Wire reeling, unreeling and arranging device with multiple connected trays

A cable arrangement device and concatenated technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problem of limited height and distance of cable arrangement, limited loading capacity, large floor space, etc. problems, to achieve the effect of eliminating cable stress concentration, avoiding cross crimping, and reducing the number of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

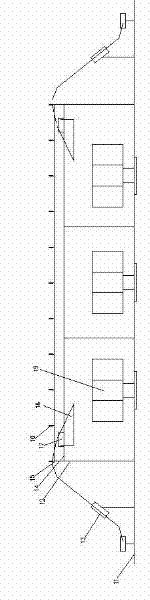

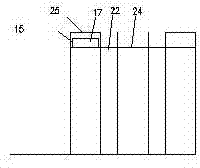

[0021] A multi-connected tray receiving, releasing, and cable arrangement device, including a base 11, a traction device 13, a column 12, a platform 14, a mobile trolley 17, an automatic cable arrangement device 18 and a tray 19, and the platform 14 is fixed on the platform through the column 12 On the base 11, a tray 19 for storing cables is set below the platform 14. The number of the trays 19 is equal to two, and the top of the platform 14 has a through wire slot 24, and the wire slot is located on the center line of the platform and connected to a plurality of trays 19. The connecting lines in the center are parallel, and a mobile trolley 17 is also set on the platform 14, which can move on the platform 14, and an automatic cable arrangement 18 for arranging lines is arranged on the mobile trolley 17, and the automatic arrangement 18 Including foot joint 26, screw lifting mechanism 27, cable arm 29 and automatic cable bogie 30, screw lifting mechanism 27 is fixed on the mob...

Embodiment 2

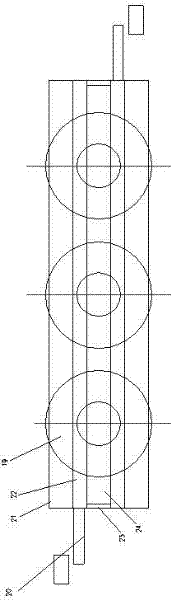

[0025]A multi-connected tray receiving, releasing, and cable arrangement device, including a base 11, a traction device 13, a column 12, a platform 14, a mobile trolley 17, an automatic cable arrangement device 18 and a tray 19, and the platform 14 is fixed on the platform through the column 12 On the base 11, a tray 19 for storing cables is arranged below the platform 14. The number of the trays 19 is equal to three, and the top of the platform 14 has a through wire slot 24, and the wire slot is located on the center line of the platform and connected with a plurality of trays 19. The connecting lines in the center are parallel, and a mobile trolley 17 is also set on the platform 14, which can move on the platform 14, and an automatic cable arrangement 18 for arranging lines is arranged on the mobile trolley 17, and the automatic arrangement 18 Including foot joint 26, screw lifting mechanism 27, cable arm 29 and automatic cable bogie 30, screw lifting mechanism 27 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com