Technical scheme for grounding of single-core cable especially for high-speed railway

A single-core cable, high-speed railway technology, applied in electrical components, circuit devices, connecting contact materials, etc., can solve the problem of metal layer carrying very large short-circuit current or circulating current, short laying distance of single-circuit cable lines, difficult on-site construction, etc. problems, to ensure the current carrying capacity and service life, improve safety and stability, and reduce the number of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

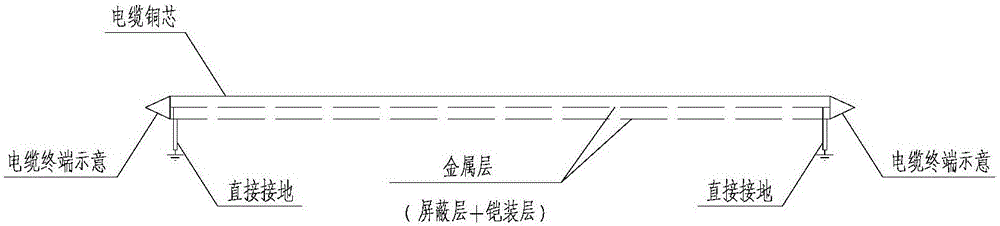

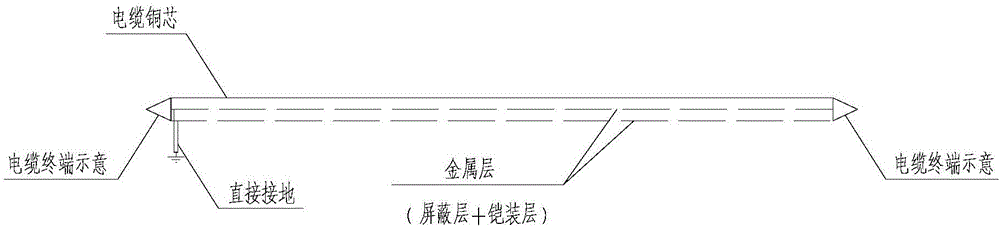

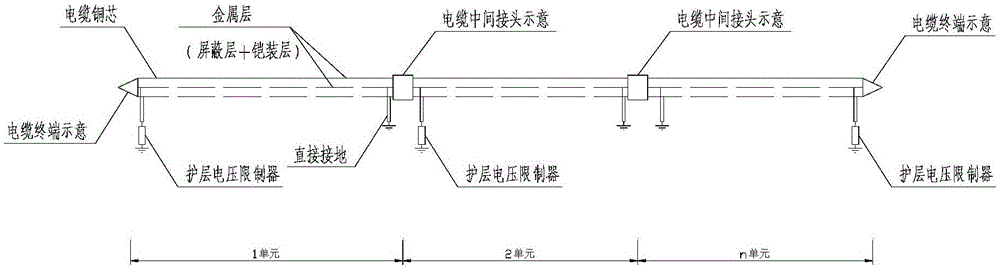

[0024] A grounding technology solution for single-core cables dedicated to high-speed railways, which is mainly applicable to 27.5kV single-core cables. According to the characteristics of high-speed railway traction power supply systems, combined with the simulation results of system models built using electromagnetic transient analysis software (PSCAD / EMTDC), cable According to the structural characteristics and engineering practice, the 27.5kV special cable for each circuit is properly divided into several grounding units, and the cable length of each grounding unit is 50m, and the metal sheath of the intermediate joint is cancelled, so as to realize the independence of the grounding unit. One end of each grounding unit is directly grounded, and the other end is grounded with a sheath voltage limiter.

Embodiment 2

[0026] A grounding technology solution for single-core cables dedicated to high-speed railways, which is mainly applicable to 27.5kV single-core cables. According to the characteristics of high-speed railway traction power supply systems, combined with the simulation results of system models built using electromagnetic transient analysis software (PSCAD / EMTDC), cable According to the structural characteristics and engineering practice, the 27.5kV special cable for each circuit is properly divided into several grounding units, and the cable length of each grounding unit is 300m, and the metal sheath of the intermediate joint is cancelled, so as to realize the independence of the grounding unit. One end of each grounding unit is directly grounded, and the other end is grounded with a sheath voltage limiter.

Embodiment 3

[0028] A grounding technology solution for single-core cables dedicated to high-speed railways, which is mainly applicable to 27.5kV single-core cables. According to the characteristics of high-speed railway traction power supply systems, combined with the simulation results of system models built using electromagnetic transient analysis software (PSCAD / EMTDC), cable According to the structural characteristics and engineering practice, the 27.5kV special cable for each circuit is properly divided into several grounding units, the cable length of each grounding unit is 450m, and the metal sheath of the intermediate joint is canceled to achieve the independence of the grounding unit. One end of each grounding unit is directly grounded, and the other end is grounded with a sheath voltage limiter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com