High-enthalpy-value flame-retardant phase-change material and preparation method thereof

A phase change material, high enthalpy technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of fire risk of electronic components, low enthalpy value of phase change materials, and only high flame retardancy, so as to avoid The effect of reducing enthalpy, improving heat storage and temperature control ability, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the high enthalpy flame retardant phase change material of the present invention may comprise the following steps:

[0038] S1. Perform surface treatment on the phase change microcapsules to eliminate easily reactive groups on the surface of the shell material.

[0039] Surface treatment of phase-change microcapsules includes: mixing and stirring silane coupling agent, water, ethanol, and ammonia water to obtain a mixed solution, mixing the mixed solution into phase-change microcapsule powder in proportion, and drying to obtain surface-treated phase-change microcapsules .

[0040] Specifically, stir silane coupling agent water, ethanol, and ammonia water in a flask at 300 rpm for 1 h to obtain a hydrolyzed silane coupling agent mixed solution, and the mass ratio of silane coupling agent, water, ethanol, and ammonia water is 1:1:1 :0.05. Then mix the mixed liquid into the phase-change microcapsule powder in proportion (silane coupling agent ma...

Embodiment 1

[0052] The raw materials are mixed with an open mill, the roll temperature is 40°C, the open mill time is 20min, and the eccentric roll distance is 0.2-0.8mm. After discharge, press film vulcanization in a flat vulcanizer, the vulcanization temperature is 120°C, the vulcanization time is 30min, and the pressure is 5MPa. The specific formula and properties are shown in Table 1.

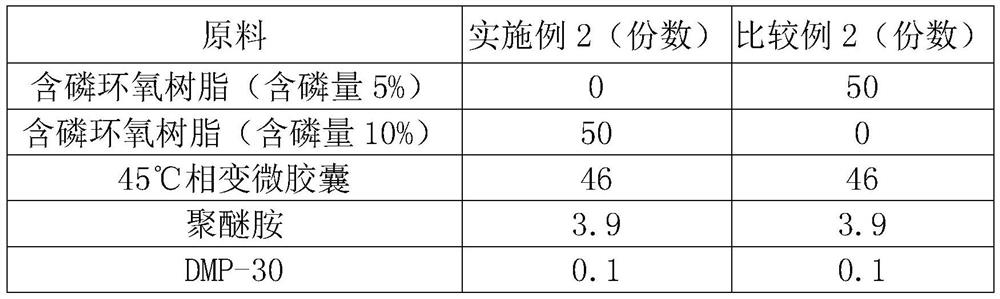

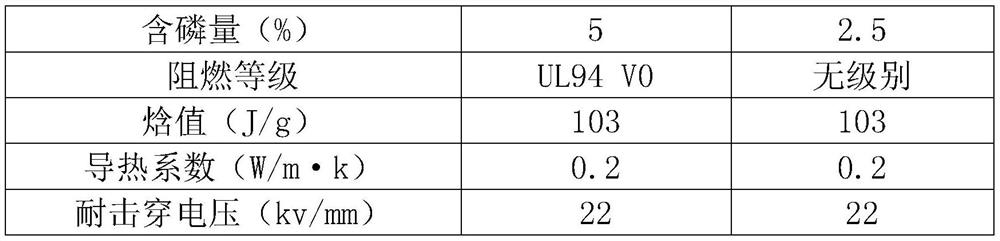

Embodiment 2

[0054] The raw materials are mixed with an internal mixer, the mixing temperature is 40° C., the mixing time is 2 hours, the top cover is not pressed down, and the rotor speed is 30 rpm. Molded after discharging, cured at 85°C, curing time 2h, normal pressure. The specific formula and properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com