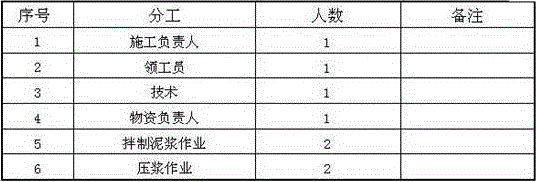

Patents

Literature

87results about How to "Reduce the number of joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-adaption gear shifting device for double-clutch automatic gearbox and realizing method thereof

ActiveCN101922545AReduce the number of jointsExtended service lifeGearing controlAutomatic transmissionRoad surface

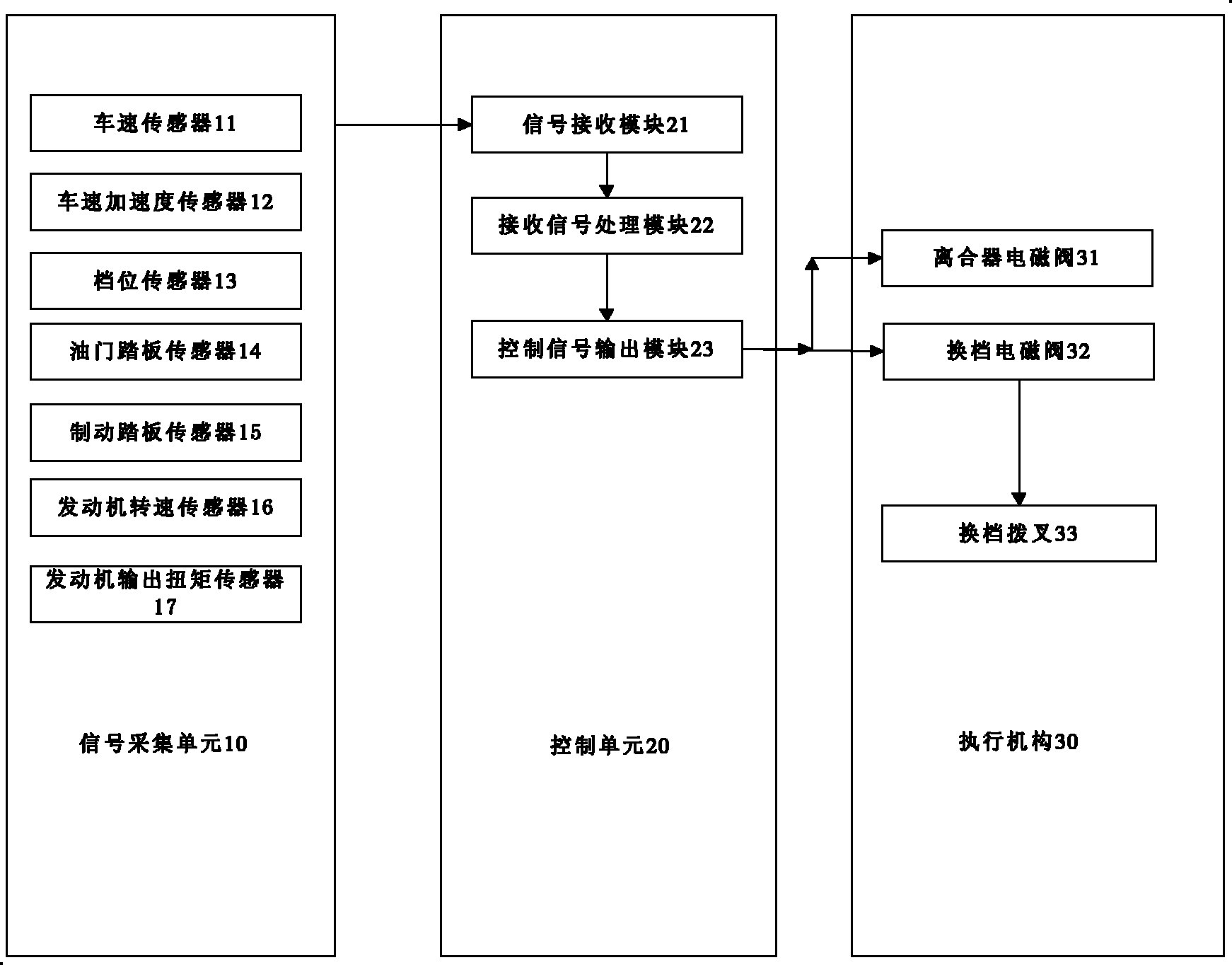

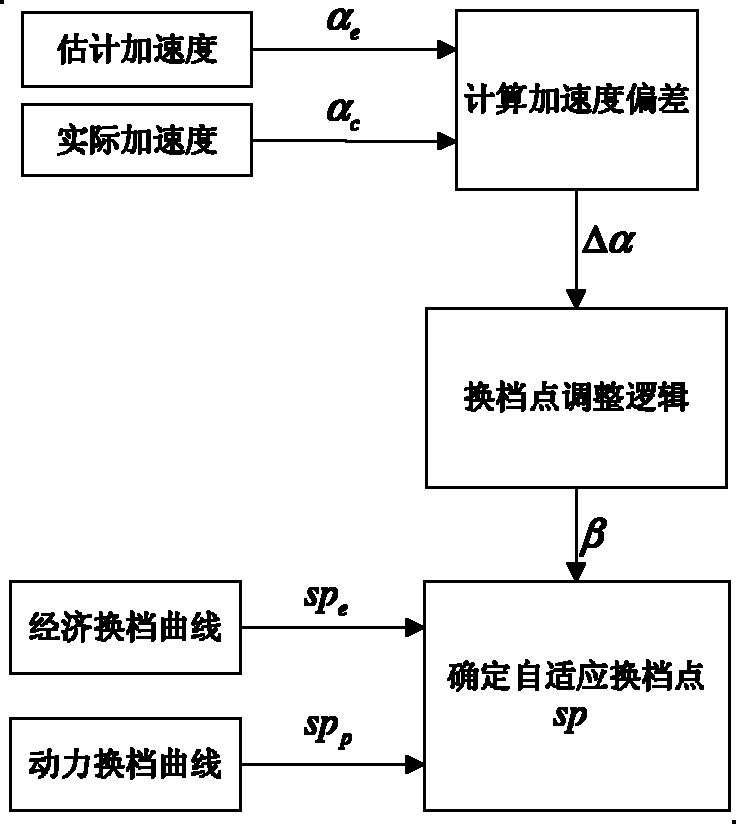

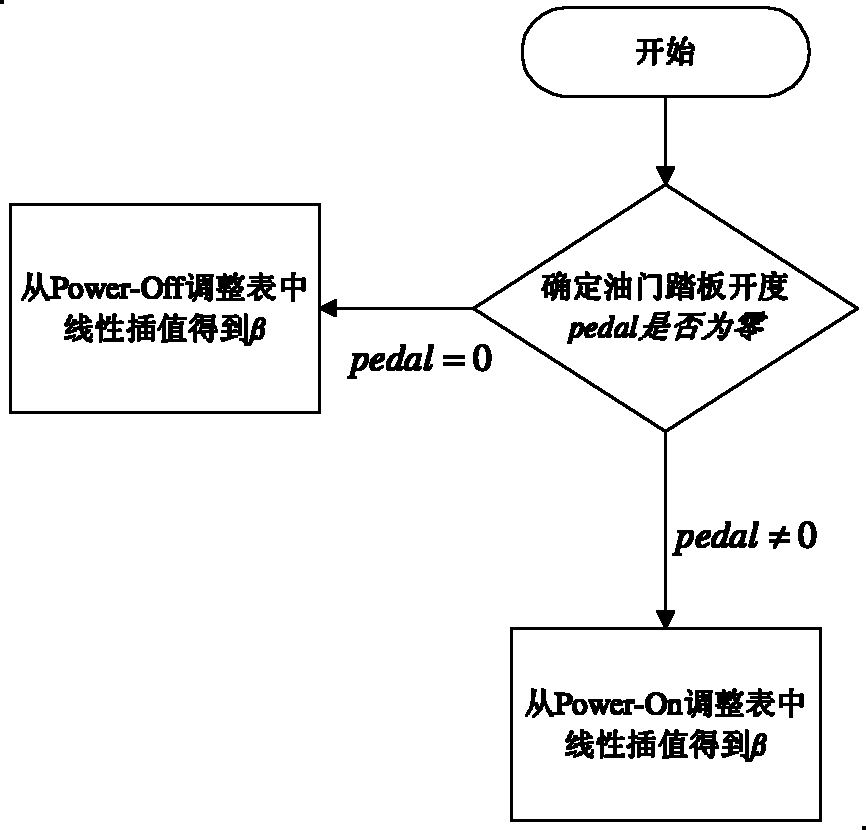

The invention relates to a self-adaption gear shifting device for a double-clutch automatic gearbox and a realizing method thereof which belong to the technical field of a vehicle gearbox. The device comprises a signal sampling unit, a control unit and an actuating mechanism, wherein the signal sampling unit is arranged in the vehicle gearbox in order to sample a driving parameter of the vehicle and output to the control unit; the control unit is arranged for receiving the driving parameter and outputting a shifting point self-adaption revision directive to the actuating mechanism according to the pavement condition; and the actuating mechanism is arranged for shifting the gearbox so as to realize the optimum matching of the vehicle shifting.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

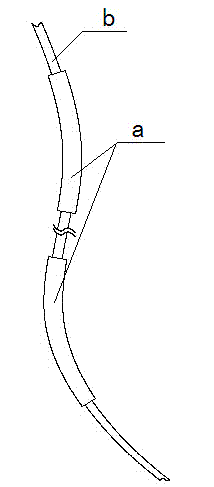

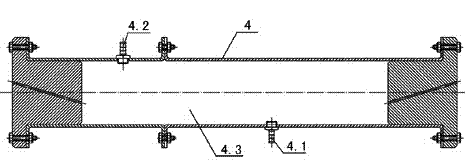

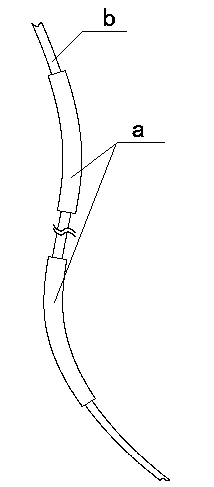

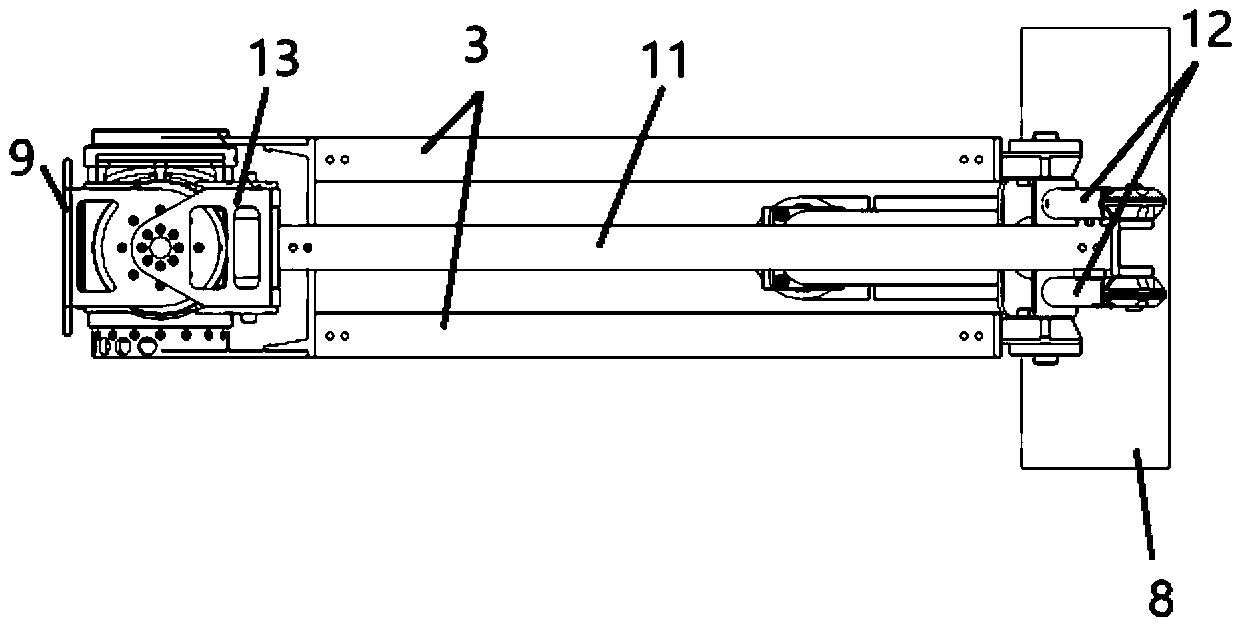

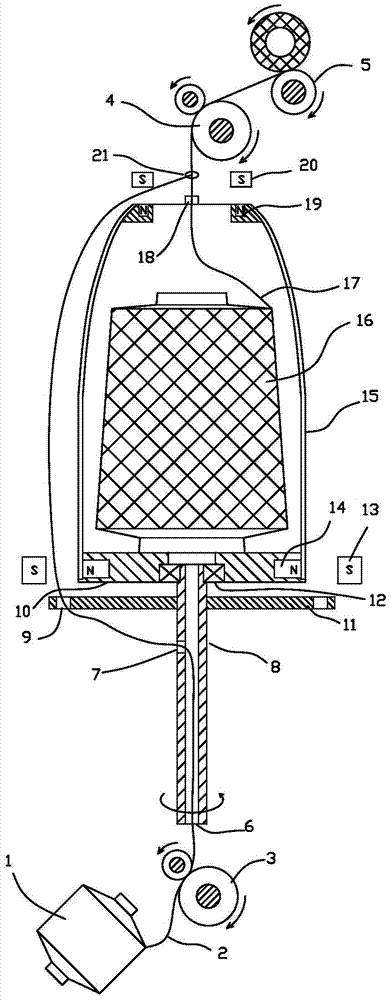

Fibre reinforced composite anti-eccentric coiled rod as well as preparation device and preparation method thereof

ActiveCN103075112AAccelerated corrosionImprove partial wear resistanceDrilling rodsDrilling casingsEpoxyThermoplastic

The invention relates to a fibre reinforced composite anti-eccentric coiled rod and a preparation device thereof. The technical scheme adopted by the invention is as follows: one or more sections of the external surface of a fibre-reinforced resin matrix composite rod body is coated with a thermoplastic wear layer; the rod body is made of one of fibreglass, carbon fibre and basalt fibre; and a resin matrix is one of epoxy resin, urethane resin and vinyl ester resin. A plastic extruder and a cooling device are arranged between a draw gear and a winding device, the plastic extruder is used for coating one thermoplastic wear layer on one or more sections of the surface of a molded sucker rod, and then the cooling device is used for performing cooling treatment, so that the fibre reinforced composite anti-eccentric coiled rod is formed. The invention has the following beneficial effects: the coiled rod has excellent anticorrosion and anti-eccentric performances; the quantity of joints is greatly reduced; the breakage probability and the piston effect are reduced; and in addition, the production efficiency is high, and the operation is simple and convenient.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

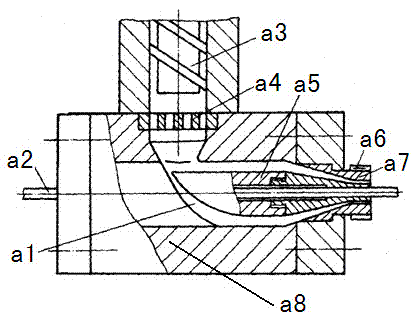

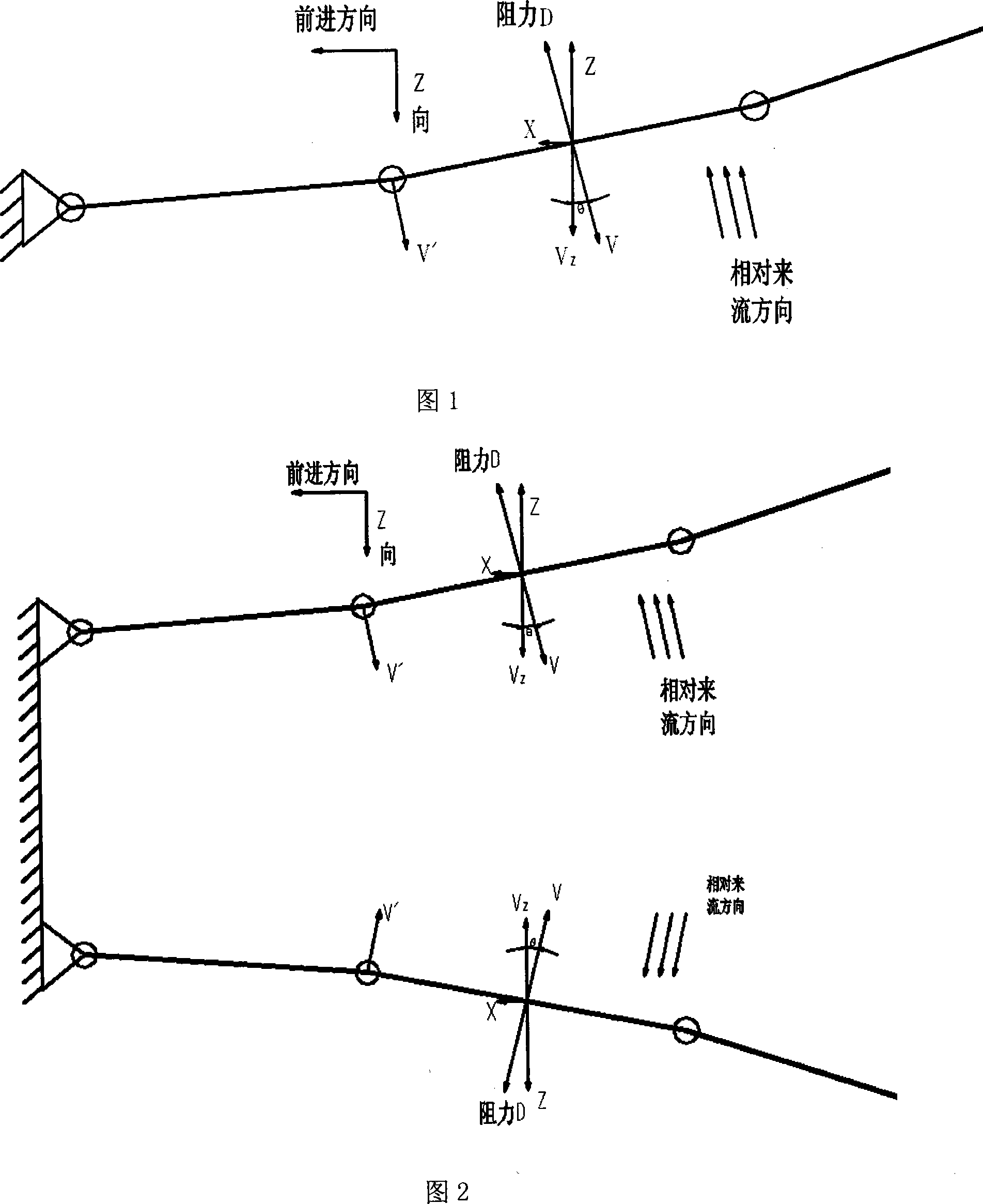

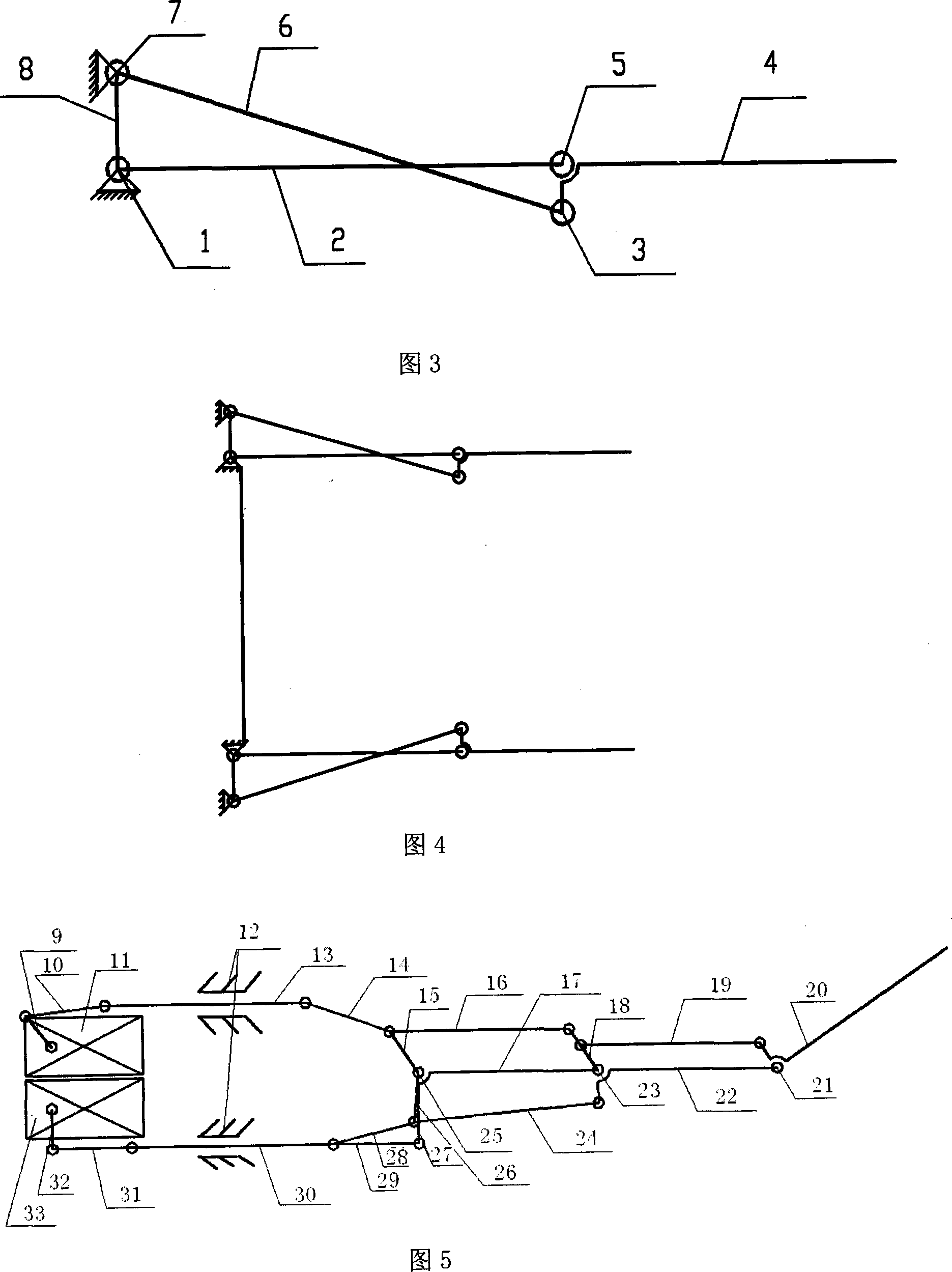

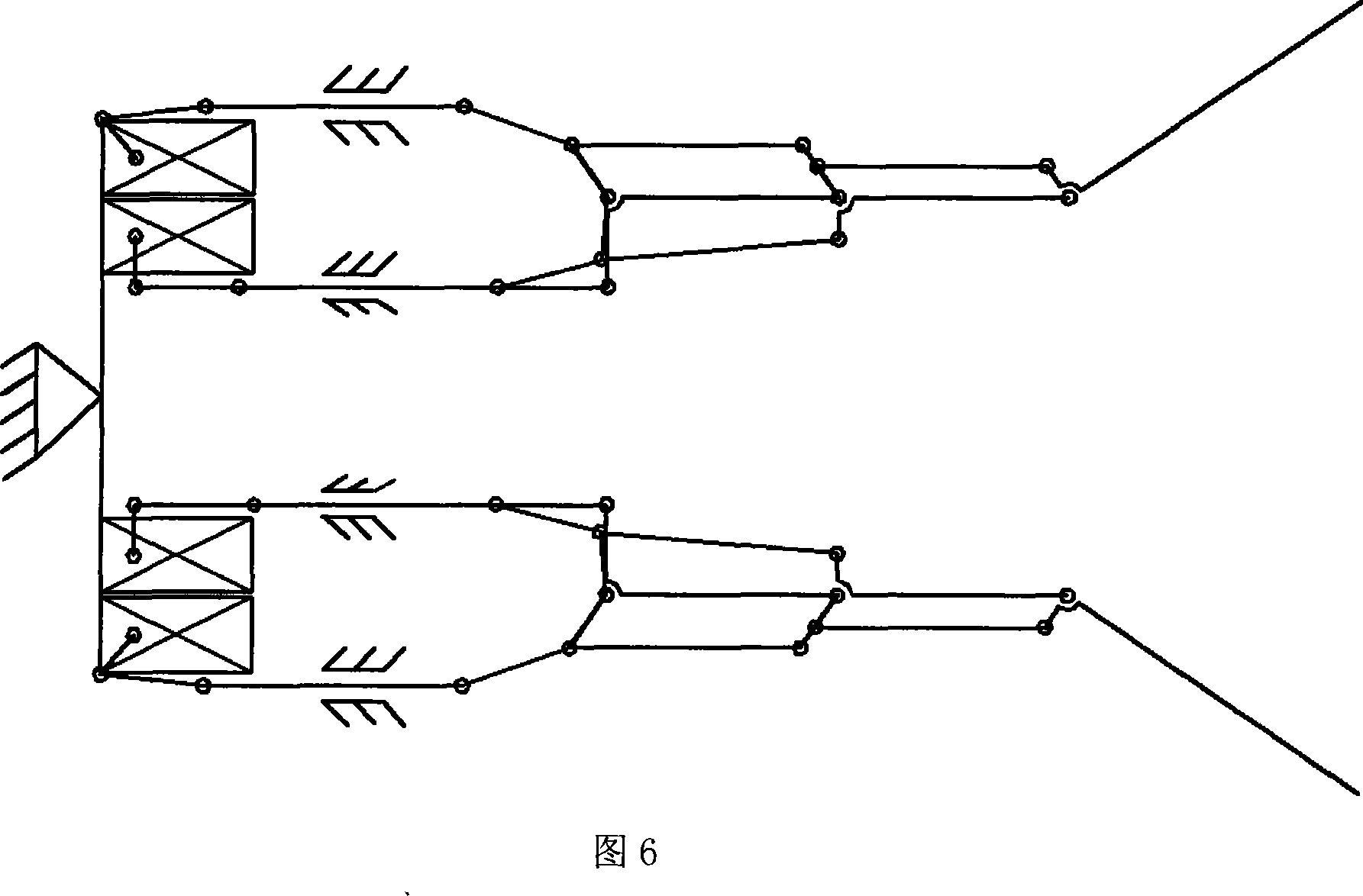

Double bodies machinery fish

InactiveCN101157381AAvoid yaw motionReduce sailing resistanceSelf-moving toy figuresPropulsive elements of non-rotary typeHead shakingPropeller

The invention provides a twin-body mechanical fish which comprises a fish head part of the mechanical fish; two sets of tail-waving drive mechanism are arranged on the back of the fish head part, and are connected with the fish head in row; compared with a mechanical fish propelled by a single tail fin, the twin-body biomimetic mechanical fish not only makes use of, and develops the advantages of the fish-liked propelling, but also overcomes the head shaking problem of the single-tail propelling, and ensures the navigating stability of the biomimetic mechanical fish, thereby, reducing the navigating resistance of the mechanical fish, and improving the efficiency of the tail-biomimetic propeller.

Owner:HARBIN ENG UNIV

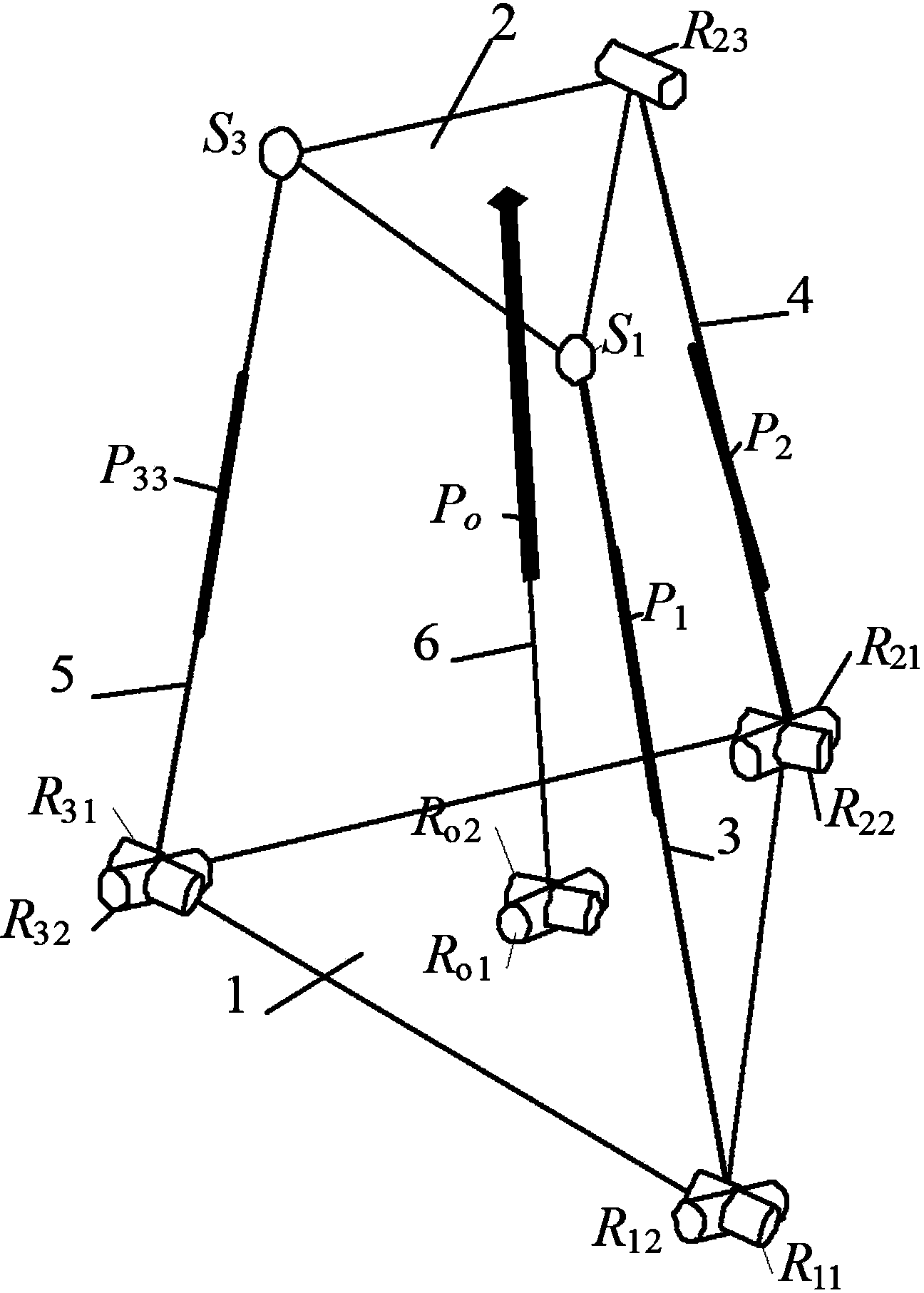

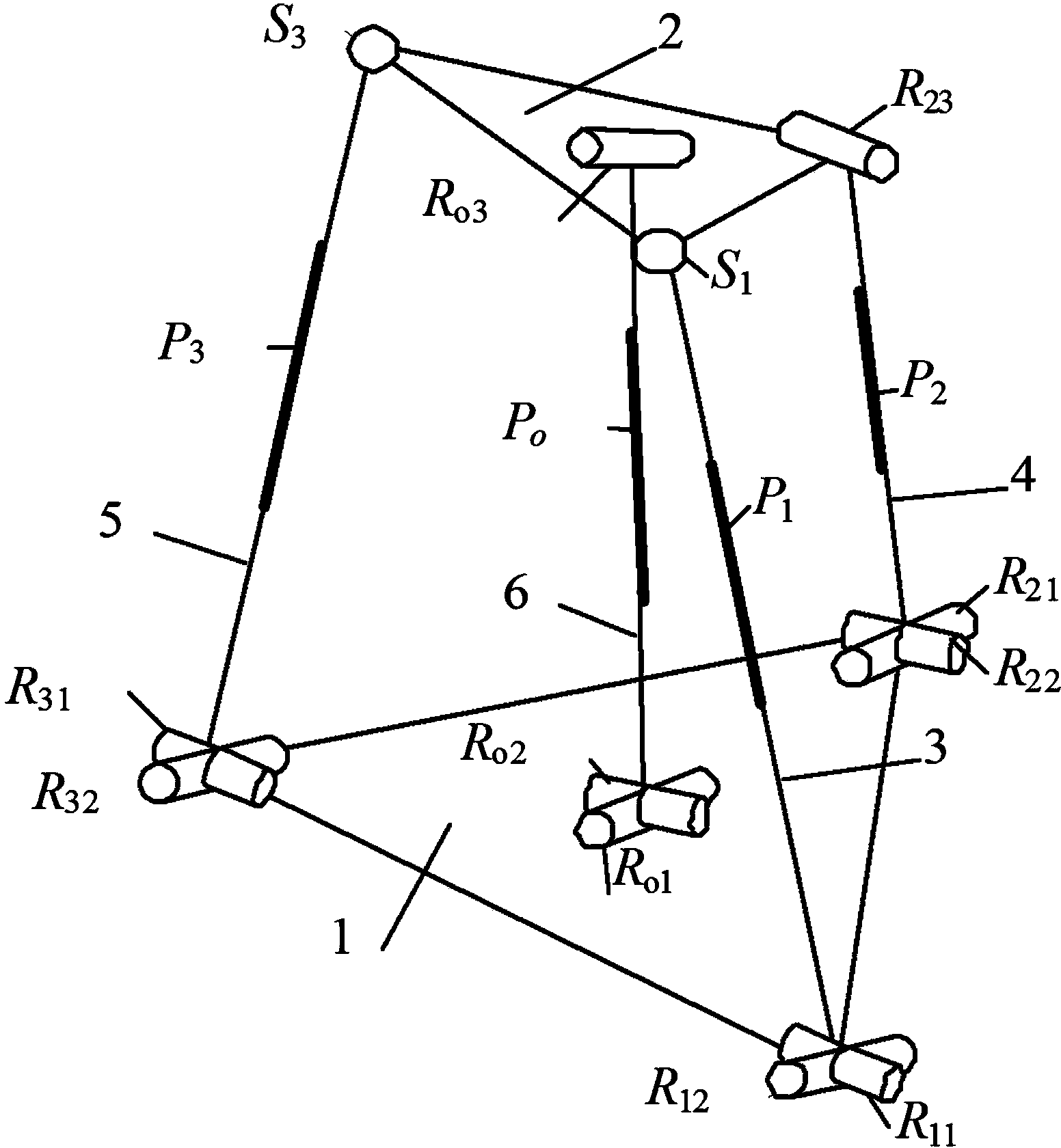

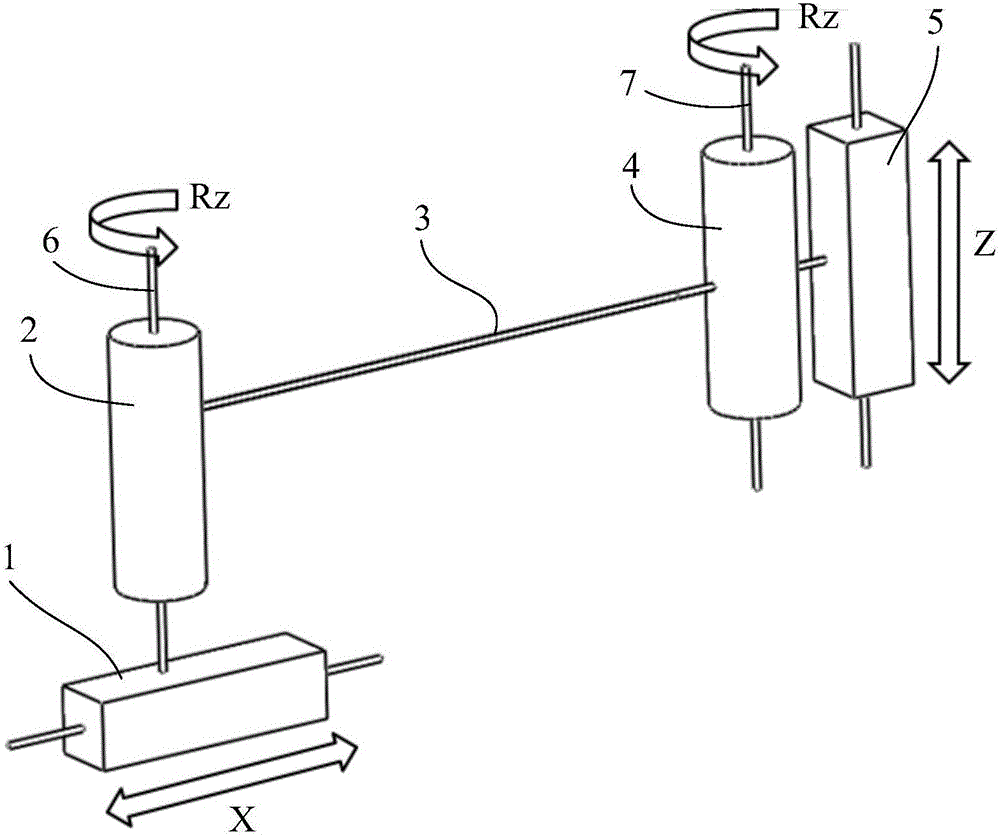

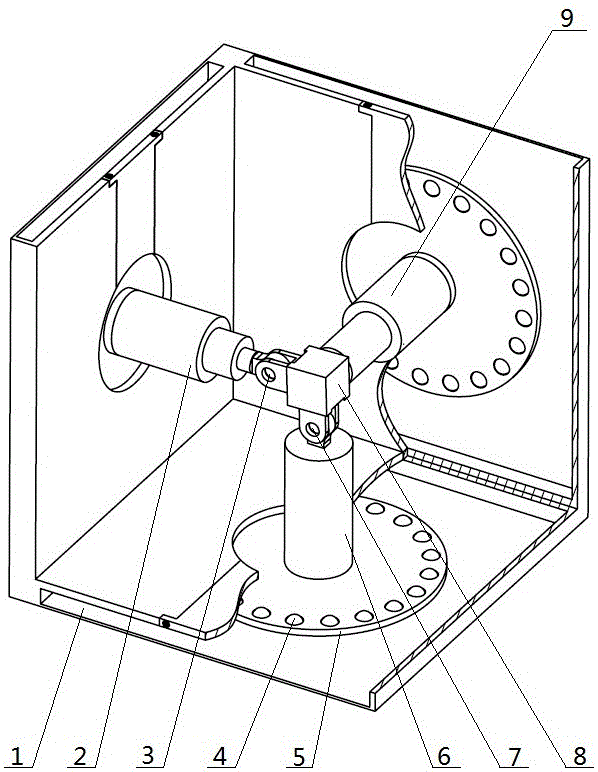

Overconstrained parallel mechanism with equivalent Tricept mechanical movement

InactiveCN104384941AGood sports characteristicsReduce the number of jointsProgramme-controlled manipulatorLarge fixed membersKinematicsEngineering

The invention discloses an overconstrained parallel mechanism with equivalent Tricept mechanical movement. First and third driving branches are the same in structure; rotating pairs at the outer sides of universal hinges of the two driving branches are connected with a fixed platform; rotating pairs at the inner sides of the universal hinges are perpendicular to movement pairs; and spherical pairs are connected with a movable platform. The rotating pair at the outer side of the universal hinge of the second driving branch is connected with the fixed platform, and is pointed to the center of the fixed platform; the rotating pair at the inner side of the universal hinge is parallel to rotating pairs at the upper ends of the branches, and is perpendicular to movement pairs of the branches; and the rotating pairs at the upper ends of the branches are connected with the movable platform, and are parallel to opposite edges of the movable platform. A rotating pair at the outer side of a universal hinge of a middle constrained branch is connected with the fixed platform, and is pointed to the lower end point of the second branch; a rotating pair at the inner side of the universal hinge is parallel to the connecting line of upper end points of the first and third branches, and is perpendicular to the movement pairs; and the movement pairs are vertically connected with the movable platform. The overconstrained parallel mechanism has equivalent kinematics with the Tricept mechanism, remains excellent movement characteristics of the Tricept mechanism, has smaller movement pairs compared with the Tricept mechanism, and has higher rigidity and movement precision.

Owner:YANSHAN UNIV

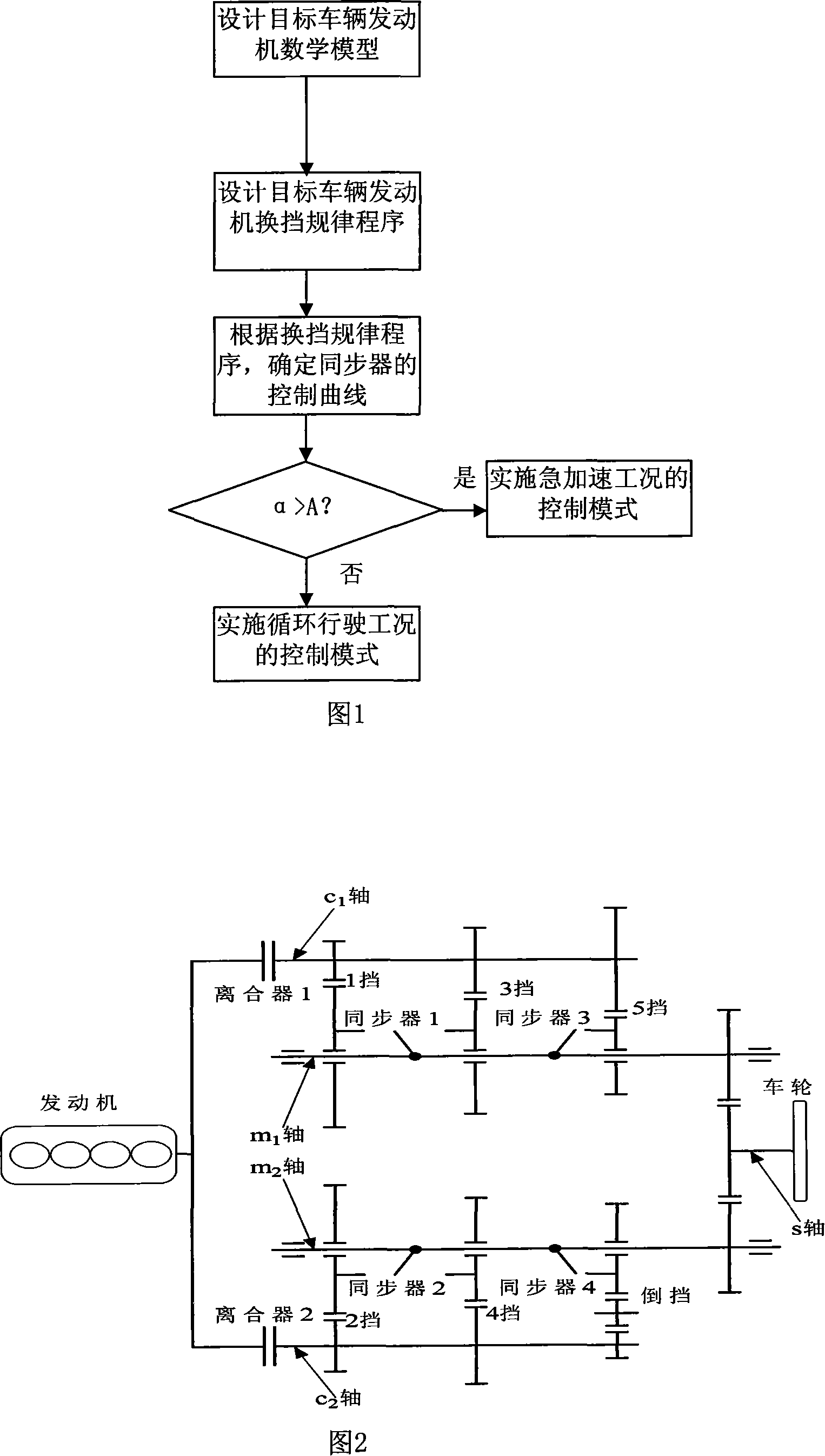

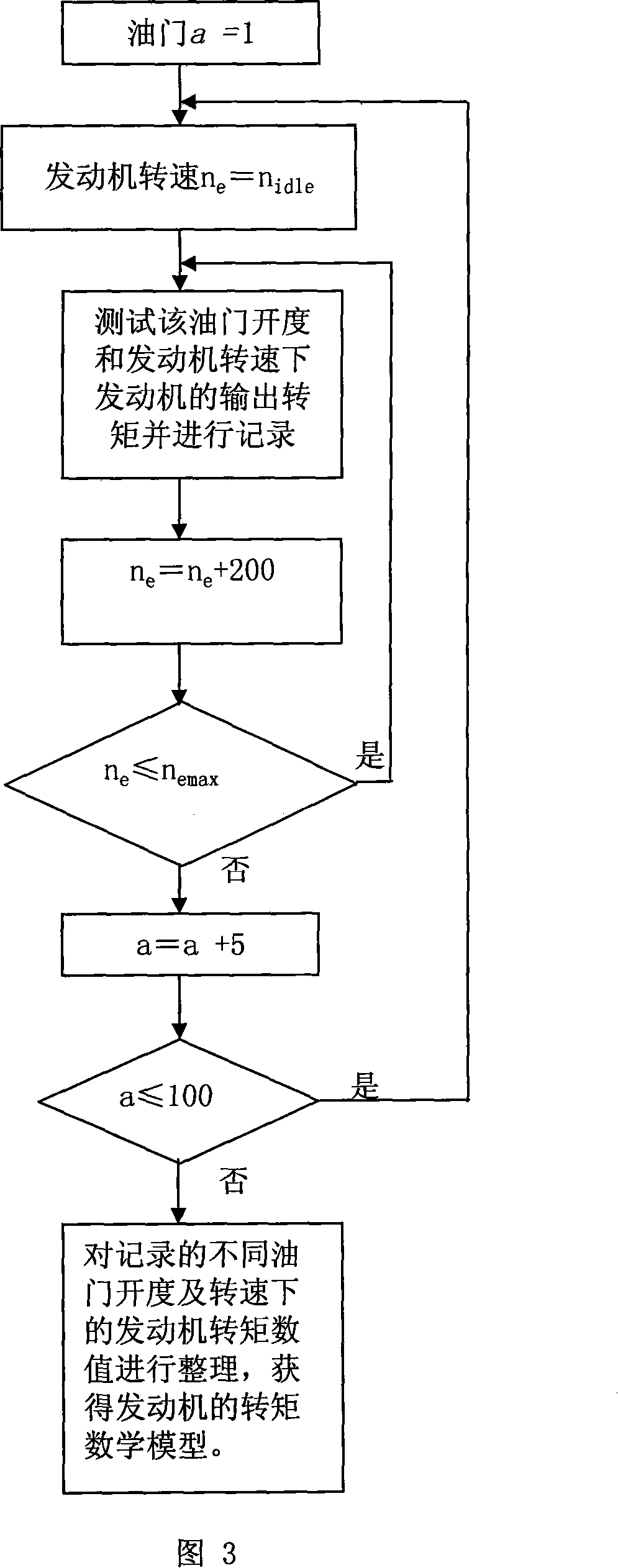

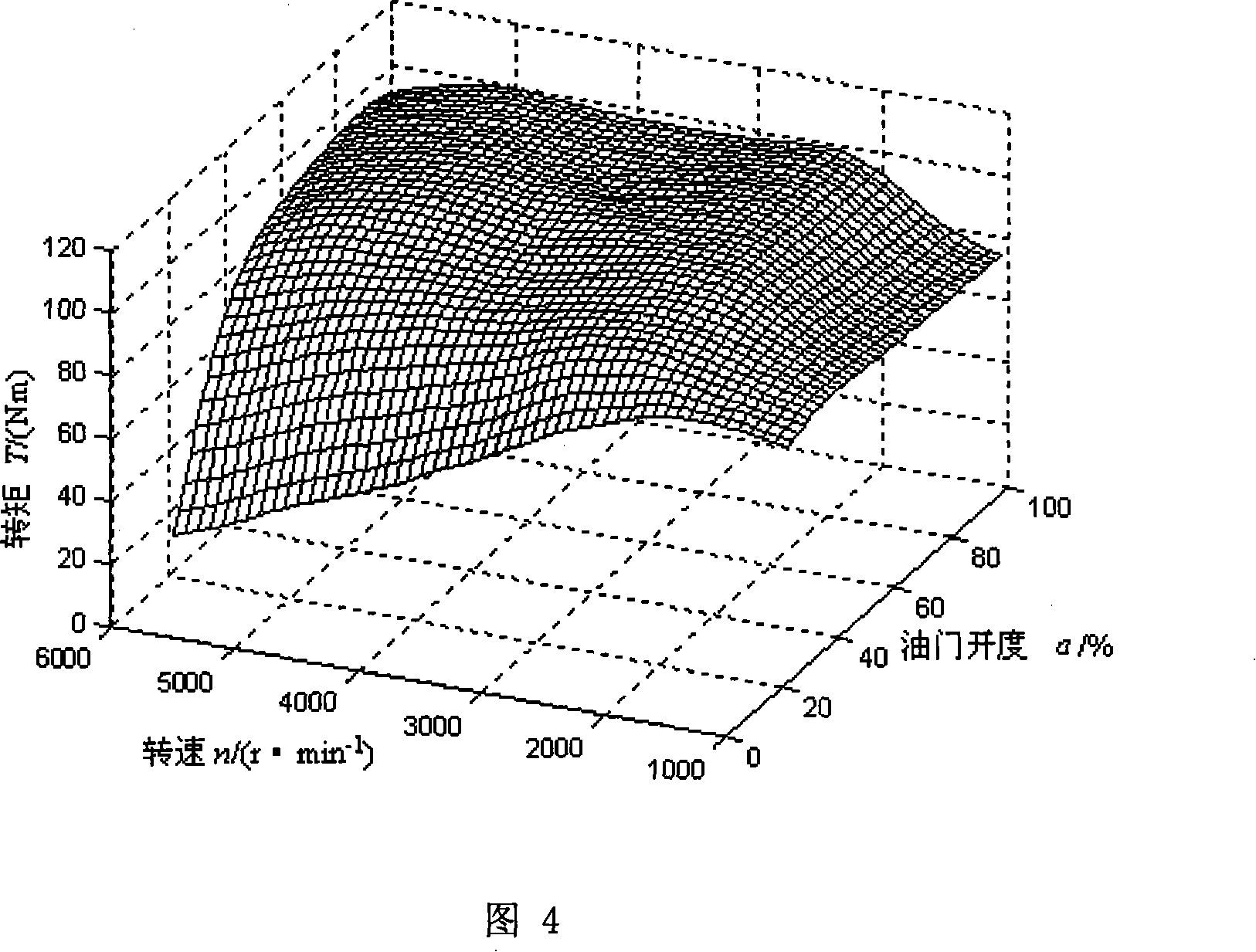

Dual-clutch automatic speed transmission synchronizer and self-adapting control method for gear switch

InactiveCN101153654AExtended service lifeReduce the number of jointsGearing controlAdaptive controlAutomatic transmissionMathematical model

The adaptive control process of a double-clutch automatic derailleur synchronizer and gear shifting is that the torque mathematical model of the target car motor is designed; the control curve of synchronizer is determined according to the program of gear shifting rule; the fact whether the opening a of an accelerograph is greater or less than the accelerograph valve A is estimated; if the opening a of the accelerograph is greater than the accelerograph A, the control mode of operating mode of urgent acceleration is actualized; if the opening a of the accelerograph is less than the accelerograph A, the control mode of operating mode of cyclic running is actualized. The invention has the advantages that the control rule of synchronizer and gear shifting of various work conditions can be in selfadaptive chosen in real time according to the degree of the opening of the accelerograph, the control rule can make sure that the rotate speed of a DCT gear is in safe range when the car is accelerated quickly, and that the times of separation and joint of synchronizer is reduced when the cyclic operating mode is actualized, which saves energy consumption and prolongs the service life of parts.

Owner:TONGJI UNIV

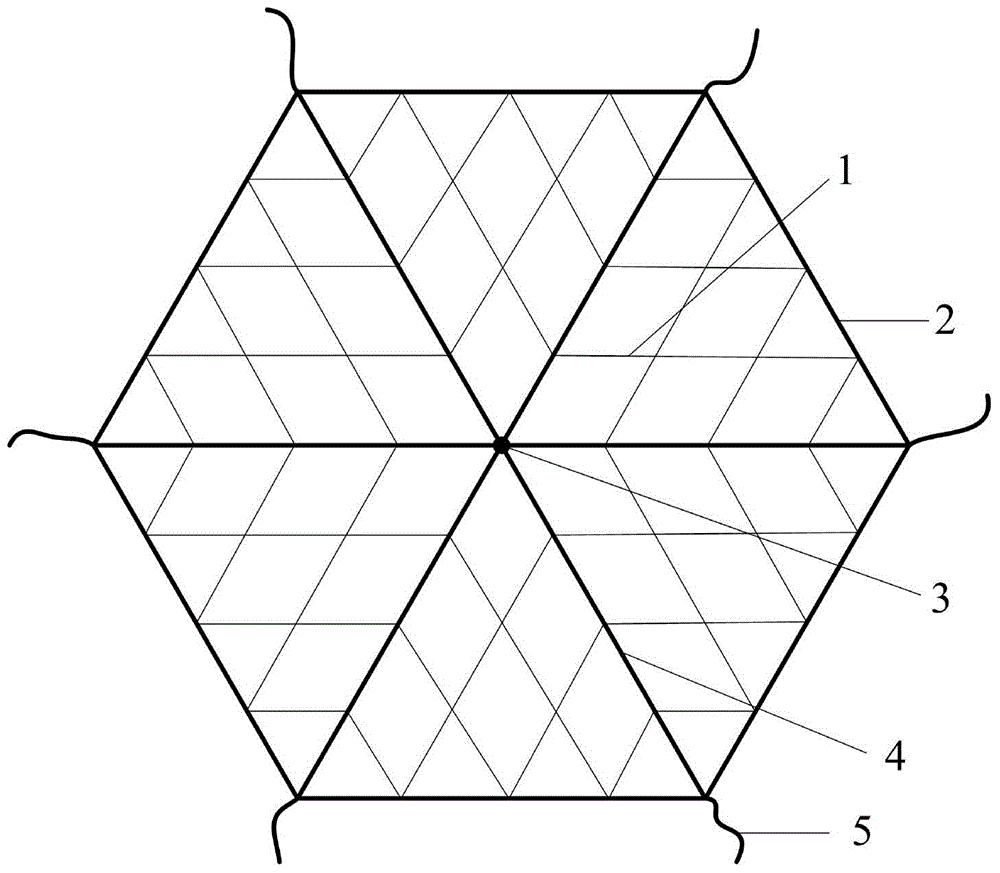

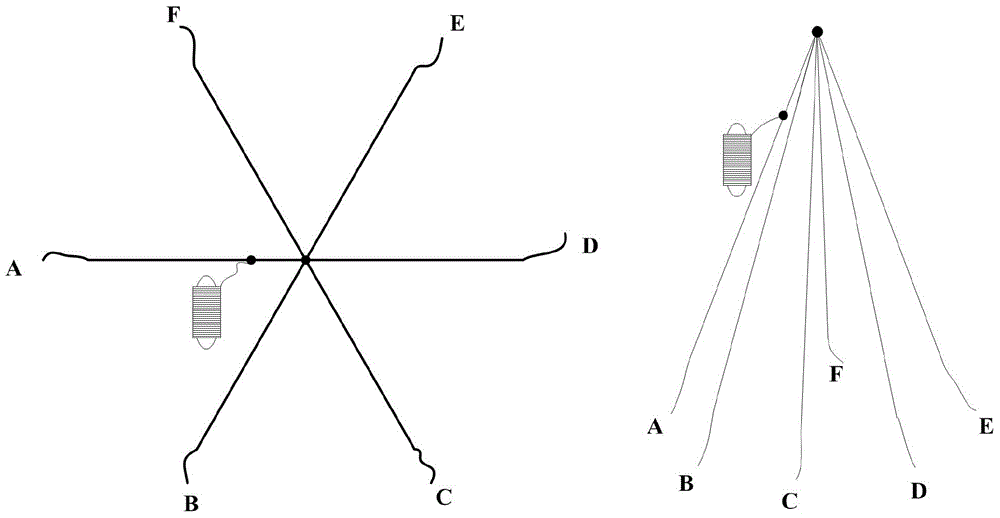

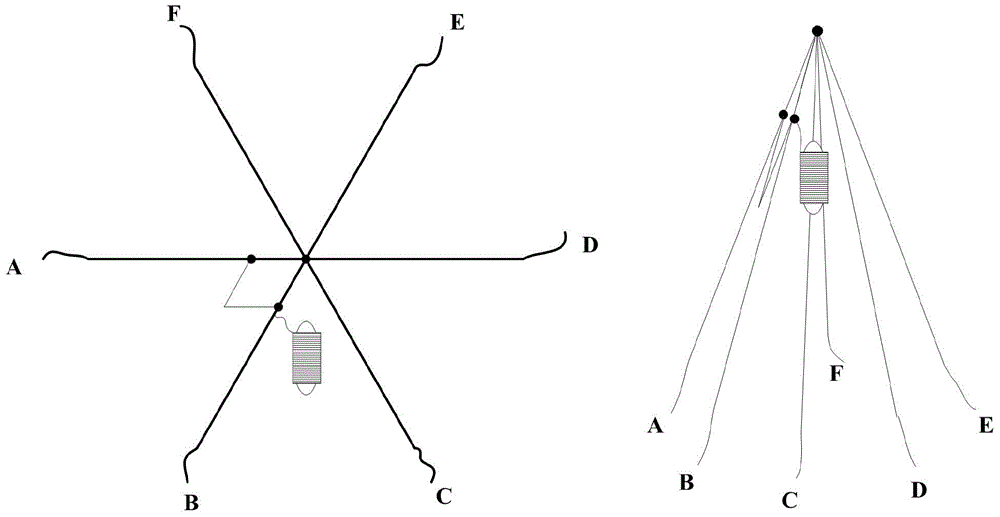

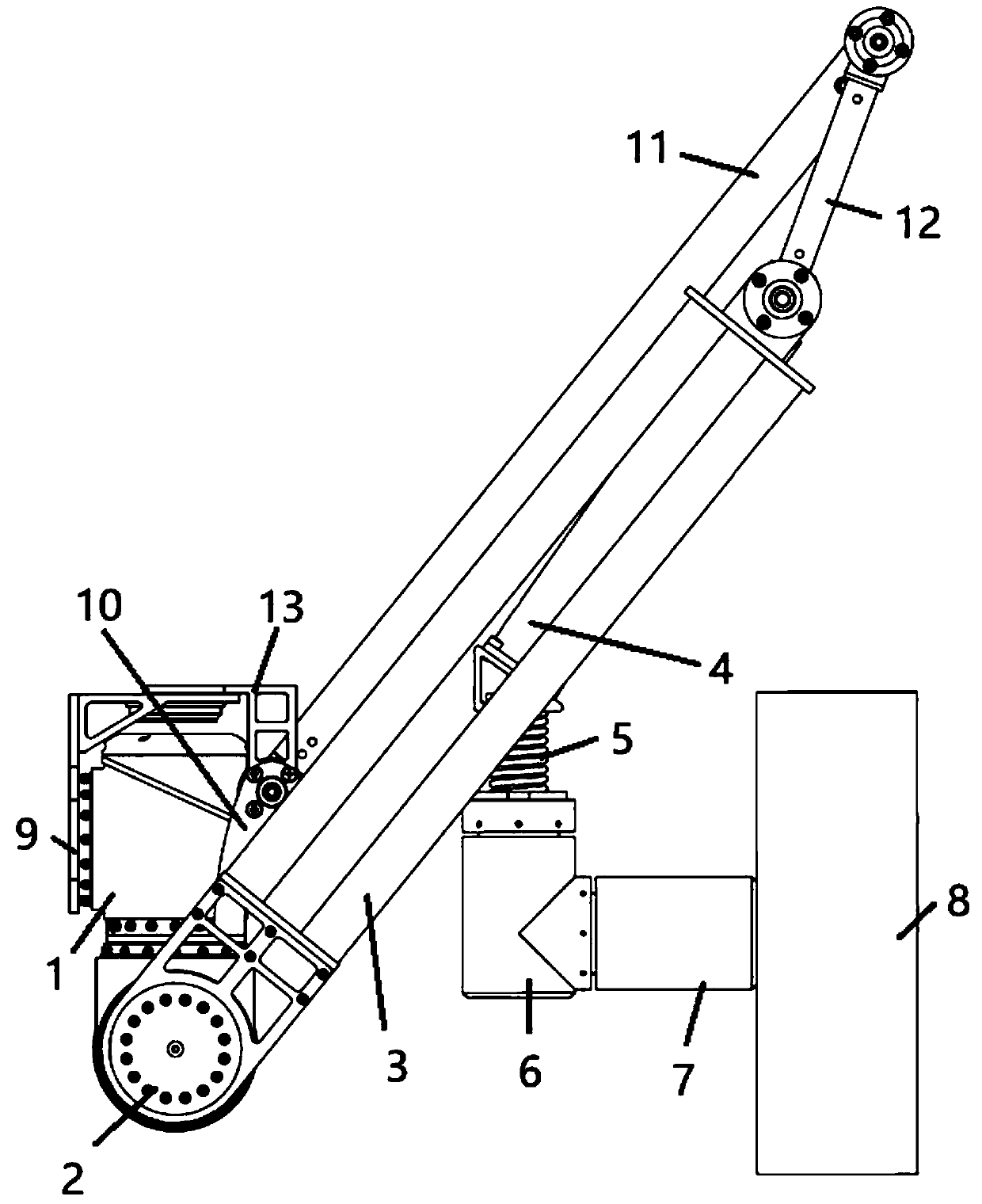

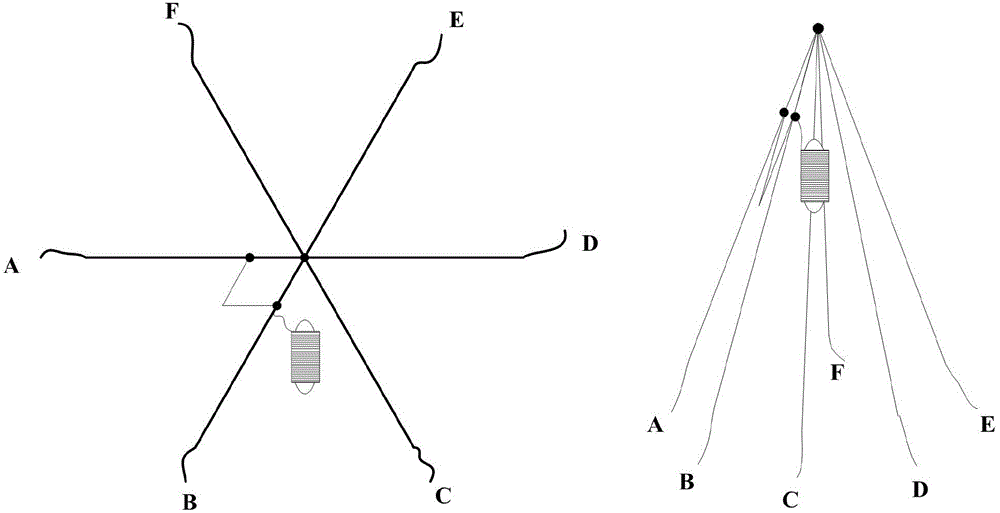

Hexagonal space capturing rope net and knotting method thereof

ActiveCN104790119AReduce the number of jointsWith variable topologyToolsKnotting netsEngineeringState consistency

The invention discloses a hexagonal space capturing rope net. The hexagonal space capturing rope net comprises six reinforcing ropes of equal length and six side line ropes of equal length, wherein ends of the six reinforcing ropes are co-knotted to form a central rope knot; the six reinforcing ribs are outwards radial by taking the central knot as a center point; the other ends of the adjacent reinforcing robes are connected through the side line ropes; the joint of each side line rope and each reinforcing robe is led out of a traction rope; more than one screen is arranged in an area formed by the reinforcing ropes and the side line ropes in a converting mode. The invention also correspondingly discloses a knotting method for hexagonal space capturing rope net. The knotting method comprises the following steps: fixing reinforcing robes, sewing the screen, and sewing the side line ropes. According to the rope net and the knotting method thereof disclosed by the invention, the storage state consistency requirements of the rope net can be met, and the inner uniformity after the ropes are stretched is guaranteed, so that the topological structure conversion requirements of the rope net from the storage state to the stretching state are effectively met, and the stretching performance of the rope net is improved.

Owner:NAT UNIV OF DEFENSE TECH

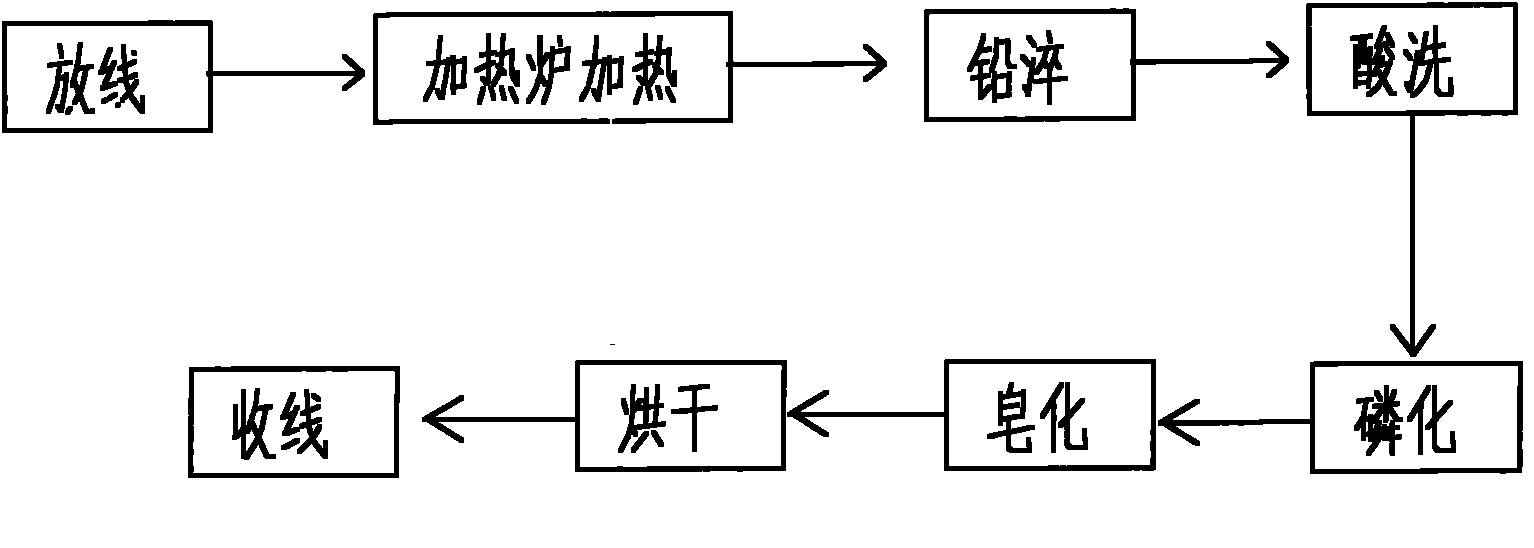

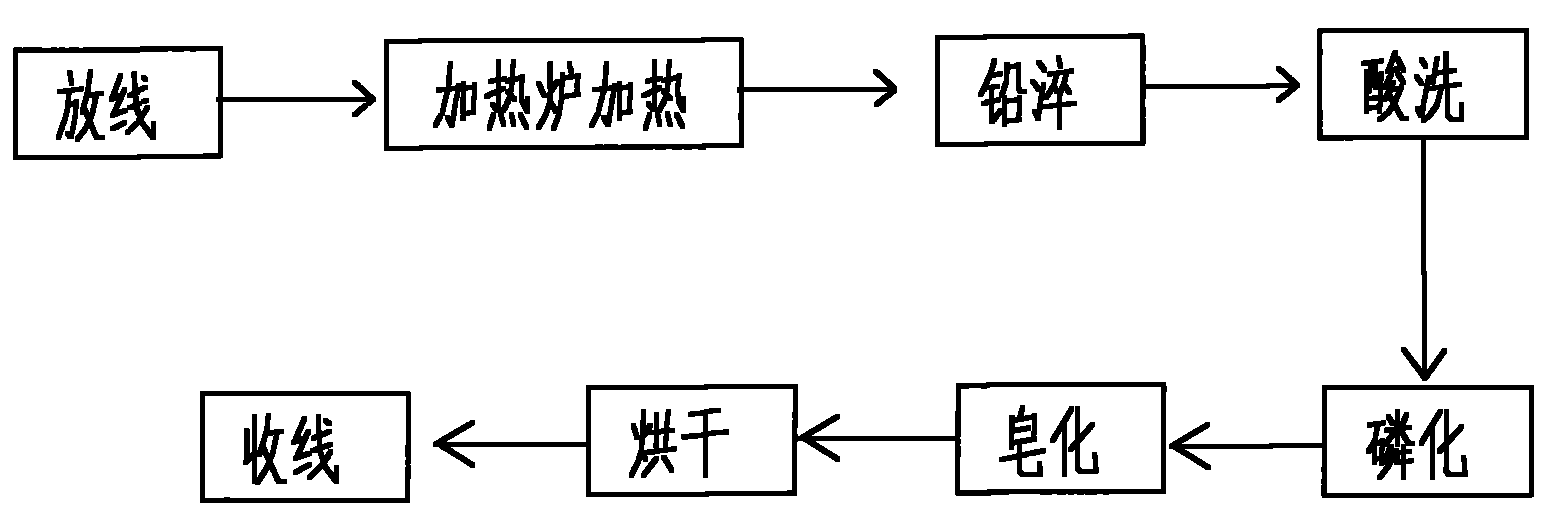

Continuous heat processing technology of steel wire

ActiveCN101985754AQuality improvementReduce the number of jointsFurnace typesMetallic material coating processesHeating furnaceQuenching

The invention relates to a continuous heat processing technology of a steel wire, which is characterized in that the steel wire penetrates into a heat processing heating furnace for heating by a pay-off rack, penetrates into a lead pool for lead quenching, penetrates into a pickling tank for pickling, then penetrates into a parkerising pool, penetrates into a saponification pool, penetrates through a drying box and finally is wound up. The continuous heat processing technology of the steel wire in the invention has the advantages that a continuous heat processing line is used, the pickling and parkerising are carried out in a mode of one line, and a steel wire technology for each specification can be adjusted by adjusting speed of the steel wire heat processing, thus reducing production cost and improving production efficiency; and all processing procedures are linked compactly; and weight of parts is improved to reduce joint number in the steel wire so as to improve quality of the steel wire.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

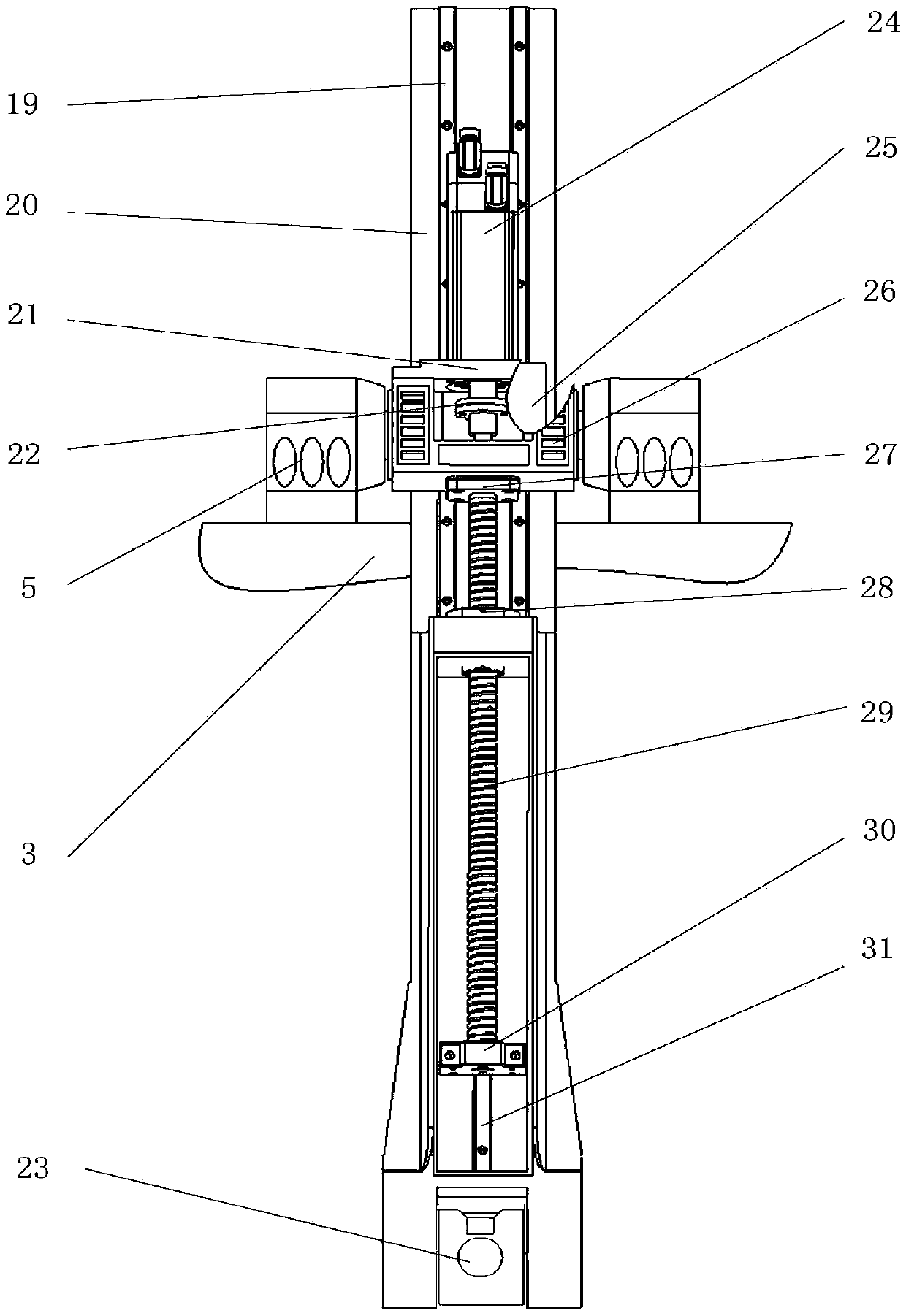

Operation robot and mechanical arm thereof

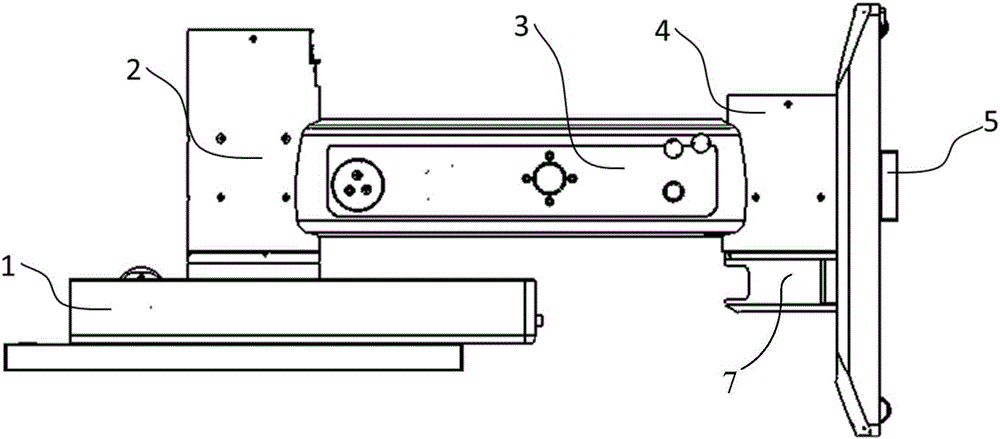

ActiveCN106175934ASmall form factorLight in massProgramme-controlled manipulatorDiagnosticsStructure relationEngineering

The invention provides an operation robot and a mechanical arm thereof. The mechanical arm comprises a horizontal moving joint, a first rotating joint, a connecting arm and a vertical moving joint. The first rotating joint comprises a first rotating shaft and a first outer cylinder arranged on the first rotating shaft in a sleeving mode, and the first outer cylinder can rotate around the first rotating shaft. The connecting arm is connected with the first outer cylinder and the vertical moving joint. The vertical moving joint comprises a connector and is used for driving an external component connected with the connector to move in the vertical direction. The horizontal moving joint is connected with the first rotating shaft and used for driving the first rotating joint to move in the horizontal direction. According to the operation robot and the mechanical arm thereof, the horizontal movement of the mechanical arm can be achieved through the horizontal moving joint, and the vertical movement of the mechanical arm can be achieved through the vertical moving joint; as the number of the joints is small, the structure relation is simplified, the appearance size of the mechanical arm is reduced, and the overall mass of the mechanical arm is reduced; besides, the precision of movement control is high, additional movement displacement can be avoided, and operation is easier and more convenient.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

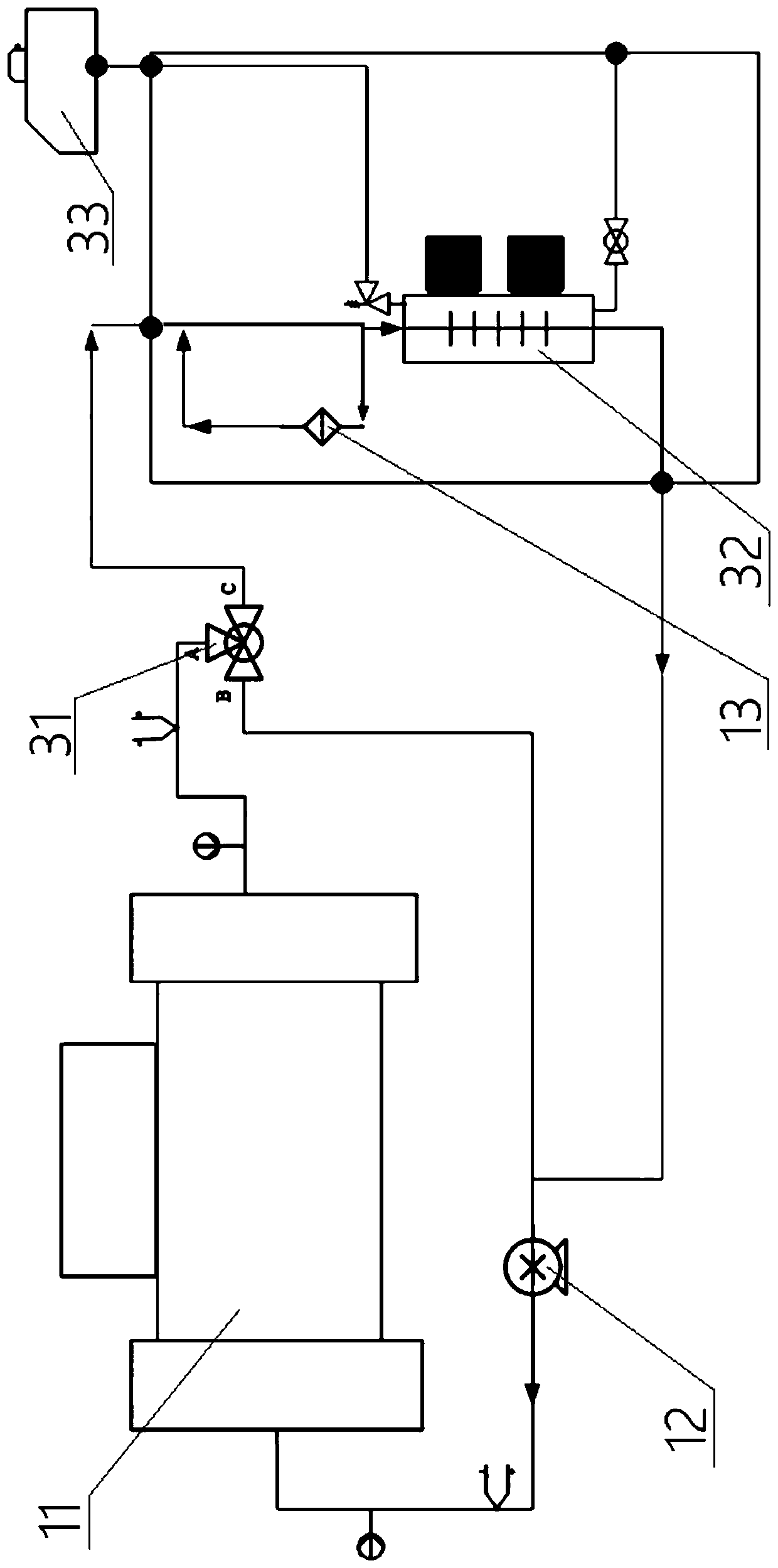

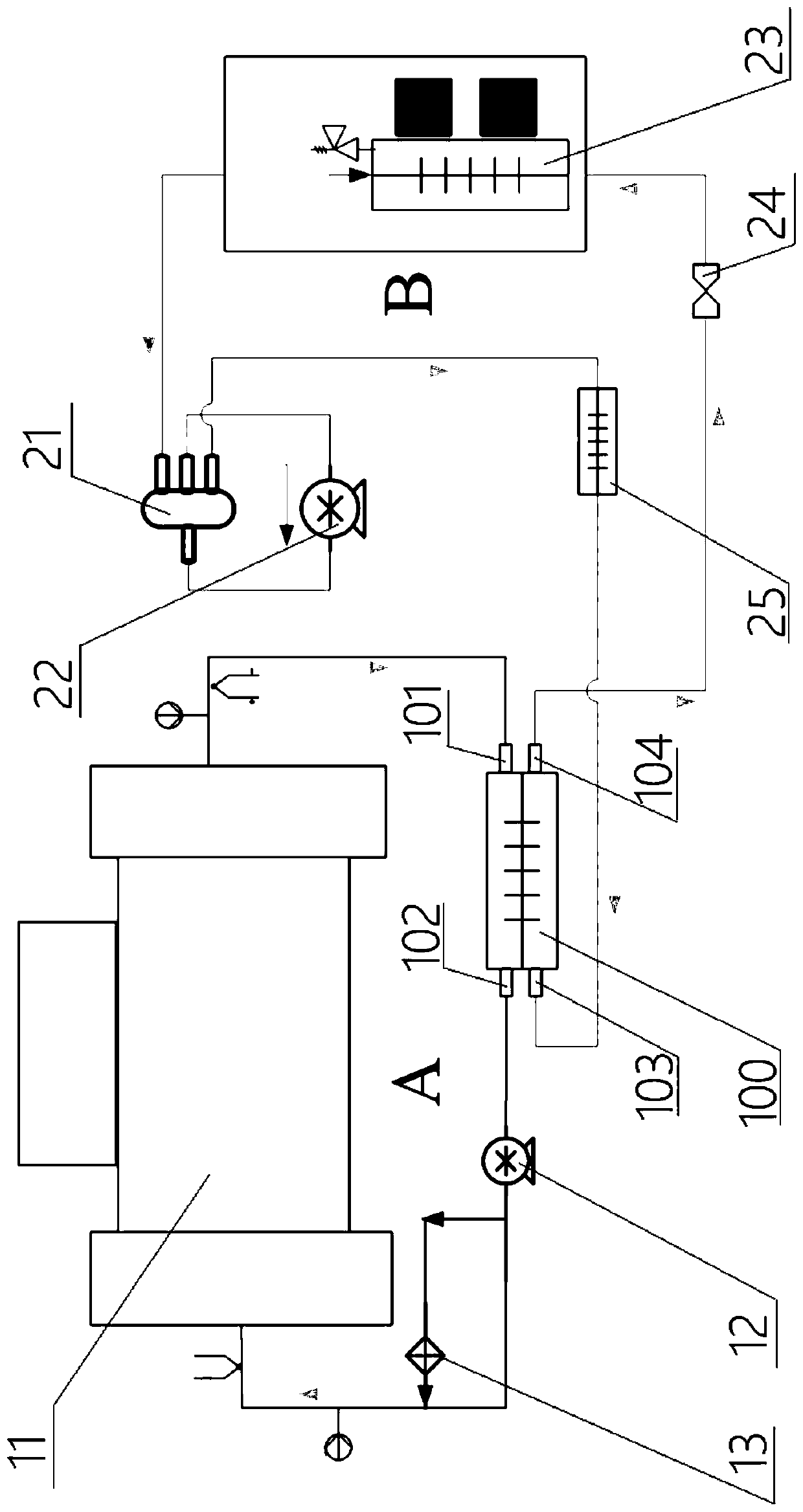

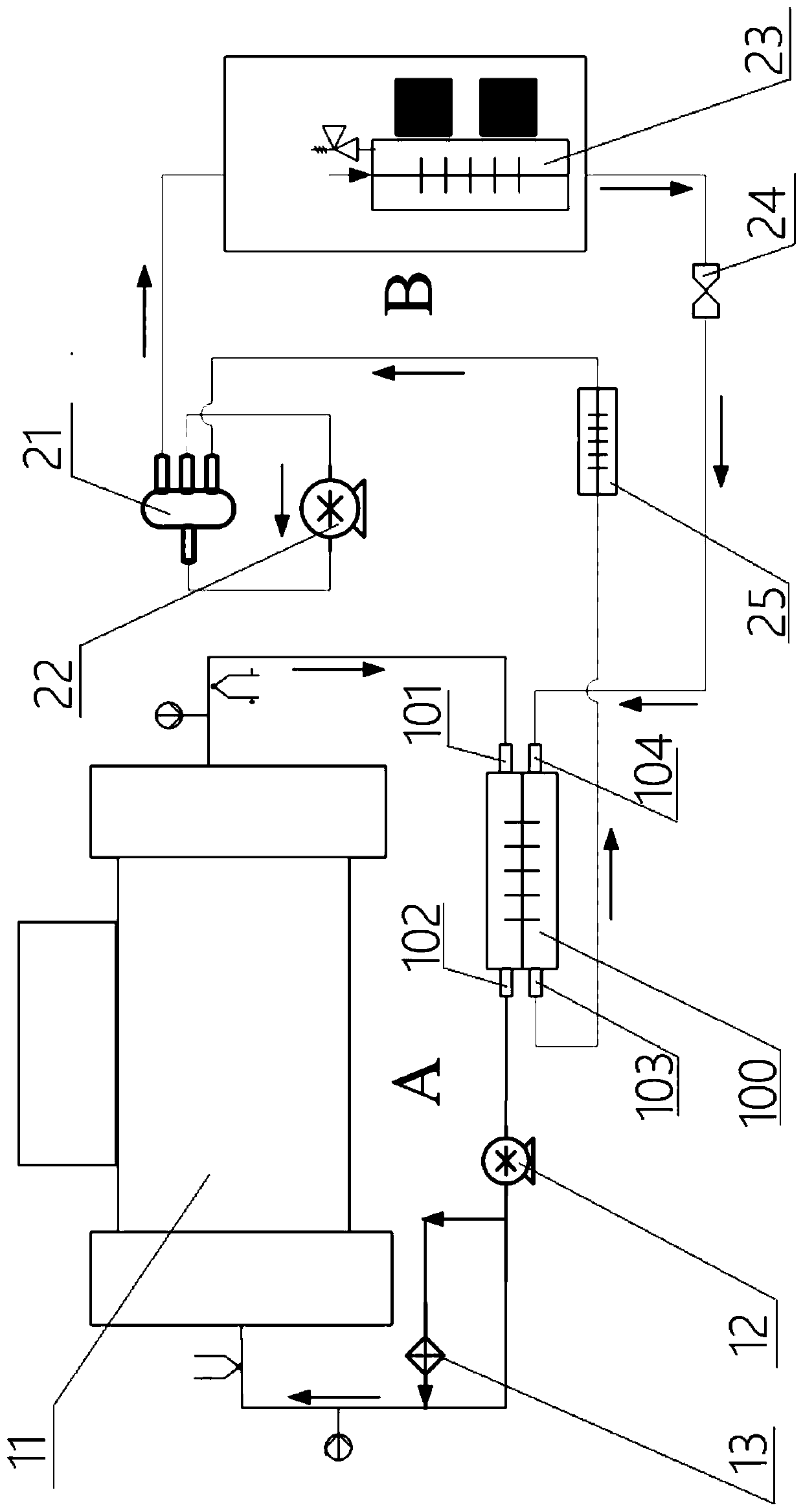

Fuel cell engine cooling system

The invention relates to a fuel cell engine cooling system which comprises an inner circulation pipeline and an outer circulation pipeline which are connected through a pipeline, wherein the internalcirculation pipeline comprises a fuel cell stack, a heat exchanger, a cooling liquid pump and a deionization filter, the heat dissipation outlet end of the fuel cell stack is sequentially connected tothe heat exchanger, the cooling liquid pump and the deionization filter and returns to the heat dissipation inlet end of the fuel cell stack, and cooling liquid circularly flows in the pipeline. Theouter circulation pipeline comprises a heat exchanger, a four-way valve, a booster pump, a whole vehicle radiator and an expansion valve, wherein the heat absorption outlet end of the heat exchanger is sequentially connected with the four-way valve, the booster pump, the whole vehicle radiator and the expansion valve and returns to the heat absorption inlet end of the heat exchanger, and the phasechange coolant circularly flows in the outer circulation pipeline. Since the heat exchanger is introduced, a traditional single cooling loop is changed into a double-circulation cooling loop, so thatthe problems that an original system radiator is too large in area, a pipeline is too long, ion precipitation is difficult to control and the like are solved, the cooling effect is good, and the design cost of a cooling system is reduced.

Owner:BEIJING NOWOGEN TECH CO LTD

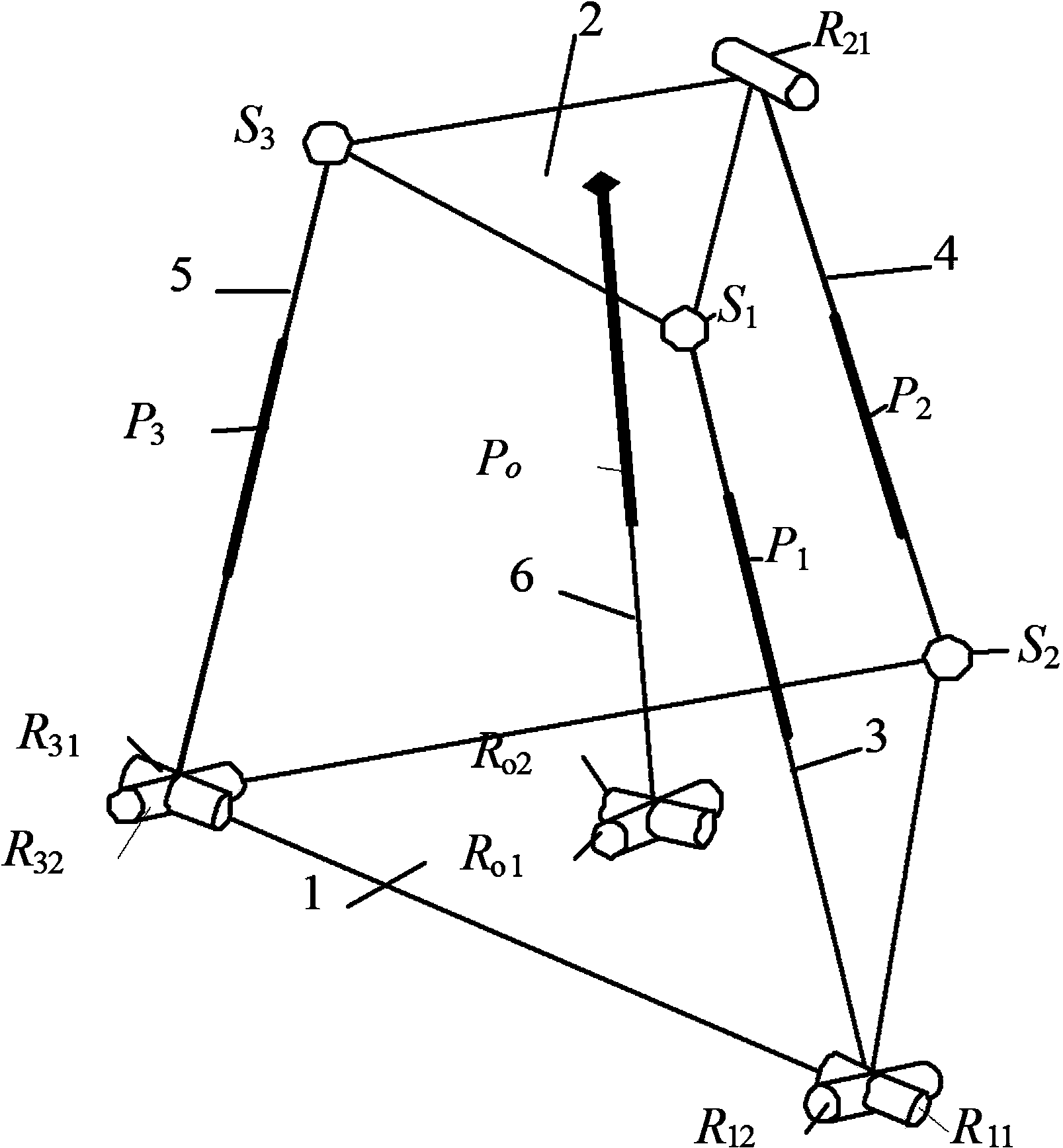

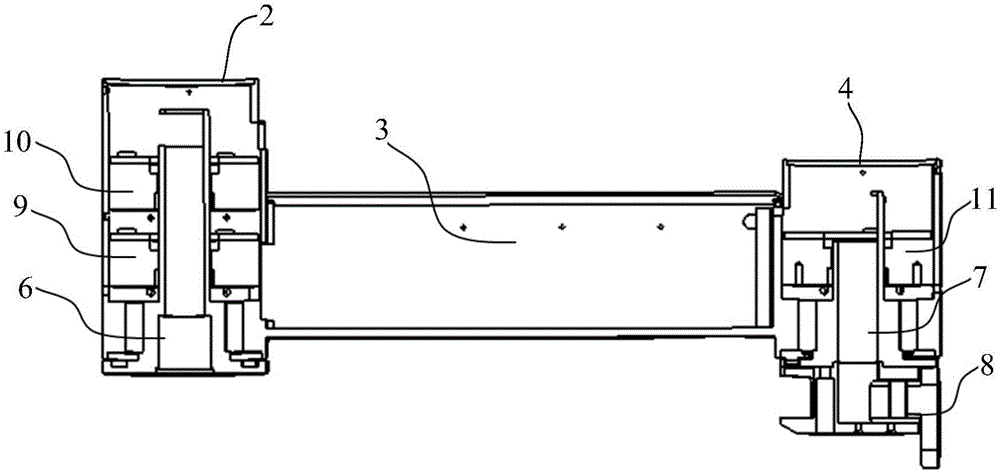

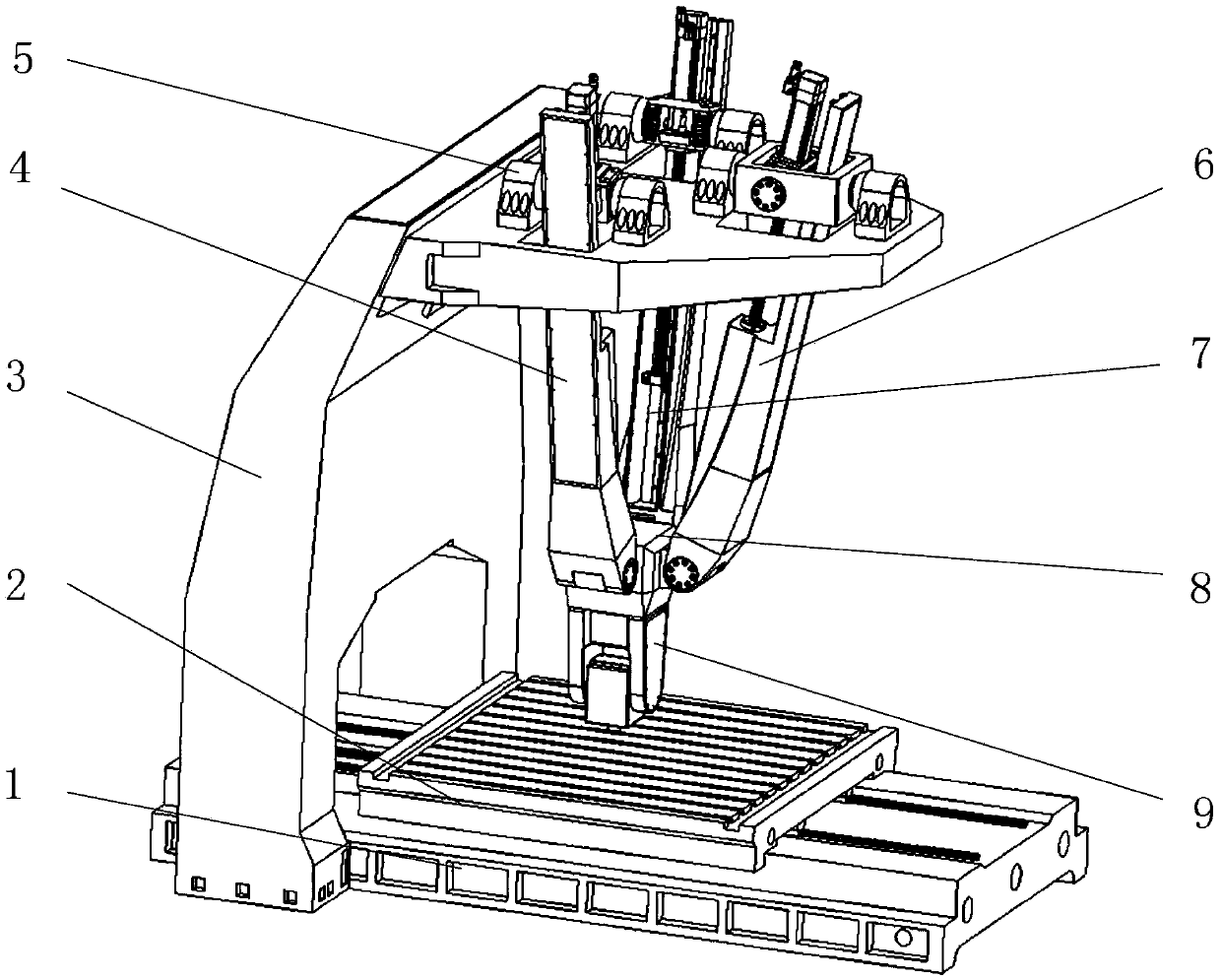

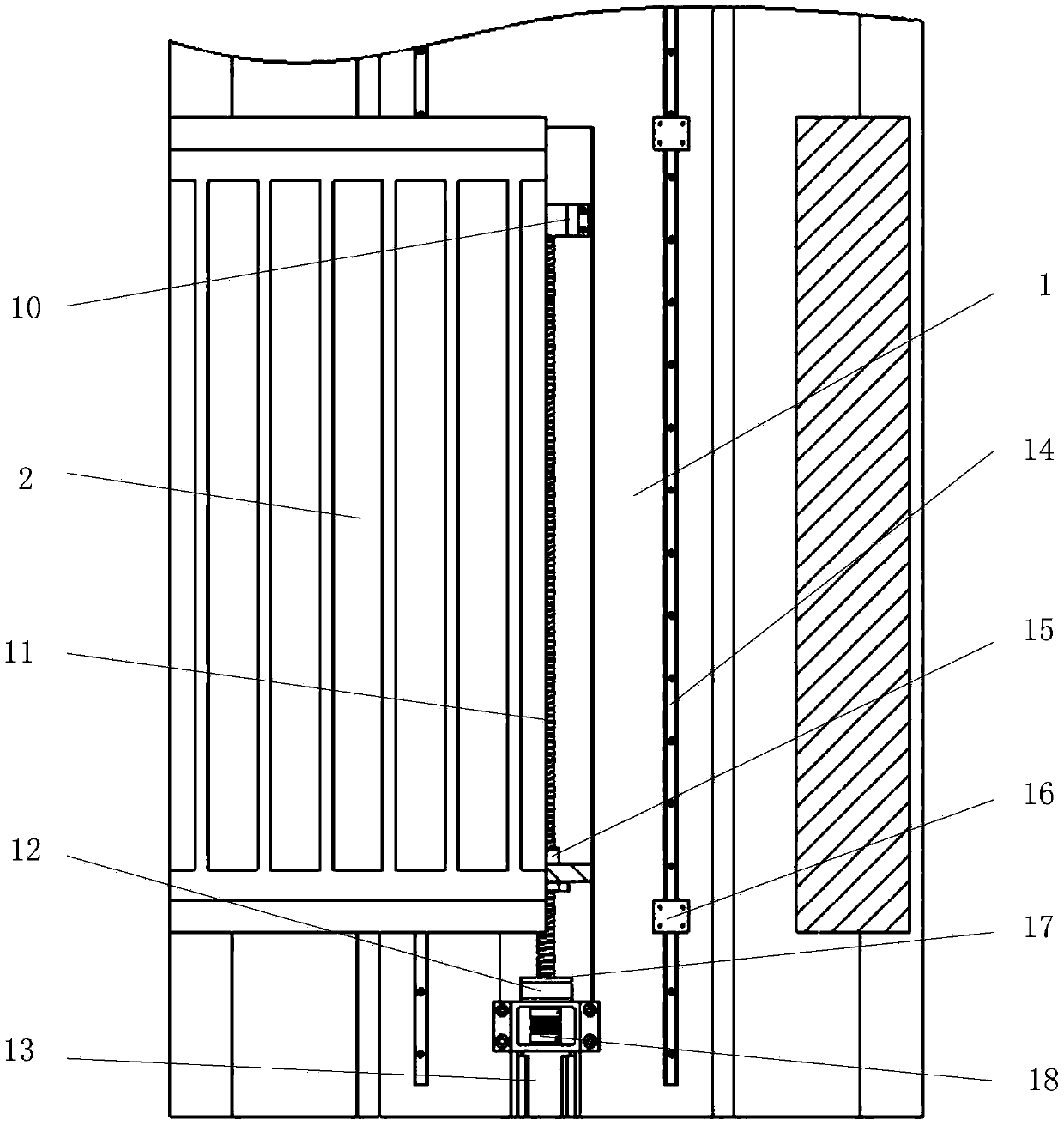

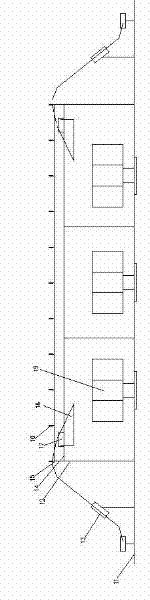

Five-degree-of-freedom hybrid robot based on 2R1T parallel mechanism

ActiveCN105364913ASimple structureReduce the number of jointsProgramme-controlled manipulatorSingle degree of freedomEngineering

A five-degree-of-freedom hybrid robot based on a 2R1T parallel mechanism comprises a fixed platform, a movable platform, an L-shaped vertical rack, a moving platform, three branch chain chains and a single-degree-of-freedom swing head. The movable platform is arranged on the fixed platform. The L-shaped vertical rack is arranged on the side face of the fixed platform. The three branch chain chains are arranged between a top platform and the moving platform of the L-shaped vertical rack. The single-degree-of-freedom swing head is arranged under the moving platform. The first branch chain and the third branch chain are identical in structure. The axis, close to the L-shaped vertical rack, of a U pair of the second branch chain is parallel to the axes of two revolute pairs of the first branch chain and the third branch chain. The axis, close to a connecting rod, of the U pair is parallel to the axis of the revolute pair of the second branch chain and perpendicular to the axis of a sliding pair. The axis of the revolute pair of the second branch chain is parallel to the axes, close to the moving platform, of the two U pairs of the first branch chain and the third branch chain. According to the five-degree-of-freedom hybrid robot based on the 2R1T parallel mechanism, the structure is simple, real-time control is facilitated, the working space of a machine tool can be enlarged easily, and the sensitivity of the machine tool is improved.

Owner:YANSHAN UNIV

Fibre reinforced composite anti-eccentric coiled rod as well as preparation device and preparation method thereof

ActiveCN103075112BAccelerated corrosionImprove partial wear resistanceDrilling rodsDrilling casingsEpoxyThermoplastic

The invention relates to a fibre reinforced composite anti-eccentric coiled rod and a preparation device thereof. The technical scheme adopted by the invention is as follows: one or more sections of the external surface of a fibre-reinforced resin matrix composite rod body is coated with a thermoplastic wear layer; the rod body is made of one of fibreglass, carbon fibre and basalt fibre; and a resin matrix is one of epoxy resin, urethane resin and vinyl ester resin. A plastic extruder and a cooling device are arranged between a draw gear and a winding device, the plastic extruder is used for coating one thermoplastic wear layer on one or more sections of the surface of a molded sucker rod, and then the cooling device is used for performing cooling treatment, so that the fibre reinforced composite anti-eccentric coiled rod is formed. The invention has the following beneficial effects: the coiled rod has excellent anticorrosion and anti-eccentric performances; the quantity of joints is greatly reduced; the breakage probability and the piston effect are reduced; and in addition, the production efficiency is high, and the operation is simple and convenient.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

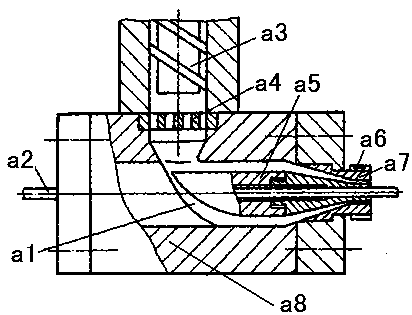

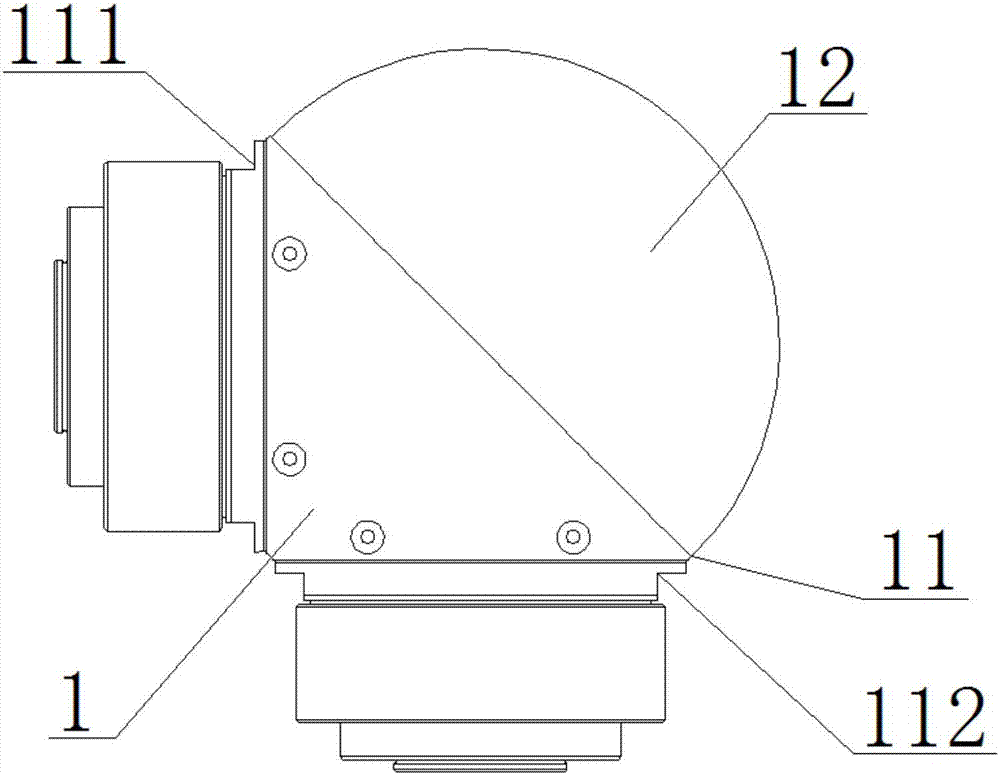

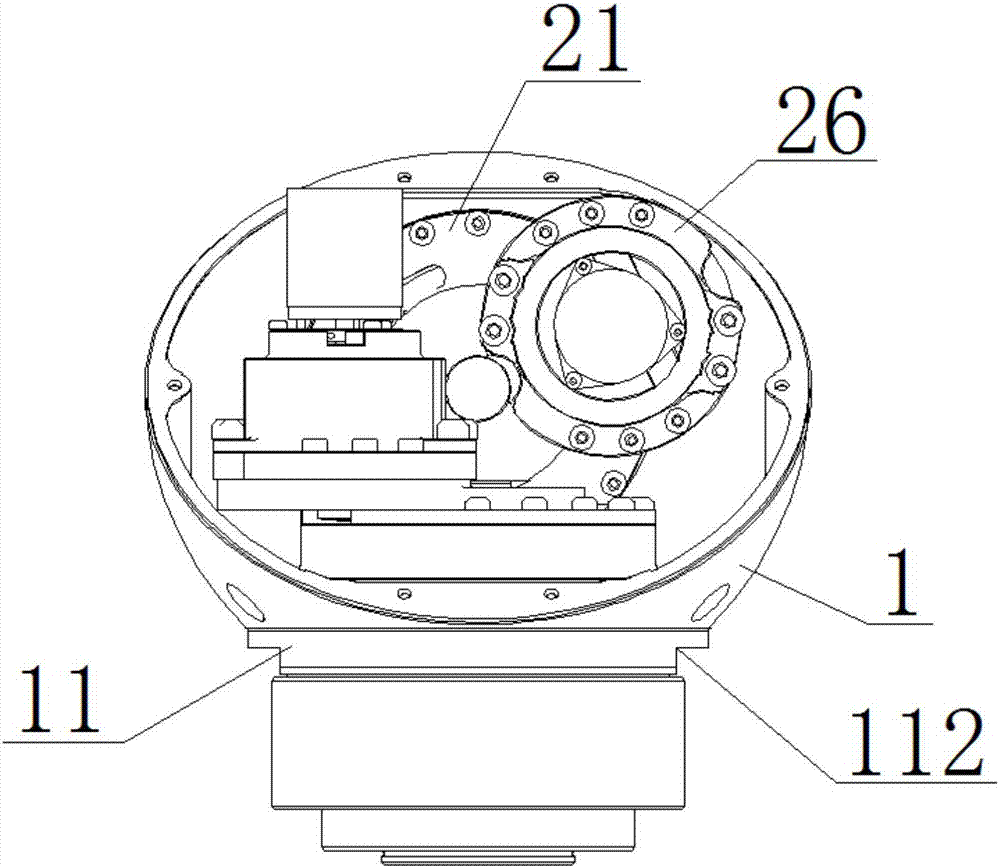

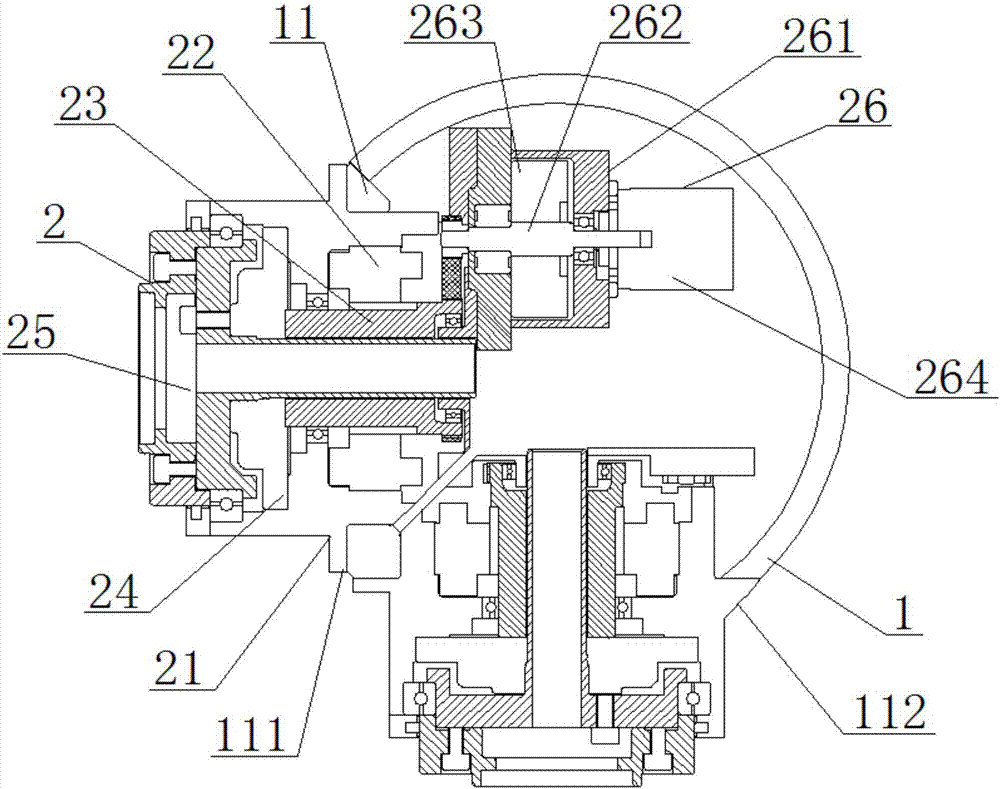

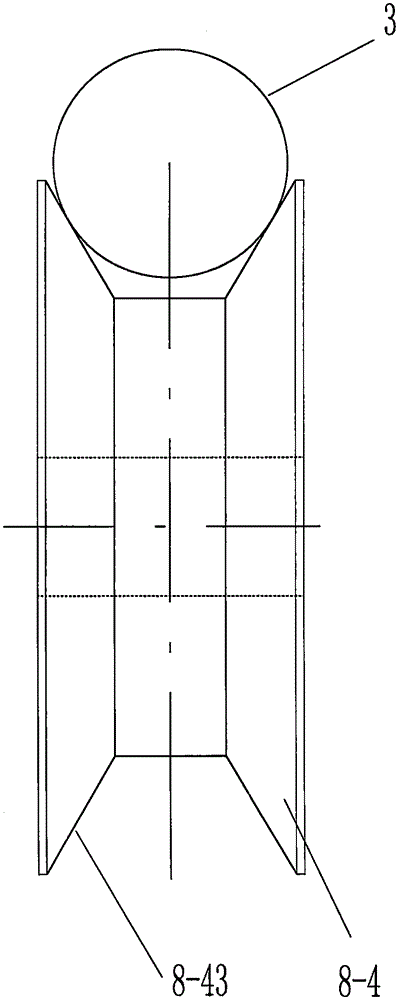

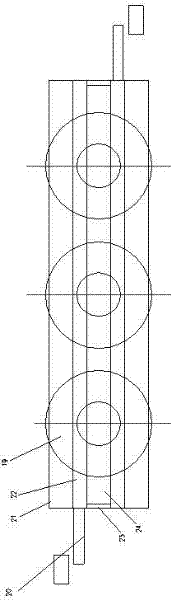

Modularized ball joint of collaborative robot

ActiveCN107186751AMiniaturizationReduce the number of jointsJointsReduction driveTorque transmission

The invention relates to mechanical arm joints, in particular to a modularized ball joint of a collaborative robot. The modularized ball joint of the collaborative robot comprises a shell and ball joint driving modules. A module supporting piece is fixedly installed on the shell, and a spherical shell cover is further installed on the shell. A first installation position and a second installation position are arranged on the module supporting piece, and the ball joint driving modules are fixedly installed on the first installation position and the second installation position and installed inside the shell in a sealing mode through the spherical shell cover. The modularized ball joint of the collaborative robot has the advantages that in the aspect of driving, hollow motors are used for driving, deceleration is conducted through harmonic speed reducers, and therefore high-torque transmission is achieved, the transmission accuracy is guaranteed, and the structure is compact and light; and in the aspect of braking, synchronous belt pulleys are utilized to conduct transmission, and therefore the driving portion and the braking portion are isolated, the space is saved, the braking performance is guaranteed, and the installation difficulty of the interior of the joint is reduced.

Owner:青岛欧开智能系统有限公司

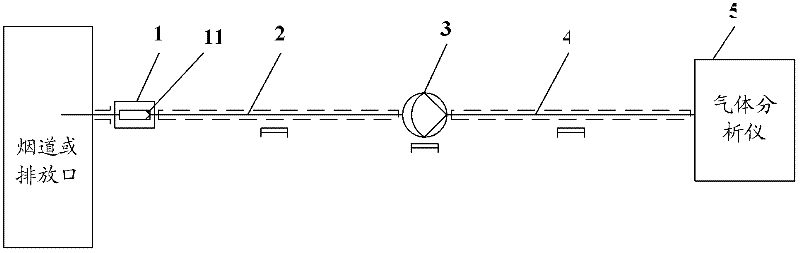

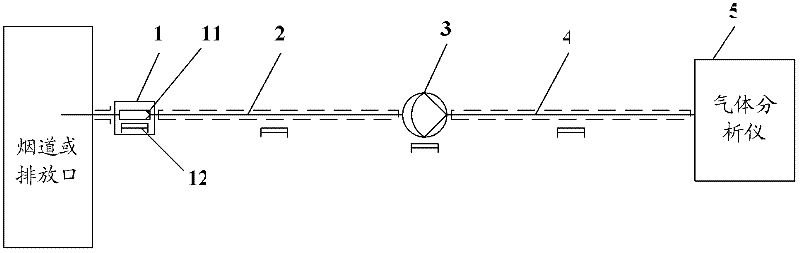

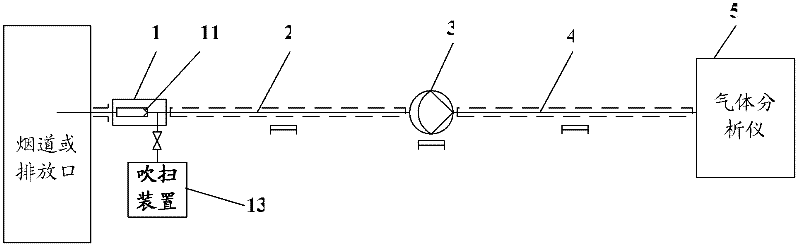

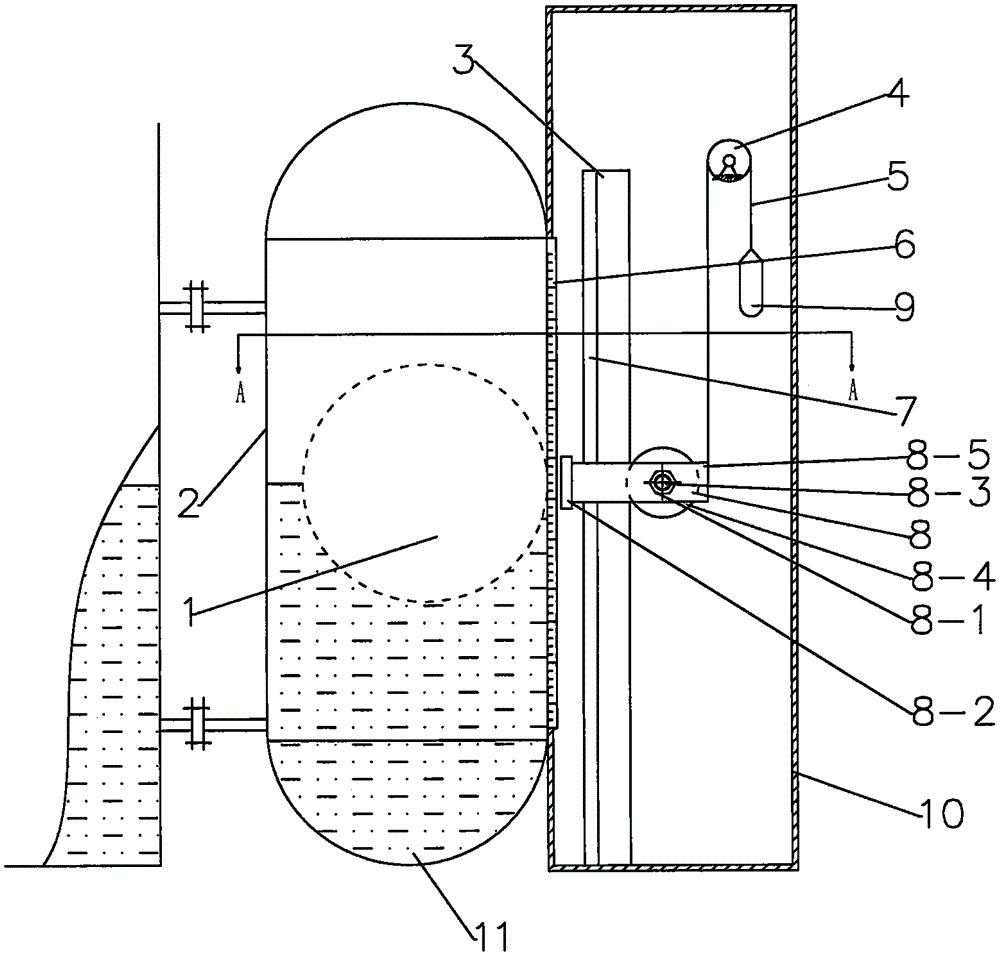

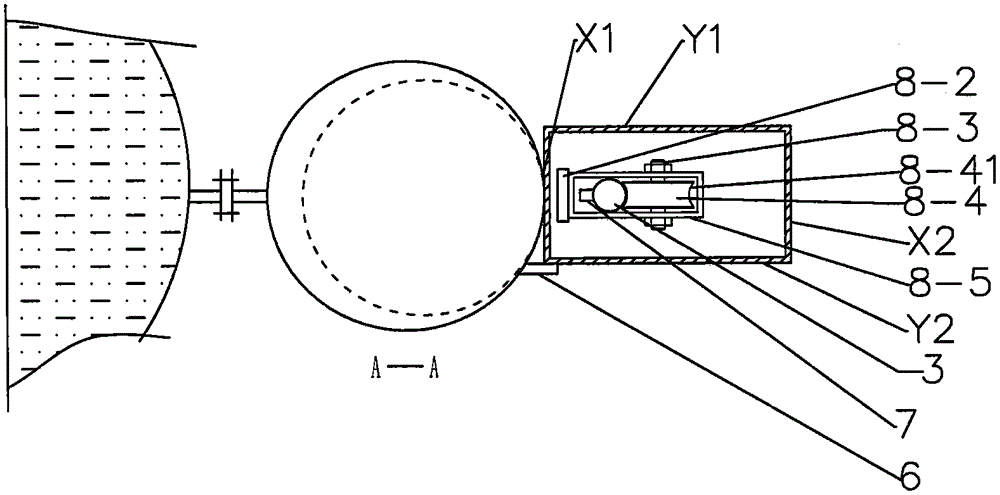

A waste incineration flue gas online analysis system

InactiveCN102288459AReduce the number of jointsReduce maintenance costsWithdrawing sample devicesPreparing sample for investigationGas compositionFlue gas

The invention discloses an on-line analysis system for waste incineration flue gas. The on-line analysis system for waste incineration flue gas sequentially includes: a sampling probe, an external heating sampling pipeline, a sampling pump, and an internal heating sampling pipeline along the transmission direction of the sample gas. and a gas analyzer; the sampling probe contains a sample gas filter that can remove dust in the sample gas; the sampling pump is accompanied by a heater to maintain the temperature of the sample gas; the gas analyzer is suitable for analysis and detection up to 200°C high temperature sample gas. After the sample gas is collected by the sampling probe, it is transmitted to the gas analyzer through the external heating sampling pipeline, sampling pump, and internal heating sampling pipeline. When the sample gas enters the gas analyzer, the composition of the sample gas collected by the sampling probe is consistent, improving High-temperature sample gas that ensures the measurement accuracy of each component content in the sample gas.

Owner:BEIJING SDL TECH

Ball float type liquidometer with vernier display

ActiveCN105277258AIncrease stiffnessGuaranteed measurement accuracyLevel indicators by floatsFloat chamberRolling-element bearing

The invention relates to a ball float type liquidometer with vernier display. The ball float type liquidometer comprises a ball float chamber and a ferromagnetic spherical floating ball arranged therein, a vernier outside the ball float chamber, a calibrated scale and a vernier guide rail. The vernier comprises magnetic steel, a frame and a rolling system which is horizontally fixed and sleeved in the frame; the rolling system comprises rolling wheels which are provided with radial grooves along a circumferential surface, rolling bearings and shafts; the magnetic steel is disposed between the ball float chamber and the frame and is fixed outside one side surface close to the ball float chamber on the frame, and the magnetic pole of the magnetic steel is right oriented towards the floating ball; the vernier guide rail is sleeved in the frame and is disposed between the magnetic steel and the rolling system; and the rolling system enables the rolling wheels to roll vertically along the vernier guide rail at groove positions through a magnetic coupling force between the magnetic steel and the floating ball. The ball float type liquidometer is simple and scientific in structure, reliable in application performance, easy to manufacture and low in cost, reduces defects in the prior art and effectively meets needs in correlation fields.

Owner:DALIAN JIAXIN ELECTROMECHANICAL INSTR CO TD

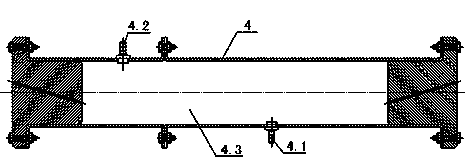

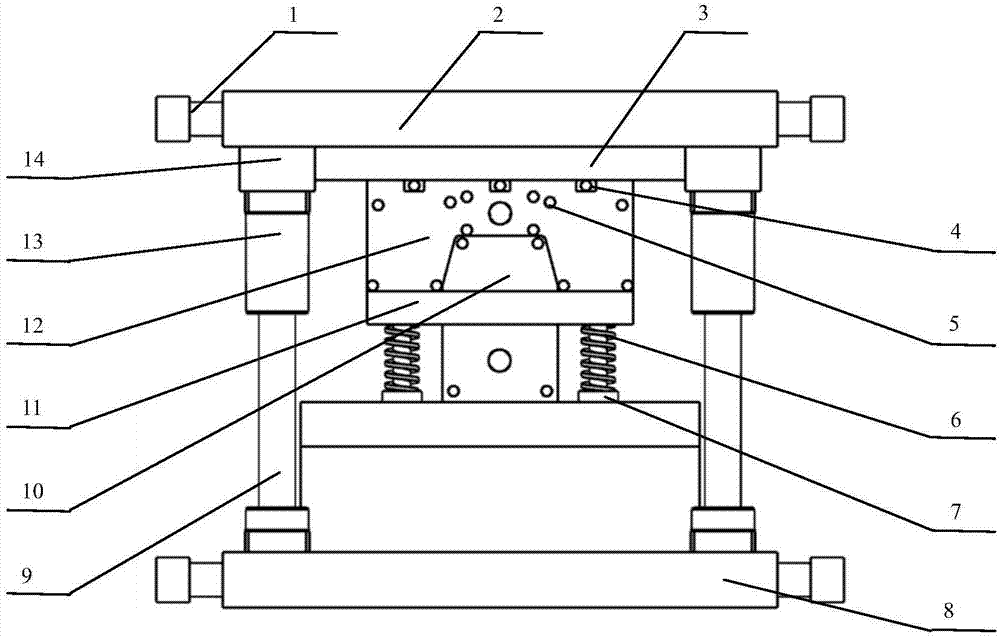

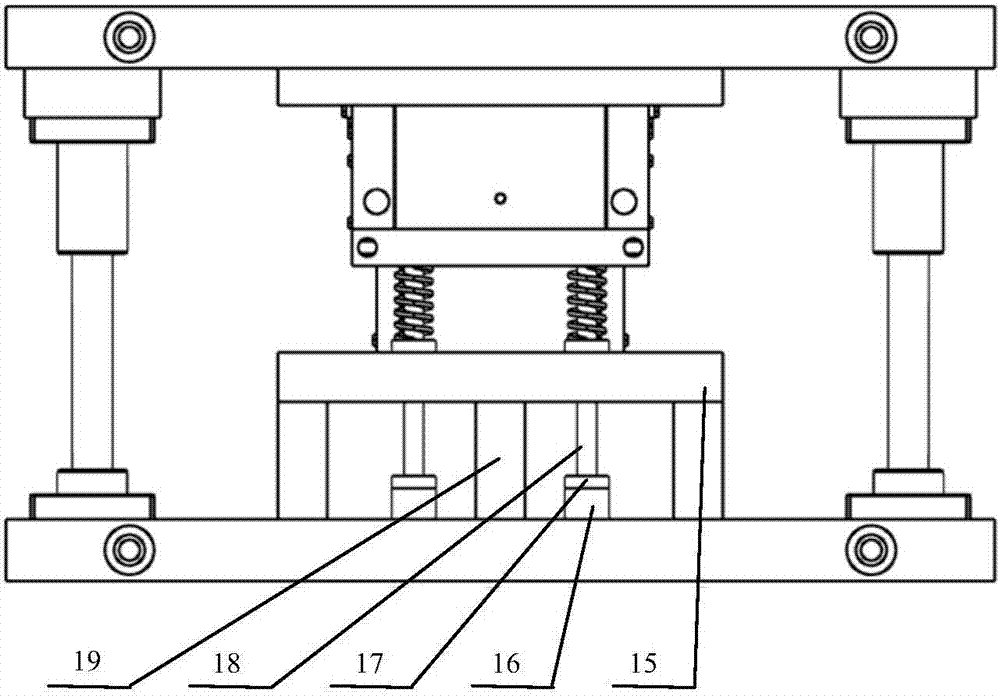

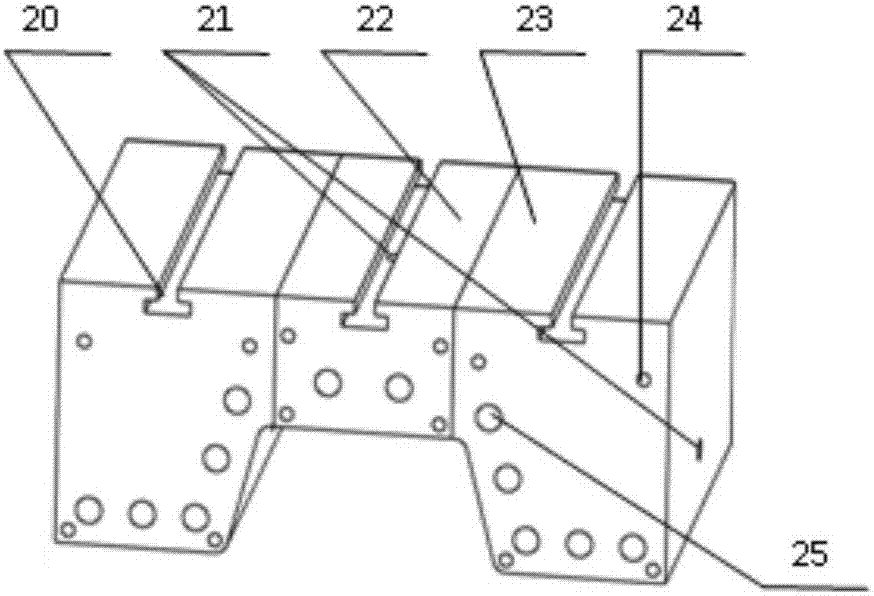

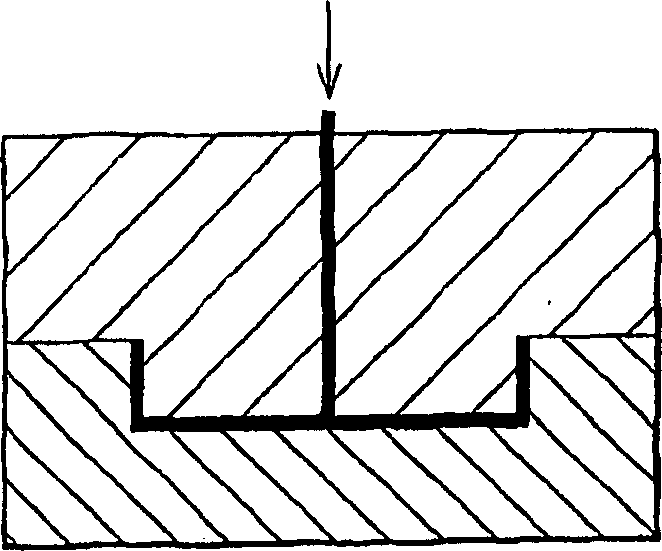

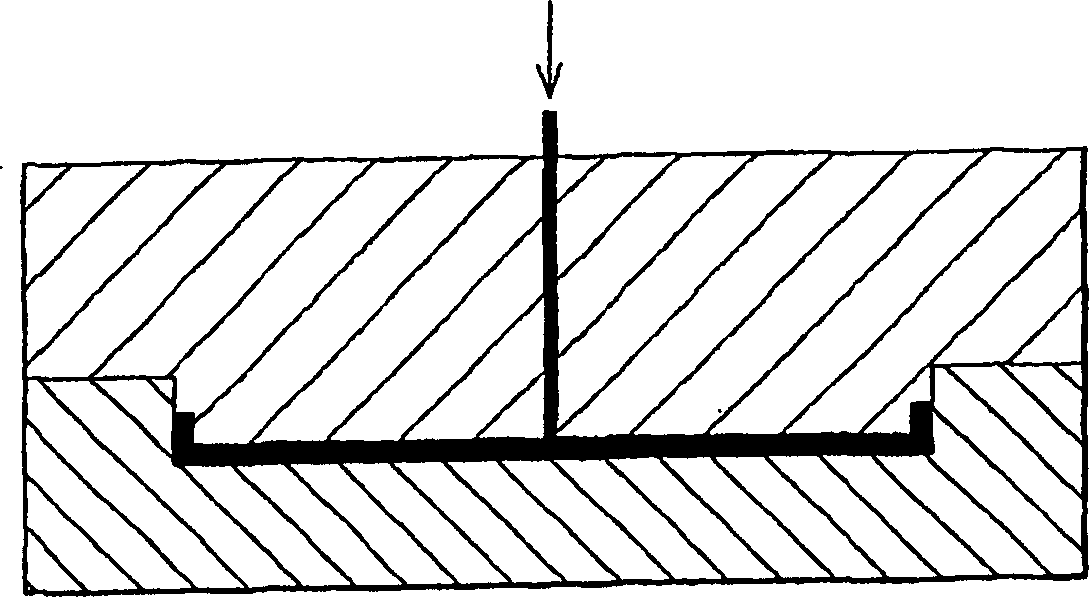

Hot stamping experiment mould

The invention discloses a hot stamping experiment mould. The water channel parameters of the mould directly affect the cooling effect of the mould. According to the technical scheme, the hot stamping experiment mould comprises an upper mould plate, a female mould fixing plate, a male mould fixing plate, a male mould, a blank holder, a female mould, a male mould fixing plate and a support plate. The hot stamping experiment mould has the advantages that the hot stamping experiment mould can achieve rapid adjustment of the cooling water channel parameters through replacement of local modules, and the cost of remanufacturing the mould is saved; cooling modules with different cooling water channel parameters are adopted in the symmetrical positions, and a contrast experiment can be conveniently and quickly completed; and the mould is provided with a fast-replacing structure, replacement of the cooling modules can be efficiently completed, and the experiment time is saved.

Owner:JIANGSU HUAQIANG MOLD TECH

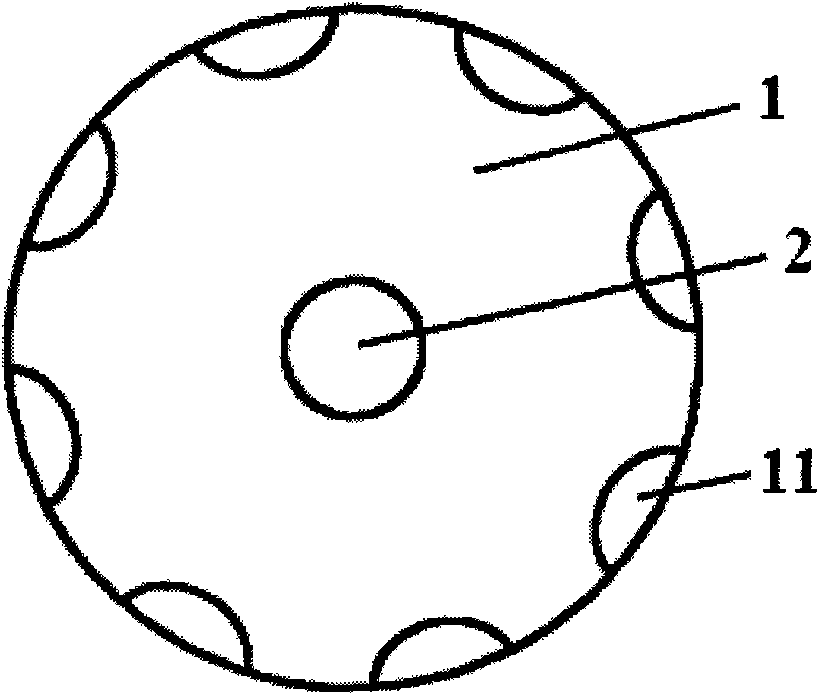

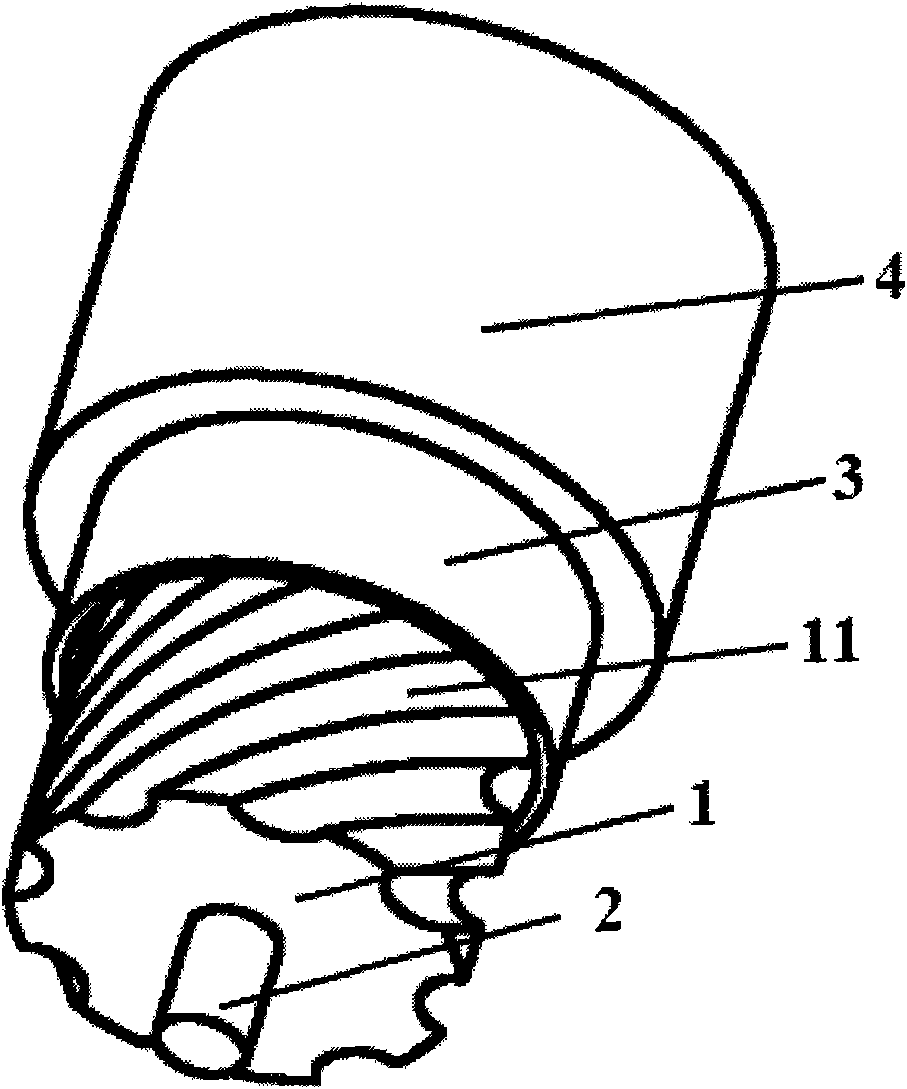

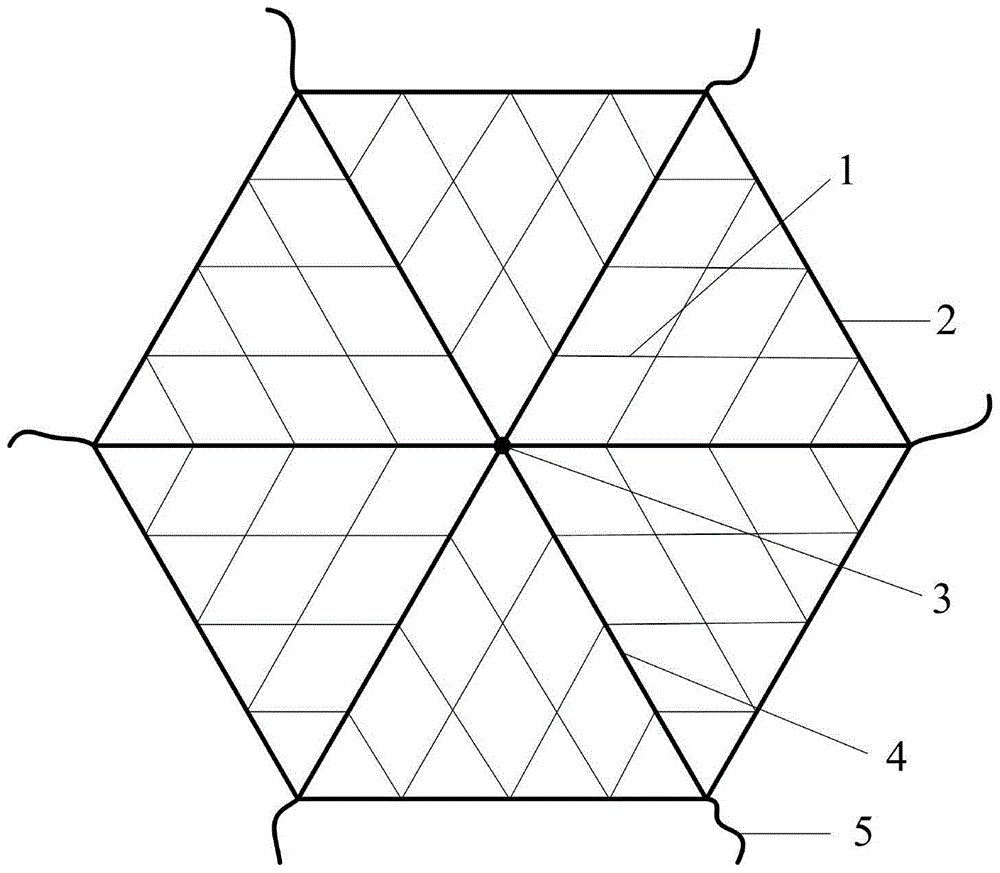

Skeleton cable

InactiveCN101685682AReduce the number of jointsReduce lossInsulated cablesInsulated conductorsEngineeringProtection layer

The invention relates to the technical field of cables, in particular to a skeleton cable, which comprises at least one group of cable conductors (5), and is characterized in that: the skeleton cablealso at least comprises a skeleton (1), a protective layer (3) and an outer protection layer (4); the skeleton is at least provided with two skeleton grooves (11); the protective layer (3) is positioned outside the skeleton; the outer protection layer (4) is positioned outside the protective layer; and the cable conductors (5) are positioned in the skeleton grooves (11). The skeleton cable has thefollowing advantages of effectively reducing joint number of the whole cable, effectively reducing connection loss, saving connection time, improving the reliability of a system, decreasing unnecessary expenses in the connection process, saving cost, and having more convenient maintenance.

Owner:沈群华

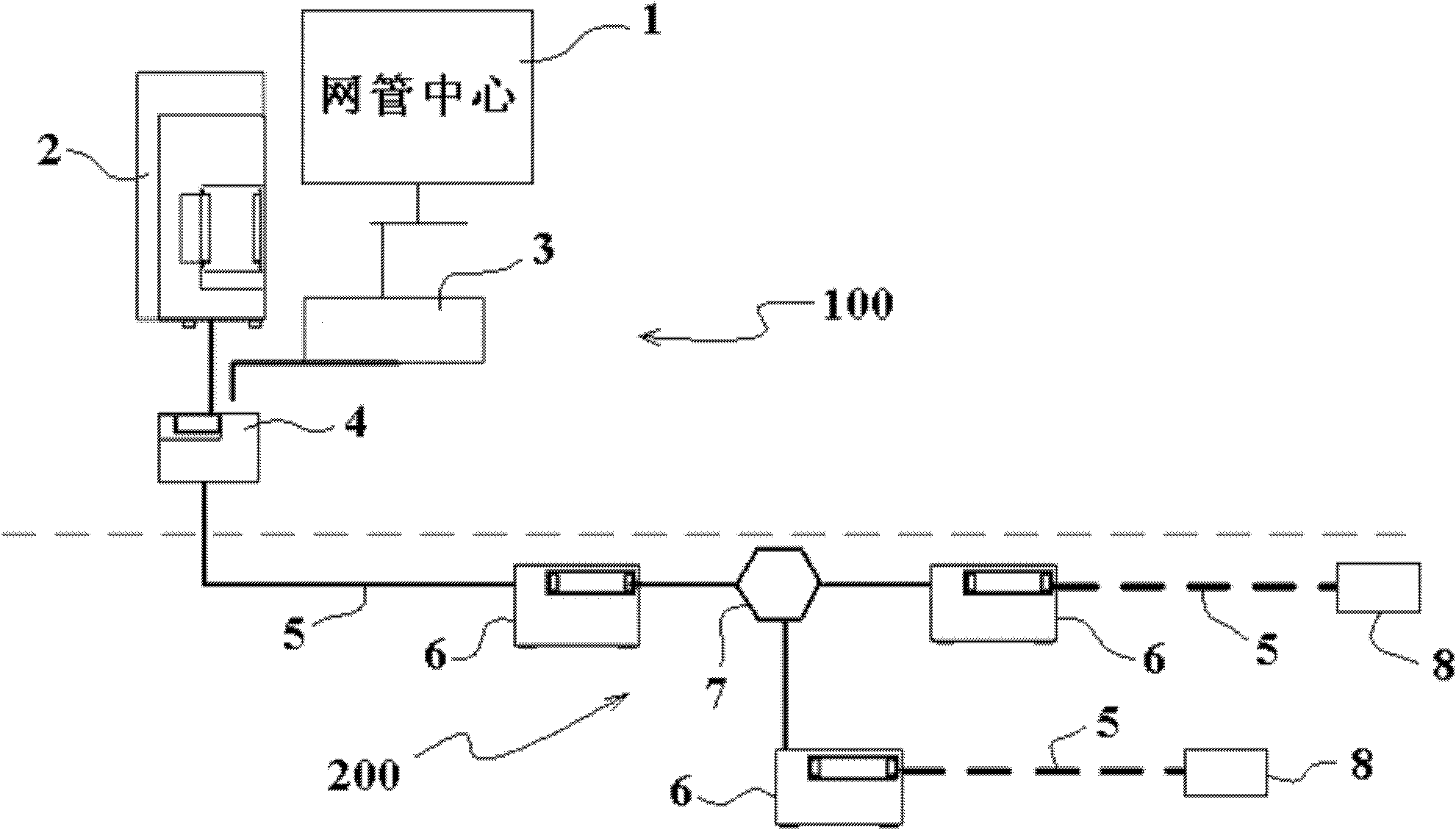

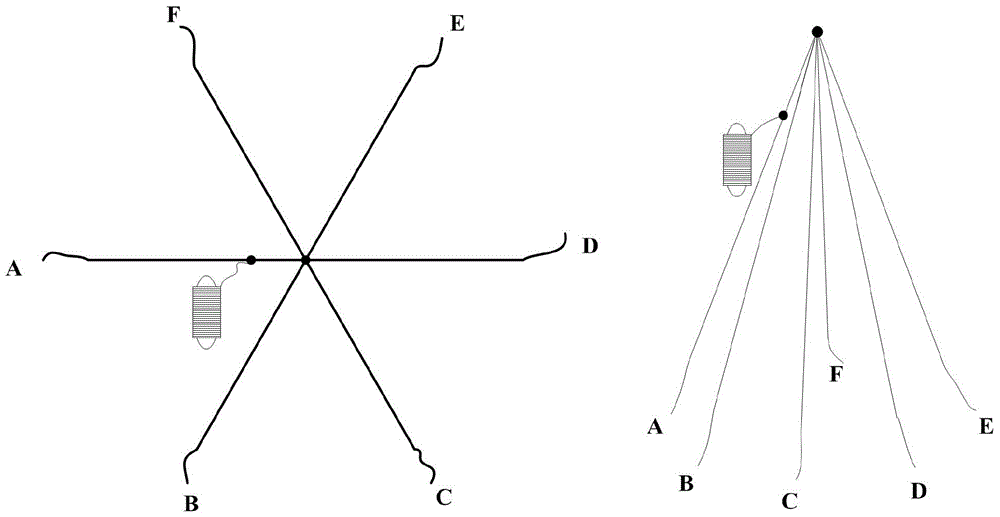

Leakage communication system with fault location and method

InactiveCN102572906AReduce in quantityReduce the number of jointsNear-field transmissionWireless communicationCommunications systemEngineering

The invention discloses a leakage communication system with fault location, comprising a base station for sending and receiving signals, repeaters for amplifying signals and a leakage cable for signal coverage. The system is characterized by comprising an equipment self-checking device for judging a single-machine state and a system-inspecting device for judging the state of the leakage cable and displaying the state of the system. A channel machine in the base station is connected with the leakage cable in a coverage area by an isolator; repeaters are arranged on the leakage cable in the coverage area at intervals of 400-550m; distributors are arranged at branch positions of roadways in the coverage area and connected with a plurality of subsequent repeaters by the leakage cable; every subsequent repeater is connected with more subsequent subsequent repeaters by the leakage cable; and load for signal matching is arranged at a coverage terminal of leakage cable. The system is capable of automatically judging operation state of the system, initiatively offering fault alarm and locating a fault onto equipment or the cable, thereby creating convenience for maintenance of users.

Owner:北京达因瑞康电气设备有限公司

Technical yarns, textile fabric and use

InactiveCN101285226AReduced number of jointsFew jointsMonocomponent polyethers artificial filamentContinuous wound-up machinesYarnEngineering

The invention discloses an industrial yarn and an industrial fabric as well as a use thereof. Yarn is the yarn which is made from a raw material of heat resistant fiber, after the yarn is weaved, the joint number of the yarn in a fabric is below 10 / 100m2. Tensile strength of the fabric, of which the longitude direction is above 500 N / 5cm based on JIS L 10968.12.1A law, and the fabric is applied in the filtering material field and a reinforcement fabric of non-woven fabric. The invention has the advantages of reducing the joint number of the yarn, reducing unevenness of yarn twist, improving strength of the fabric and stability of ventilation degree value and improving overall performance of the finished product.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

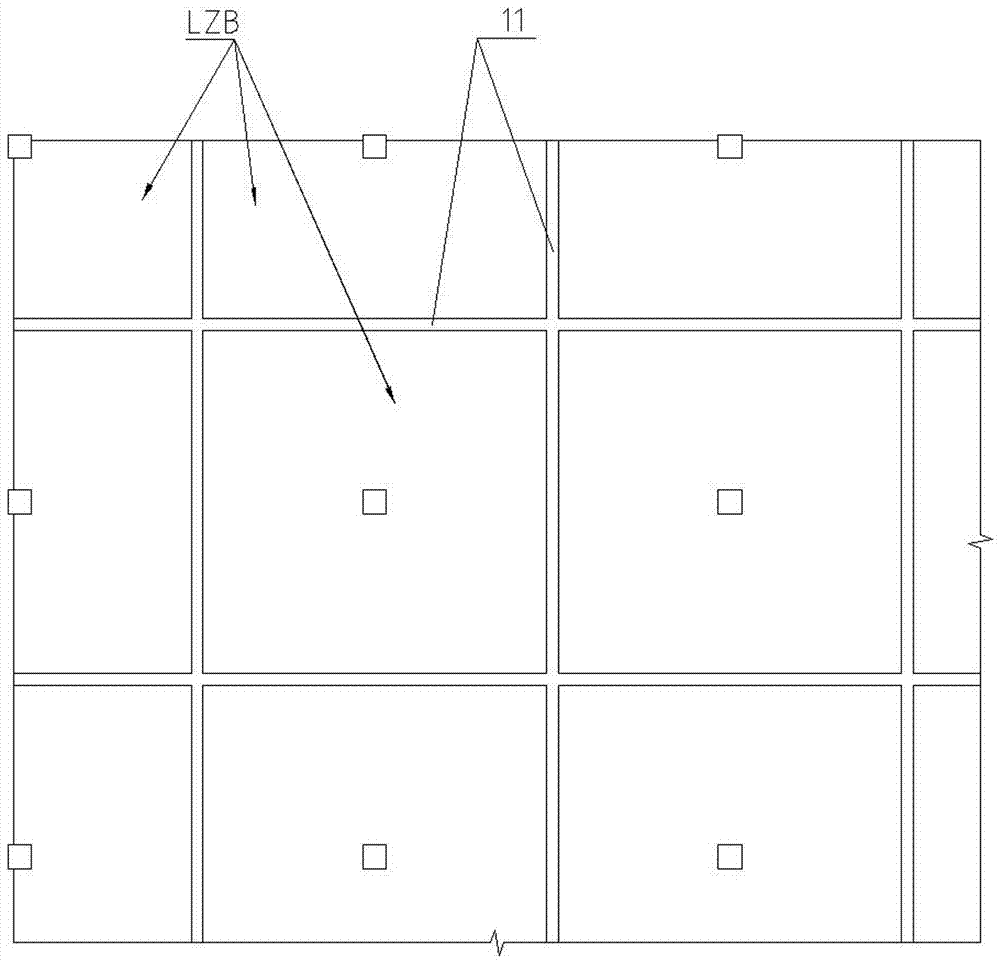

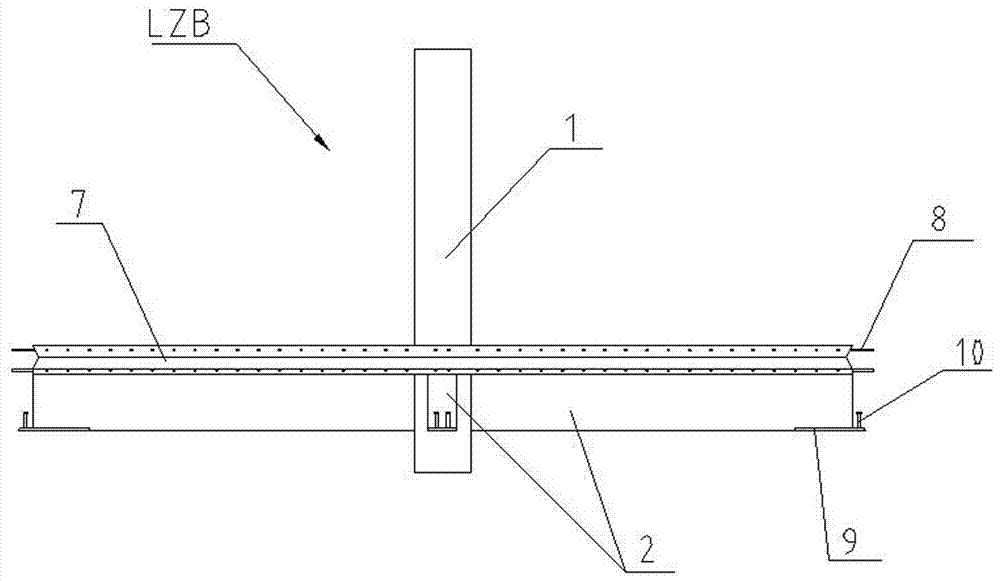

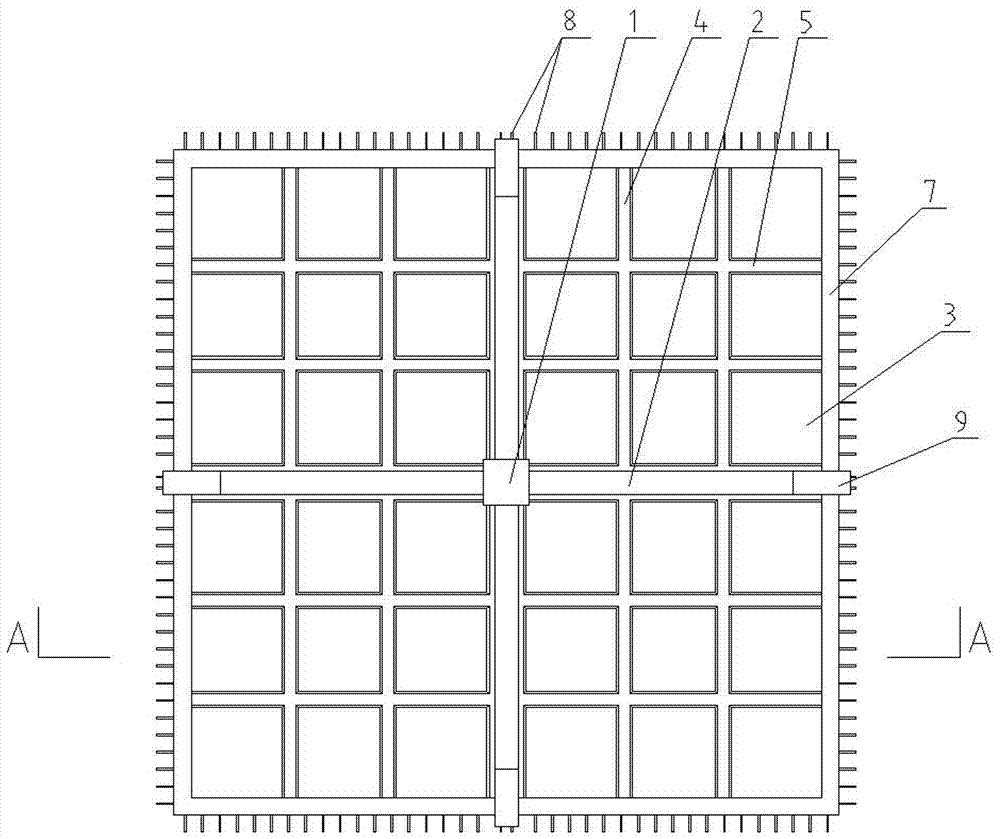

Super-high performance concrete frame structure fabricated building and construction method thereof

The invention discloses a super-high performance concrete frame structure fabricated building and a construction method thereof. A splicing unit at least comprises beam, column and floor integrated pieces prefabricated by super-high performance concrete. The height of each column is the height of a building storey; the beams are perpendicular to the side walls of the columns; the floors are located on the upper surfaces of the beams; connecting parts are arranged on the side edges of the floors; and the two ends of the columns stretch out of the end faces of the floors and the beams. When fabricating is constructed, after the prefabricated integrated pieces adjacent to the building plane, the super-high performance concrete is poured into joints between the connecting parts of the side edges of the floors to enable the prefabricated integrated pieces to form a whole. The upper storey and the lower storey of the building are connected through the columns of the beam, column and floor integrated pieces. The prefabricated integrated pieces adopt the super-high performance concrete as structure materials, and the reasonable connecting arrangement is configured, so that the average thickness of the floor and the amount of connectors and the joints between prefabricated members both are decreased substantially. The self-weight of the building is reduced substantially under the premise of guaranteeing the rigidity and strength of the building, and construction difficulty is reduced.

Owner:HUNAN UNIV

Wheel-leg composite type robot moving device and wheel-leg composite type robot

ActiveCN111391934ASolve the problem of many jointsReduce the number of jointsVehiclesLeg typeDrive wheel

The invention discloses a wheel-leg composite type robot moving device and a wheel-leg composite type robot. The wheel-leg composite type robot moving device comprises an installation part used for being connected with a robot body, a crotch joint driving part, a hip joint driving part, a first rod, a second rod, an ankle joint driving part, a wheel driving part and wheels, wherein the crotch joint driving part, the hip joint driving part, the first rod, the second rod, the ankle joint driving part, the wheel driving part and the wheels are connected successively in series. The second rod andthe ankle joint driving part are in fixed connection and other parts are in rotating connection. The installation part is connected with the crotch joint driving part. The crotch joint driving part isused for driving the hip joint driving part to rotate around the axis of the output end of the crotch joint driving part. The hip joint driving piece is used for driving the first rod to rotate around the axis of the output end of the hip joint driving piece. The ankle joint driving piece is used for driving the ankle joint driving piece to rotate around the axis of the output end of the ankle joint driving piece. The wheel driving piece is used for driving the wheel to rotate around a rotating shaft of the wheel. Compared with a traditional wheel leg type moving device, the wheel-leg composite type robot moving device has advantages that the number of joints is smaller, and control is simpler.

Owner:SHANGHAI AEROSPACE SYST ENG INST

A hexagonal space capture rope net and its preparation method

ActiveCN104790119BReduce the number of jointsWith variable topologyToolsKnotting netsEngineeringRopes course

Owner:NAT UNIV OF DEFENSE TECH

Decoupled two-translation one-rotation parallel robot

InactiveCN105108742AAchieve freedom of movementRealize decoupling controlProgramme-controlled manipulatorDegrees of freedomEngineering

The invention provides a decoupled two-translation one-rotation parallel robot. The robot comprises a fixed platform, a disc slider, a motion worktable and three branch chains connected between the disc slider and the motion worktable. The robot is characterized in that the fixed platform is provided with three mutually orthogonal planes, and each plane comprises a rectangular hollow structure; the disc slider is movably embedded into the rectangular hollow structures of the fixed platform through balls inlaid in the edge; one end of a first telescopic rod of the first branch chain is connected with the motion worktable through a first rotation pair, and the other end is fixedly connected with the disc slider; one end of a fixed-length rod of the second branch chain is connected with the motion worktable through a second rotation pair, and the other end is fixedly connected with the disc slider; one end of a second telescopic rod of the third branch chain is fixedly connected with the motion worktable, and the other end is fixedly connected with the disc slider. The robot adopts the first telescopic rod, the second telescopic rod and the rotation pairs in one branch chain as driving joints, and complete decoupling control at two-translation one-rotation degrees of freedom is realized.

Owner:SHANDONG UNIV OF TECH

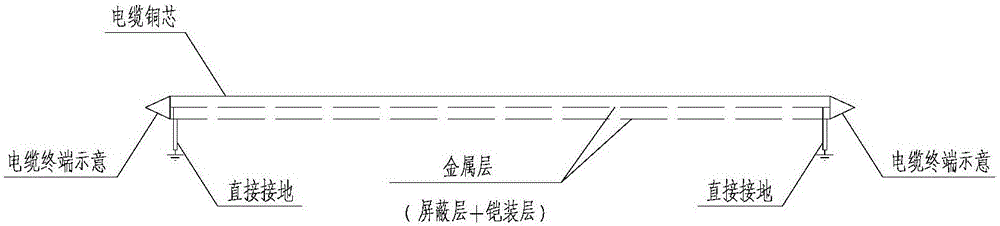

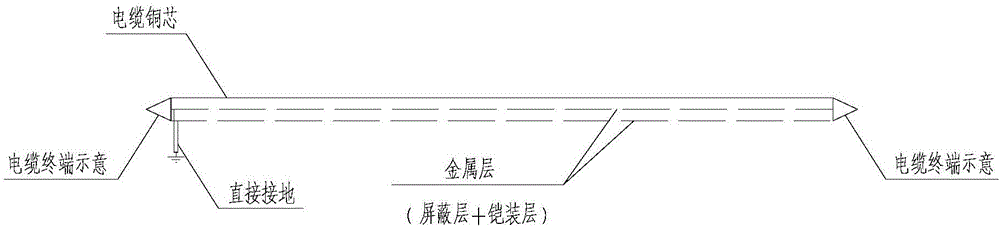

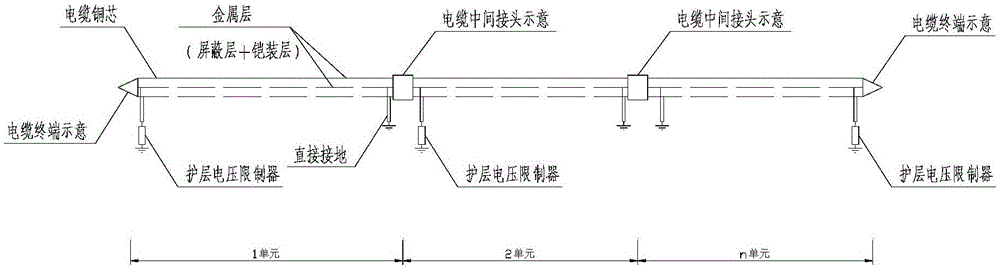

Technical scheme for grounding of single-core cable especially for high-speed railway

InactiveCN106129991AIncrease the lengthThe induced voltage value increasesEmergency protective arrangements for limiting excess voltage/currentConnection contact member materialTraction power supplyProtection layer

The invention relates to a technical scheme for grounding of a single-core cable especially for a high-speed railway, wherein the technical scheme is mainly suitable for a 27.5-kV single-core cable. According to the technical scheme, on the basis of characteristics of the high-speed railway traction power supply system, a 27.5-kV cable is divided into a plurality of units by combining a simulation result of a system model established by using a PSCAD / EMTDC, structural characteristics of a cable, and practical engineering information; and one end of the 27.5-kV cable in each unit is grounded directly and the other end is grounded by a protection layer voltage limiting device. The length of the cable of each grounding unit does not exceed 600m and a metal protection layer of an intermediate connector of each two grounding units is removed, thereby realizing independence of the grounding units. The cable grounding requirement at the two ends of the intermediate connector between each two grounding unit and the grounding requirement of the protection layer voltage limiting device match the grounding requirement of the 27.5-kV cable power supply loop.

Owner:CHINA RAILWAY ELECTRIFICATION SURVEY DESIGN & RES INST

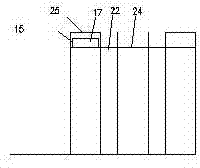

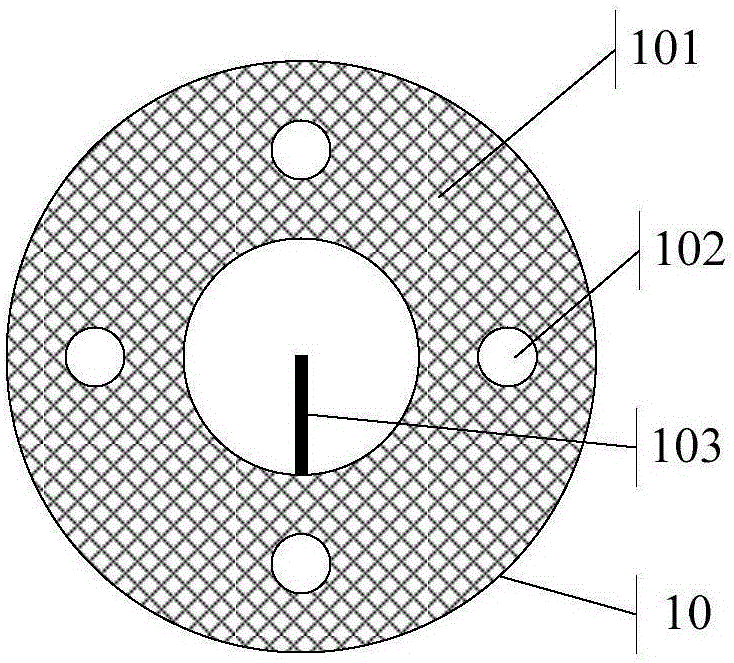

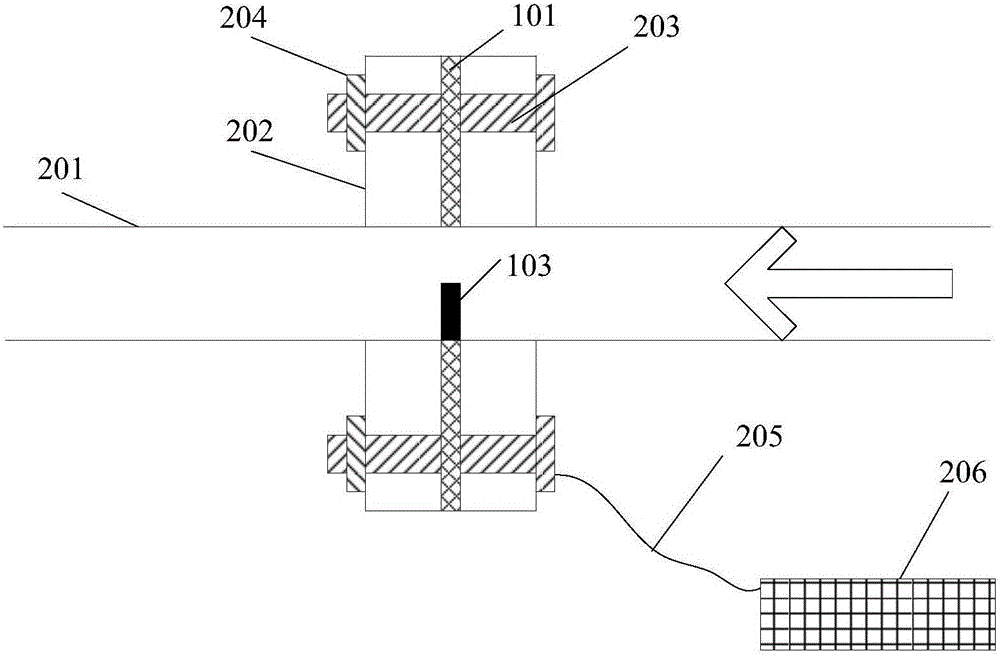

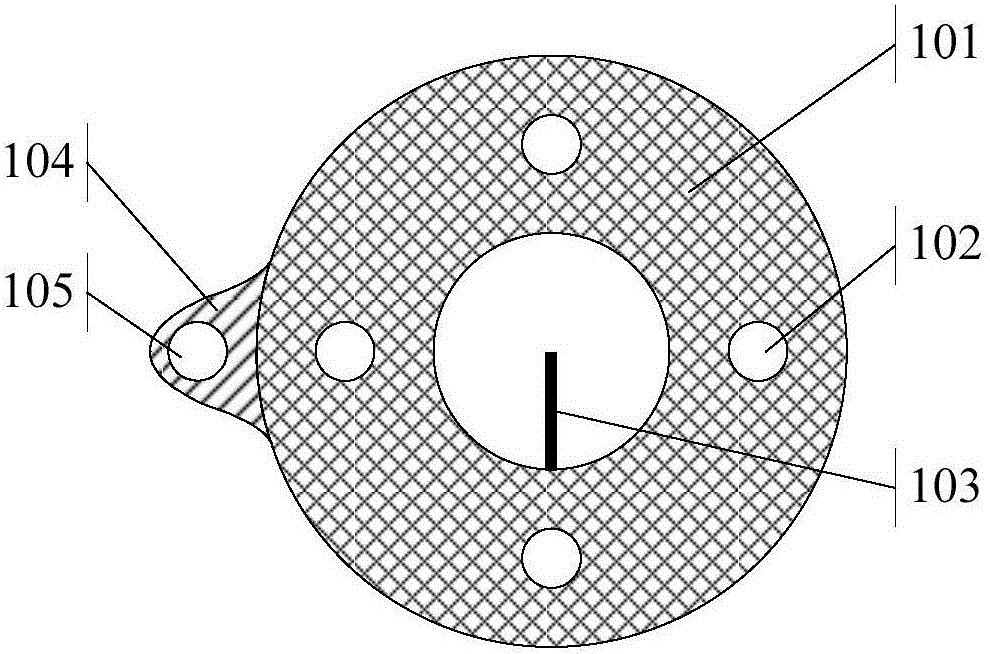

Equipotential electrode and installation method

ActiveCN105118825ASimple structureReduce the number of jointsSemiconductor/solid-state device detailsSolid-state devicesFlangePetroleum engineering

An embodiment of the invention discloses an equipotential electrode comprising a ring, at least two through holes arranged in the ring and used to connect a converter valve water pipe flange, and at least one equipotential pin. The outer diameter of the ring corresponds to the outer diameter of the converter valve water pipe flange connected with the ring, and the inner diameter of the ring corresponds to the inner diameter of the converter valve water pipe flange connected with the ring. One end of the equipotential pin is fixed to the inner diameter of the ring, and the other end of the equipotential pin extends to the inside of the ring along the radial direction of the ring. Another embodiment of the invention discloses an installation method of the equipotential electrode.

Owner:NR ELECTRIC CO LTD +2

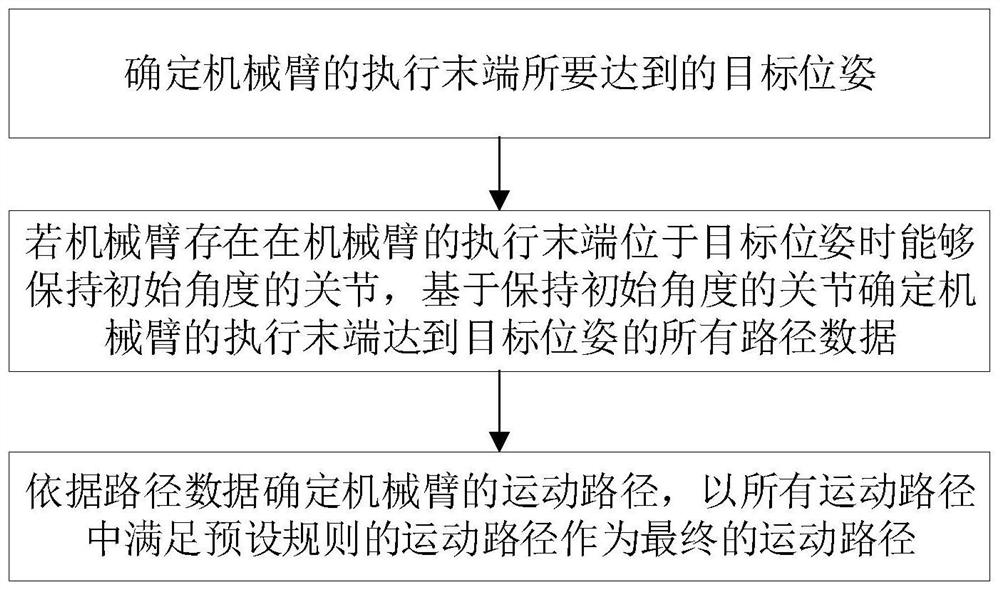

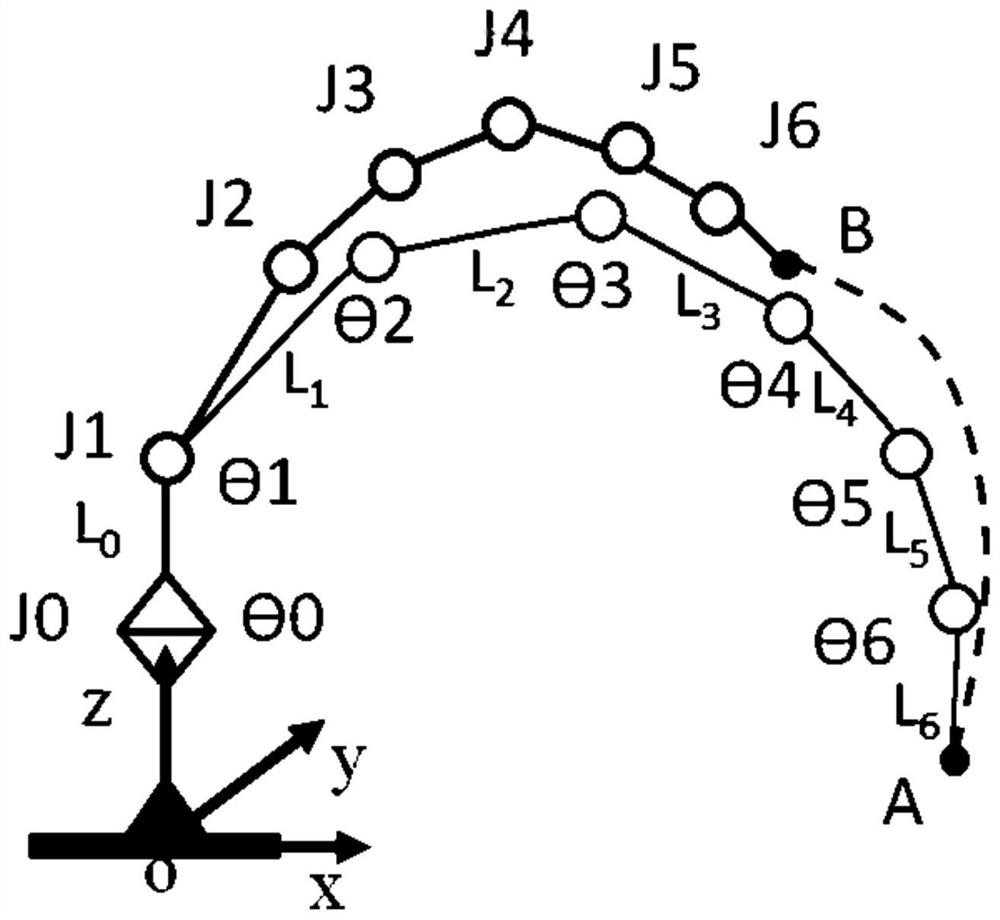

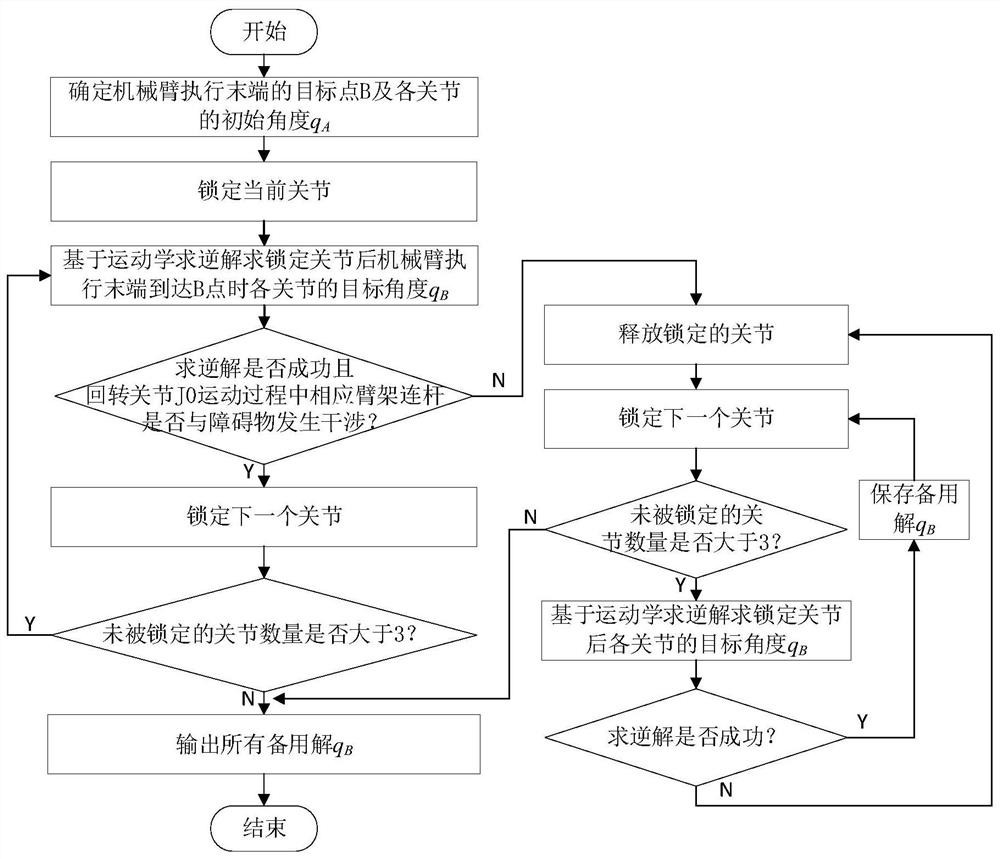

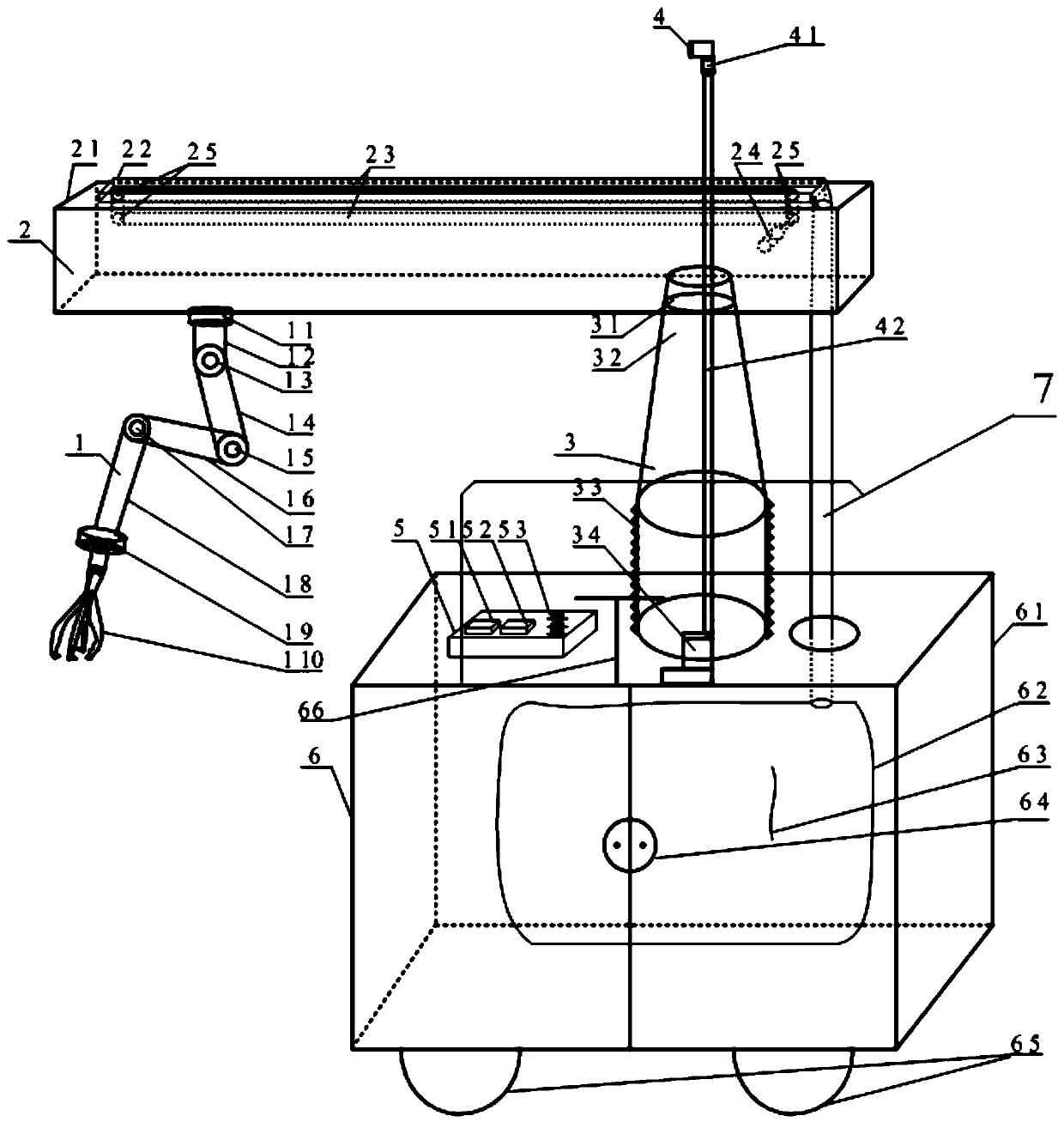

Redundant-degree-of-freedom mechanical arm path planning method and device and engineering machinery

ActiveCN113799120AReduce the number of jointsReduce jitterProgramme-controlled manipulatorControl engineeringLocking joints

The invention provides a redundant-degree-of-freedom mechanical arm path planning method and device and engineering machinery, and relates to the technical field of mechanical arm path planning. The redundant-degree-of-freedom mechanical arm path planning method comprises the steps of determining a target pose to be reached by an execution tail end of a mechanical arm; determining joints which can keep the initial angles when the execution tail end of the mechanical arm is located at the target pose in all joints of the mechanical arm; determining path data of the execution tail end of the mechanical arm reaching the target pose based on the determined joints, specifically, the path data comprise the target angles of all the joints of the mechanical arm, and the target angle of at least one joint is equal to the initial angle of the joint; and determining the motion paths of the mechanical arm according to the path data, and making the motion path meeting the preset rule in the motion paths as the final motion path of the mechanical arm. According to the redundant-degree-of-freedom mechanical arm path planning method, the motion path of the mechanical arm is planned based on the locked joints, and thus the shaking of the execution tail end of the mechanical arm in the motion process can be effectively reduced.

Owner:ZOOMLION HEAVY IND CO LTD

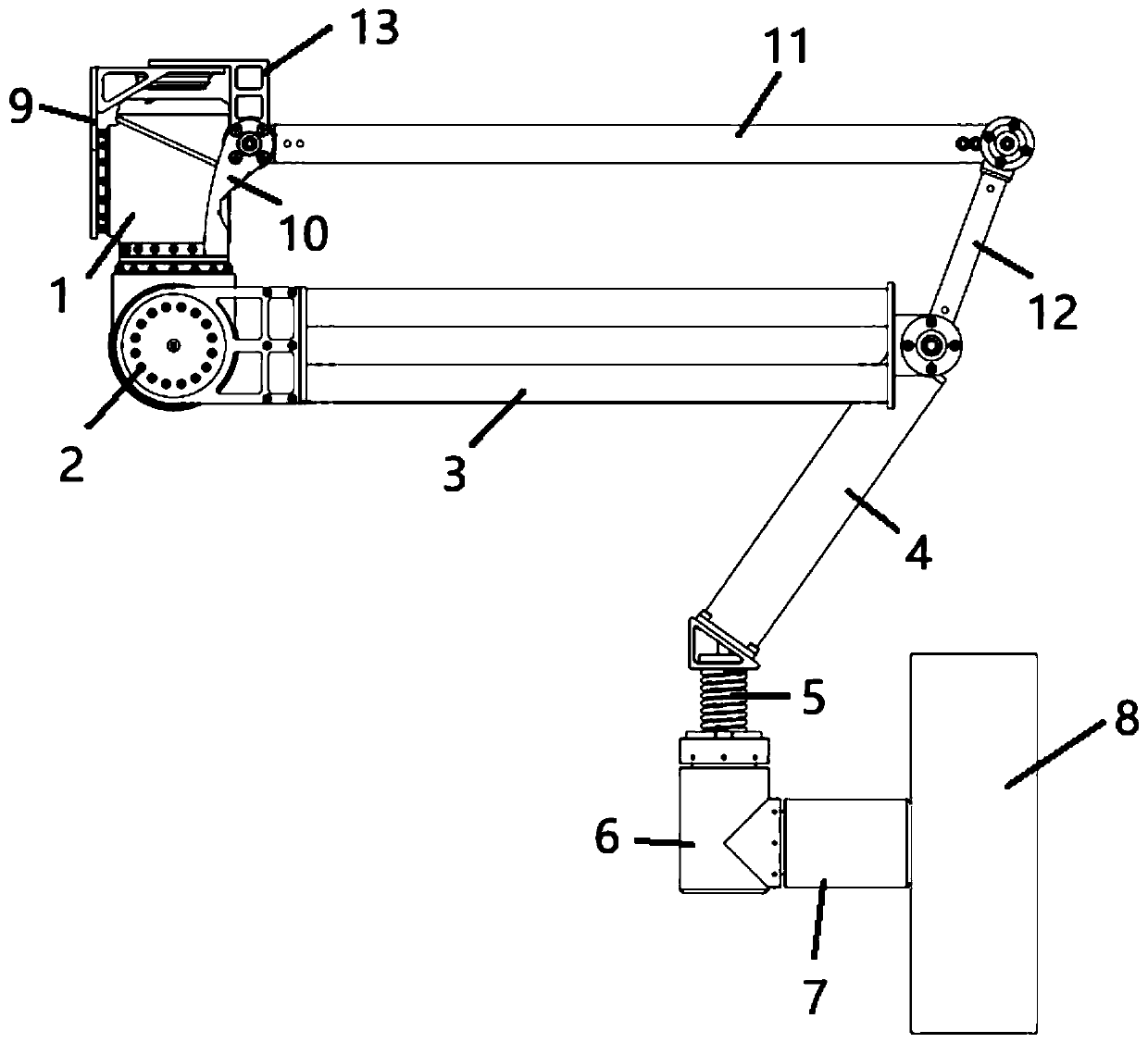

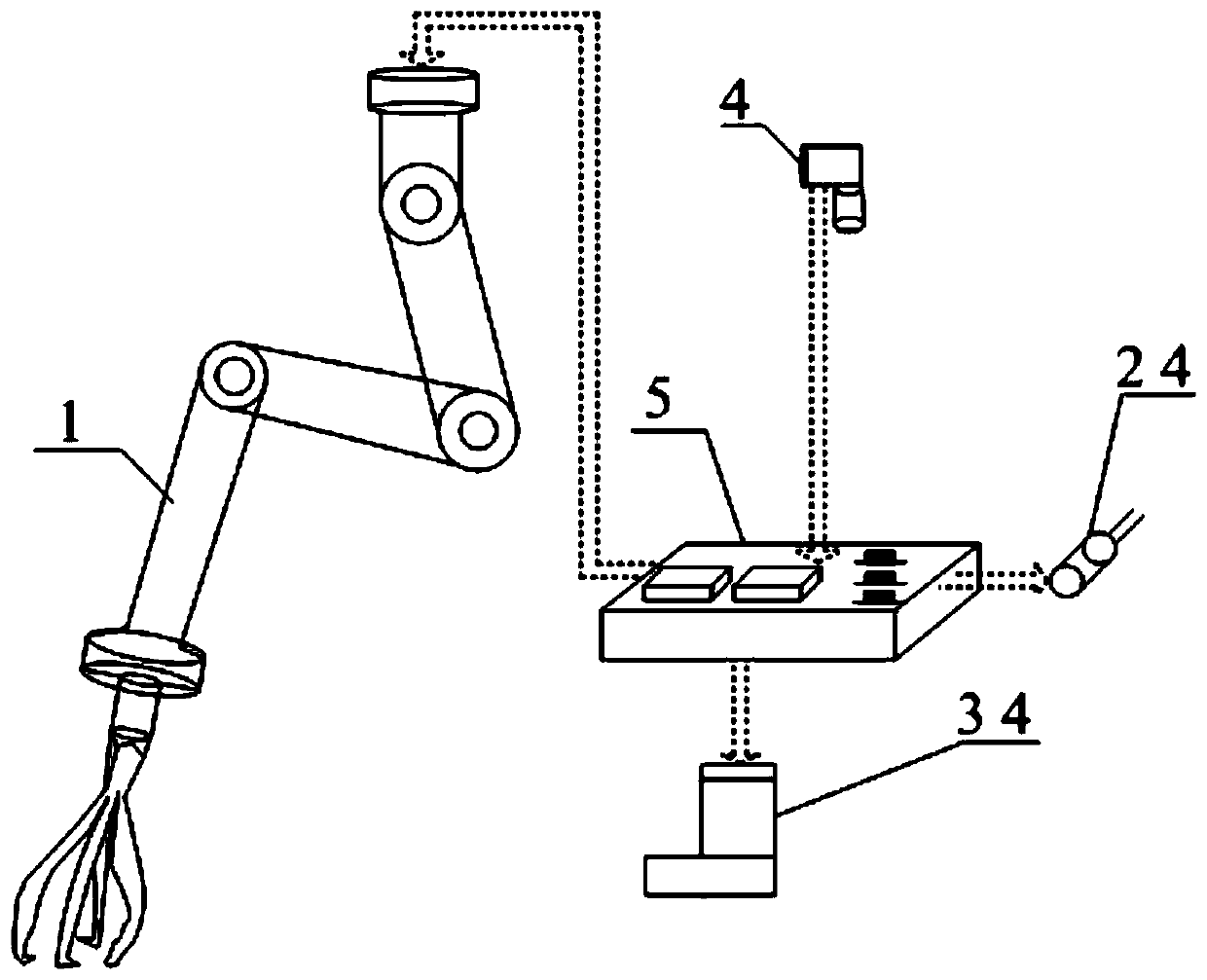

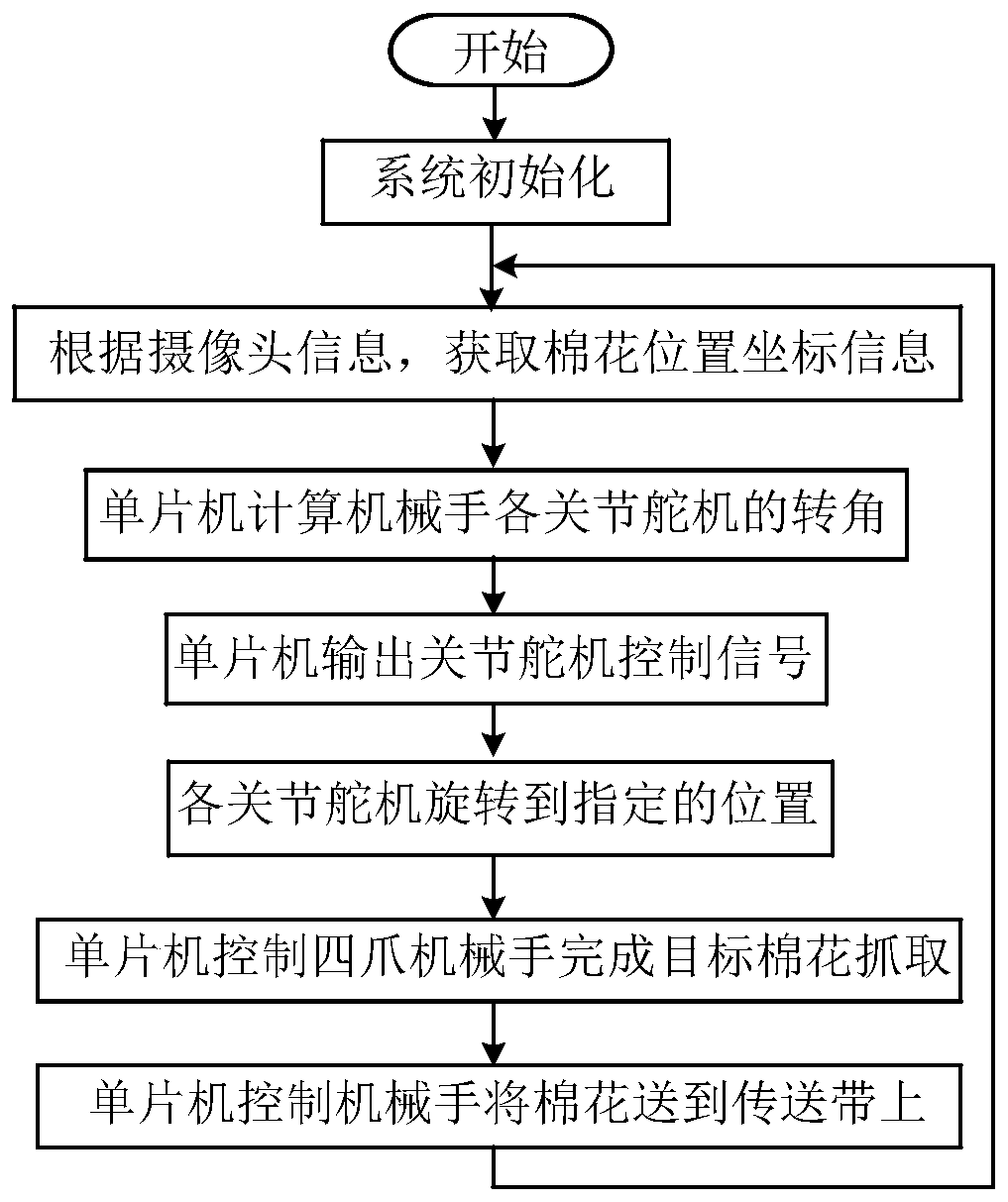

Intelligent cotton picker and control method thereof

The invention discloses an intelligent cotton picker and a control method thereof. The intelligent cotton picker comprises a cotton picking manipulator, a tower arm, a tower pole, a camera shooting component and a cotton receiving component; the tower pole is installed on the top of the cotton receiving component, the tower arm is installed on the top of the tower pole, the cotton picking manipulator is installed at the bottom of the other end of the tower arm, the camera shooting component penetrates through the tower arm to be fixed to the tower pole, a single-chip microcomputer control component is arranged at one end of the top of the cotton receiving component, and a cotton sampling hose is arranged at the other end of the top of the cotton receiving component. The invention further discloses the intelligent cotton picker control method. The whole system is simple in structure and easy to control, the joint number and arm length of the cotton picking manipulator are reduced, the control difficulty is reduced, the complexity of a control program is lowered, the cotton picking speed is increased, and the cotton picking efficiency is improved.

Owner:YANCHENG ZHENGBANG ENVIRONMENTAL PROTECTION TECH +1

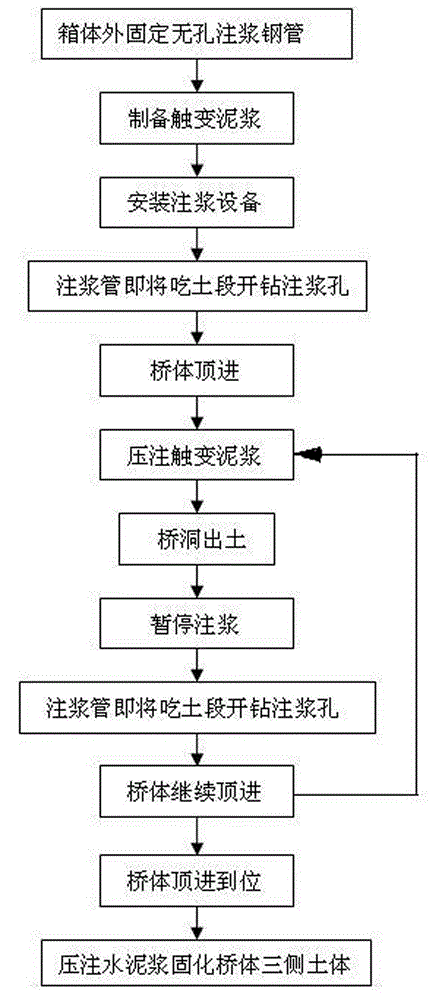

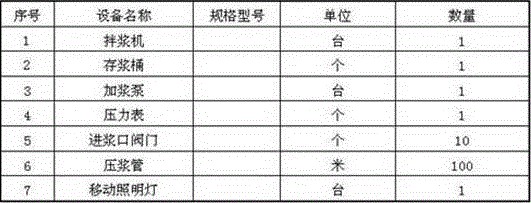

Construction method for following up and injecting thixotropic slurry outside box body in pipe roofing supporting and pushing construction

The invention discloses a construction method for following up and injecting thixotropic slurry outside a box body in pipe roofing supporting and pushing construction, and belongs to the technical field of bridge and culvert construction. The method comprises the following steps: fixing a slurry injection pipe without holes outside a box body; preparing thixotropic slurry; mounting slurry ejection equipment; drilling an slurry injection hole in a soil immersion section of the slurry ejection pipe; jacking the box body; performing pressure injection on the thixotropic slurry; discharging soil of a culvert; suspending slurry injection; drilling the slurry injection hole in the soil immersion section of the slurry ejection pipe, continuously jacking the box body, and circulating the subsequent processes till the box body is jacked to a proper position; performing pressure injection on cement past to solidify the soil bodies on three sides of the box body. The method solves the problems that in the prior art, the quantity of slurry injection pipe connectors is large, a large quantity of conveying pipes are required, the construction technology is relatively complex, the construction period is relatively prolonged, and the construction cost is high.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

Processing device for yarn wrapping

InactiveCN107022821AQuality improvementReduce the frequency of changing outer yarn reelsContinuous wound-up machinesYarnYarnGuide wires

The invention discloses a processing device for yarn wrapping. The device comprises a rack, a feeding roller, a drafting roller, a rotation shaft, a rotation disk, a supporting disk, a protective cover and a tensioner, wherein a core yarn coiling drum is disposed on the supporting disk and located in the protective cover; core yarns pass through the tensioner and then penetrates a third yarn guide hole; outer wrapping yarns pass through the feeding roller, then successively pass the center hole of the rotation shaft, a first yarn guide hole and second yarn guide hole and finally wrap the core yarns at the third yarn guide hole; and the wrapped yarns formed after wrapping are drafted by the drafting roller. Through application of the invention, quality of the wrapped yarns is increased, and continuous production is promoted.

Owner:DONGHUA UNIV

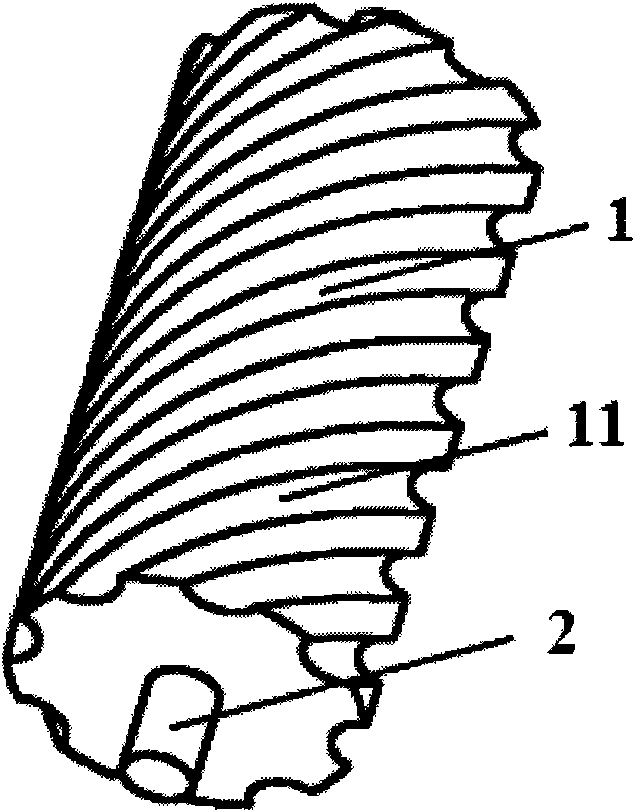

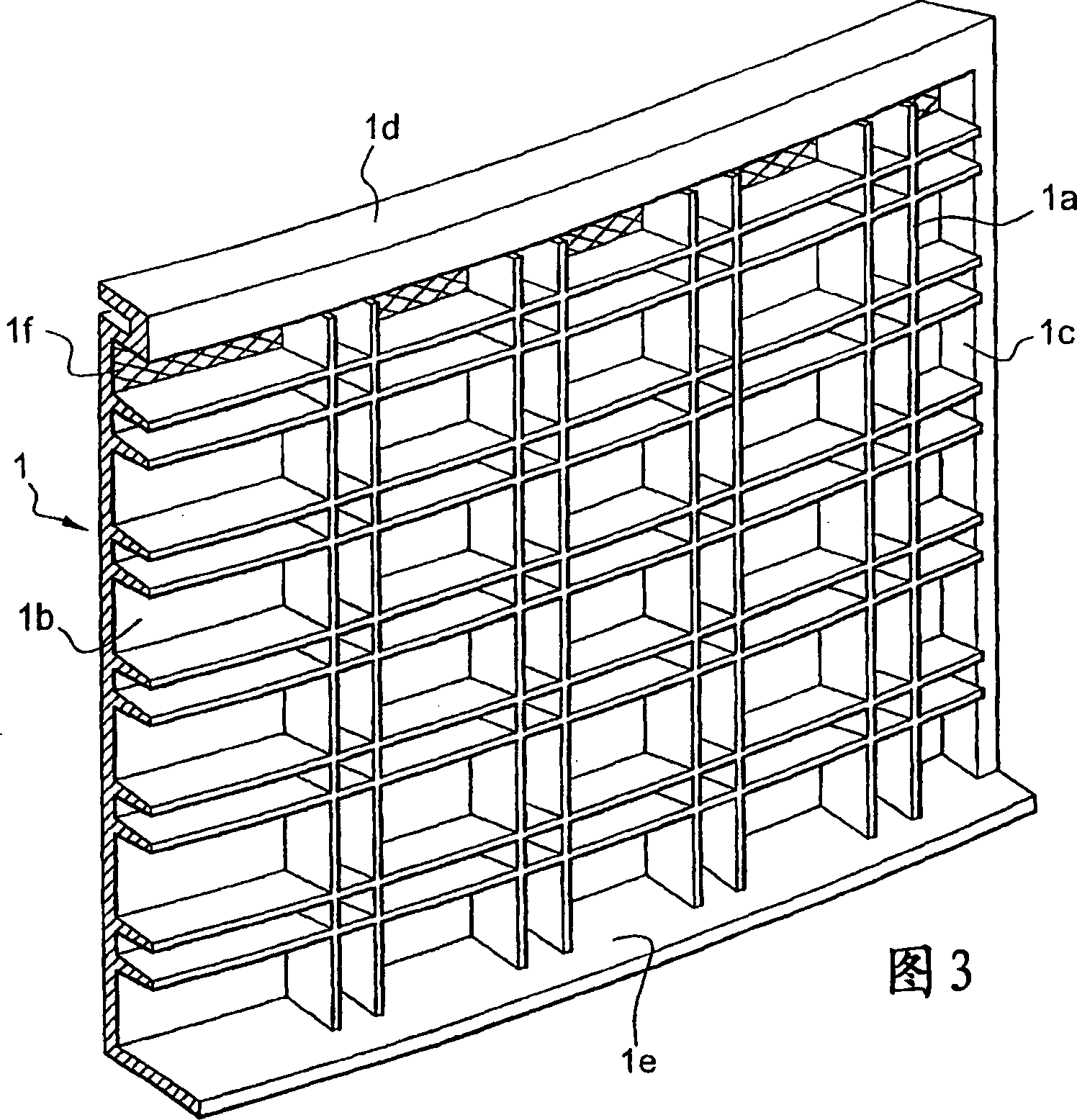

Panel for the production of a swimming pool

InactiveCN1809675AIncreasing the thicknessReduce the number of jointsGymnasiumSwimming poolsPlastic materialsEngineering

The invention relates to a panel which is used to produce a swimming pool. The inventive panel is obtained using a method involving the compression injection of a plastic material, in particular, a recycled plastic material. The panel is provided with an essentially flat or curved quadrangular shape which is perfectly rectilinear along all of the dimensions thereof. Moreover, at least one of the faces of said panel is provided with stiffening ribs (1a).

Owner:PISCINES DESJOYAUX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com