Heating device capable of producing hot stamping parts with segmented-strength and production line with same and hot stamping forming method

A heating device and hot stamping technology, applied in the field of heating devices for hot stamping parts, can solve the problems of unsatisfactory and unrealizable soft zone process, narrow transition zone of soft and hard zone, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

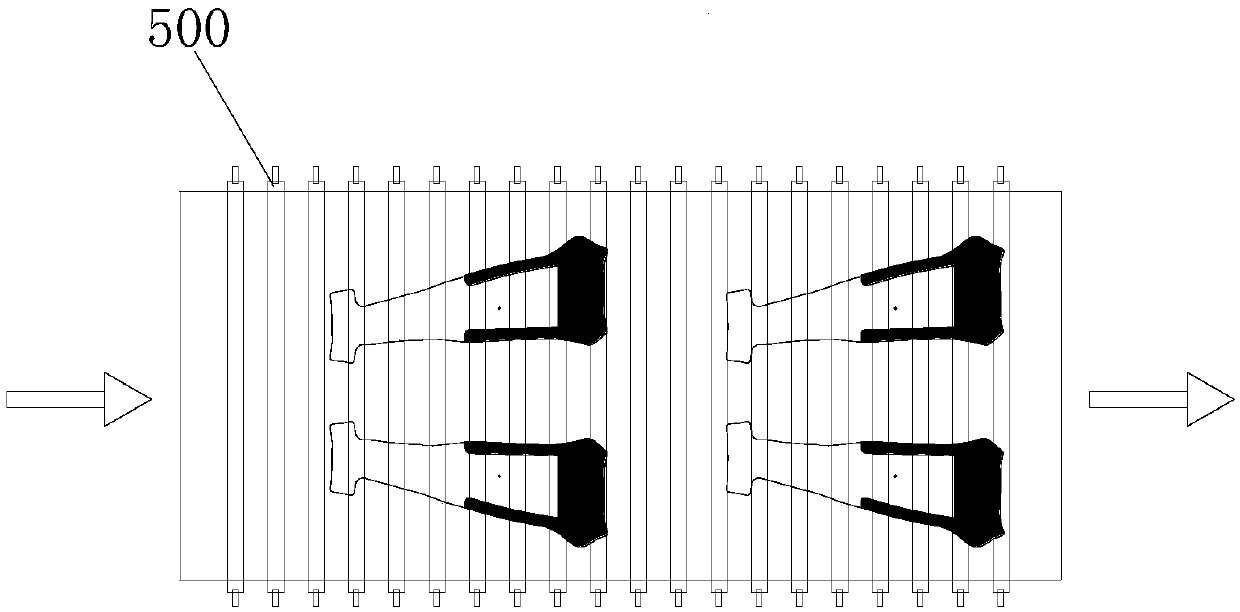

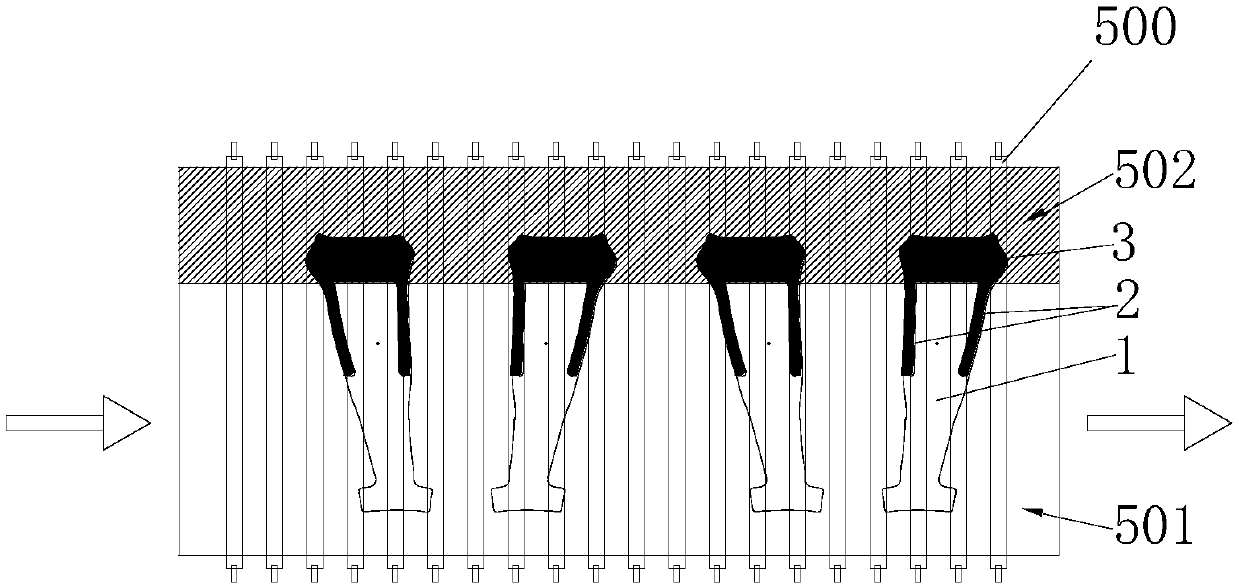

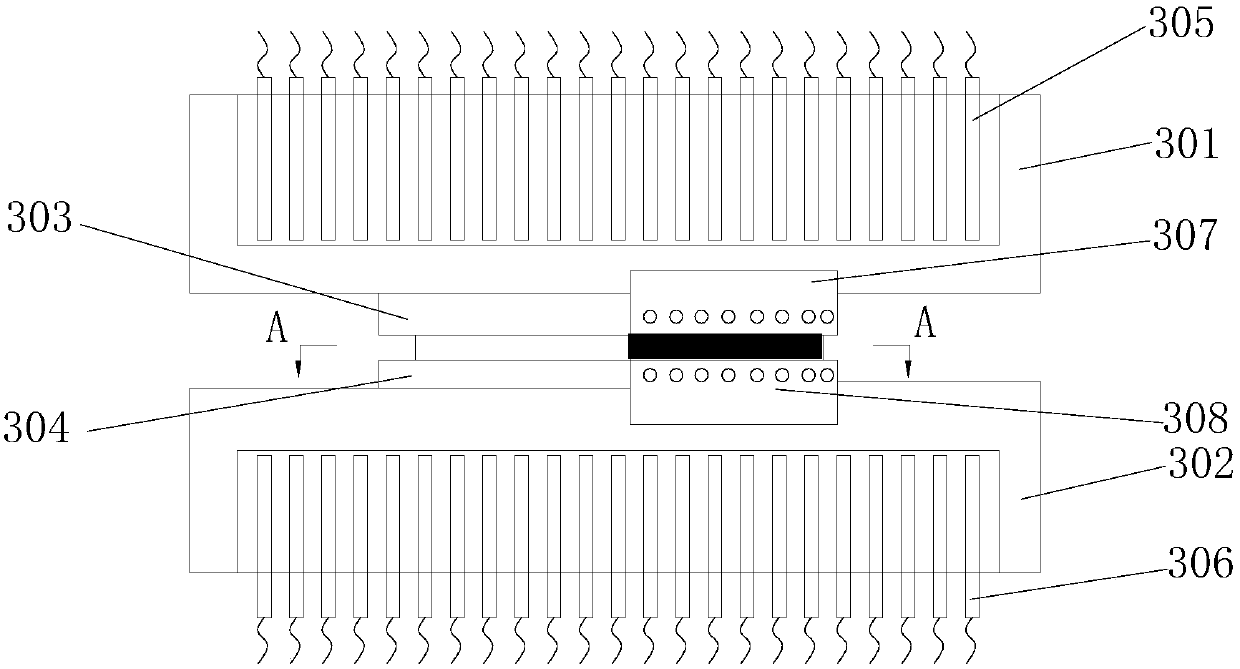

[0053] see Figure 3-5 A heating and cooling device 30 is shown, generally speaking, the heating and cooling device 30 includes a profiling heater and a pressurizing device, and the pressurizing device pressurizes the profiling heater. The pressurizing device preferably uses a hydraulic cylinder, which is a prior art and is not the focus of the present invention, and is not shown in the figure.

[0054] The heating and cooling device 30 includes: an upper heat insulating shell 301 and a lower heat insulating shell 302 arranged oppositely, one or both of the upper heat insulating shell 301 and the lower heat insulating shell 302 are connected to the pressurizing device , and pushed by the pressure device. The upper profiling heat transfer plate 303 and the lower profiling heat transfer plate 304 respectively arranged on the oppositely arranged surfaces of the upper adiabatic housing 301 and the lower adiabatic housing 302 are arranged on the upper adiabatic housing 301 and the...

Embodiment 2

[0070] This embodiment is basically the same as the first embodiment, the main difference lies in the structure of the heating and cooling device 30 .

[0071] In the first embodiment above, the soft regions 2 and 3 of the sheet are located at the outer periphery, but in this embodiment, the soft region 1b of the sheet is located inside, see Figure 6 . Between the soft zone 1b and the hard zone 1a of the web is a transition zone 1c of defined size.

[0072] The heating and cooling device 30 proposed by the invention is also well adapted to Figure 6 Thermoforming process of the blank shown. The specific solution is also similar to the first embodiment, that is, adjacently arranged profiling heat transfer plates and cooling blocks are arranged on the heat insulating shell, the profiling heat transfer plates correspond to the outline of the hard zone 1a, and the cooling blocks Corresponding to the contour of the soft zone 1b, the cooling block is surrounded by profiled heat ...

Embodiment 3

[0074] Furthermore, the idea of the present invention is also applicable to a more complicated arrangement of soft and hard areas of the material. For example, a tablet has a hard zone, a subhard zone and a soft zone, wherein the hard zone needs to achieve complete austenite transformation, so the temperature after final heating is above 860°C, preferably above 900°C; the secondary hard zone needs Realize partial austenite transformation, so the temperature after final heating is between 700°C and 860°C, preferably between 750°C and 820°C; the soft zone does not need to realize austenite transformation, so the temperature after final heating Below 700°C, preferably only around 600°C.

[0075] Correspondingly, the structural arrangement of the heating and cooling device 30 is as follows: corresponding to the hard area, sub-hard area and soft area, the first profiling heat transfer plate, the second profiling heat transfer plate, Hot plate and cooling block. Each profiling h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com