Patents

Literature

40results about How to "No hot spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

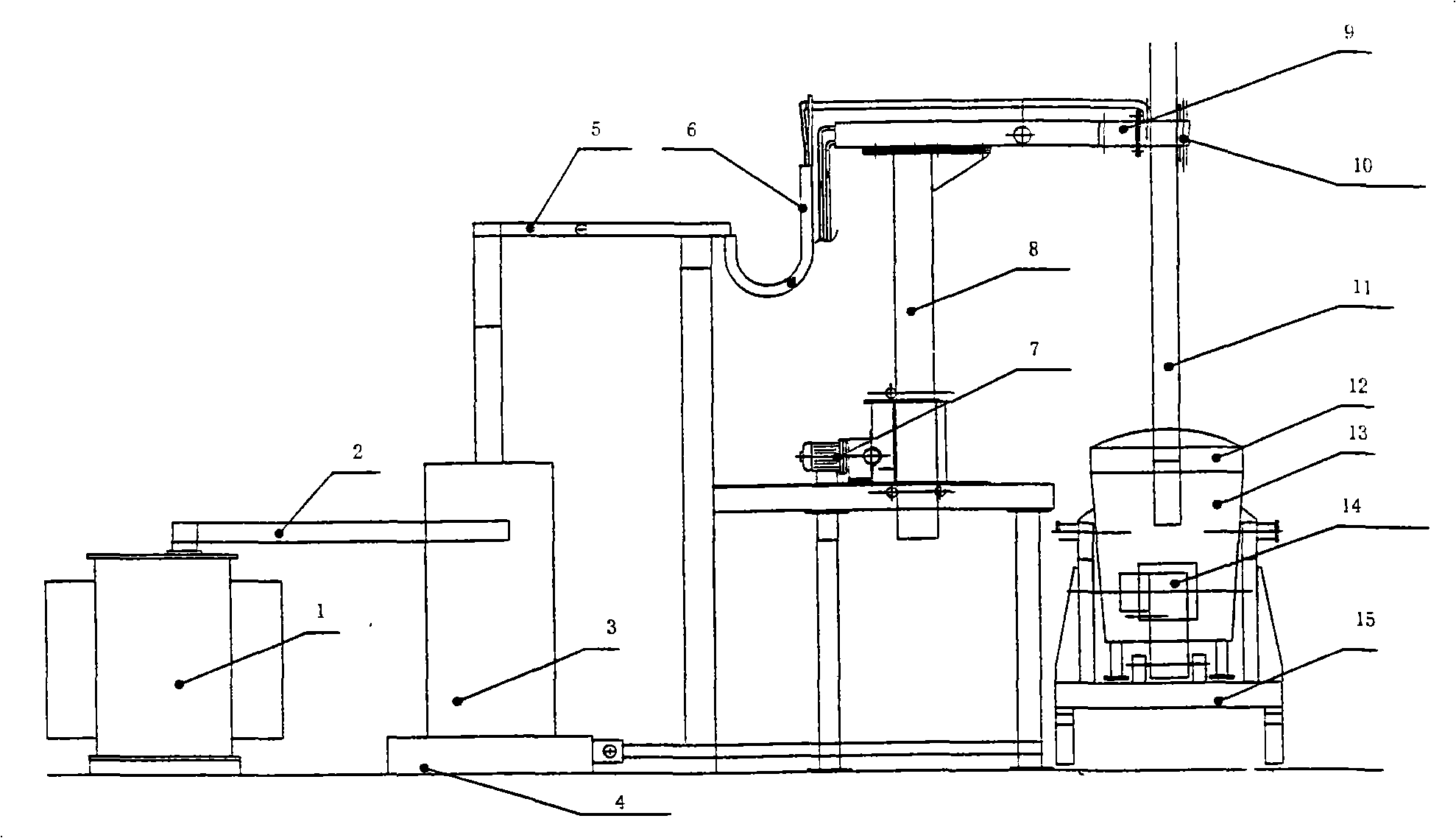

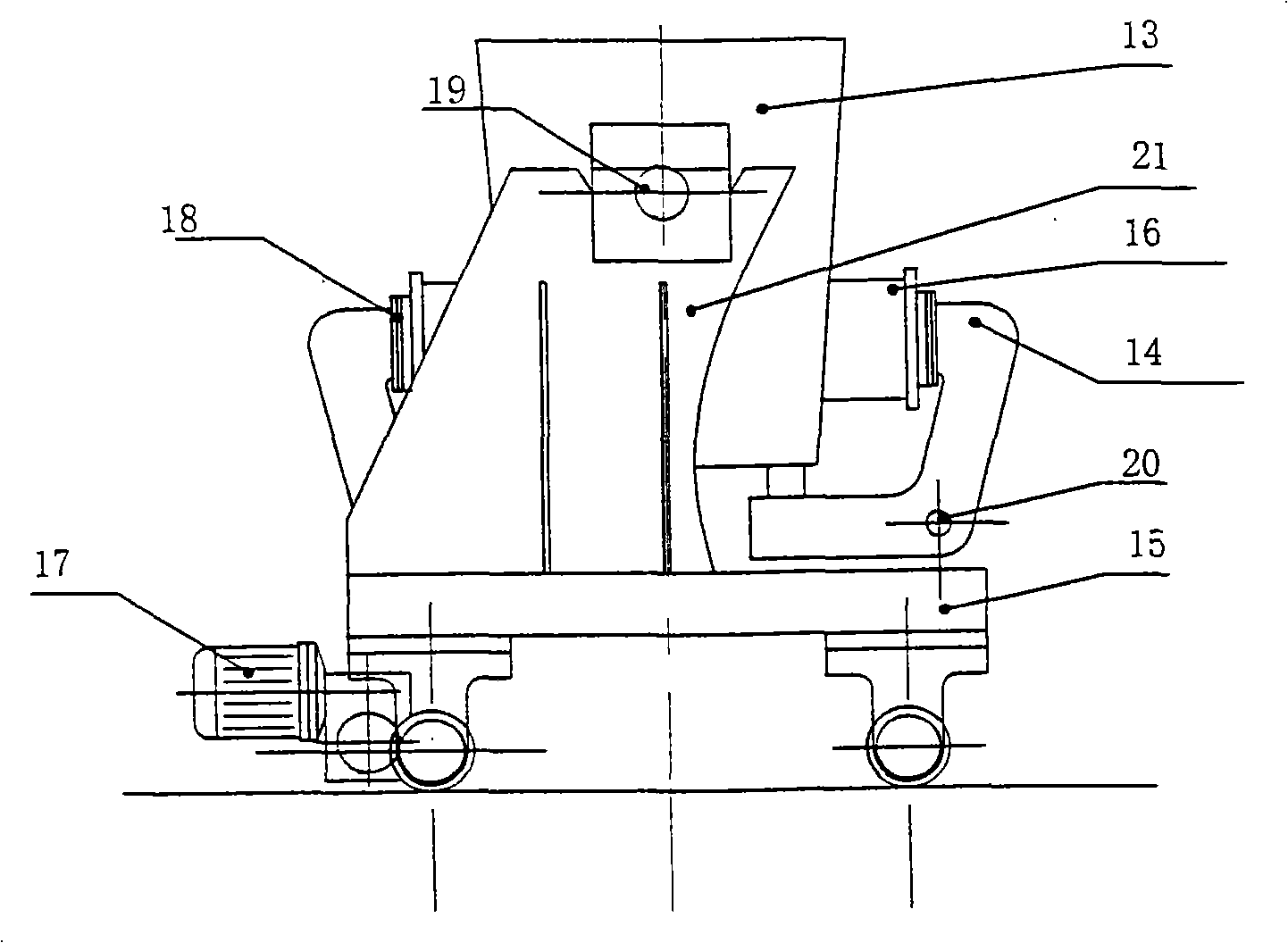

Motor car wheel tread sweeper shape-repair grinding device and preparation method thereof

ActiveCN107188456ANo damageVisibly repairs wheel surface imperfectionsVehicle cleaningBrake arrangement with braking memberRoom temperatureGraphite

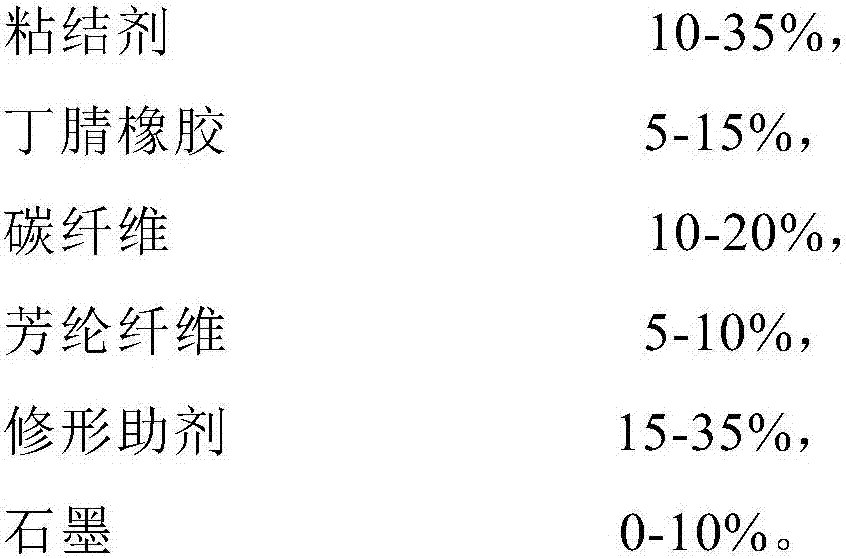

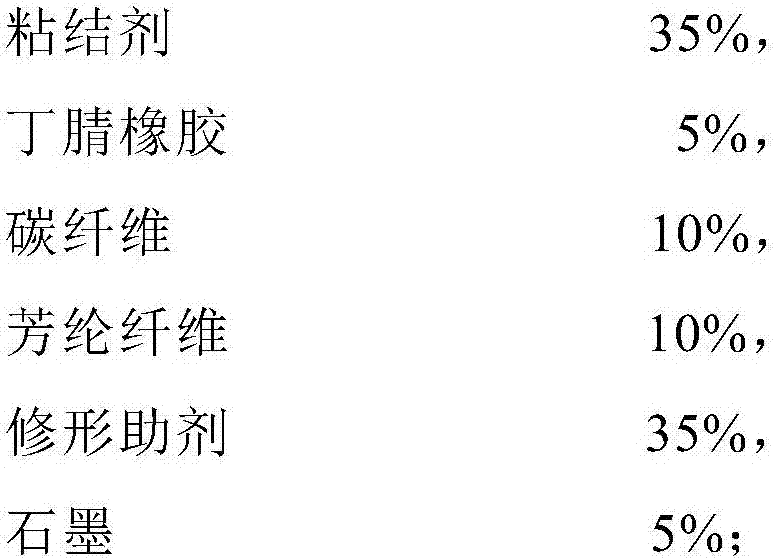

The invention relates to a motor car wheel tread sweeper shape-repair grinding device and a preparation method thereof. The preparation method comprises: preparing the following raw materials by weight: 10-35% of a binder, 5-15% of nitrile butadiene rubber, 10-20% of carbon fiber, 5-10% of aramid fiber, 15-35% of a shape-repair aid, and 0-10% of graphite; adding the raw materials to a high speed plow harrow type material mixer in steps according to a certain ratio, mixing for 5-10 min, carrying out a reaction for 200-500 s in a molding mold at a temperature of room temperature to 150 DEG C under a pressure of 200-600 kg / cm<2>, and carrying out high temperature sintering on the molded grinding device for 5-20 h at a sintering temperature of 100-140 DEG C so as to obtain the motor car wheel tread sweeper shape-repair grinding device. Compared to the grinding device in the prior art, the grinding device of the present invention is used in the Changke standard multiple units, can significantly repair the wheel surface defects and the non-roundness, has characteristics of no undesirable phenomena such as cracks, hot spots, sparks, metal embedding, layering, shedding and the like, no damage to the dual, and good effect.

Owner:SHANGHAI REINPHEN NEW MATERIAL TECH CO LTD

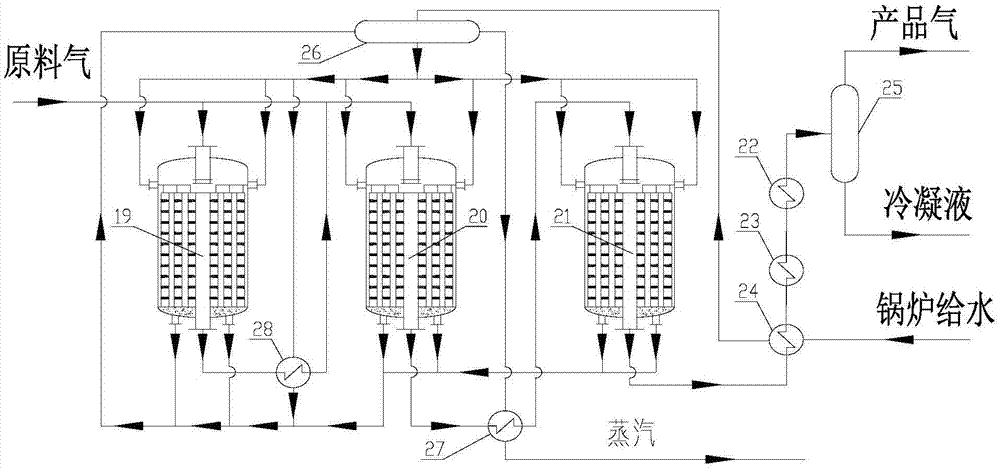

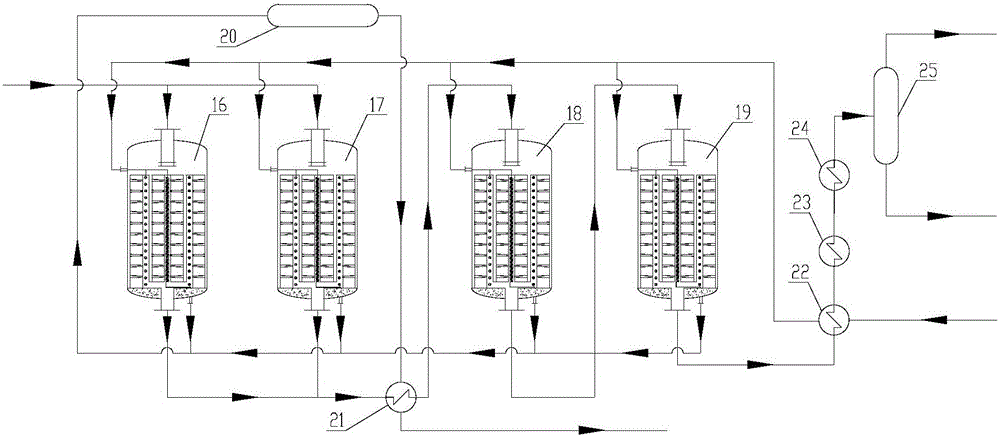

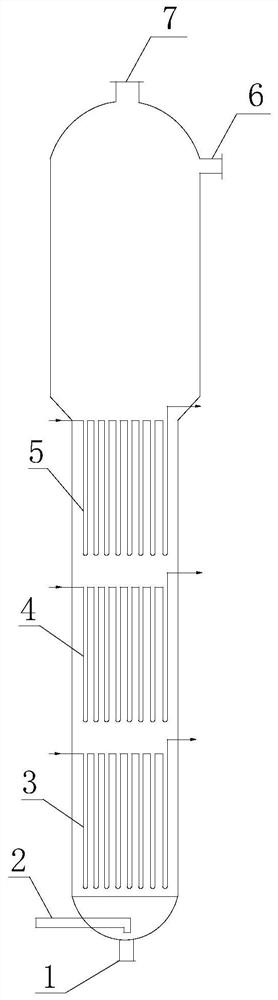

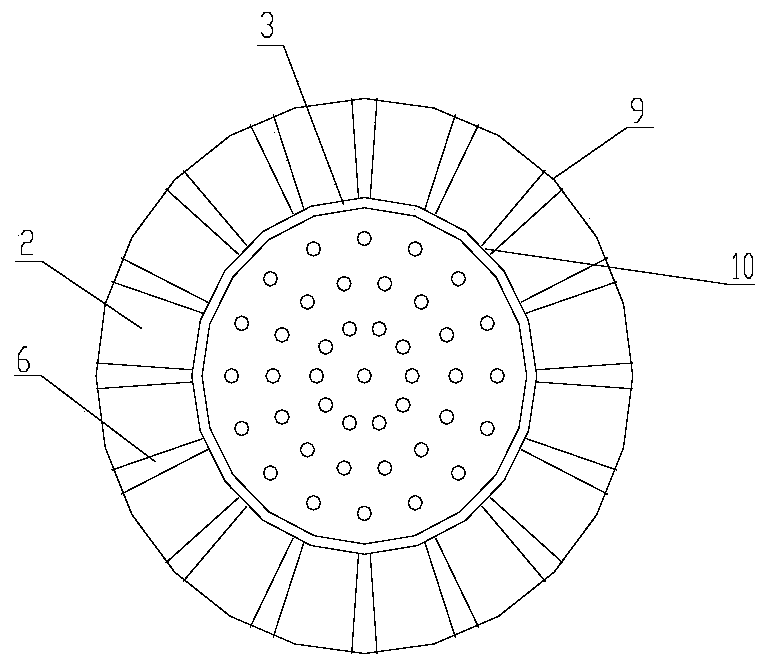

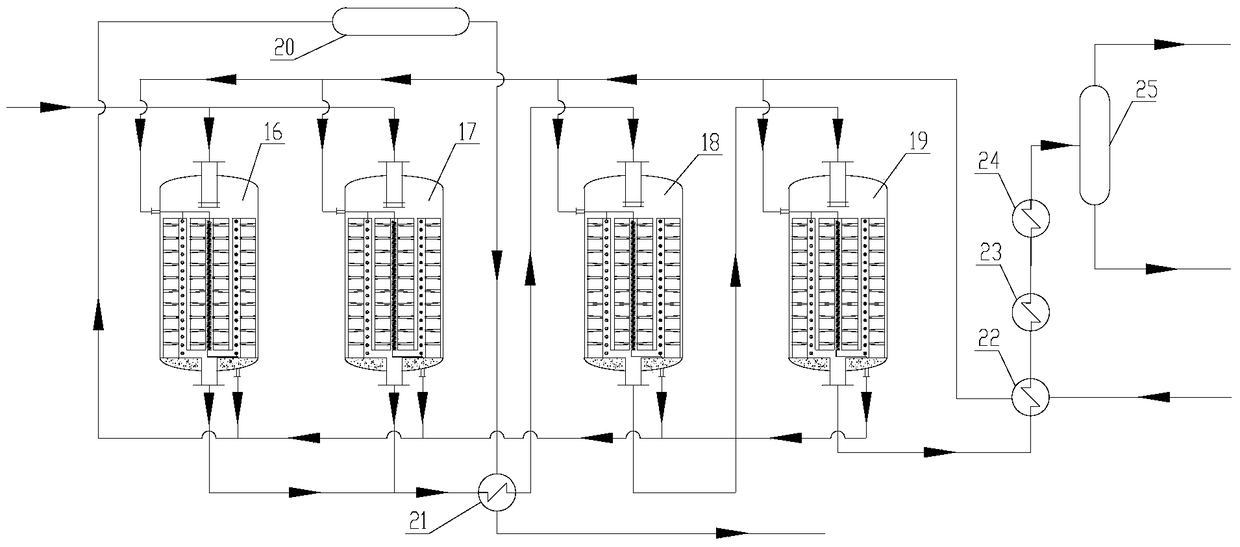

Methanation reactor and methanation process

ActiveCN107224940AIncreased turbulenceImprove conversion rateGaseous fuelsChemical/physical processesMethanationEconomic benefits

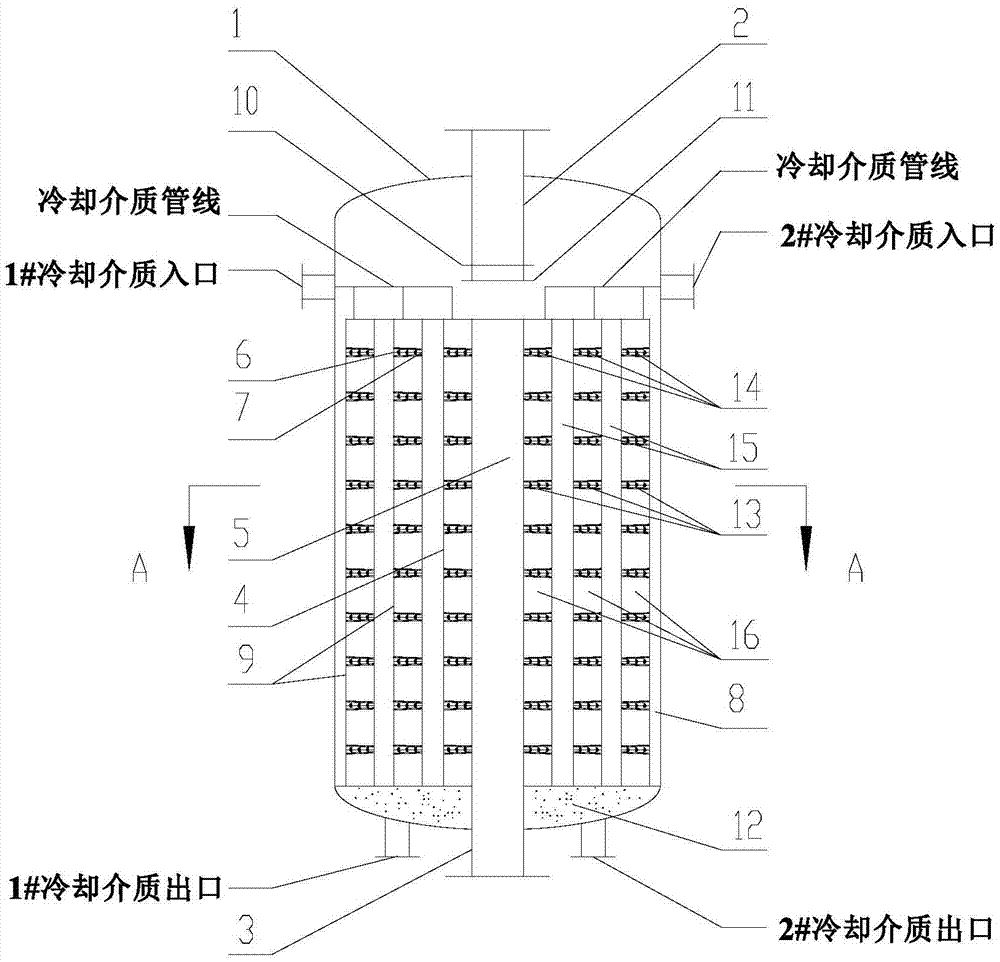

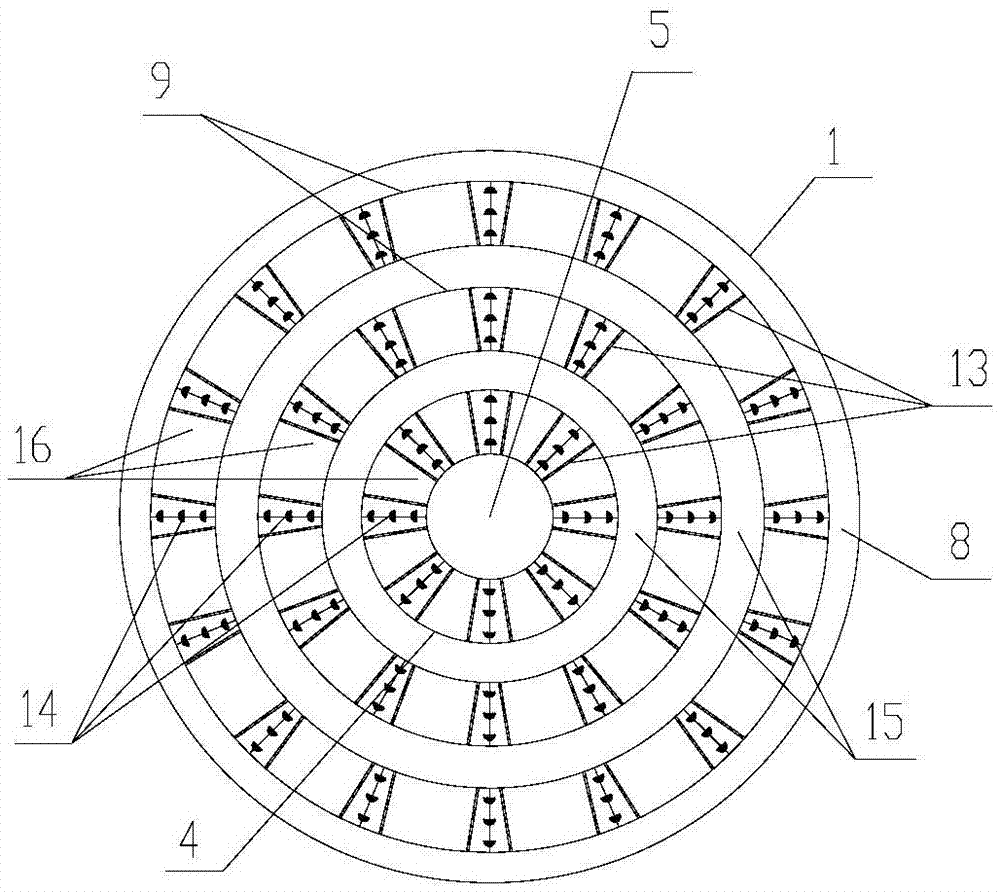

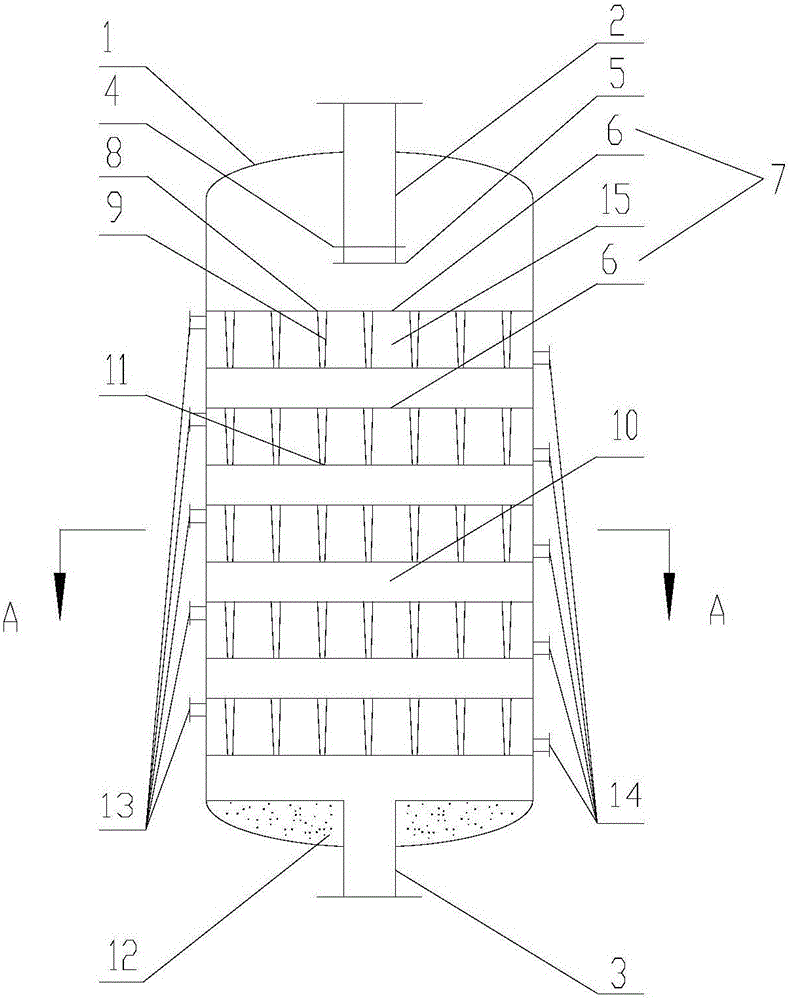

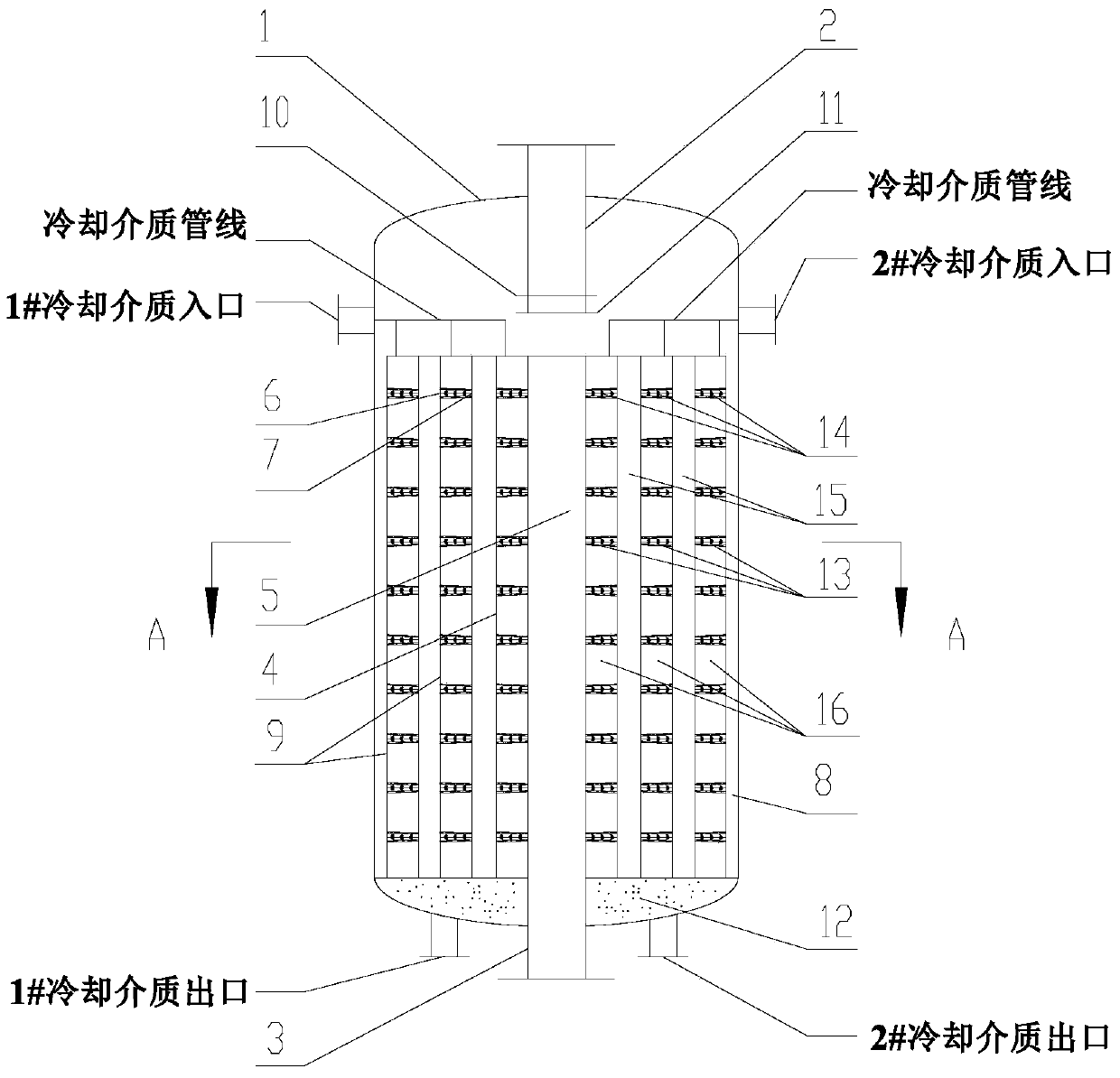

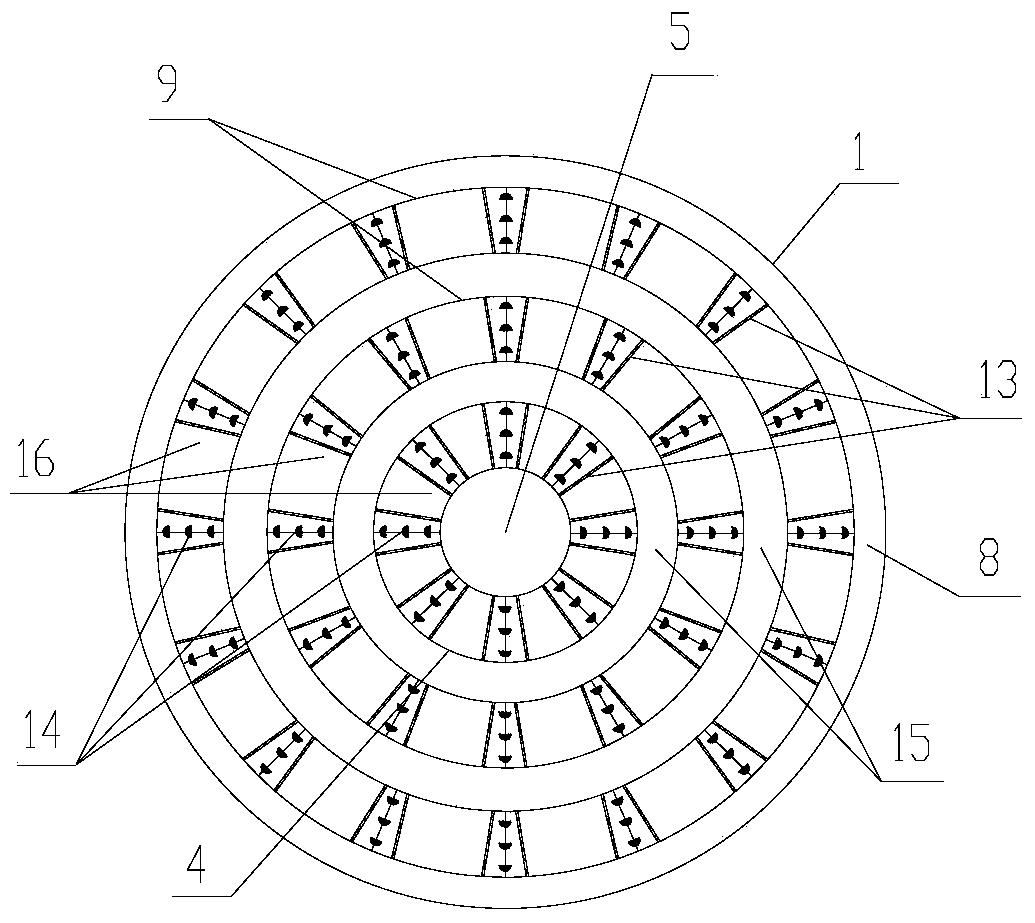

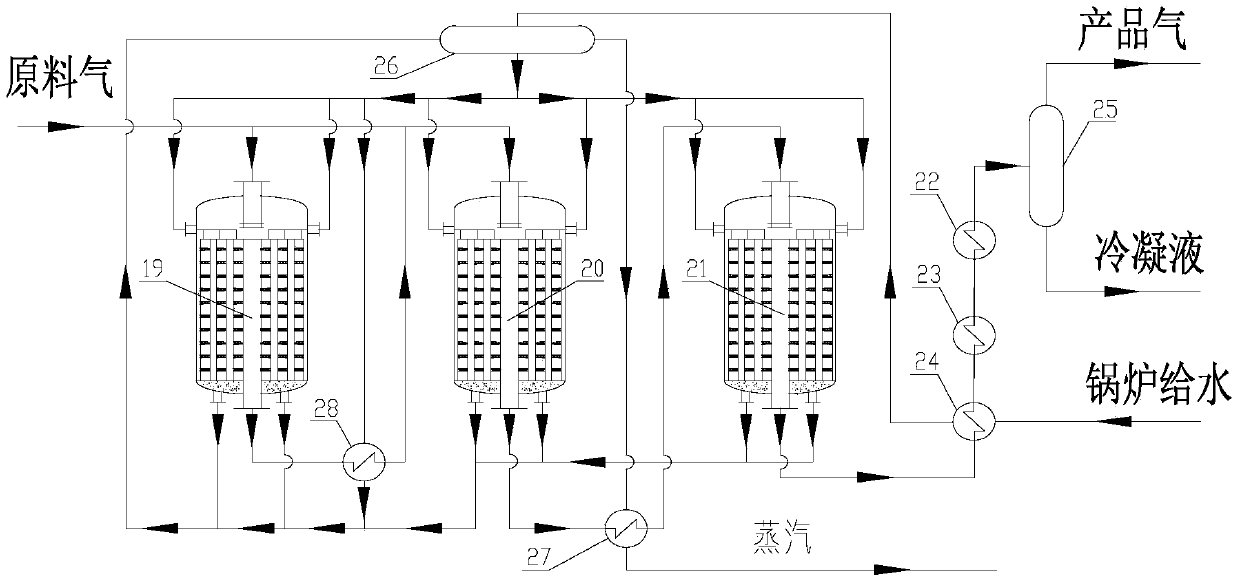

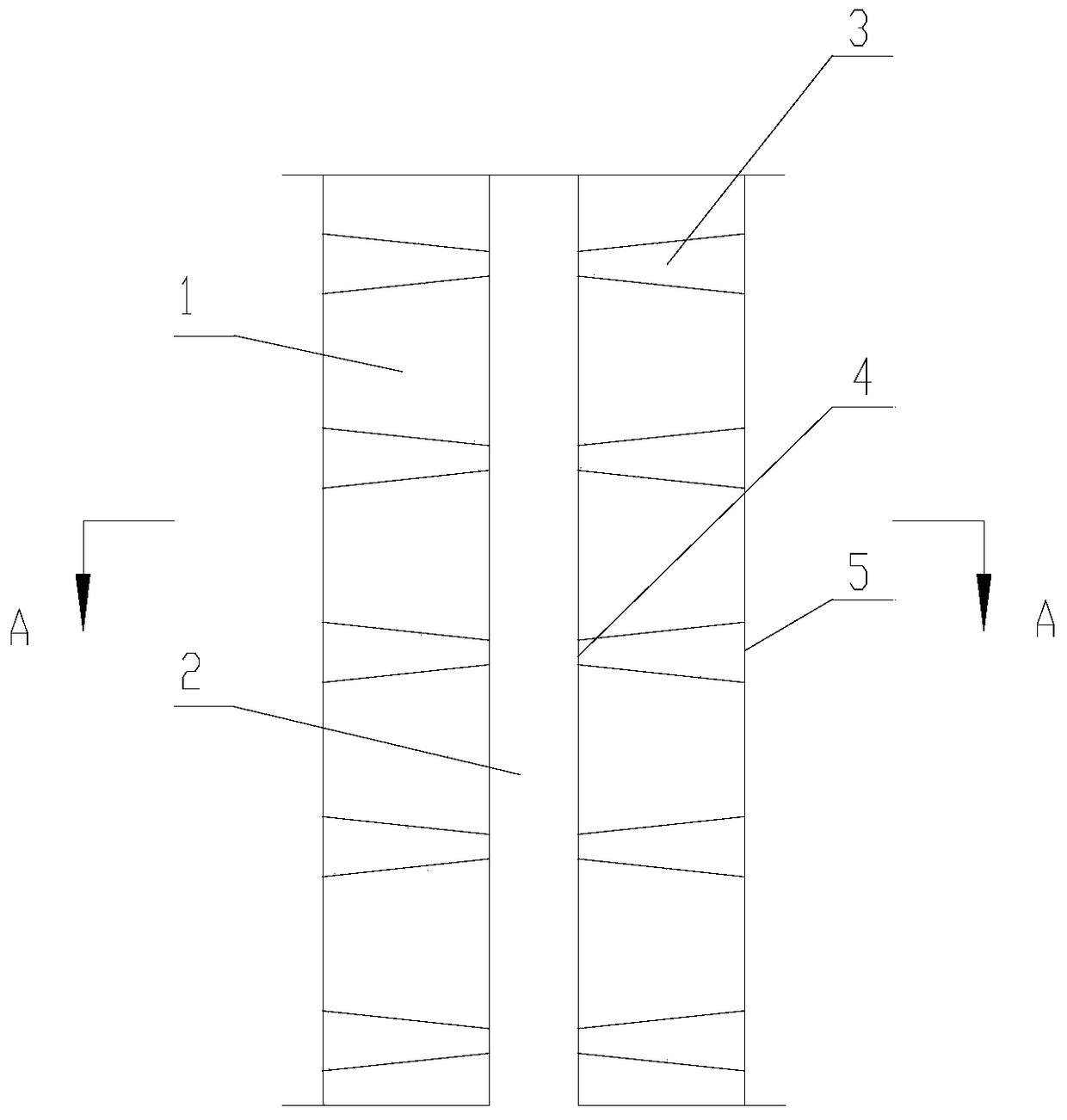

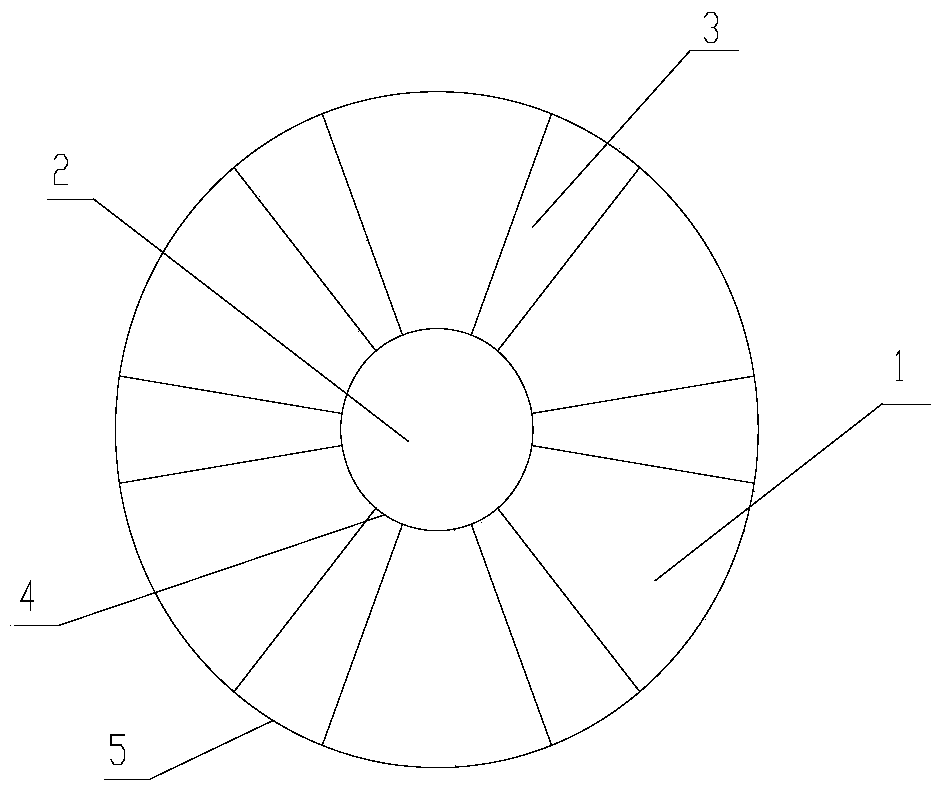

The invention discloses a methanation reactor and a methanation process. The reactor comprises a cylindrical sealed pressure-bearing shell body (1), a gas inlet pipe (2), a gas outlet pipe (3), a radial catalytic reaction zone and heating equipment, wherein the gas inlet pipe (2) extends inside the shell body from the top of the shell body (1), the gas outlet pipe (3) extends inside the shell body from the bottom of the shell body (1), and the radial catalytic reaction zone is formed in the shell body (1) below the gas inlet pipe (2) and above the gas outlet pipe (3) and comprises the heating equipment. Compared with the prior art, the methanation reactor and the methanation process have the advantages that the methanation reactor disclosed by the invention is low in active metal consumption and smaller in equipment size, and the methanation process adopting the methanation reactor is low in bed layer pressure drop and high in feedstock conversion ratio, is free of gas bias and short-circuit phenomena and has the characteristics of high economic benefit, low comprehensive energy consumption and the like.

Owner:SINOPEC ENG +1

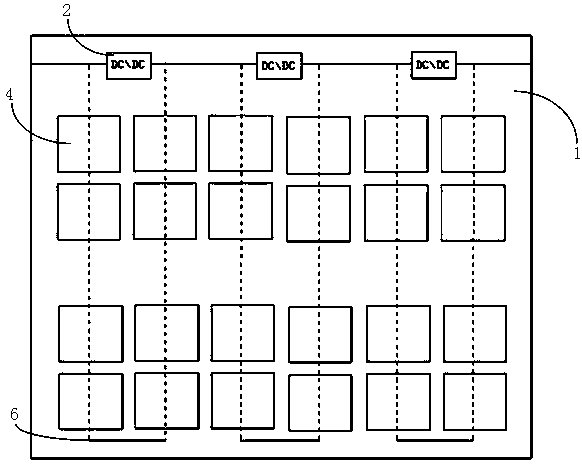

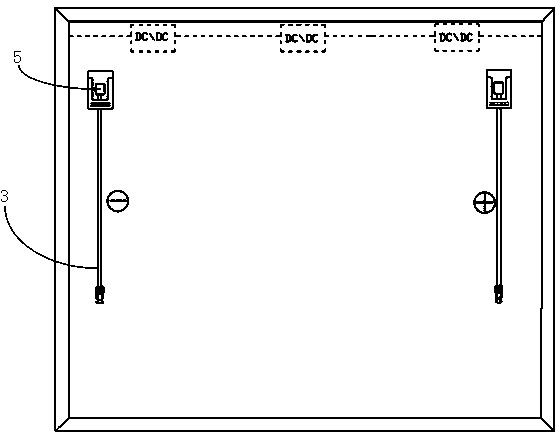

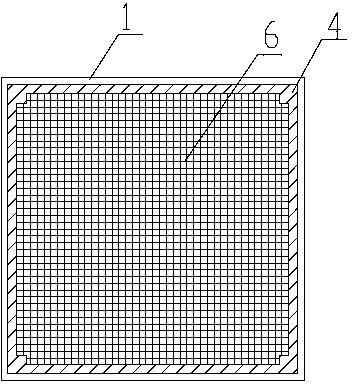

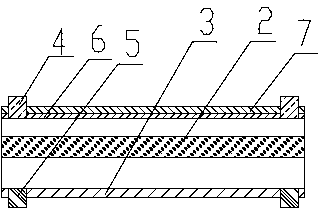

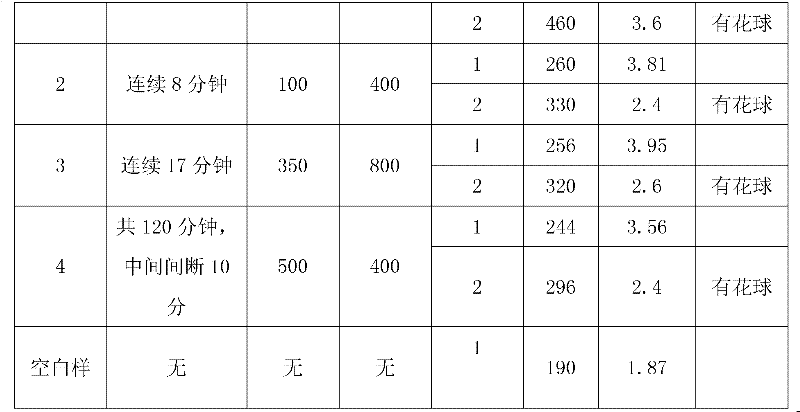

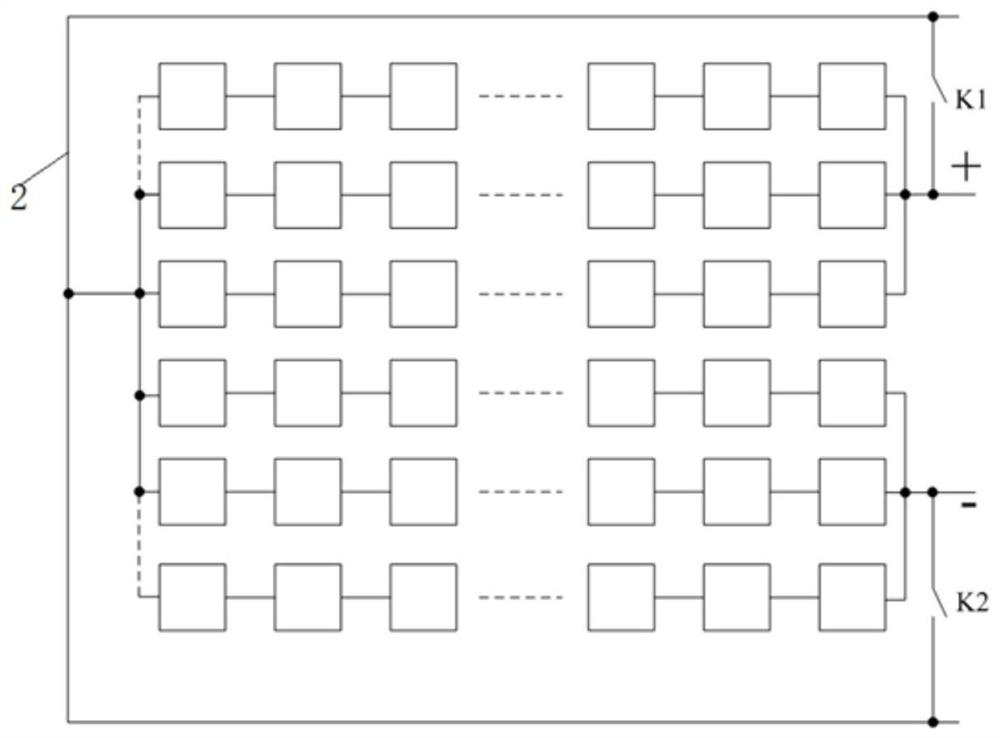

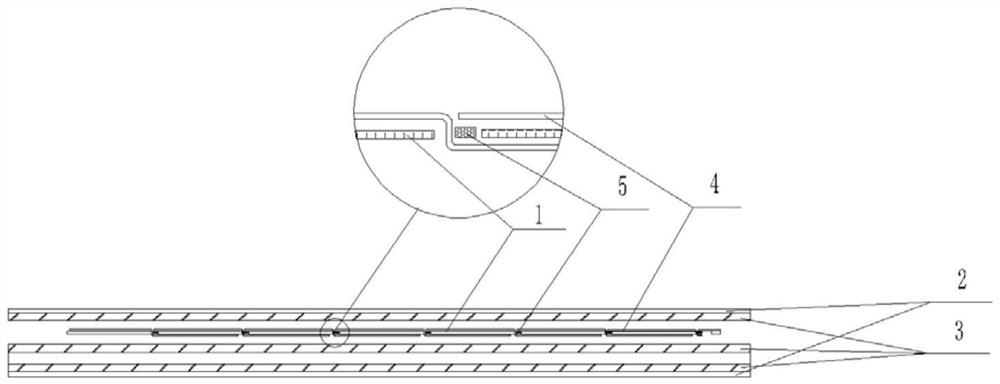

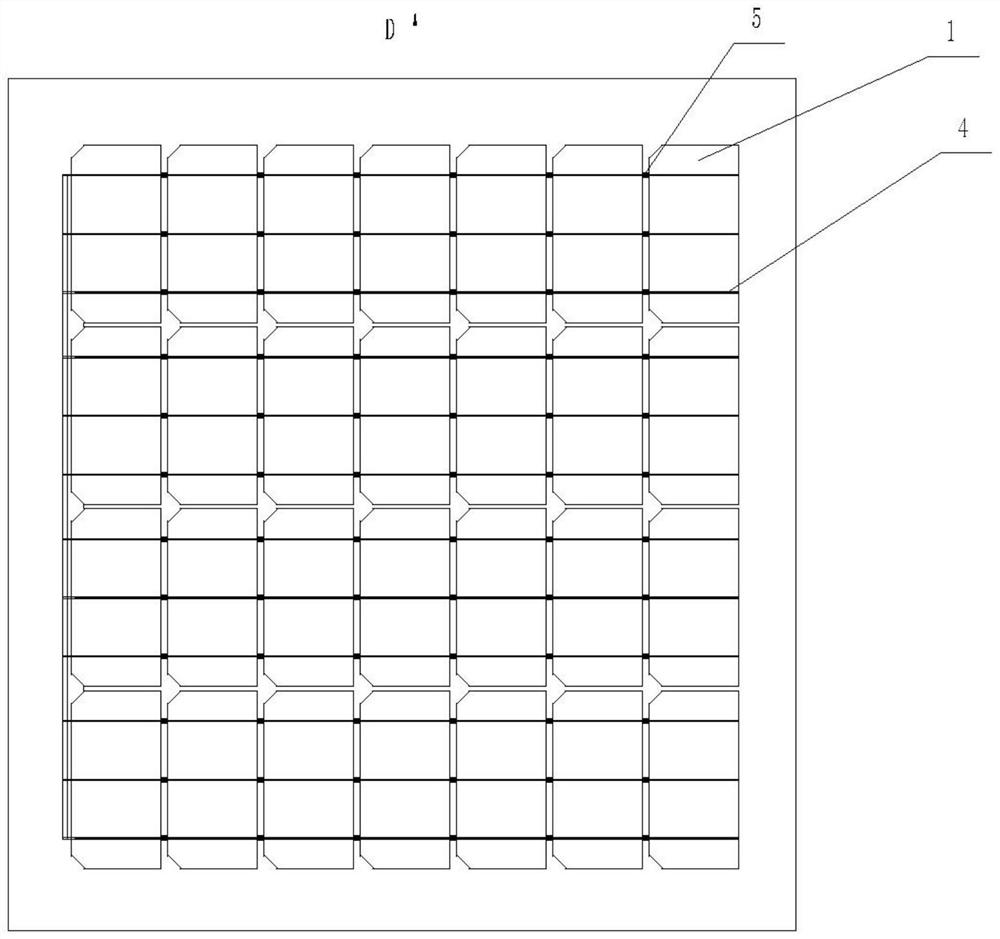

Intelligent photovoltaic module internally provided with chip

InactiveCN104078524AImprove reliabilityExtended service lifeSolid-state devicesPhotovoltaicsSemiconductor chipEngineering

The invention discloses an intelligent photovoltaic module internally provided with a chip. The intelligent photovoltaic module comprises tempered glass, EVA layers, a back plate and a solar cell slice layer. The two sides of the solar cell slice layer are provided with the EVA layers. The sides, away from the solar cell slice layer, of the two EVA layers are provided with the tempered glass and the back plate respectively. The intelligent photovoltaic module further comprises the intelligent chip and a split wiring leading-out terminal without diodes, wherein the intelligent chip is arranged on the side, close to the tempered glass, of the solar cell slice layer, and the split wiring leading-out terminal is arranged on the side, away from the EVA layers, of the back plate. The solar cell slice layer is provided with at least one solar cell slice. According to the intelligent photovoltaic module, the intelligent semiconductor chip is used for being packaged inside the photovoltaic module, cell cascade-stage MPPT optimization is carried out, the maximum power output obtained when the module is shielded is improved, and meanwhile the reliability of the module is improved.

Owner:GD SOLAR

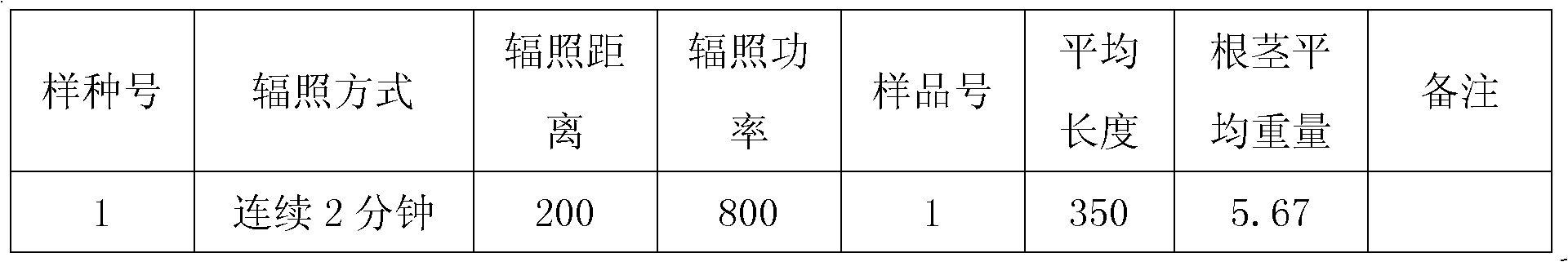

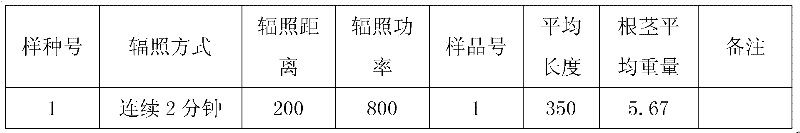

Far field microwave breeding method

ActiveCN101978804AImprove the effect of increasing productionIncrease productionSeed and root treatmentSocial benefitsMicrowave

The invention discloses a far field microwave breeding method, which comprises the following steps of: regularly irradiating active seeds of a crop by using far field microwave, and stimulating the potentials of the active seeds by using energy memory effect to obtain optimized active seeds of the crop with high yield increasing effect. Experiments such as large-headed atractylodes rhizome breeding and the like show that the method has remarkable advantage on the aspect of improving the yield compared with other methods for obtaining optimized active seeds of crops, the method has little probability of causing seed gene mutation and high safety, and the method is easy to realize diversification of optimized varieties and put into production practice, so the method has great economic benefit and social benefit.

Owner:曾文海 +2

Pouring sealant based on phase-change microcapsules and preparation method of pouring sealant

PendingCN111269689ALow viscosityImproved heat storage and temperature control capabilitiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesTemperature controlCompound a

The invention relates to the technical field of thermal management of electronic components, and particularly discloses a flame-retardant, insulating and reliable pouring sealant based on phase-changemicrocapsules, which is prepared from the following components in percentage by mass: 25 to 40 percent of double-component pouring sealant, 25 to 35 percent of phase-change microcapsules, 30 to 45 percent of flame retardant and 1 to 15 percent of other auxiliary agents. The invention also discloses a preparation method of the pouring sealant. The preparation method comprises the following steps:carrying out surface treatment on the phase-change microcapsules; compounding a flame retardant; and preparing the pouring silica gel. The surface of the phase change microcapsule is treated, so thatthe dispersity of the phase change microcapsule in colloid is improved, and meanwhile, the stability of the system is improved. By adding the phase change microcapsules, the heat storage and temperature control capability of the pouring sealant can be enhanced. The pouring sealant provided by the invention has good heat storage and temperature control performance and good high-temperature and high-humidity resistance.

Owner:STONEPLUS THERMAL MANAGEMENT TECH

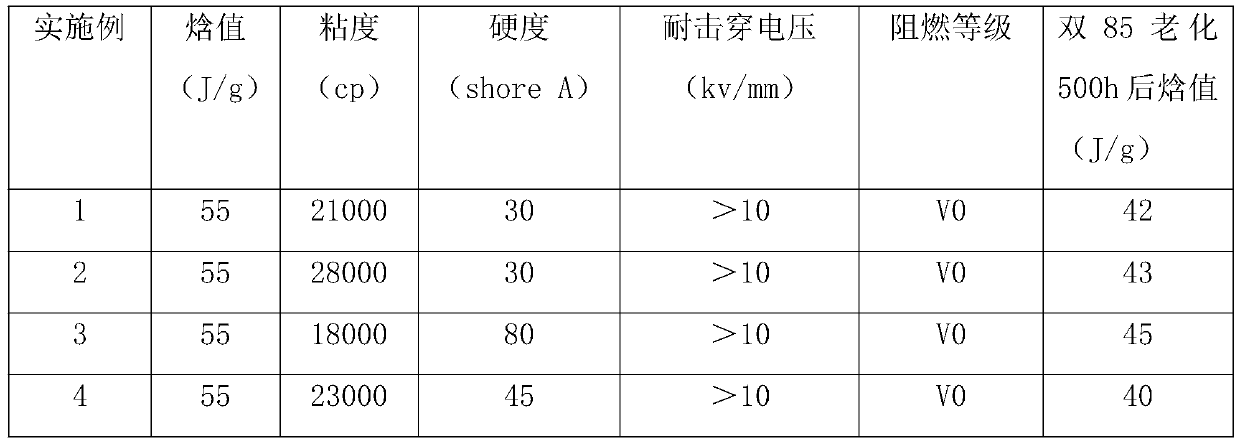

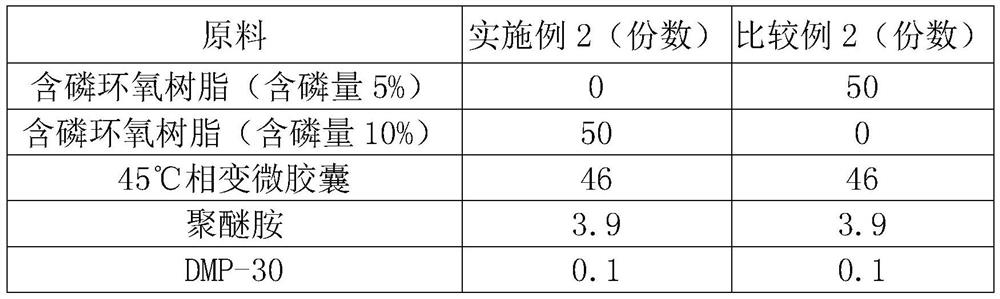

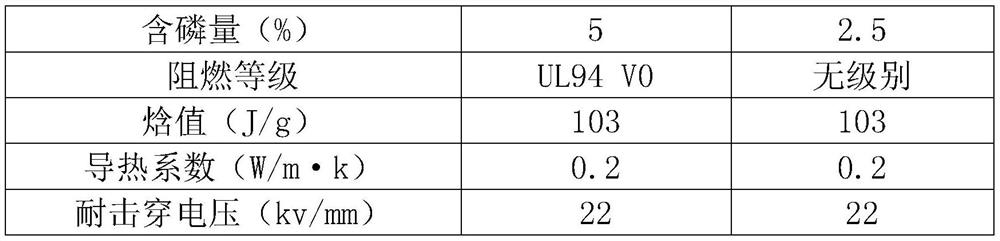

High-enthalpy-value flame-retardant phase-change material and preparation method thereof

PendingCN112029199AImprove reliabilityImprove insulation performanceHeat-exchange elementsEpoxyHeat management

The invention discloses a high-enthalpy-value flame-retardant phase-change material and a preparation method thereof. The high-enthalpy-value flame-retardant phase-change material is prepared from thefollowing raw materials in parts by mass: 25-55 parts of a base material, 45-70 parts of phase-change microcapsules subjected to surface treatment and 10-55 parts of a flame retardant, wherein the base material comprises one or more of ethylene propylene diene monomer, phosphorus-containing epoxy resin and addition type silica gel; the enthalpy value of the high-enthalpy-value flame-retardant phase change material is higher than 100 J / g. The flame-retardant phase-change material disclosed by the invention realizes unification of flame retardance and high enthalpy value, not only improves thesafety of the phase-change material, but also improves the heat storage and temperature control capacity of the phase-change material, is particularly suitable for heat management of application scenes such as high-power charging, high-heat-flux chips and high-density battery packs, ensures that a device has no local overheating area, and the stability and reliability of a product is increased.

Owner:SHENZHEN FRD SCI & TECH

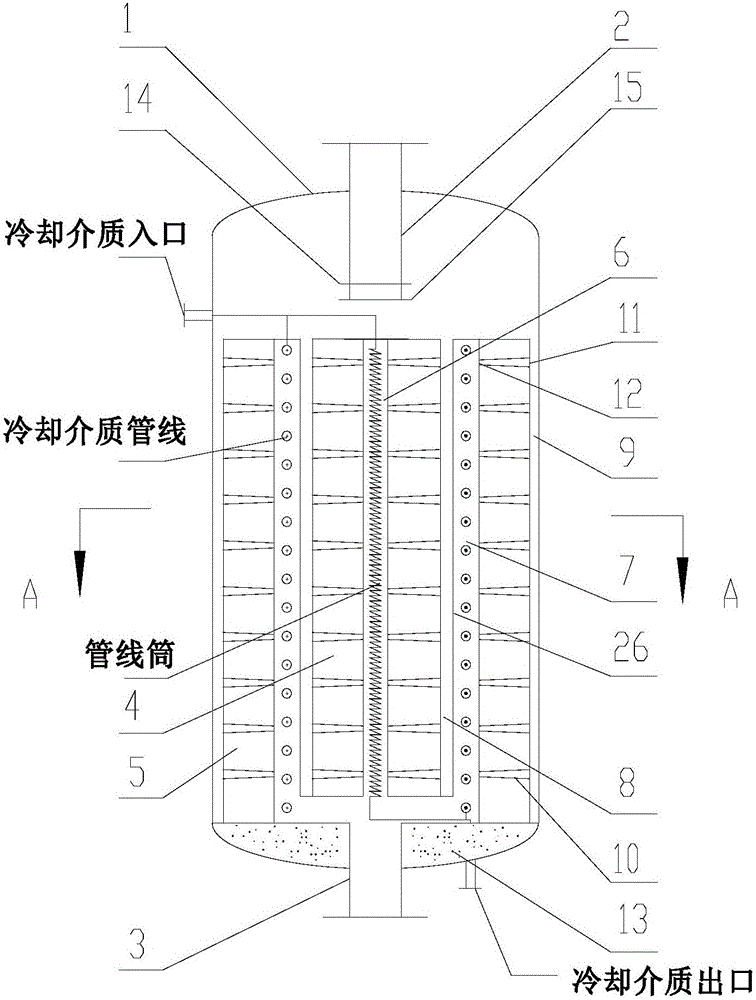

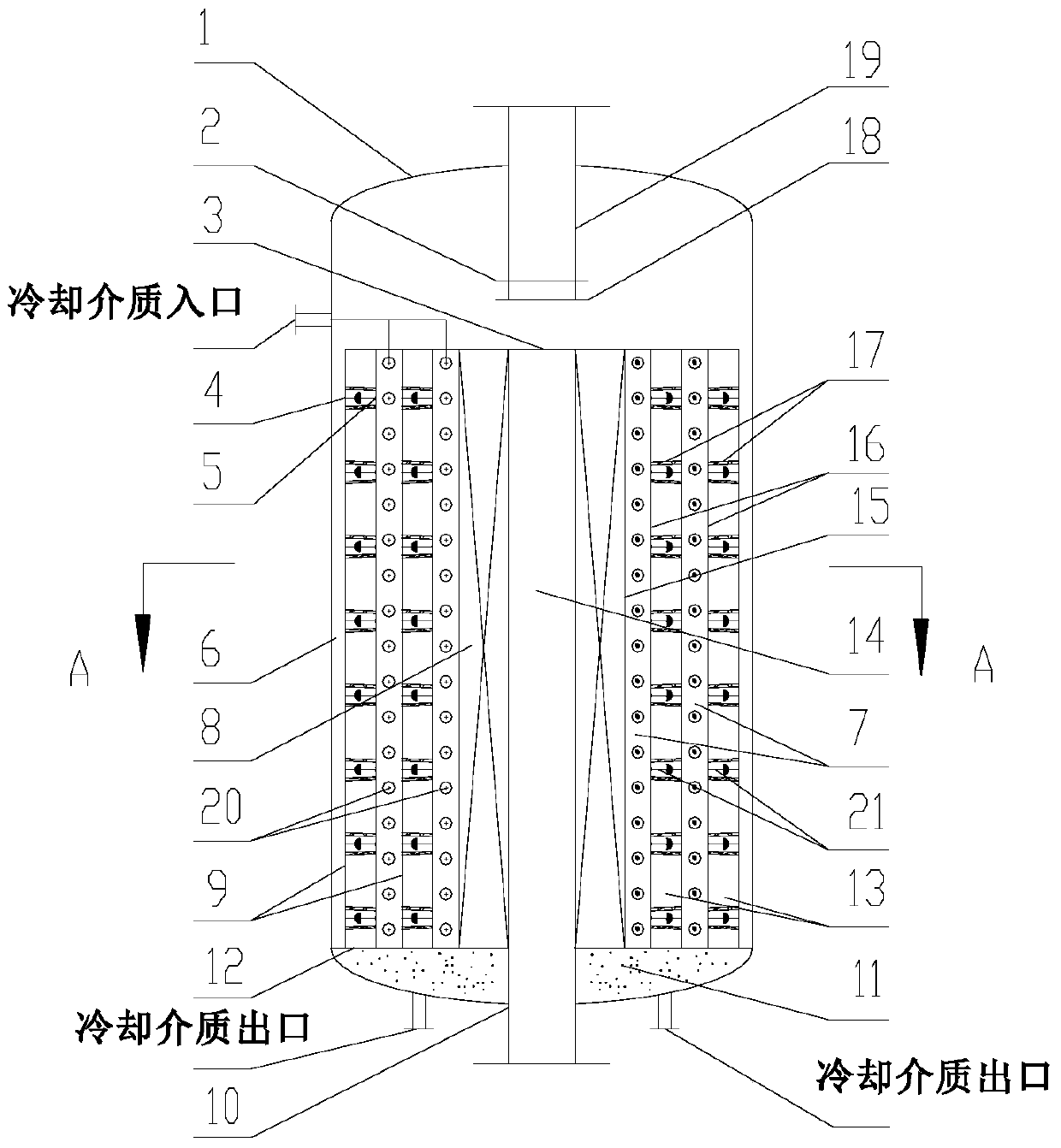

Methanation reactor and methanation process

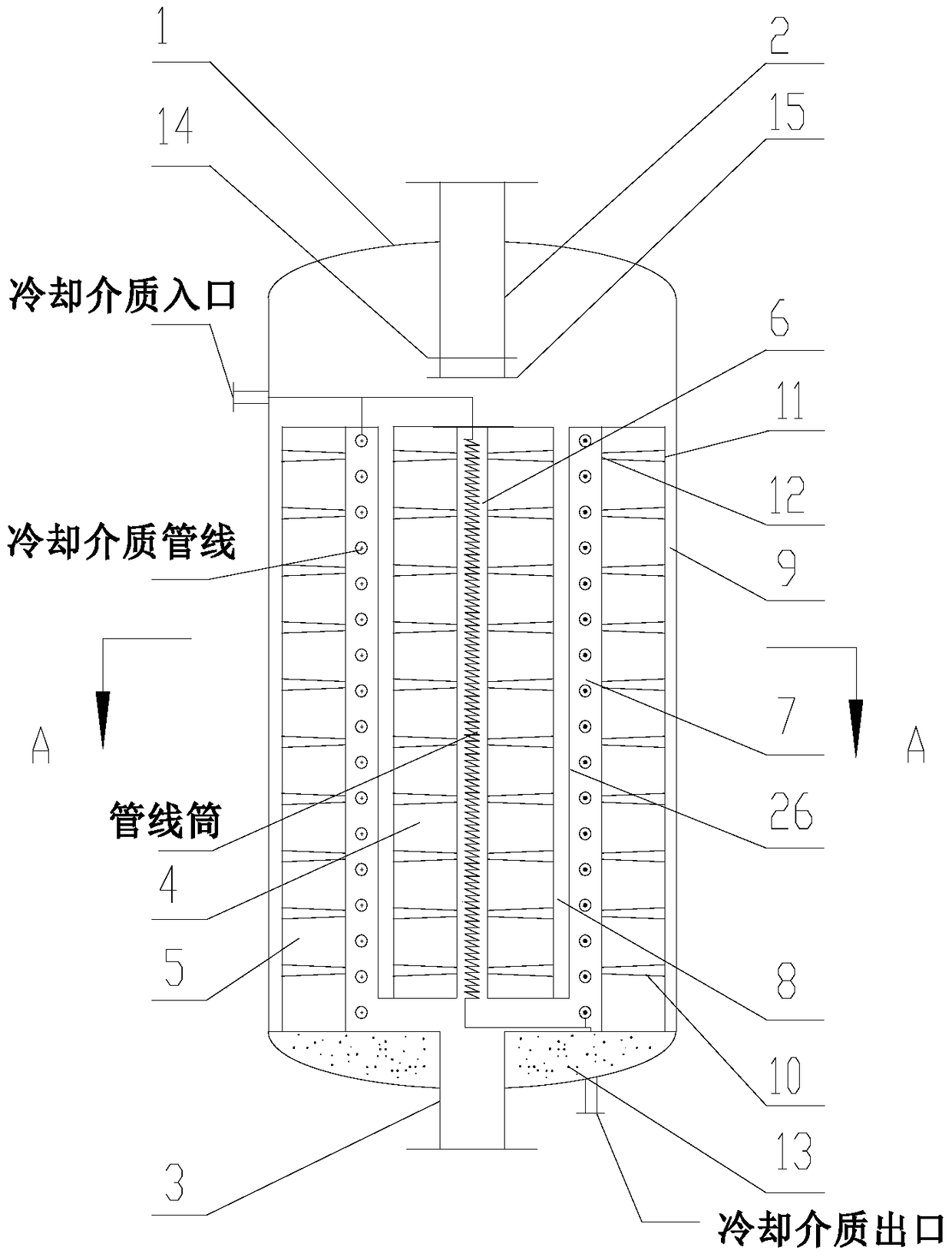

ActiveCN106693839AGreat driving forceShort stayHydrocarbon from carbon oxidesGaseous fuelsActive componentMethanation

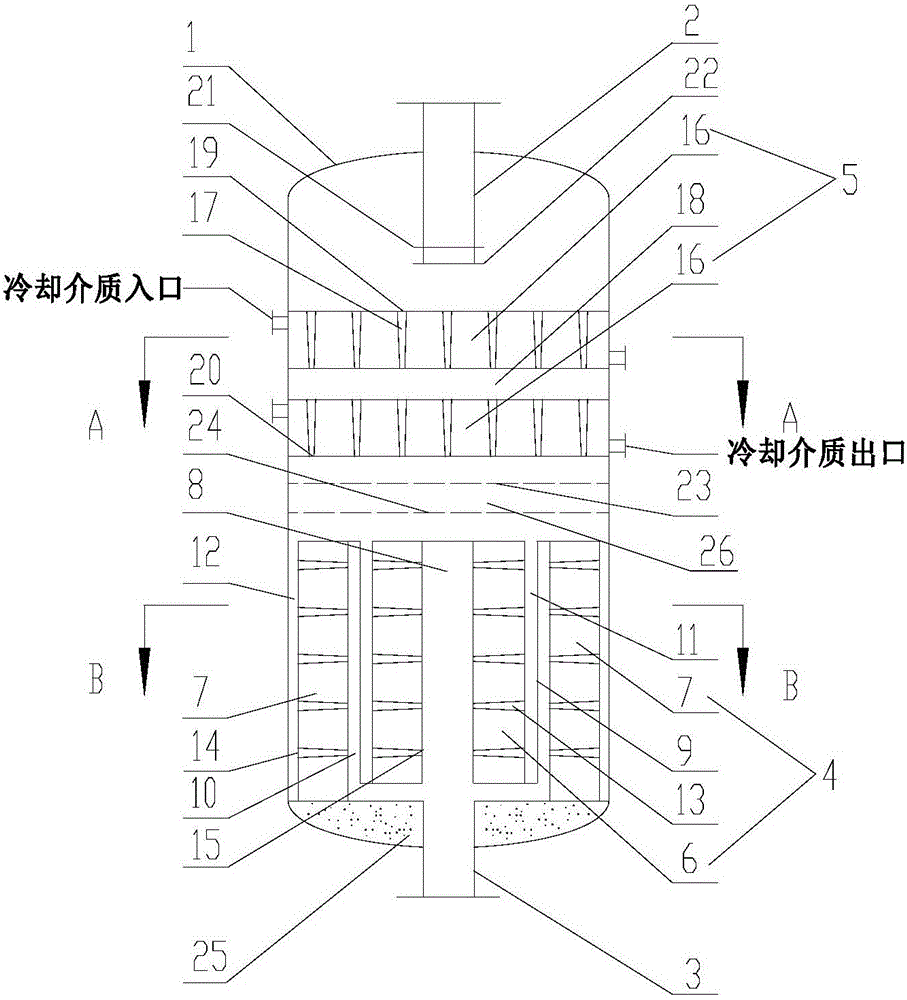

The invention discloses a methanation reactor and a methanation process; the methanation reactor comprises a shell body, a gas inlet pipe, a central cylinder, a central pipe, a gas outlet pipe, a cooling medium inlet, a cooling medium outlet and a micro reaction channel, and includes or does not include a sleeve; the micro reaction channel can be internally loaded with a catalytic active component. Compared with the prior art, the methanation reactor has less catalyst use amount; according to the methanation process adopting the methanation reactor, the bed pressure is reduced, the gas residence time is short, the space utilization rate of a reaction bed is high, and gas bias current and short-circuit phenomena do not exist.

Owner:SINOPEC ENG +1

Bottom anode side conductive direct current ladle furnace

InactiveCN101323892AUniform compositionGuaranteed symmetric distributionLighting and heating apparatusLadle furnaceArc length

The invention discloses a ladle furnace which is conductive and direct-current at a bottom anode side. The ladle furnace of the invention comprises a buggy ladle part and a ladle part and is characterized in that a buggy ladle body is provided with a side bottom anode automatic clamping device which has two symmetrical clamping chunks, wherein, the clamping face of each clamping chunk is connected with a heavy-current water-cooling switch the outside of which is provided with a water cooling pipe; two side bottom anode conductive bumps, which have a compound structure of a metallic part and a non-metallic part respectively, are arranged at the side face of the bottom of a ladle body as bottom anodes and connected with the ladle detachably. By adopting the ladle furnace which is conductive and direct-current at the bottom anode side, the consumption by graphite electrodes is greatly reduced and the noise is relatively low, the arc length short, the submerged arc good, temperature rise fast and carburetion of the molten steel low. In addition, the ladle furnace of the invention is applicable to heat and refine low-carbon steel and ultra-low-carbon steel and less refractories are consumed by the ladle with high heating efficiency so as to save energy.

Owner:NORTHEASTERN UNIV

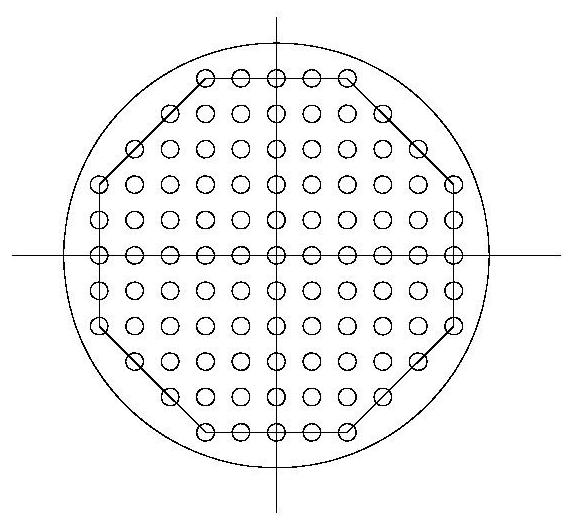

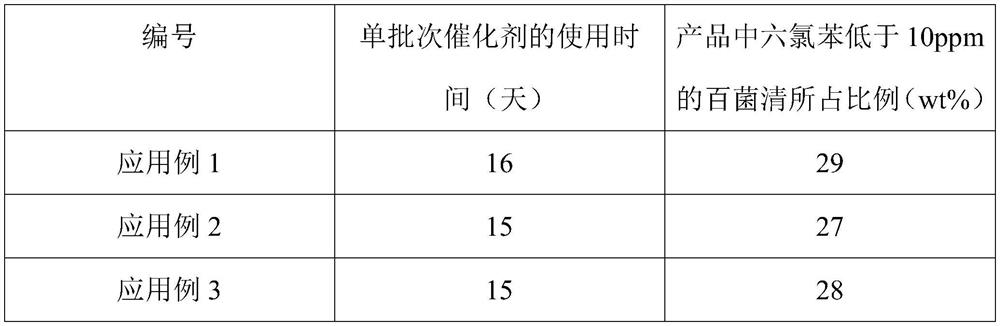

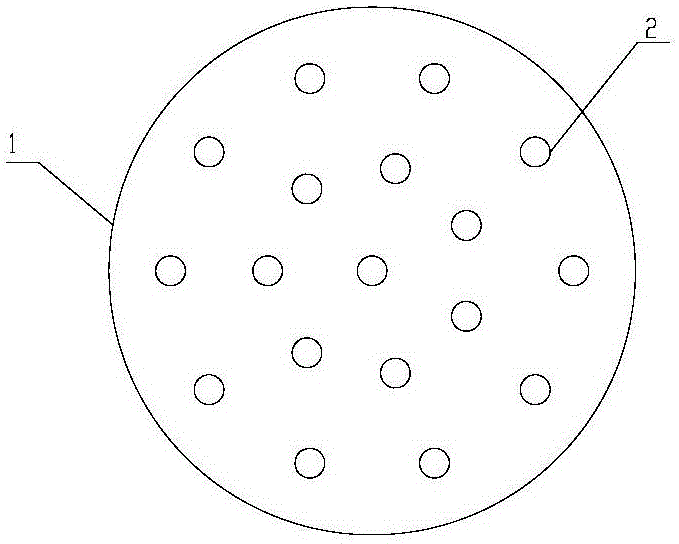

Fluidization reaction device and method for producing chlorothalonil by using same

PendingCN112619567AGuaranteed accuracyReasonable temperatureCarboxylic acid nitrile preparationOrganic compound preparationThermodynamicsChlorobenzene

The invention provides a fluidization reaction device and a method for producing chlorothalonil by using the fluidization reaction device. The fluidization reaction device comprises a first heat exchange tube group, a second heat exchange tube group and a third heat exchange tube group which are independent of one another and are sequentially arranged in a reactor main body from top to bottom, the ratio of the heights of the first heat exchange tube group, the second heat exchange tube group and the third heat exchange tube group to the height of the reactor main body is (0.05-0.2): 1 independently, so that the reaction temperatures of the reactor main body at different axial heights can be well controlled, the temperature distribution in the reactor main body is uniform, no local overheating area exists, and the heat exchange efficiency is improved. The catalyst is prevented from coking in the reactor main body; according to the method for producing chlorothalonil by using the fluidization reaction device, the service life of a single batch of catalysts can be prolonged, and the proportion of chlorothalonil with hexachlorobenzene lower than 10ppm in the product is increased.

Owner:JIANGSU XINHE AGROCHEM

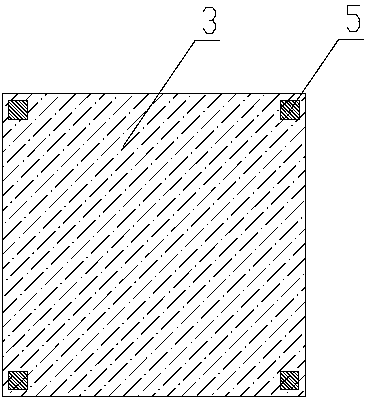

Solar cell and assembly and manufacturing method thereof

ActiveCN103811565AReduce dead areaImprove power generation efficiencyFinal product manufacturePhotovoltaic energy generationElectricityElectrical battery

The invention discloses a solar cell and assembly and a manufacturing method thereof and relates to the technical field of solar cells. The solar cell comprises a cell body, and the cell body comprises a cell PN junction portion and a back field portion. The solar cell is characterized in that the front surface of the cell body is provided with front surface electrodes and grid wires, the back surface of the cell body is provided with back electrodes, wherein the four front surface electrodes are arranged on the four corners or four edges of the top surface of the cell body, the grid wires are connected is a mutually crossed mode, the front surface electrodes are electrically connected with the grid wires, and the four back surface electrodes are arranged on the four corners and the four edges of the bottom surface of the cell body. The assembly manufactured from the solar cell can be welded in any directions for usage, avoid heat spots due to grid breakage, achieve good oxidation resistance, improve resistance to PID (potential induced decay), reduce leakage current, and be high in utilization rate, convenient to use and low in cost.

Owner:HENGSHUI YINGLI NEW ENERGY

Methanation reactor and methanation technology

InactiveCN106693849AGreat driving forceShort stayGaseous fuelsChemical/physical/physico-chemical processesActive componentMethanation

The invention discloses a methanation reactor and a methanation technology. The methanation reactor comprises a shell, a gas inlet tube, a cylinder, a gas outlet tube and a micro-reaction channels, and a catalytic active component can be loaded in the micro-reaction channels. Compared with methanation reactors in the prior art, the methanation reactor disclosed in the invention has the advantages of small use amount of a catalyst, low bed pressure drop, short gas retention time, high reaction bed space utilization rate, no gas flow deflection and no short circuit in the methanation reaction process.

Owner:SINOPEC ENG +1

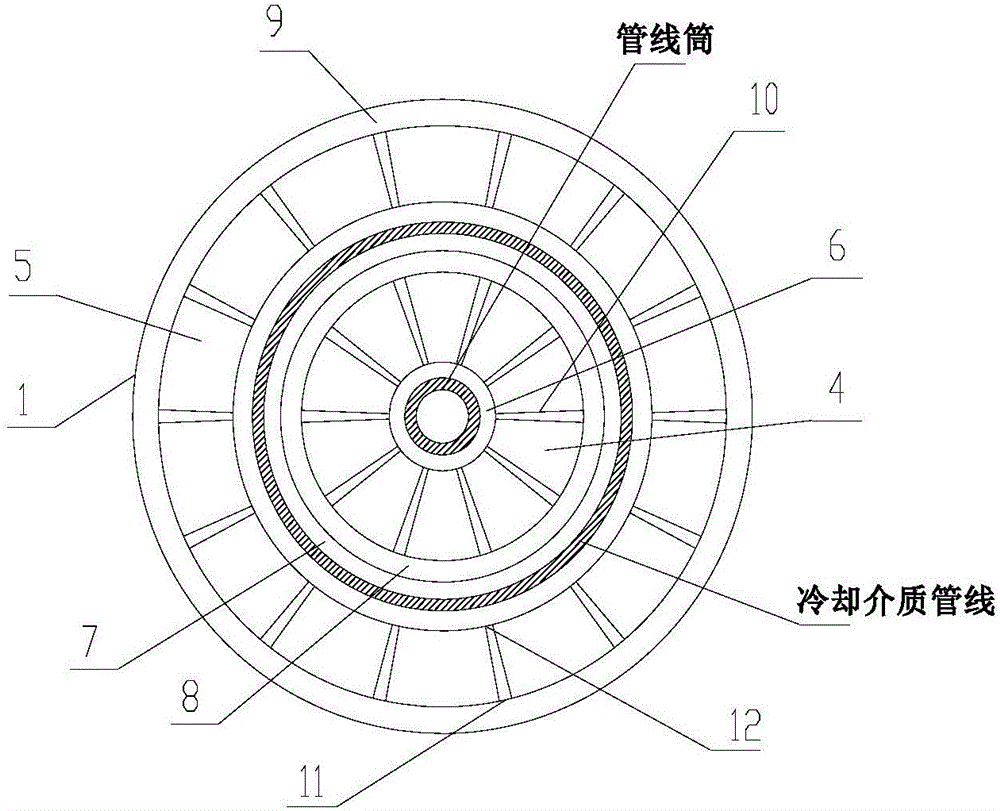

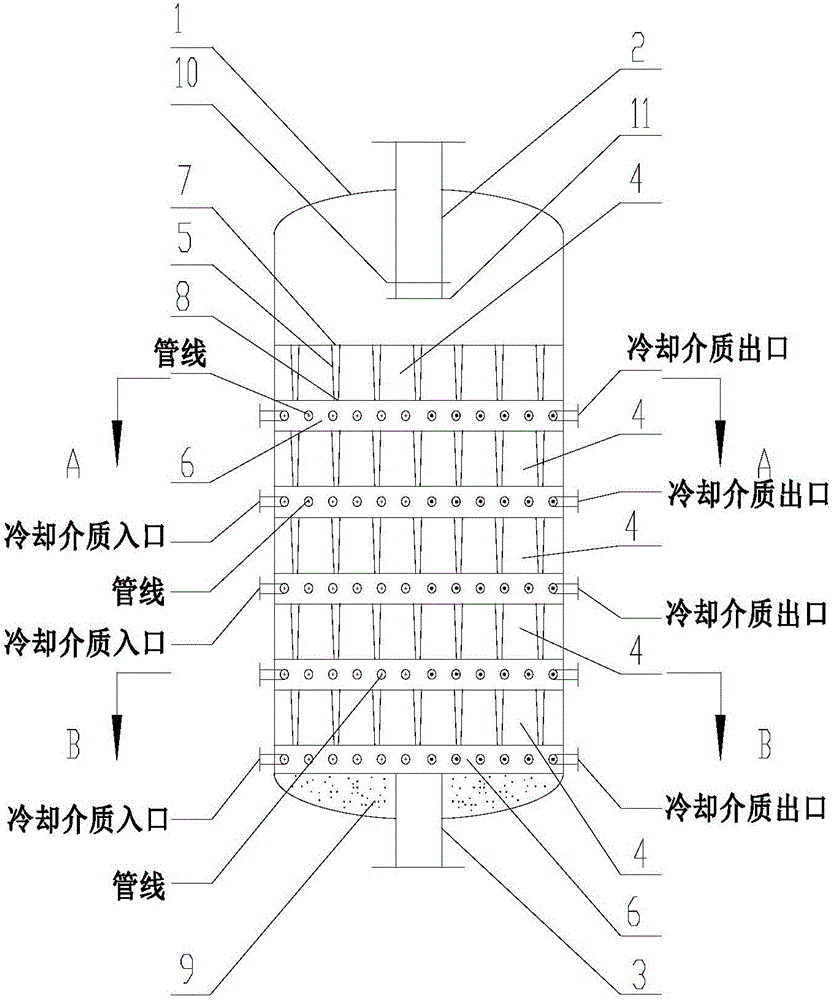

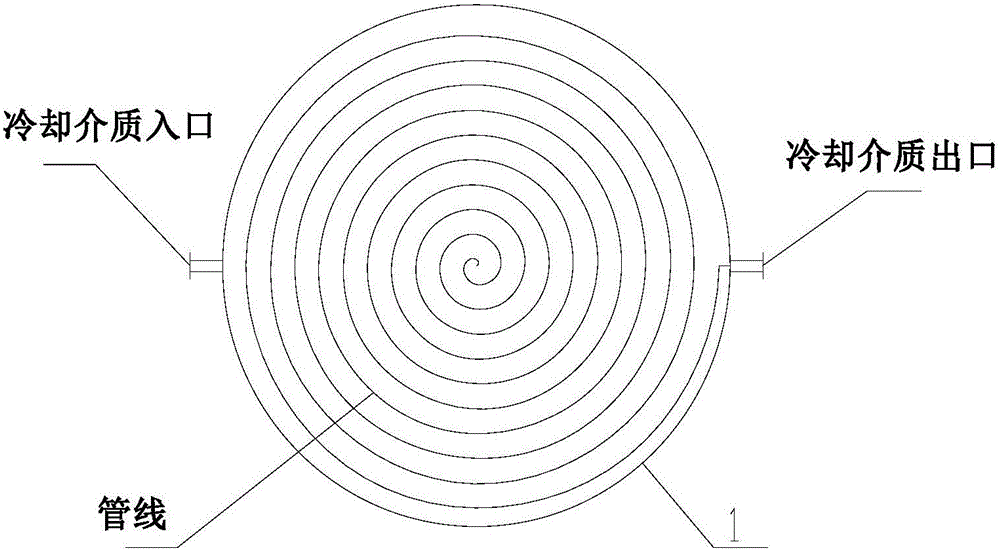

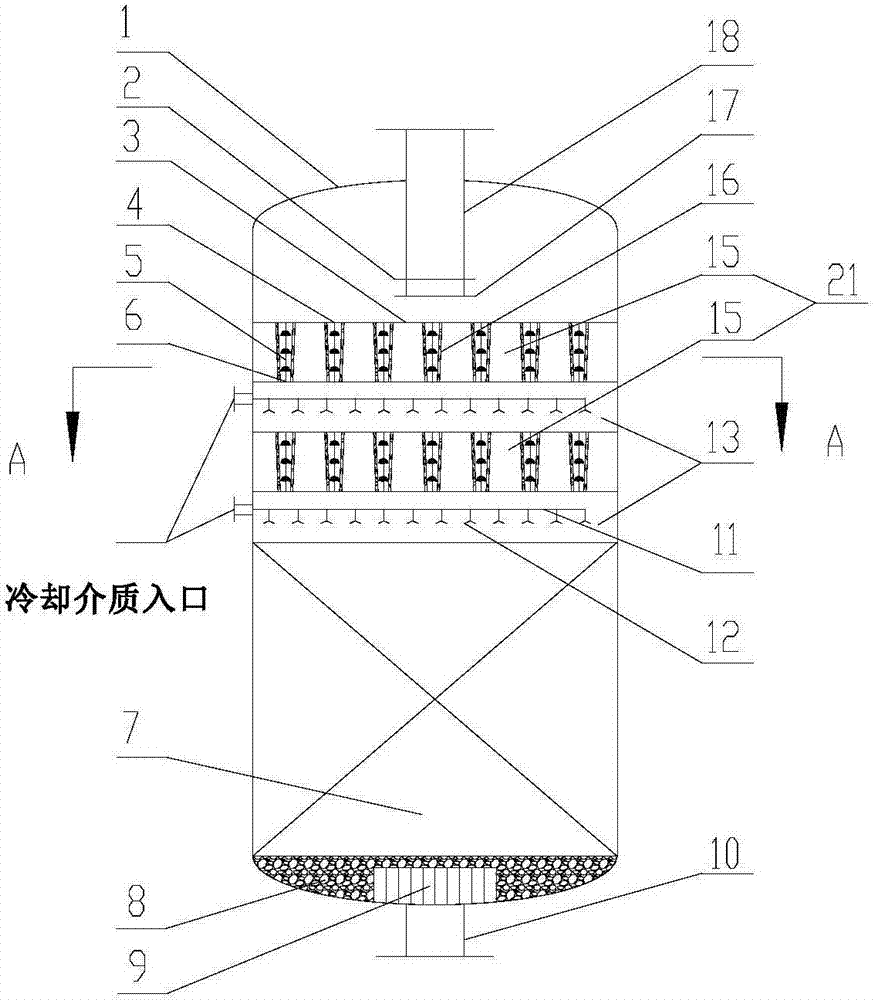

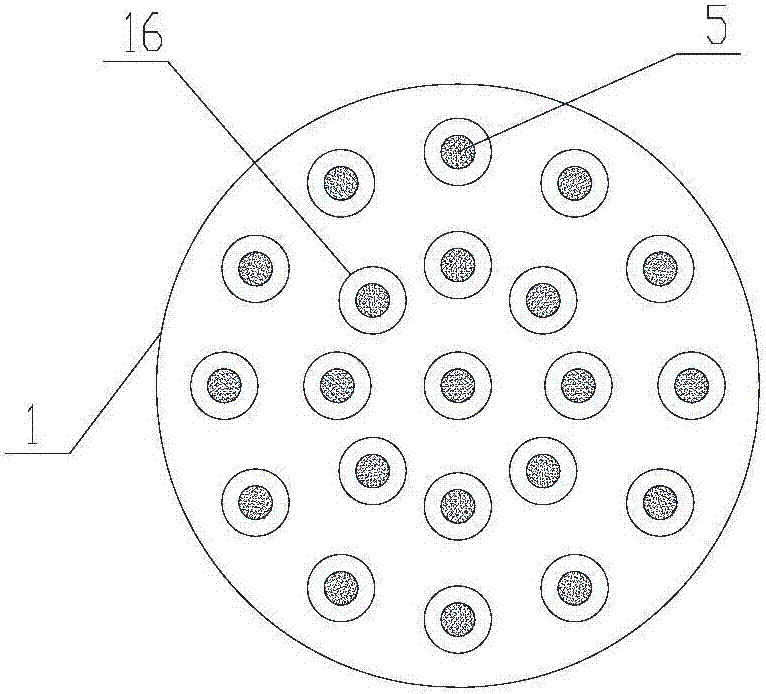

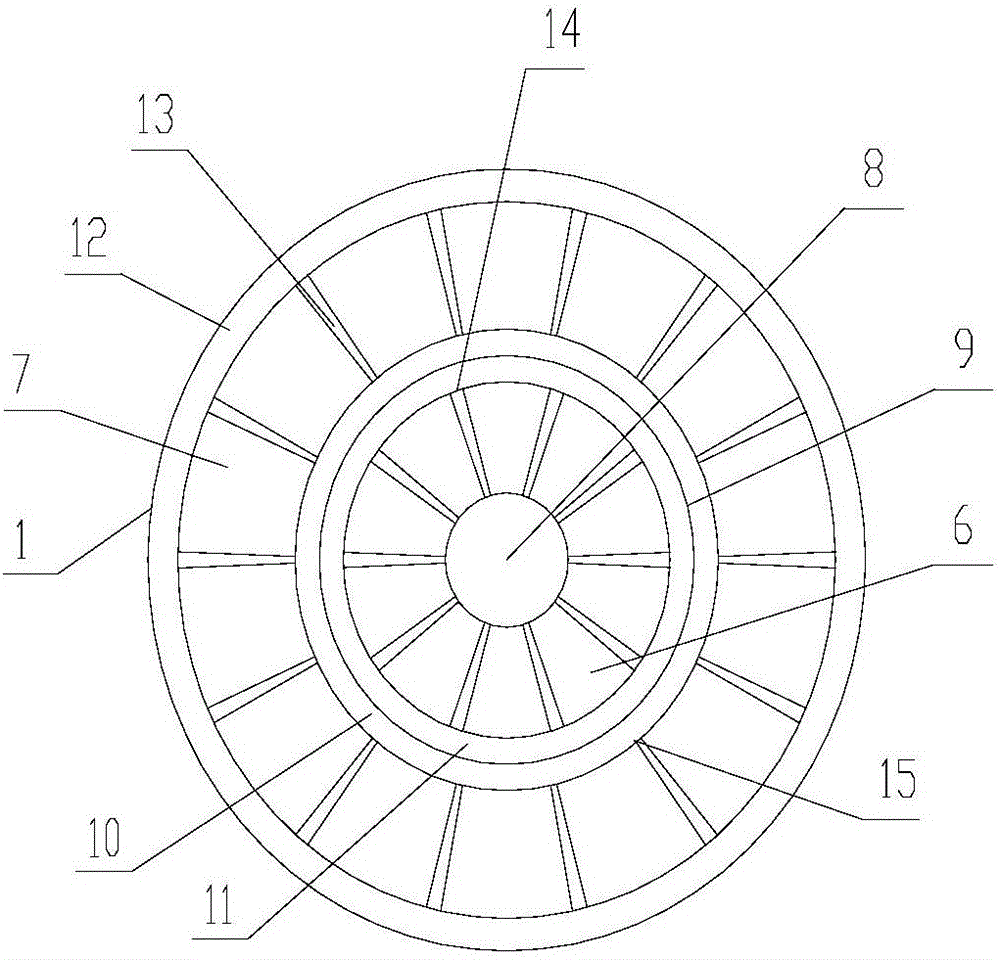

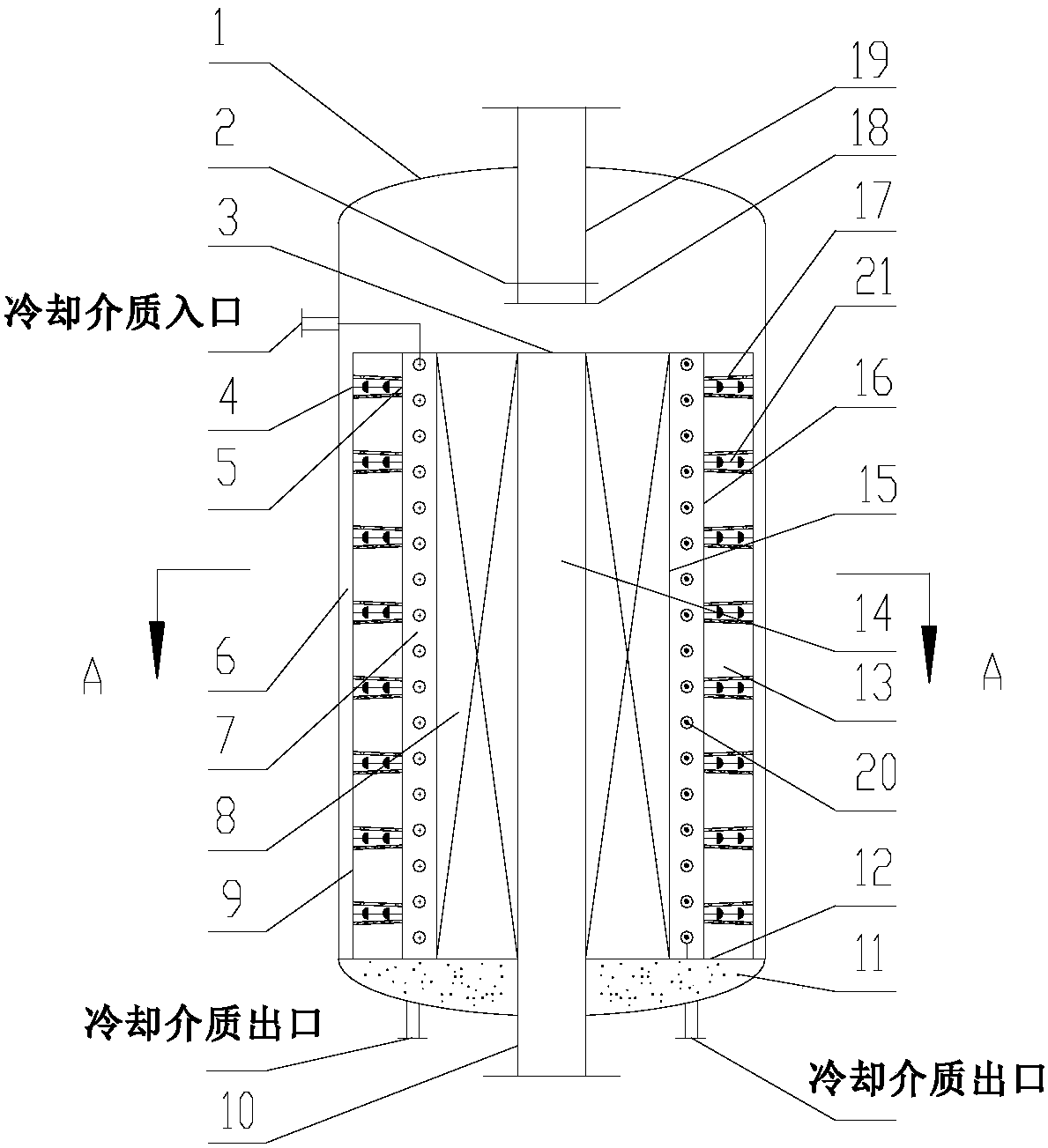

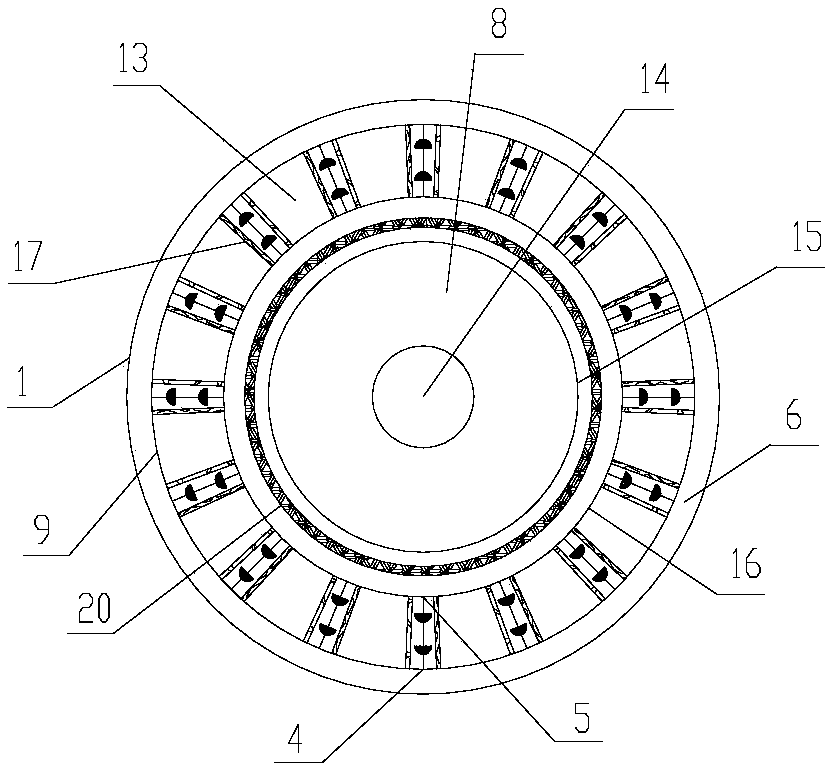

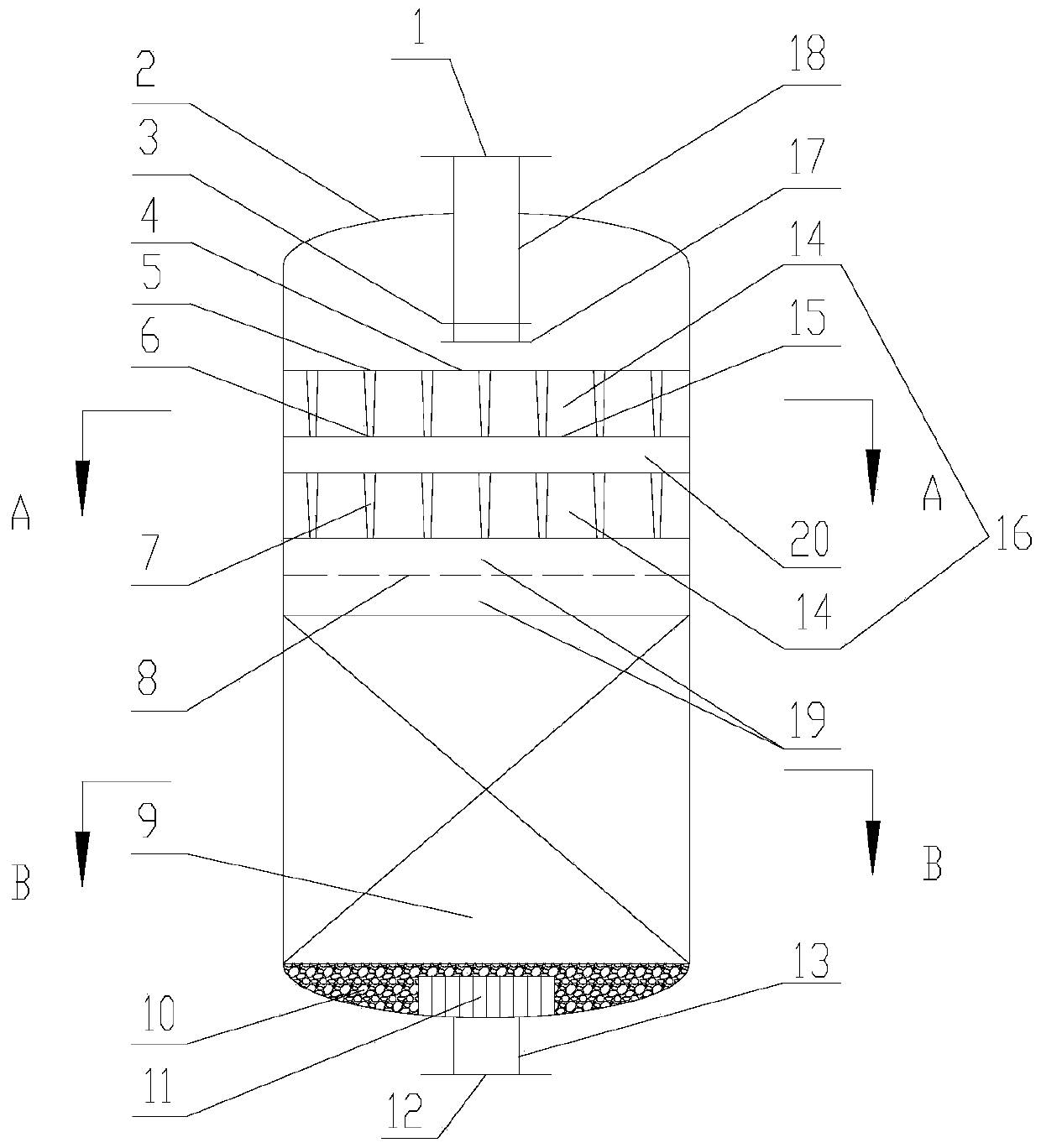

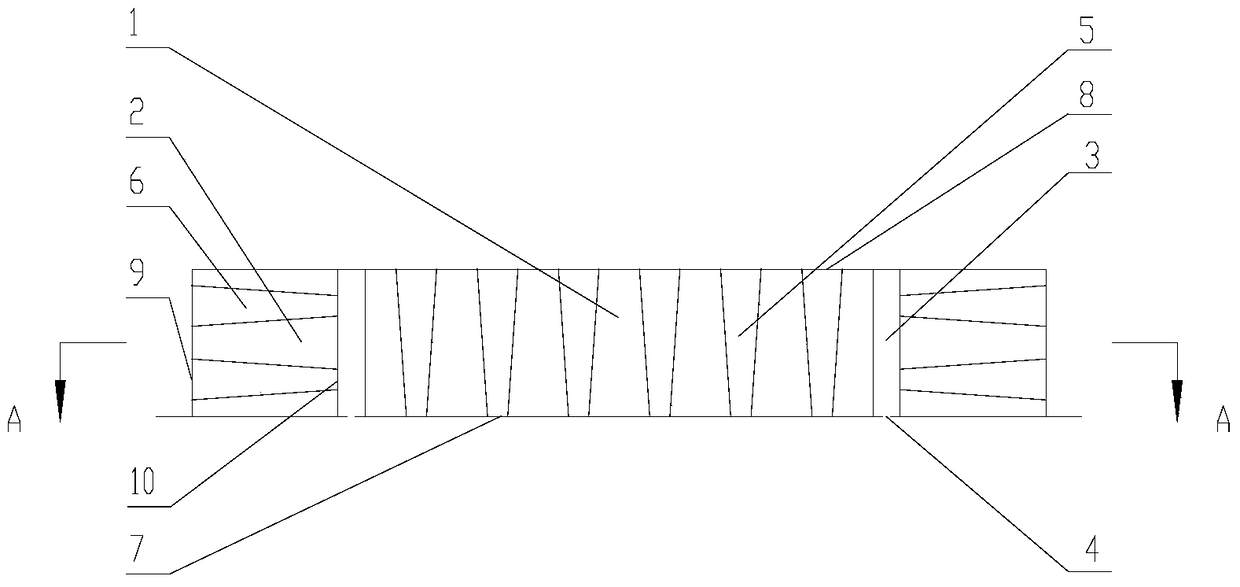

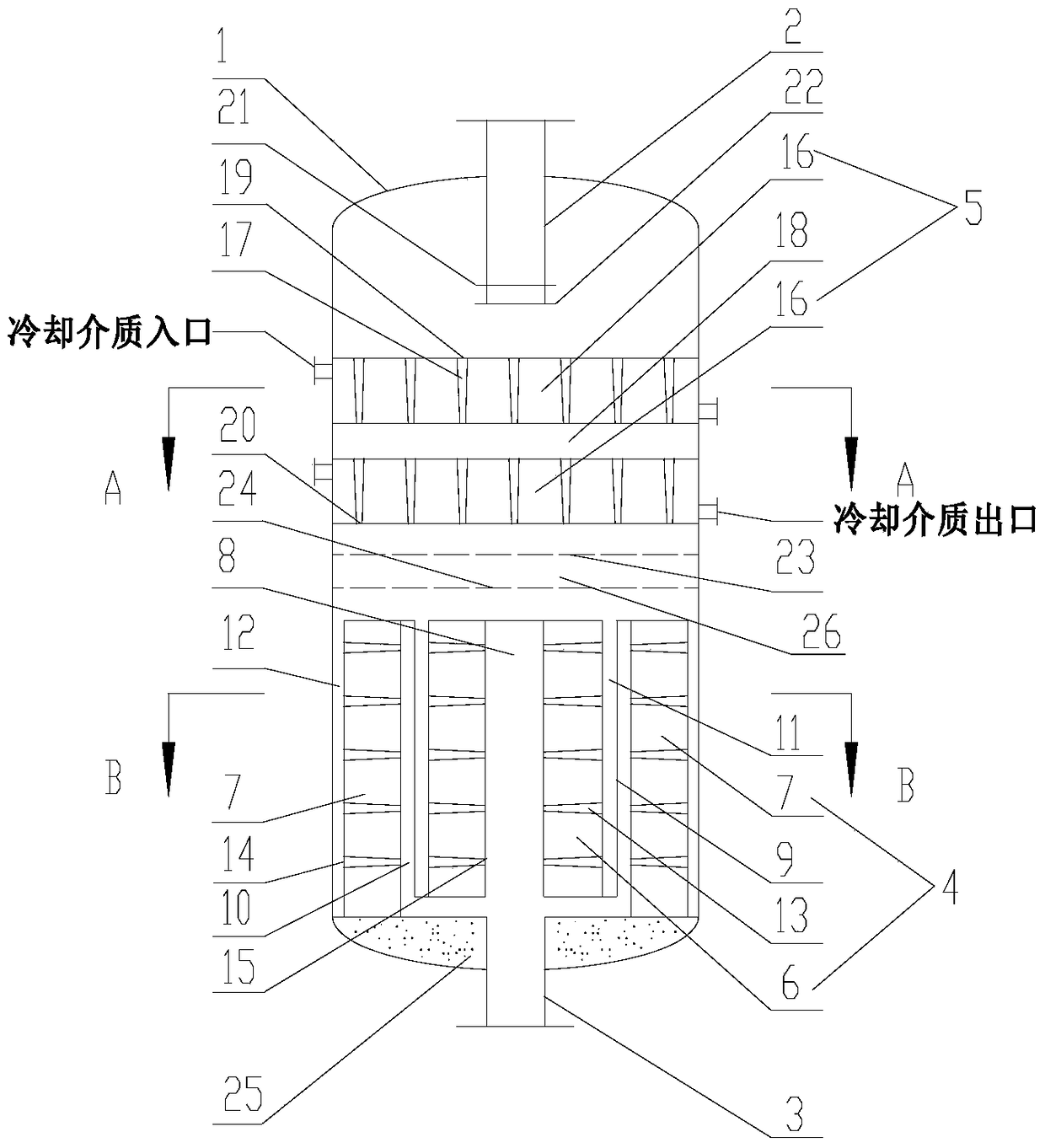

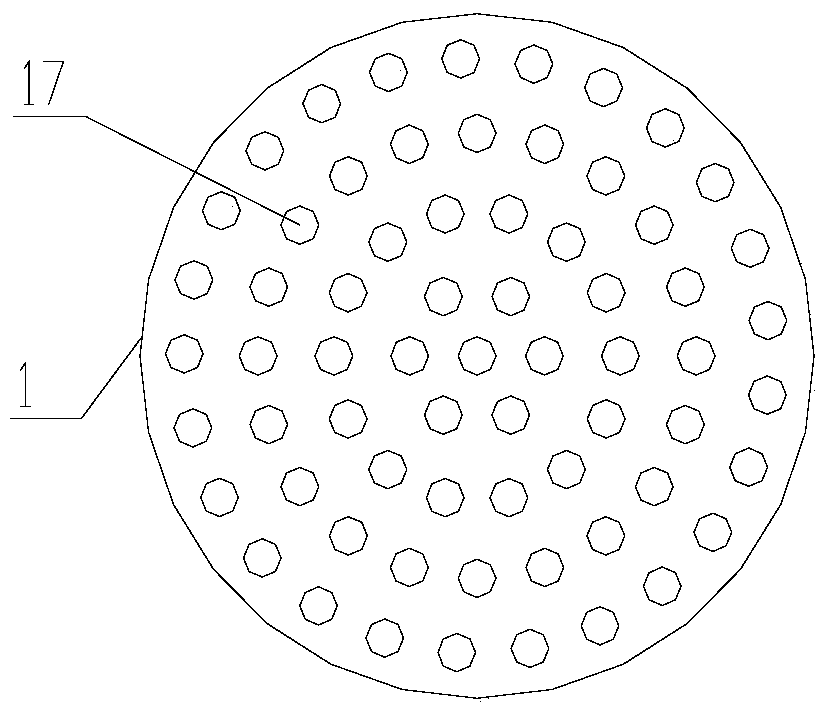

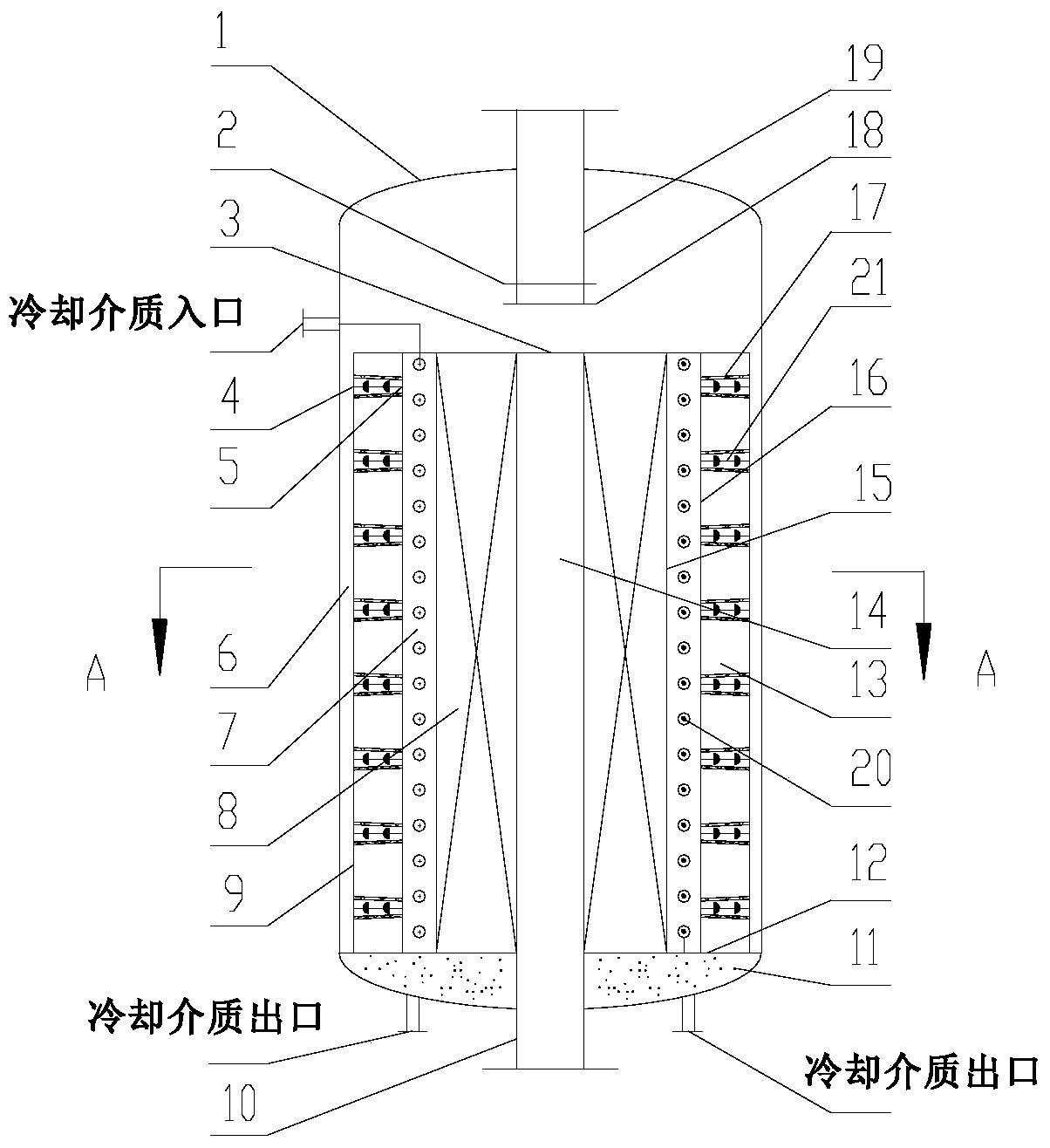

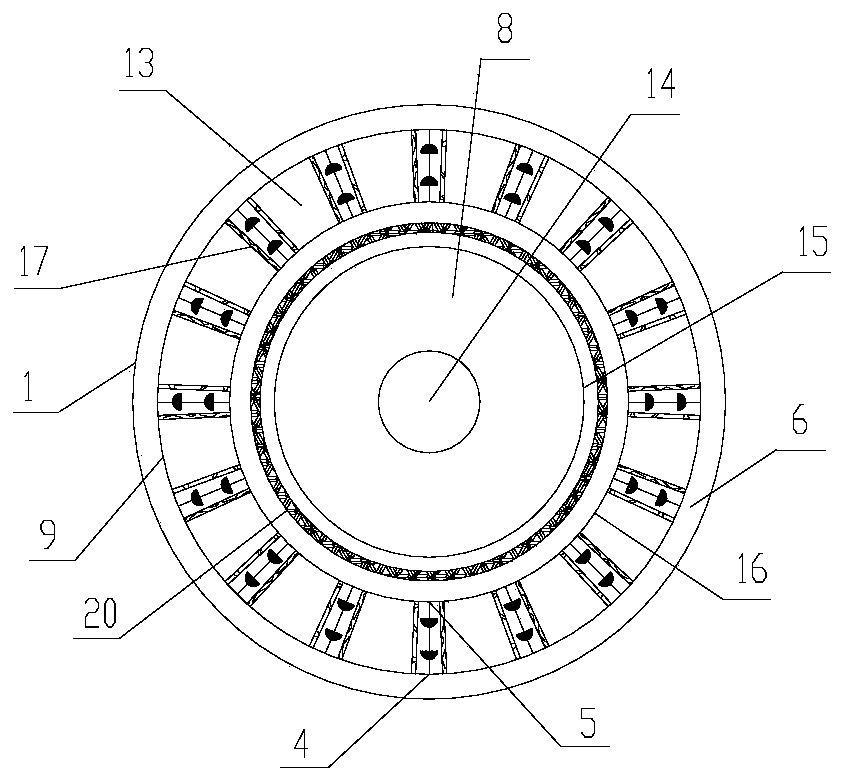

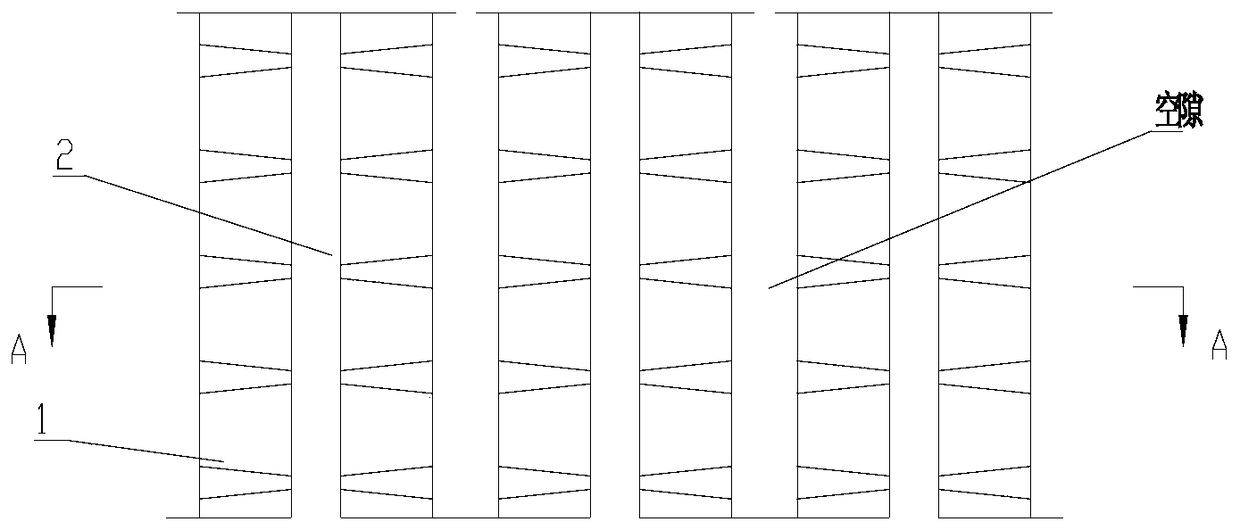

Quench-type reactor

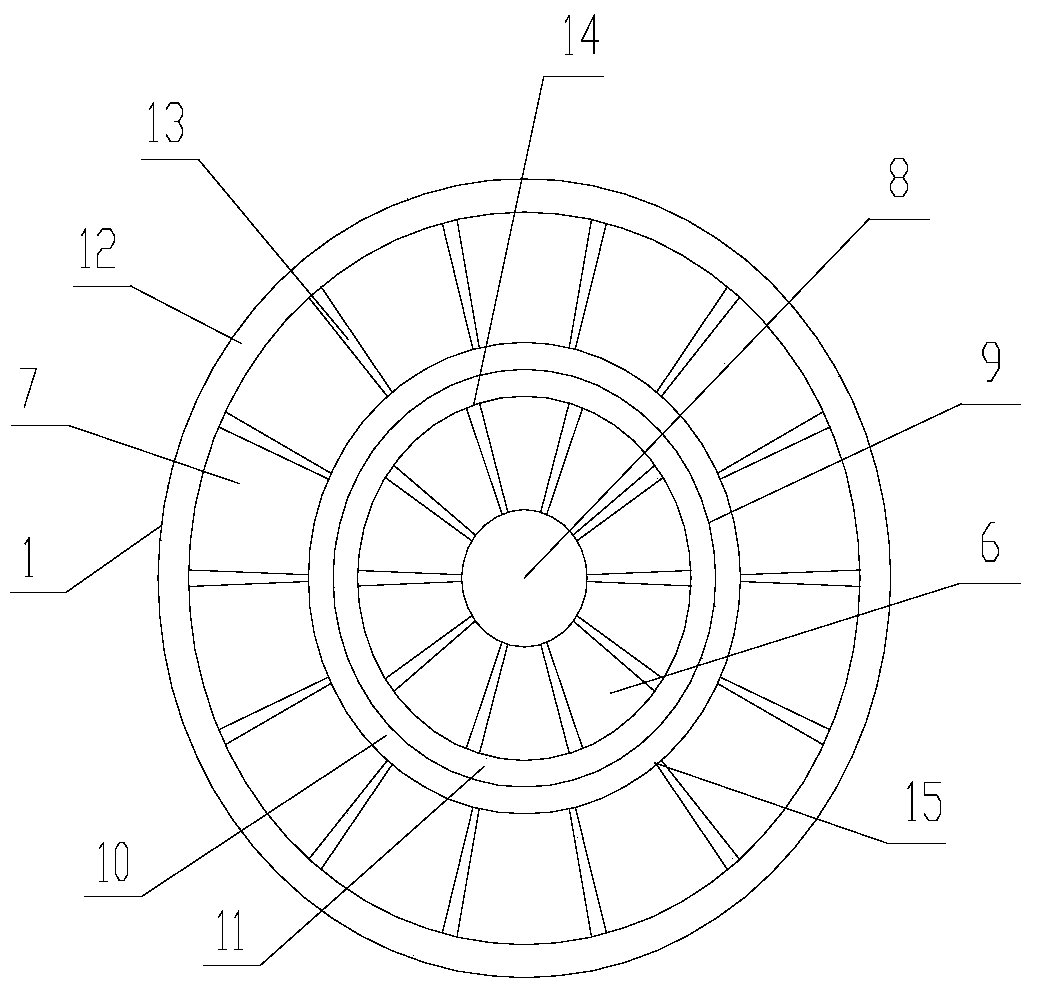

ActiveCN107398237APlay the role of distributing the reaction materialNo drift phenomenonChemical/physical/physico-chemical microreactorsLine tubingNuclear engineering

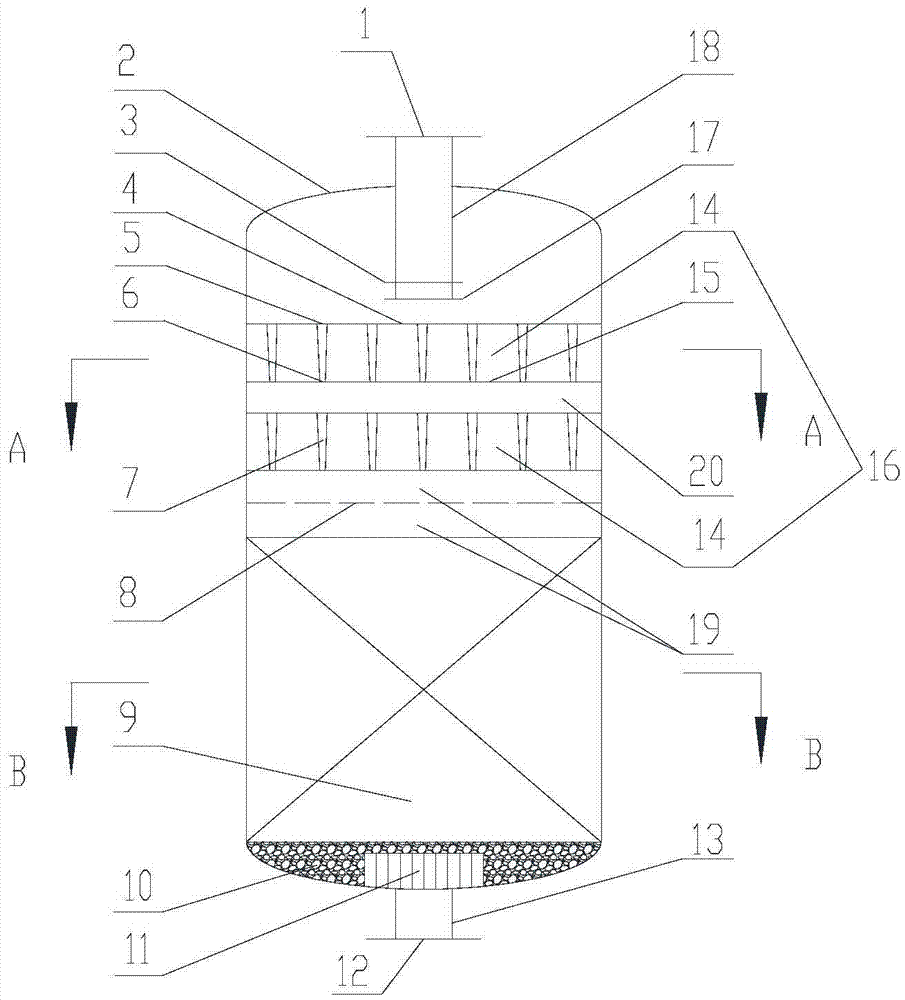

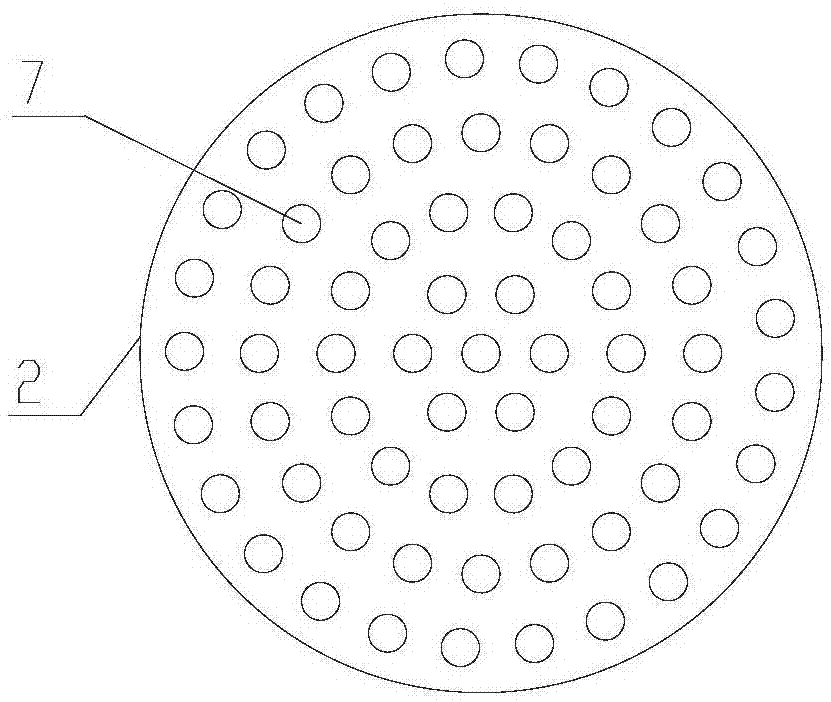

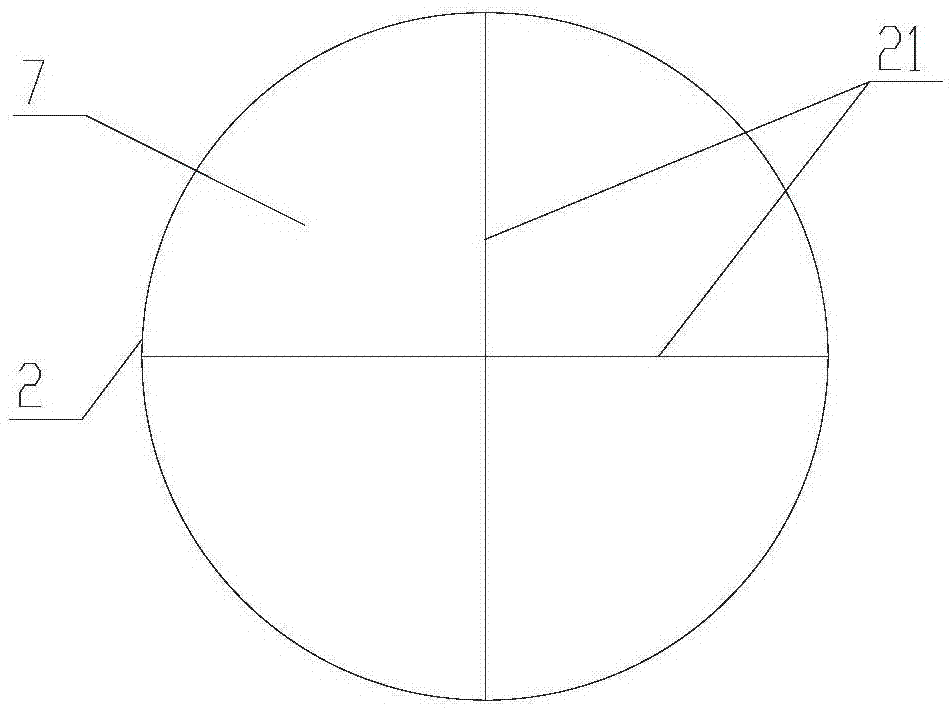

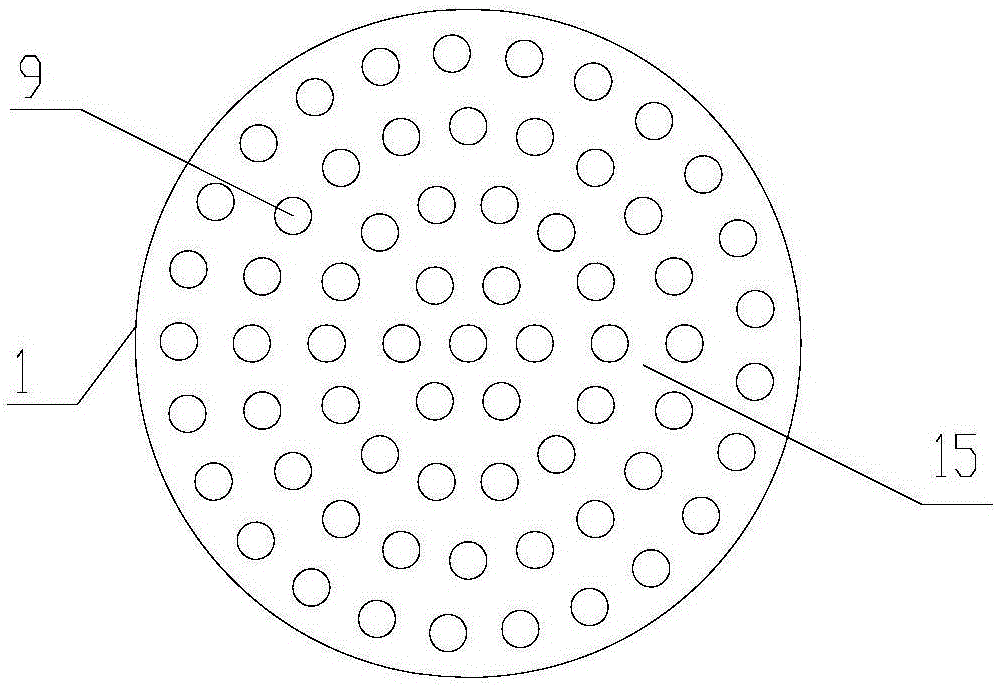

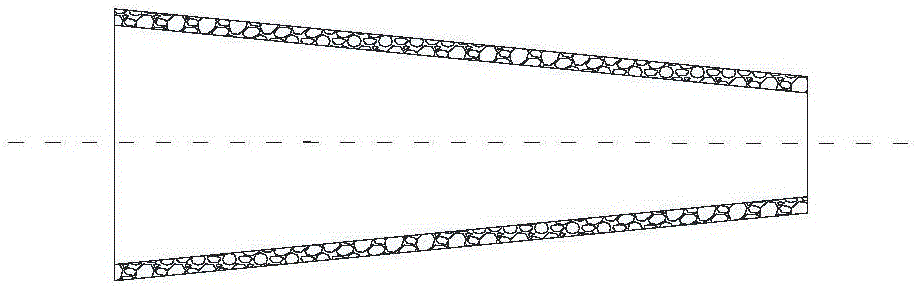

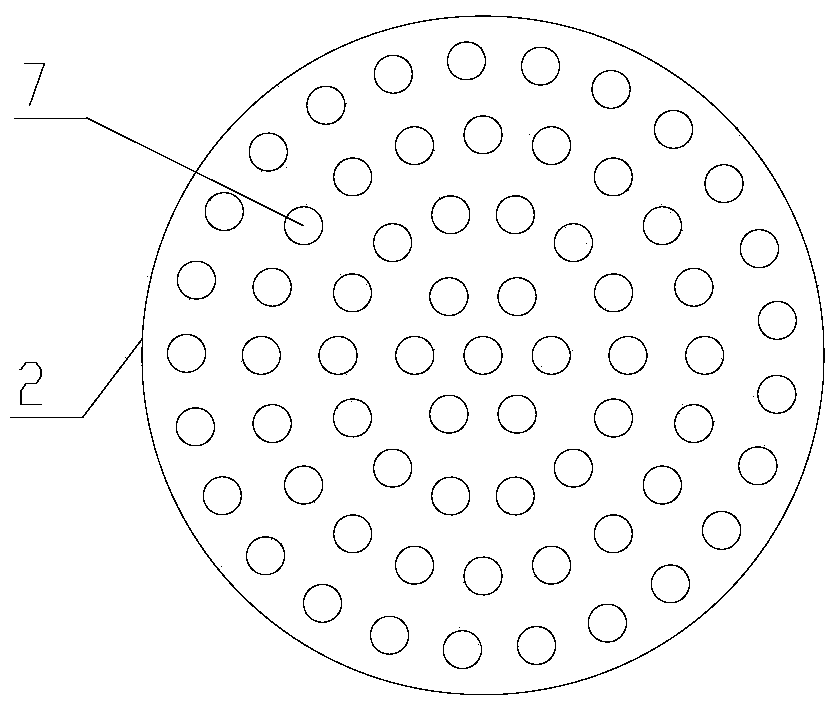

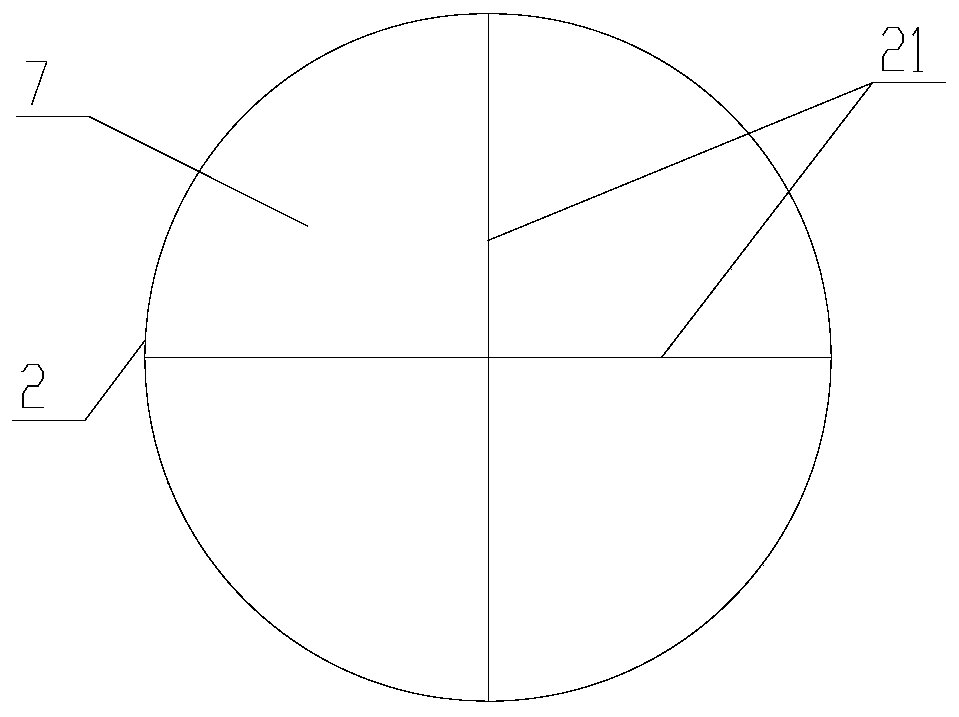

The invention discloses a quench-type reactor. The reactor comprises a radial cylindrical sealed pressure-bearing shell (1), an air inlet pipe (18), an air outlet pipe (10), as well as an axial micro-channel reaction zone (21) and an axial catalytic reaction zone (7), wherein gaps (13) are formed between the axial micro-channel reaction zone (21) and the axial catalytic reaction zone (7); cooling medium distributors (11) are arranged in the gaps (13); at least one cooling medium inlet is formed in the shell (1) corresponding to the side face of each gap (13); the cooling medium inlets are connected with the cooling medium distributors (11) through cooling medium pipelines. The reactor is small in usage amount of active ingredients of the catalyst, low in pressure drop and low in bed temperature and avoids a 'temperature runaway' phenomenon.

Owner:SINOPEC ENG +1

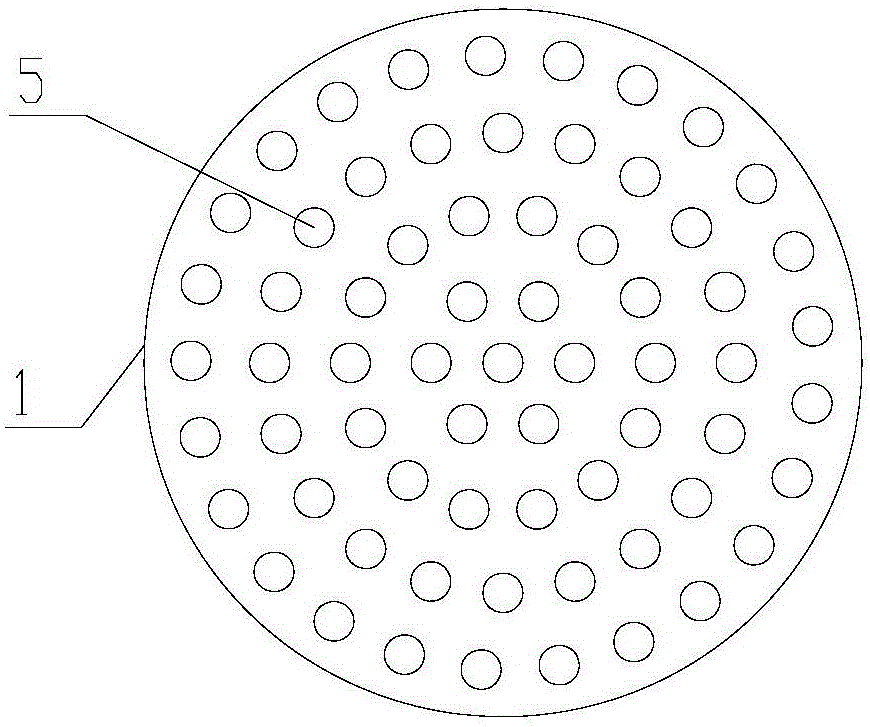

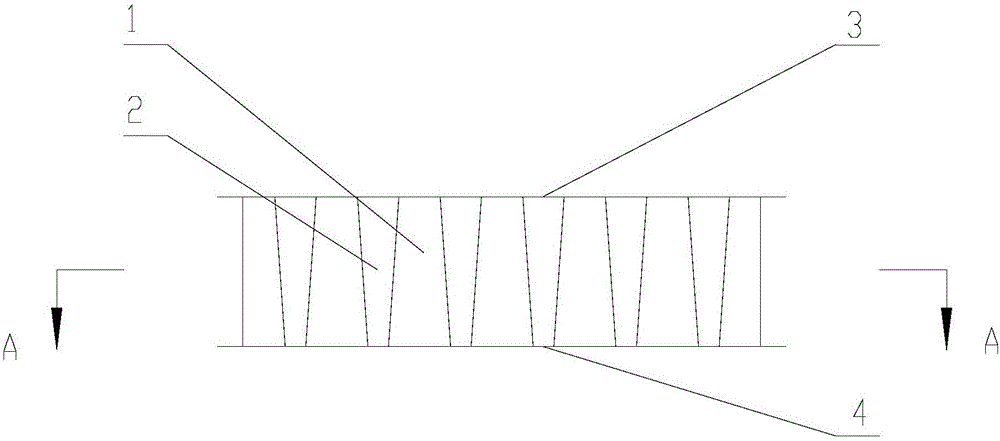

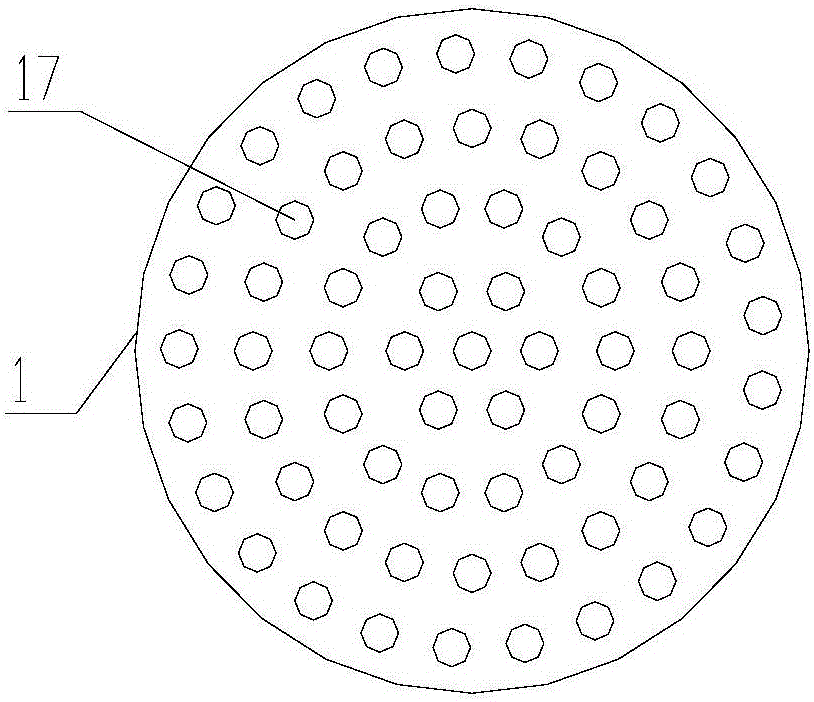

Axial micro-catalytic reaction unit and application thereof

ActiveCN106378067AGreat driving forceShort stayChemical/physical/physico-chemical processesRetention timeUtilization rate

The invention discloses an axial micro-catalytic reaction unit and application thereof. The axial micro-catalytic reaction unit is characterized in that the axial micro-catalytic reaction unit comprises a column and micro-reaction channels axially penetrating the column; the place above the column is communicated with a fluid below the column only through the micro-reaction channels; and the the micro-reaction channels are provided with upper micro-reaction channel openings and lower micro-reaction channel openings with different diameters. The axial micro-catalytic reaction unit provided by the invention can be applied to reactions with changes in reaction volume, enables the usage amount of a catalyst to be small, and is low in pressure drop, short in retention time, high in space utilization rate and free of the phenomena of bias current and short circuit of gas.

Owner:SINOPEC ENG +1

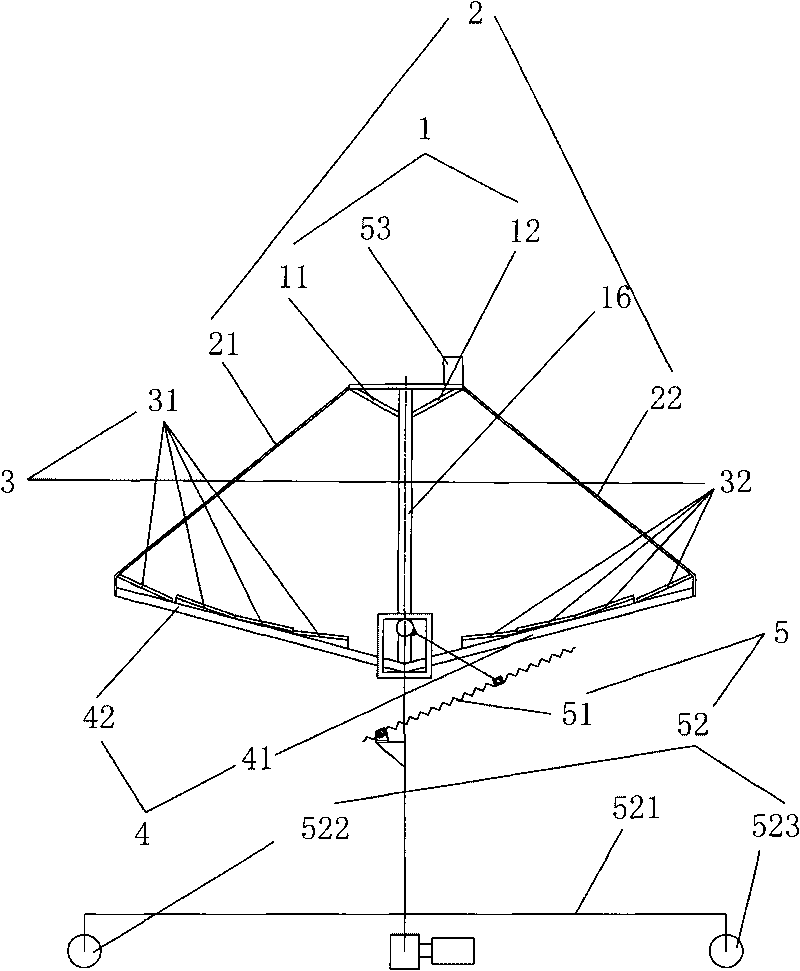

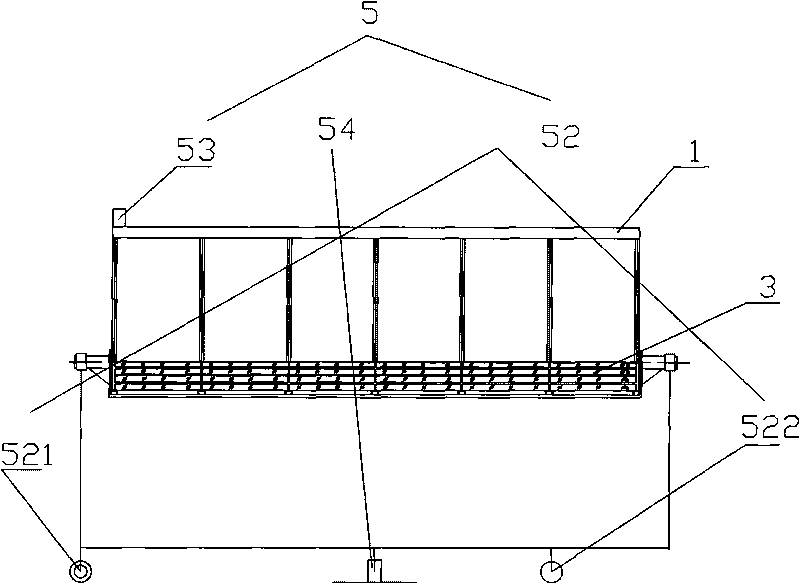

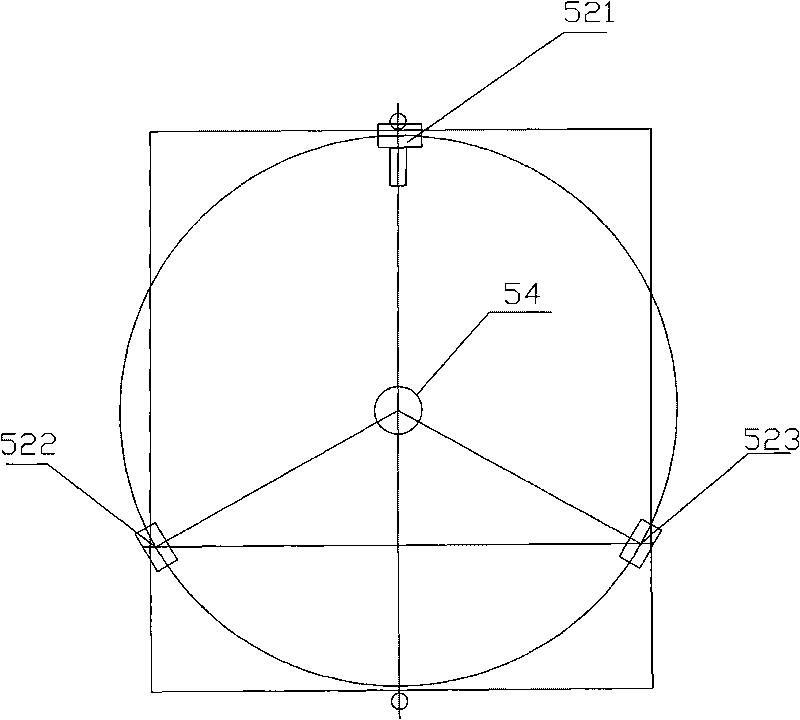

Inclined-surface suspended reflecting condenser

InactiveCN101753058AUniform reflectionBest stiffness/weight ratioPhotovoltaicsMountingsCells panelPlane mirror

The invention relates to an inclined-surface suspended reflecting condenser, which comprises a solar module array, a plane mirror array, a condenser steel frame and an automatic sun-following rotating device, wherein the condenser steel frame is used to install solar modules and plane mirrors, and the automatic sun-following rotating device is used to drive the modules to act. The automatic sun-following rotating device is formed by a plane mirror frame and condenser steel frame driving device, a chassis driving device and a sun ray angle real-time judging control system. The condenser steel frame is a triangular steel structure formed by two symmetrical inclined-surface steel structures, a cell panel support and suspended steel pipes. One end of each plane mirror is directly fixed on the inclined-surface steel structure and the other end of the plane mirror changes the angle of the plane mirror by using an angle adjusting device fixed on the inclined-surface steel structure. The invention has the advantages of good manufacturability, low cost, high cost performance, high reflection mirror utilization ratio and large scale.

Owner:ROPEOK TECHNOLOGY GROUP CO LTD

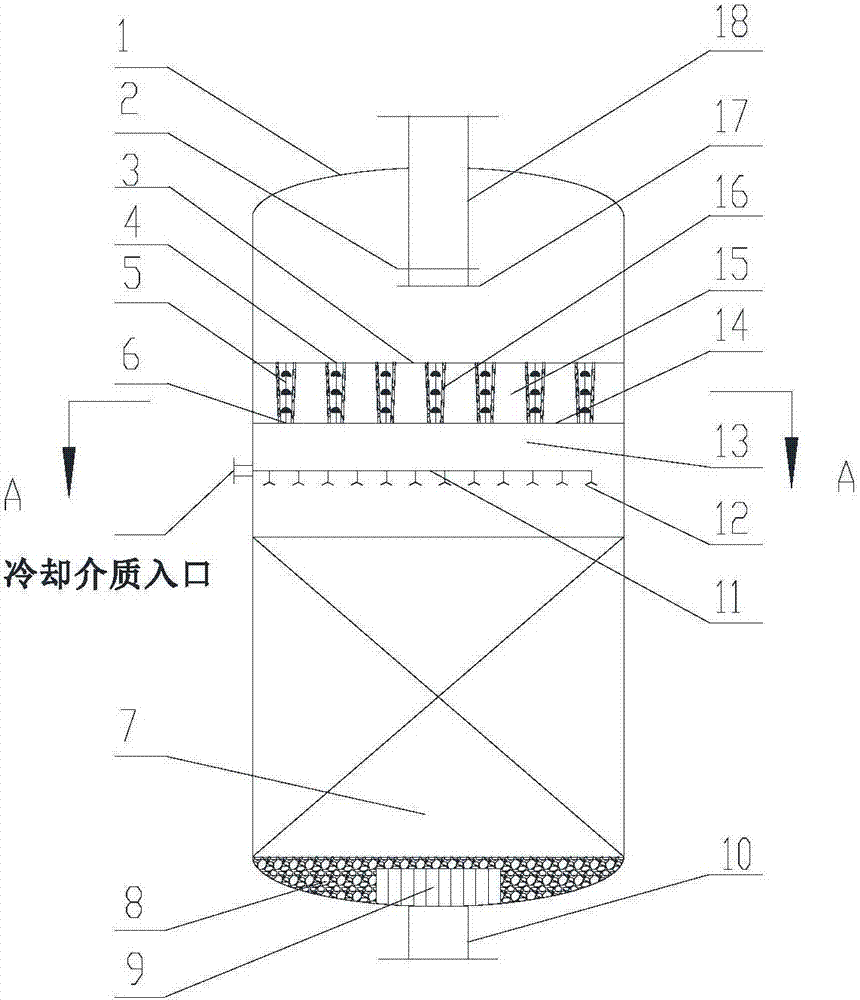

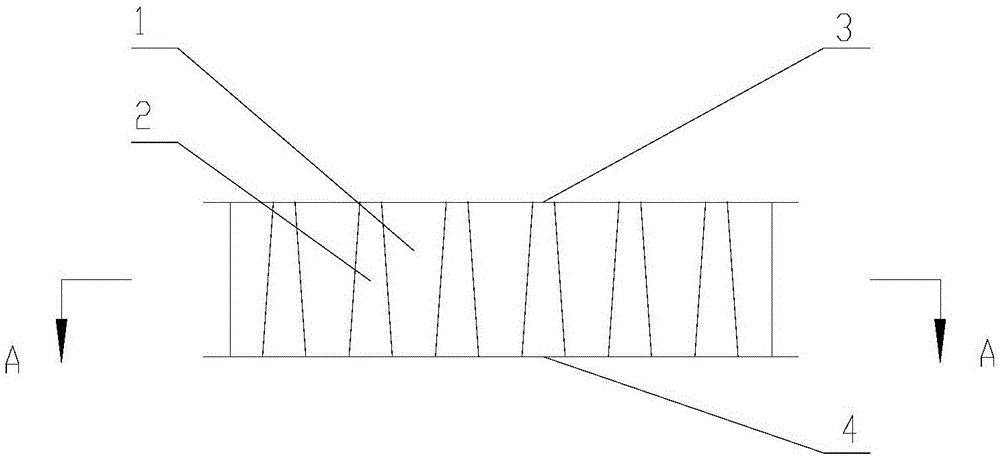

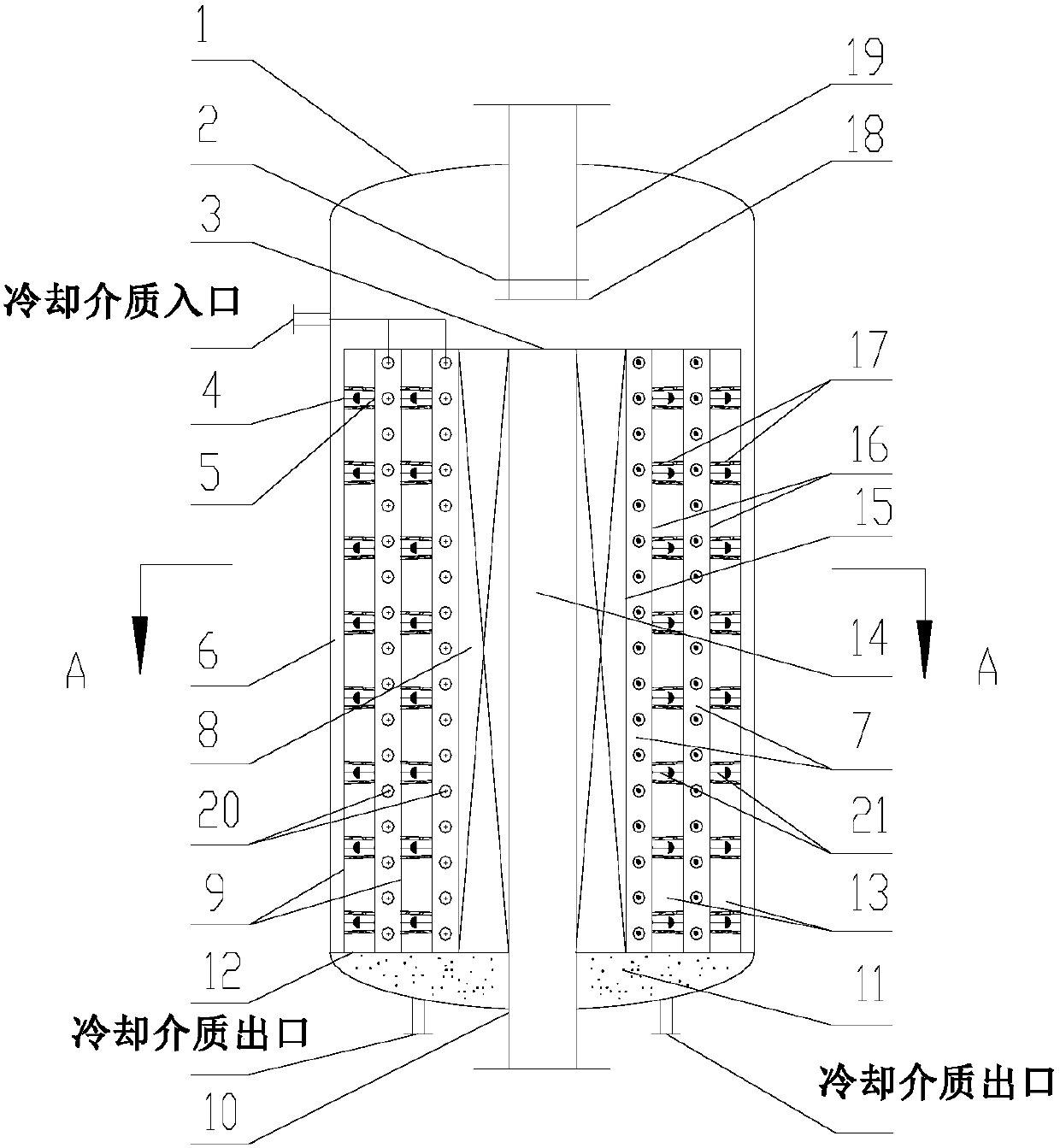

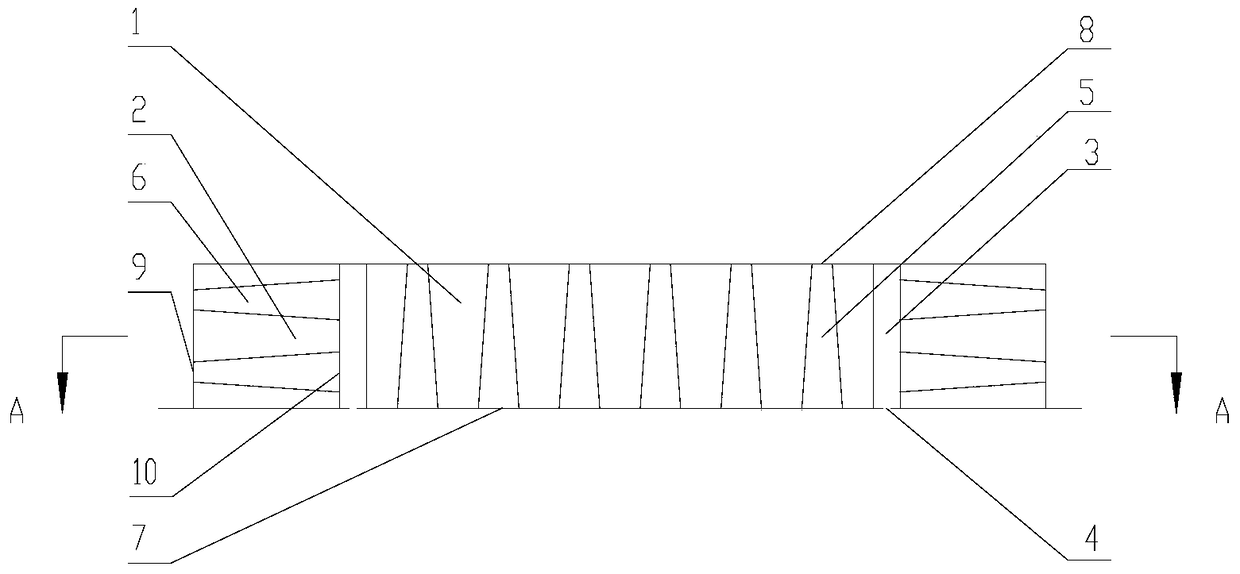

Axial reactor

ActiveCN107224939AImprove uniformityImprove conversion rateChemical/physical processesRetention timeProduct gas

The invention discloses an axial reactor. The reactor comprises a radial cylindrical sealed pressure-bearing shell body (2), a gas inlet pipe (18), a gas outlet pipe (13), an axial microchannel reaction zone (16) and an axial catalytic reaction zone (9), wherein the axial microchannel reaction zone (16) is located above the axial catalytic reaction zone (9); the axial microchannel reaction zone (16) comprises one or more disk-shaped axial microchannel reaction units (14) which are connected in series up and down; each axial microchannel reaction unit (14) has a plurality of axial microreaction channels (7); and the axial catalytic reaction zone (9) can contain at least one catalyst bed layer, and reactant fluid can flow through the catalyst bed layers from top to bottom for a catalytic reaction. Compared with the prior art, the reactor disclosed by the invention is compact in structure, low in active metal consumption, low in bed layer pressure drop, short in gas product retention time and high in bed layer space utilization ratio and is free of gas bias and short-circuit phenomena.

Owner:SINOPEC ENG +1

Axial micro-channel coupling reactor and applications thereof

ActiveCN106582468AGuaranteed conversion rateSimple processChemical/physical/physico-chemical processesNuclear engineeringHigh energy

The present invention discloses an axial micro-channel coupling reactor and applications thereof. The axial micro-channel coupling reactor comprises a cylindrical sealing pressure bearing shell, inlets and outlets for two kinds of raw material gases, and an axial catalysis reaction zone arranged in the shell, wherein the axial catalysis reaction zone comprises a plurality of axial micro-reaction channels coated with catalytic active components on the inner surface and the outer surface. According to the present invention, with the axial micro-channel coupling reactor, the two reactions such as heat release and heat absorption can be achieved in the one reactor, and particularly the reactor is suitable for one of the catalytic reactions having the significant volume change; the heat release reaction and the heat absorption reaction are integrally performed in the same reactor so as to simplify the original process and reduce the equipment cost; and the reactor has advantages of low catalyst active component consumption, high space utilization rate, high energy utilization rate, and high raw material conversion rate.

Owner:SINOPEC ENG +1

Methanation reactor and methanation process

ActiveCN106378063AGreat driving forceShort stayHydrocarbon from carbon oxidesGaseous fuelsMethanationProcess engineering

The invention discloses a methanation reactor and a methanation process. The methanation reactor comprises a shell, a gas inlet pipe, a transverse catalytic reaction unit, a longitudinal catalytic reaction unit, a gas outlet pipe, axial micro-reaction channels and radial micro-reaction channels, wherein a component with catalytic activity may be loaded in the axial micro-reaction channels and radial micro-reaction channels. Compared with the prior art, the invention has the advantages that the methanation reactor is reduced in the usage amount of a catalyst; and when the methanation reactor is used for methanation, pressure drop among beds is reduced, gas retention time is short, the utilization rate of the space of reaction beds is high, and the phenomena of bias current and short circuit of gas do not occur.

Owner:SINOPEC ENG +1

Catalytic reactor

ActiveCN107617392AImprove uniformityImprove conversion rateChemical/physical processesStraight tubeEngineering

The invention discloses a catalytic reactor. The reactor includes a cylindrical sealed pressure-bearing housing (1), a first straight tube (19) extending from the top of the housing (1) to the insideof the housing, a second straight tube (10) extending from the bottom of the housing (1) to the inside of the housing, and a catalytic reaction unit arranged inside the housing (1), below the first straight tube (19), and above the second straight tube (10). Compared with a catalytic reactor in the prior art, the catalytic reactor is compact in structure, less in active metal consumption, high intarget product selectivity, small in bed pressure drop, and low in temperature, and the phenomenon of temperature runaway isn't taken place in the bed.

Owner:SINOPEC ENG +1

A kind of methanation reactor and methanation process

ActiveCN107224940BIncreased turbulenceImprove conversion rateGaseous fuelsChemical/physical processesMethanationEconomic benefits

Owner:SINOPEC ENG +1

an axial reactor

ActiveCN107224939BImprove uniformityImprove conversion rateChemical/physical processesRetention timeProduct gas

The invention discloses an axial reactor. The reactor comprises a radial cylindrical sealed pressure-bearing shell body (2), a gas inlet pipe (18), a gas outlet pipe (13), an axial microchannel reaction zone (16) and an axial catalytic reaction zone (9), wherein the axial microchannel reaction zone (16) is located above the axial catalytic reaction zone (9); the axial microchannel reaction zone (16) comprises one or more disk-shaped axial microchannel reaction units (14) which are connected in series up and down; each axial microchannel reaction unit (14) has a plurality of axial microreaction channels (7); and the axial catalytic reaction zone (9) can contain at least one catalyst bed layer, and reactant fluid can flow through the catalyst bed layers from top to bottom for a catalytic reaction. Compared with the prior art, the reactor disclosed by the invention is compact in structure, low in active metal consumption, low in bed layer pressure drop, short in gas product retention time and high in bed layer space utilization ratio and is free of gas bias and short-circuit phenomena.

Owner:SINOPEC ENG +1

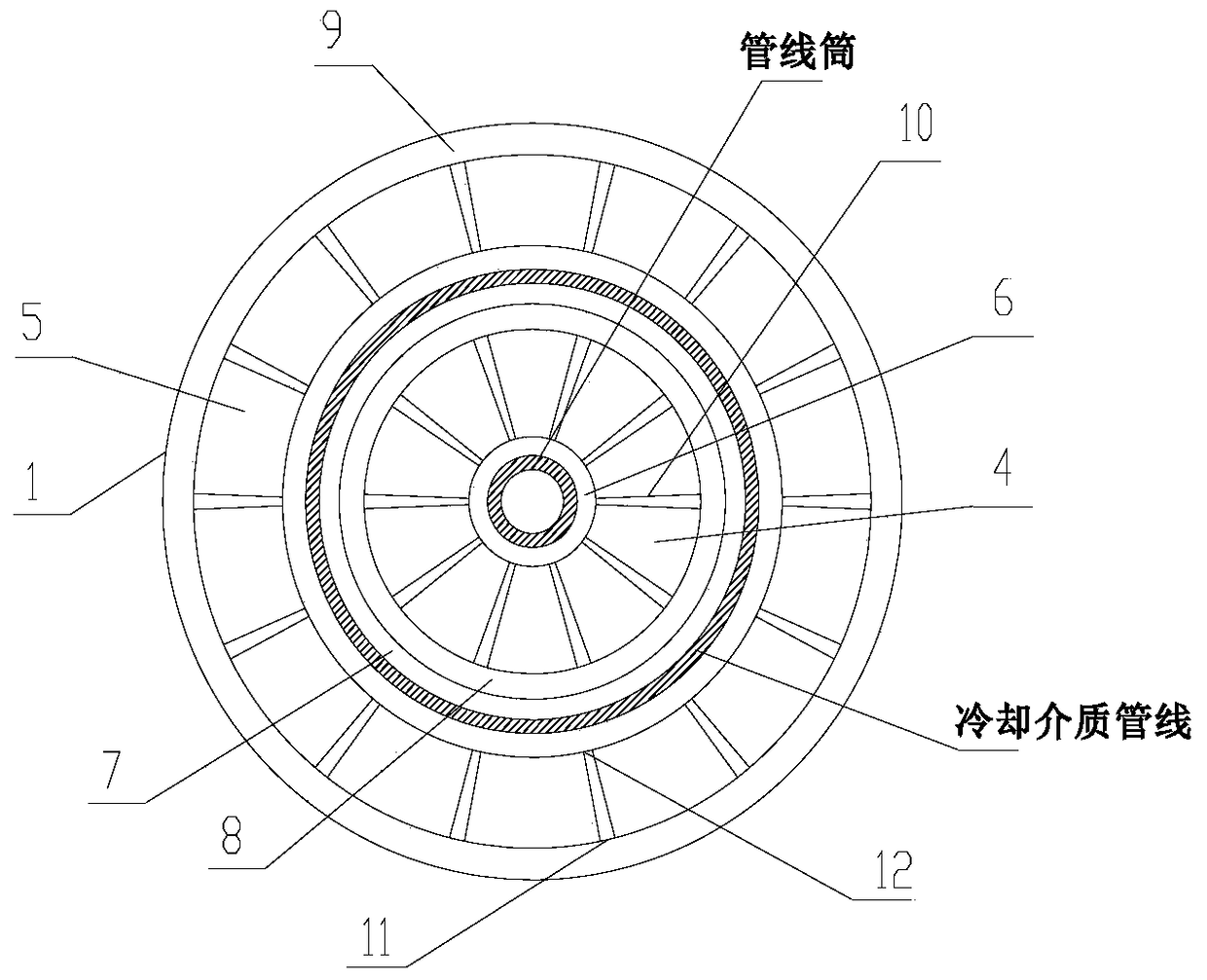

Axial radial micro-catalysis reaction unit and its application

ActiveCN106693848BGreat driving forceShort stayChemical/physical/physico-chemical processesRetention timeChemistry

The invention discloses an axial-radial micro-catalytic reaction unit and application thereof. The axial-radial micro-catalytic reaction unit contains a central column and a sleeve which coaxially sleeves the central column. The central column has axial micro-reaction channels which axially pass through the central column. Radial micro-reaction channels which pass through the sleeve are arranged in the radial direction of the sleeve. The axial-radial micro-catalytic reaction unit provided by the invention can be used for a reaction with reaction volume changing. In addition, use amount of a catalyst is small; pressure drop is low; retention time is short; utility rate of space is high; and there is no gas bias current or short circuit phenomenon.

Owner:SINOPEC ENG +1

Far field microwave breeding method

ActiveCN101978804BImprove the effect of increasing productionIncrease productionSeed and root treatmentSocial benefitsGenes mutation

The invention discloses a far field microwave breeding method, which comprises the following steps of: regularly irradiating active seeds of a crop by using far field microwave, and stimulating the potentials of the active seeds by using energy memory effect to obtain optimized active seeds of the crop with high yield increasing effect. Experiments such as large-headed atractylodes rhizome breeding and the like show that the method has remarkable advantage on the aspect of improving the yield compared with other methods for obtaining optimized active seeds of crops, the method has little probability of causing seed gene mutation and high safety, and the method is easy to realize diversification of optimized varieties and put into production practice, so the method has great economic benefit and social benefit.

Owner:曾文海 +2

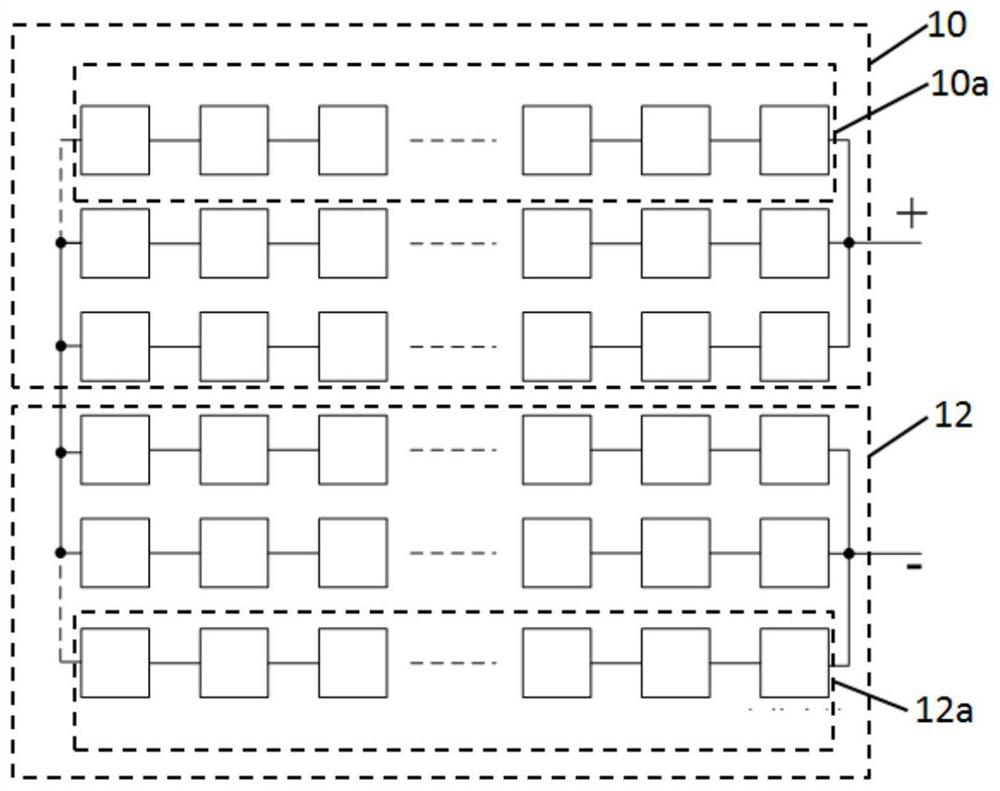

Photovoltaic module and photovoltaic system

ActiveCN113206162AImprove powerLittle impact on output powerPhotovoltaicsPhotovoltaic energy generationElectrical batteryEngineering physics

The embodiment of the invention discloses a photovoltaic module and a photovoltaic system, relates to the technical field of photovoltaic, and aims to prolong the service life of a shielded battery to a certain extent and further prolong the service life of the photovoltaic module while improving the output electric quantity of the photovoltaic module. The photovoltaic module comprises at least two battery string groups, wherein at least two battery string groups are connected in series, and each battery string group comprises at least two battery strings connected in parallel; and two ends of at least two battery string groups connected in series are respectively a positive electrode output end and a negative electrode output end. The invention is suitable for converting solar energy into electric energy.

Owner:BEIJING DYNAMIC POWER CO LTD

A kind of methanation reactor and methanation process

ActiveCN106378063BGreat driving forceShort stayHydrocarbon from carbon oxidesGaseous fuelsMethanationProcess engineering

The invention discloses a methanation reactor and a methanation process. The methanation reactor comprises a shell, a gas inlet pipe, a transverse catalytic reaction unit, a longitudinal catalytic reaction unit, a gas outlet pipe, axial micro-reaction channels and radial micro-reaction channels, wherein a component with catalytic activity may be loaded in the axial micro-reaction channels and radial micro-reaction channels. Compared with the prior art, the invention has the advantages that the methanation reactor is reduced in the usage amount of a catalyst; and when the methanation reactor is used for methanation, pressure drop among beds is reduced, gas retention time is short, the utilization rate of the space of reaction beds is high, and the phenomena of bias current and short circuit of gas do not occur.

Owner:SINOPEC ENG +1

A kind of methanation reactor and methanation process

ActiveCN106693839BGreat driving forceShort stayHydrocarbon from carbon oxidesGaseous fuelsMethanationActive component

The invention discloses a methanation reactor and a methanation process; the methanation reactor comprises a shell body, a gas inlet pipe, a central cylinder, a central pipe, a gas outlet pipe, a cooling medium inlet, a cooling medium outlet and a micro reaction channel, and includes or does not include a sleeve; the micro reaction channel can be internally loaded with a catalytic active component. Compared with the prior art, the methanation reactor has less catalyst use amount; according to the methanation process adopting the methanation reactor, the bed pressure is reduced, the gas residence time is short, the space utilization rate of a reaction bed is high, and gas bias current and short-circuit phenomena do not exist.

Owner:SINOPEC ENG +1

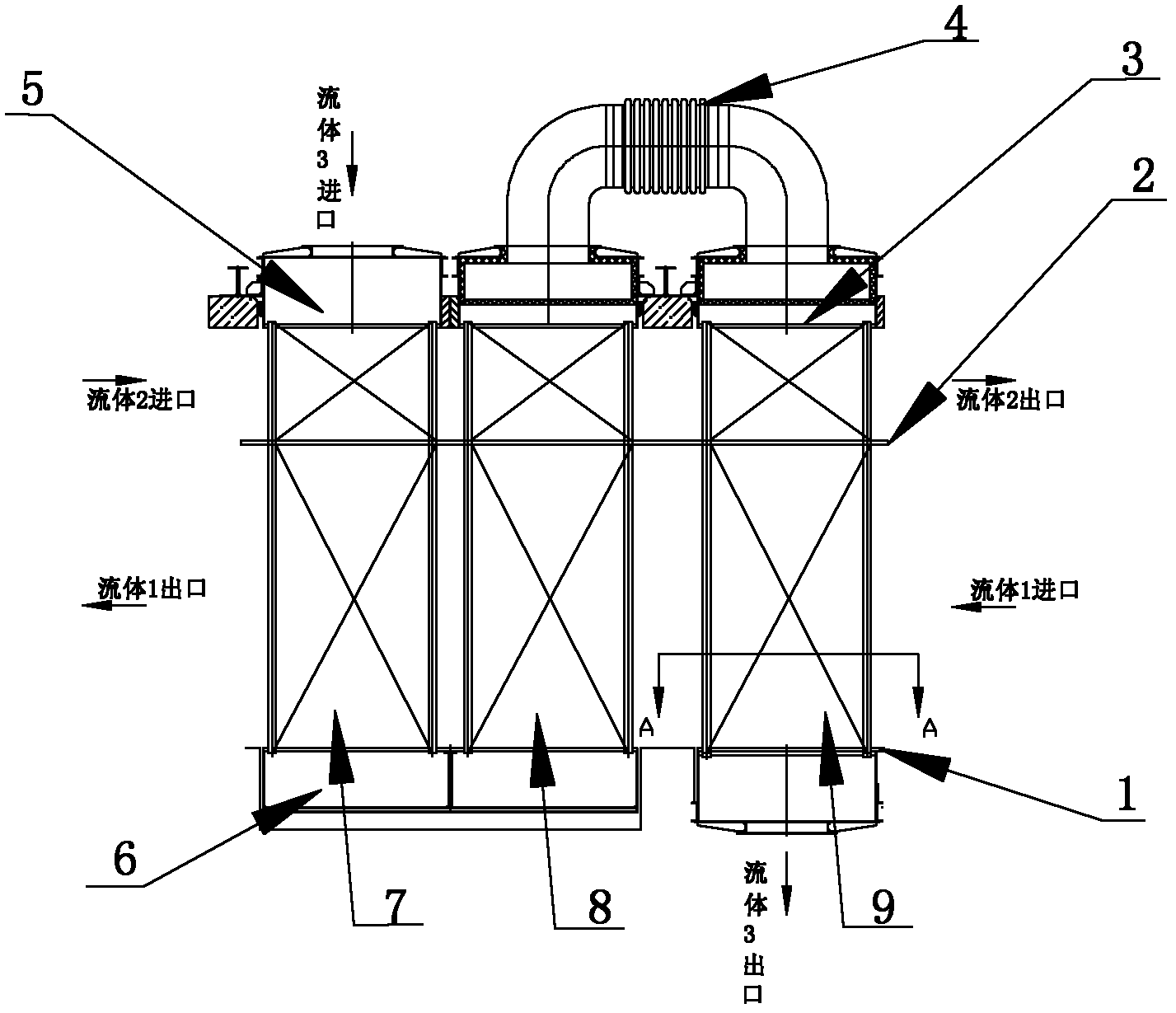

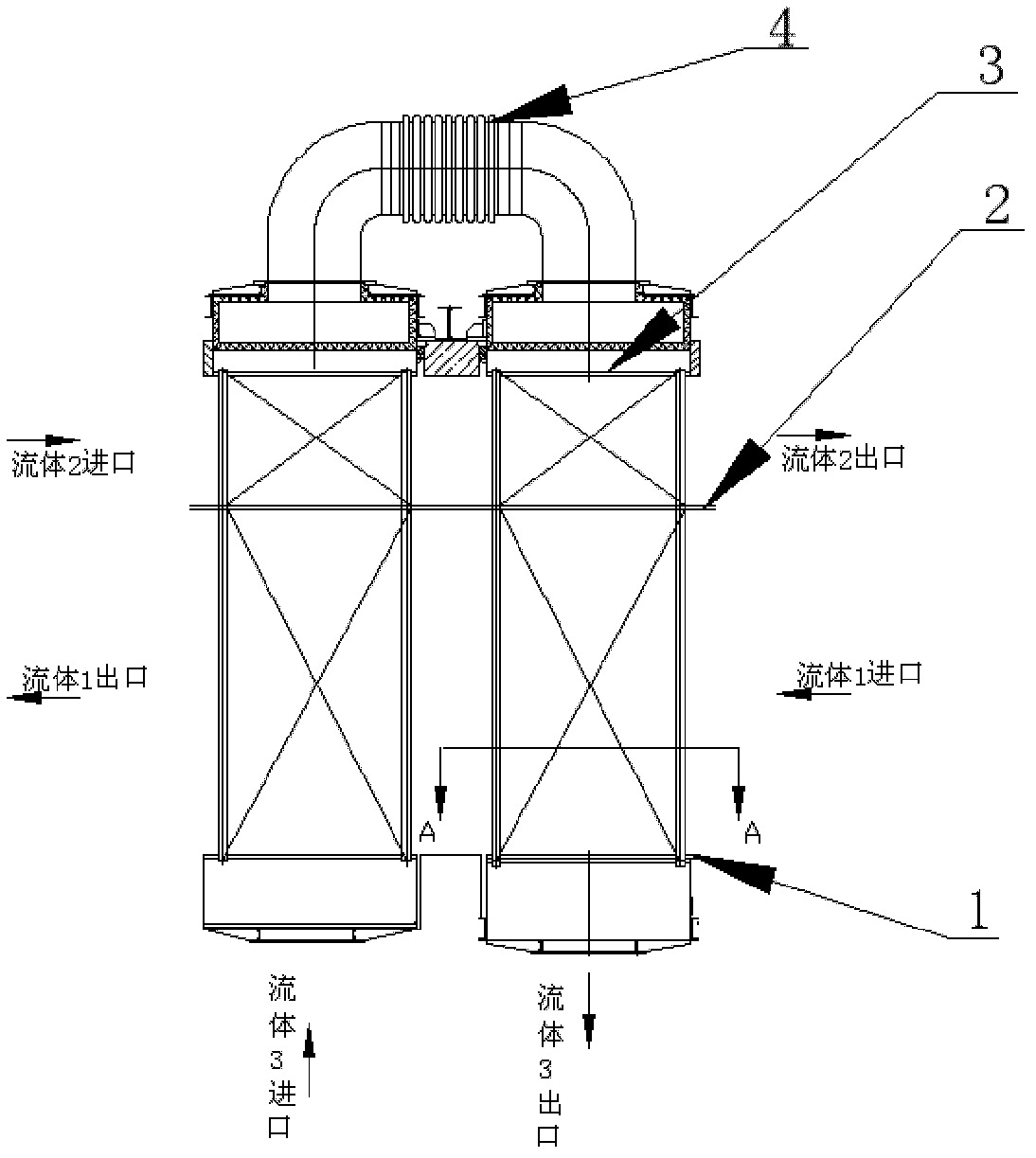

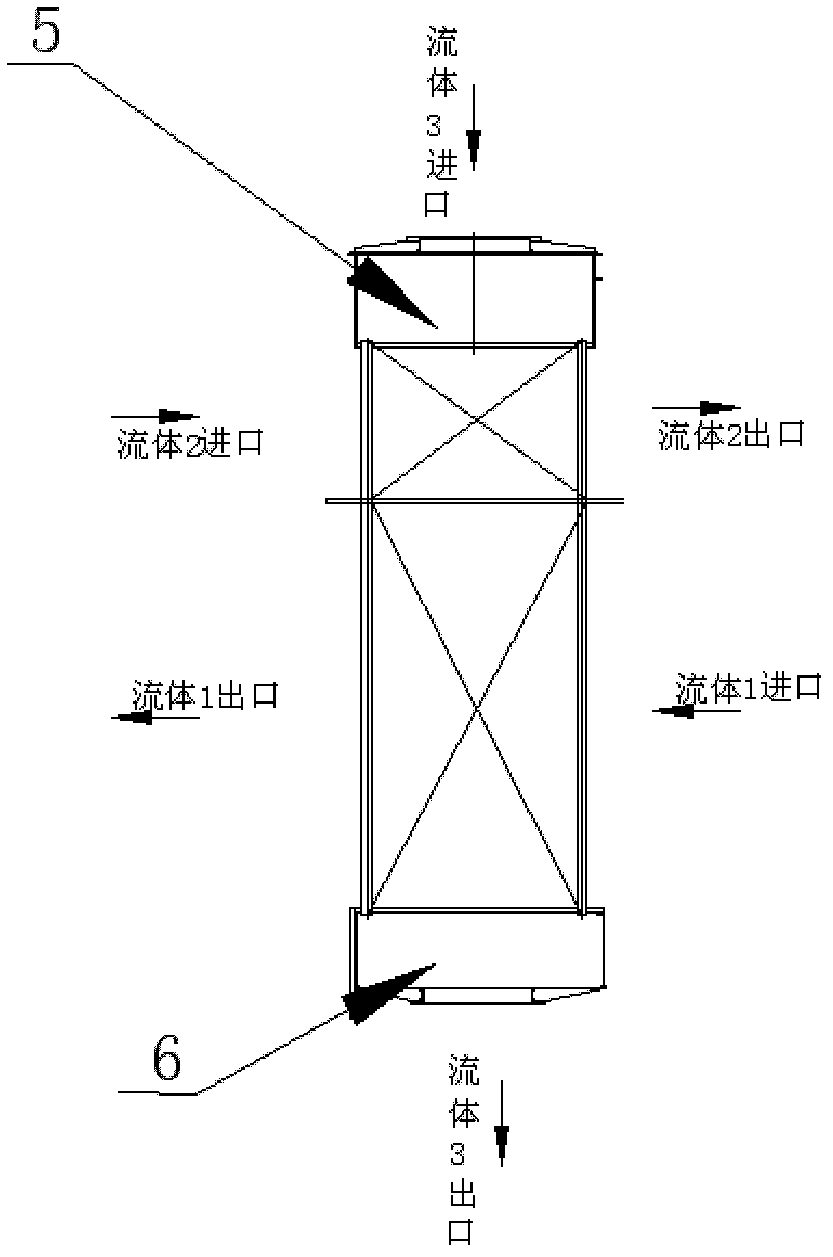

Three-fluid sleeve type heat-pipe heat exchanger

InactiveCN103017580AUniform temperatureRaise the outlet temperatureIndirect heat exchangersWorking temperatureRecuperator

The invention provides a three-fluid sleeve type heat-pipe heat exchanger, and relates to the technology of a heat exchanger. The three-fluid sleeve type heat-pipe heat exchanger comprises a heat pipe, an upper clapboard, a middle clapboard, a lower clapboard, a peripheral interface and three flow channels, i.e. a heat pipe lower layer flow channel arranged between the lower clapboard and the middle clapboard, a heat pipe upper layer flow channel arranged between the middle clapboard and the upper clapboard, and a flow channel formed by an inner pipe of a heat pipe bundle, an upper header box and a lower header box. When the three-fluid sleeve type heat-pipe heat exchanger runs, thermal fluid passes through the heat pipe lower layer flow channel or a sleeve inner layer pipe flow channel, the heat pipe is quickly started after the heat is absorbed from a lower end and an inner layer pipe, and the whole pipe is even in temperature and free from warm spots, and two cold fluids pass through the other two flow channels, so that the heat exchange efficiency can be greatly improved. The three-fluid sleeve type heat-pipe heat exchanger is a device where the dividing wall type heating is carried out on a plurality of cold fluids by one thermal fluid at the same time, the device is used for the heat exchange of the high-temperature fluid, and the heat energy of the high-temperature fluid is used for heating up the other two cold fluids, so that the cold fluids with different properties are higher in outlet temperature, the outlet temperature of the thermal fluid can be reduced, and the thermal pollution can be avoided. The three-fluid sleeve type heat-pipe heat exchanger is particularly suitable for the condition where the fluid cooling operation is not large in pressure, and the outlet work temperature is required to be higher.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

a catalytic reactor

ActiveCN107617392BImprove uniformityImprove conversion rateChemical/physical processesStraight tubePhysical chemistry

Owner:SINOPEC ENG +1

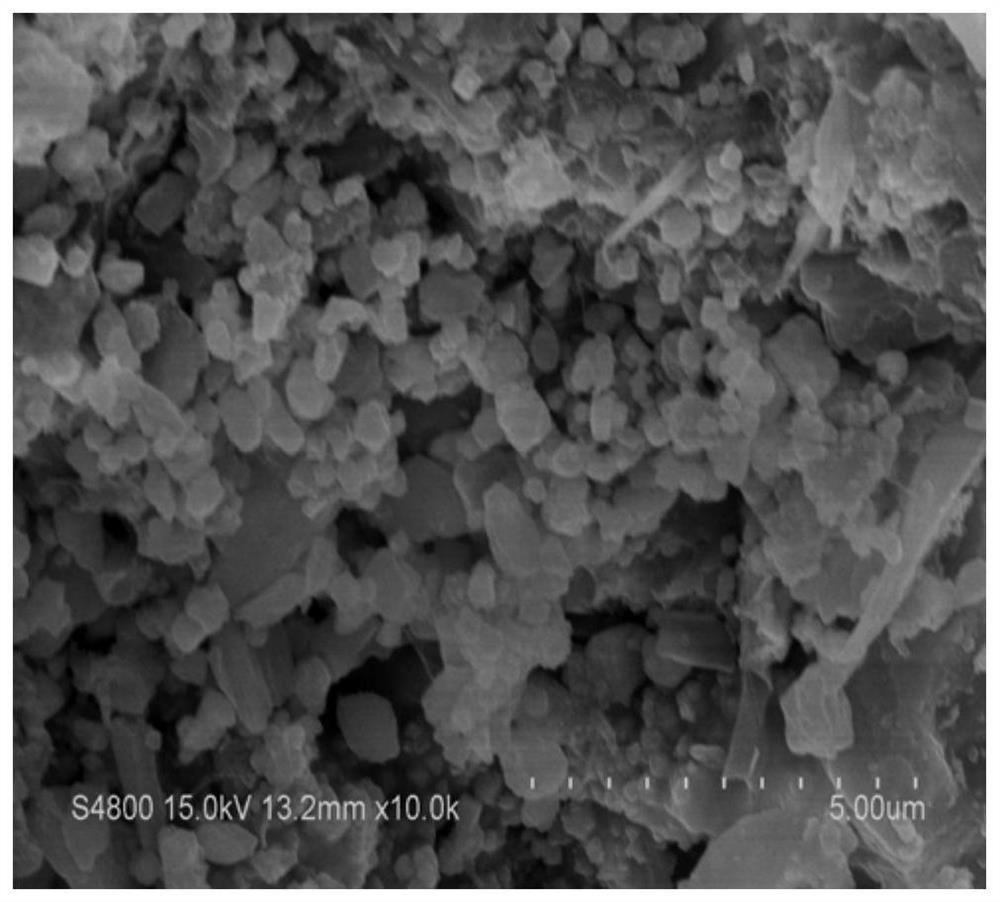

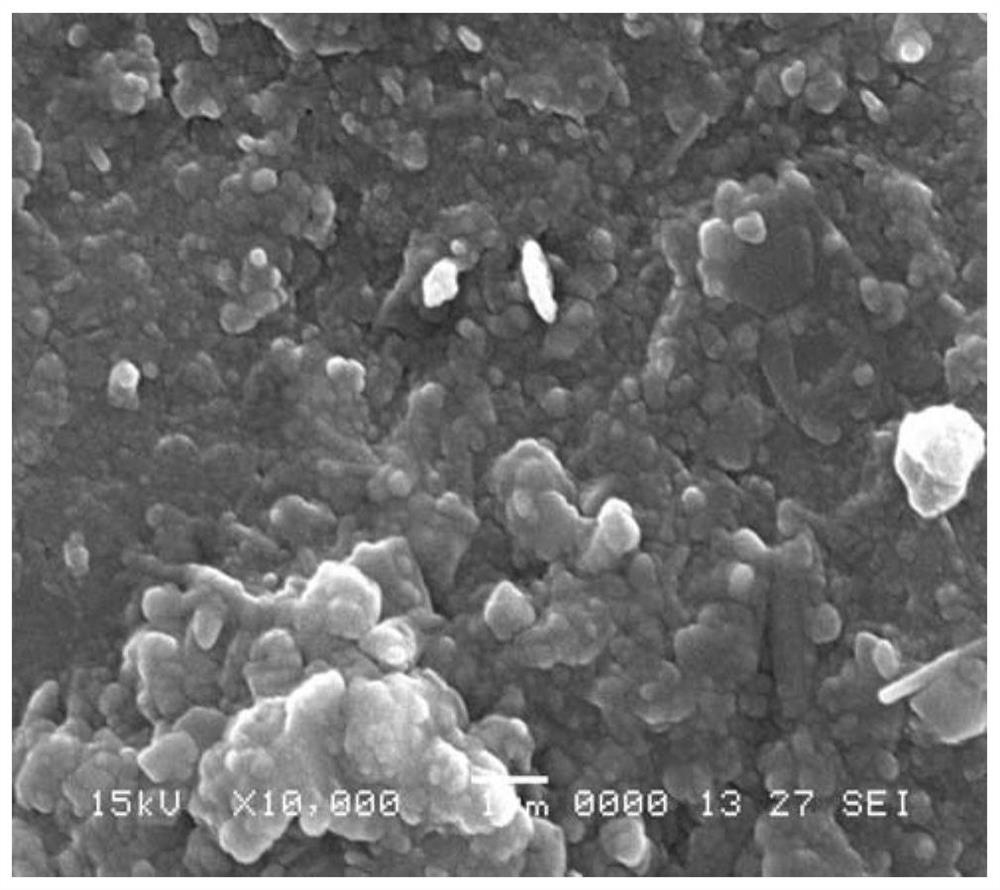

A 160km/h express truck brake pad for preventing thermal cracking of brake disc and manufacturing method thereof

ActiveCN109667865BImprove defects such as thermal crackingReduce wearOther chemical processesFriction liningButyl rubberTruck

The invention relates to a 160km / h express freight car brake pad for preventing thermal cracking of the brake disc and a manufacturing method thereof. The 160km / h express truck brake pads for preventing heat cracking of the brake discs include the following components and weight percentages: boron modified phenolic resin 20%-40%, butyl rubber 10%-18%, reinforcing fiber 6% ‑10%, carbon fiber 10%‑18%, sepiolite fiber 1%‑5%, vermiculite 1%‑8%, fluorite 2%‑8%, magnesium oxide 2%‑9%, clay 2%‑8 %, dispersant 0.2%‑3%. Compared with the prior art, the brake disc of the invention has a lower density, is more convenient to use, and can reduce vehicle quality. The brake pad of the present invention has a microporous structure, and the micropores play the role of heat dissipation, which can effectively reduce the friction temperature, the friction coefficient does not decline at a high temperature of 600°C, and the brake disc has no hot spots and cracks, effectively protecting the couple. The wear of the brake pads is low and the service life is longer than that of similar products.

Owner:SHANGHAI REINPHEN NEW MATERIAL TECH CO LTD

A radial micro-catalytic reaction unit and its application

ActiveCN106693847BGreat driving forceShort stayGaseous fuelsChemical/physical/physico-chemical processesRetention timeEngineering

The invention discloses a radial micro-catalytic reaction unit and application thereof. The radial micro-catalytic reaction unit comprises a central cylinder having a central tube. One end of the central tube is an opening. The outboard of the central cylinder is in fluid communication with the central tube through micro-reaction channels which radially penetrate through the central cylinder. The micro-reaction channels have micro-channel inside openings and micro-channel outside openings which have different diameters. The micro-catalytic reaction unit can be used for a reaction with reaction volume changing. In addition, use amount of a catalyst is small; pressure drop is low; retention time is short; utility rate of space is high; and there is no gas bias current or short circuit phenomenon.

Owner:SINOPEC ENG +1

Preparation method of solar cell module applied to near-space aircraft

PendingCN112420874ASolve the technical problem that it is impossible to add a diode to each single batterySolve the problem of output power lossFinal product manufacturePhotovoltaic energy generationElectrical batterySolar cell

The invention discloses a preparation method of a solar cell module applied to a near-space aircraft. The method comprises the steps: preparing a first lamination layer and a second lamination layer;orderly arranging solar cells on the first lamination layer; correspondingly arranging a diode beside each solar cell; welding a welding strip on a positive electrode main grid of each solar cell; connecting the first end of the solder strip with a negative electrode of the corresponding diode; connecting the second end of the solder strip with a positive electrode of the corresponding diode and the negative electrode of the next adjacent solar cell; placing the second lamination layer on all the solar cells to obtain a solar cell module; laminating the solar cell module; and cutting the solarcell module. According to the preparation method, the diodes are added at the serial gaps of battery strings, so that the technical problem that the diodes cannot be added on each single battery of atraditional monocrystalline silicon series solar battery is solved.

Owner:中电科蓝天科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com