Patents

Literature

426results about How to "Meet normal production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

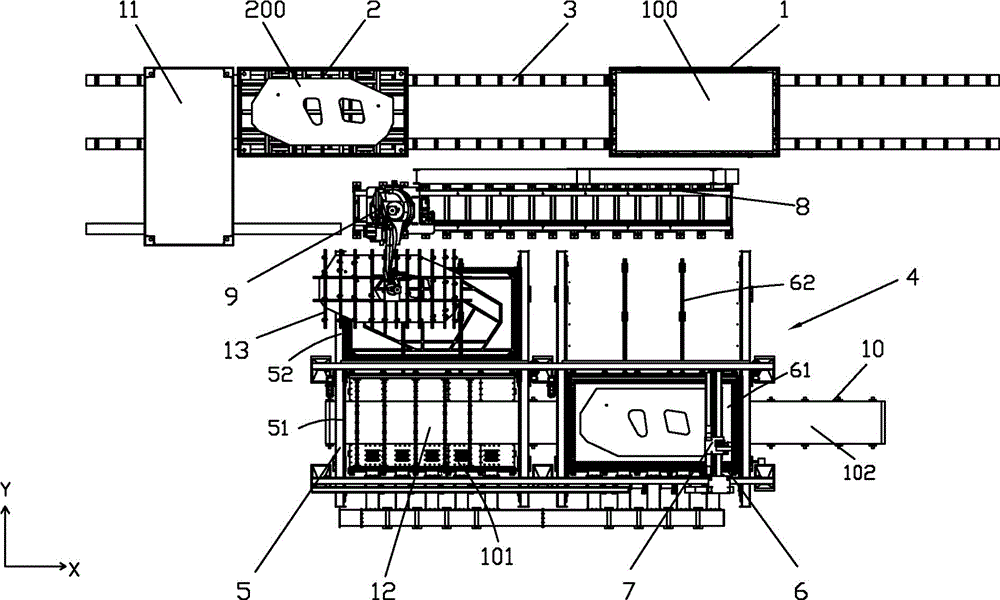

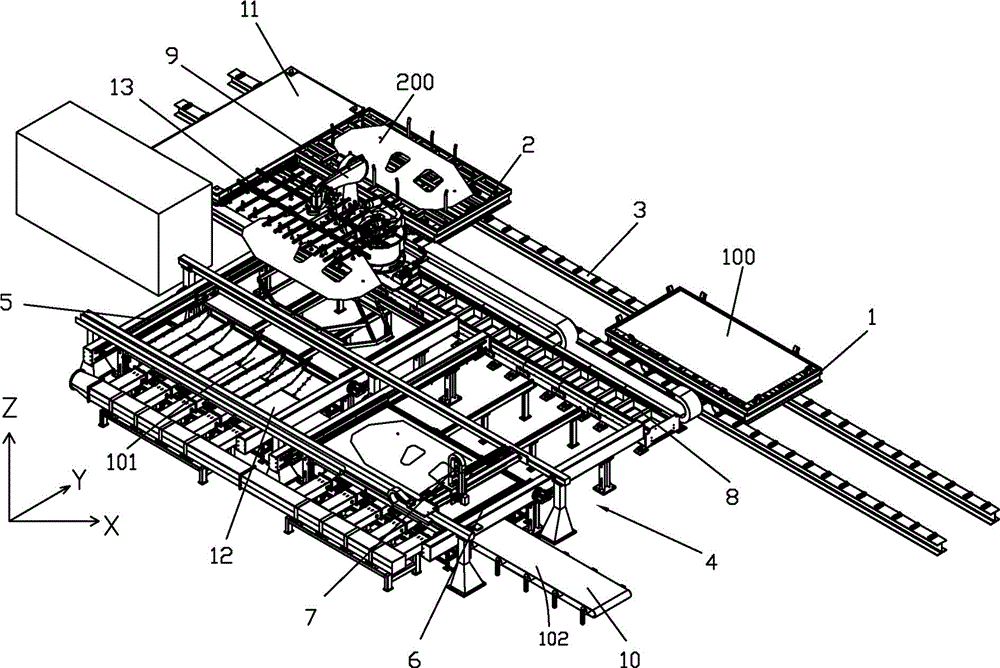

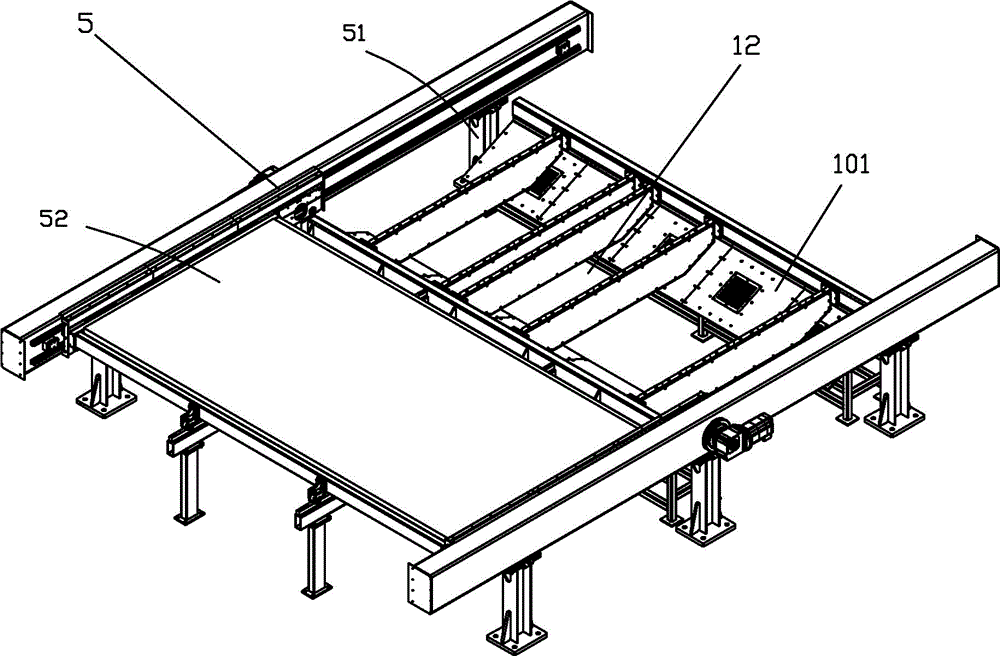

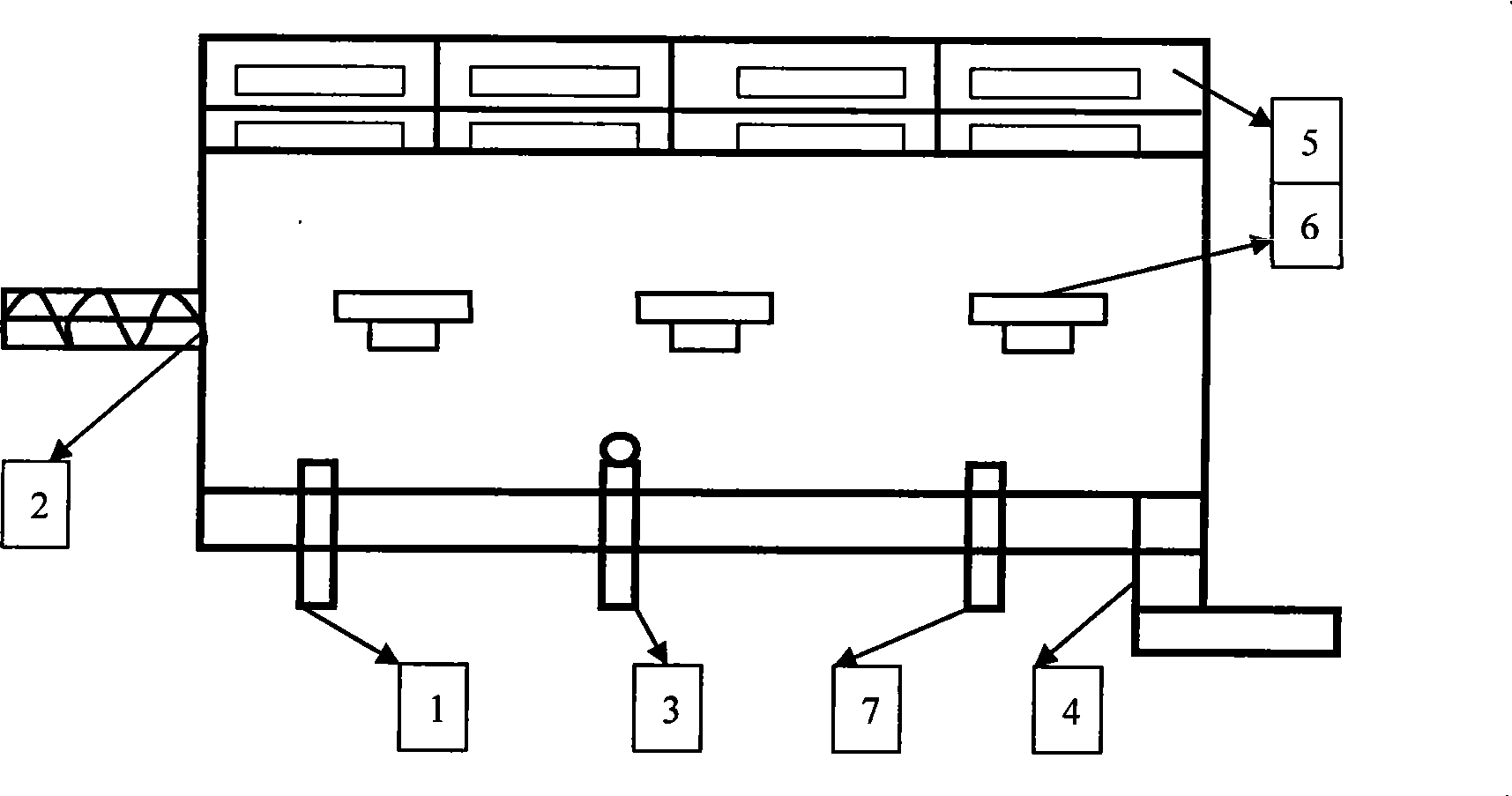

Metal plate feeding, discharging and cutting method and system

ActiveCN103600171AChange the cutting method and systemLow costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

A metal plate feeding, discharging and cutting method and system comprises a group material trolley, a sheet material trolley, a cutting working unit, a moving and stacking robot and a waste material conveying device. The group material trolley and the sheet material trolley are arranged on a guide track. The cutting working unit is arranged on one side of the guide track and comprises a first fast moving table and a second fast moving table which are arranged in parallel and further comprises a laser cutting head. The two fast moving tables are perpendicular to the guide track and provided with cutting positions and material waiting positions. The laser cutting head crosses two cutting positions through the guide track. The material waiting positions correspond to the group material trolley and the sheet material trolley and are arranged on one side of the guide track. The moving and stacking robot is arranged between the cutting working unit and the guide track of the group material trolley and the sheet material trolley. An external shaft of the robot is parallel to the trolley guide track and crosses the material waiting positions of the two fast moving tables of the cutting working unit. The waste material conveying device is arranged below the two cutting positions of the cutting working unit. By means of the method and system, use efficiency of materials can be effectively improved, production and machining range is further expanded, and the method and system is especially suitable for production of small-batch trolley models and trial production of new models.

Owner:BAOSHAN IRON & STEEL CO LTD +1

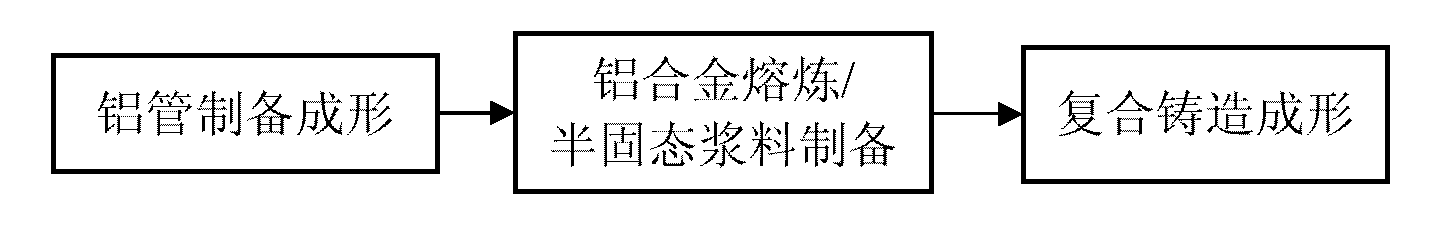

Composite casting method of aluminum cooling plate

InactiveCN102069172AAchieve near net shapeReduce consumptionSemiconductor/solid-state device detailsSolid-state devicesAviationMetallic materials

The invention relates to a composite casting method of an aluminum cooling plate, belonging to the field of metal materials. The composite casting method comprises the following steps: fixing industrial pure aluminum or an aluminum alloy pipe which is used as a cooling liquid passageway in a mold cavity; and then fully filling liquid or semi-solid aluminum alloy melt in the mold cavity and coagulating, so as to prepare the aluminum cooling plate. By using the composite casting method, the problem that when the aluminum alloy is casted in an aluminum tube, a casting is wasted because the aluminum tube is melted and deformed is solved, thereby achieving the near-net forming of the aluminum cooling plate, reducing the consumption of materials for subsequent processing procedures and improving the production efficiency. Because the aluminum tube and an aluminum cooling plate substrate are made of aluminum materials, thereby eliminating an electrochemical corrosion phenomenon; and the aluminum cooling plate can be integrally retrained or recycled, thereby reducing the waste of the material and lowering the production cost. The total density of the casting is the same as that of an aluminum casting, thus the casting can be applied to the fields of aviation, ships and the like which have strict requirements on the weights of parts.

Owner:UNIV OF SCI & TECH BEIJING

Anti-sliding glaze, anti-sliding brick and preparation method thereof

The invention discloses an anti-sliding glaze which contains the following chemical components by weight percent: 42.8%-48.5% of SiO2, 19.1%-22.8% of Al2O3, 0.1%-0.2% of Fe2O3, 7.0%-9.5% of CaO, 2.5%-5.2% of MgO, 2.1%-8.6% of Na2O, 0.9%-4.1% of K2O, 1.1%-3.3% of ZnO and 2.8%-6.2% of ZrO2. The invention also discloses an anti-sliding ceramic tile and a preparation method for the anti-sliding ceramic tile. The anti-sliding ceramic tile disclosed by the invention can achieve an excellent anti-sliding effect after a layer of anti-sliding glaze is applied to the surface of the anti-sliding ceramic tile, the technology is simple and the cost is low.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK

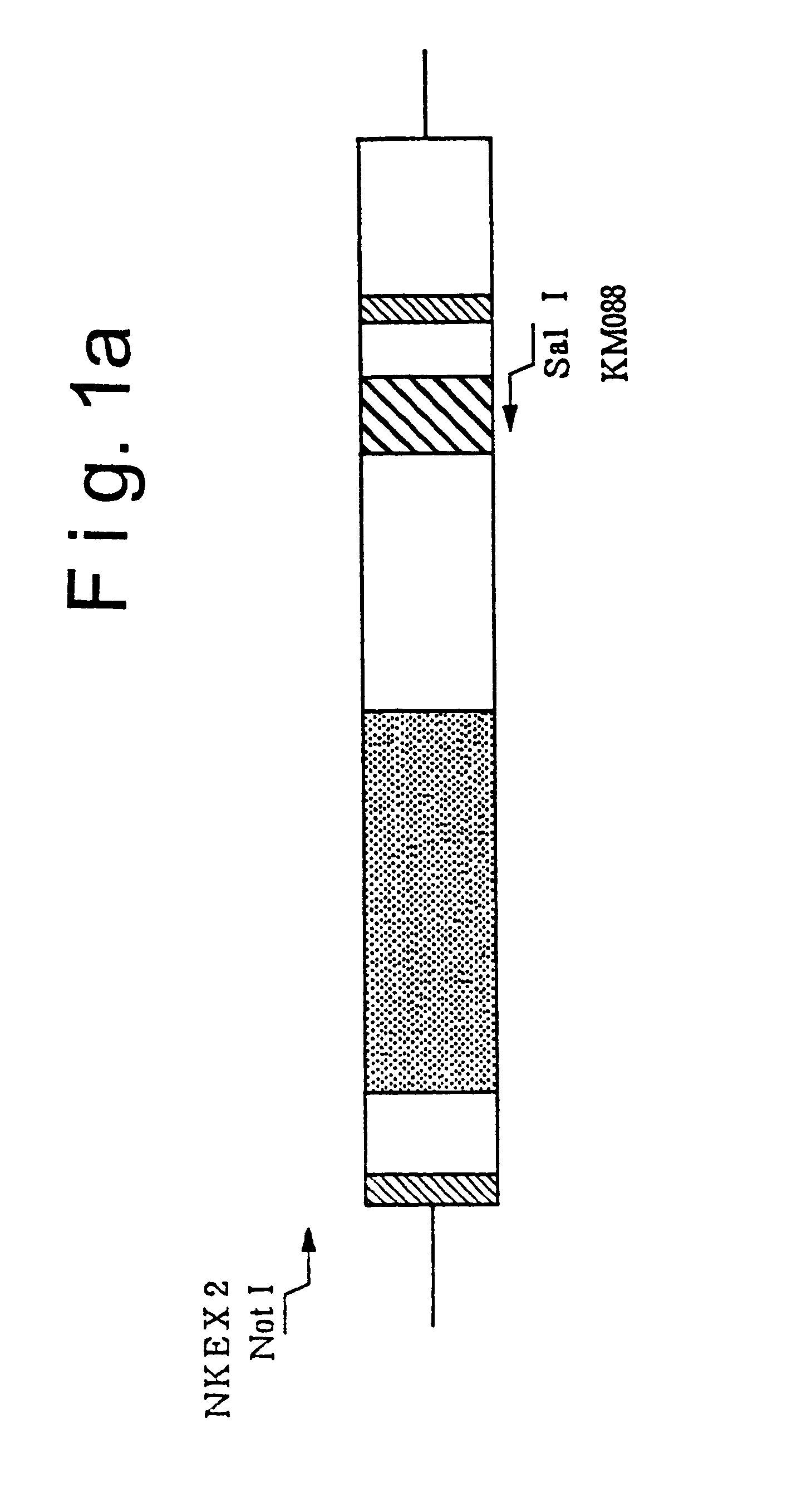

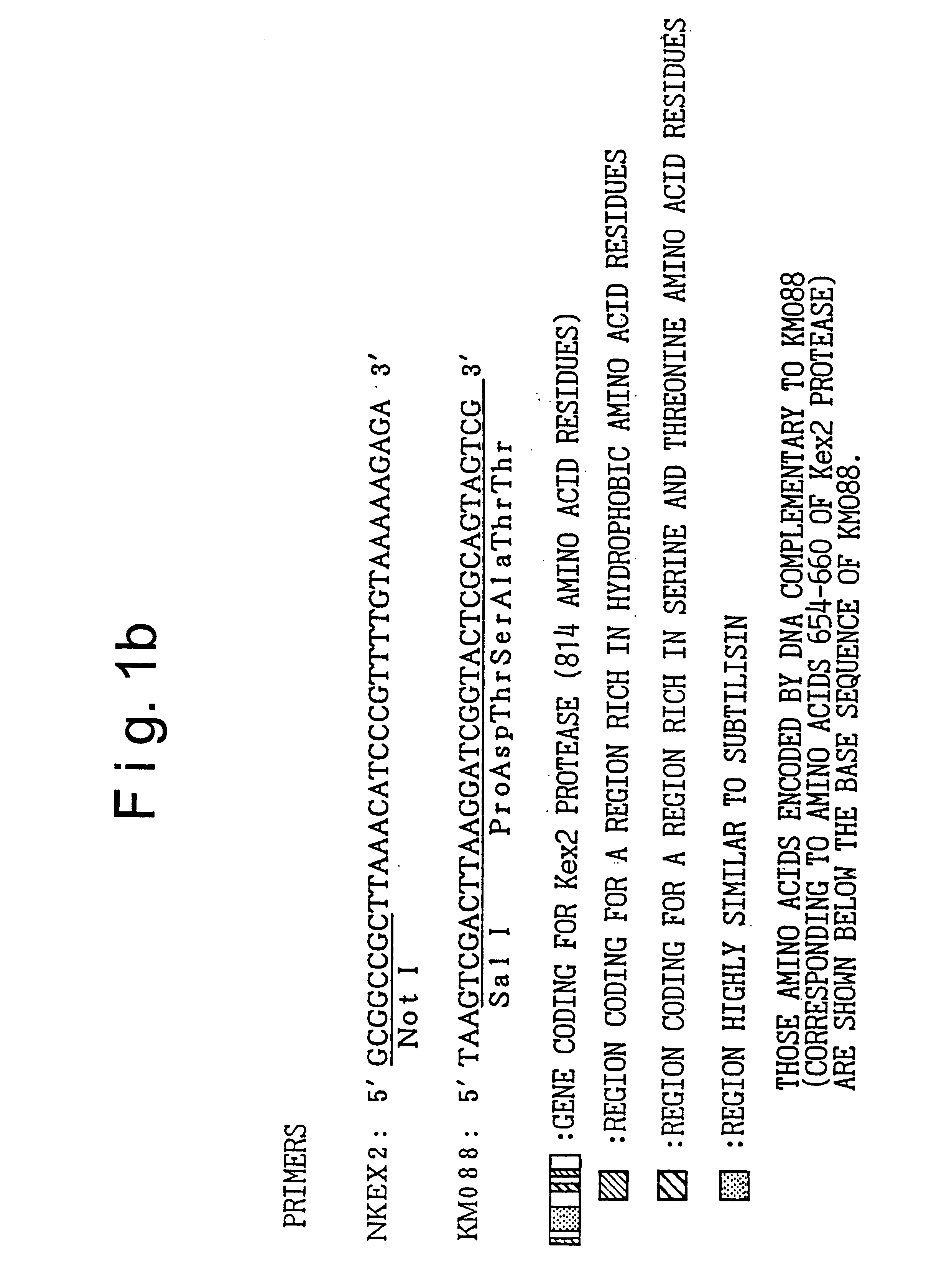

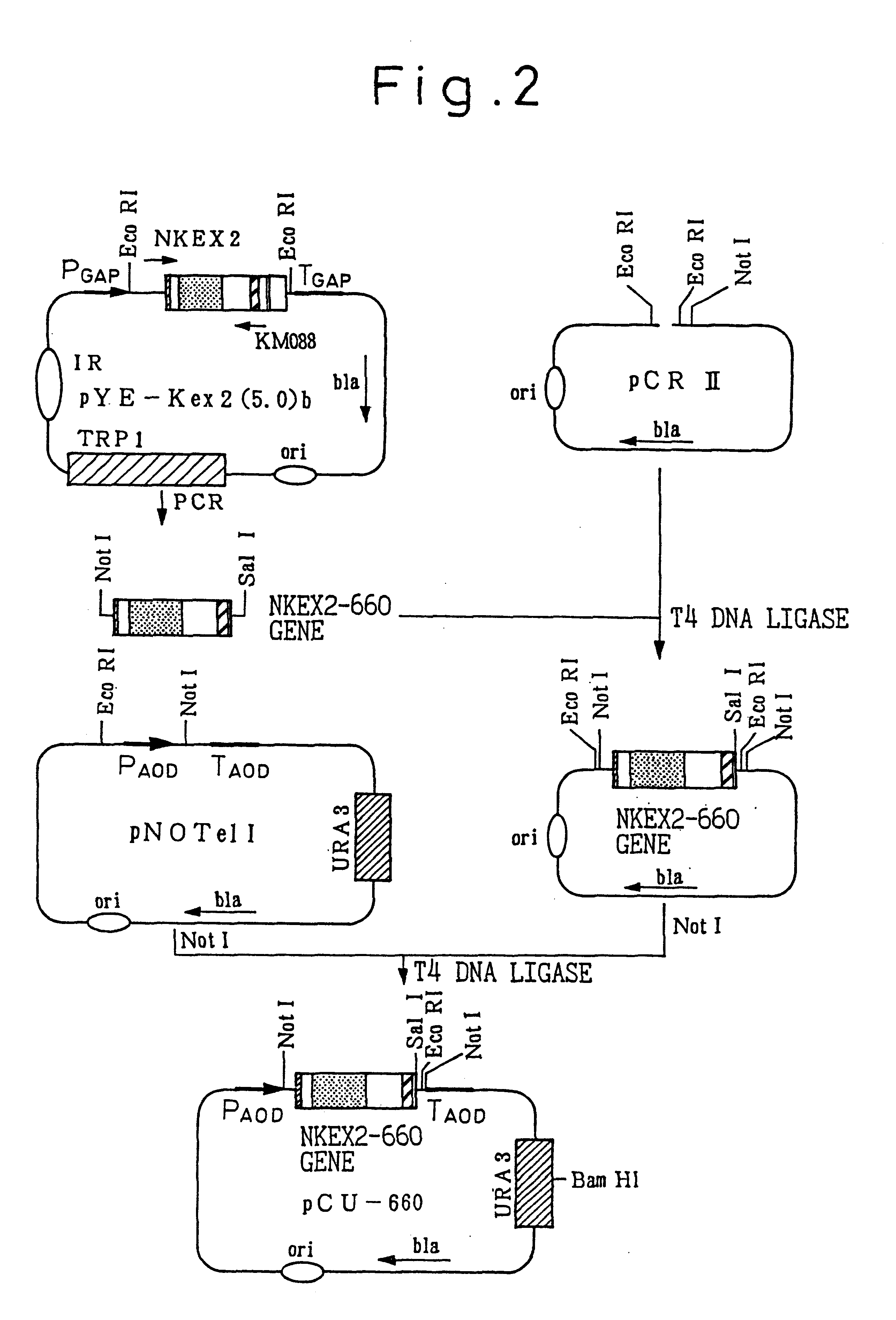

Method for culturing microorganisms having a methanol metabolic pathway

The present invention discloses a method for culturing microorganisms having a methanol metabolic pathway in which an expression unit is introduced that comprises a target gene linked downstream from a promoter that can be induced by methanol; wherein, during the culturing period, and including the period during which methanol is continuously or periodically added, the rate of addition is adjusted to a rate equal to or less than the maximum methanol consumption rate of said microorganisms.

Owner:ASUBIO PHARMA

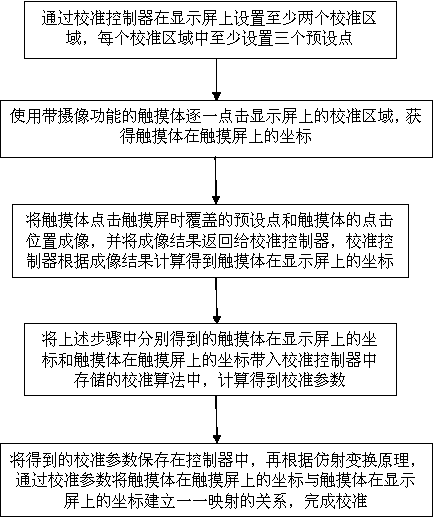

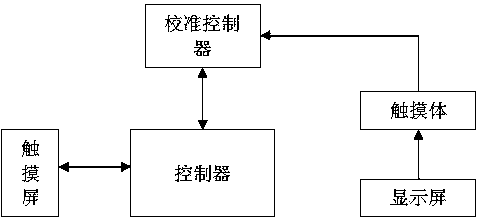

Calibration method of touch display screen

Owner:GENERAL TOUCH CO LTD

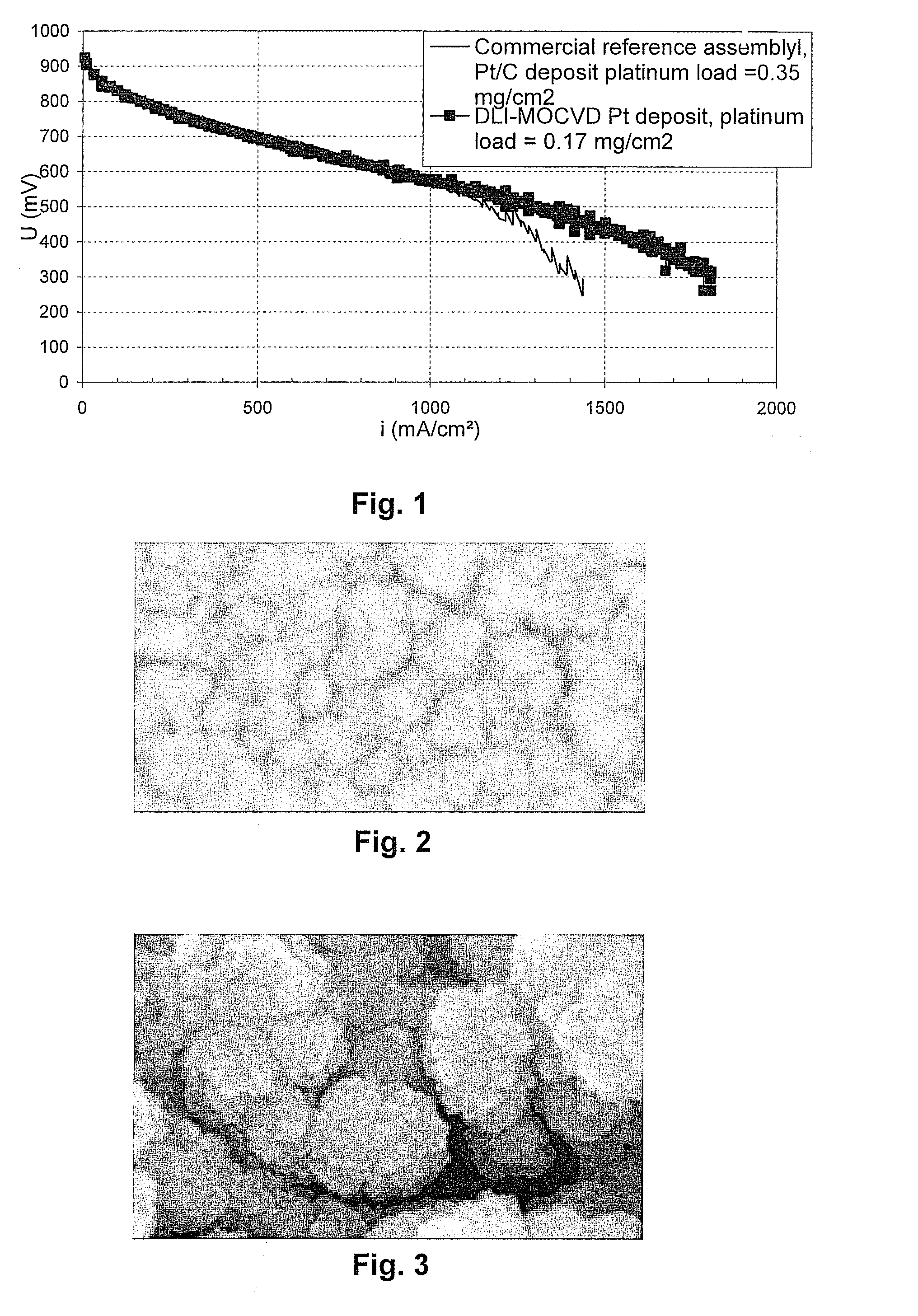

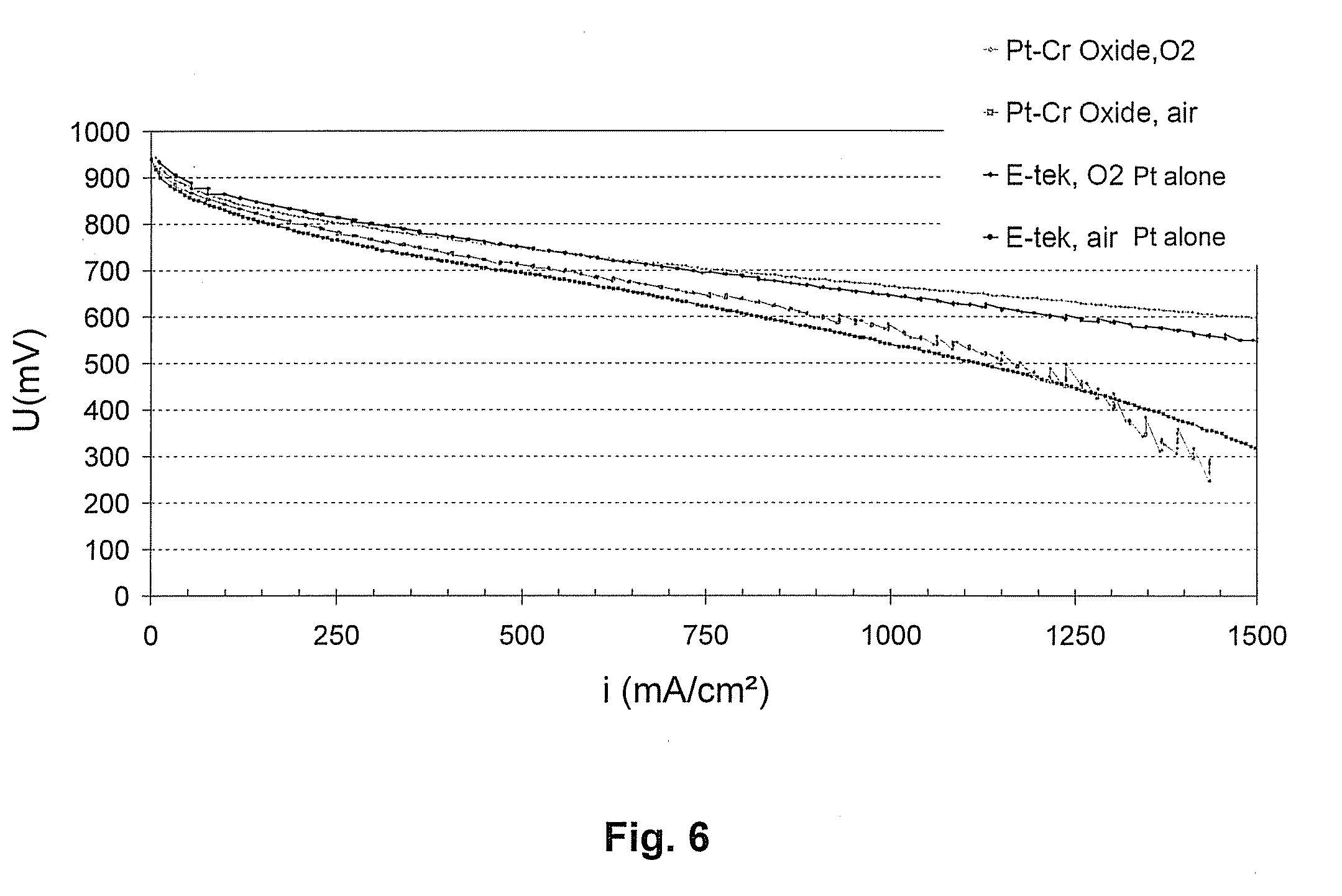

Cathode for electrochemical reactor, electrochemical reactor incorporating such cathodes and method for making said cathode

InactiveUS20090029236A1Improve electrochemical performanceReduce loadMaterial nanotechnologyFinal product manufactureElectrochemical responsePartial oxidation

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Aluminium foil material for tableware and manufacturing method of aluminium foil for tableware

InactiveCN101812616AHigh strengthReduce supersaturationMetal rolling arrangementsAluminum foilGrain growth

The invention relates to an aluminium foil material for tableware and a manufacturing method of aluminium foils for the tableware, belonging to the technical field of manufacture of aluminium alloy materials and the aluminium foils. The aluminium foil material comprises the following components in percentage by weight: 0.2-0.30% of Si, 1.40-1.50% of Fe, 0.05% of Cu, 0.50-0.60% of Mn, 0.05% of Mg, 0.01% of Cr, 0.05% of Zn, 0.05% of Ti, and the balance of Al, wherein the components are smelted into an alloy. The manufacturing method of the aluminium foils for the tableware comprises the following steps of: a, smelting; b, casting; c, uniform annealing; d, cold rolling; e, foil rolling; and f, finished product annealing. The invention can prevent an aluminium coil from generating grain growth during the uniform annealing and also has better machining property and easy rolling.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Copper-containing steel heating method and copper-containing steel produced by the same

The present invention discloses one kind of copper-containing steel and its heat treatment process. The copper-containing steel may be used in producing plate and shaped section. Its heat treatment process includes the following two steps: 1. heating copper-containing steel blank at 1000-1050 deg.c; and 2. heating to 1250-1290 deg.c within 30-90 min. The copper-containing steel after being rolled has no crack.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

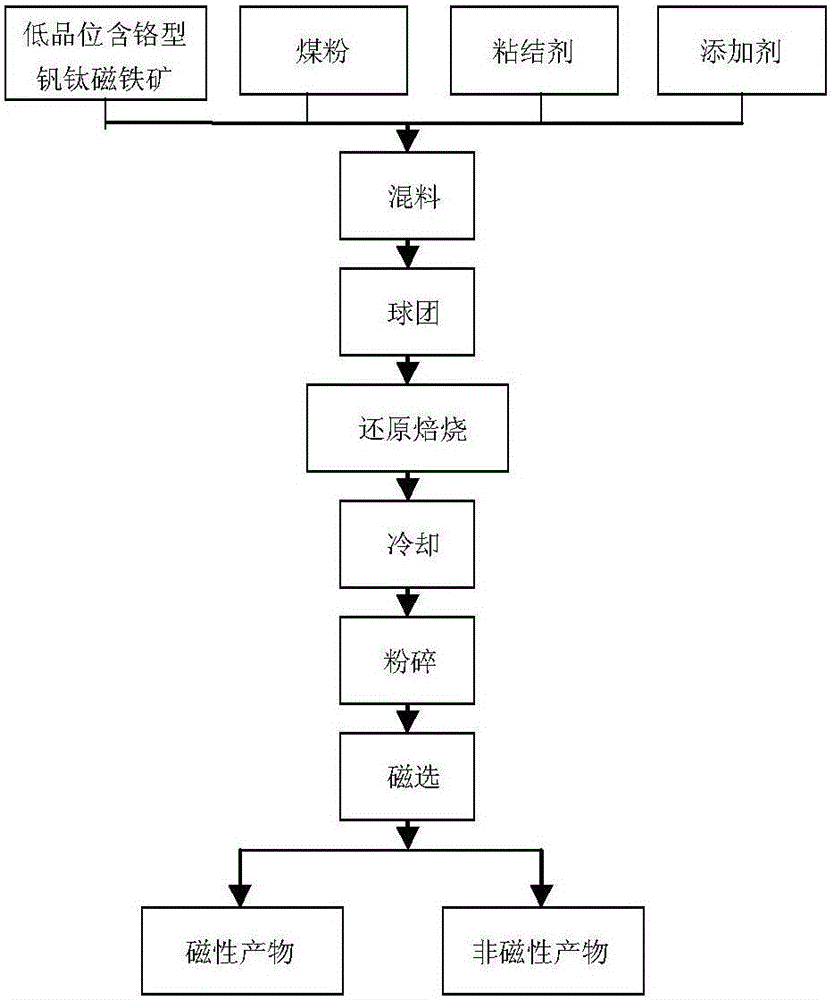

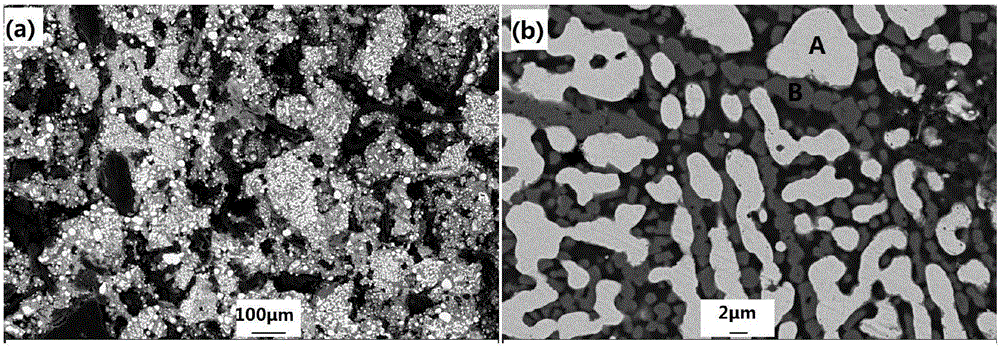

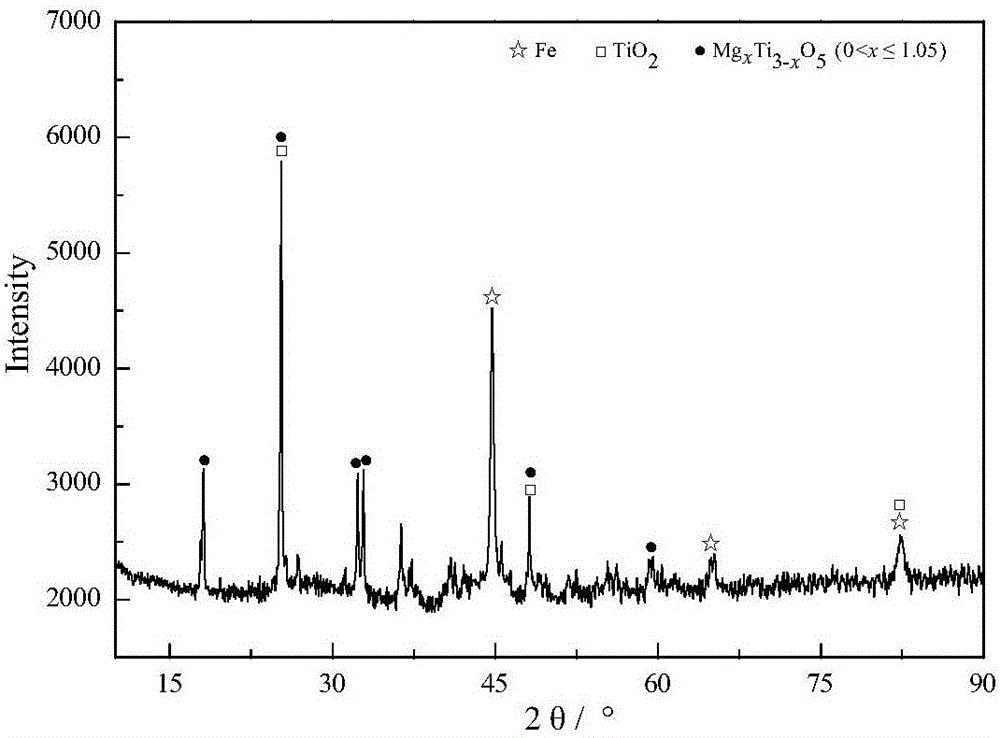

Magnetic separation method for low-grade chromium-containing vanadium titanium magnetite metalized pellet

The invention discloses a magnetic separation method for a low-grade chromium-containing vanadium titanium magnetite metalized pellet, belonging to the technical field of non-blast furnace smelting in comprehensive utilization methods of low-grade chromium-containing vanadium titanium magnetite powder. The method is carried out through the following steps of (1) mixing low-grade chromium-containing vanadium titanium magnetite powder, reduced pulverized coal, a binder and an additive by weighing; (2) preparing a pellet from the mixture, and drying; (3) carrying out coal-based pellet self-reduction high-temperature roasting on the dried pellet; (4) cooling the metalized pellet subjected to high-temperature roasting; and (5) smashing the cooled metalized pellet to obtain metalized pellet powder, and then, carrying out magnetic separation by using a magnetic separation tube to obtain an iron-enriched magnetic matter and titanium-enriched nonmagnetic matters. By using the method, the utilization ratios of strategic metal vanadium, titanium and chromium are maximized on the premise that the metallization ratio and iron recovery ratio for coal-based forced reduction of the low-grade chromium-containing vanadium titanium magnetite metalized pellet are increased.

Owner:NORTHEASTERN UNIV

Method for producing glucose and cellobiose using cellulose complex enzyme

InactiveCN101603065AIncrease saccharification rateSatisfy productionMicroorganism based processesFermentationFiberConcentrations glucose

A method for producing glucose and cellobiose using cellulose complex enzyme is the technology using the cellulose complex enzyme as a catalyst and realizing the high saccharification rate conversion of cellulose by adding cellulose enzyme activator at the optimized stirring speed. Glucose concentration can reach 150g / L after using cellulose enzymatic hydrolysis, and the method is a cellulose saccharification production technology with economic feasibility. With the technology used, low cost, low usage of enzyme and high saccharification rate can be realized, and the productions of cellulose alcohol and biochemical products (lactic acid, succinic acid and the like) are satisfied. In the whole technology, no beta-glucosaccharase is added additionally, no sugar concentrating device is added, and the technology is simple, the equipment cost is low and the industrialized prospect is good.

Owner:CHINA THREE GORGES UNIV

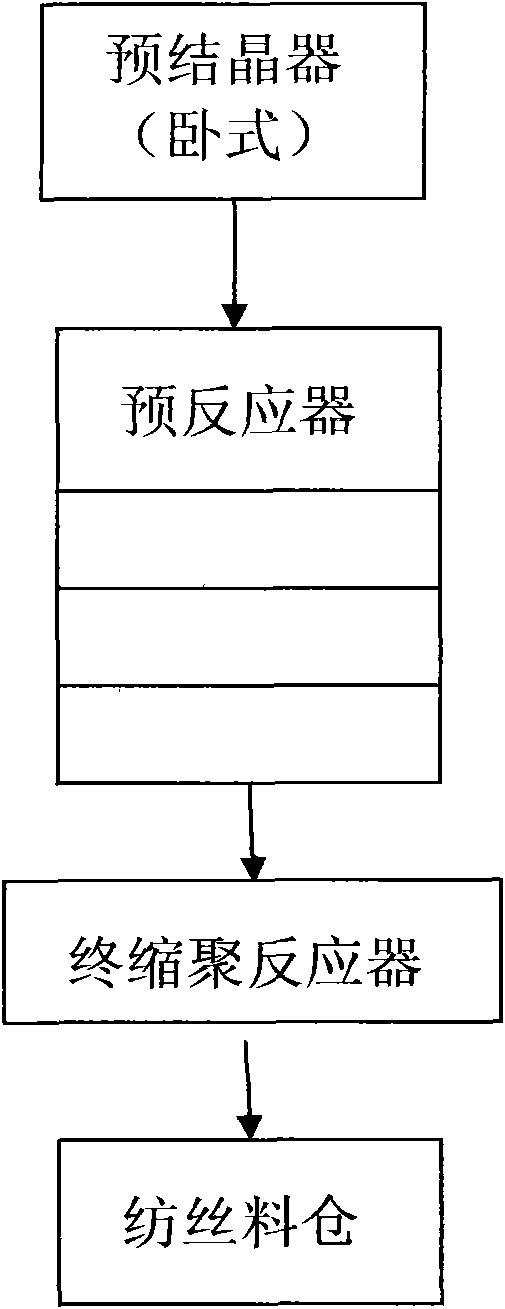

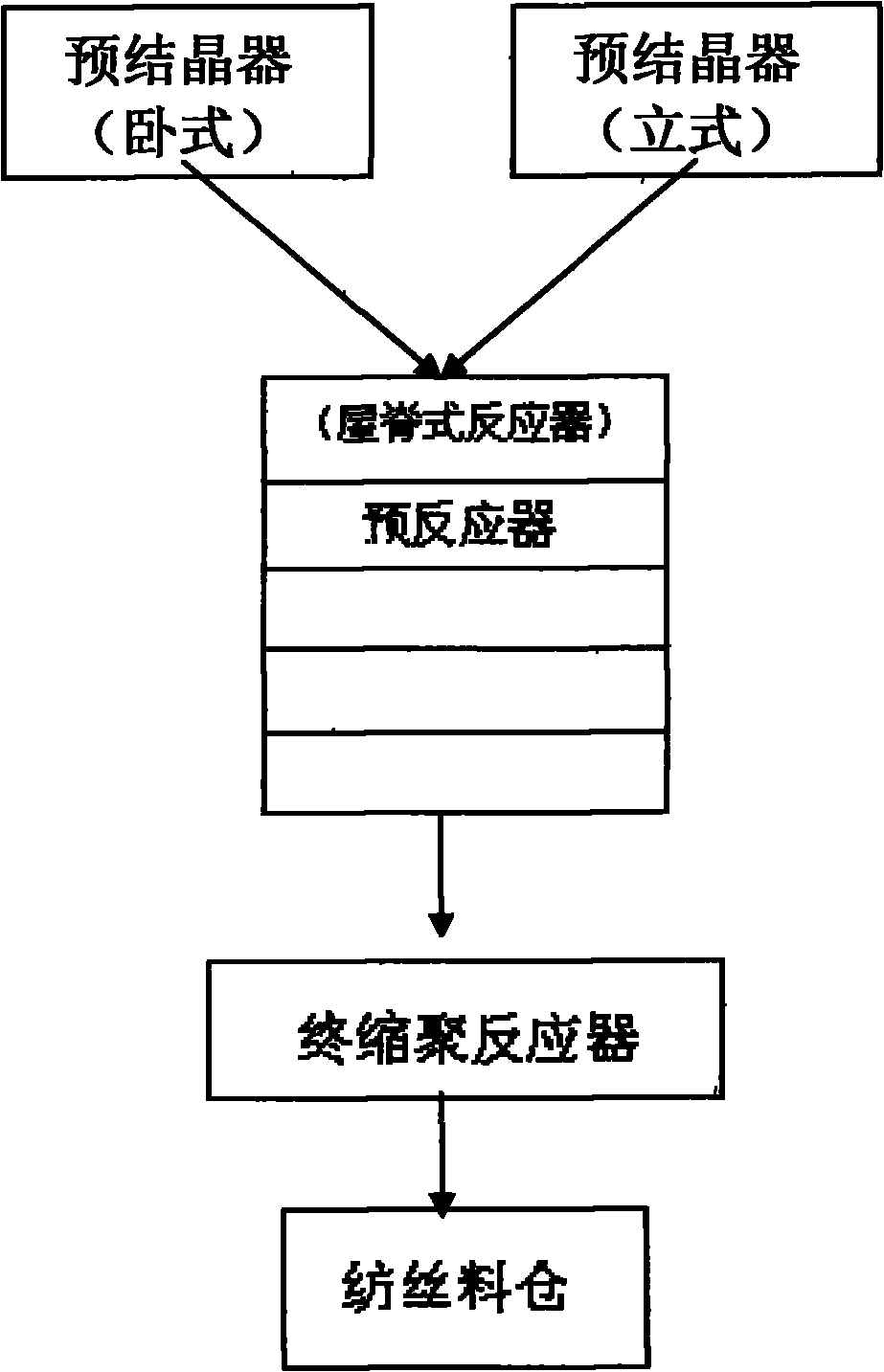

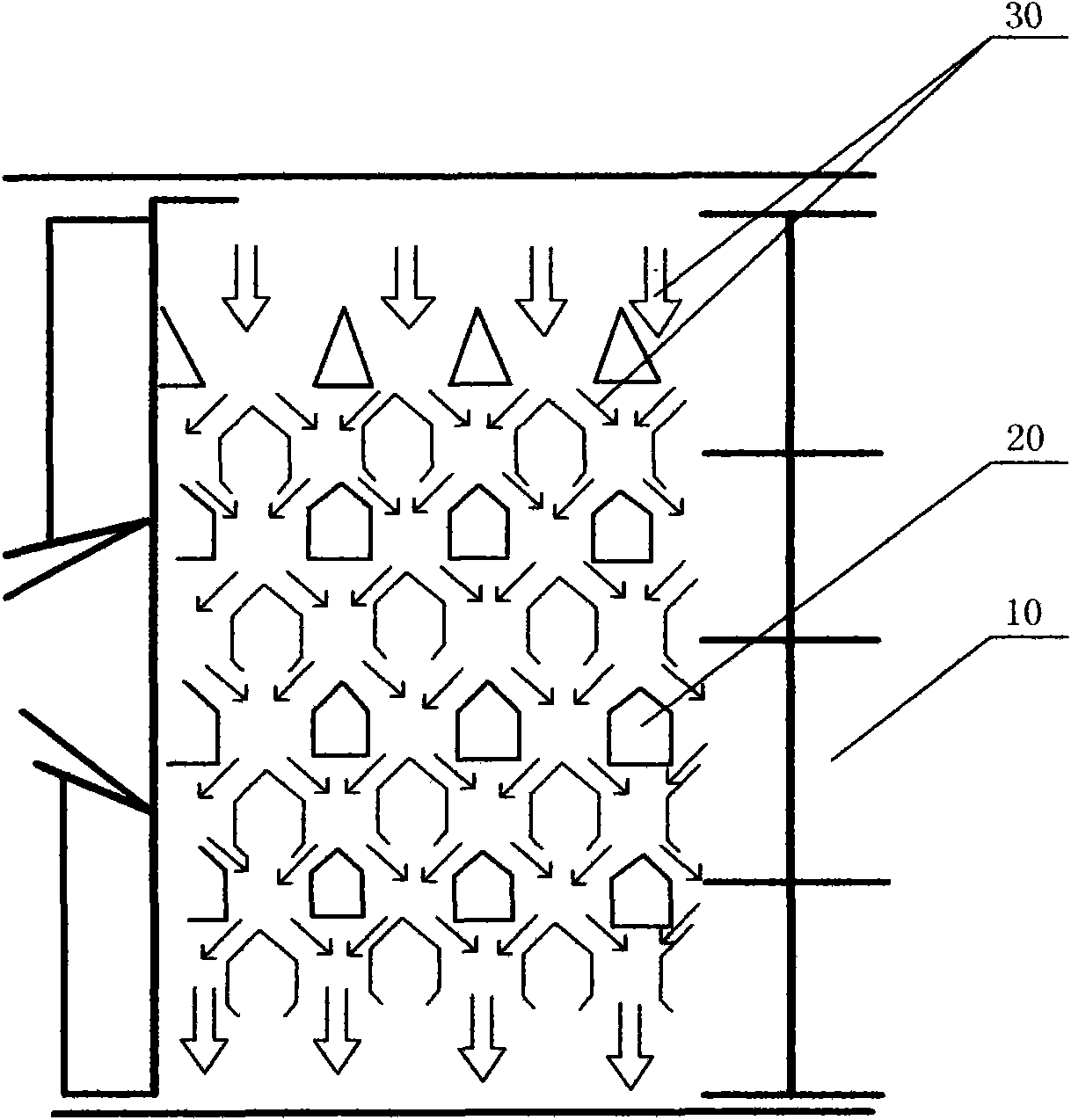

Production process of high-uniformity high-viscosity SSP (Solid State Polycondensation) polyester chip

ActiveCN101921388AEvenly distributedIncrease temperatureMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a production process of a high-uniformity high-viscosity SSP polyester chip, belonging to the technical field of chemical fiber production and comprising the following steps of: (1) precrystallizing: respectively feeding polymerized and input chips the viscosity of about 0.67dl / g into two parallel precrystallizer from the upward side of the precrystallizers, and supplying hot air with the temperature of 177 DEG C from the downward side thereof, and then crystallizing for 12-15min and then outputting the chips from the crystallizers; (2) prereacting: feeding the chips output from the precrystallizers into a prereactor, wherein the upper part of the prereactor is additionally provided with a ridge-type reactor, and the viscosity of the chip output from the prereactor can reach 0.82dl / g; and (3) final polycondensation reaction: the maximum viscosity value of the chips output from a polycondensation reactor can reach 1.09dl / g. The invention optimizes the traditional SSP process flow, i.e. controls a precrystallizing process, a prereacting process and a final polycondensation process, thereby effectively ensuring the successful preparation of the high-uniformity high-viscosity polyester chip.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

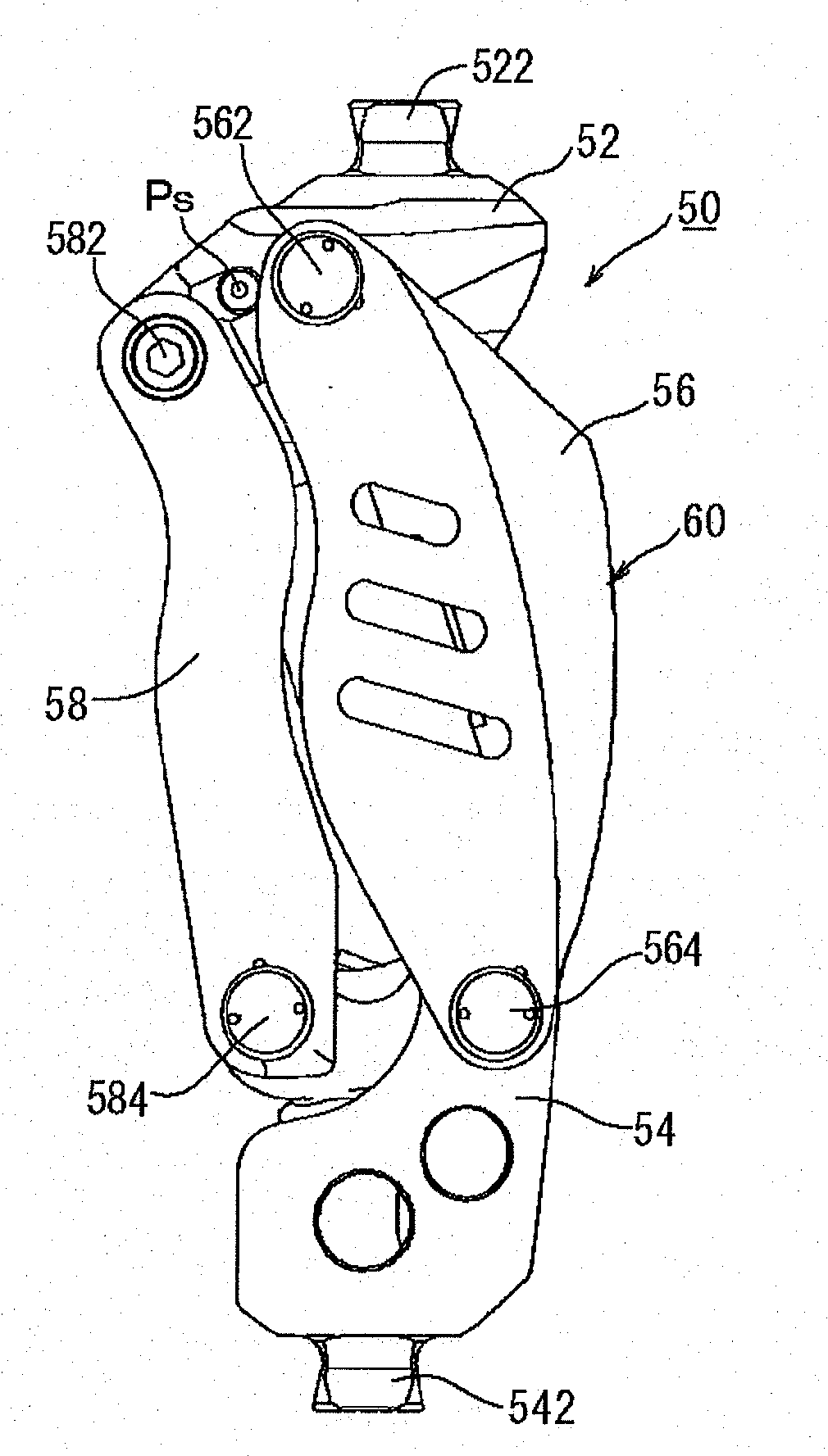

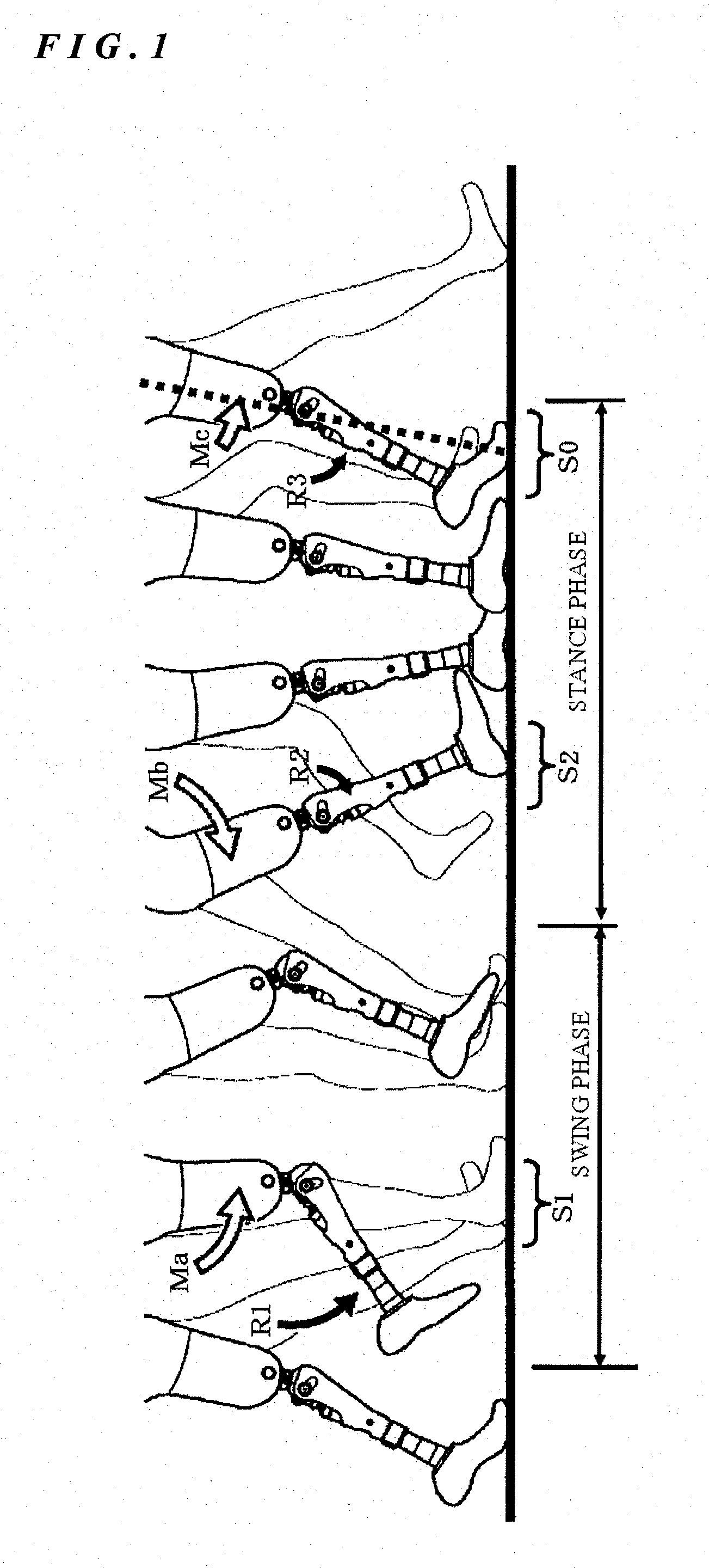

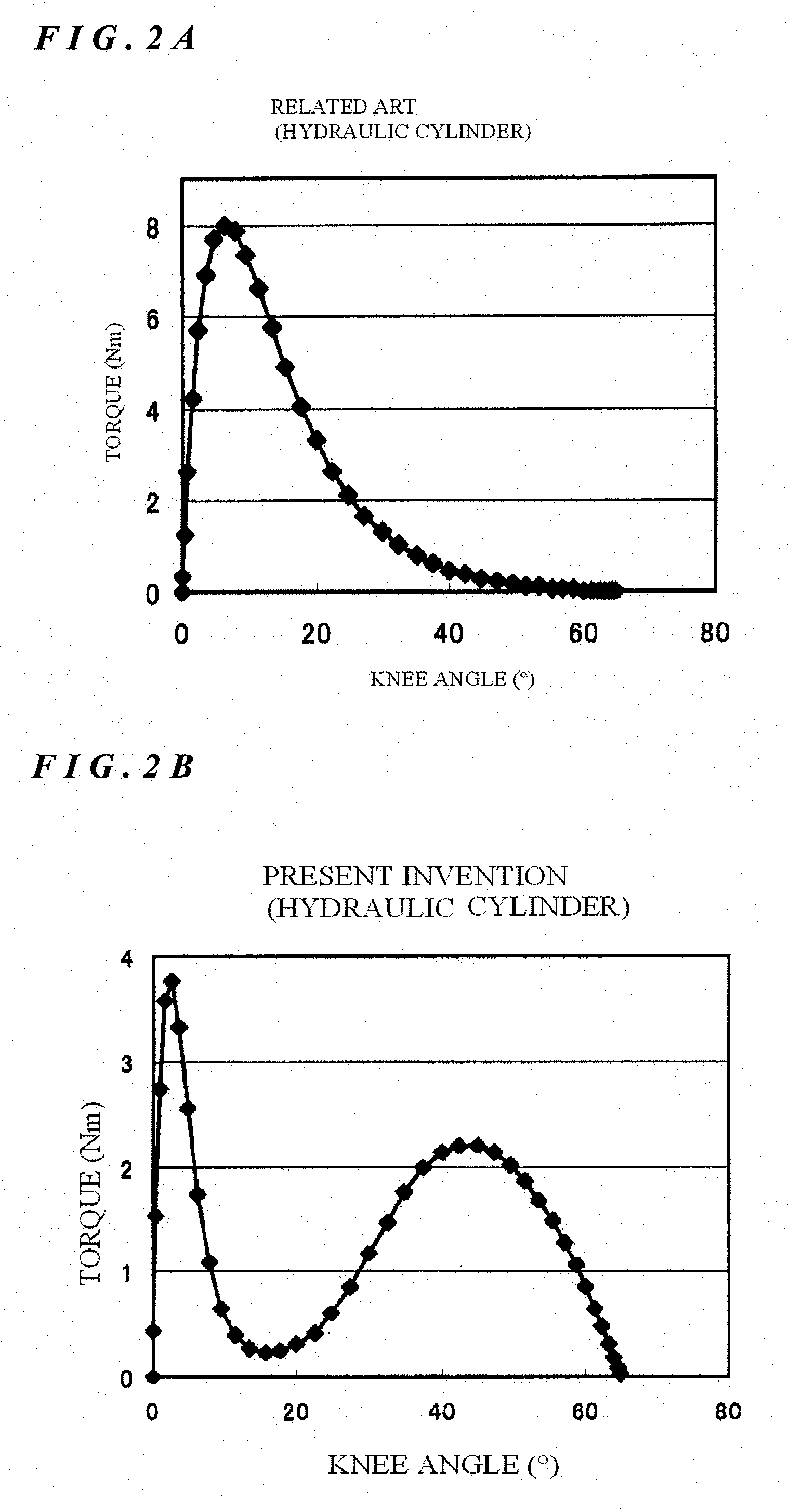

Prosthetic limbs with means capable of reducing torque in the initial period of bend of knee joint

ActiveUS20100049334A1Reduce the burden onSimple constitutionArtificial legsHydraulic cylinderPhysical medicine and rehabilitation

A technology for making the sensation at use of prosthetic limbs utilizing a hydraulic cylinder and a spring cylinder as comfortable as at use of those utilizing a pneumatic cylinder and further for improving walk following properties. In particular, the arrangement of drag generating means, such as a hydraulic cylinder and a spring cylinder, per se is specified. Accordingly, the resistance produced by the drag generating means in accordance with an increase of knee angle is increased. The first torque T1 at the first stage of initial period of bend of knee joint is made small, while the second torque T2 at the second stage of final period of the further advanced bend of knee joint is made large, thereby satisfying a relation of T1≦T2, as different from conventional ones.

Owner:NABLESCO CORP

Fluxing apparatus of LCD glass melting furnace

InactiveCN101381197AHigh clarification temperatureClarification temperature is goodGlass furnace apparatusGlass productionViscosityGlass production

The invention relates to a liquid-crystal glass tank furnace fluxing device and a method for solving the difficult problems that liquid-crystal glass is high in melting temperature, high in high temperature viscosity, low in melting rate and high in volatility when melting. A tank bottom between a charging opening and a bubble of a tank furnace is provided with a row of electrodes; the tank bottom in a clarification area close to a liquid flow hole is provided with a row of electrodes as well; and a pure oxygen burner jetting flame into the furnace is arranged on the tank furnace. The device aids in melting through a plurality of fluxing modes, homogenizes the temperature of molten glass, raises the internal temperature of the molten glass, speeds up convection, accelerates glass clarification process, reduces crystallization tendency, and can obtain the glass with higher quality. Therefore, the device is especially applicable to the liquid-crystal glass production harsh in requirement on glass quality.

Owner:HENAN ANFEI ELECTRONICS GLASS

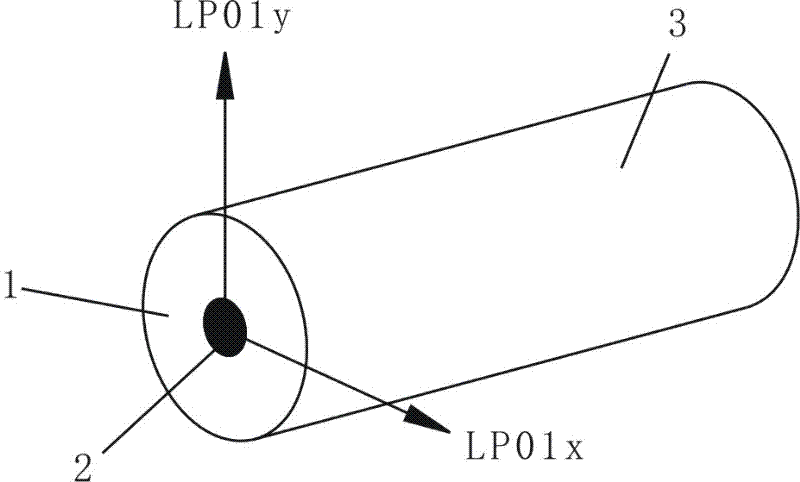

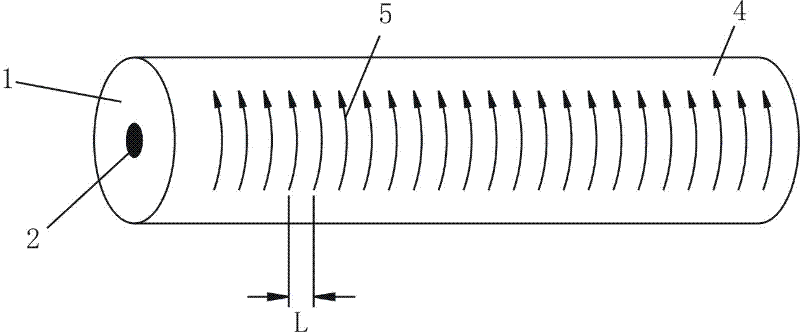

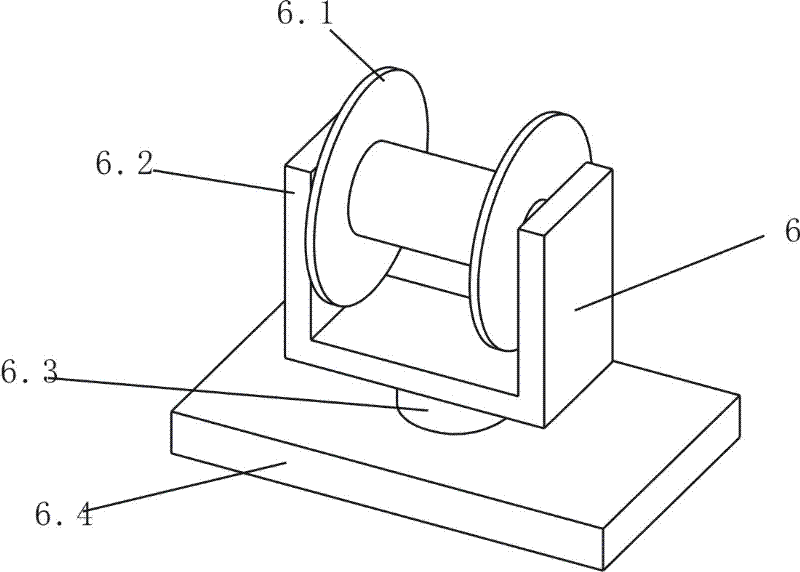

Method for manufacturing rotary optical fiber and rotary fiber winding device

The invention discloses a method for manufacturing a rotary optical fiber. The method comprises a step of manufacturing an optical fiber preform and a step of drawing the optical fiber preform, wherein in the step of drawing the optical fiber preform, a lower end of the rotary optical fiber is rotated along an axial direction of the optical fiber under fiber drawing, and rotation formed in the optical fiber is fixed in the cooling process. The rotary fiber winding device for manufacturing the rotary optical fiber comprises a fiber winding disc arranged in a fiber drawing tower and under the drawn optical fiber, wherein the fiber winding disc has a shape of a spool and is used for rotating with a drawn optical fiber as a rotating axis so as to drive the lower end of the optical fiber to rotate and for rotating with a central shaft of the fiber winding disc as a rotating axis so as to wind the optical fiber. By an ultralow double refraction optical fiber product manufactured by the process and equipment, because the rotation is not generated or cured in a drawing furnace, influence of the rotation in a high-temperature melting state on optical and mechanical properties is avoided, the manufactured ultralow double refraction optical fiber has long-term reliability and stability, and the using requirement of a sensing optical fiber in a harsh environment is met.

Owner:武汉长盈通光电技术股份有限公司

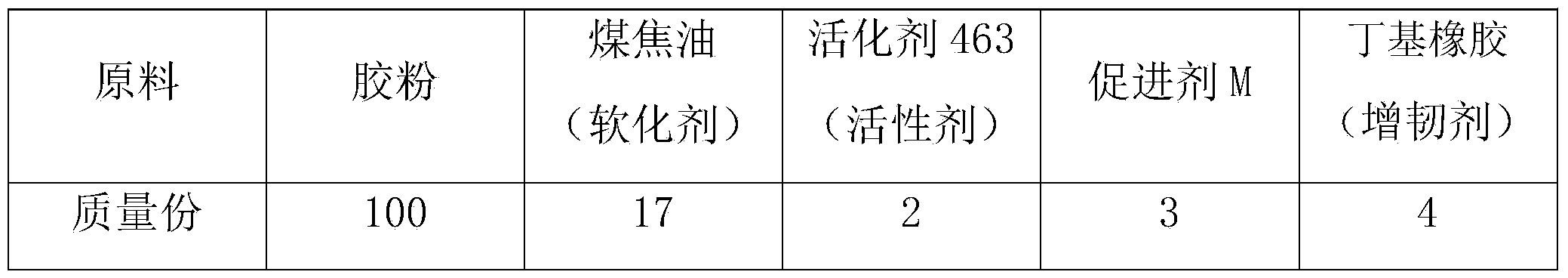

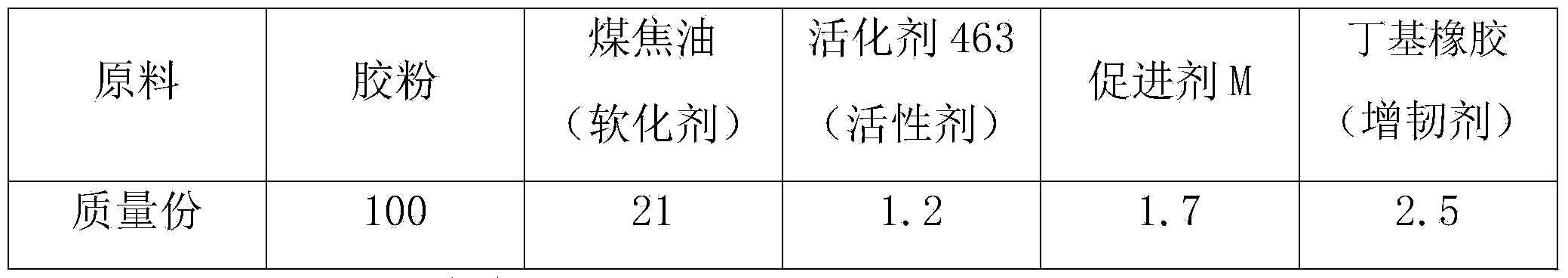

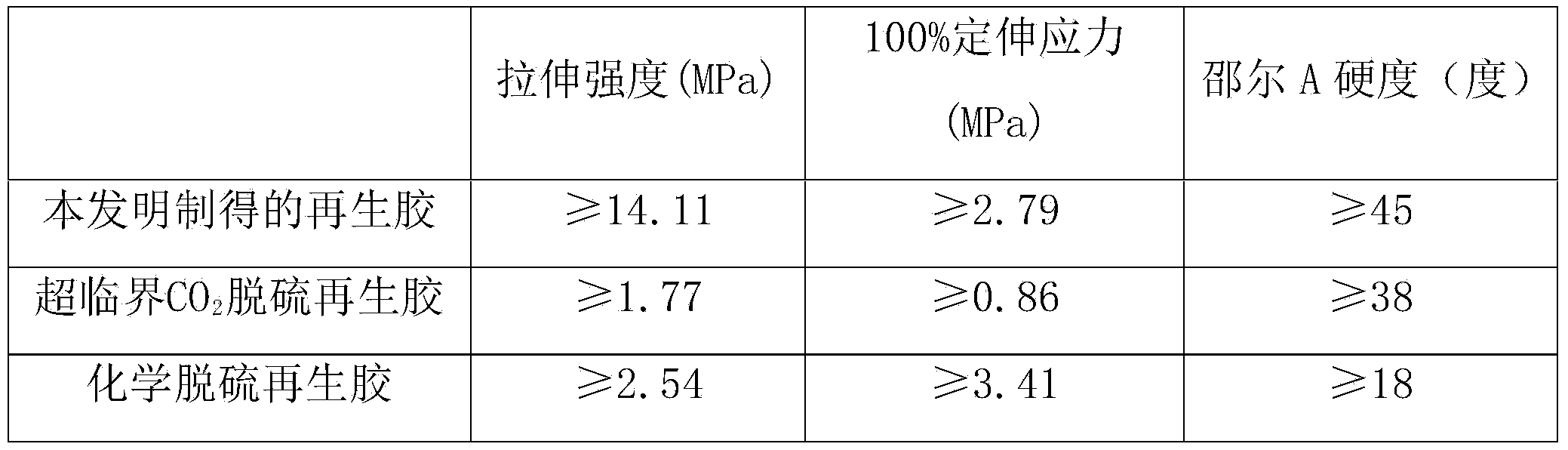

Reclaiming method of reclaimed rubber and manufacturing method of rubber rain shoes by using reclaimed rubber

InactiveCN103772738ATargetedAvoid limitationsPlastic recyclingDomestic footwearMicrowave methodEngineering

The invention discloses a reclaiming method of reclaimed rubber and a manufacturing method of rubber rain shoes by using reclaimed rubber. The reclaiming of the reclaimed rubber comprises the following steps of: (a) designing a reclaiming process by adopting a taguchi method; (b) sorting and primarily processing raw materials; (c) cutting rubber; (d) crushing waste and old rubber at a low temperature; (e) treating after crushing; (f) desulfurizing by a microwave method; and (g) processing and treating the reclaimed rubber. Simultaneously, the reclaimed rubber prepared by the reclaimed method is used to produce the rubber rain shoes by the following steps of: (a) designing a production process by adopting the taguchi method; (b) weighing and clearing the raw materials; (c) mixing the raw materials; (d) sulfurizing the rubber; (e) pressing and forming soles; (f) pressing and forming uppers; and (g) bonding and forming. The reclaiming method disclosed by the invention has the advantages that the reclaimed rubber is adopted for replacing the traditional natural rubber and synthetic rubber, and therefore the manufacturing cost of a product is reduced and the considerable economic benefit is brought; the non-reclaimed resources can be reclaimed, so that the environmental pollution is avoided, the energy-saving and environmental-friendly effects are achieved, and the production of the rain shoes steps into economic circle with good circulation.

Owner:浙江佰利鞋业有限公司

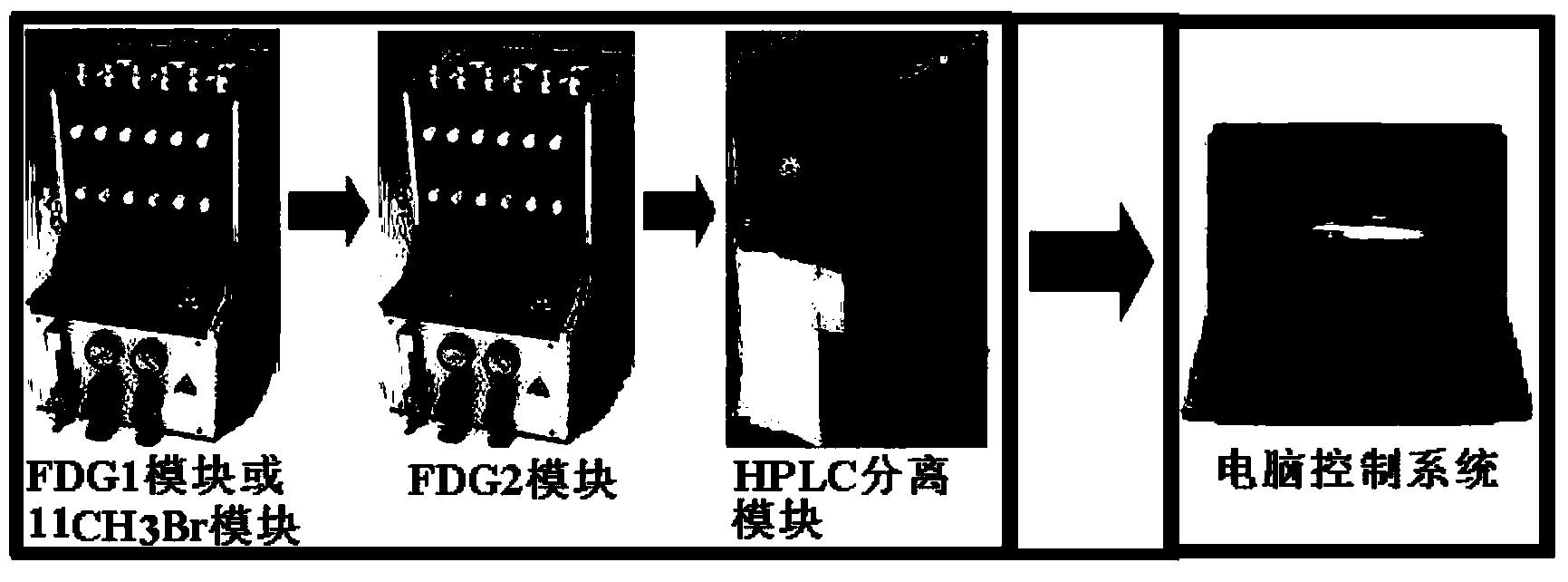

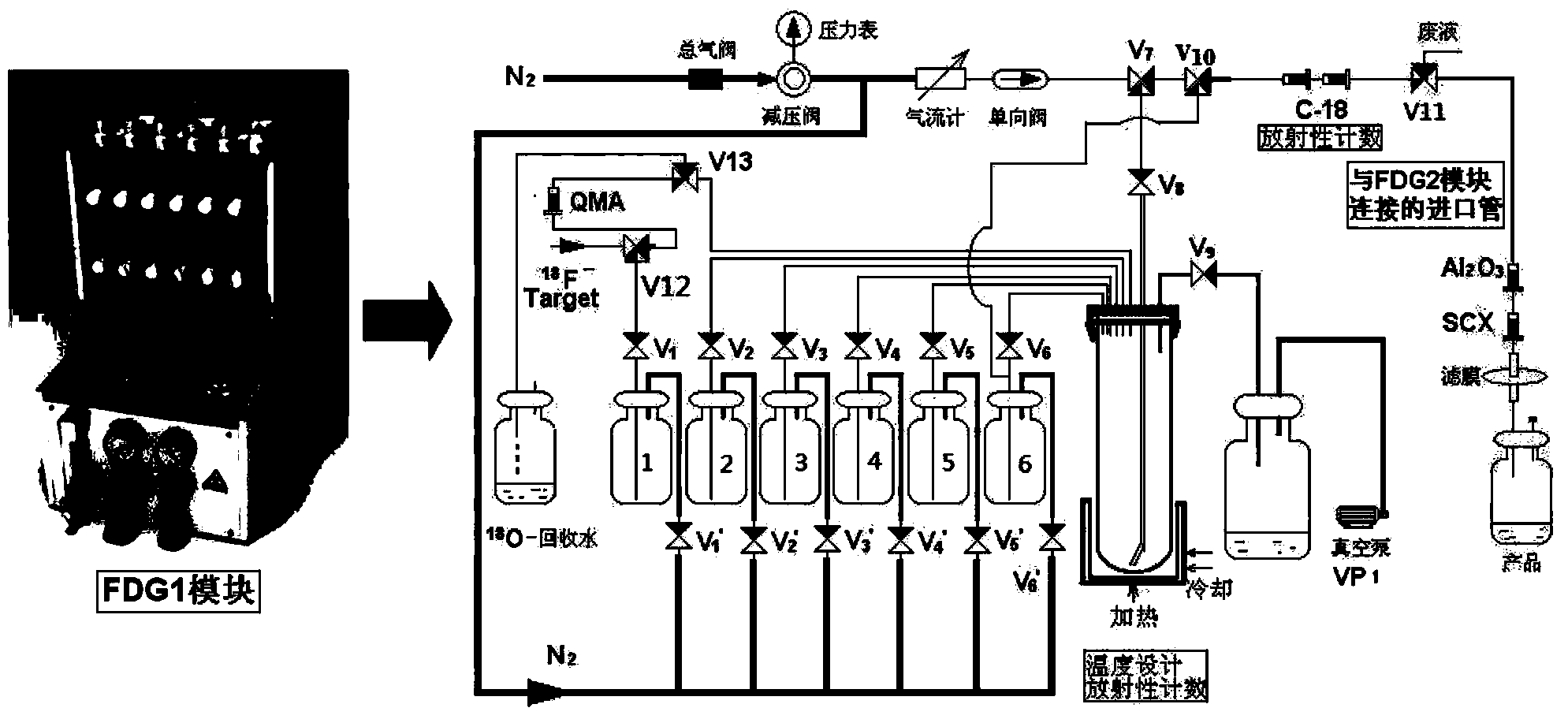

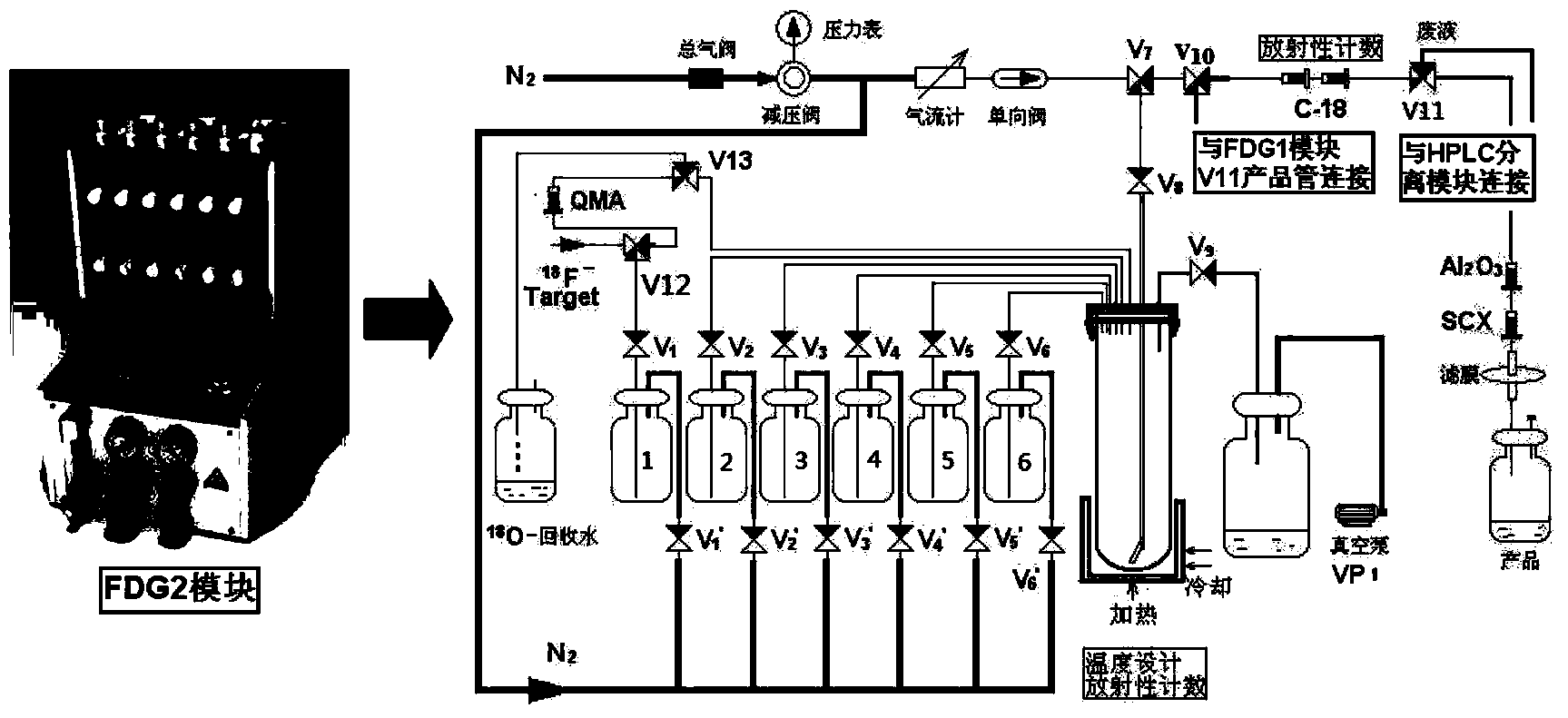

Small modular multifunctional automatic 18F labelling PET (positron emission tomography) drug synthesizer

ActiveCN104262073AChange connection methodGuaranteed ease of maintenanceConversion outside reactor/acceleratorsIsotope introduction to organic compoundsControl systemComputer module

The invention provides a small modular multifunctional automatic 18F labelling PET (positron emission tomography) drug synthesizer and relates to an automatic PET drug synthesizer. The small modular multifunctional automatic 18F labelling PET drug synthesizer comprises a single FDG (fluorodeoxyglucose) synthesis module or two FDG synthesis modules which are connected in series, namely a module FDG1 and a module FDG2, a PET drug product separating system and a control system, wherein the single FDG synthesis module or the two FDG synthesis modules which are connected in series are used for independently completing FDG synthesis or continuously completing double-batch FDG synthesis in a combined manner; the PET drug product separating system is connected with the single FDG synthesis module or a second module, namely the module FDG2, in the two FDG synthesis modules which are connected in series; and the control system is used for connecting and controlling the FDG synthesis module and the PET drug product separating system. The small modular multifunctional automatic PET drug synthesizer has the characteristics of ingenious structure, small size, simple mounting, friendly interface, simple operation, safety, stability, reliability, convenience in maintenance, powerful function and flexibility, is simple to mount and operate, and convenient to maintain, and the production requirement of 18F labelling PET drugs for the current market and scientific research can be met.

Owner:BEIJING SHANWEIZHENGZI MEDICAL TECH

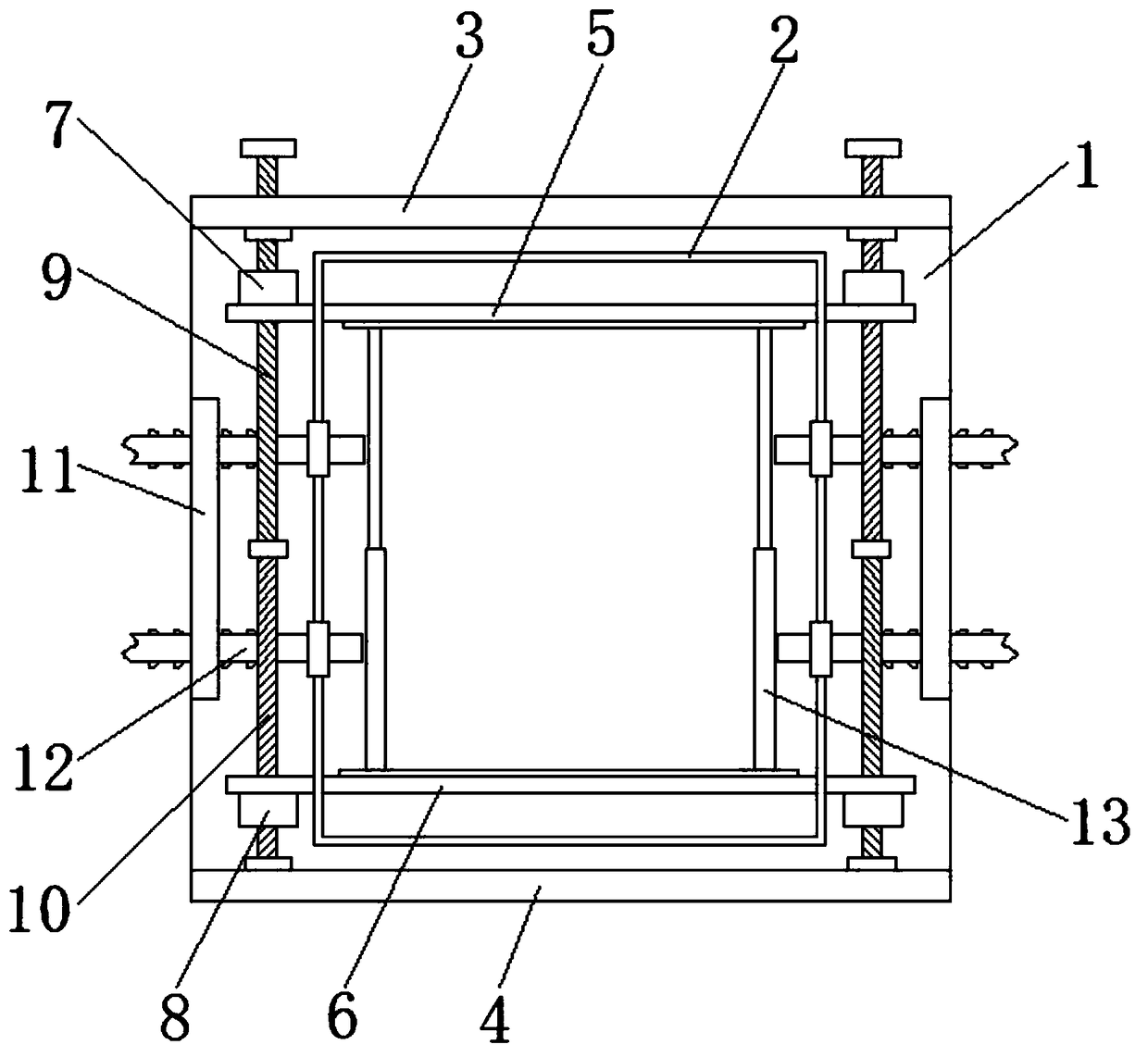

Framework with adjustable size for reinforced concrete stone plate

InactiveCN108908659AEasy to useChange lengthMouldsMould fastening meansReinforced concreteEngineering

The invention discloses a framework with adjustable size for a reinforced concrete stone plate, and relates to the technical field of reinforced concrete of buildings. The framework comprises a fixedplate, wherein the front side of the fixed plate is fixedly connected with a formwork; the top part and bottom part of the fixed plate are respectively fixedly connected with a first installation plate and a second installation plate; both sides of the inner wall of the formwork are respectively glidingly connected with a first formwork and a second formwork from top to bottom; both sides of the top part of the second formwork are respectively glidingly connected with telescopic plates; the top part of each telescopic plate is glidingly connected with the bottom part of the first formwork; both sides of the first formwork penetrate through the formwork and extend to both sides of the formwork. The framework with adjustable size for the reinforced concrete stone plate has the advantages that the good size adjusting function is realized; the size can be conveniently adjusted, the adjusting time is shortened, and the labor intensity in adjusting is decreased; the production requirements of the reinforced concrete stone plates with different sizes can be met, and the usability of the framework for the reinforced concrete stone plate is greatly improved.

Owner:芜湖青悠静谧环保科技有限公司

Container foil material and method for manufacturing container foil

InactiveCN102409200AHigh strengthSatisfy productionMetal rolling arrangementsPunchingUltimate tensile strength

The invention relates to a manufacture method of an aluminum alloy material, concretely relates to a container foil material and a method for manufacturing a container foil. The alloy of the container foil material comprises the following compositions by weight percentage: 0.20-0.26% of Si, 0.42-0.50% of Fe, 0.05% of Cu, 0.15-0.20% of Mn, 0.01% of Mg, 0.1% of Zn, 0.04% of Ti and the balance of Al. According to the invention, the content of Fe and Si are re-allocated by the material on the basis of a 8011 alloy, and certain Mn element is added, so that the material intensity can be raised, and the material has good processing performance and is easy to roll. The detection of the material shows that the when aluminum foil thickness is 0.05-0.06mm, the tensile strength is 120-160MPa, the elongation percentage is greater than or equal to 12% and the cupping value is greater than or equal to 5.0. The material of the invention has good punching performance, and can be used for producing various aviation tableware.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Smelting method for stainless steel material

ActiveCN104962800AUnique methodIngredients have no effectProcess efficiency improvementElectric arc furnaceSS - Stainless steel

The invention relates to a smelting method, in particular to a smelting method for a stainless steel material. The smelting method comprises the following steps: preparing materials, carrying out EAF (electric arc furnace) smelting, carrying out LF (low frequency) furnace primary smelting, carrying out VOD furnace smelting and carrying out LF furnace re-smelting. The smelting method disclosed by the invention is unique, improves the quality of molten steel, reduces the production cost and solves the problem of smelting various molten steel in the same EAF furnace by the enterprises.

Owner:KOCEL STEEL

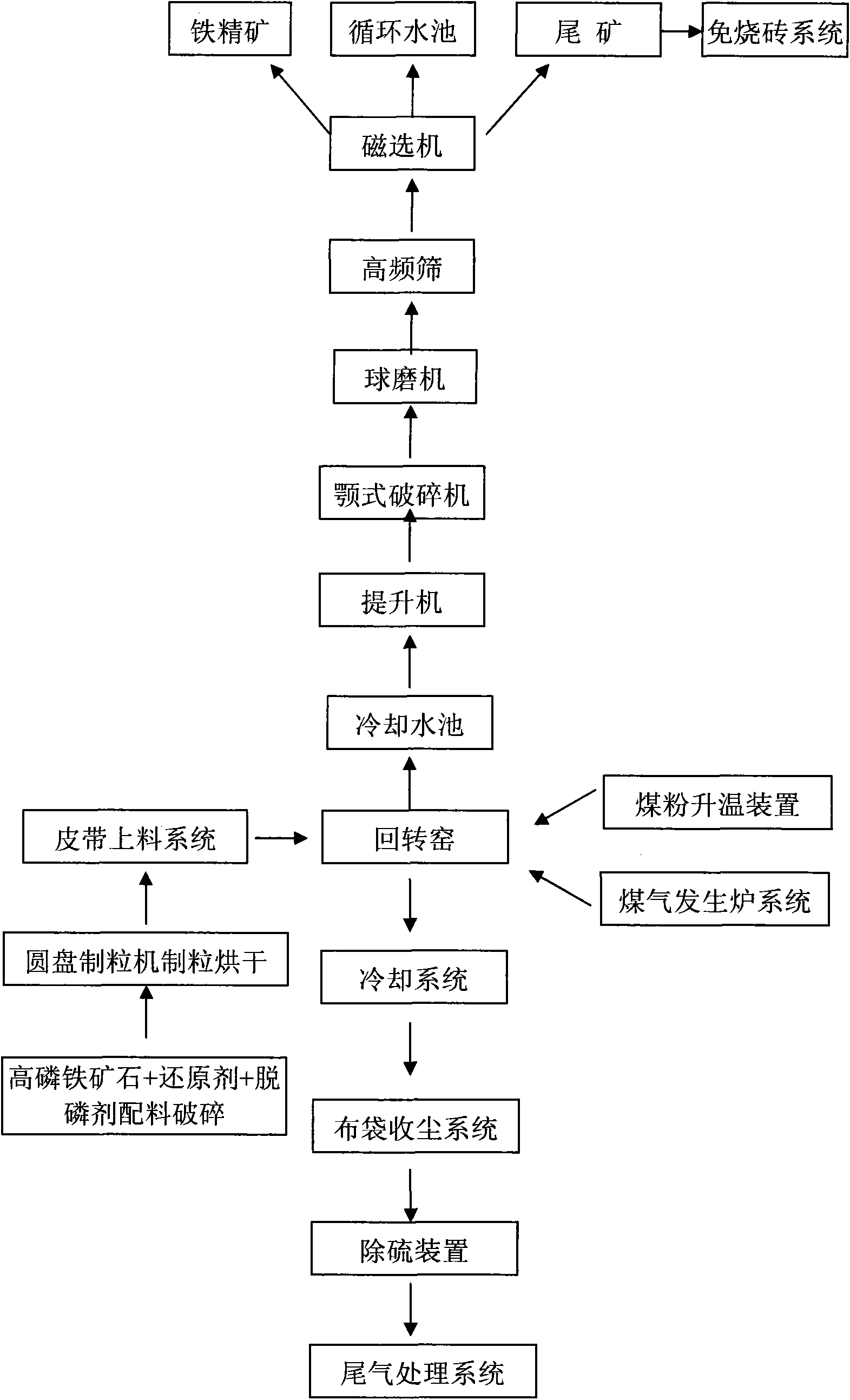

Method for rapidly reducing and roasting as well as synchronously dephosphorizing and extracting iron at high temperature of high-silicon high-phosphorus iron ore

The invention relates to a method for rapidly reducing and roasting as well as synchronously dephosphorizing and extracting iron at high temperature of high-silicon high-phosphorus iron ore, which is characterized in that first, the high-silicon high-phosphorus iron ore, reducing agent and dephosphorizing agent are crushed to be 150mm, wherein, the reducing agent is common brown coal accounting for 8-12% of the total weight, the dephosphorizing agent is white lime accounting for 20-25% of the total weight, and the iron ore, the reducing agent and the dephosphorizing agent are evenly mixed together to be pelletized and dried, and then is reduced and roasted in a rotary kiln; coal dust and coal gas are sprayed into a head of the kiln to lead the temperature to raise to 1100-1200 DEG C, and the time used for reducing and roasting is 2-2.5hours; after reducing and roasting, the product is crushed and processed by two-section ball milling and three-section magnetic separation, so that low-silicon low-phosphorus iron-rich refined powder can be obtained. The method has the advantages of short reduction time, low energy consumption, large treatment capacity and production scale, environmental protection as well as having dephosphorizing rate of 80%, iron recovery rate of 70%, low cost and the like compared with a mineral dressing dephosphorizing method, a chemical dephosphorizing method, other smelting dephosphorizing methods and a microbial dephosphorizing method.

Owner:湖南建湘高科新技术开发有限公司

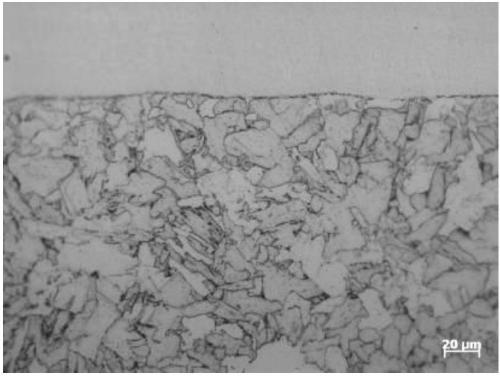

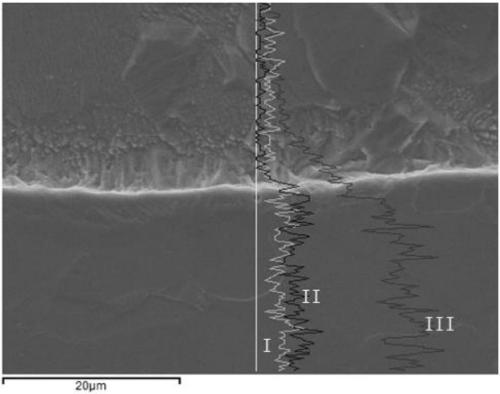

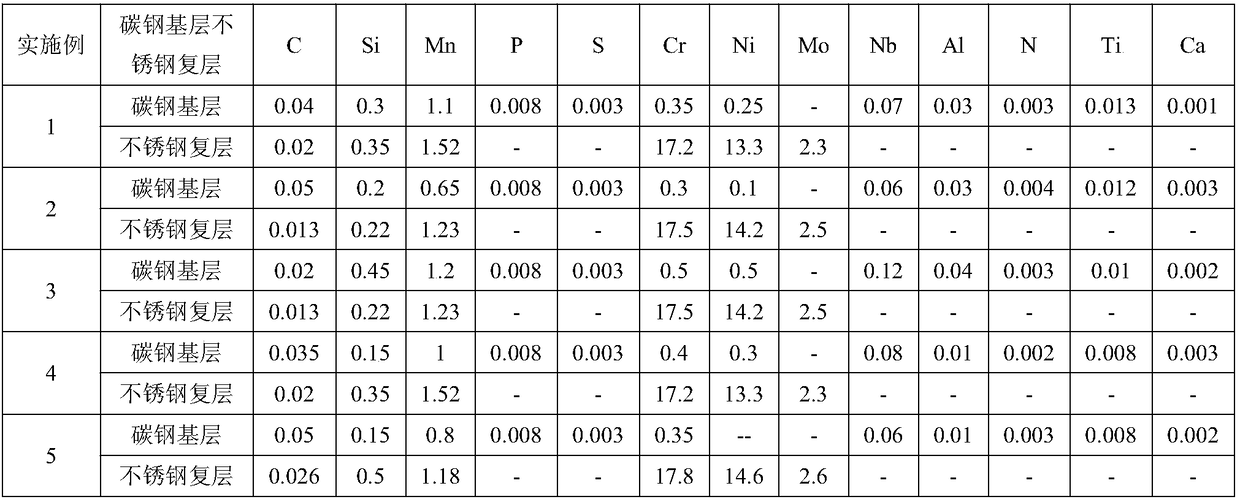

Anti-acid pipeline clad steel plate with corrosion resistance and manufacturing method of anti-acid pipeline clad steel plate

InactiveCN109306436AAccelerated corrosionSatisfy productionMetal rolling arrangementsAusteniteCarbon steel

The invention discloses an anti-acid pipeline clad steel plate with corrosion resistance. The anti-acid pipeline clad steel plate with corrosion resistance comprises a carbon steel base layer and stainless steel cladding composited with the carbon steel base layer in a rolled manner. The stainless steel cladding is austenitic stainless steel. The carbon steel base layer comprises chemical elementsincluding, by mass percent, 0.02%-0.05% of C, 0.6%-1.20% of Mn, 0.30%-0.50% of Cr, 0.06%-0.12% of Nb, 0%-0.50% of Ni, 0.005%-0.02% of Ti, 0.05%-0.45% of Si, 0.01%-0.05% of Al, 0.001%-0.003% of Ca, and the balance Fe and other unavoidable impurities. The invention further discloses a manufacturing method of the anti-acid pipeline clad steel plate with the corrosion resistance. The anti-acid pipeline clad steel plate with the corrosion resistance can meet the using requirement of pipes of a welded pipeline in mechanical performance and welding performance and also has the high corrosion resistance, and the performance requirement of an anti-acid pipeline clad steel plate product can be met without heat treatment.

Owner:BAOSHAN IRON & STEEL CO LTD

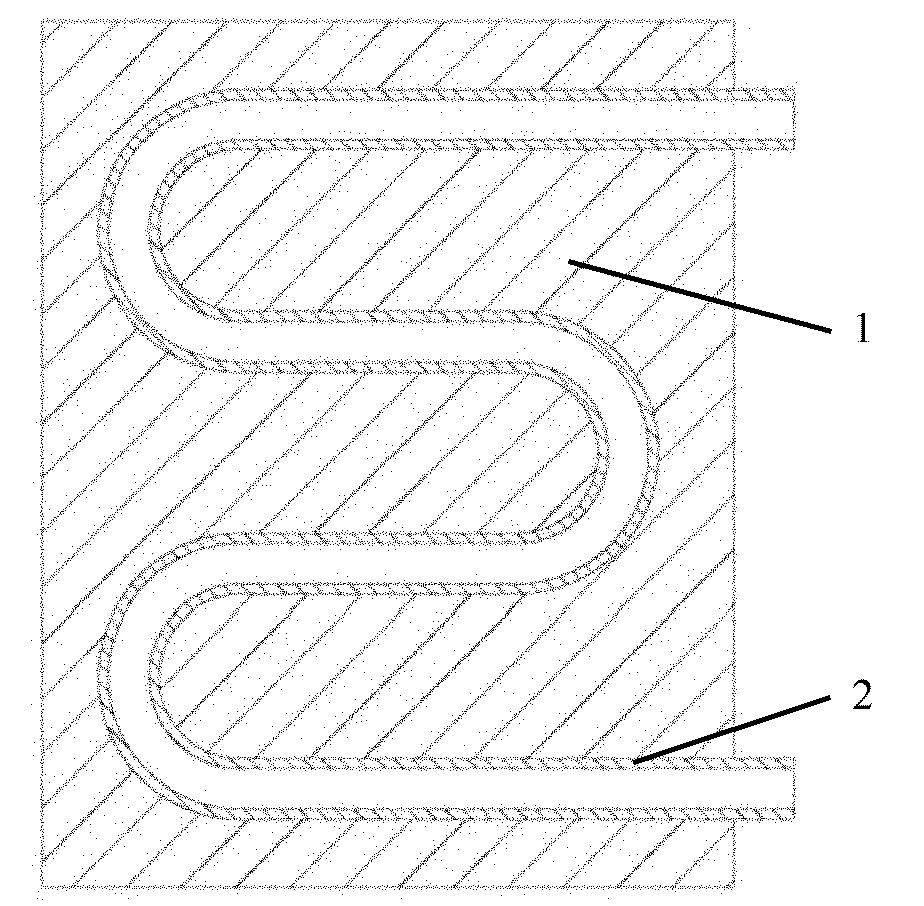

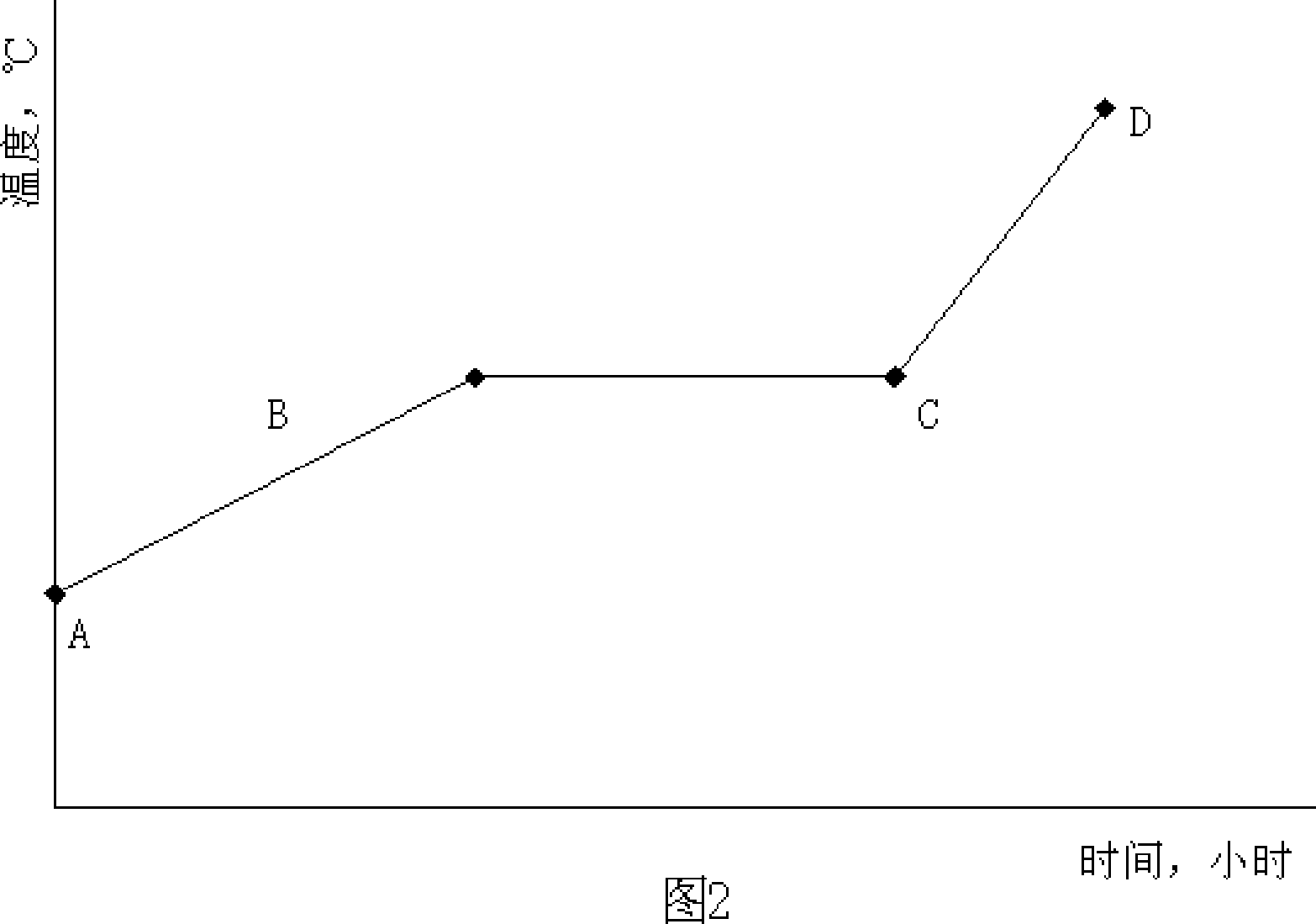

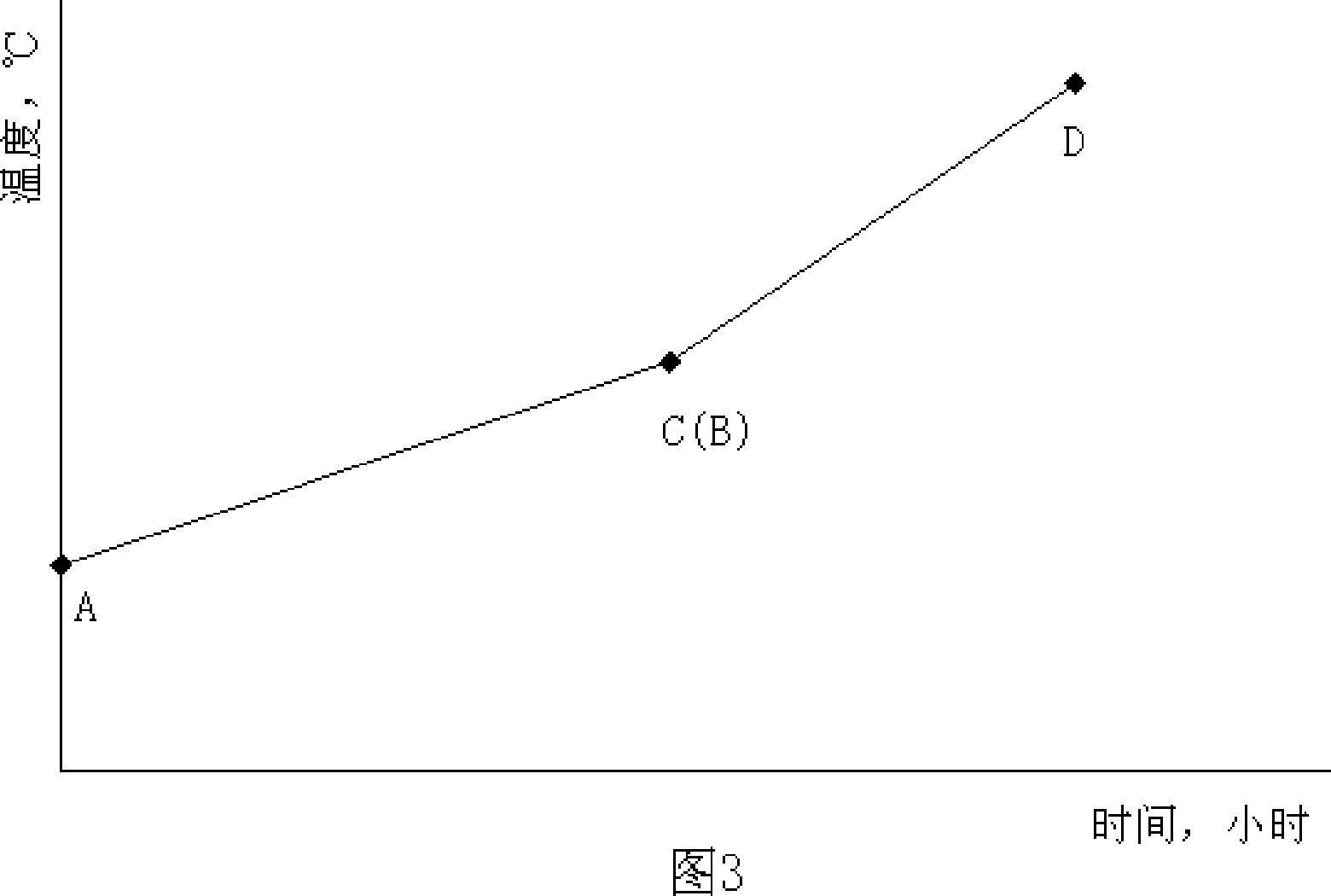

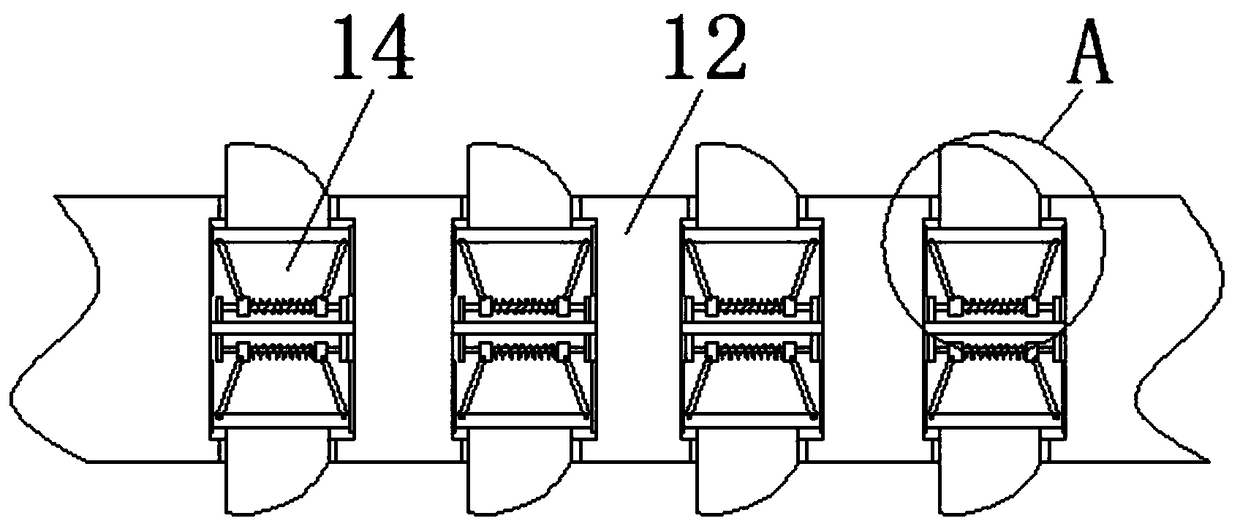

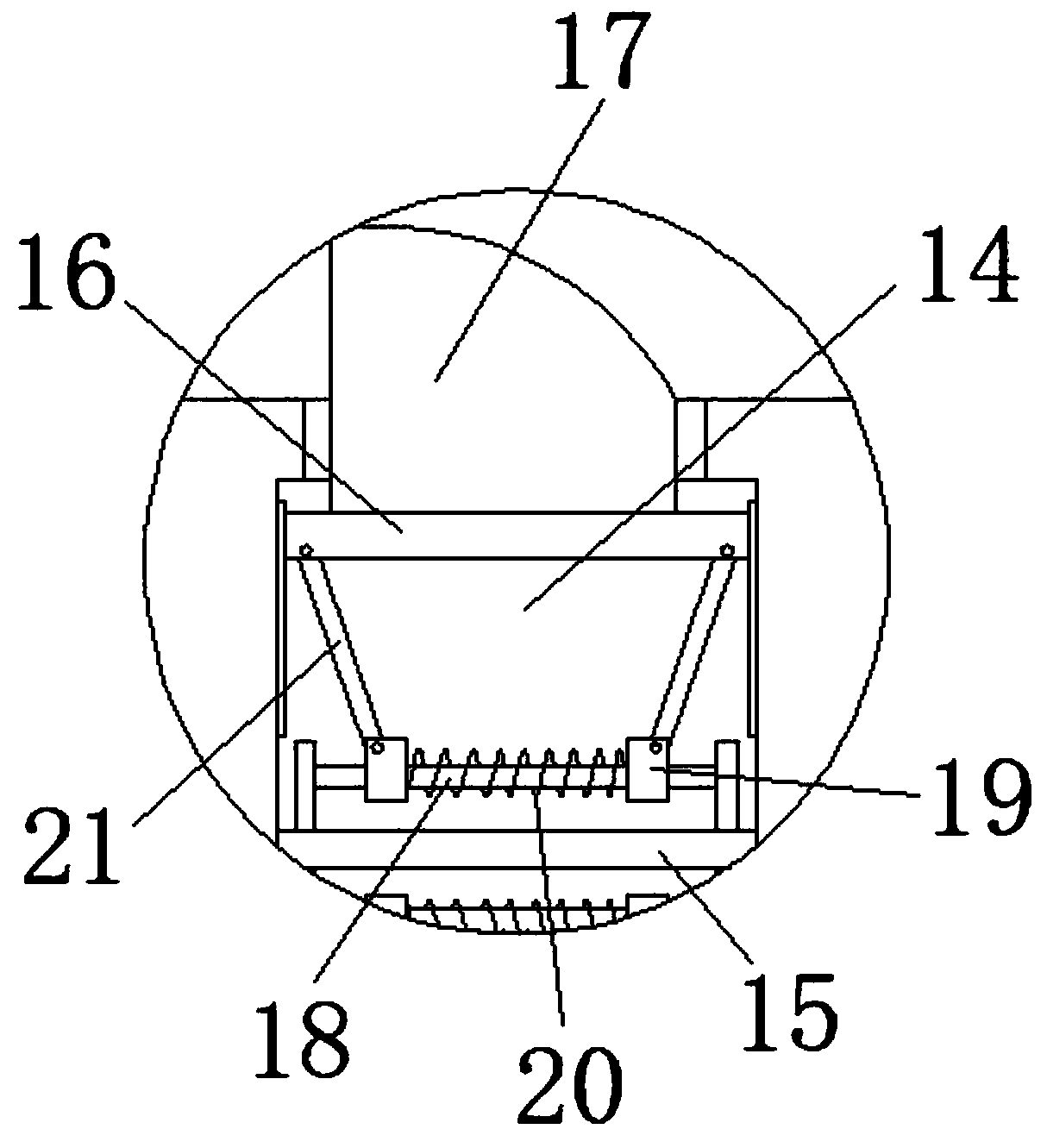

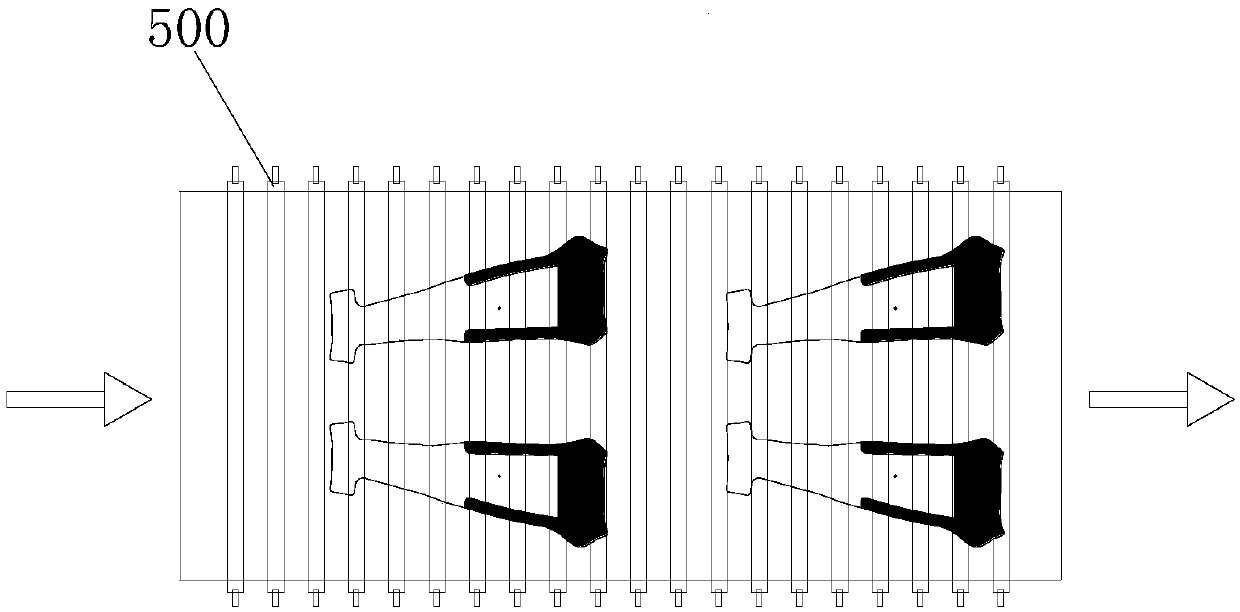

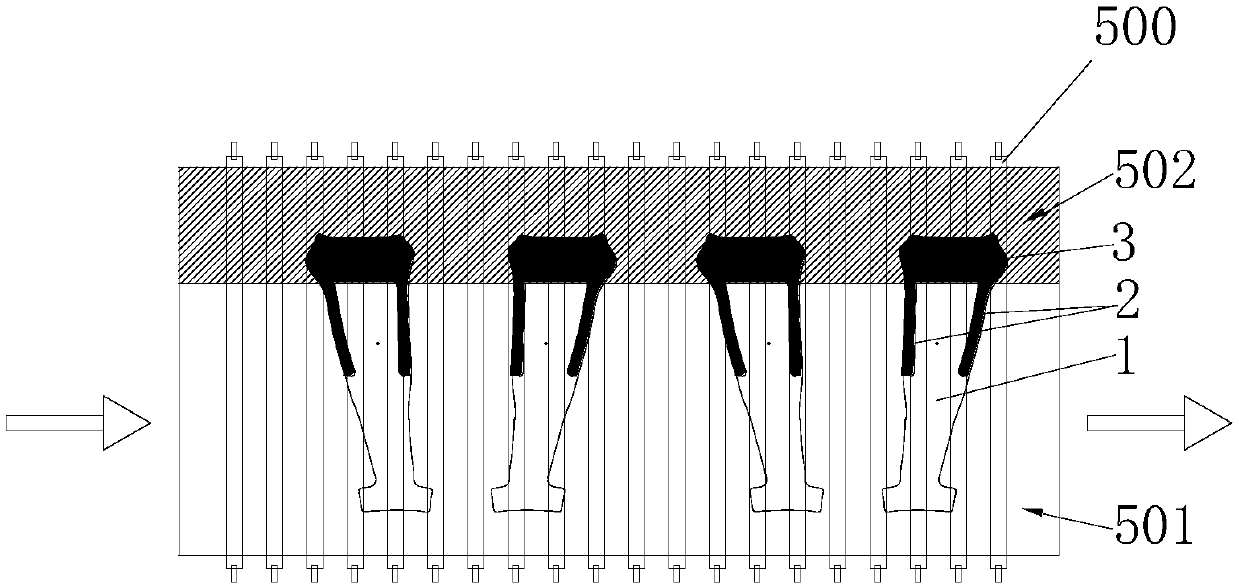

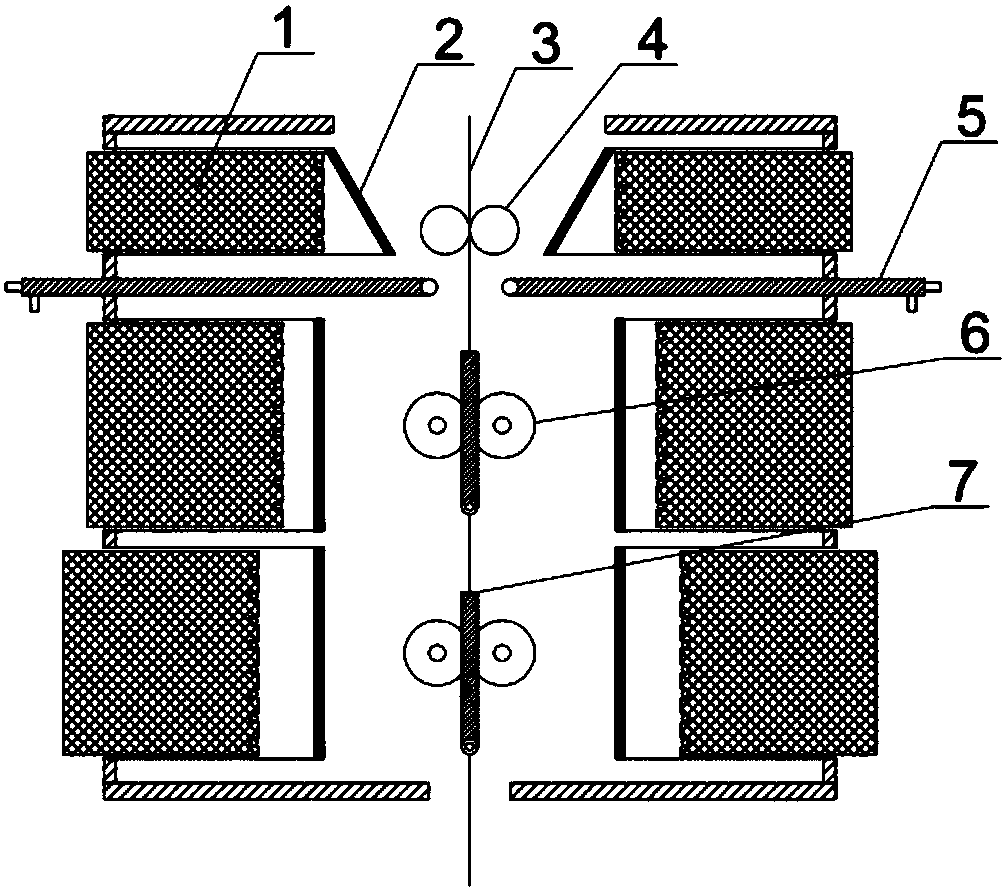

Heating device capable of producing hot stamping parts with segmented-strength and production line with same and hot stamping forming method

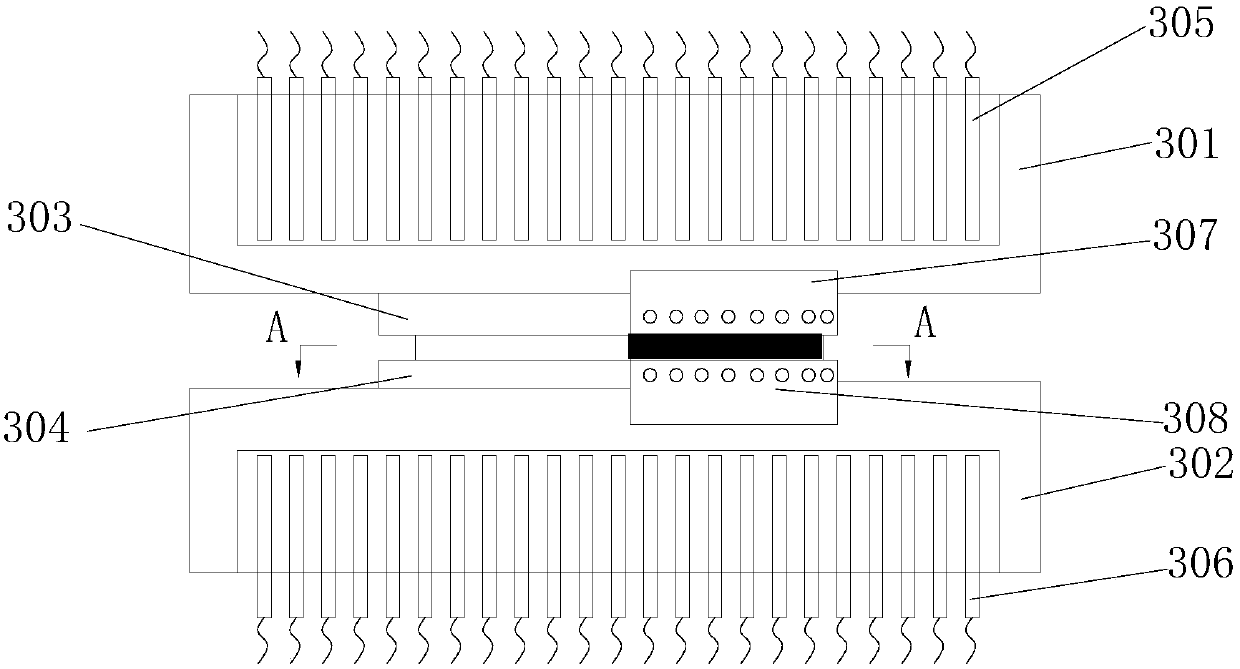

ActiveCN107552625AMeet normal productionShaping toolsQuenching devicesHot stampingProcess engineering

The invention discloses a heating device capable of producing hot stamping parts with segmented-strength and a production line with the same and a hot stamping forming method. The heating device comprises a separated heating and cooling device and a final heating device; the heating and cooling device comprises an upper heat insulation shell and a lower heat insulation shell which are oppositely arranged; a pressurization device which is connected with one or both of the upper heat insulation shell and the lower heat insulation shell; and at least one of the oppositely arranged surfaces of theupper heat insulation shell and the lower heat insulation shell is provided with a copying heat transfer plate and a cooling block, the copying heat transfer plate and the cooling block are adjacently arranged, a heater is arranged at the copying heat transfer plate, and a cooling water channel is arranged in the cooling block. According to the heating device capable of producing the hot stampingparts with segmented-strength and the production line with the same and the hot stamping forming method, the material sheet is static in the heating and cooling device, the positions, the curves andthe directions of different strength areas can be randomly arranged, and soft and hard transition areas can be quite narrow.

Owner:江西普热斯勒先进成型技术有限公司

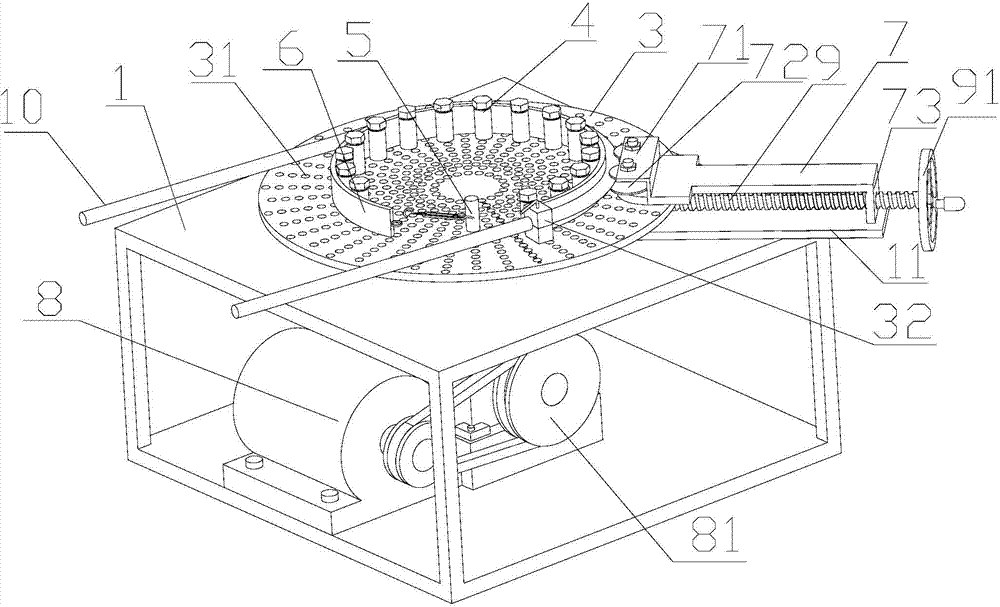

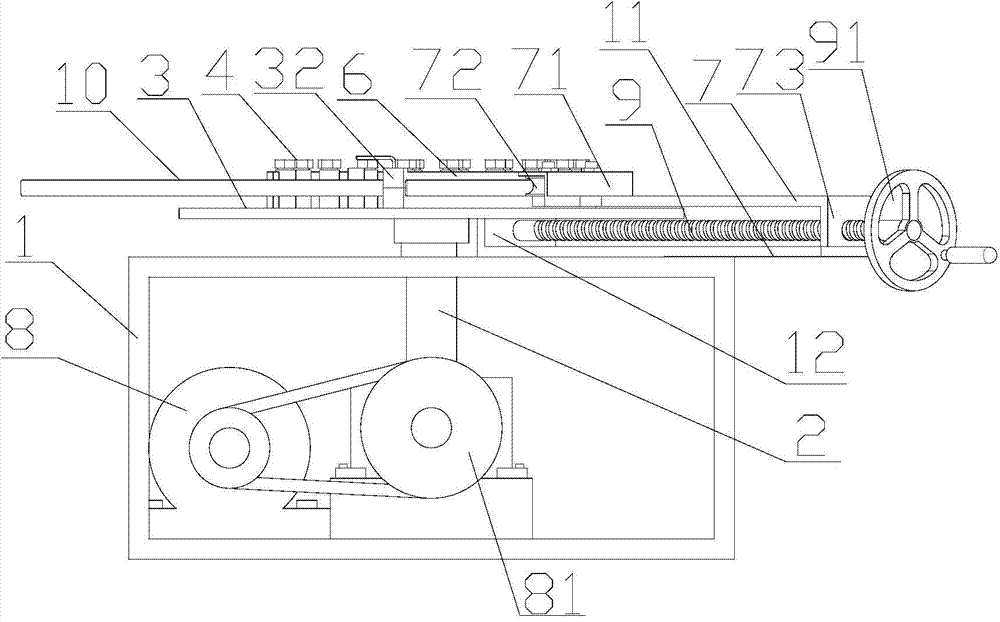

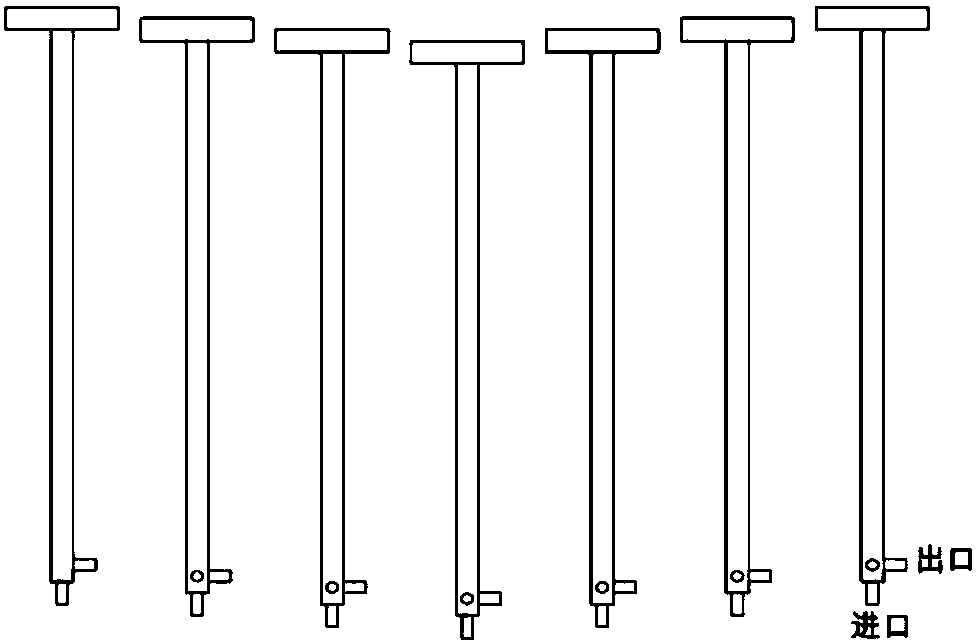

Automatic tube bending machine

InactiveCN104492885ASatisfy productionEasy to operateMetal-working feeding devicesPositioning devicesDrive shaftTube bending

The invention provides an automatic tube bending machine which comprises a rack, a driving device, a driving shaft, a rotating disc, a plurality of positioning rods, a positioning column, a sleeve plate and a pressing rod, wherein the driving device is used for providing power and is in transmission connection with the driving shaft; one end of the driving shaft is fixedly mounted in the center of the rotating disc; a plurality of positioning holes are formed in the circumferences with the center of the rotating disc as the circle center and different diameters; the positioning rods and the positioning column are detachably mounted inside positioning holes in the circumference with the same diameter; the sleeve plate is an annular steel plate with a notch; the sleeve plate sleeves the outer sides of the positioning rods; two ends of the sleeve plate are fixed on the positioning column; a fixing device for fixing a tube is detachably mounted on the rotating disc; the fixing device is positioned on the outer side of the sleeve plate; the pressing rod is mounted on the rack; a pressing head is arranged at the end part of the pressing rod; the gap between the pressing head and the sleeve plate is identical to the diameter of the tube. As the positioning holes are formed in circumferences with different diameters on the rotating disc, bent tubes with different diameters can be all produced without replacing any component, the operation is convenient and rapid, and the production efficiency is greatly improved.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

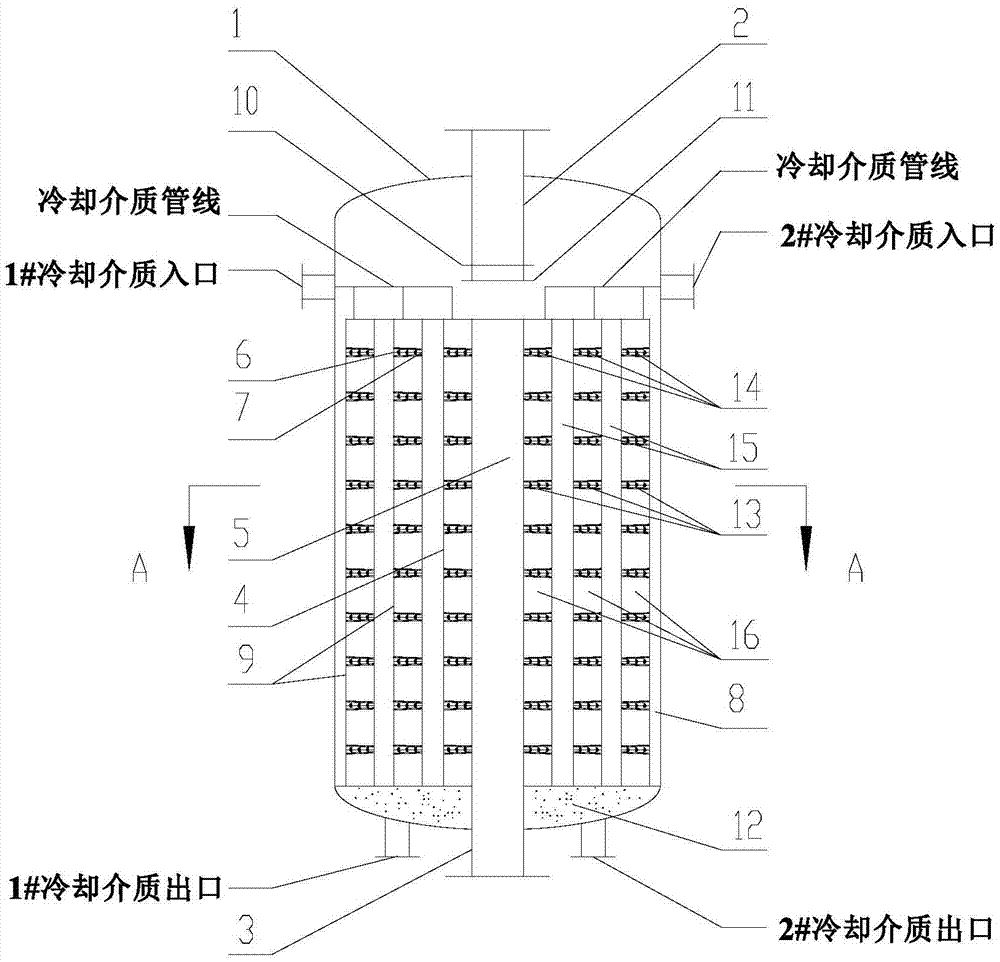

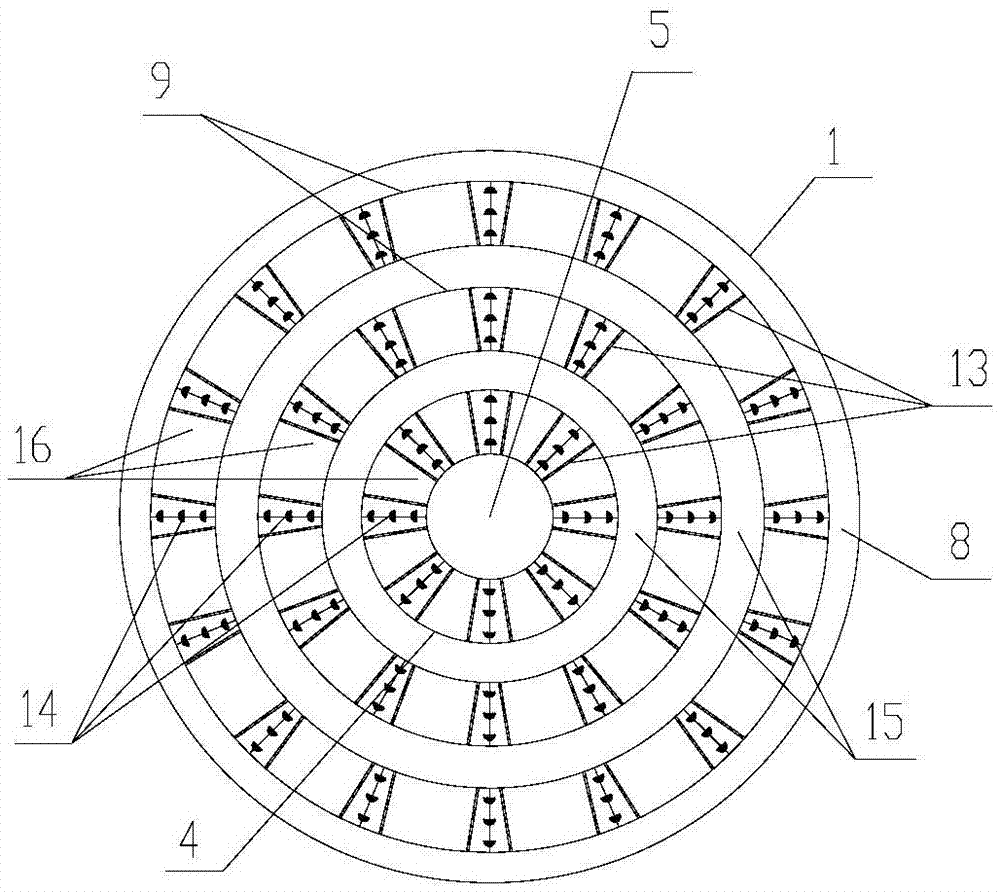

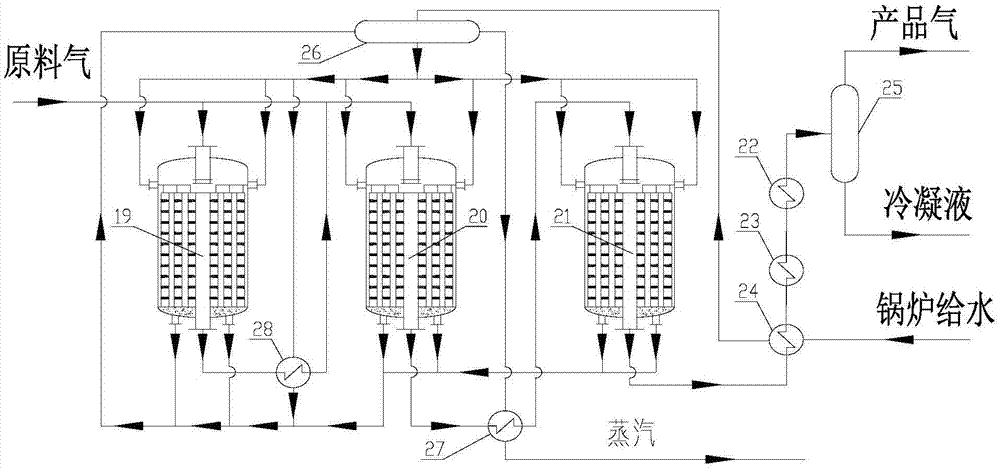

Methanation reactor and methanation process

ActiveCN107224940AIncreased turbulenceImprove conversion rateGaseous fuelsChemical/physical processesMethanationEconomic benefits

The invention discloses a methanation reactor and a methanation process. The reactor comprises a cylindrical sealed pressure-bearing shell body (1), a gas inlet pipe (2), a gas outlet pipe (3), a radial catalytic reaction zone and heating equipment, wherein the gas inlet pipe (2) extends inside the shell body from the top of the shell body (1), the gas outlet pipe (3) extends inside the shell body from the bottom of the shell body (1), and the radial catalytic reaction zone is formed in the shell body (1) below the gas inlet pipe (2) and above the gas outlet pipe (3) and comprises the heating equipment. Compared with the prior art, the methanation reactor and the methanation process have the advantages that the methanation reactor disclosed by the invention is low in active metal consumption and smaller in equipment size, and the methanation process adopting the methanation reactor is low in bed layer pressure drop and high in feedstock conversion ratio, is free of gas bias and short-circuit phenomena and has the characteristics of high economic benefit, low comprehensive energy consumption and the like.

Owner:SINOPEC ENG +1

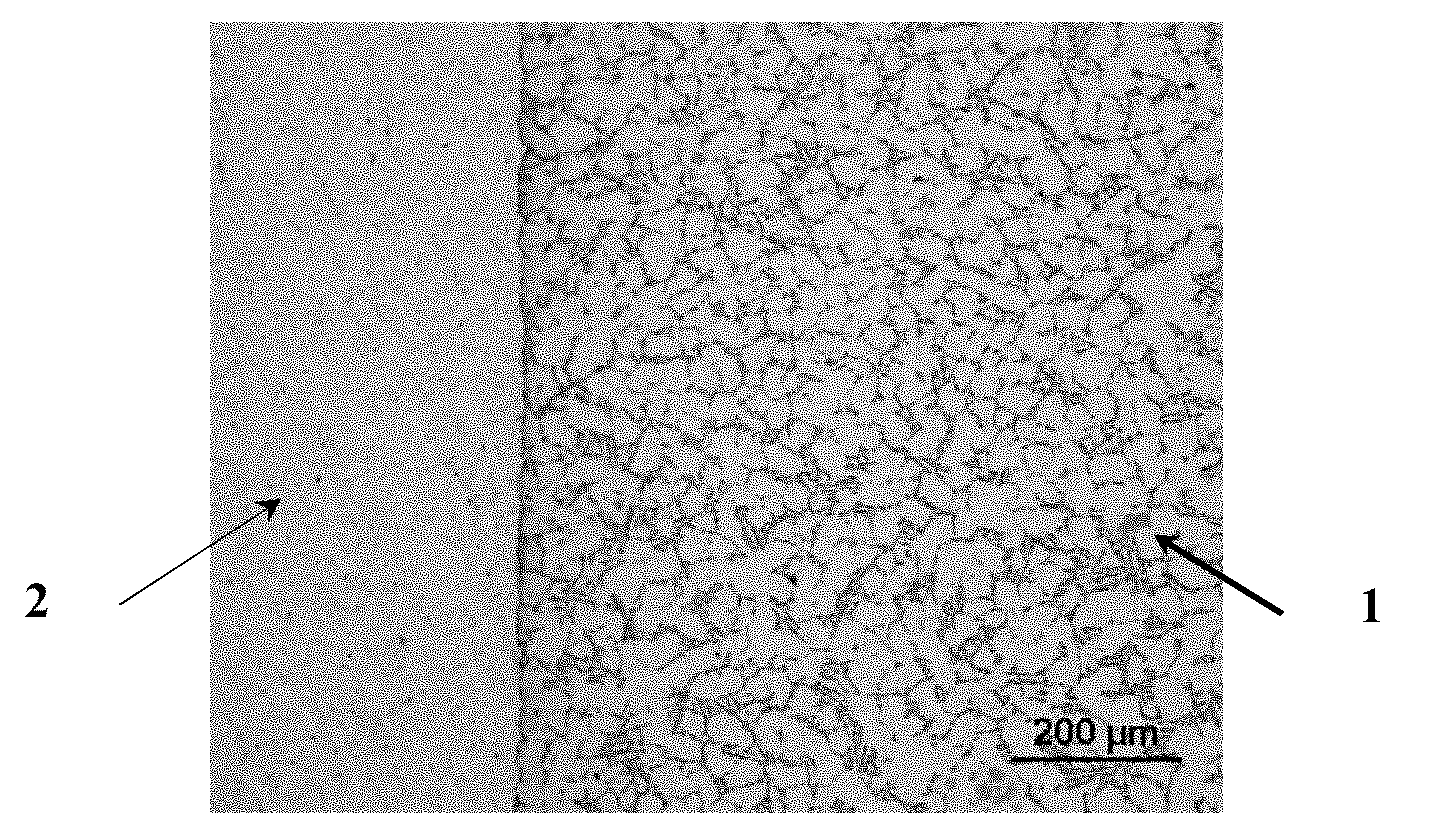

Siallite-natural rubber composite material and method for making same

The invention discloses a siallite-natural rubber composite material, which can be used for making natural rubber products such as tires, hoses and shoes, etc., and a preparation method thereof. The material has the advantages of low cost, tear resistance, being stretch-proof, good moisture and slide resistance, and being difficult to generate heat. The material comprises the following components according to weight proportion: 100 parts of natural rubber or natural rubber latex calculated according to stem rubber; 10 to 60 parts of siallite; 0.1 to 2.0 parts of coupling agent, 0.1 to 1.5 parts of crosslinking agent and other processing agent. The preparation method comprises steps that: the natural rubber is used as a raw material; the siallite is evenly dispersed on the natural rubber in routine combining, mixing or coprecipitating processes to make the siallite-natural rubber composite material; the composite material can be vulcanized by adopting routine technique.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Shaping method suitable for flexible glass drawing

ActiveCN108249743ARapid coolingPrecise temperature controlGlass forming apparatusEngineeringSilicon carbide

The invention relates to a shaping method suitable for flexible glass drawing and belongs to the technical field of flexible glass drawing and shaping. Shaping is conducted by a shaping furnace; a glass tape flows out of a platinum leakage plate mouth, is stretched thinly by an edge drawing machine, is pulled by a pull roller and enters the shaping furnace; the shaping furnace comprises three layers of heating modules which are arranged symmetrically; a polycrystal silicon carbide soaking plate is arranged on one side, facing towards the glass tape, of each heating module; a cooling device isarranged between the first layer of heating module and the second layer of heating module; the machine head of the edge drawing machine is arranged between the first layer of heating modules which arearranged symmetrically; the pull roller is arranged between the second layer of heating modules which are arranged symmetrically; and the pull roller is arranged between the third layer of heating modules which are arranged symmetrically. The shaping method provided by the invention is stable in shaping effect; and in the drawn flexible glass, the thickness is 0.04 mm, the thickness different ineffective size is less than or equal to 10 um, and the warping degree is less than or equal to 0.1 percent.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE +1

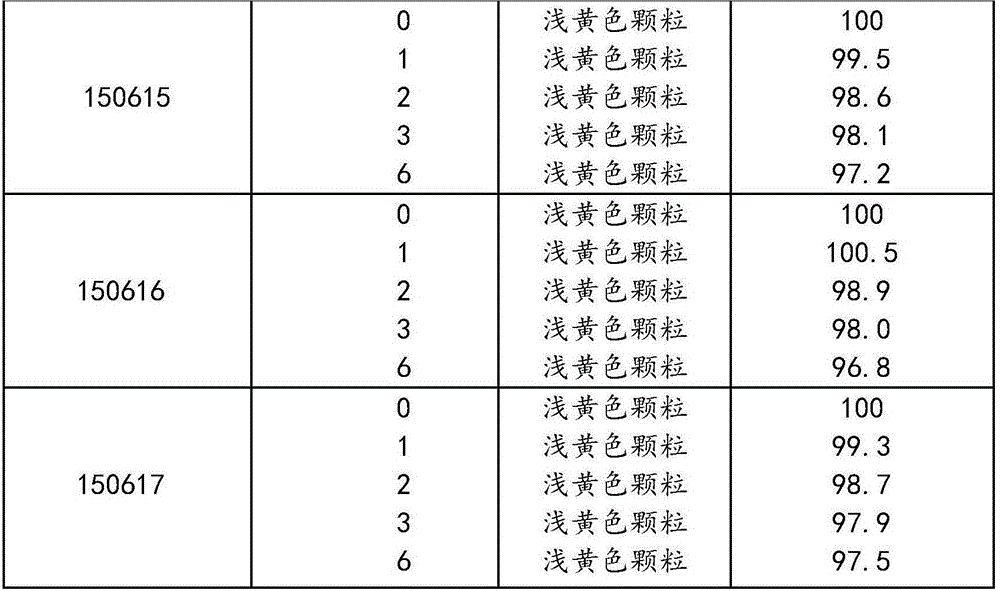

Acetylisovaleryl tylosin tartrate granular preparation and preparation method thereof

ActiveCN106361707AEvenly dispersedWell mixedAntibacterial agentsOrganic active ingredientsSpray GranulationDispersity

The invention discloses an acetylisovaleryl tylosin tartrate granular preparation and a preparation method thereof. The acetylisovaleryl tylosin tartrate granular preparation comprises the following steps: (1) preparing, namely, respectively weighing acetylisovaleryl tylosin tartrate and a carrier auxiliary material according to a formula ratio for later use; (2) mixing, namely, heating to melt the carrier auxiliary material, uniformly stirring, mixing acetylisovaleryl tylosin tartrate with the molten carrier auxiliary material, shearing, uniformly stirring so as to obtain a uniform dispersed system, and preparing mixed liquid; and (3) performing condensation spraying pelletization, namely, pumping the mixed liquid of step (2) to a condensation spray granulation system, performing centrifugal spray pelletization so as to prepare acetylisovaleryl tylosin tartrate granules, cooling, screening by using an oscillation sieve being 20-120 meshes, and collecting, thereby obtaining a product. According to the acetylisovaleryl tylosin tartrate granules prepared by the invention, the main medicine is uniformly distributed, the granules are round and tidy, the flowability and the dispersity of the granular preparation can be improved, and the acetylisovaleryl tylosin tartrate granular preparation can be easily mixed with feed; in addition, the acetylisovaleryl tylosin tartrate granular preparation adopts a simple production process, and is good in smell masking effect and good in slow-release effect.

Owner:GUANGDONG WENS DAHUANONG BIOTECH

Seabuckthorn leaf instant tea and preparation method

The present invention relates to a seabuckthorn leaf instant tea, it is a seabuckthorn instant tea powder made up by utilizing water extract of seabuck thorn leaf through the processes of drying and blending. Its preparation method includes the following steps: making the seabuckthorn leaf undergo the processes of steaming to retain its green colour, rolling and stir-drying, soaking in boiling water, extracting, filtering, concentrating, drying, blending and forming to obtain the product which can be directly drunk, and can be mixed with auxiliary materials of fruit juice and sugar for drinking so as to meet requirements of different consumers. In its processing course the impurities of scales, heavy metal, sand and pesticide residue can be completely removed with tea dregs, so that it is a pure clean beverage.

Owner:SHANXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com