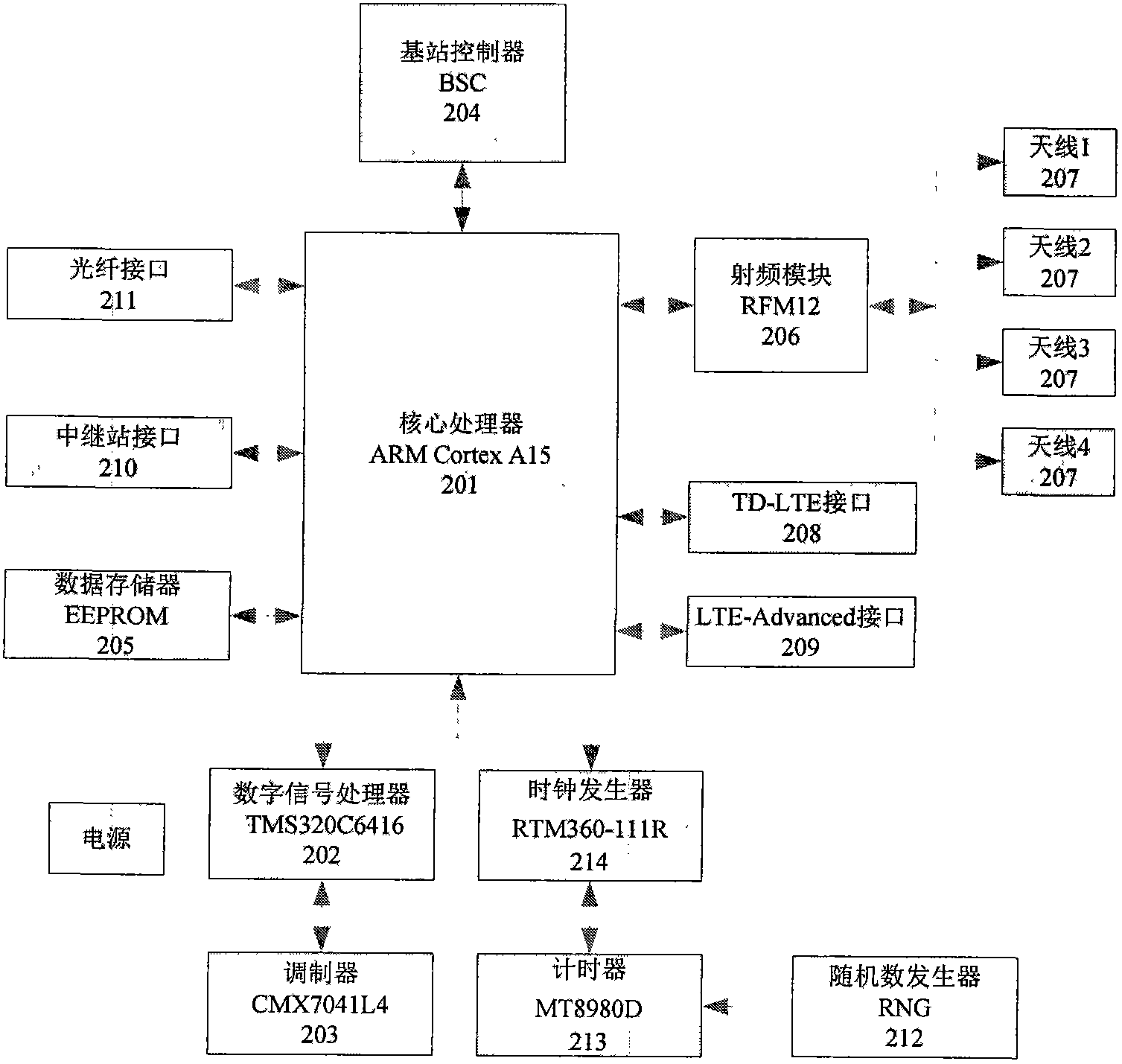

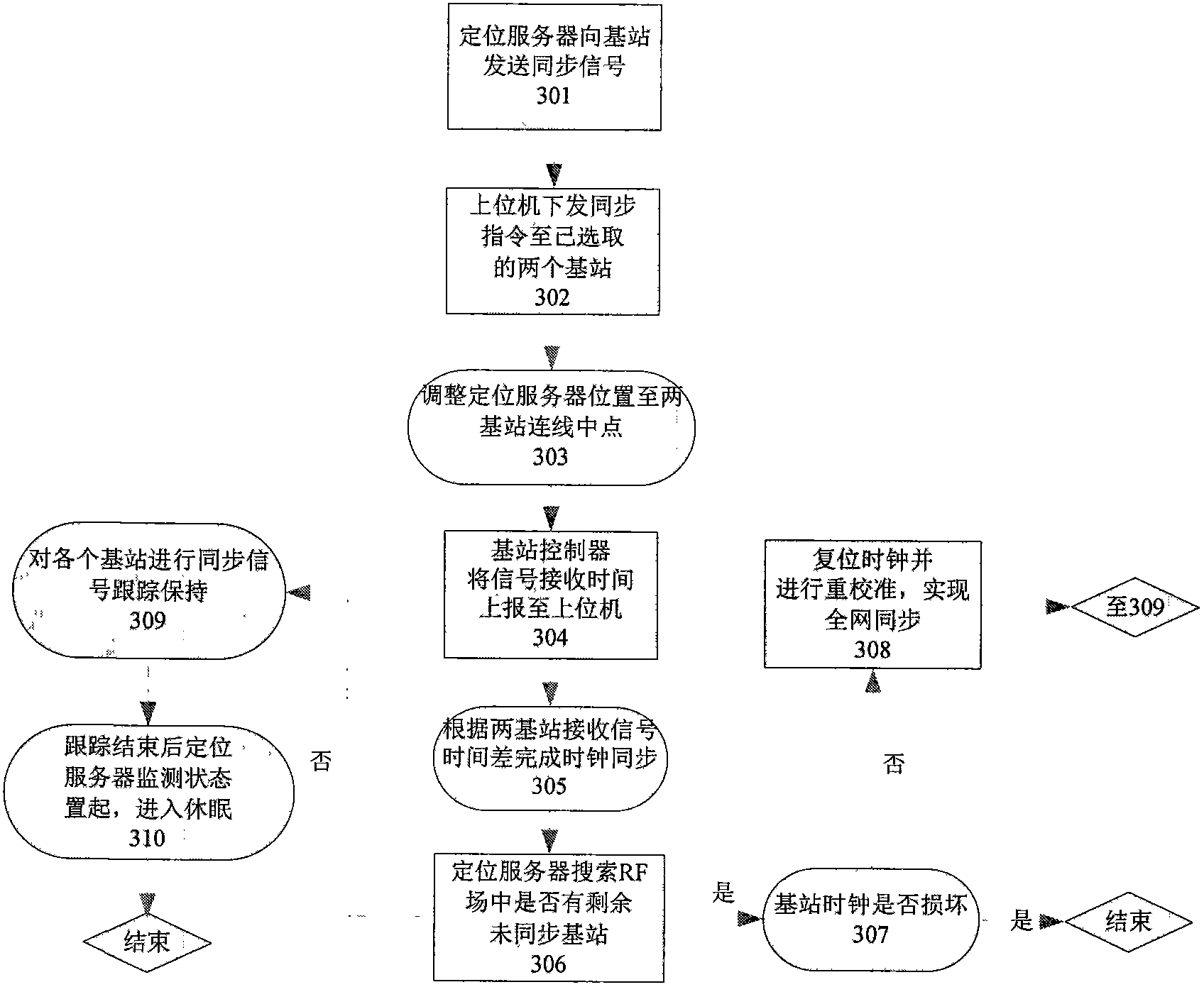

System for underground communication and staff monitoring based on TD-LTE technology

ActiveCN102802173AReduce transmission delayReduce latencySpatial transmit diversityNetwork topologiesExchange networkTransmission channel

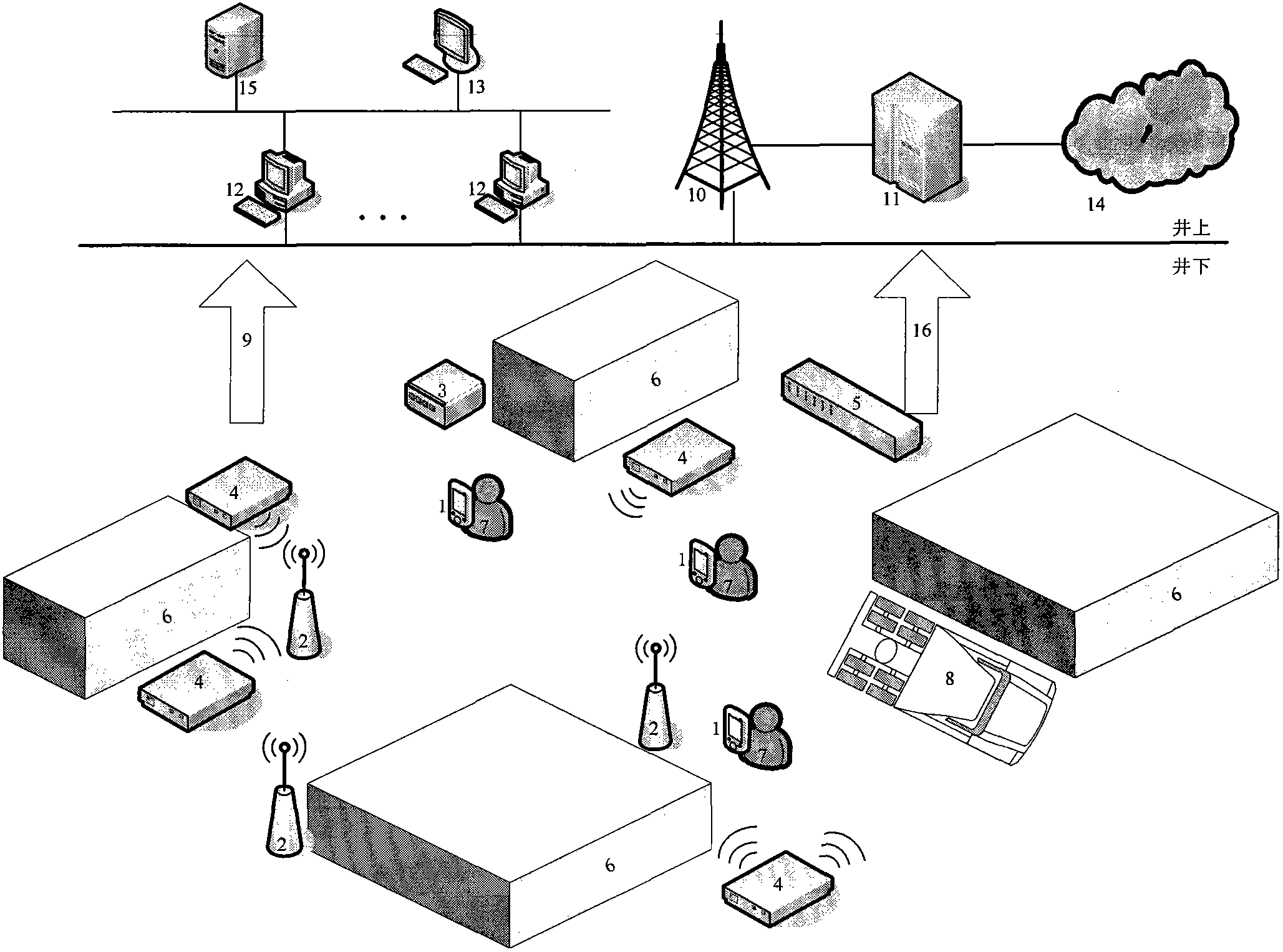

The invention relates to a system for underground communication and staff monitoring based on a TD-LTE technology. The system comprises mobile terminals, a relay station, a communication base station, a location server, a switchboard, a core network device, host computers, and transmission lines. The mobile terminals and underground base station nodes and the location server are connected with each other through wireless interfaces, and trinity communication monitoring environment is formed. The switchboard gathers a plurality of underground base station nodes through optical fibers, and connects the gathered underground base station nodes with a ground base station. The ground base station accesses a public switched telephone network through the core network device. Main transmission channels of the system uses wired optical fibers. Wireless channel uses an orthogonal frequency-division multiple access technology and a multiple-input multiple-output modulation technology. An original underground monitoring positioning algorithm is improved by using a mixed measurement mode of signal transmits-receive time measurement and angular measurement. Information of underground staff positions is obtained by using a circle coordinate setting method. The improved system and algorithm effectively solves problems of difficulties of high quality communication and monitoring positioning under complex and harsh conditions in mines.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

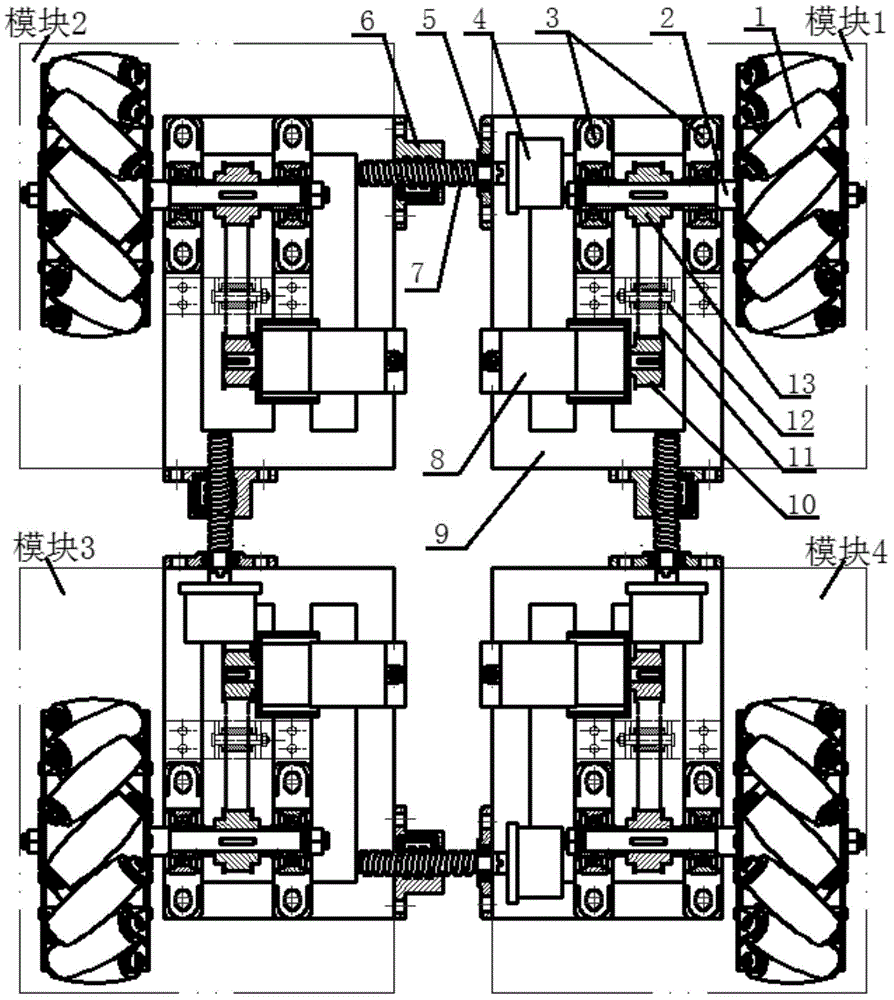

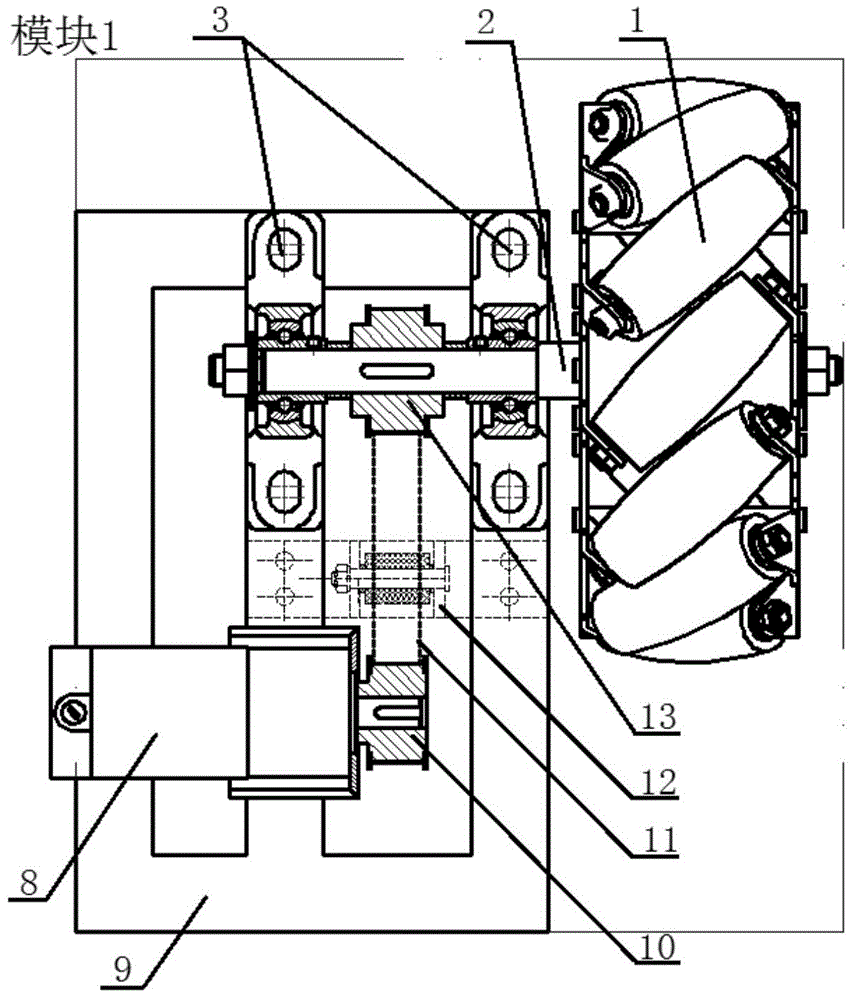

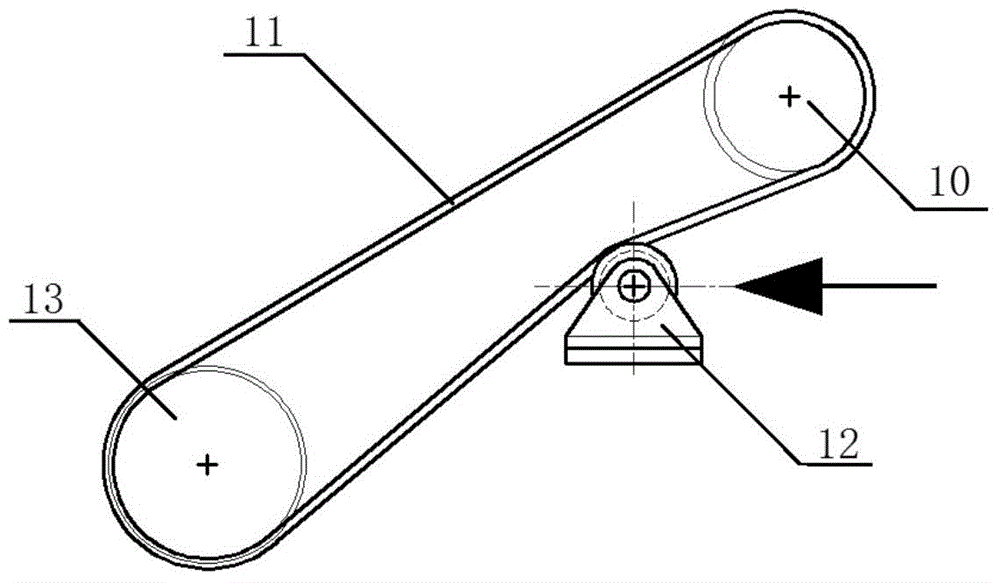

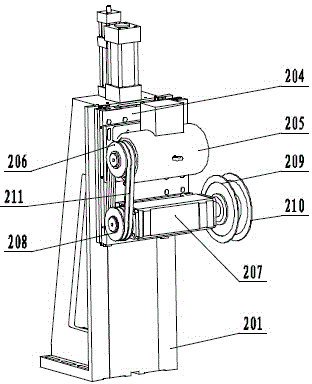

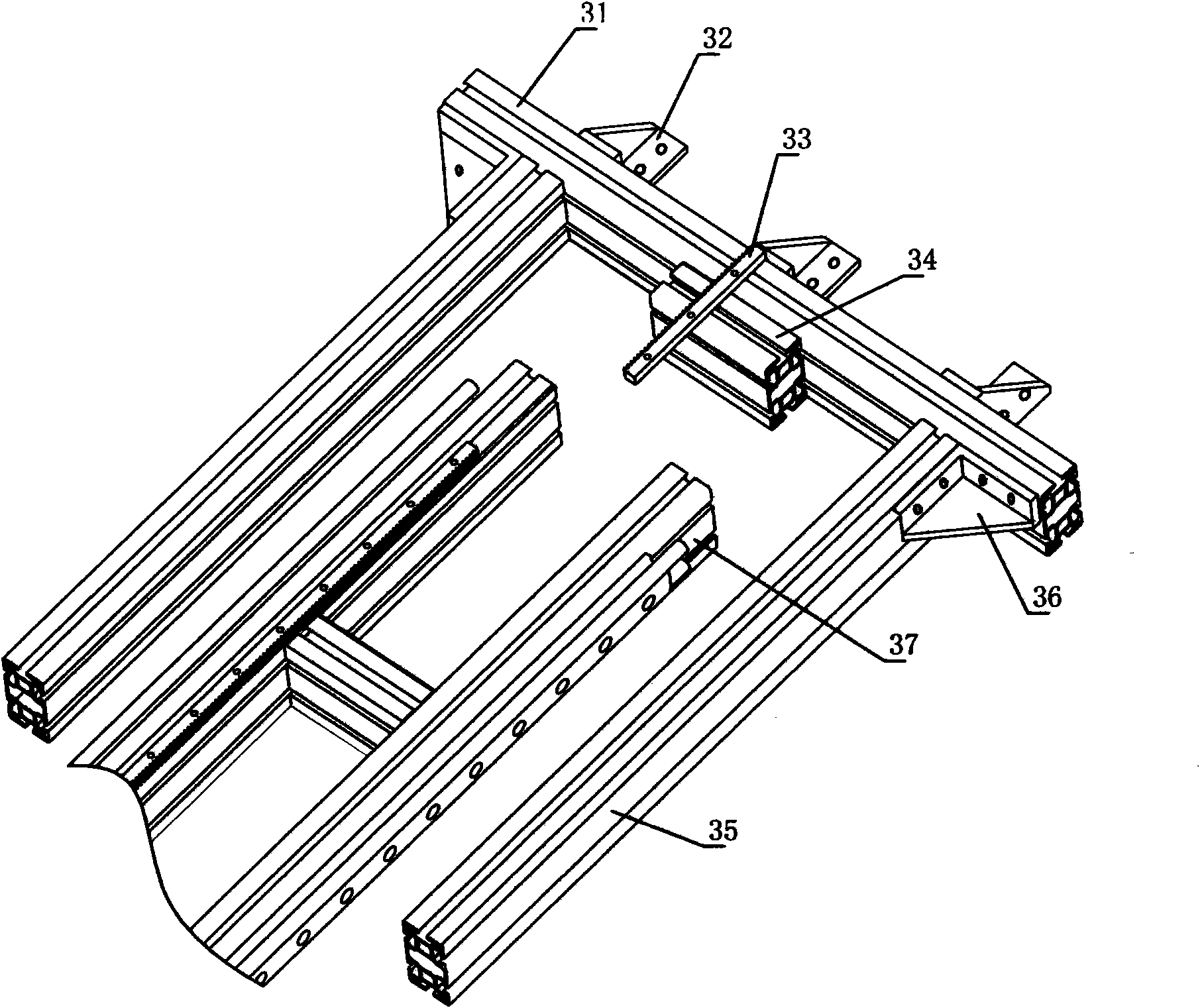

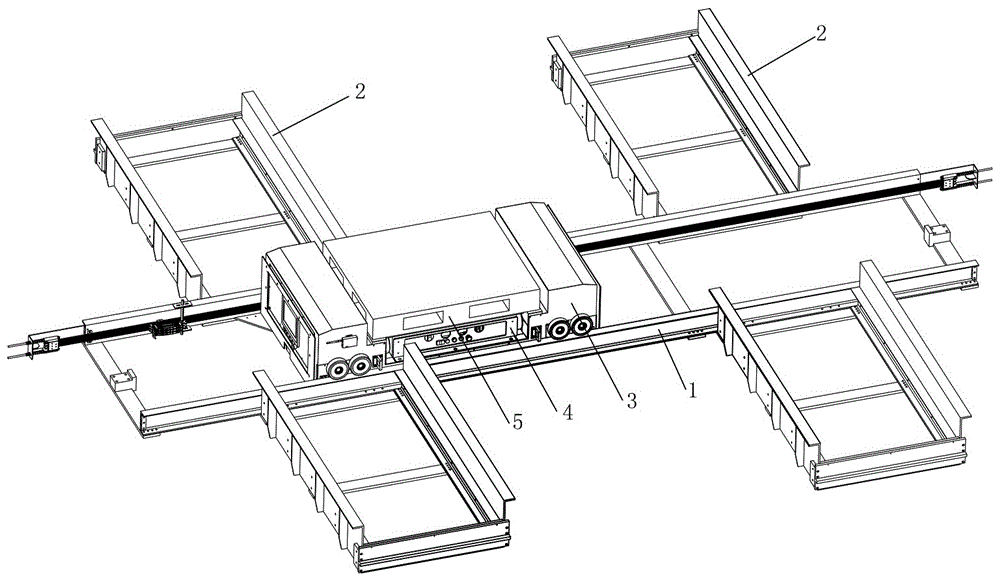

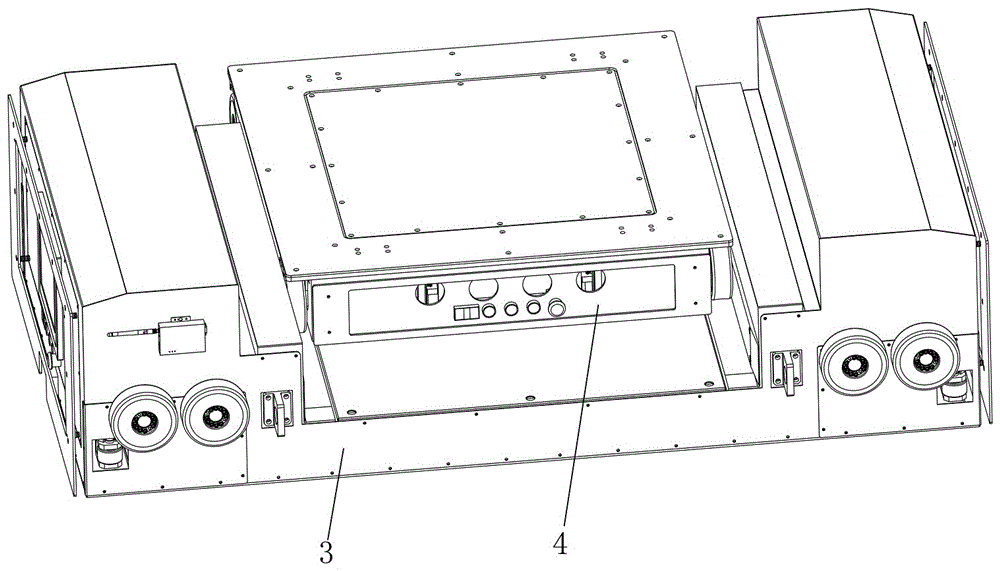

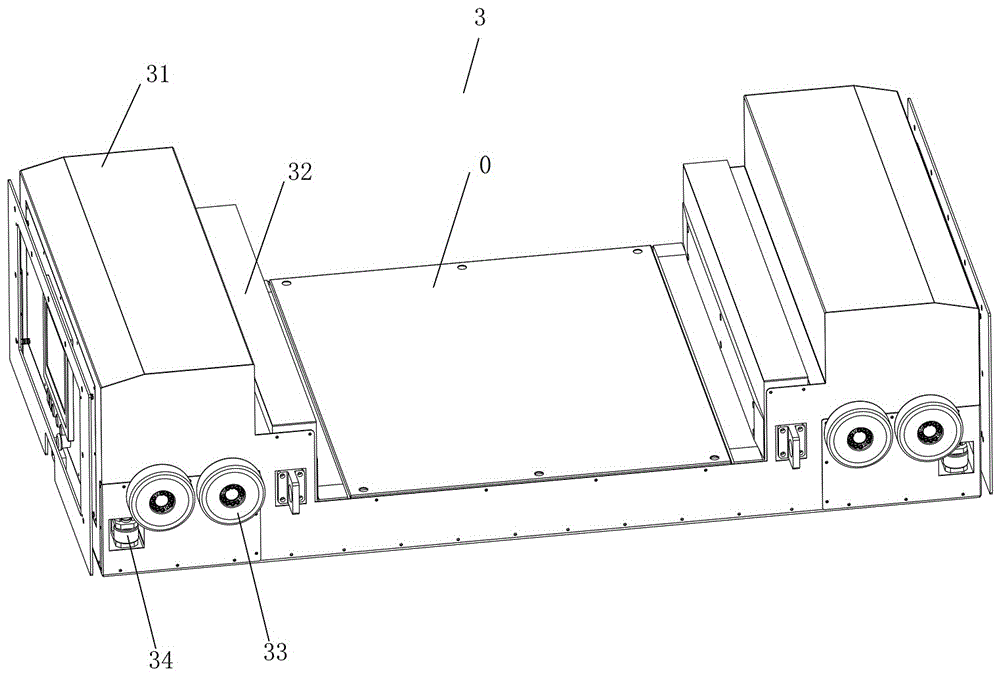

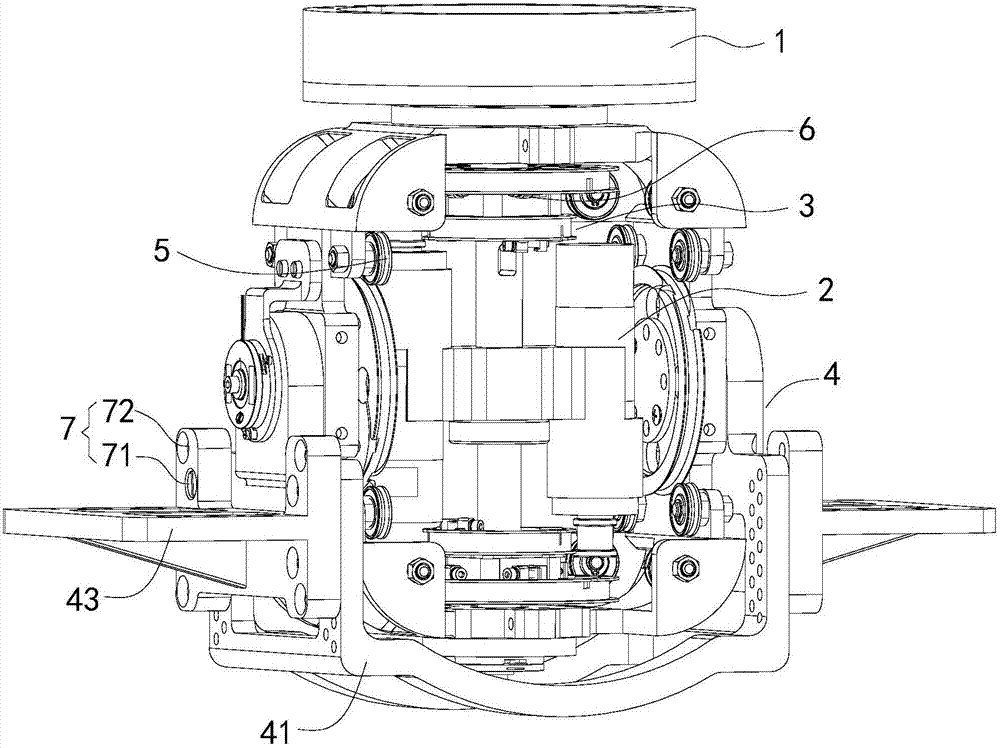

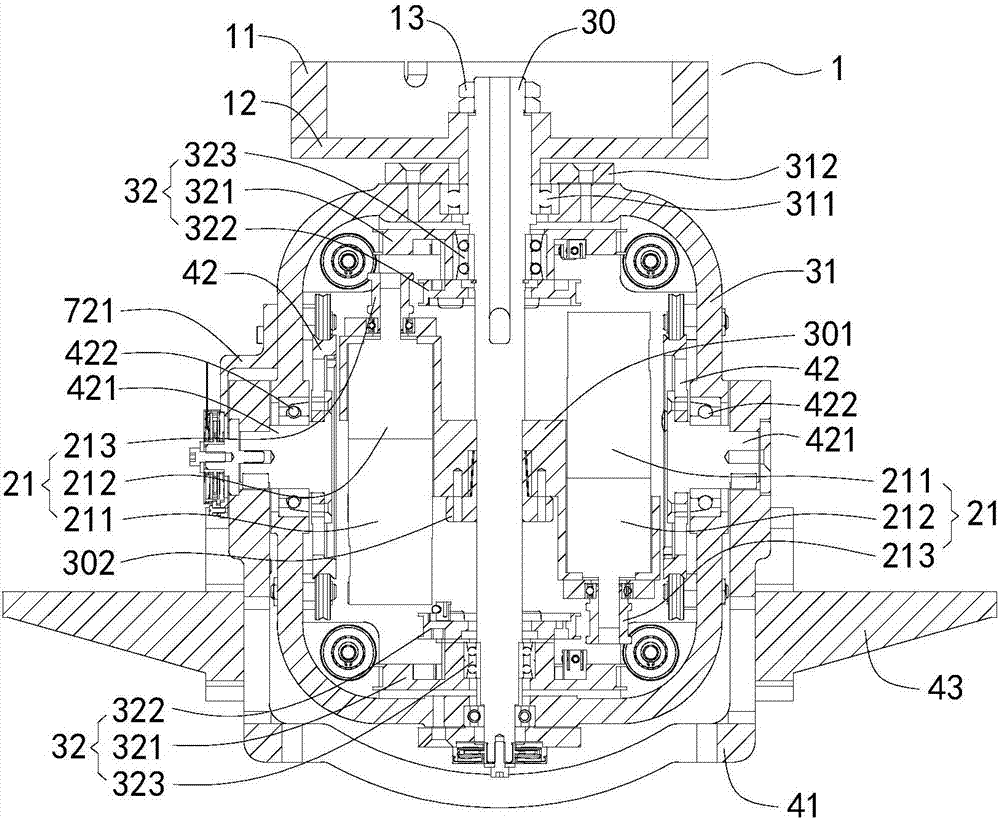

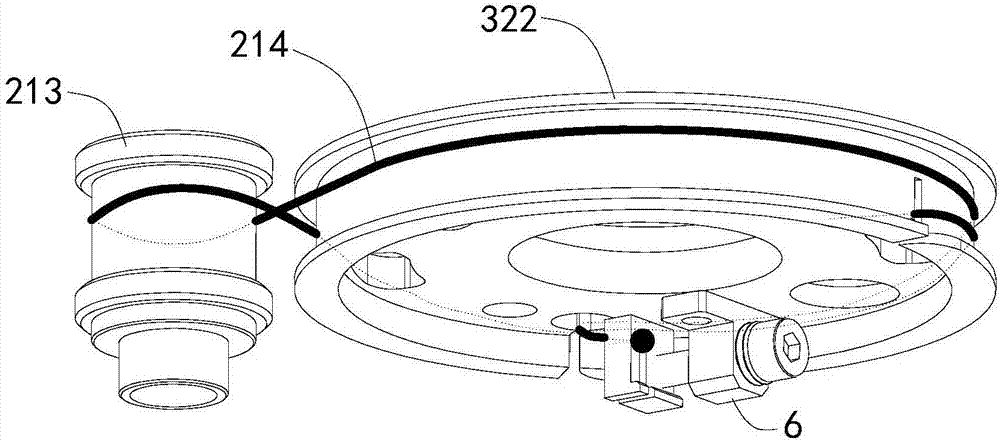

Wheel track stepless regulation type omnibearing mobile platform truck chassis

InactiveCN104149857ASolve shipping problemsGuaranteed transmission accuracyUnderstructuresVehicle modificationsTruckMotor drive

The invention provides a wheel track stepless regulation type omnibearing mobile platform truck chassis for industrial and agricultural transport. Modular design concept is adopted in the wheel track stepless regulation type omnibearing mobile platform truck chassis. The whole car chassis comprises four modules, structures of a module 1 and a module 2 are in a bilaterally symmetrical type, a module 3 and the module 1 are identical in structure, and a module 4 and the module 2 are identical in structure. The module 1, the module 2, the module 3 and the module 4 are connected through ball screws in sequence, and the module 4 is connected with the module 1 through another ball screw. In each module, a direct-current servo motor drives a small synchronous wheel to rotate, a synchronous cog belt transfers power to a large synchronous wheel to drive an axle to rotate, and Mecanum omnidirectional wheels are driven to rotate. By means of the wheel track stepless regulation type omnibearing mobile platform truck chassis, a platform truck can move forwards, move transversely and perform pivot steering, transport under the conditions of lack of space is achieved effectively, and stepless regulation can be performed on the wheel track of the platform car according to the width of the road and the volume of loads.

Owner:BEIHANG UNIV

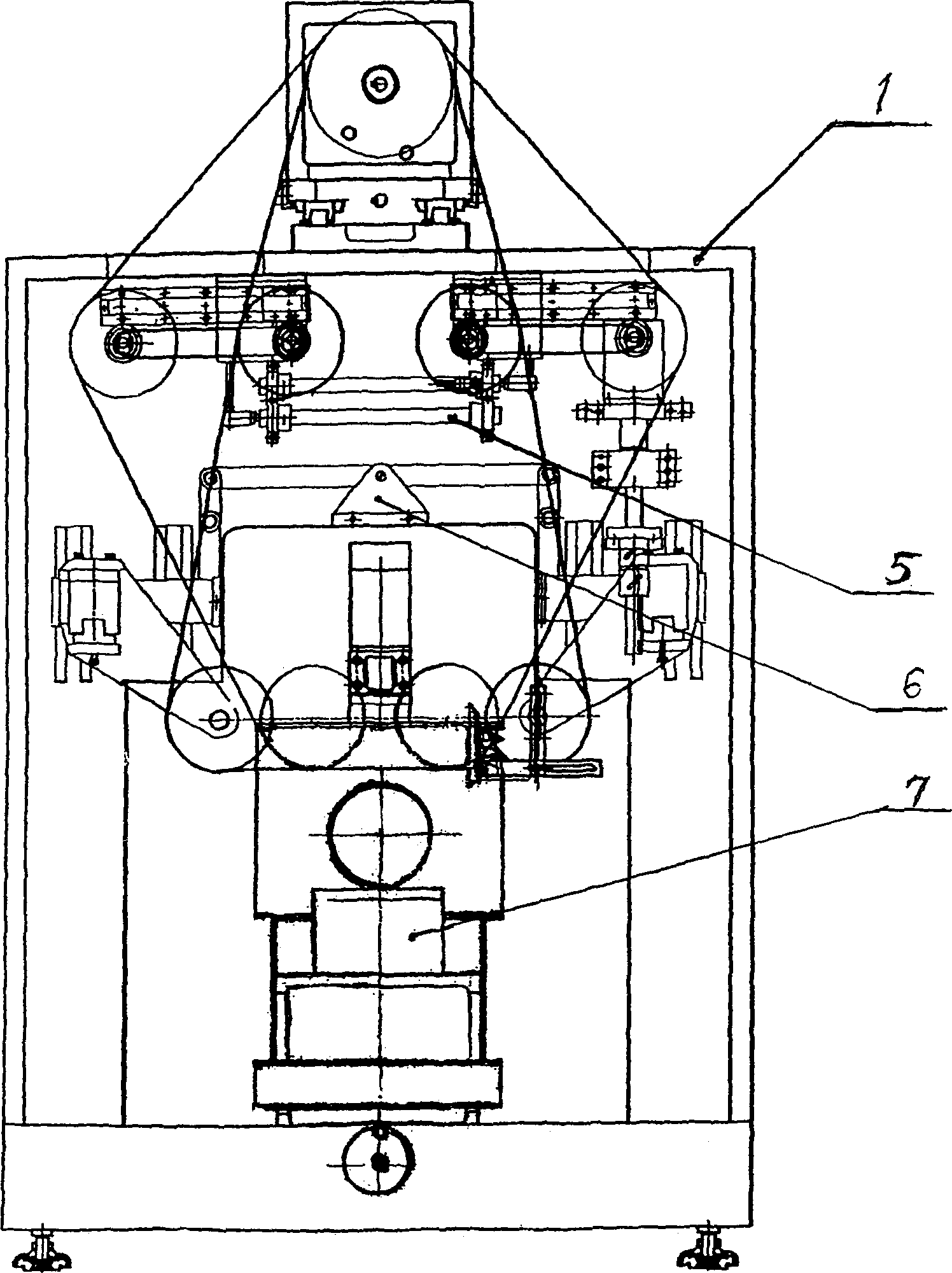

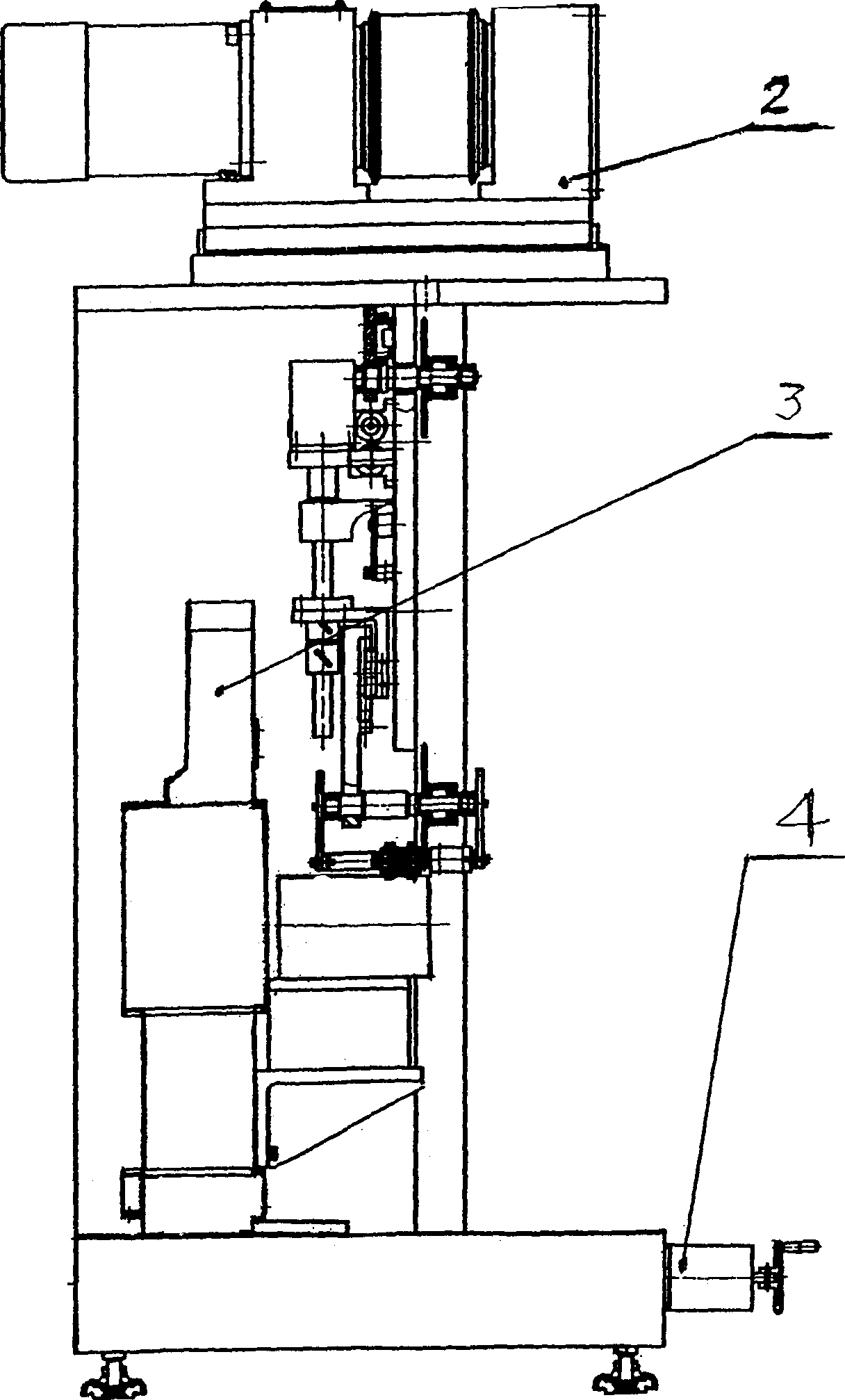

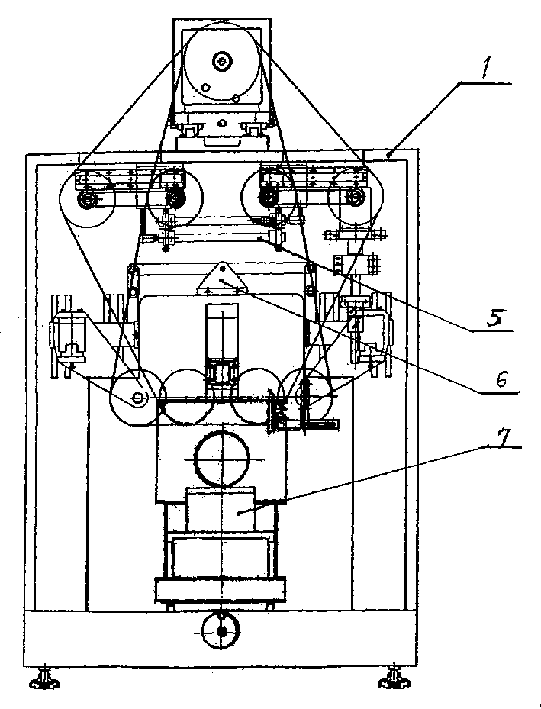

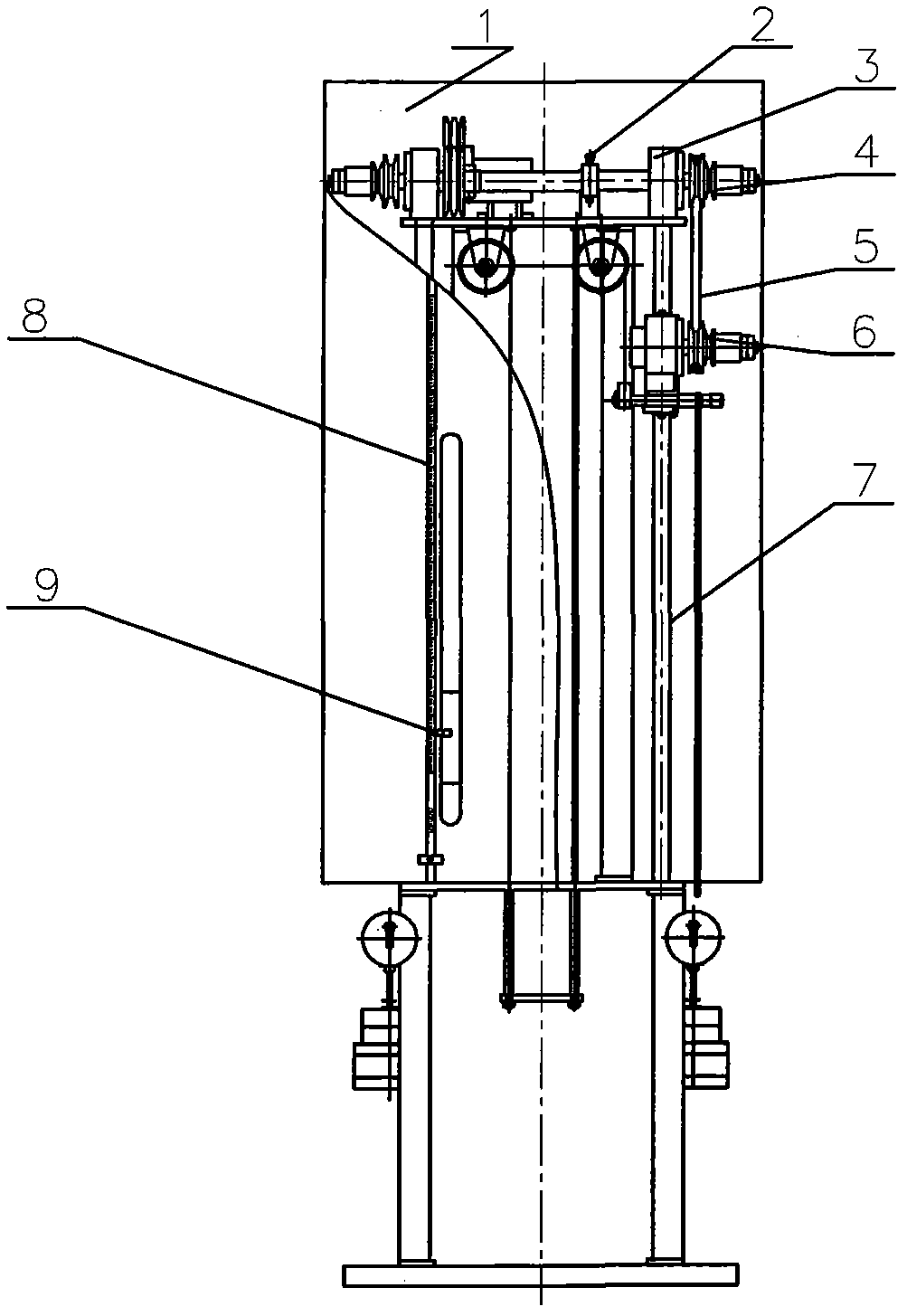

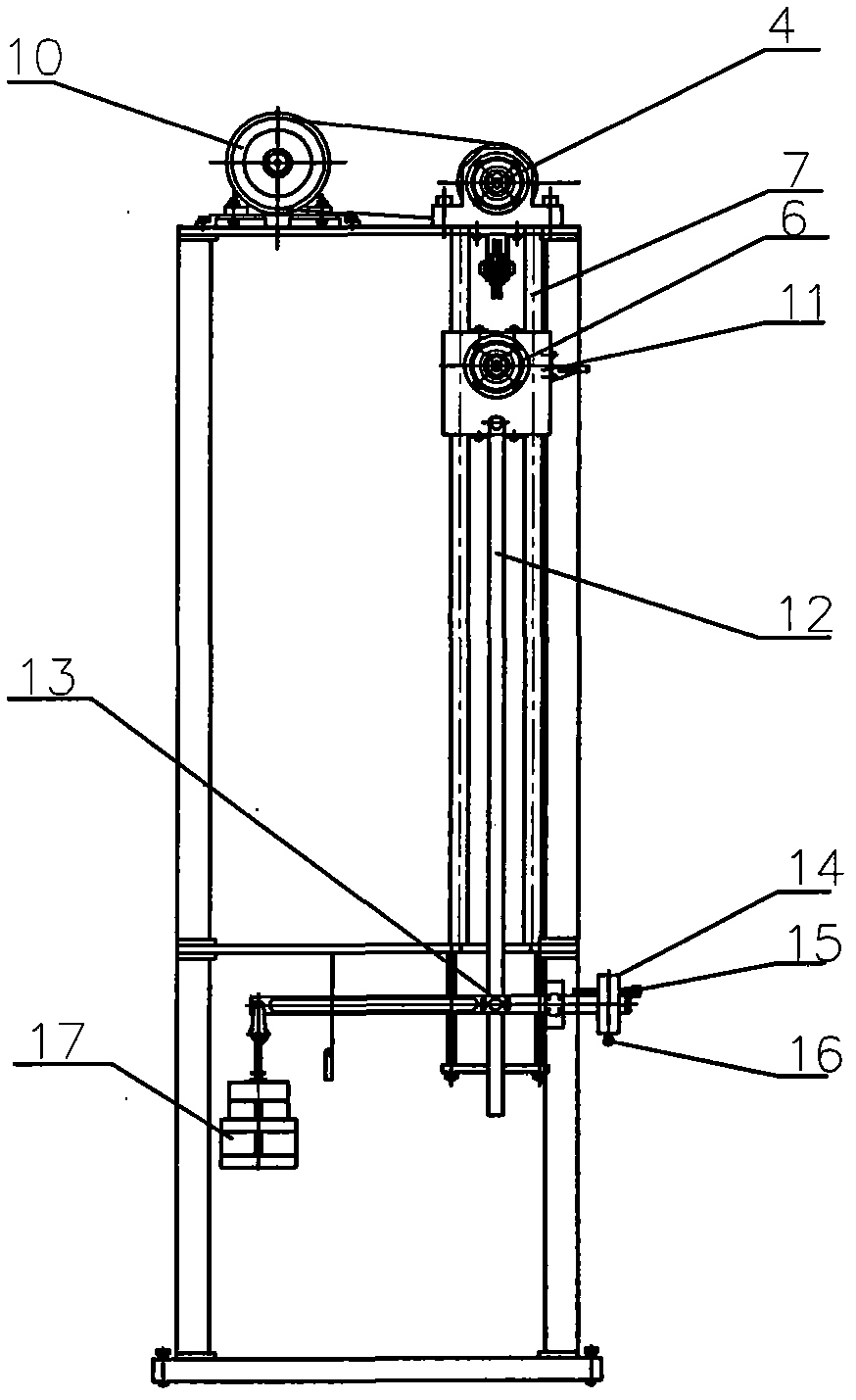

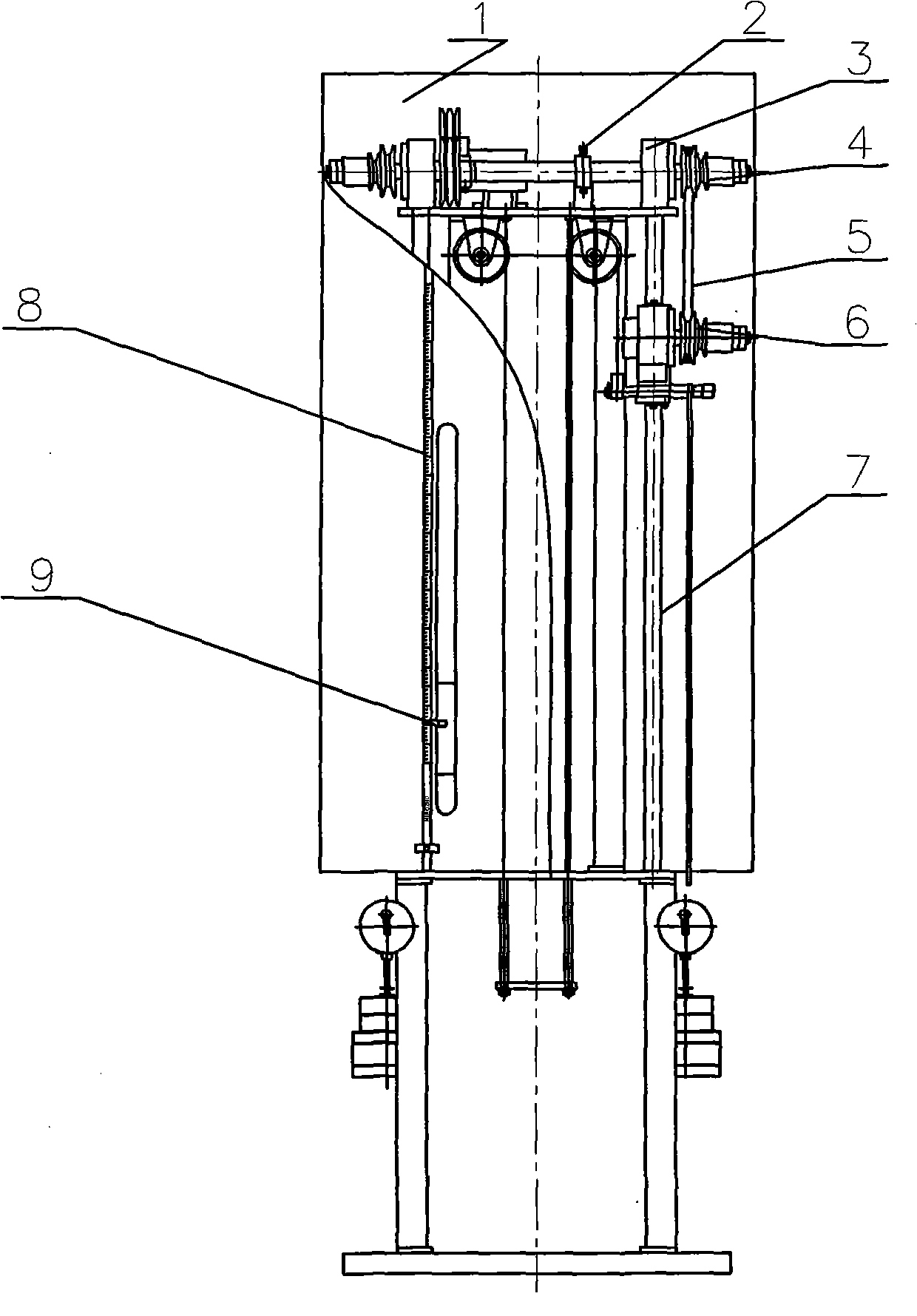

Automatically controlled high-precision crystal wire electrode cutting machine

InactiveCN1387979AImprove rigidityAvoid deformationFine working devicesMetal working apparatusEngineeringMechanical engineering

The present invention relates to cutting equipment and is especially one computerized efficient and high-precision wire electrode cutting machine. The cutting machine consists of frame, winding cylinder driven by one DC motor to rotate in either right direction or reverse direction, Z-axis bench, Y-axis bench, tension mechanism with one pair of tension wheels controlled by one pair of micro cylinders to support the cutting wire, oscillating mechanism with one pair of oscillating support wheels and fixture. The cutting machine is used mainly for cutting silicon wafer, quartz glass, ceramic, jewel, magnesia and other hard and fragile material.

Owner:沈阳科晶设备制造有限公司

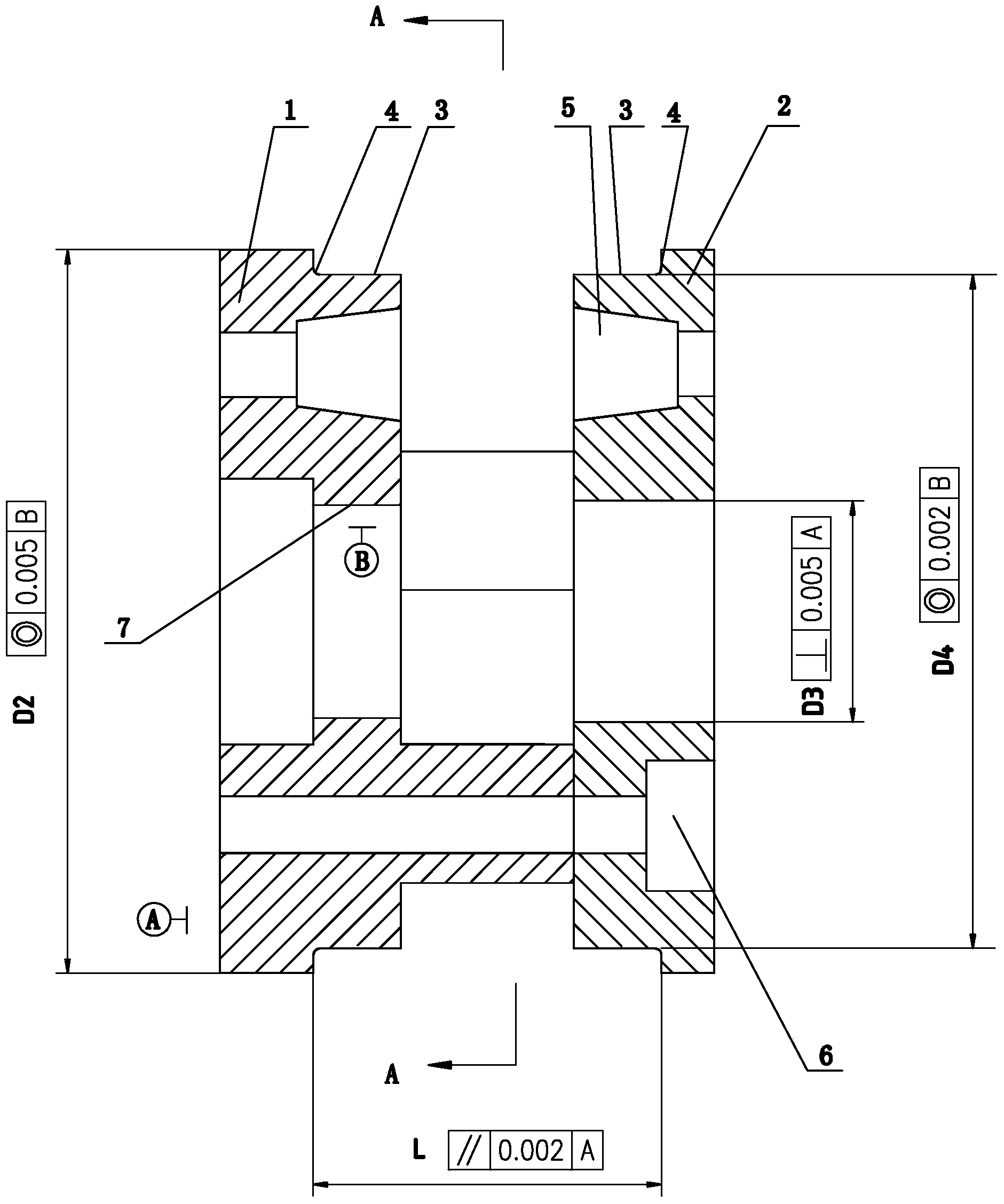

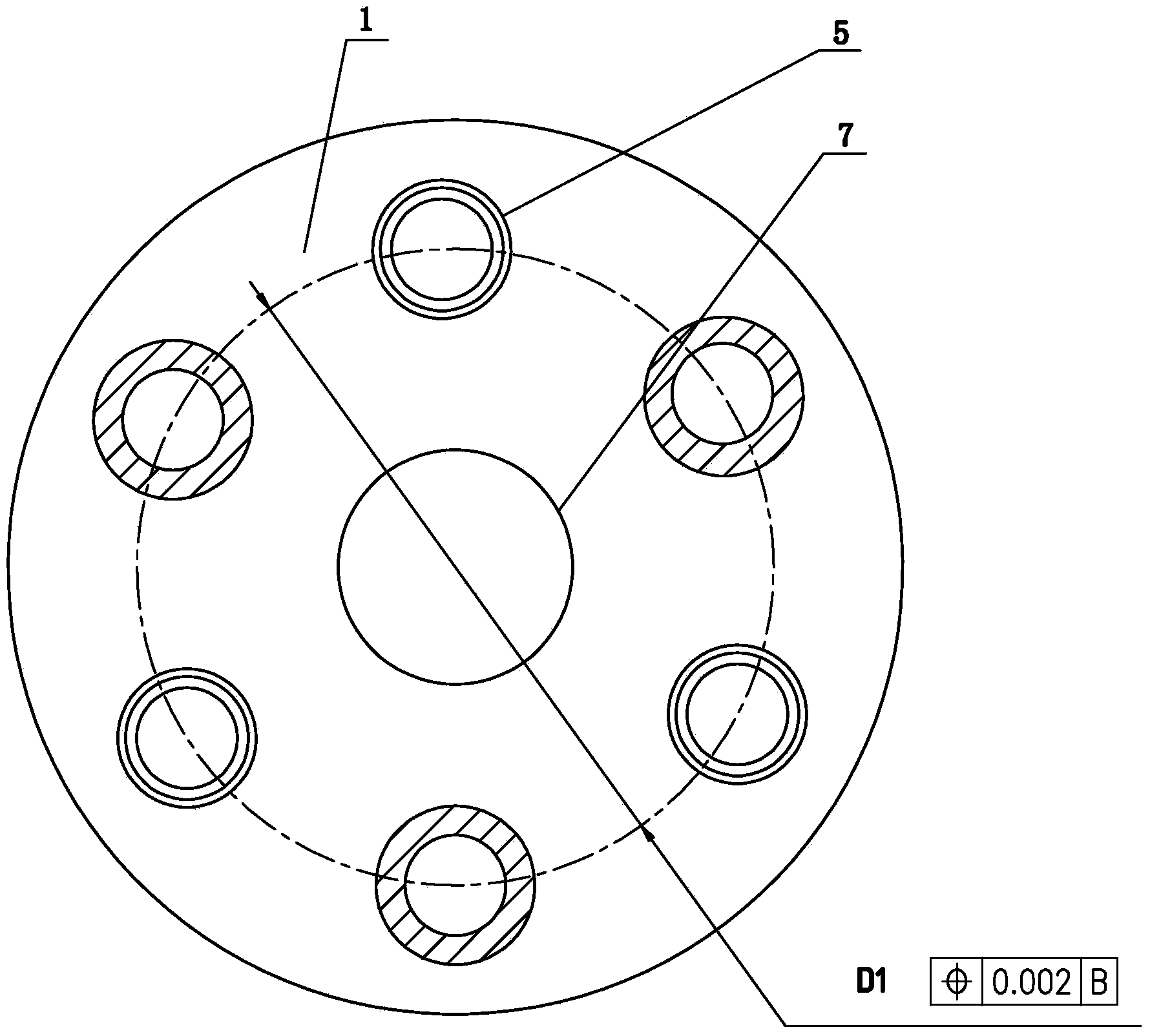

Method for manufacturing harmonic reducer of robot

The invention discloses a method for manufacturing a harmonic reducer of a robot, which belongs to the technical field of harmonic reducer processing and includes the steps of manufacturing flexible gears and the steps of manufacturing rigid gears. The steps of manufacturing the flexible gears include: forging solid billets of the flexible gears; performing heat treatment for the solid billets of the flexible gears to reach the hardness of HRC (Rockwell hardness) 38-40; turning the solid billets of the flexible gears after heat treatment into thin-wall semi-finished flexible gears; supporting inner cavities of the semi-finished flexible gears by a flexible gear tensioning fixture; and grinding the supported semi-finished flexible gears to form external gear rings of the flexible gears on a grinder. By the method, the efficiency and the precision of machining the flexible gears and the rigid gears are improved, the hardness of the flexible gears is enhanced, the service life of the harmonic reducer is prolonged, and the method is widely applied to production of harmonic reducers.

Owner:SHANDONG SHKE MACHINERY MFG

Filter speed reducer

InactiveCN101725673AImprove carrying capacityImprove seismic performanceToothed gearingsLow speedEngineering

The invention discloses a filter speed reducer, which comprises an eccentric shaft, a split spine half-axle dual gear, a fixed gear, an output gear and a rubber alloy layer. The split spine half-axle dual gear, the fixed gear and the output gear are helical bevel gears which are organically meshed to form a backlash-free precise transmission pair and can adaptively compensate for abrasion of tooth surfaces; the rubber alloy layer adhered on the split spine half-axle dual gear can ensure that a transmission component filters fluctuation caused by the conversion of a low speed and high torque into a high speed and low torque of a motor, processing and mounting errors and the like through a controllable elastic distortion quantity in a designed transmission accuracy and bearing capacity range, effectively prevents generation of nonlinear coupled vibration of a transmission system caused by influences of extreme working conditions and special environments, and solves the problems of generation of jam even inflexible lock and the like of the transmission component. Thus, the filter speed reducer has the advantages of high precision, high reliability, long service life, high torque, low energy consumption, small volume and the like, and can be widely applied to equipments in engineering fields, such as robots, space flights, ships and vehicles.

Owner:重庆奔腾科技发展有限公司

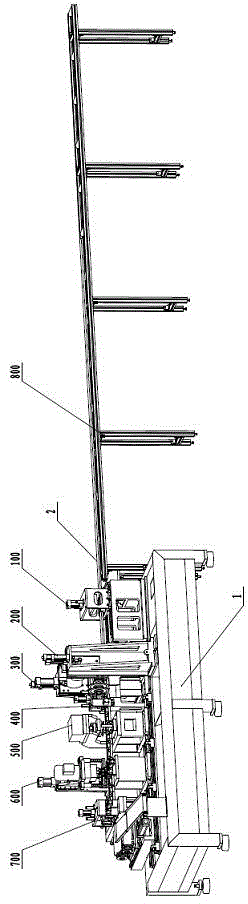

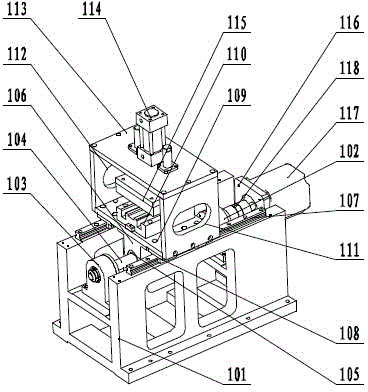

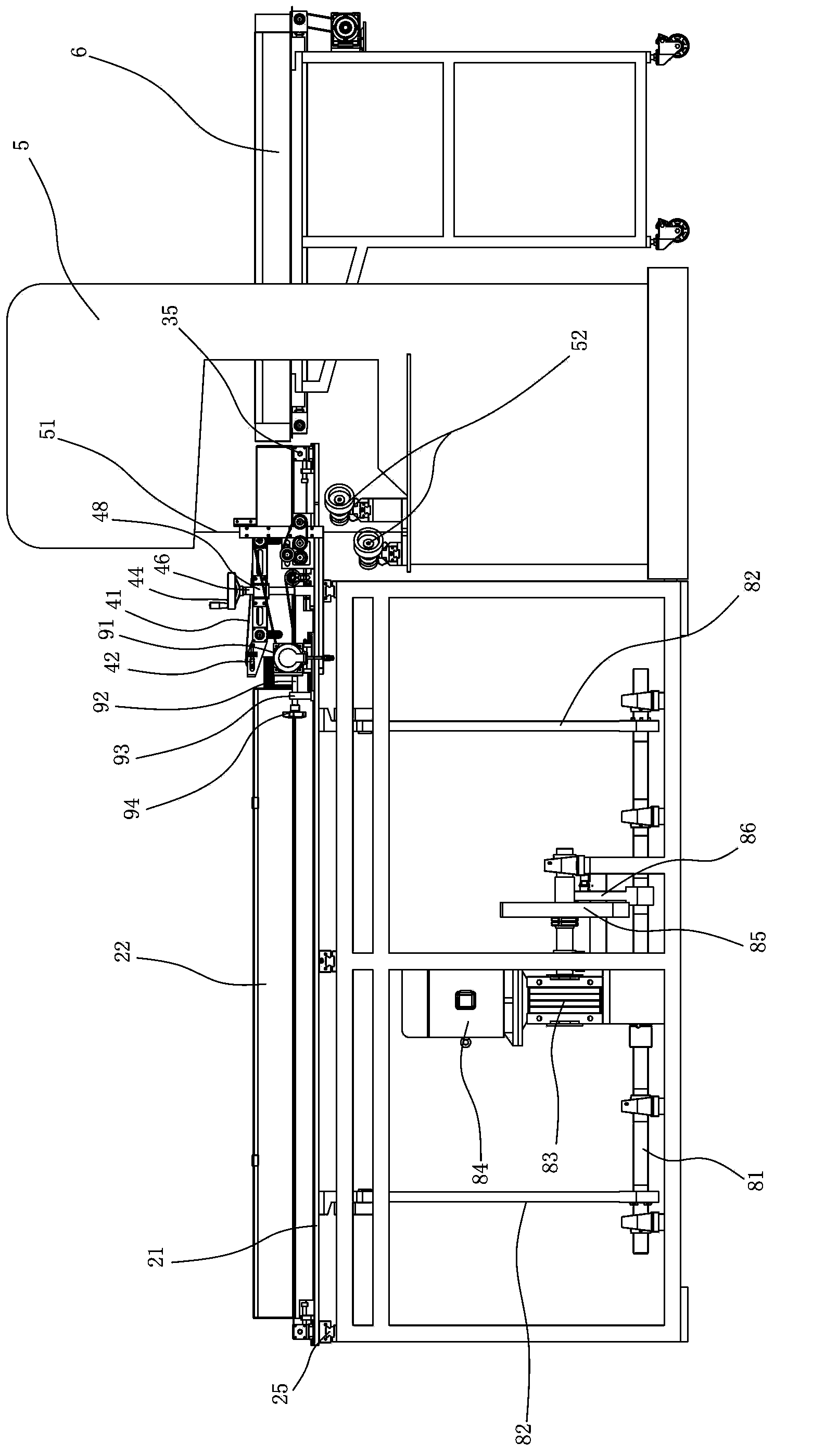

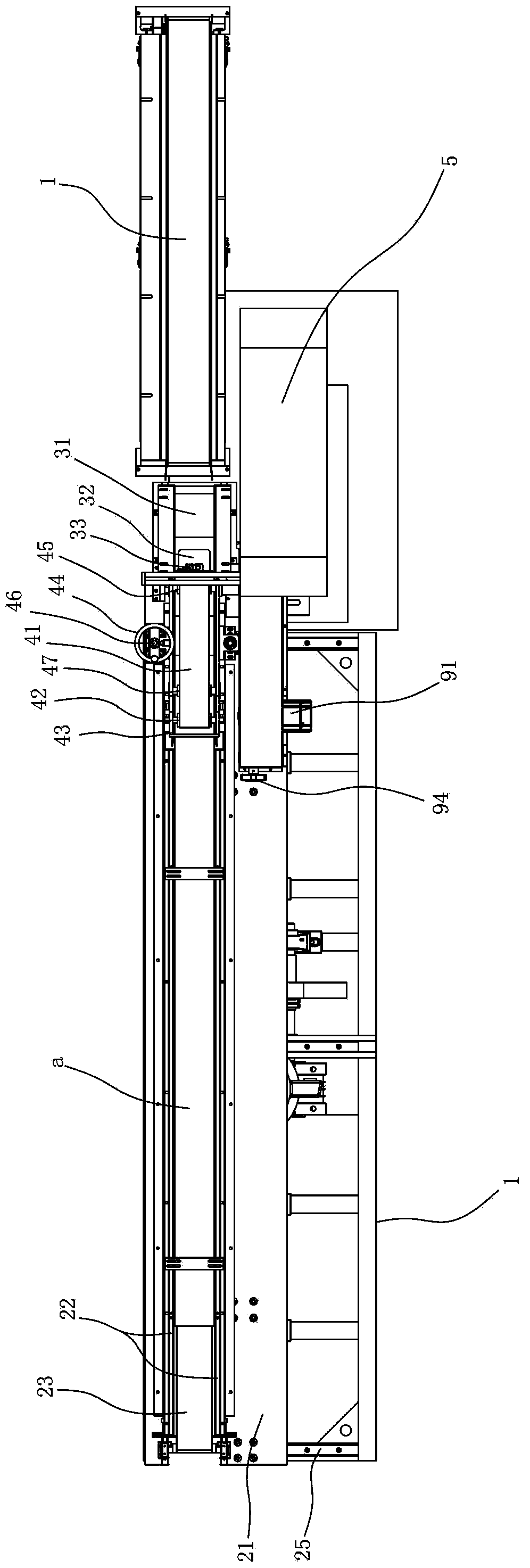

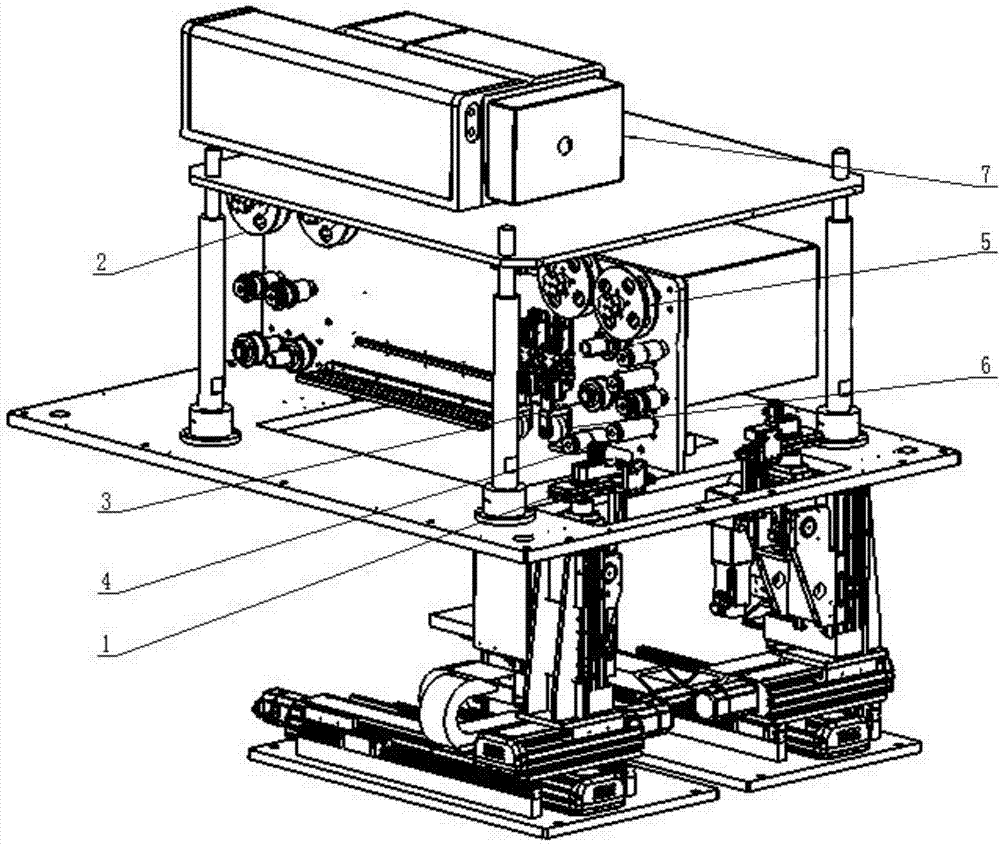

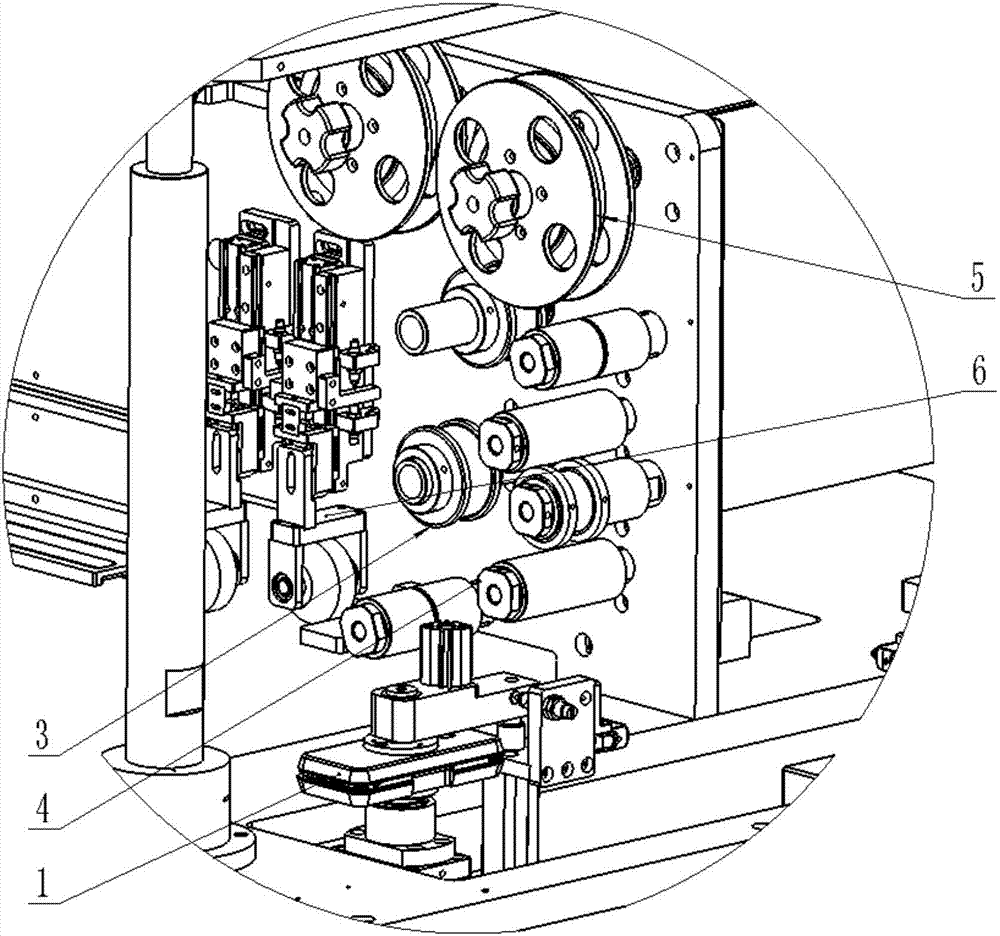

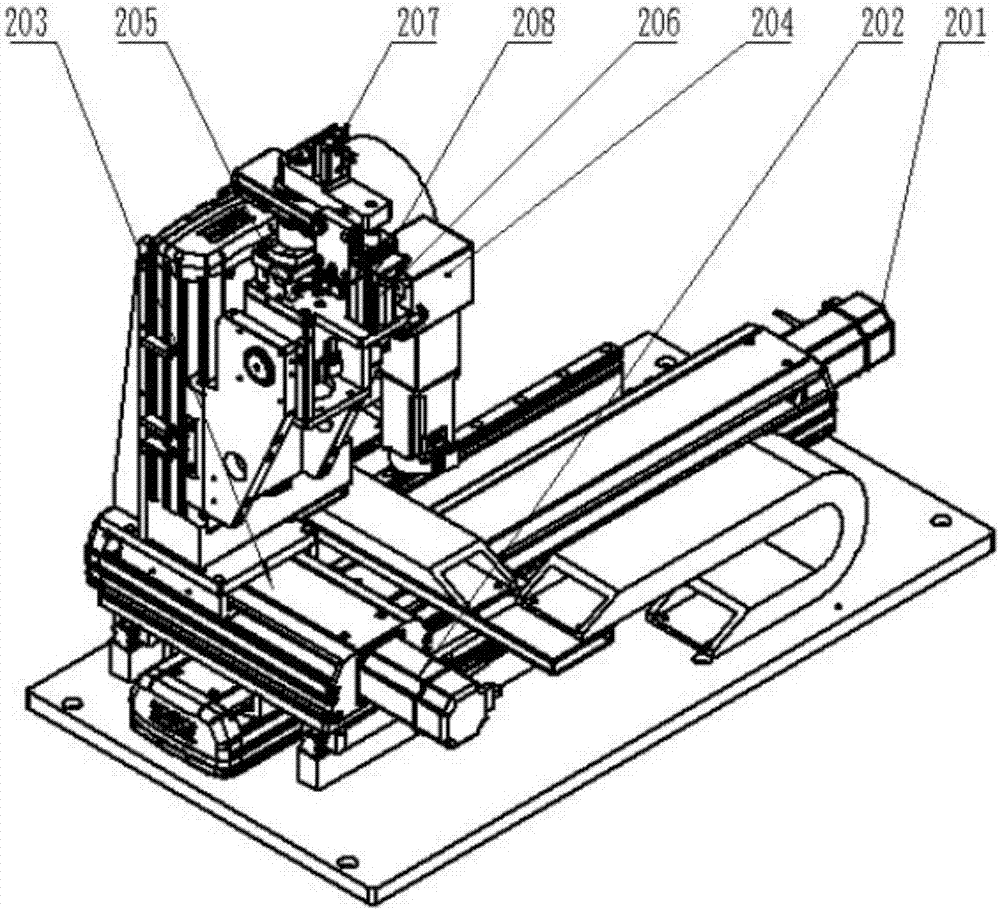

Hinge machining host and machining method

ActiveCN104647049AReasonable positioningScientific and reasonable conceptionMetal sawing devicesFeeding apparatusMotor drivePunching

The invention discloses a hinge machining host. The hinge machining host comprises a lathe bed, a control system and a hydraulic system; an automatic feeding device, a sawing device, a sawing compacting device, a punching device, a drilling device and a cutting device are arranged sequentially on the lathe bed along the feeding direction; the sawing device further comprises a front sawing device and a rear sawing device, the structure of the front sawing device is the same as the structure of the rear sawing device, the front and back sawing devices are arranged symmetrically front and back; a supporting device is arranged on the right side of the automatic feeding device; a service motor drives the feeding, the transmission precision is high; each station machines at the same time, the progresses are the same, and the machining efficiency is high. The invention further discloses a method for machining the hinge by the device disclosed by the invention; the method comprises the following steps: the feeding device compacts profiles and feeds; each station compacts the profiles; the sawing, punching, drilling and cutting devices machine the profiles at the same time; each station returns; the feeding device releases the profiles; the feeding device returns back to the initial position; the feeding device compacts the profiles again; each station looses the profiles; the feeding device feeds again; and then the next process is performed.

Owner:济南天辰智能装备股份有限公司

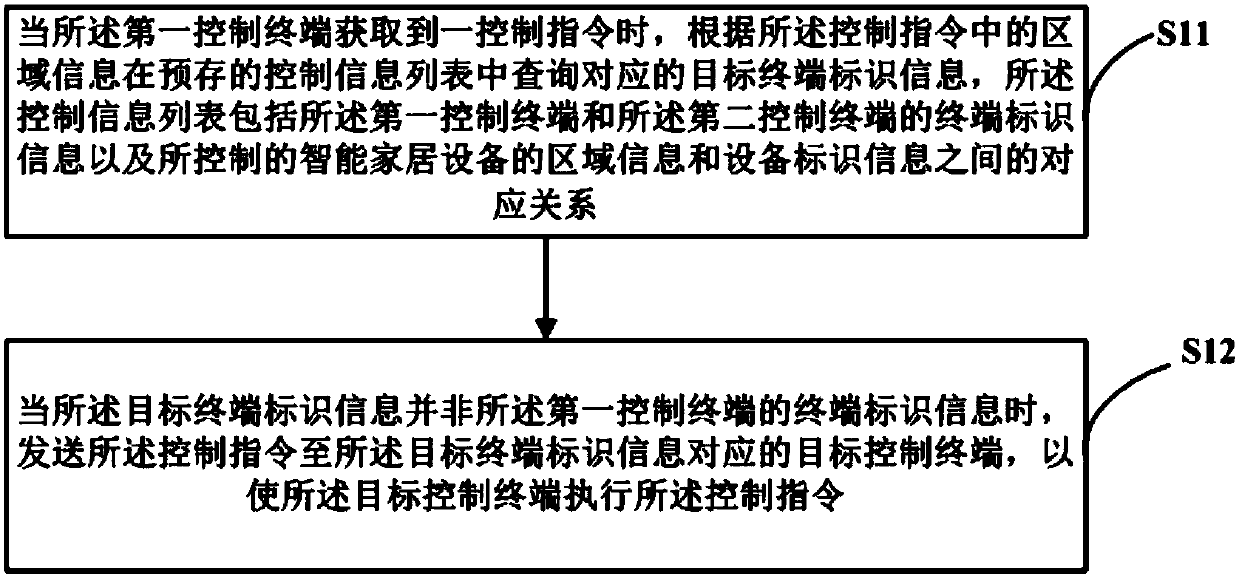

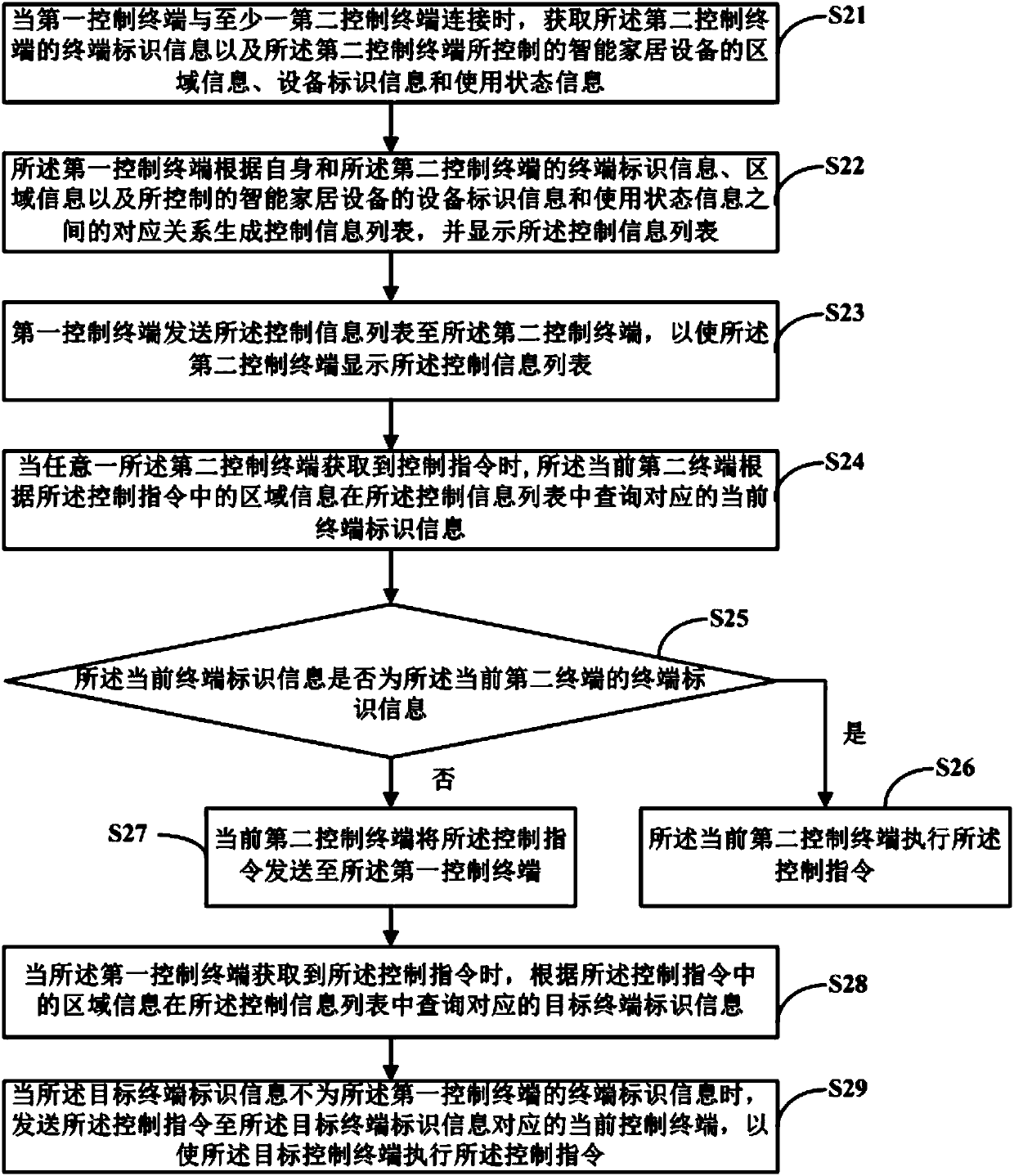

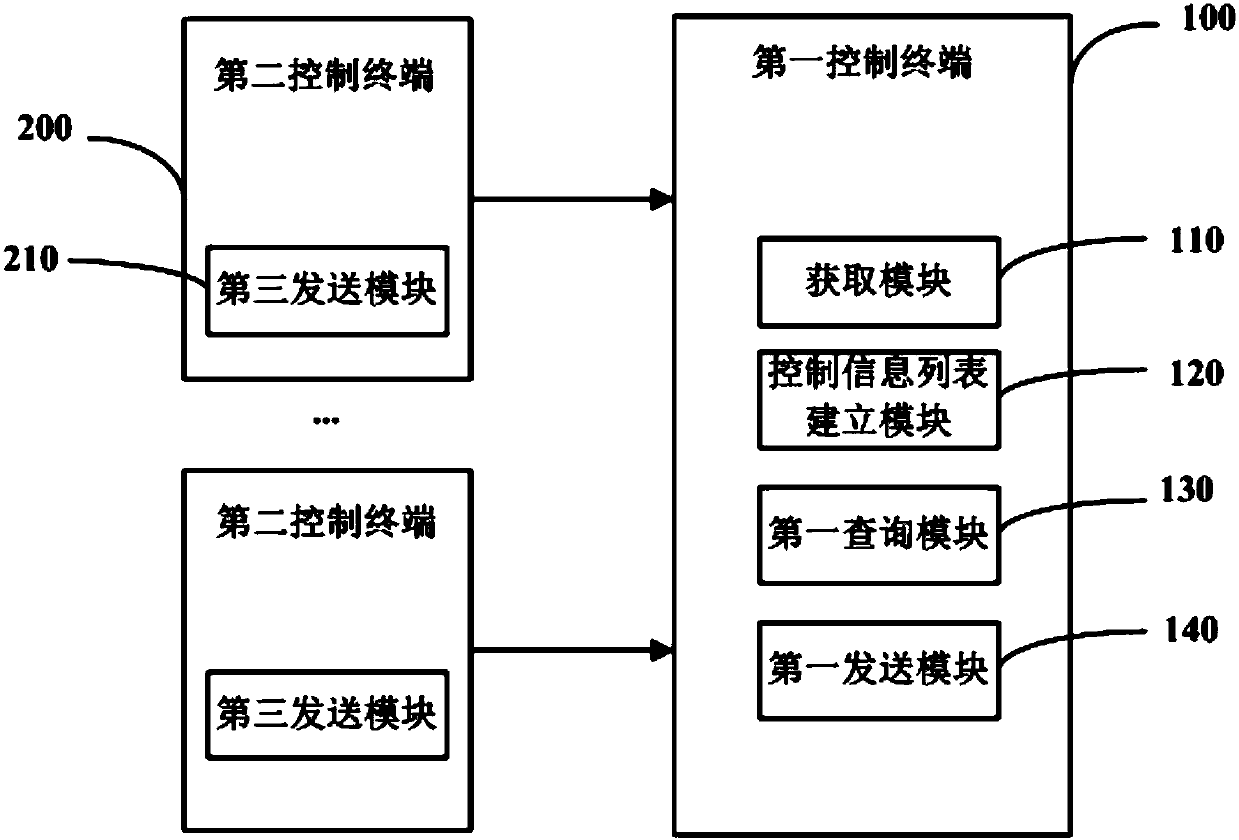

Equipment control method, smart home system, storage medium and computer equipment

InactiveCN107612796AEasy to manageGuaranteed transmission accuracyData switching by path configurationTarget controlComputer terminal

The invention discloses an equipment control method, a smart home system, a storage medium and computer equipment. The method comprises the following steps: when a control instruction is acquired, querying corresponding target terminal identification information in a pre-stored control information list according to area information in the control instruction, wherein the control information list includes terminal identification information of a first control terminal and a second control terminal as well as a corresponding relationship between the area information and equipment identificationinformation of controlled smart home equipment; and when the target terminal identification information is not the terminal identification information of the first control terminal, sending the control instruction to a target control terminal corresponding to the target terminal identification information to ensure that the target control terminal executes the control instruction. The smart home equipment in each area can be controlled by the first control terminal, and thus the management of the smart home equipment can be facilitated.

Owner:SHENZHEN ATTE INTELLIGENT TECH CO LTD

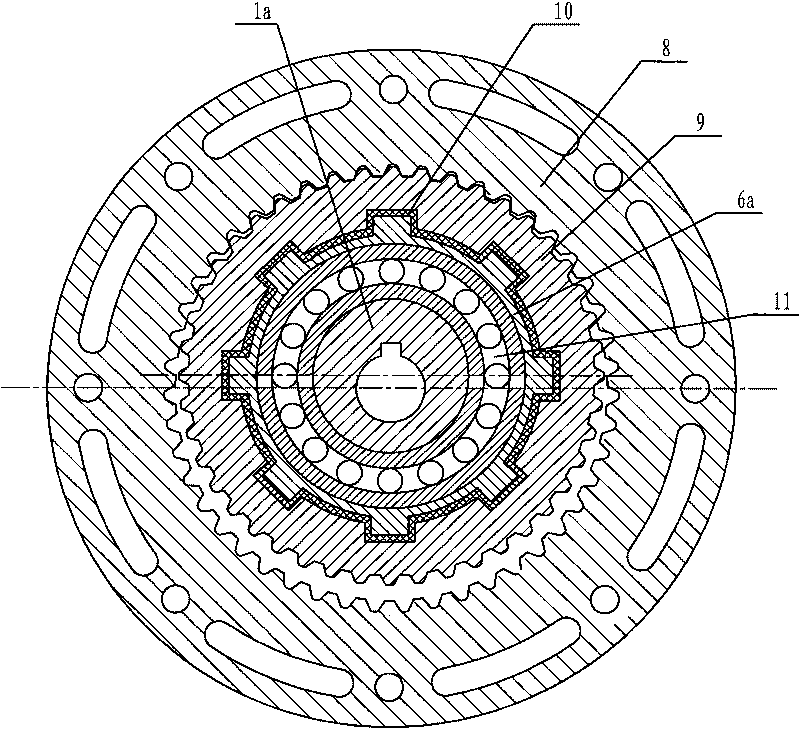

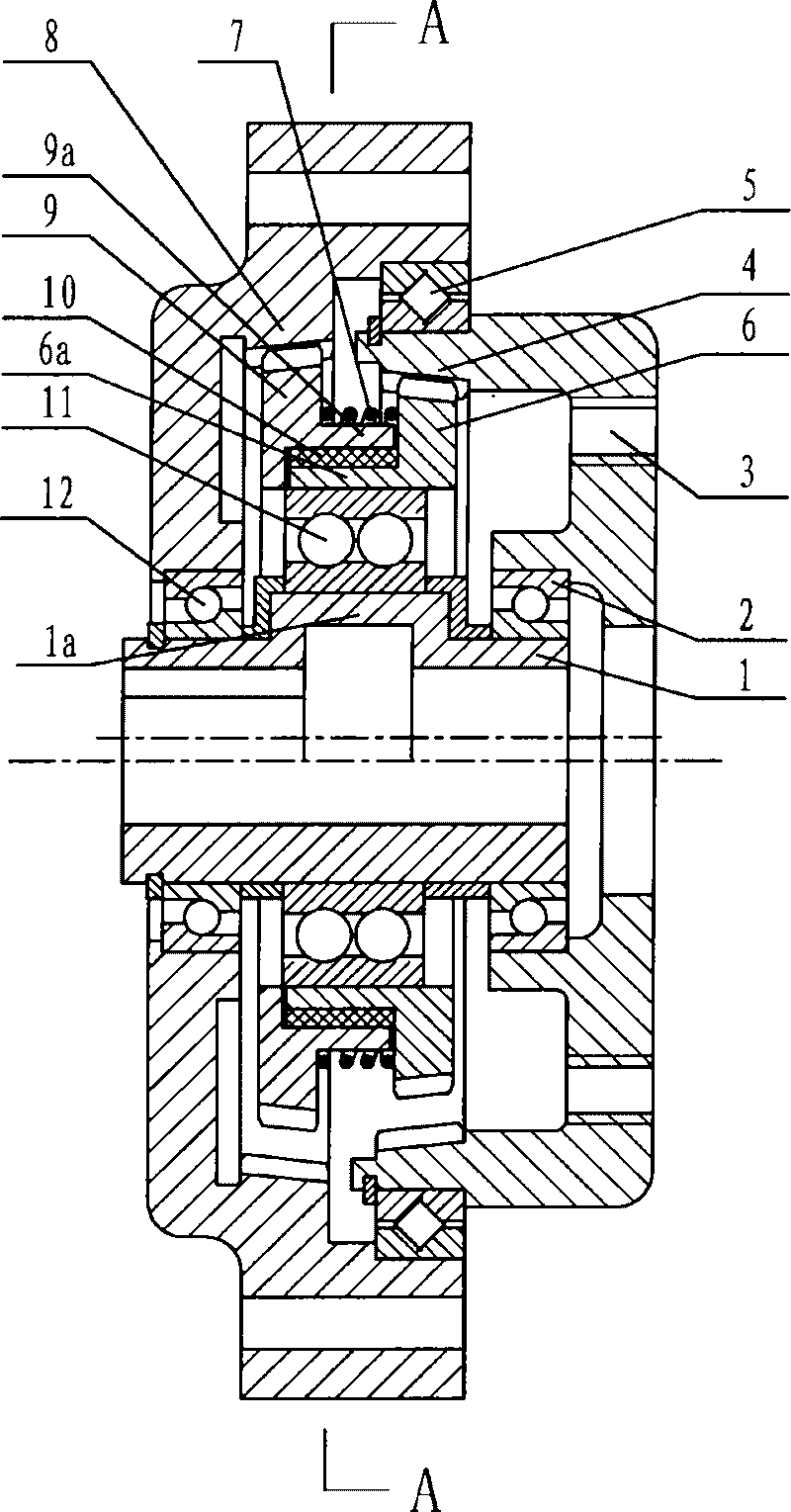

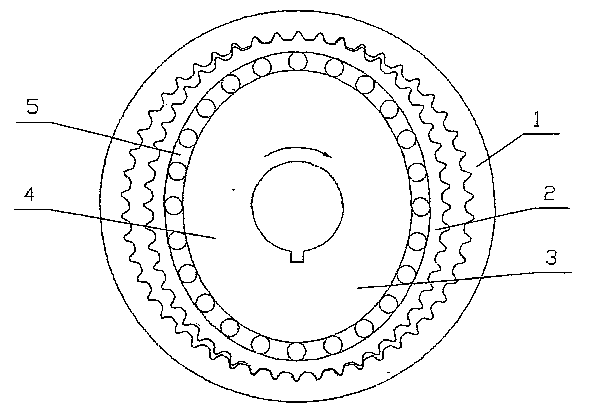

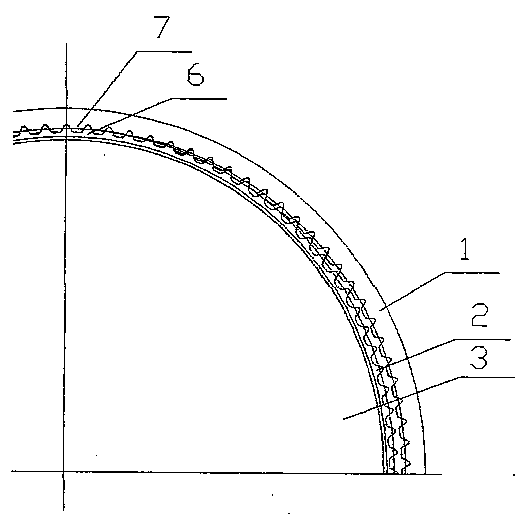

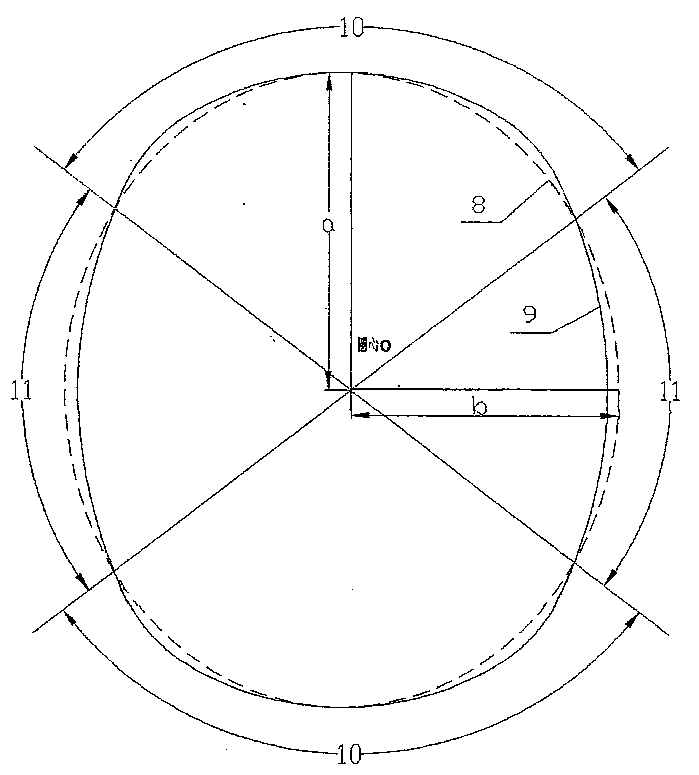

Novel harmonic speed reducer of wave generator

The invention discloses a novel harmonic speed reducer of a wave generator. The inner surface of a circular rigid wheel is provided with rigid internal teeth; a wave generator is arranged in the circular rigid wheel; the wave generator consists of an oval rigid cam and a flexible bearing embedded into the outer ring of the rigid cam; a flexible wheel is sleeved on the outer circle of the bearing of the wave generator; the outer surface of the flexible wheel is provided with outer teeth which are matched with the inner teeth of the circular rigid wheel; the flexible wheel and a circular rigid gear are configured coaxially; the wave generator is driven by a motor, and is taken as a rotary driving source; and the shape curve of the wave generator cam has a specific expression. According to the novel harmonic speed reducer, the specific expression of the shape curve of the wave generator cam is provided, and the flexible wheel and the rigid wheel are better meshed via the wave generator, so that the stress distribution on a meshed tooth surface between the flexible bearing and the gear is improved, and the bottom stress of the flexible gear is reduced.

Owner:上海鑫君传动科技有限公司

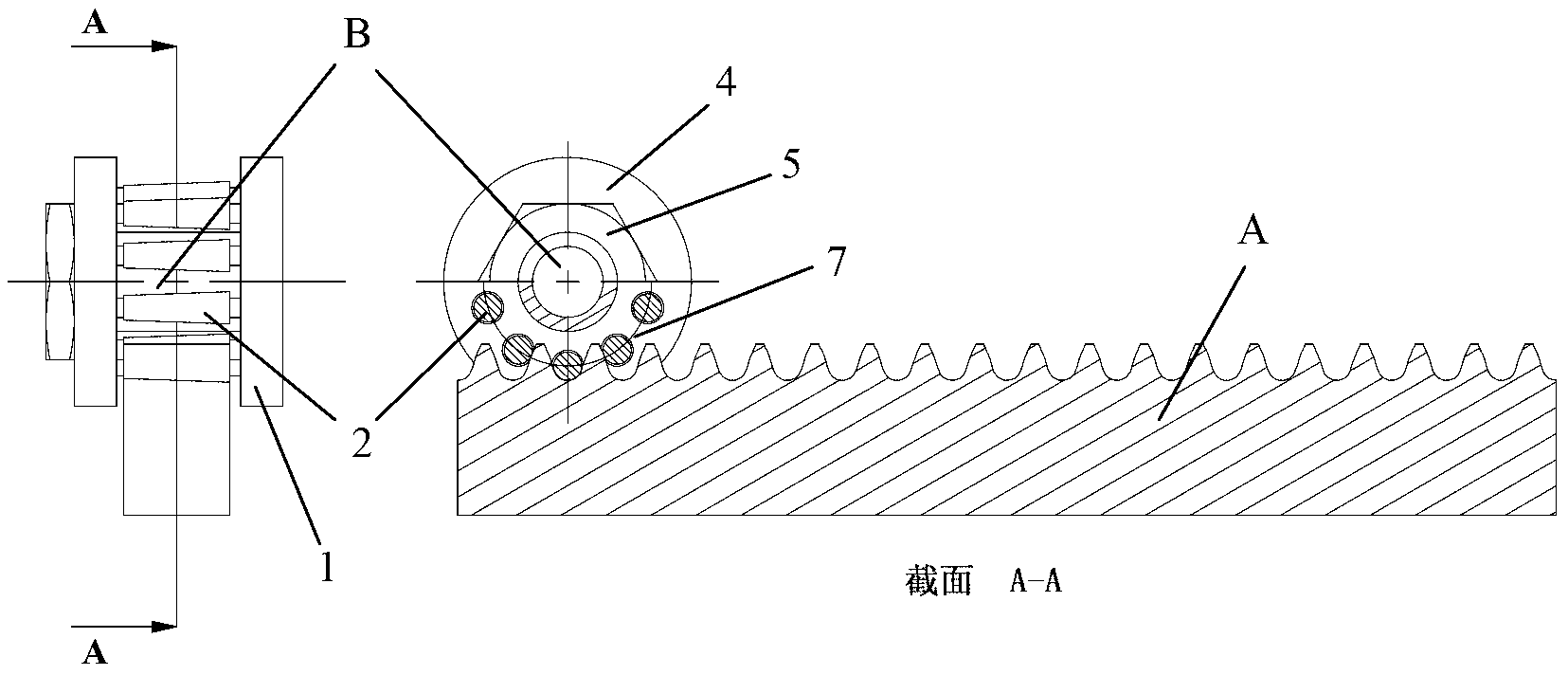

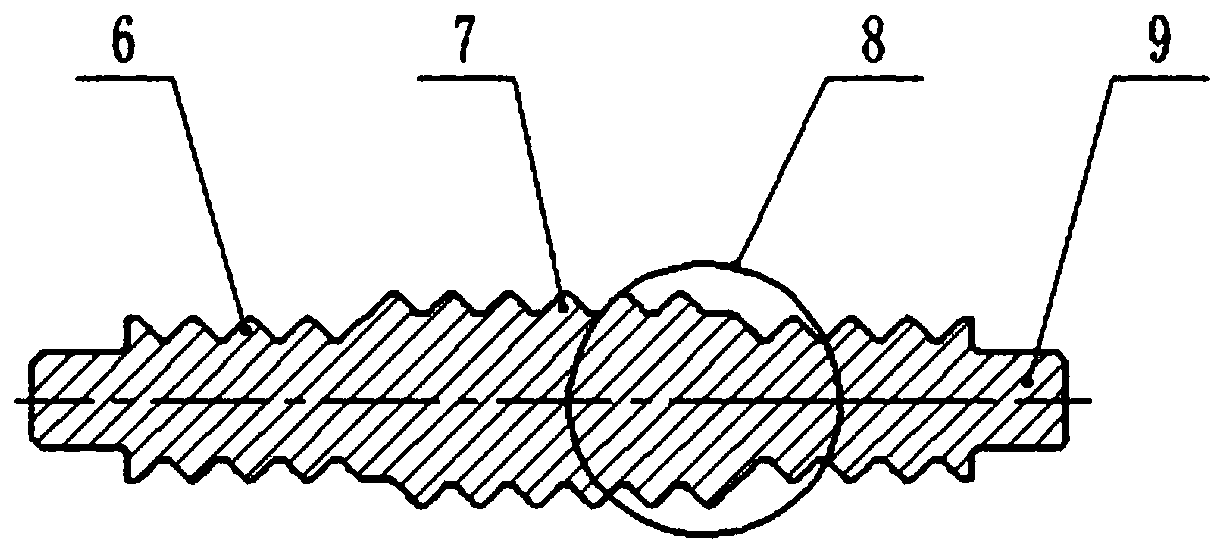

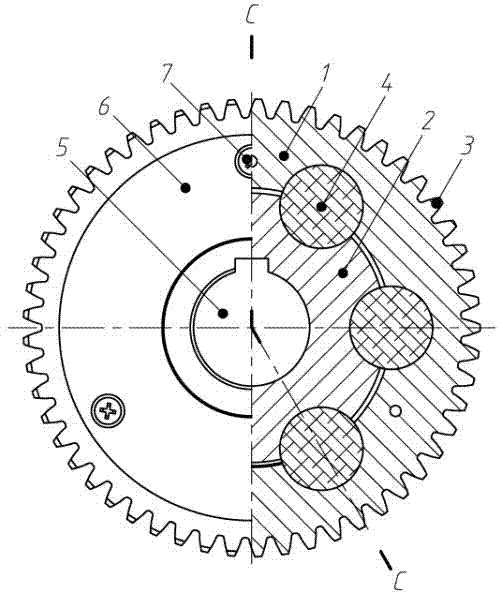

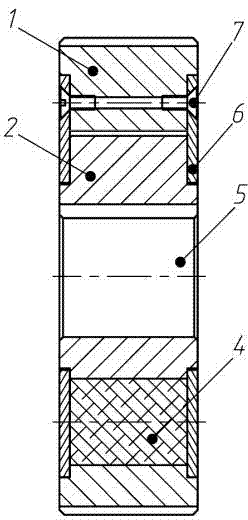

Anti-backlash transmission comprising trochoid gears and roll pins with conical teeth

InactiveCN103062348AImprove interchangeabilityExtended service lifePortable liftingFriction gearingsGear wheelEngineering

The invention relates to an anti-backlash transmission comprising trochoid gears and roll pins with conical teeth, and belongs to the technical field of mechanical transmission. The anti-backlash transmission mainly comprises a pin gear and a trochoid rack, and a rack pair consisting of the pin gear and the trochoid rack realizes movement transmission. Working tooth profiles of teeth of the trochoid rack are flat trochoid internal equidistant lines, and each tooth has a certain conical degree along the tooth width direction. The pin gear meshed with the trochoid rack is provided with a plurality of roll pins, and conical degrees of the roll pins are identical to a conical degree of the rack. The anti-backlash transmission has the advantages that the anti-backlash transmission is good in interchangeability, low in maintenance cost, high in transmission precision and long in service life, backlash is prevented in a meshing procedure, tooth gaps caused by abrasion in a transmission procedure can be compensated, smooth transition between clockwise rotation and anticlockwise rotation can be realized, and the like.

Owner:BEIJING UNIV OF TECH

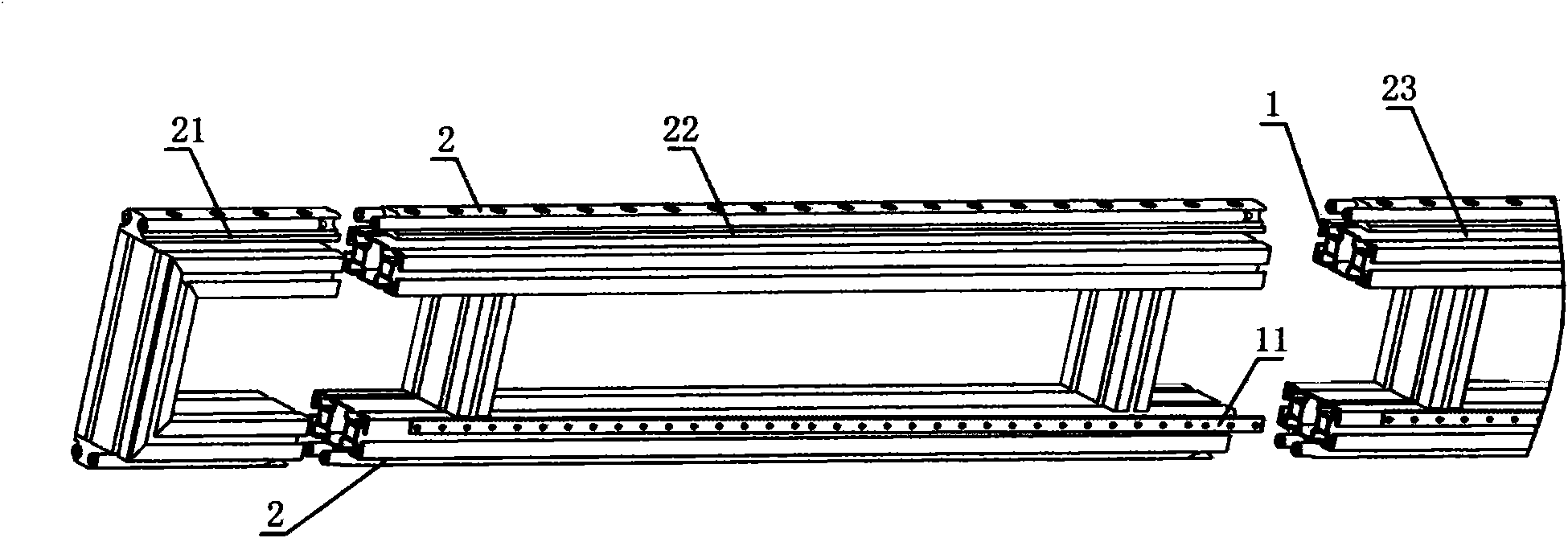

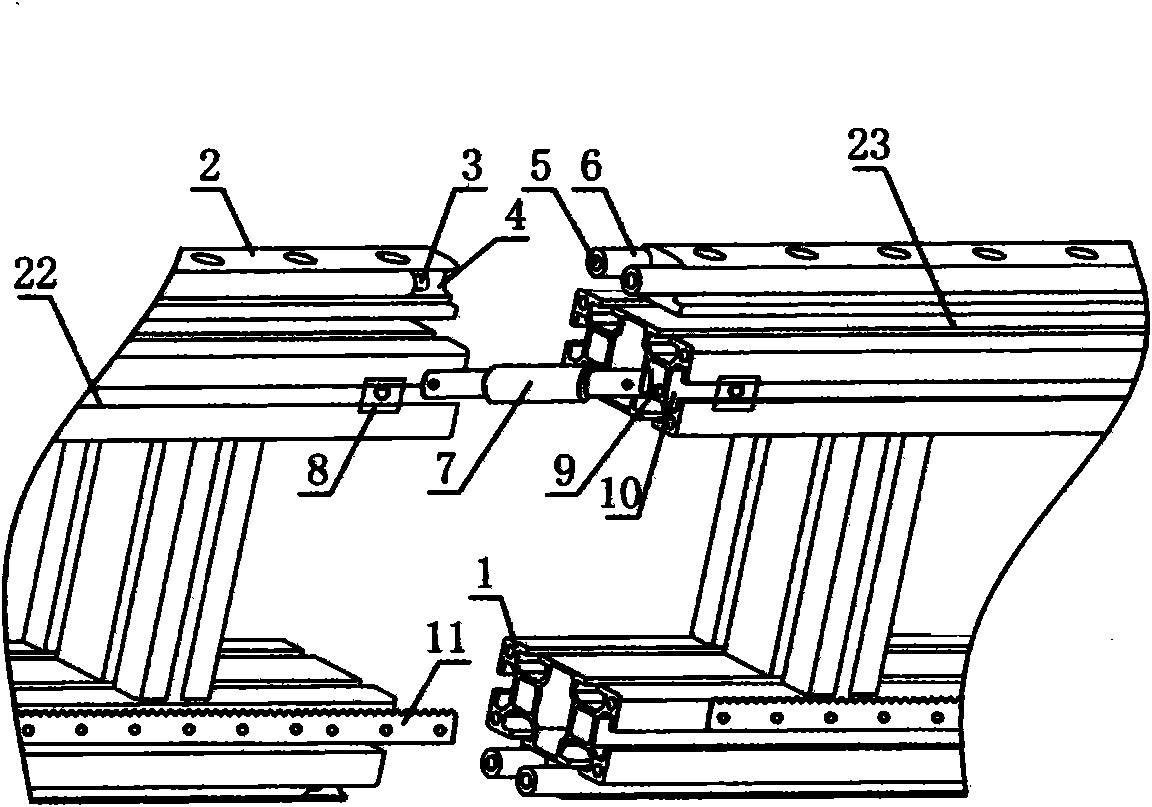

Portable spliced guide rail, butt joint method and work fixture

InactiveCN102152162AReduce weightEasy to assemble and disassembleLinear bearingsAssembly machinesButt jointEngineering

The invention discloses a portable spliced guide rail, a butt joint method and a work fixture. The spliced guide rail is divided into a base section part, an extension section and a tail section which are mutually in butt joint along a cross section direction, wherein butt joint faces are connected in a mutual intersection manner, so that the defects of poor butt-joint stability, low connection strength and difficult in precision guarantee on the same horizontal plane are avoided. On the butt joint faces of a guide rail body, two pairs of positioning pins and positioning holes are adopted, sothat the positioning is accurate and the positional connection is reliable; guide posts and guide faces are mutually matched so that the splicing accuracy is enhanced; and auxiliary dowel shafts are used for fixed connection so that the structural stability and the integrity of the spliced guide rail are ensured, and the specially designed work fixture ensures that the butt joint process of the guide rail is more accurate and easier to operate. The entire spliced guide rail has a simple structure, is convenient for butt joint, and can be dismounted and assembled without professional personnel, and the extended guide rail is beneficial to enlargement of an applicable range for product processing and is suitable for popularization and application in various industries and fields.

Owner:北京灿烂阳光科技发展有限公司

Shuttle child-mother vehicle for automatically carrying materials in and out from warehouse

InactiveCN106429156AImprove carrying capacityGuaranteed stabilityStorage devicesAutomotive engineering

The invention discloses a shuttle child-mother vehicle for automatically carrying materials in and out from a warehouse. The shuttle child-mother vehicle comprises at least two lanes spaced in parallel, and rails vertically connected to two sides of the lanes; and the lanes and the rails form material transportation rails. The shuttle child-mother vehicle further comprises a mother vehicle, and a child vehicle slidingly arranged on the mother vehicle; the mother vehicle is arranged on the lanes, and linearly slides along the lanes in a reciprocating manner; a child vehicle groove inwards recessed is formed in the middle part of the mother vehicle; slide ways are respectively formed in two sides of the child vehicle groove; the child vehicle is arranged in the child vehicle groove; child wheels on two sides of the child vehicle are put on the slide ways for supporting the child vehicle; a walking module and an ejecting module are arranged in the child vehicle, and adopt independent driving mechanisms; the walking module drives the child vehicle to linearly slide on the slide ways or the rails; and the ejecting module drives an object carrying plate to lift in the vertical direction. The shuttle child-mother vehicle matches the mother vehicle with the child vehicle to realize full-automatic material carrying, effectively promotes the carrying efficiency, and reduces the carrying cost.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

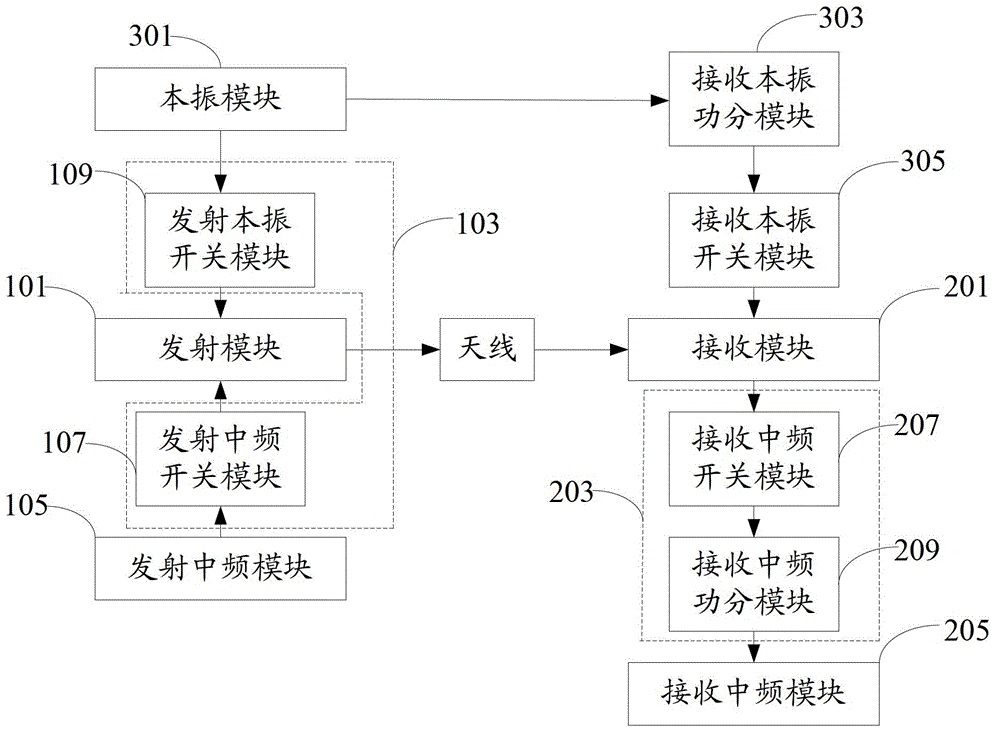

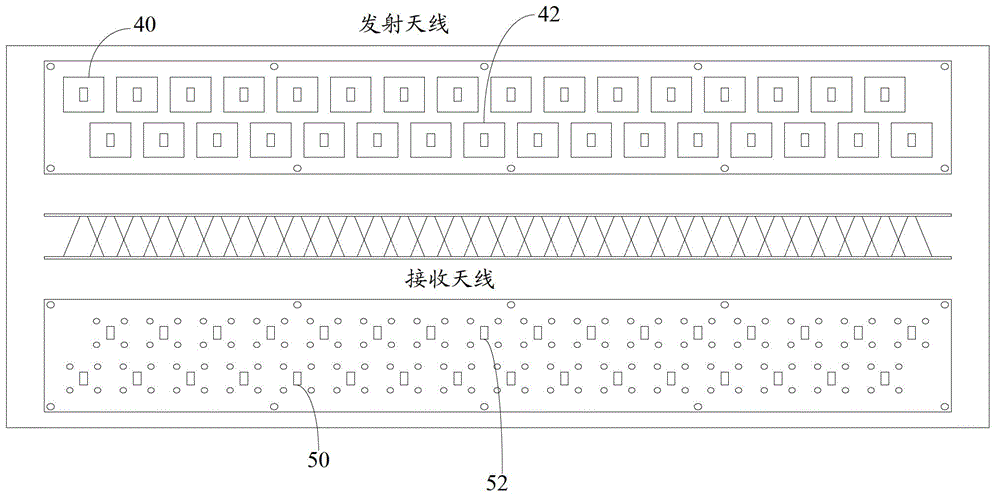

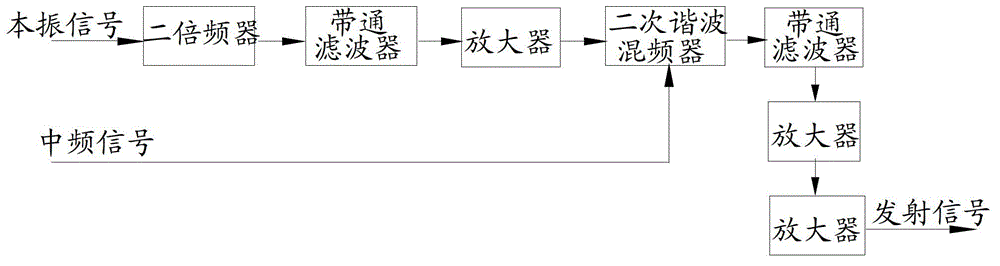

Multichannel transmission system of millimeter-wave signals

ActiveCN103067080AGuaranteed transmission accuracyControl the amount receivedFree-space transmissionLocal oscillator signalControl signal

The invention discloses a multichannel transmission system of millimeter-wave signals. The multichannel transmission system of the millimeter-wave signals comprises a transmitting module, a receiving module, a local oscillator module, a transmitting switch module, and a receiving switch module. The transmitting module is used for being connected with a transmitting end of transmitting antennas, and the transmitting module is used for sending transmitting signals through the transmitting antennas. The receiving module is used for being connected with a receiving end of receiving antennas, and the receiving module is used for receiving the transmitting signals sent by the transmitting module and changing the transmitting signals into intermediate frequency signals. The local oscillator module is connected with the transmitting module and the receiving module, and the local oscillator module is used for providing local oscillator signals for the transmitting module and the receiving module. The transmitting switch module is connected with the transmitting module, and the transmitting switch module is used for controlling the number of transmitting channels of the transmitting signals sent by the transmitting module. The receiving switch module is connected with the receiving module, and the receiving switch module is used for controlling the number of receiving channels of receiving signals received by the receiving module. Signals transmitting numbers and signals receiving numbers are controlled accurately, so transmitting accuracy of signals is guaranteed.

Owner:珠海中科先进科技产业有限公司

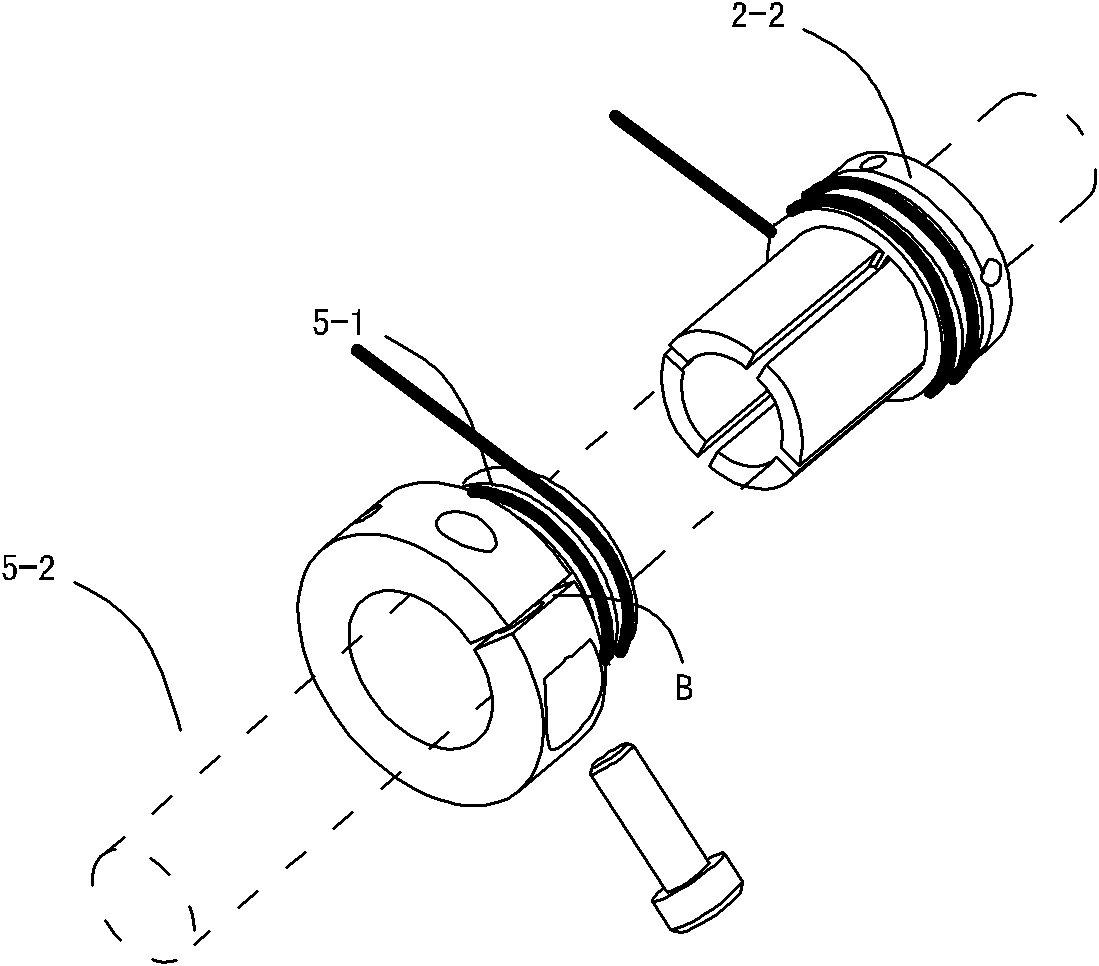

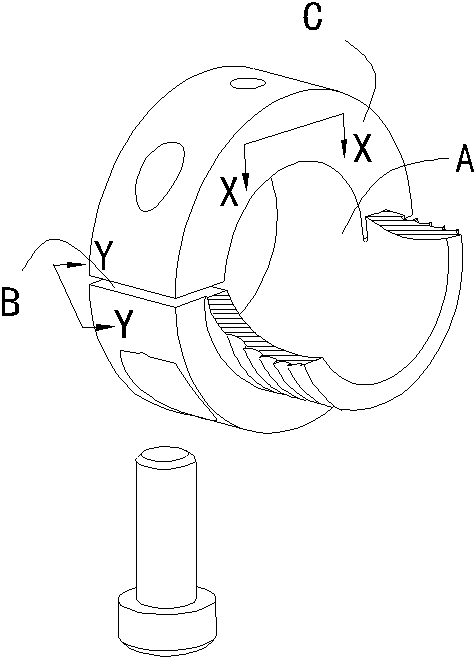

Wire fixing mechanism for wire transmission system

The invention discloses a wire fixing mechanism for a wire transmission system, which comprises an outer wire fixing wheel on which a shaft hole is formed, an inner wire fixing wheel on which a shaft hole is formed and of which the bottom is provided with a smooth shaft section and a wire fixing wheel locking block, wherein a plurality of grooves are formed on the side wall of the smooth shaft section of the inner wire fixing wheel along the axial direction of the side wall; the inner and outer wire fixing wheels are provided with wire grooves; the smooth shaft section of the inner wire fixing wheel is inserted into the shaft hole of the outer wire fixing wheel and is in clearance fit with the shaft hole of the outer wire fixing wheel; the wire fixing wheel locking block is connected withthe lower part of the outer wire fixing wheel through a connecting screw; and the smooth shaft section of the inner wire fixing wheel can be clasped on a rotating shaft arranged in the shaft hole of the inner wire fixing wheel through the wire fixing wheel locking block. Due to the adoption of the mechanism, a closed loop steel wire rope can be reliably tensioned during transmission, the condition that the wire transmission system is always in a tensioning state during operation is ensured, the wire transmission system can be adjusted and calibrated during operation, and transmission accuracyis ensured.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

Technique for processing connecting rod bearing shell

The invention discloses a processing technique of a connecting rod bush. According to working procedure sequence, the processing technique of the connecting rod bush includes the following steps: casting a rough part which needs to be provided with a technical chuck; placing the rough part in open air alone for 50-70 days for natural inactivation; milling the rough part into two halfliners, and placing the halfliners in a workshop for 35-45 days for natural inactivation; combining the two halfliners into a whole by a clamping band, roughly lathing an internal circle and an external circle and keeping a margin of 5-7mm; roughly milling a bush mouth; placing the bush in a processing workshop alone for 3 days for natural inactivation; semi-finish turning of the internal circle and the external circle; semi-finish milling of the bush mouth; lathing an anti-change groove on the technical chuck, correcting and finely turning the internal circle and the external circle, with machining precision being IT8-IT5, and cutting off the technical chuck; drilling an assemble hole of the connecting rod bush and righting the shape of the assemble hole; finish-milling the bush mouth and a bush mouth inclined plane. The invention provides a processing technique of a connecting rod bush product which has long service life and can lead to high running precision of a crank link mechanism.

Owner:JIER MACHINE TOOL GROUP

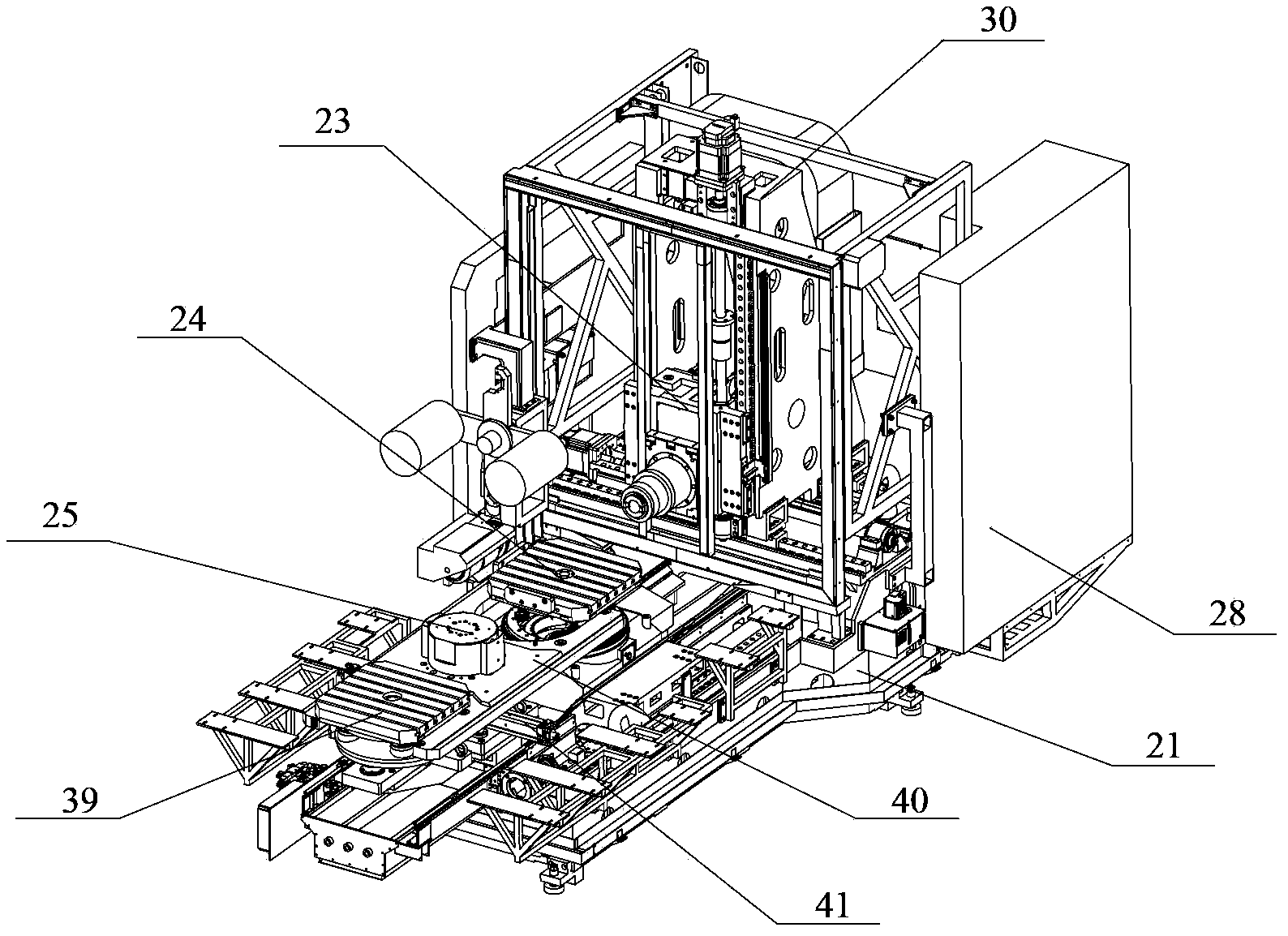

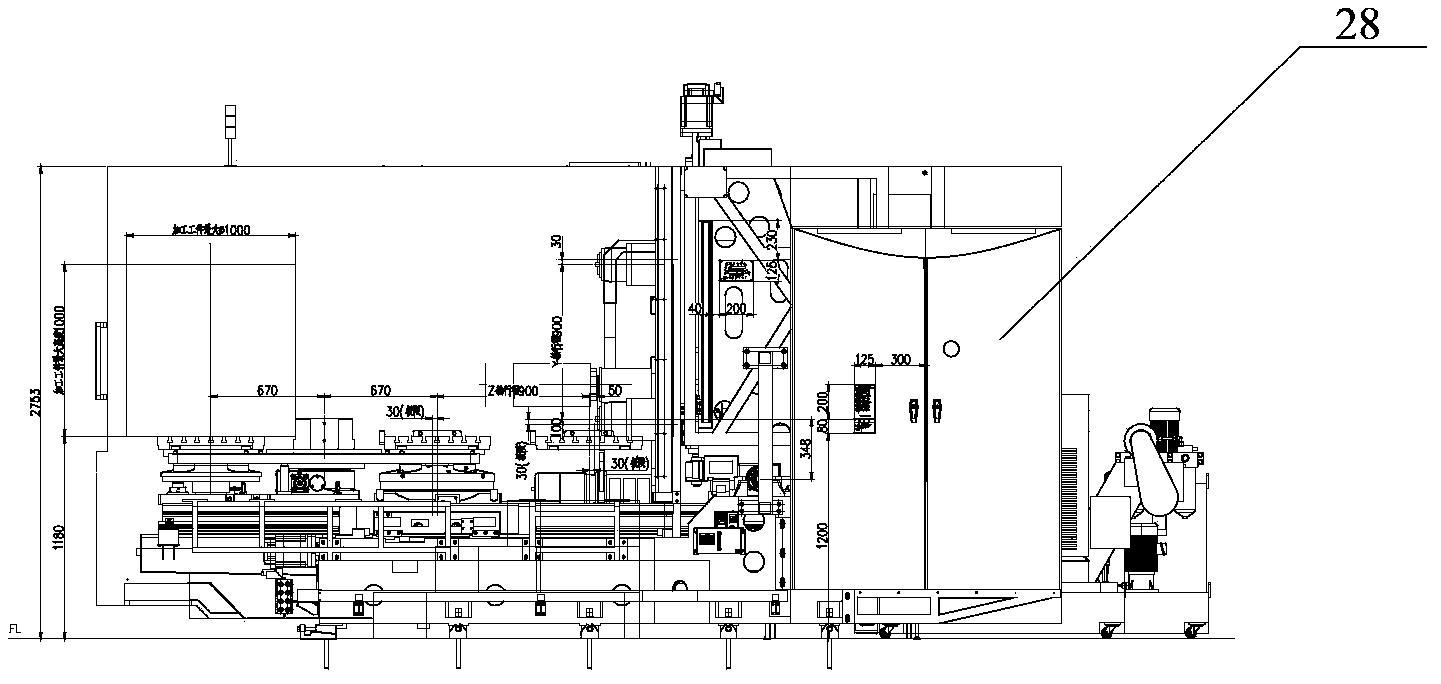

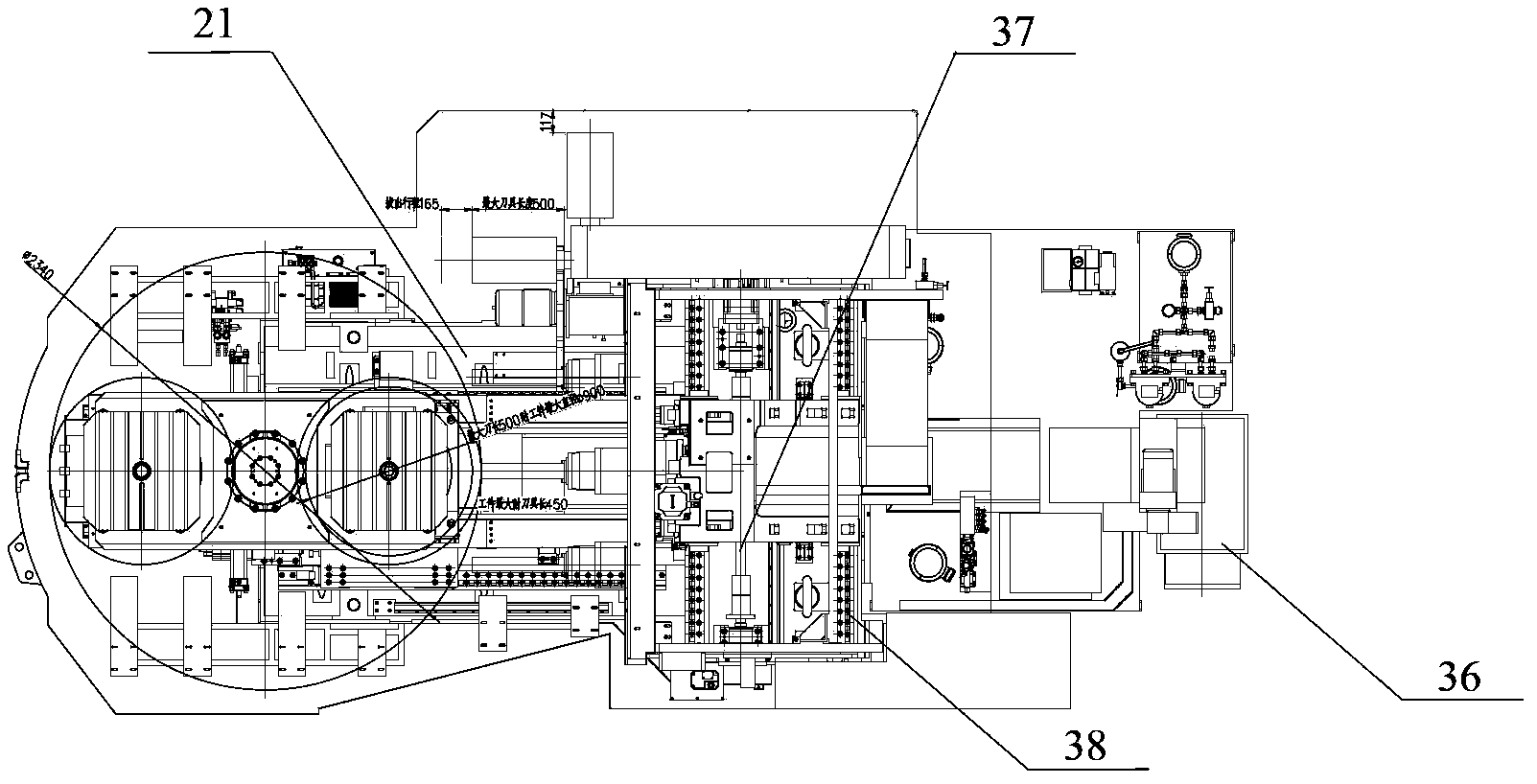

Efficient complete machine structure for horizontal machining center and manufacturing method thereof

ActiveCN103358186AResidue reductionAvoid harmFeeding apparatusLarge fixed membersManufacturing technologyTransmitted power

The invention relates to the field of machine manufacturing equipment, in particular to an efficient complete machine structure for a horizontal machining center and a manufacturing method thereof, and belongs to the design of a numerically controlled machining center of a machine tool and manufacturing technique. The complete machine structure comprises a lathe bed, a column, a headstock, a tool magazine and the like, wherein backwater holes are formed in the declined surface of the rigidity lathe bed; the gantry framework type column which moves horizontally on the lathe bed adopts a *-shaped rib arrangement; a motor directly connected ZF reduction gearbox on a headstock which moves vertically on the column transmits power to a spindle through the belt; a loosely clamped knife adopts a gas-liquid conversion pressurized cylinder; a swivel table that moves along the lathe bed forwards and backwards adopts a modularized design; a variable-frequency ATC (Air Traffic Control) at the left side of the lathe bed is in rigid connection with a square tool magazine body; an L-shaped electrical cabinet is arranged at the right side of the lathe bed; a structure of combing a large-flow cutting fluid fling mechanism with a chain plate chip cleaner is adopted in the middle of the lathe bed; a function setting interface, a maintenance plan function and an energy saving function are possessed. The structure provided by the invention solves the problems that a common horizontal machining center is large in size, high in energy consumption, complex in maintenance in the prior art.

Owner:SHENYANG MASCH TOOL CO LTD

Heavy-load SCARA (selective compliance assembly robot arm) transfer robot

InactiveCN105500359AHigh precisionLarge transmission ratioProgramme-controlled manipulatorJointsBall bearingCarrying capacity

The invention discloses a heavy-load SCARA (selective compliance assembly robot arm) transfer robot and belongs to the technical field of industrial robots. The robot comprises a rack, a first rotating joint, a second rotating joint and a wrist mechanism, an engine seat in the rack is fixedly connected with a big-arm steel wheel flange in the first rotating joint through bolts, a big arm in the first rotating joint is fixedly connected with a second harmonic speed reducer in the second rotating joint through bolts, and a small arm in the second rotating joint is connected with the wrist mechanism through a deep groove ball bearing and a double row angular contact ball bearing. The heavy-load SCARA transfer robot has the advantages of compact structure, easiness in machining and manufacturing, low machining cost, high load carrying capacity and relatively simple transmission.

Owner:ANHUI HUACHUANG INTELLIGENT EQUIP

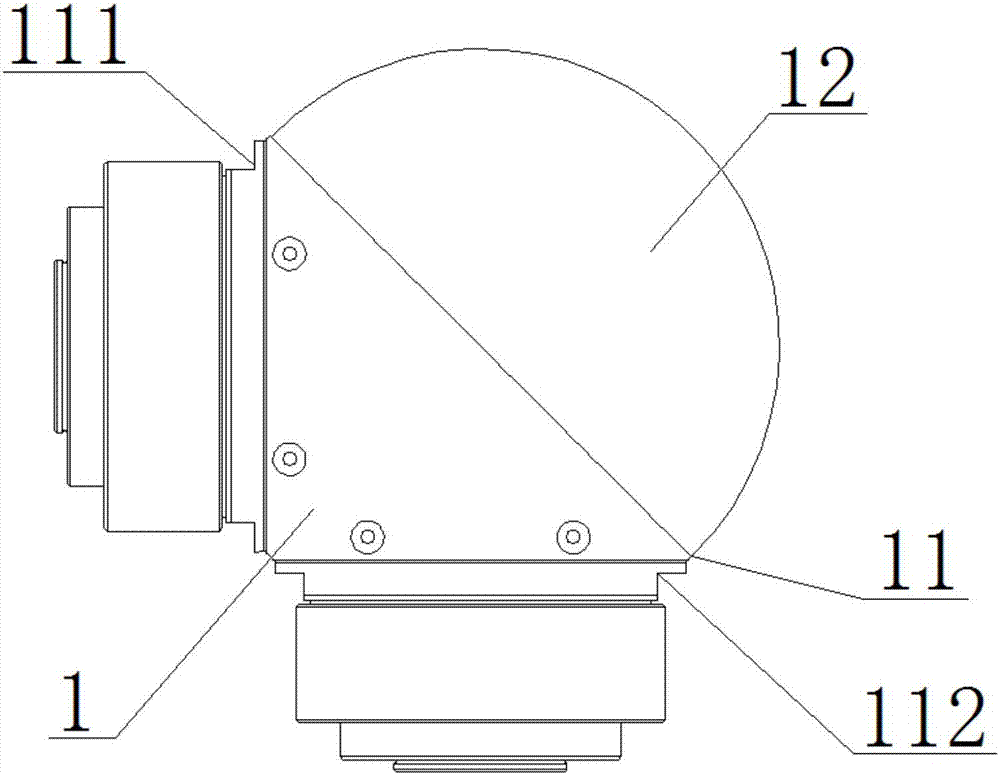

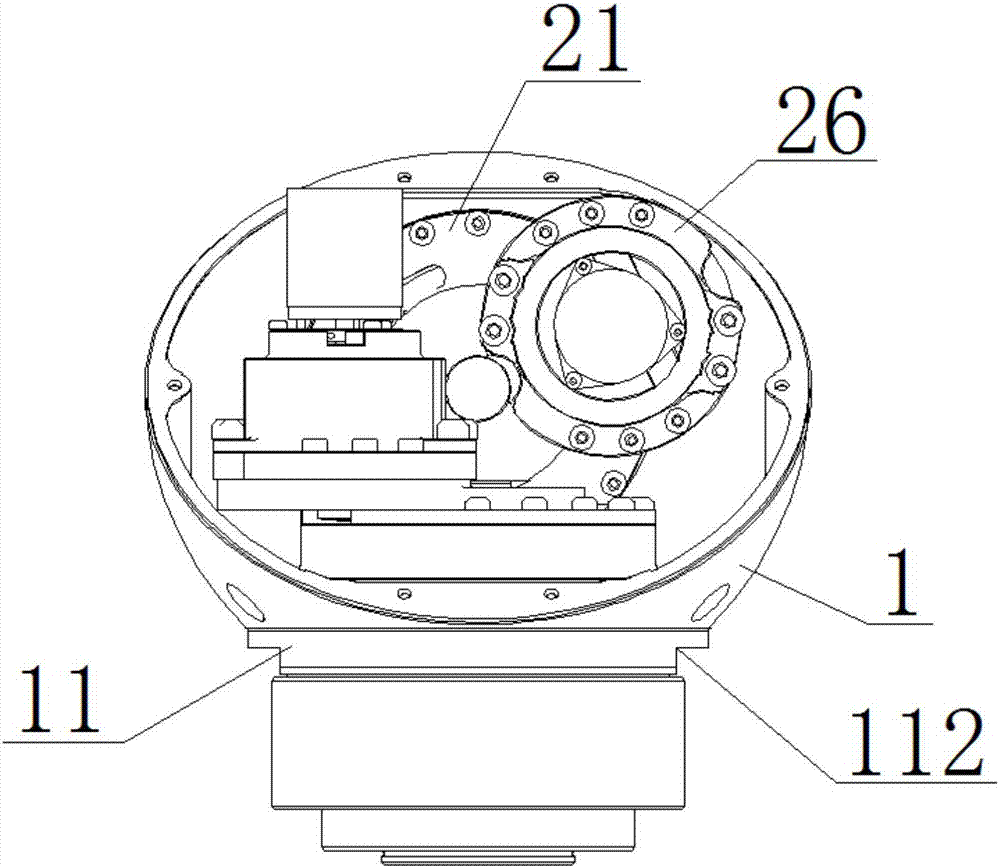

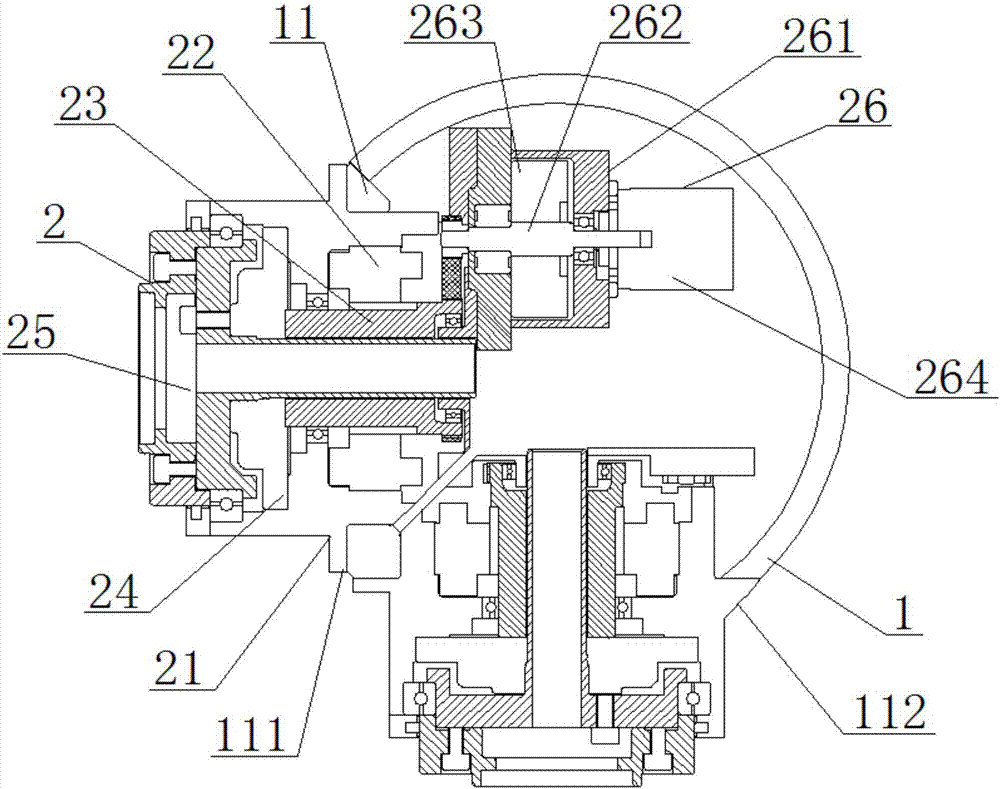

Stable platform with differential structure based on flexible cable transmission

ActiveCN107246870AImprove adaptabilityCompact structureNavigation by speed/acceleration measurementsElectric machineEngineering

The invention discloses a stable platform with a differential structure based on flexible cable transmission. The stable platform comprises a platform body, a driving unit and a differential mechanism, wherein the differential mechanism comprises an azimuth axle, a pitching axle and a flexible cable component; the azimuth axle and the pitching axle are driven by the flexible cable component; the azimuth axle is rotationally arranged on the platform body; the pitching axle is rotationally arranged on the azimuth axle and is orthographic to the axis of the azimuth axle; and the output end of the driving unit is in driving connection with the azimuth axle. According to the stable platform disclosed by the invention, the limitation that a load weight ratio of an existing integral stable platform is difficult to increase can be broken, and high torque is outputted by a small motor; besides, higher transmission precision is ensured; the contradiction between precision requirements of the platform and transmission properties of the mechanism is effectively coordinated; the conflict between the compact design of the platform and improvement on adaptability is overcome; and the stable platform has the characteristics of high loading capacity, high adaptability, light weight, high precision and compact structure.

Owner:NAT UNIV OF DEFENSE TECH

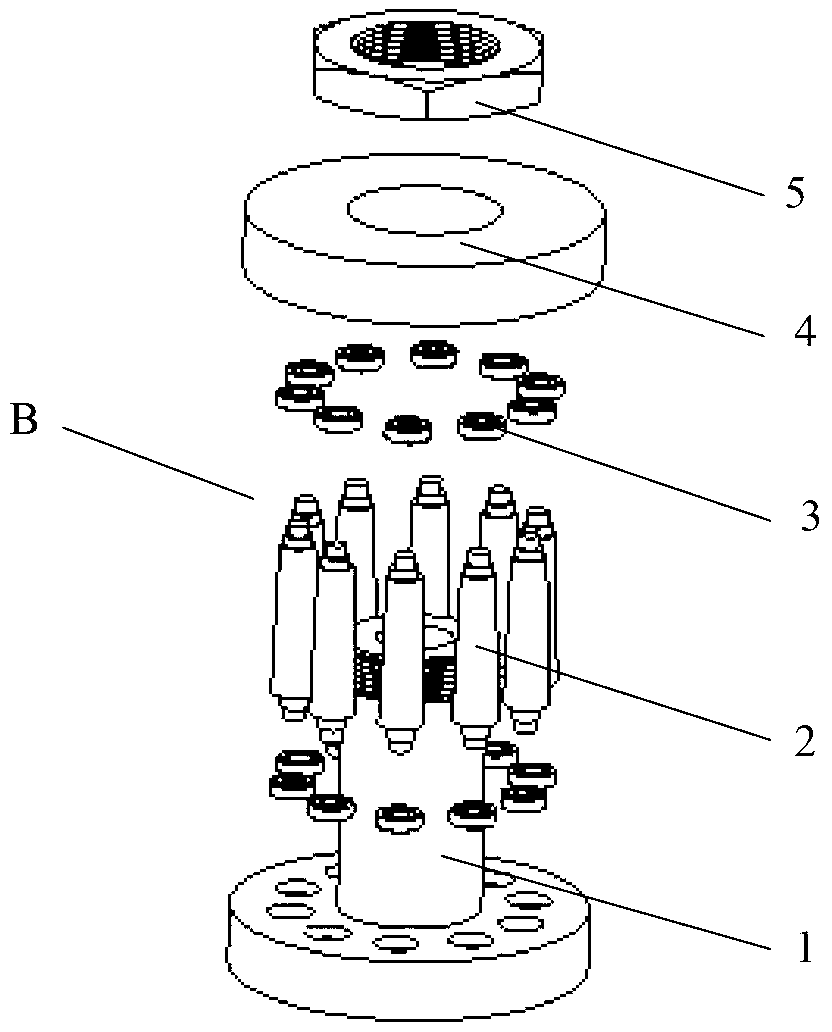

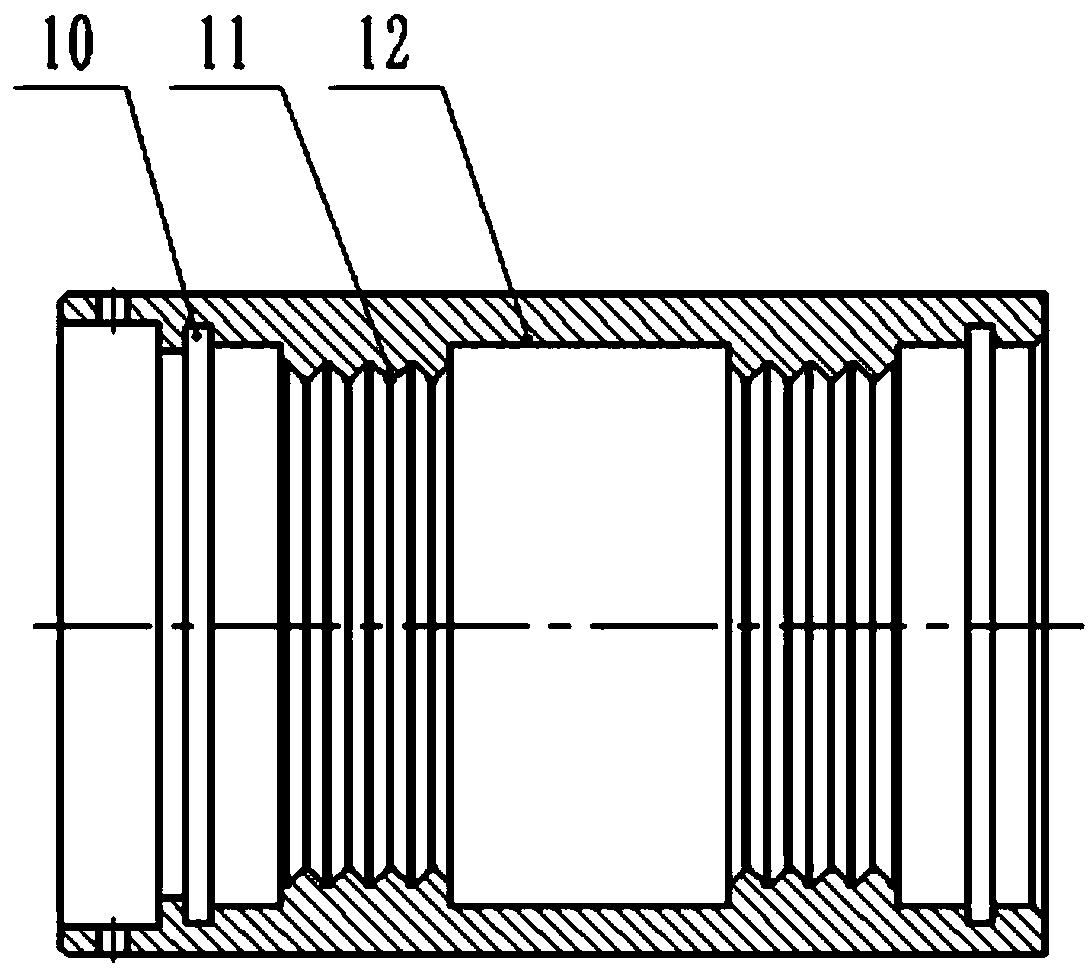

Planet roller screw electric cylinder

PendingCN109667901AGuaranteed transmission accuracyHigh precisionGearingRoller screwPulp and paper industry

The invention discloses a planet roller screw electric cylinder. The planet roller screw electric cylinder comprises a motor, a cylinder body, a power pipe and a planet roller screw pair transmissionmechanism. The motor outputs power to a lead screw. The power pipe is fixedly connected with a nut. The planet roller screw pair transmission mechanism is arranged inside the cylinder body. The powerpipe extends out of the cylinder body. The planet roller screw electric cylinder has the active and progressive effects that a novel planet roller screw pair structure is adopted, the planet roller screw electric cylinder does not slip under the heavy-load condition, the transmission precision is guarantee, and the engineering actual requirements of high precision, high-speed heavy-load and long service life can be met; the motor is can be arranged into a returning type and also can be arranged into a linear type; moving parts are arranged inside the cylinder body, seal parts are arranged inside a left end cover and a right end cover of the two ends of the cylinder body, the moving parts are isolated from the external environment, and the influence of the external environment on the key moving parts is completely eradicated; and the planet roller screw pair structure can be dismounted and replaced as needed, and modularized design can be achieved easily.

Owner:SEENPIN PROD ZHEJIANG

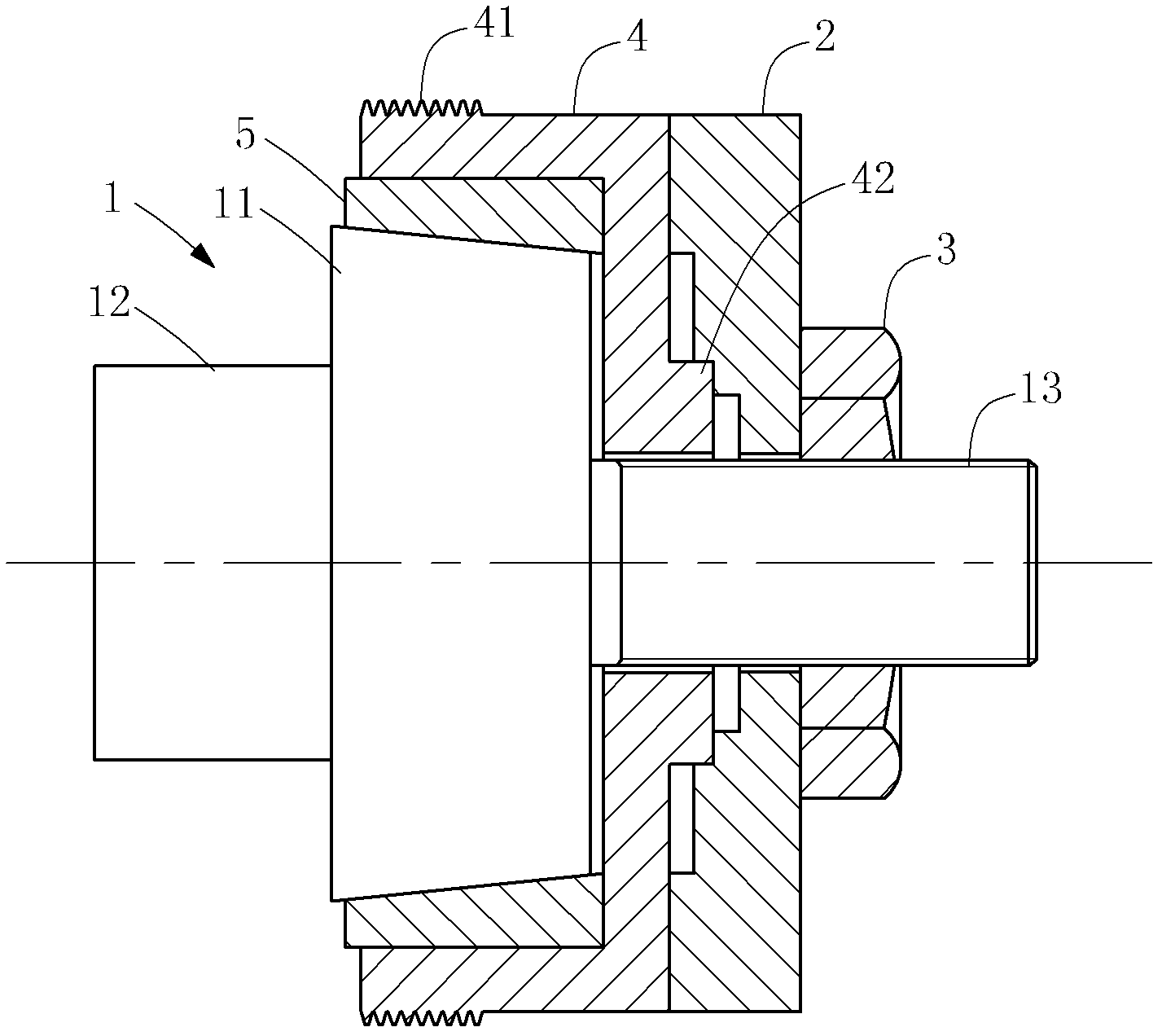

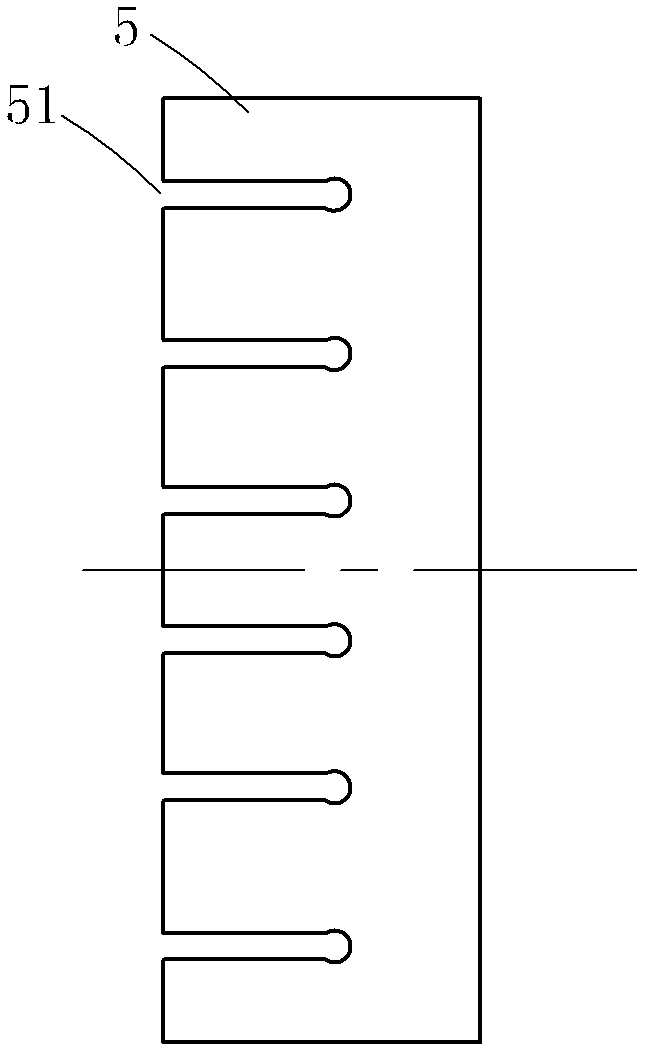

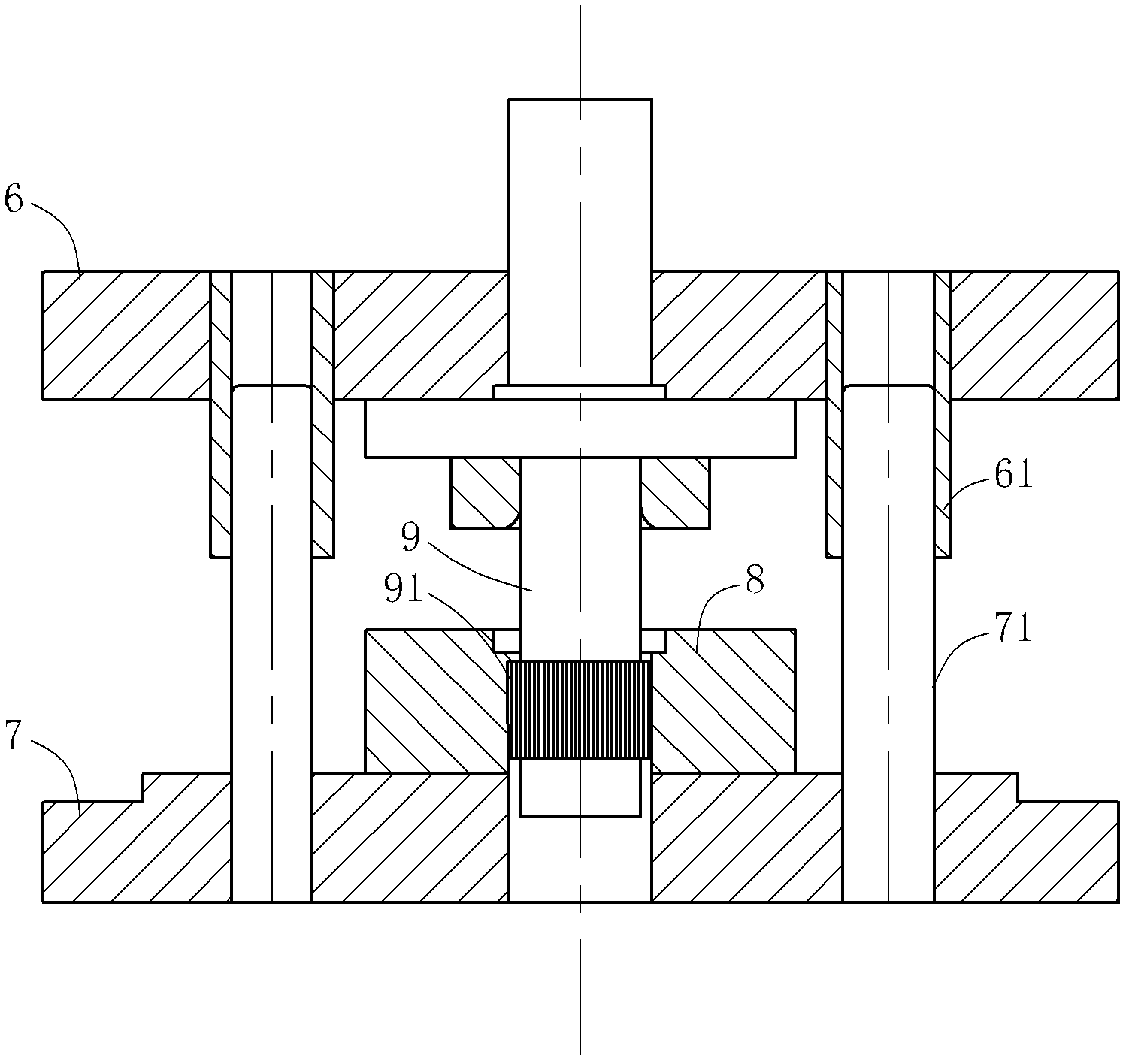

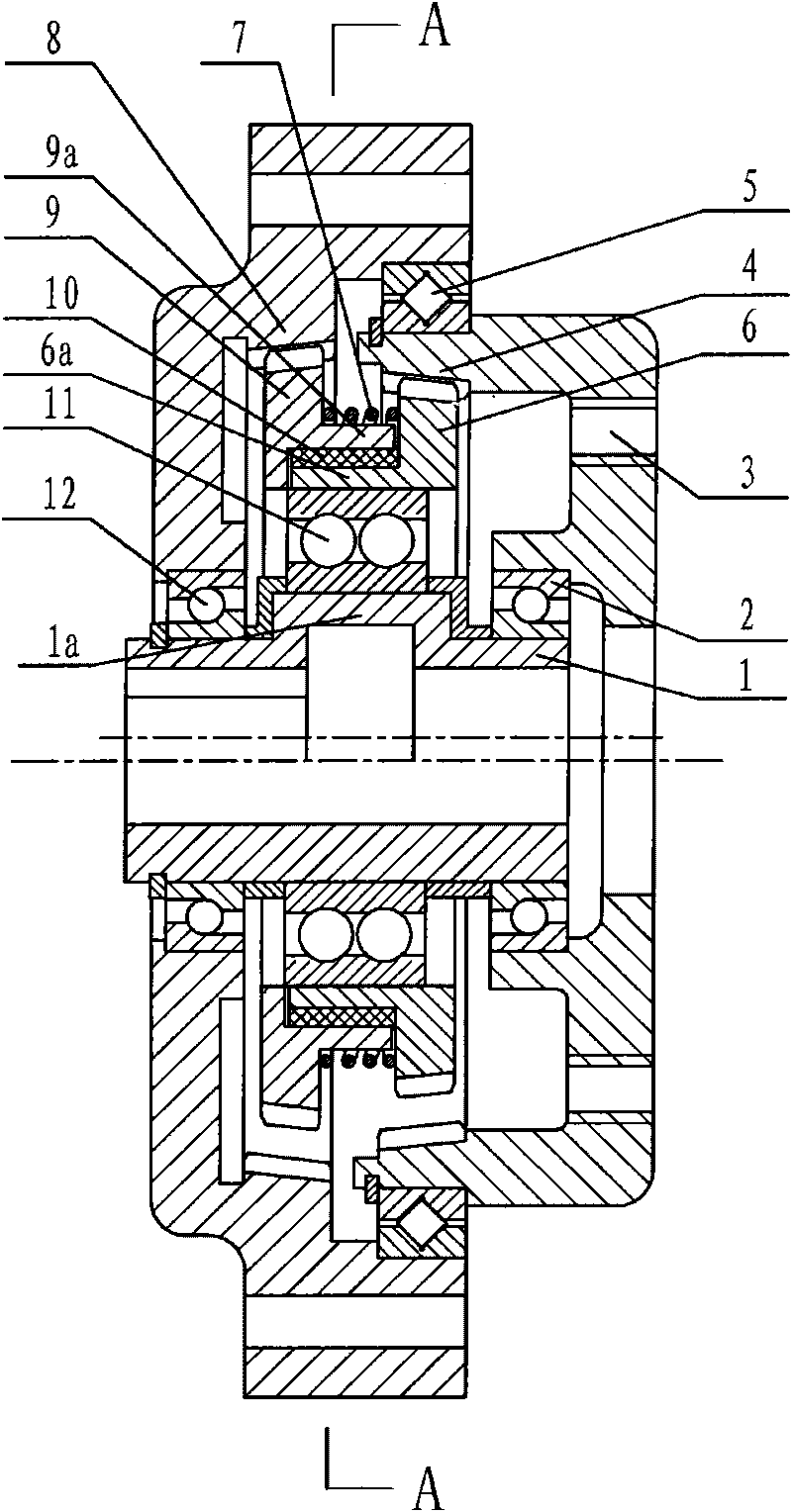

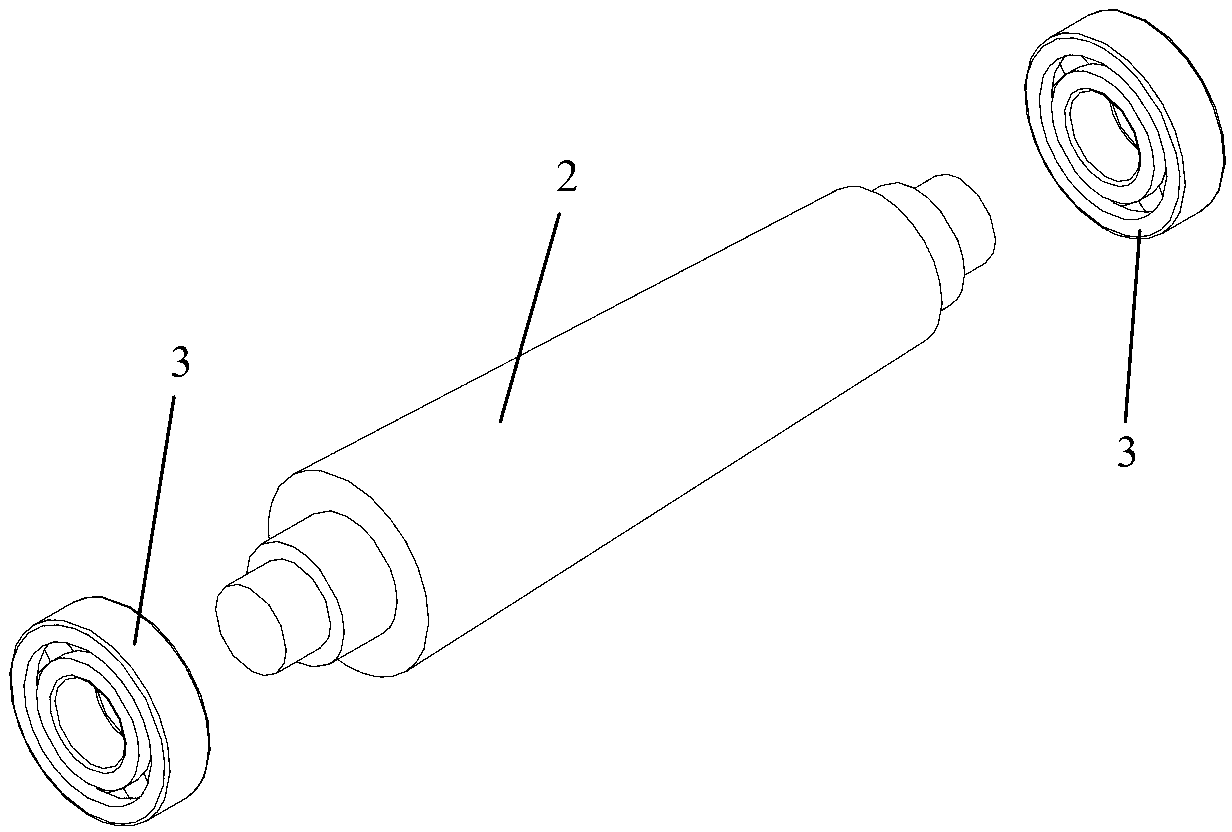

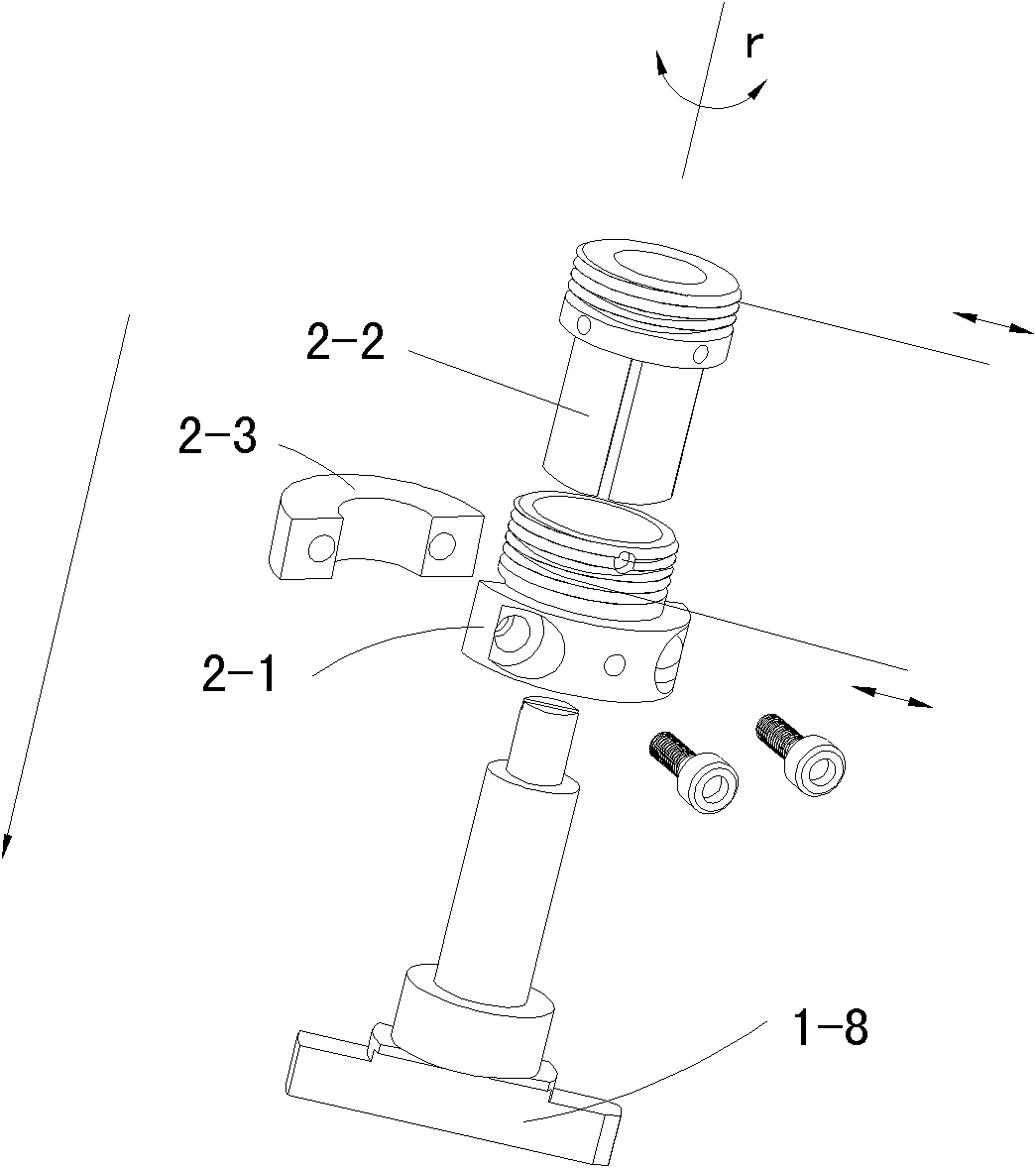

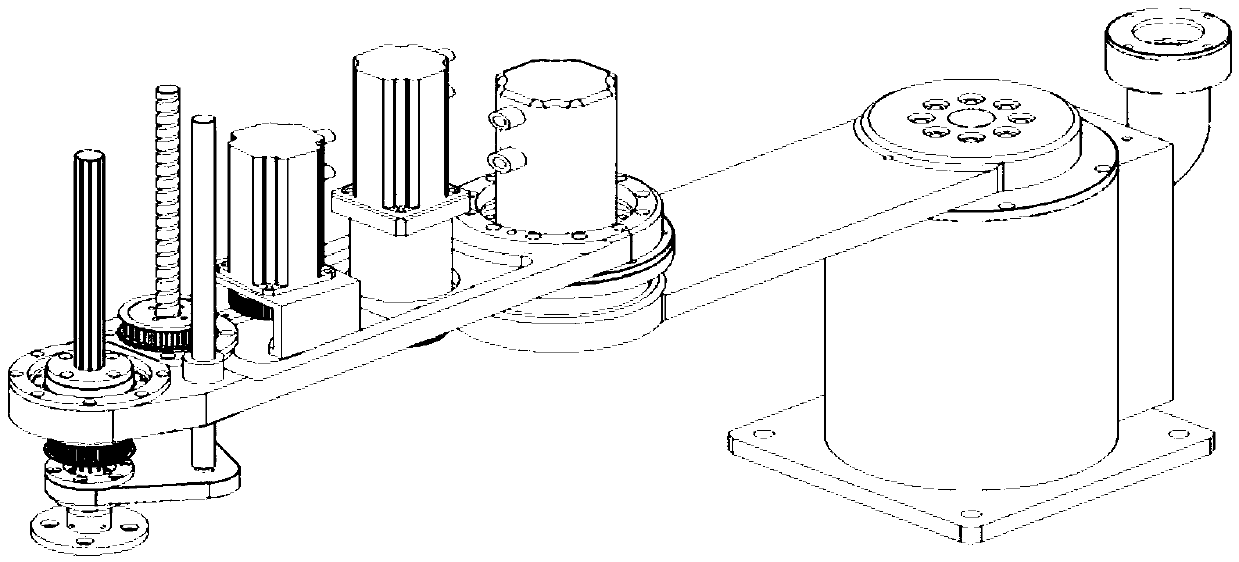

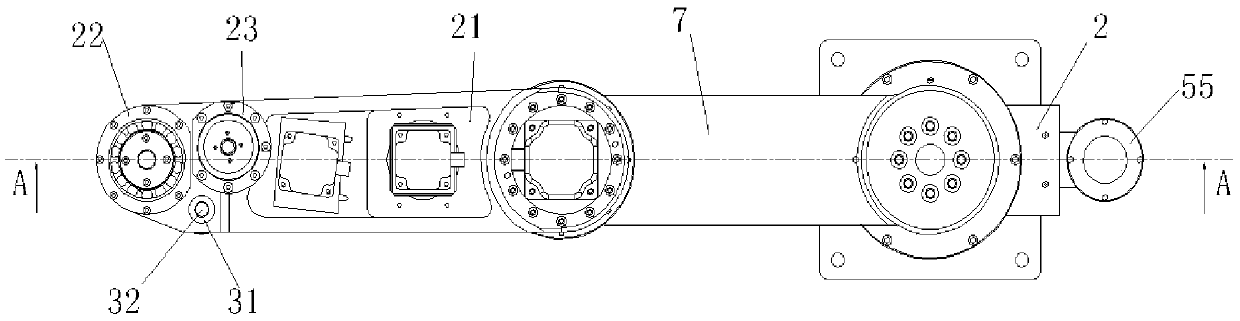

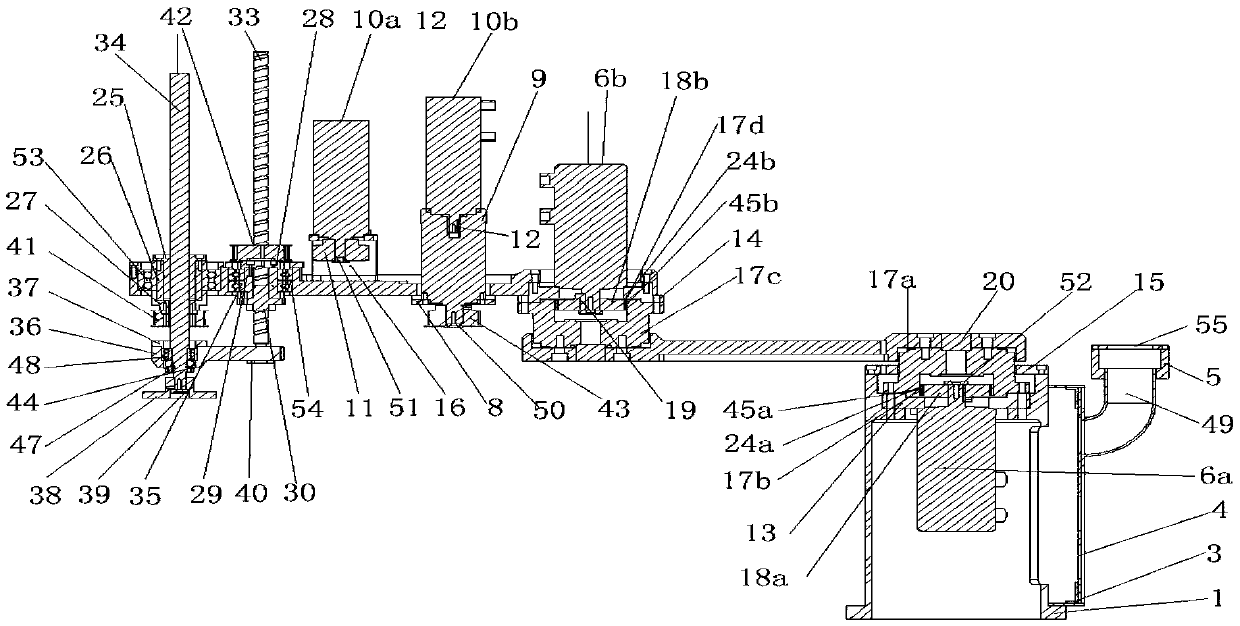

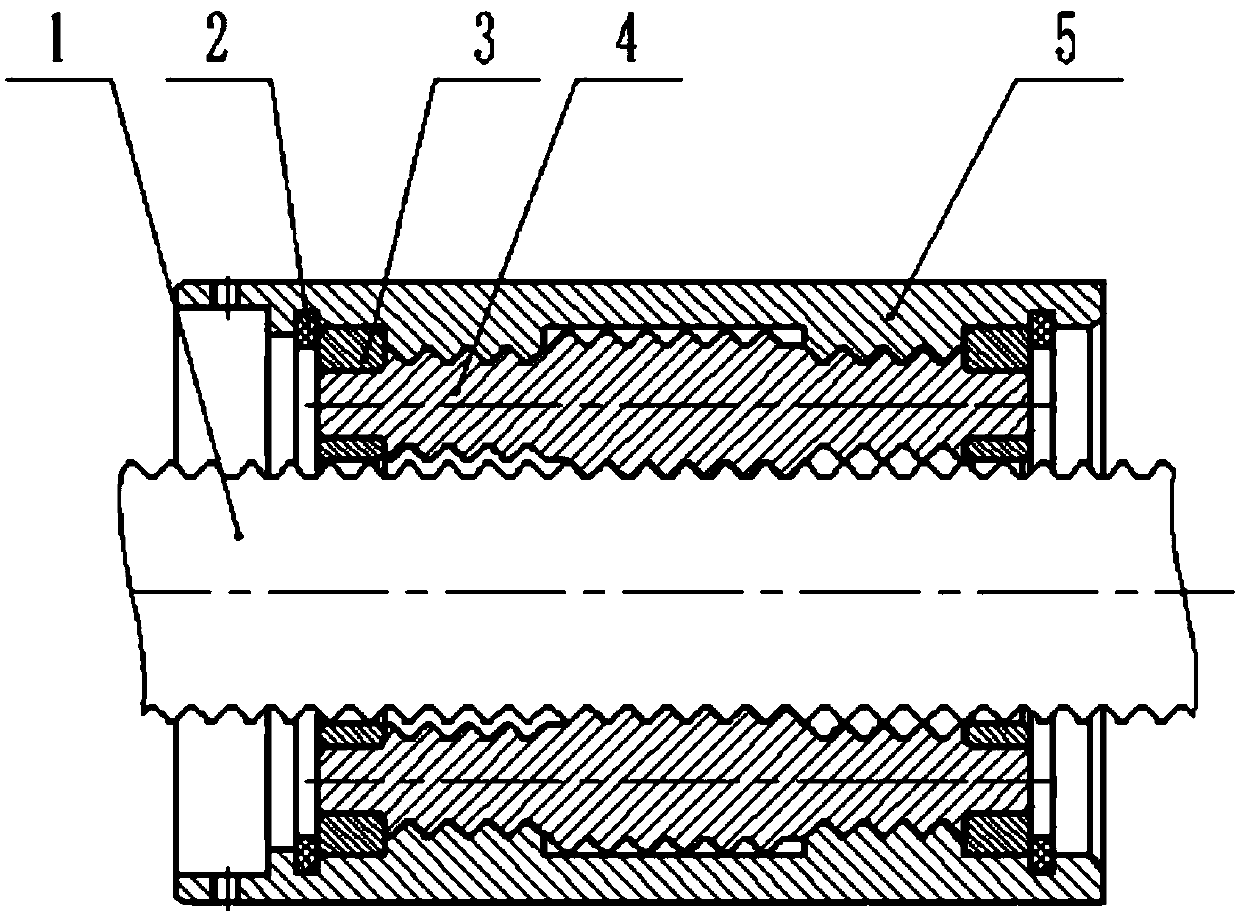

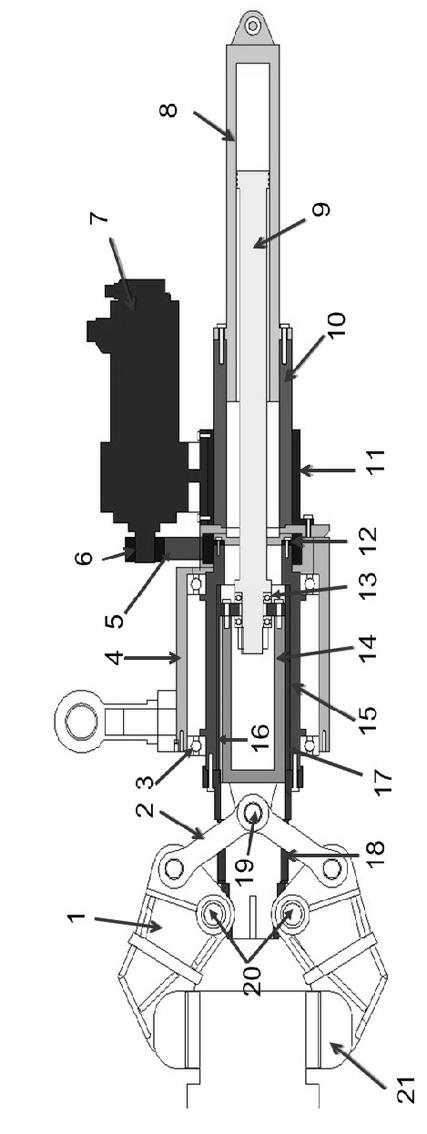

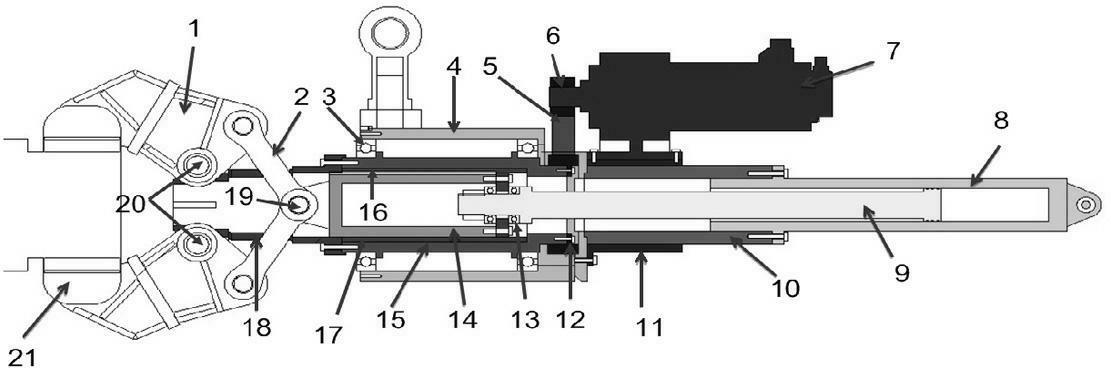

Claw rod mechanism of forging manipulator

InactiveCN102581198ASimple structureEasy to manufactureForging/hammering/pressing machinesStructural reliabilityBall bearing

The invention relates to a claw rod mechanism of a forging manipulator, which mainly comprises a jaw clamping mechanism and a claw arm rotating mechanism, wherein the jaw clamping mechanism comprises a claw arm (1), a connecting rod (2), a hydraulic piston cylinder (8), a piston rod (9), a thrust bearing A (12), a thrust bearing B (13), a connecting piece (14), a claw shell B (18), a pin A (19), a pin B (20) and a jaw (21); and the claw arm rotating mechanism mainly comprises a deep groove ball bearing (3), a claw shell A (4), a synchronous belt (5), a small belt wheel (6), a rotary driver (7), a claw shell C (10), a large belt wheel (11), the thrust bearing A (12), the thrust bearing B (13), the connecting piece (14), a rotating body (15), a guiding key (16) and a barrel sleeve (17). The claw rod mechanism of the forging manipulator has the advantages of a simple structure, a regular shape of each member and being easy in manufacturing and disassembly; and the piston rod and the oil cylinder have no torque loads so that the claw rod mechanism is high in structural reliability.

Owner:广州市优斯兰敦金属制品有限公司

Rigid-flexible composite filtering gear

InactiveCN104500693AGuaranteed transmission accuracyGuaranteed torsional rigidityPortable liftingToothed gearingsElastomerGear wheel

Owner:CHONGQING UNIV

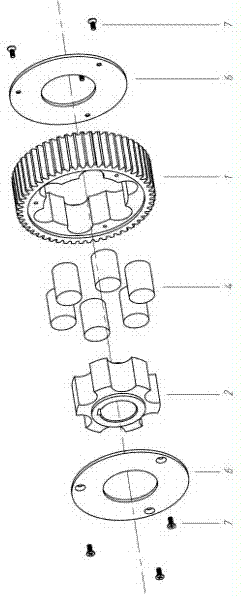

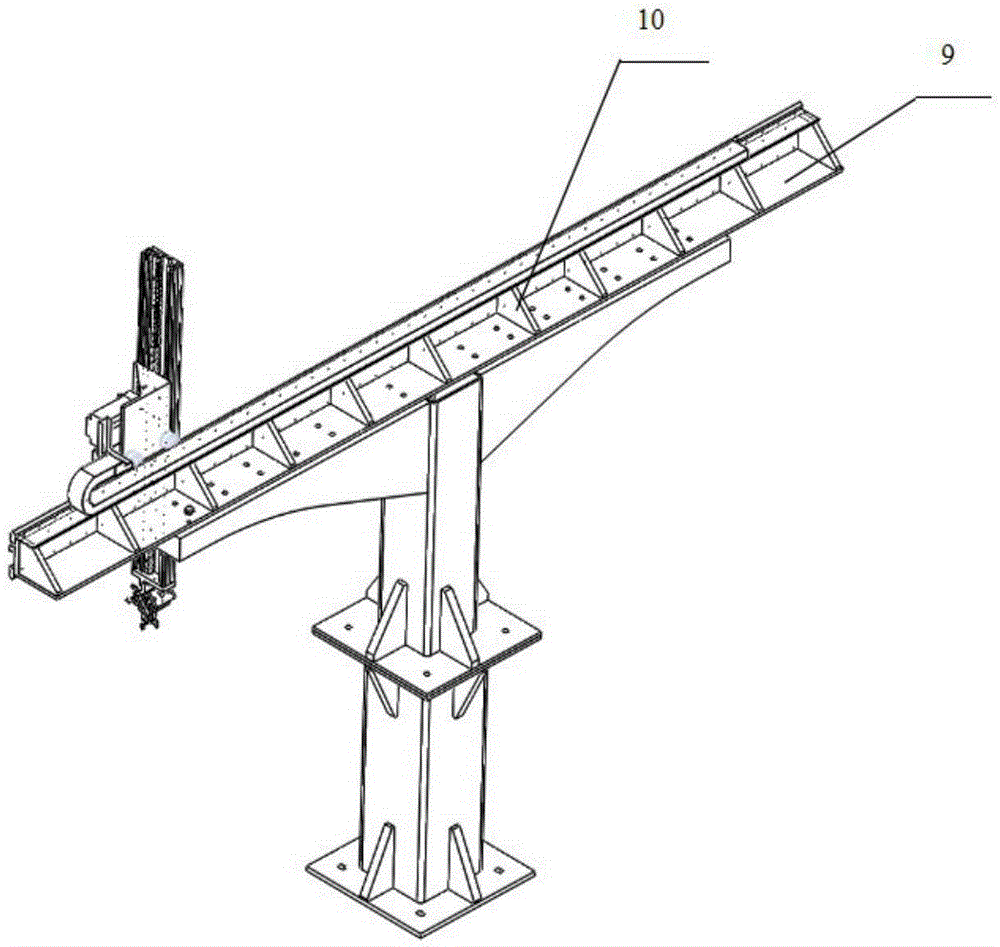

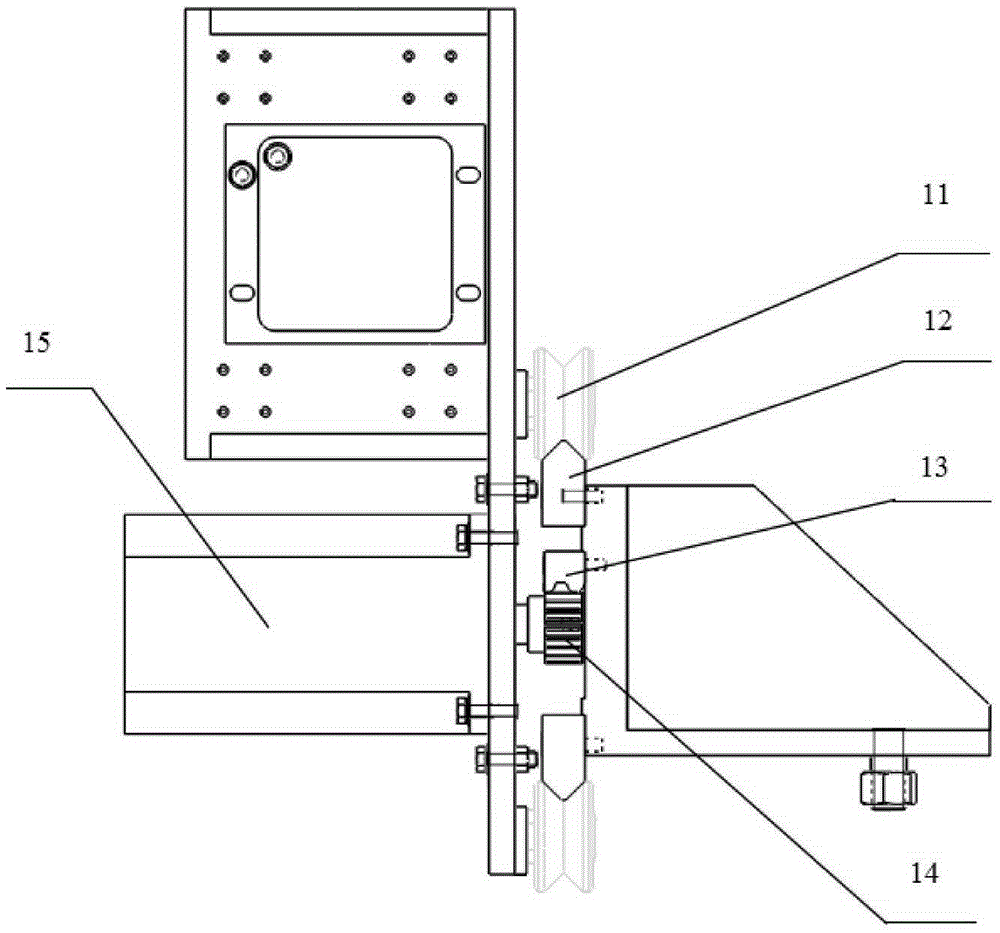

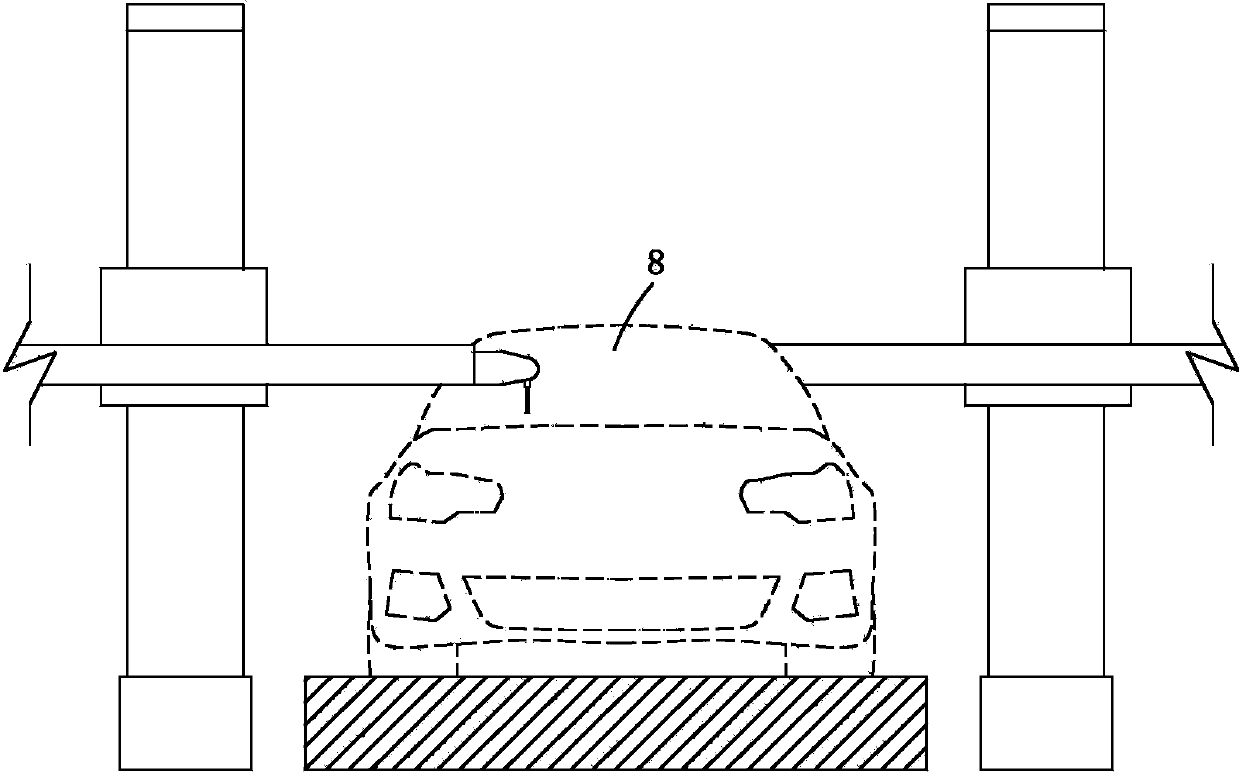

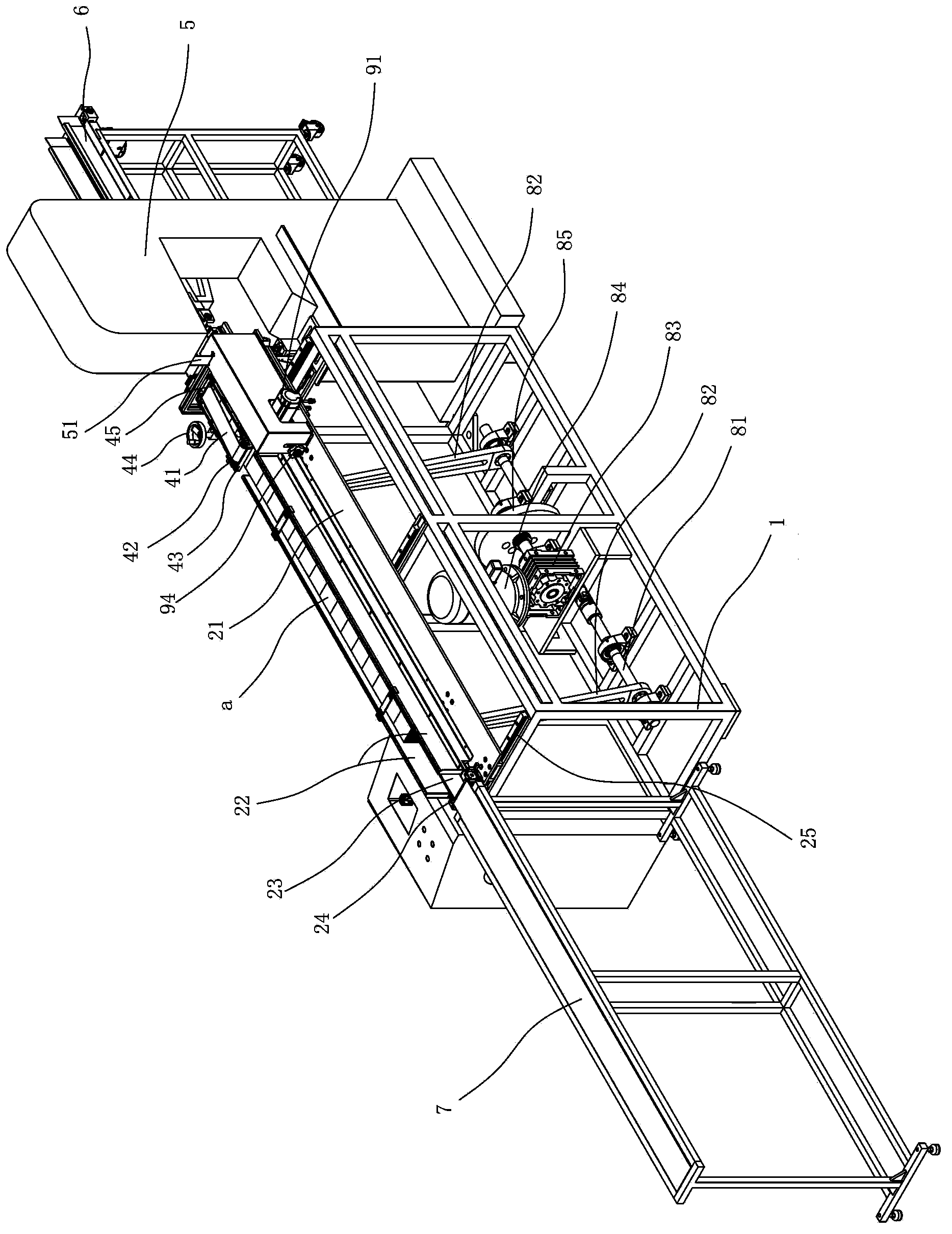

Truss manipulator for loading and unloading

InactiveCN105364932AHigh strengthIncrease stiffnessProgramme-controlled manipulatorGear wheelEngineering

The invention relates to a truss manipulator for loading and unloading. The truss manipulator for loading and unloading is composed of a support structure, a horizontal movement assembly, a vertical movement assembly, an automatic handgrip, and a transition connection plate between two shafts, wherein the horizontal movement assembly is fixedly installed at the top end of the support structure; the vertical movement assembly runs on the horizontal movement assembly; and the automatic handgrip is installed at the bottom end of the vertical movement assembly. According to the invention, a single-vertical-column supporting main body structure is adopted, and reinforcing ribs are designed and used for improving the strength and the rigidity of the truss main body structure; and transmission in a horizontal movement is realized in a manner of matching a V-shaped slide rail with independent gear and rack, each of the gear and the rack is provided with modulo-two oblique teeth with an accuracy class of 6, the transmission manner can greatly meet requirements on a high speed, and the transmission accuracy can be controlled to be less than 0.1mm.

Owner:TIANJIN TIANSEN INTELLIGENT EQUIP CO LTD

Integrated machining method of planet carrier of robot RV reducer

The invention discloses an integrated machining method of a planet carrier of a robot RV reducer, and belongs to the technical field of robot RV reducer machining. The method comprises the steps as follows: forging a first casing and a second casing, and performing hot extrusion on the first casing and the second casing respectively; performing thermal refining; performing tempering; performing finish machining on end surfaces respectively; connecting the first casing with the second casing to be clamped to a clamp, and performing finish machining on inner holes formed in the first casing and the second casing with a center of gyration serving as a locating basis; performing finish machining on outer surface with the locating basis; directly machining inner rings of rolling bearings on the first casing and the second casing; accurately grinding an outer track on each inner ring simultaneously; and performing finish machining bearing positions of three tapered roller bearings on the first casing and the second casing with the location reference, and directly machining outer rings of the tapered roller bearings. With the adoption of the method, the mounting accuracy, the manufacturing accuracy and the transmission accuracy are ensured, the requirement for high accuracy is met, the service life is prolonged, machining and assembling errors and accumulative errors are reduced, the output torque is increased, and the machining cost is effectively reduced.

Owner:SHANDONG SHKE MACHINERY MFG

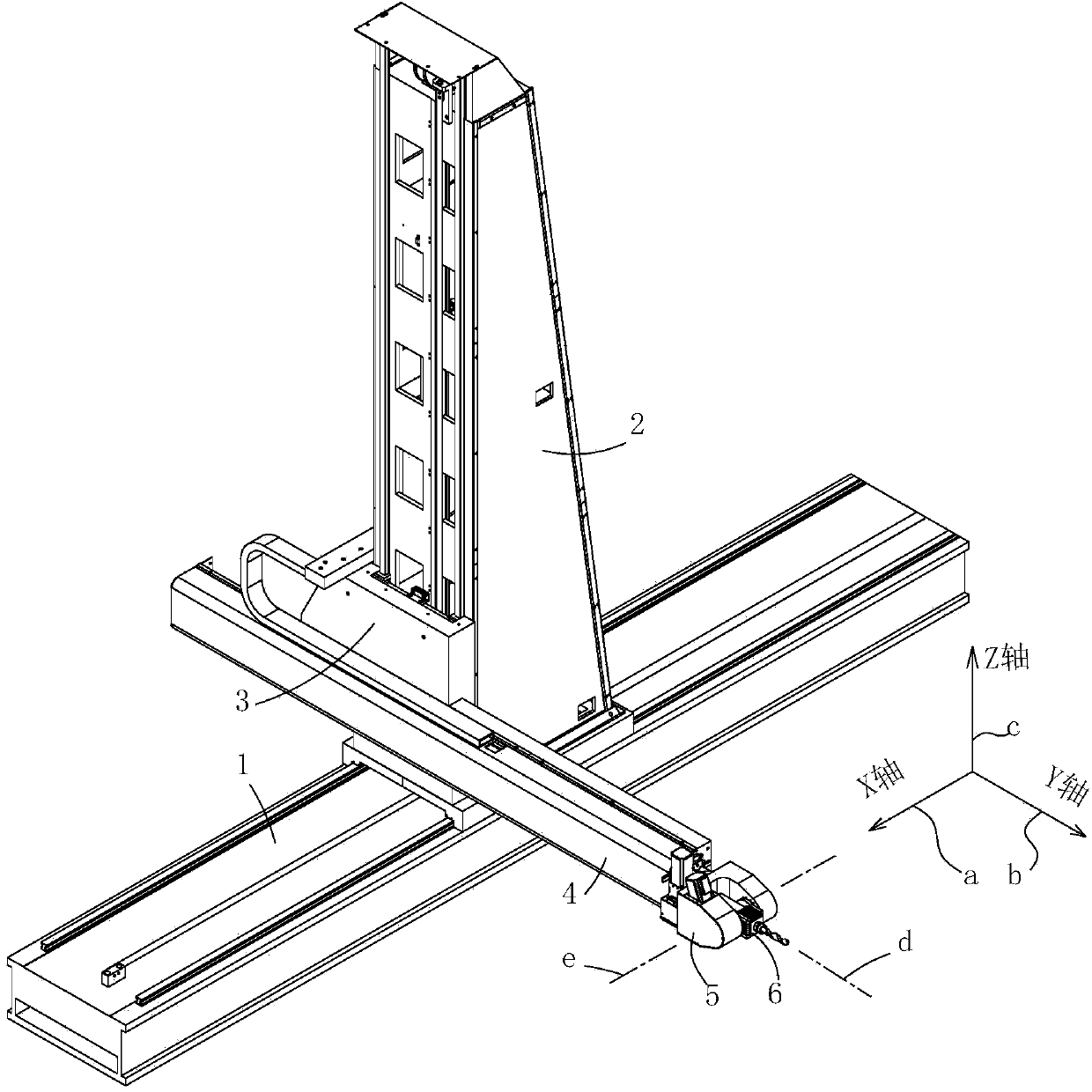

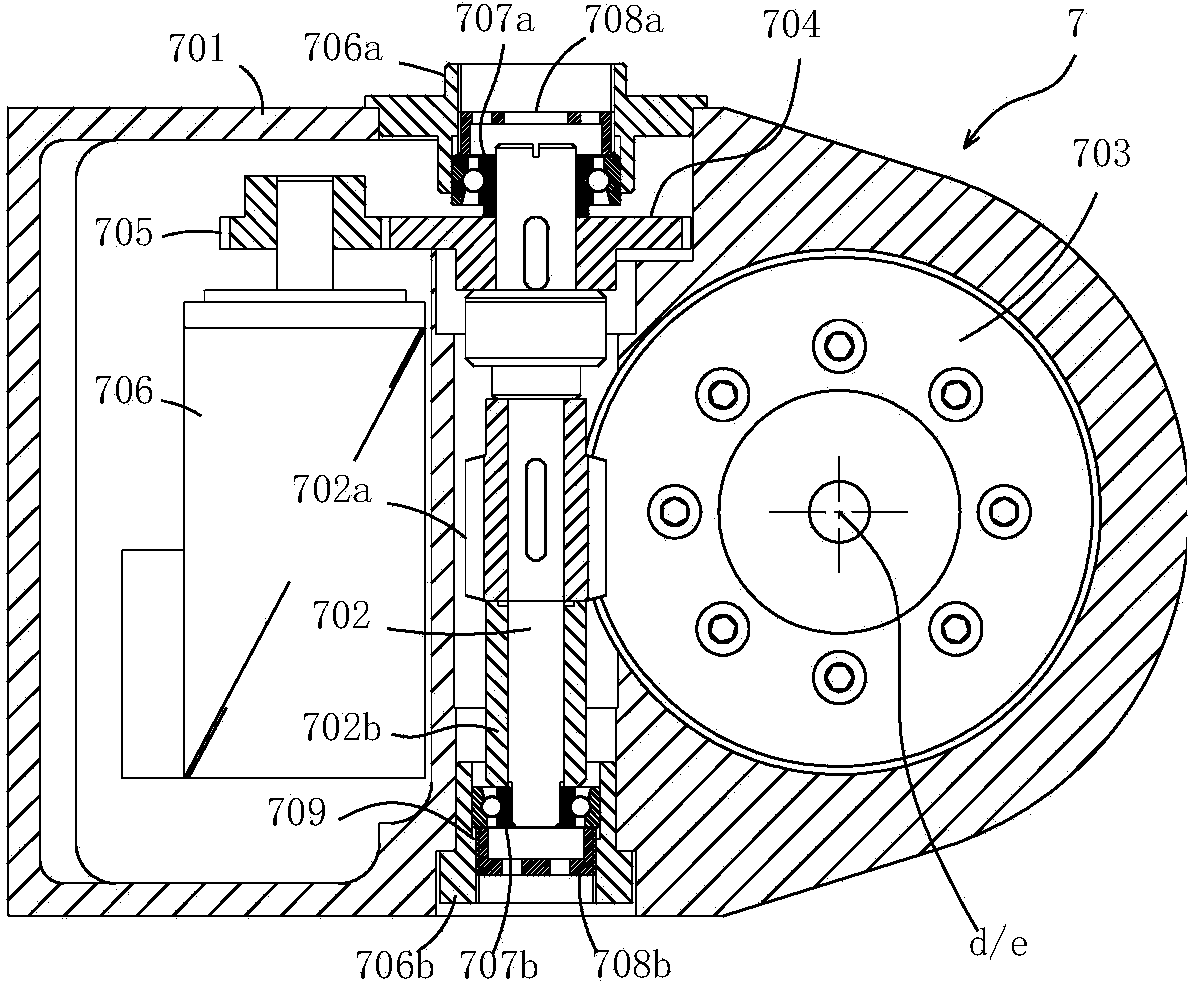

Three-dimensional soft model cutting forming machine and method

ActiveCN103433755AThe device takes up little spaceHigh compactnessProfiling/shaping machinesLarge fixed membersCantileverReciprocating motion

The invention discloses a three-dimensional soft model cutting forming machine and a three-dimensional soft model cutting forming method using the forming machine to achieve high efficiency machining, wherein the three-dimensional soft model cutting forming machine is compact in structure, and smooth and fast to machine. The forming machine comprises a base, a stand column, a fixed cantilever, a movable cantilever, an angle cutter head base and a cutter head body. The stand column is installed on the base through a first guide drive mechanism and can reciprocate along the horizontal X axis, the fixed cantilever is installed on the stand column through a second guide drive mechanism and can reciprocate along the horizontal Y axis, the angle cutter head base is installed at the front end of the movable cantilever through a fourth guide drive mechanism and can swing in the two directions around a first reference axis parallel to the horizontal Y axis under the action of the fourth guide drive mechanism, and the cutter head body is installed on the angle cutter head base through a fifth guide drive mechanism and can swing in the two directions around a second reference axis perpendicular to the first reference axis under the action of the fifth guide drive mechanism.

Owner:API ZC PRECISION INSTUMENT CO LTD

Modularized ball joint of collaborative robot

ActiveCN107186751AMiniaturizationReduce the number of jointsJointsReduction driveTorque transmission

The invention relates to mechanical arm joints, in particular to a modularized ball joint of a collaborative robot. The modularized ball joint of the collaborative robot comprises a shell and ball joint driving modules. A module supporting piece is fixedly installed on the shell, and a spherical shell cover is further installed on the shell. A first installation position and a second installation position are arranged on the module supporting piece, and the ball joint driving modules are fixedly installed on the first installation position and the second installation position and installed inside the shell in a sealing mode through the spherical shell cover. The modularized ball joint of the collaborative robot has the advantages that in the aspect of driving, hollow motors are used for driving, deceleration is conducted through harmonic speed reducers, and therefore high-torque transmission is achieved, the transmission accuracy is guaranteed, and the structure is compact and light; and in the aspect of braking, synchronous belt pulleys are utilized to conduct transmission, and therefore the driving portion and the braking portion are isolated, the space is saved, the braking performance is guaranteed, and the installation difficulty of the interior of the joint is reduced.

Owner:青岛欧开智能系统有限公司

Soft extraction paper slitting device

A soft extraction paper slitting device comprises a machine frame, a band-sawing machine, an intermittence paper feeding mechanism, a main driving mechanism and a control device, wherein the intermittence paper feeding mechanism is arranged on the machine frame in the longitudinal direction in a horizontal sliding mode, the main driving mechanism is arranged on the machine frame, is connected with the intermittence paper feeding mechanism and makes horizontal and reciprocating motion in the longitudinal direction, the control device is respectively connected with the intermittence paper feeding mechanism, the band-sawing machine and the main driving mechanism, the intermittence paper feeding mechanism comprises a sliding seat which is arranged on the machine frame in the longitudinal direction in a horizontal sliding mode, a first belt conveying mechanism which is transversely and horizontally arranged on the sliding seat and is used for conveying soft extraction paper to the band-sawing machine, a second belt conveying mechanism which is arranged on the sliding seat, is located above the first belt conveying mechanism and is used for compressing the soft extraction paper before the soft extraction paper is cut, a third belt conveying mechanism which is arranged on the sliding seat and is used for conveying the cut soft extraction paper, and a servo motor which drives the first belt conveying mechanism, the second belt conveying mechanism and the third belt conveying mechanism to work through a transmission mechanism. The soft extraction paper slitting device has the advantages of being high in cutting efficiency, good in quality and the like.

Owner:JINJIANG HAINA MACHINERY

Automatic 3D film attaching device for mobile phone

Owner:无锡沃格自动化科技股份有限公司

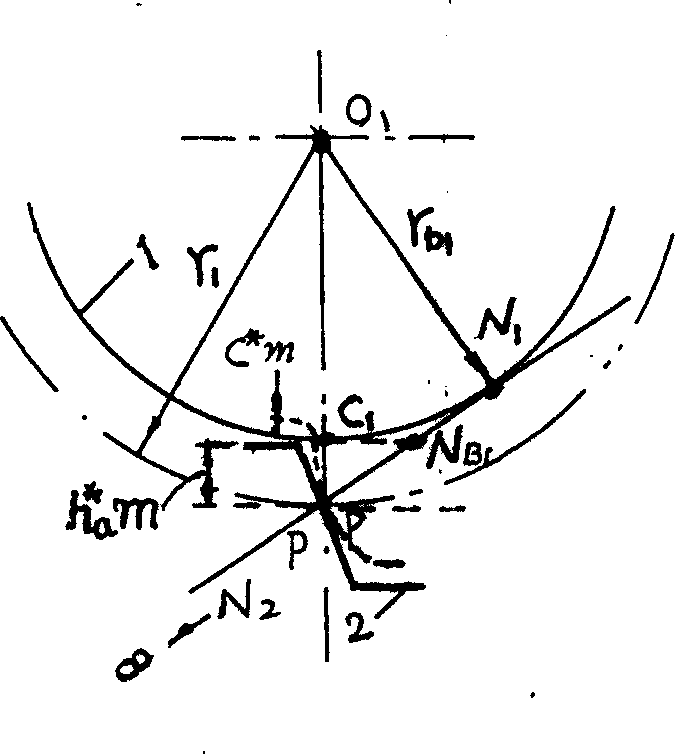

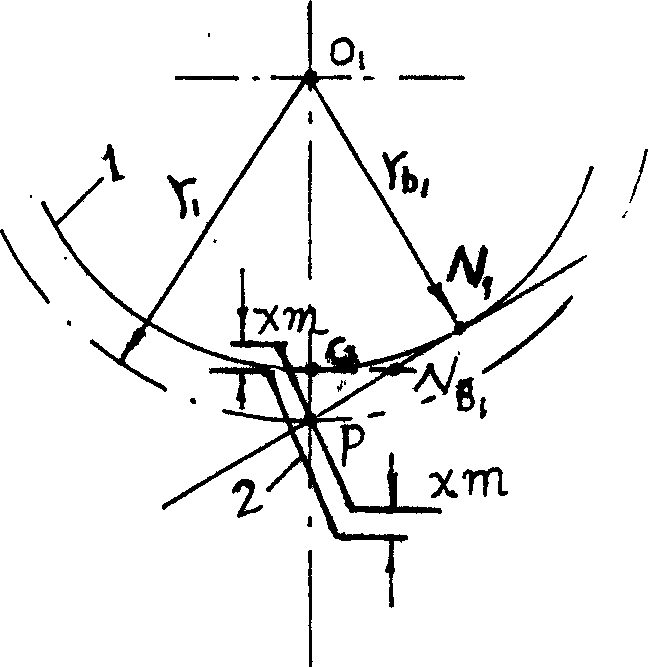

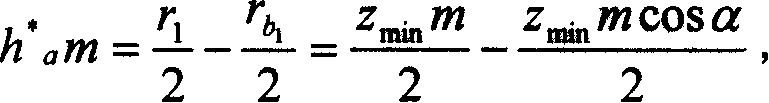

Method for machining involute gear

InactiveCN1660534AInfluence intensityGuaranteed transmission accuracyGear teethGear wheelInvolute gear

A technology for machining the involute gear is disclosed. When the tooth top line of standard rack bar tool is tangent with the base circle of gear to be machined, it is an extreme position of advancing tool. When it is said extreme position, the crossing point between said tooth top line and the engaging line is the extreme engaging point. When said tooth top line is advanced to the extreme engaging point, the minimal number of the teeth on the gear is 33.16. When the number of the teeth on the gear is less than 33.16, the rack bar tool moves is the base circle of the gear of machine the involute gear.

Owner:喻胜

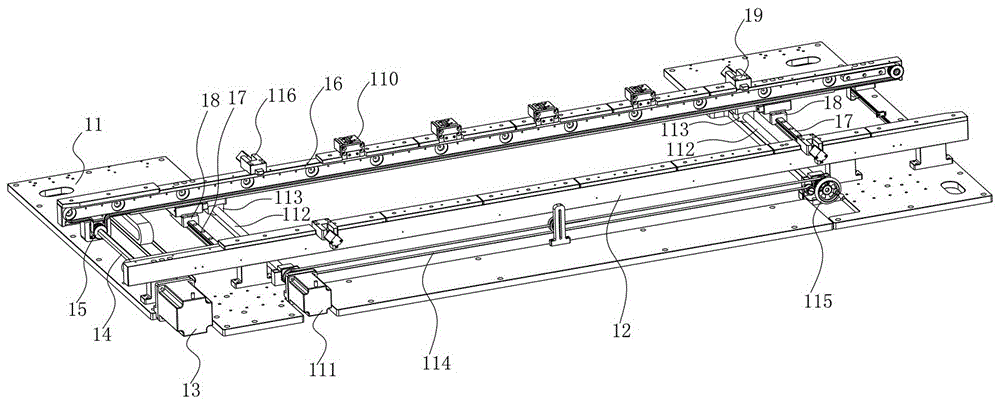

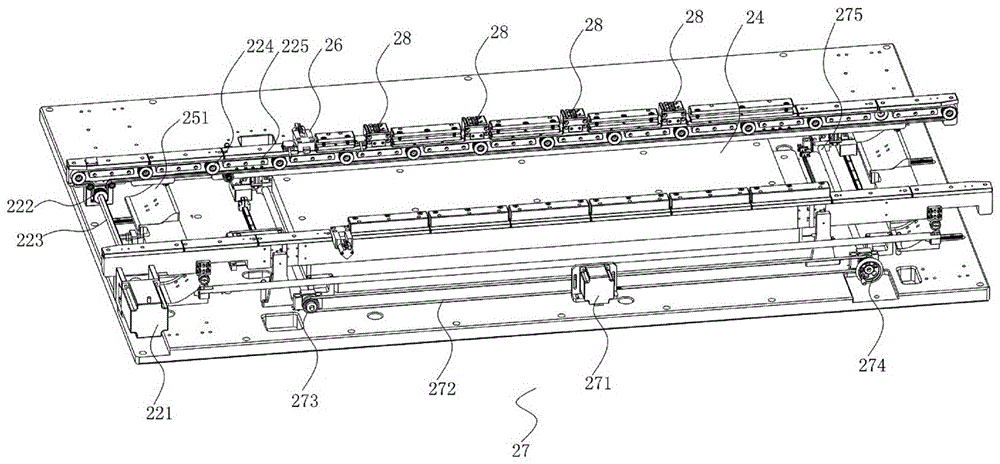

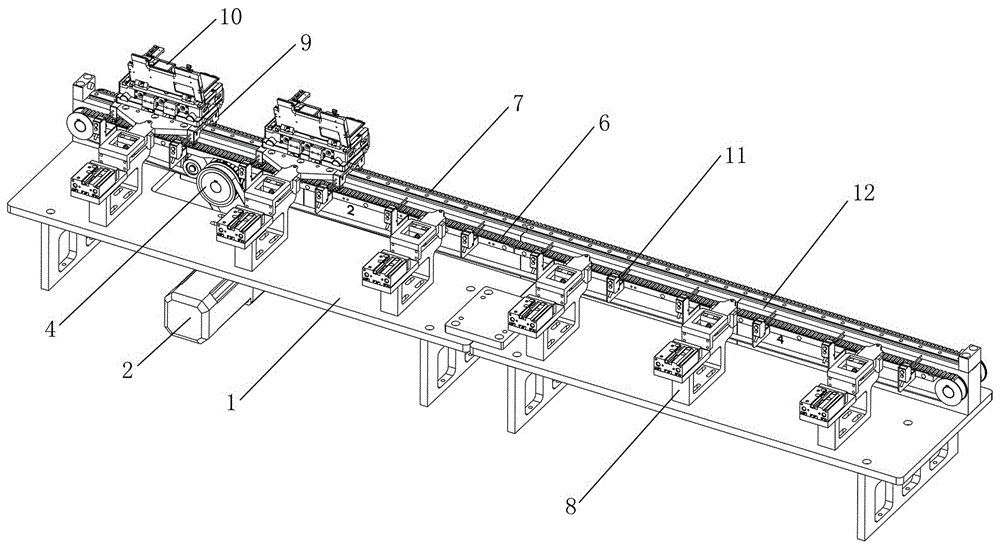

Quick positioning type automatic transmission device

ActiveCN106335762AGuaranteed transmission accuracyGuaranteed transmission stabilityMechanical conveyorsAutomatic transmissionEngineering

The invention discloses a quick positioning type automatic transmission device. The quick positioning type automatic transmission device comprises a transmission platform, a transmission mechanism, a first synchronous belt, a second synchronous belt, at least two transmission seats, a jig and at least two positioning mechanisms, wherein a strip-shaped support seat is arranged on the transmission platform; the first synchronous belt and the second synchronous belt are respectively arranged on both sides of the support seat; the transmission mechanism is respectively connected with the first synchronous belt and the second synchronous belt; the at least two transmission seats are arranged on the first synchronous belt and the second synchronous belt and are driven to move forward by the first synchronous belt and the second synchronous belt; the jig is fixedly arranged on the transmission seats; and the at least two positioning mechanisms are arranged beside the support seat at intervals, the positioning mechanisms protrude towards the support seat, and the transmission seats are buckled and connected with the positioning mechanisms when the transmission seats move to the positioning mechanisms, so that the transmission seats are blocked and positioned by virtue of the positioning mechanisms. The quick positioning type automatic transmission device has the advantage of simple design; a single-guide rail guide structure is adopted, so that the transmission precision and stability are effectively increased; passive positioning is adopted, so that the positioning time is effectively shortened.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Multifunctional V-belt fatigue test machine

InactiveCN102384872AGuarantee job stabilityNo reduction in transmission accuracyMaterial strength using tensile/compressive forcesEngineeringMechanical engineering

The invention relates to a multifunctional V-belt fatigue test machine, which comprises a controller and a motor, wherein the motor is arranged on a support frame, the output end of the motor is connected with a test device, the test device comprises a driving belt wheel and a driven belt wheel, the driven belt wheel is arranged on a slide seat capable of upwards and downwards moving, the lower end of the slide seat is connected with a load adding device through a pull rod, and a transmission disc is respectively connected between the motor and the driving belt wheel as well as between the driving belt wheel and the driven belt wheel. The multifunctional V-belt fatigue test machine has the following advantages that: 1, the transmission disc is respectively connected between the motor and the driving belt wheel as well as between the driving belt wheel and the driven belt wheel, so when the belt wheel needs to be replaced according to conditions, the belt wheels do not need to be dismounted from a main shaft, the belt wheels are dismounted from the transmission disc, then, the new belt wheel is connected onto the transmission belt, the mounting and the dismounting are very convenient, and the test precision is ensured; and 2, the multifunctional V-belt fatigue test machine adopts a central processing unit (CPU) for control, the control precision is further improved, and the work stability of the test machine is also greatly ensured.

Owner:江苏明珠试验机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com