Fluidization reaction device and method for producing chlorothalonil by using same

A fluidized reaction and reactor technology, which is used in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of removing heat from the fluidized bed, prone to local overheating, etc., to ensure the reaction Accuracy of temperature gradient, uniform internal temperature distribution, effect of increasing reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

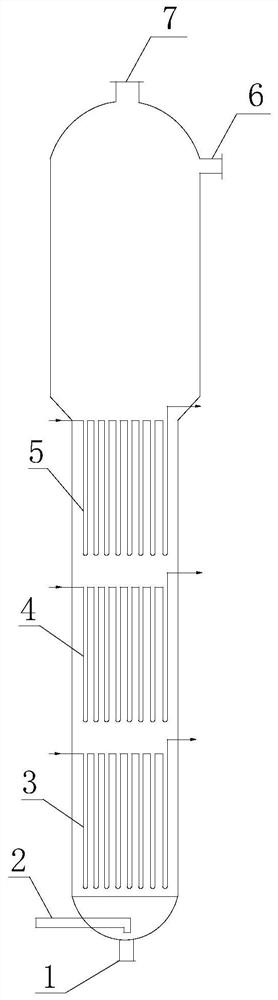

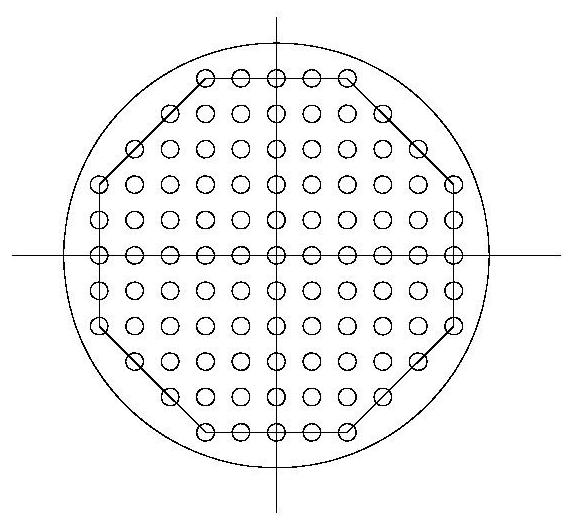

[0069] This embodiment provides a fluidized reaction device, such as figure 1 As shown, the fluidized bed reaction device includes a reactor main body, which includes a first heat exchange tube group 5, a second heat exchange tube group 4, and a third heat exchange tube group that are independent from each other from top to bottom in the reactor body. Group 3, all are U-shaped heat exchange tubes with only a single inlet and outlet, and are all arranged in a regular octagon, such as figure 2 As shown; the catalyst outlet 1 is arranged at the bottom of the reactor main body, an air inlet channel 2 is arranged between the third heat exchange tube group 3 and the catalyst outlet 1, the outlet of the air inlet channel 2 faces the catalyst outlet 1, and the air inlet channel 2 is connected The gas inlet is set on the lower side of the reactor main body, the gas outlet 6 is set on the upper side of the reactor main body, and is set on the upper part of the first heat exchange tube ...

Embodiment 2

[0072] This embodiment provides a fluidized reaction device, the difference between the fluidized bed reaction device and embodiment 1 is only the height of the first heat exchange tube group, the second heat exchange tube group and the third heat exchange tube group and the reaction The ratio of the height of the main body of the device is respectively 0.125, 0.125 and 0.15, and the rest are the same as in Example 1.

Embodiment 3

[0074] This embodiment provides a fluidized reaction device, the difference between the fluidized bed reaction device and embodiment 1 is only the height of the first heat exchange tube group, the second heat exchange tube group and the third heat exchange tube group and the reaction The ratio of the height of the main body of the device is respectively 0.15, 0.15 and 0.1, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com