Three-fluid sleeve type heat-pipe heat exchanger

A heat pipe heat exchanger, sleeve-pipe technology, applied in the field of three-fluid heat exchangers, can solve the problems of low heat exchange efficiency, achieve the effects of reducing exhaust gas temperature, uniform pipe wall temperature, and increasing outlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is a three-fluid casing heat pipe heat exchanger, which adopts the casing heat pipe technology, and has differences in structure arrangement and flow channel layout, and is a completely new type of heat exchanger.

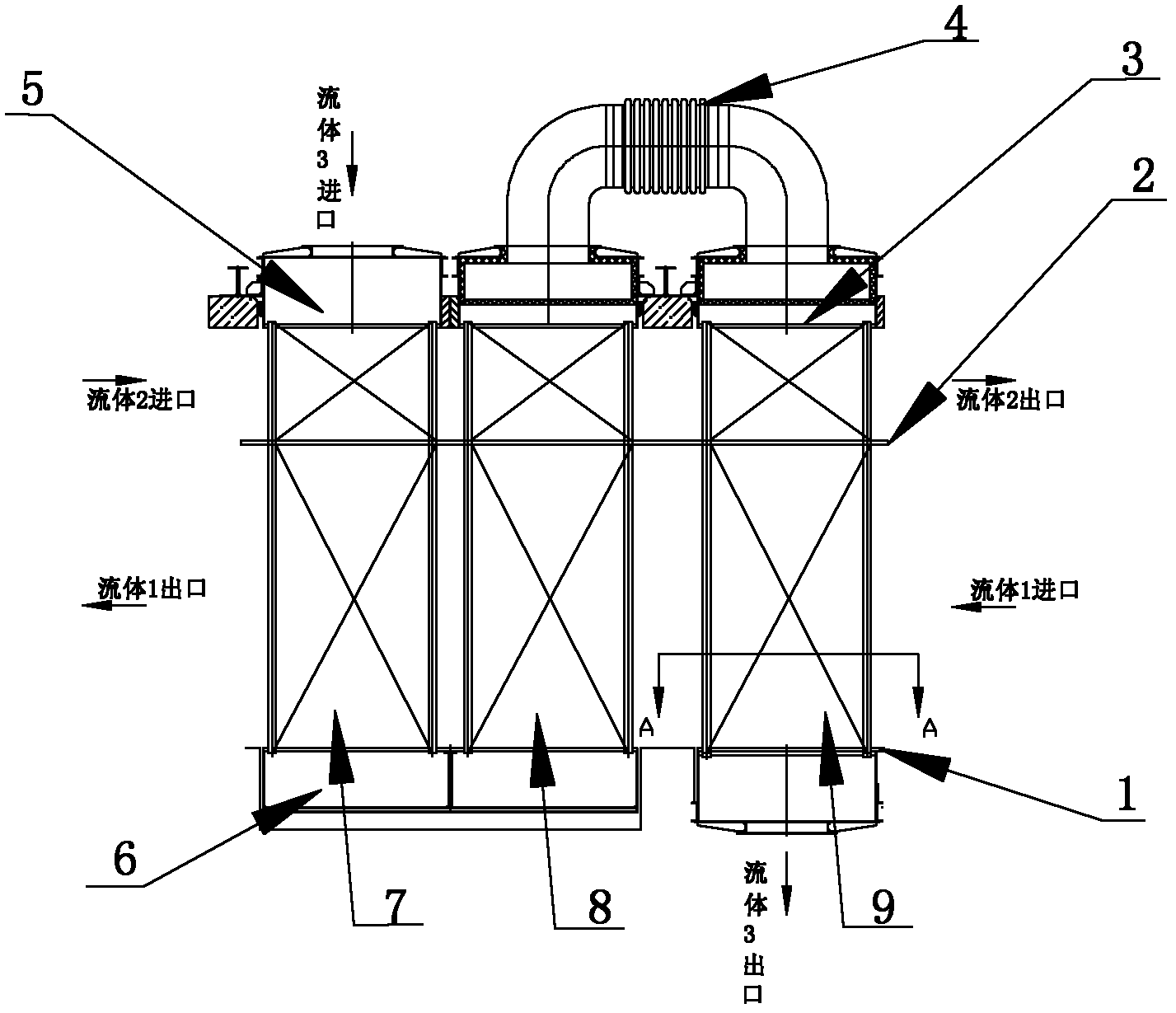

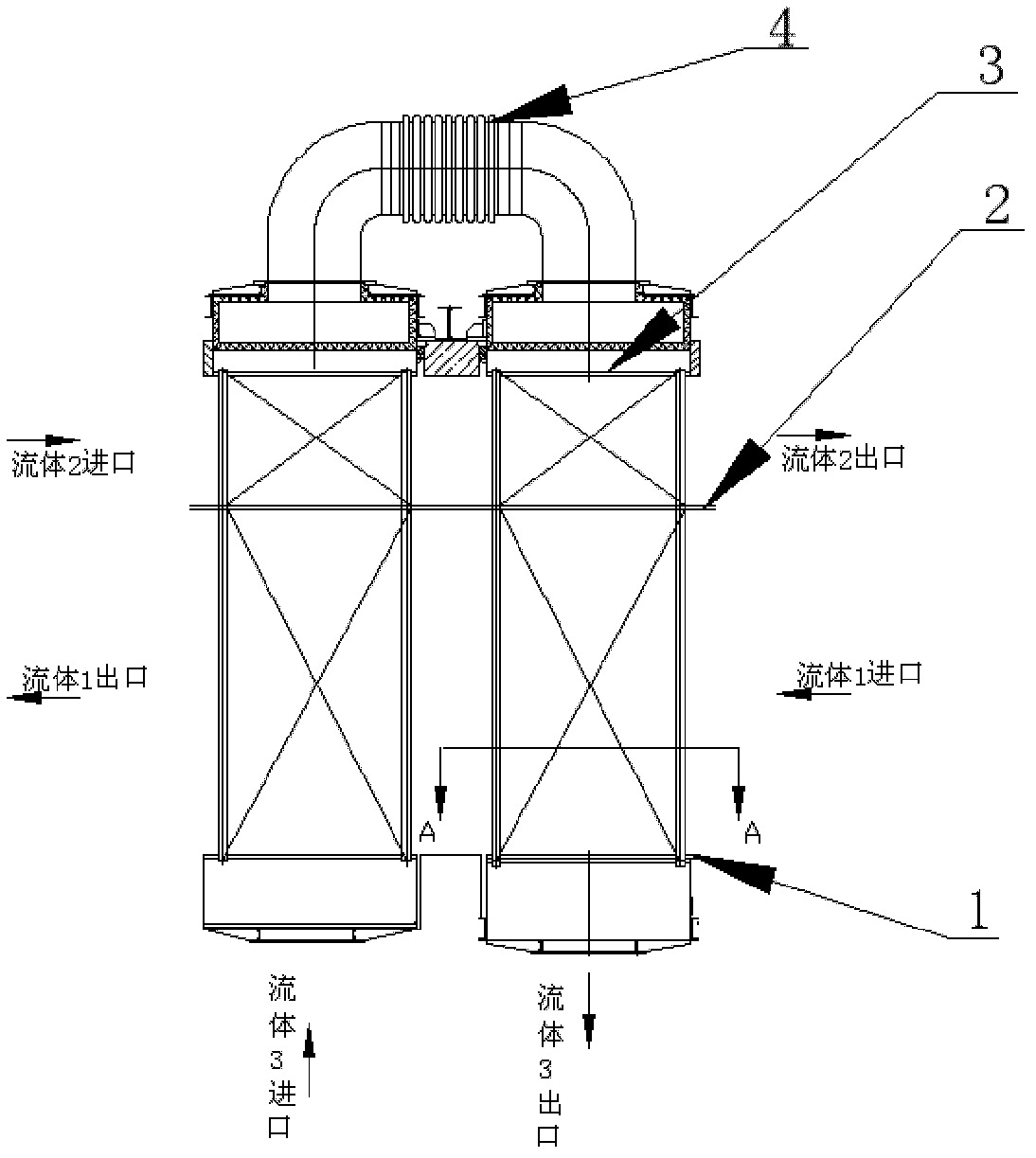

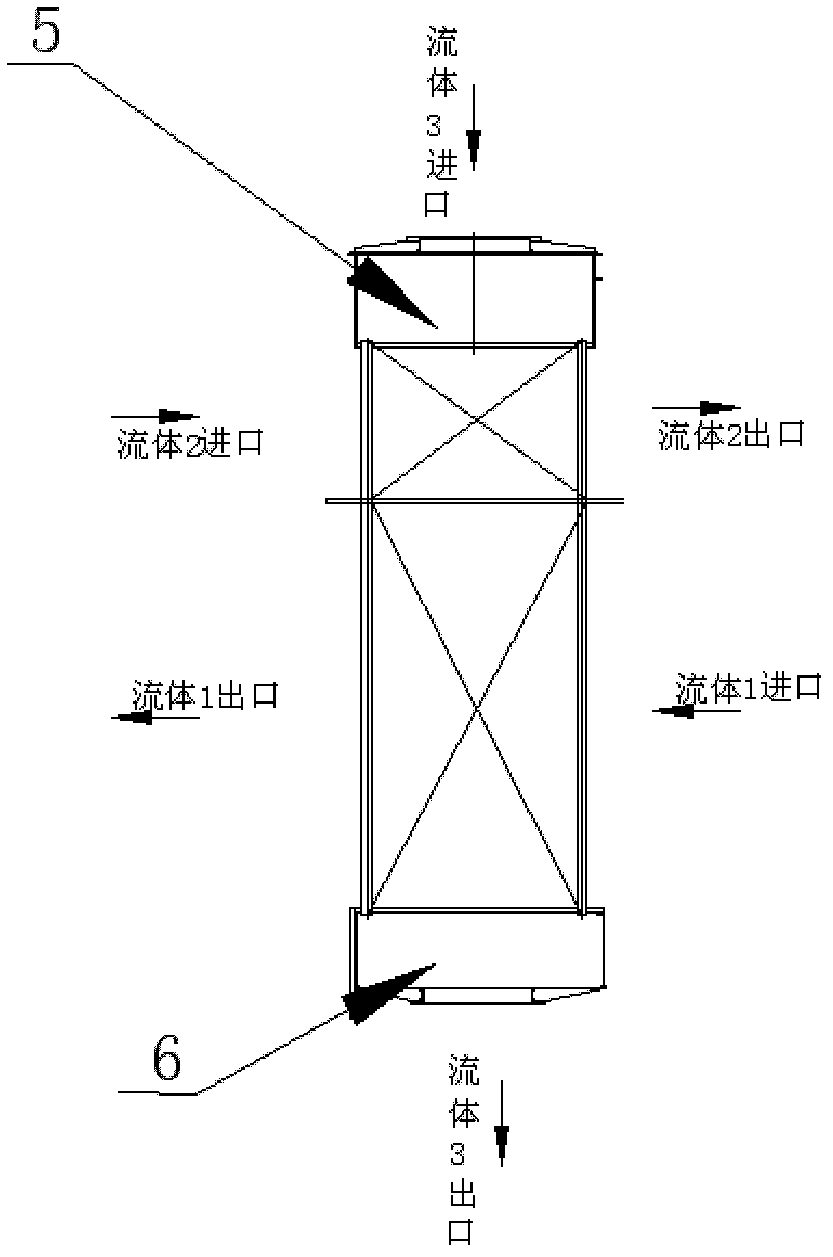

[0029] Figure 1- image 3 As shown, use Figure 1a Embodiment 1 is described as follows: the following partition 1, the middle partition 2 and the upper partition 3 divide the casing heat pipe bundle into two upper and lower fluid circulation channels, and isolate the upper and lower ends of the heat pipes from the two flow channels , the upper header 5 communicates with the lower header 6 through the inner tube of the heat pipe bundle, forming a third fluid circulation channel. The heat pipe bundle can be divided into three areas, forming a normal temperature heat exchange area 7, a medium temperature heat exchange area 8 and a high temperature heat exchange area 9. According to practical applications, it is also possible to divide onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com