Methanation reactor and methanation process

A methanation reactor and reactor technology, applied in chemical instruments and methods, petroleum industry, chemical/physical processes, etc., can solve problems such as difficulty in eliminating thermal expansion and contraction stress, large pressure drop in the reactor, and difficulty in bearing high pressure. , to achieve the effect of improving the conversion rate of raw materials, increasing the degree of turbulence, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

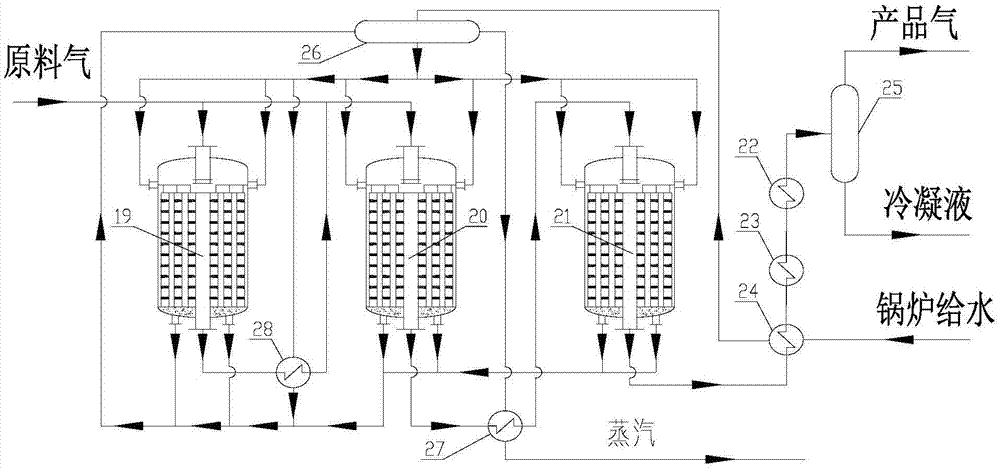

[0084] Such as image 3 As shown, the reaction device of this embodiment consists of 1# main methanation reactor 19, 2# main methanation reactor 20, 1# supplementary methanation reactor 21, 1# cooler 22, 2# cooler 23, boiler Feed water heater 24, product separator 25, steam drum 26, steam superheater 27 and 1# waste heat boiler 28 are connected. 1# main methanation reactor 19 and 2# main methanation reactor 20 are connected in series and parallel.

[0085] The operation steps are as follows:

[0086] 1. Put H 2 The / CO volume ratio is 3.0 (M=3.0), the synthesis gas with a pressure of 3.5MPa and a temperature of 280°C is divided into two streams, and the first stream enters the 1# main methanation reactor 19 for the 1# main methanation reaction. The temperature is 650°C, the pressure is 3.48MPa, and the volumetric space velocity is 9000h -1 , the reacted gas passes through the 1# waste heat boiler 28 to remove part of the heat, and enters the 2# main methanation reactor 20 ...

Embodiment 2

[0096] Such as Figure 6 As shown, the difference between the process used in this example and Example 1 is that 2# waste heat boiler 30 and 2# supplementary methanation are set between 1# supplementary methanation reactor and boiler feed water heater 24 in this example The reactor 29, the internal radial catalytic reaction zone of the main methanation reaction and supplementary methanation reactor are also different from the embodiment 1.

[0097] After passing through the 1# supplementary methanation reactor 21, the reaction materials are sent to the 2# supplementary methanation reactor 29 to continue the supplementary methanation reaction through the 2# waste heat boiler 30 to remove part of the heat, and the second product obtained is passed through the boiler feed water After the heater 24, the 2# cooler 23 and the 1# cooler 22 are lowered in temperature, the methanation product is separated after the product separator 25; the conversion rate of carbon monoxide is 99.99% ...

Embodiment 3

[0101] Such as Figure 9 As shown, the process adopted in this embodiment is the same as that in Embodiment 1. The difference is that the main methanation reactor used in this embodiment is different from the heat extraction equipment inside the supplementary methanation reactor, such as Figure 7 , Figure 8 shown.

[0102] In this embodiment, the conversion rate of carbon monoxide is 100%, the selectivity of methane is 97%, and superheated steam of 10.4MPa and 530°C is produced as a by-product.

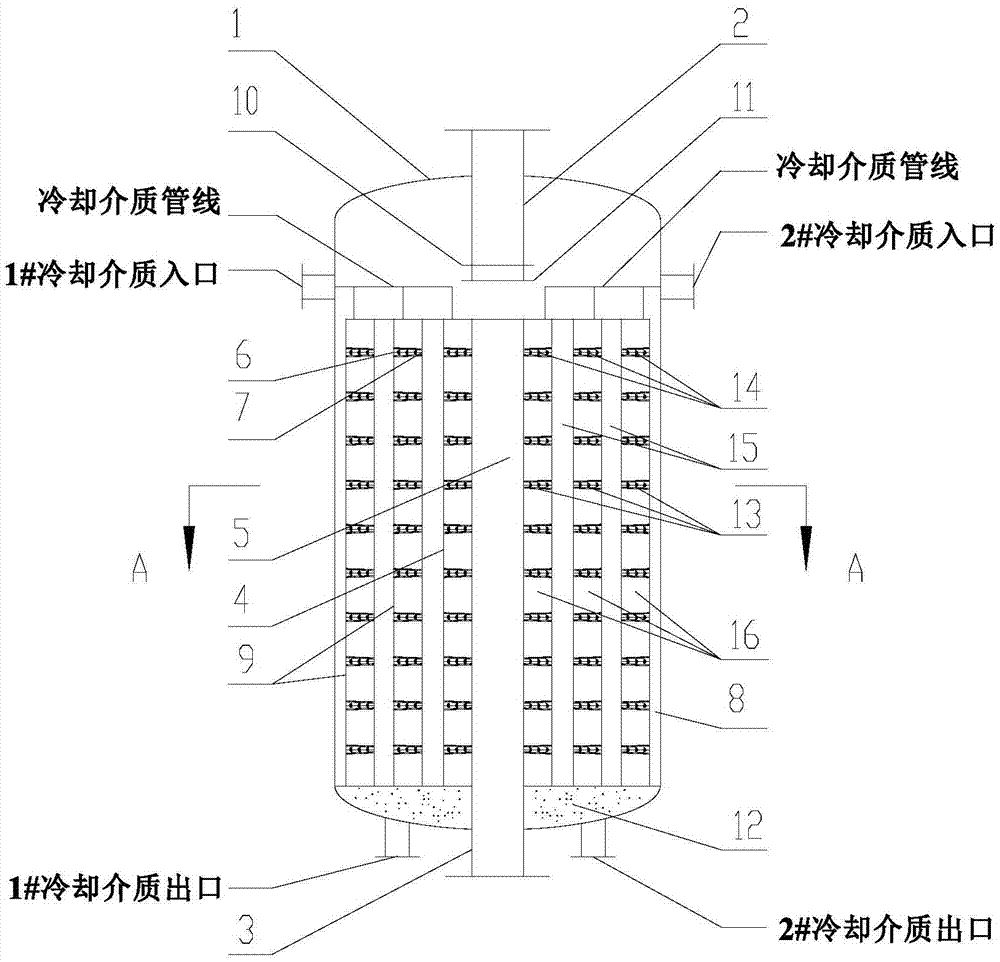

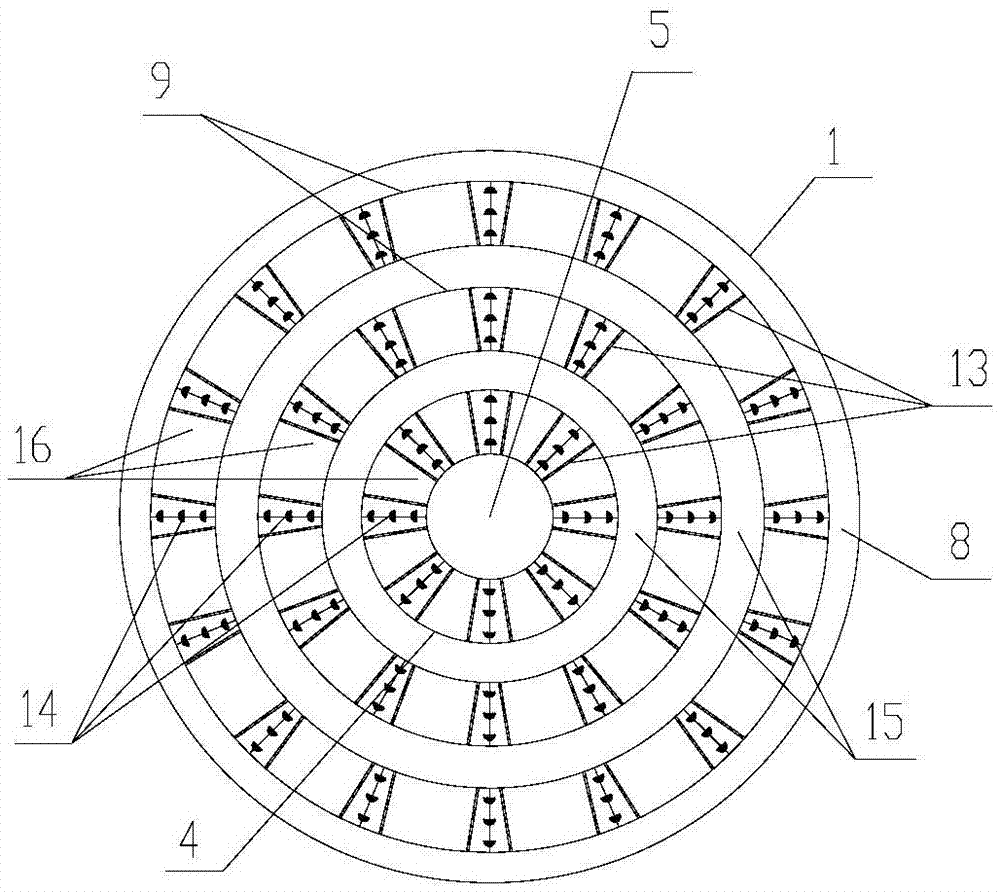

[0103] The difference between the methanation reactor used in this example and the methanation reactor used in Example 1 is that the heat extraction equipment in the methanation reactor used in this example is arranged in two collectors 15 , the cooling medium inlet and the medium outlet are in fluid communication through the cooling medium pipeline arranged in the manifold 15 and surrounding the central cylinder 4 and the sleeve 9 . The cooling medium enters the interior of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com