Modularized ball joint of collaborative robot

A ball joint and modular technology, applied in the field of robotic arm joints, can solve problems such as the inability to realize the two-degree-of-freedom operation of the same joint, increase the number of joints, compactness of the whole machine, movement space, and stability effects, etc., to promote further development , to ensure the braking performance and reduce the number of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

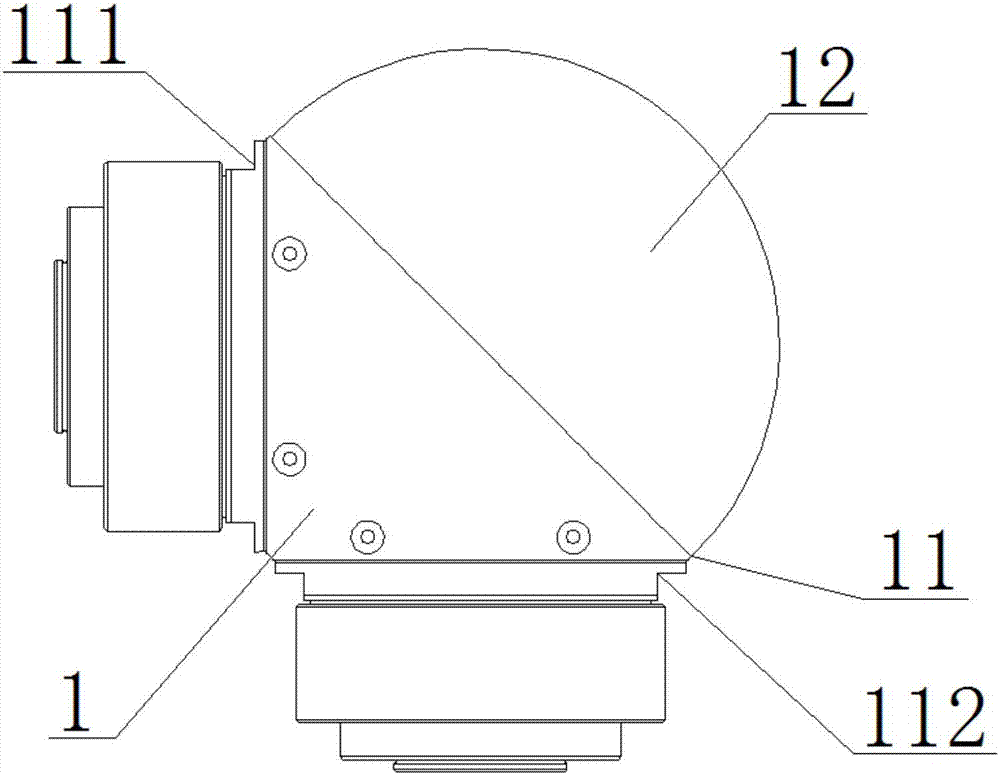

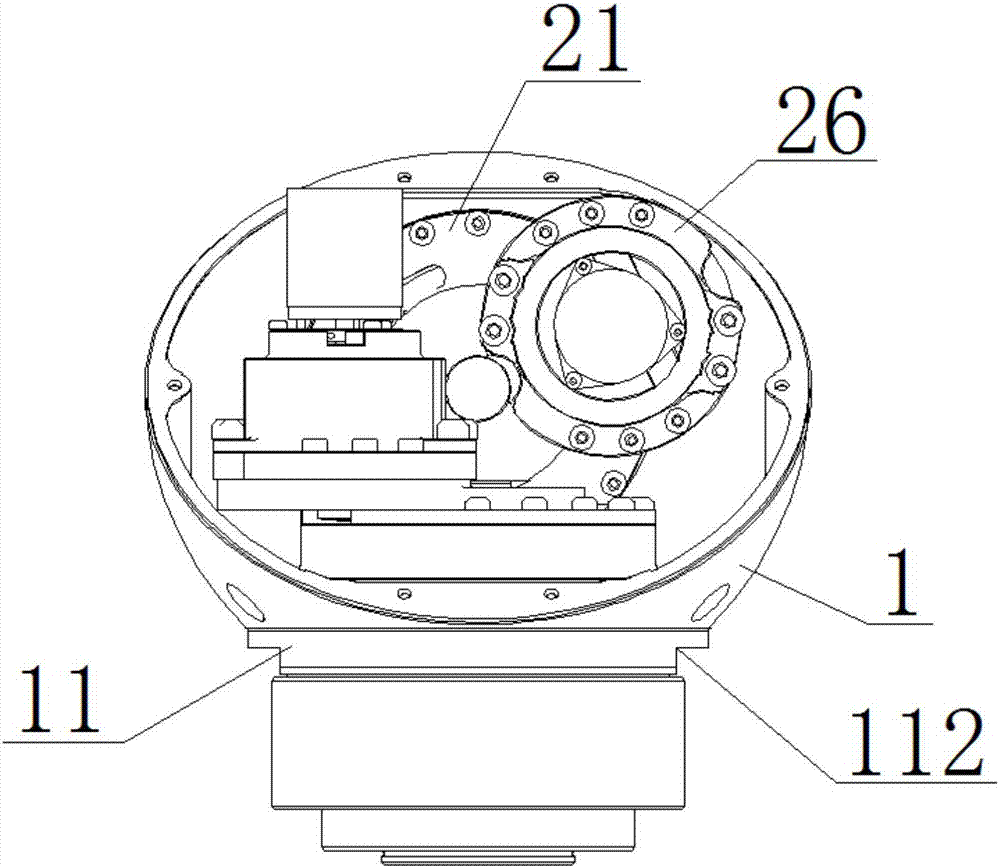

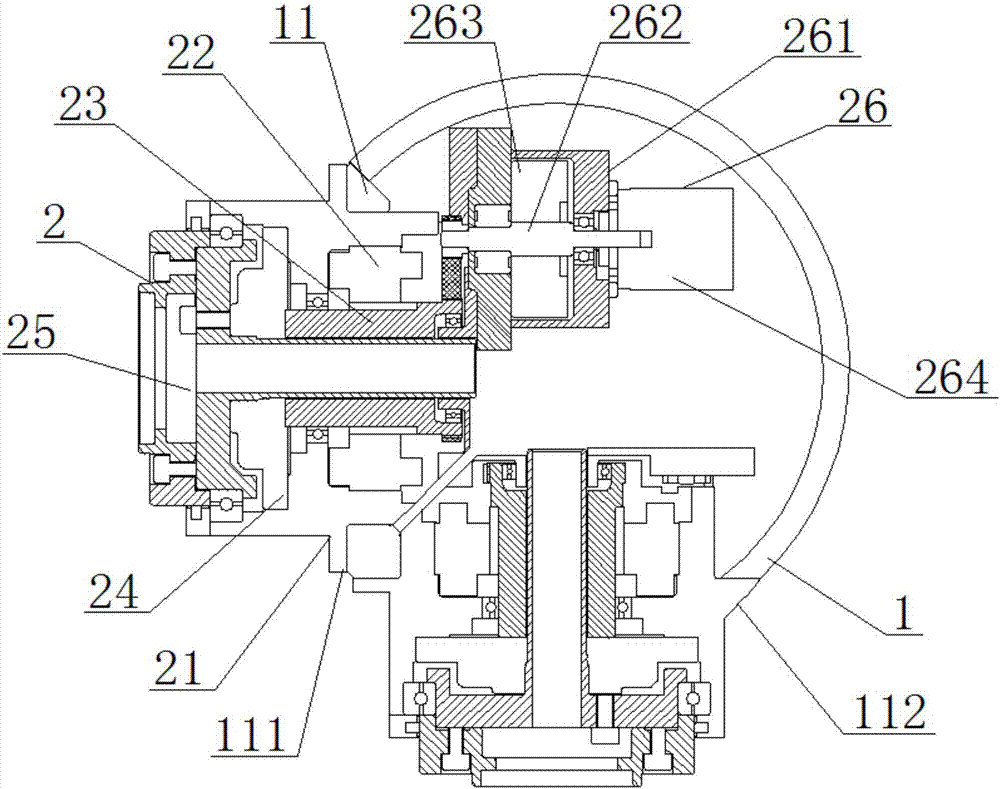

[0016] Figure 1~3 As shown, a collaborative robot modular ball joint includes a housing 1 and a ball joint drive module 2, a module support 11 is fixedly installed on the housing 1, and a spherical shell cover 12 is also installed on the housing 1 , the module support 11 is provided with a first installation position 111 and a second installation position 112, the ball joint drive module 2 is fixedly installed on the first installation position 111 and the second installation position 112, the The ball joint drive module 2 is encapsulated inside the housing 1 through a spherical shell cover 12, the output ends of the ball joint drive modules 2 are all set outside the housing 1, and each ball joint drive module 2 can function in the control system run independently. The present invention adopts a joint structure with two degrees of freedom, and the entire internal structure of the joint can be assembled at will according to the functions and performances required by the joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com