Patents

Literature

152results about How to "Reasonable temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

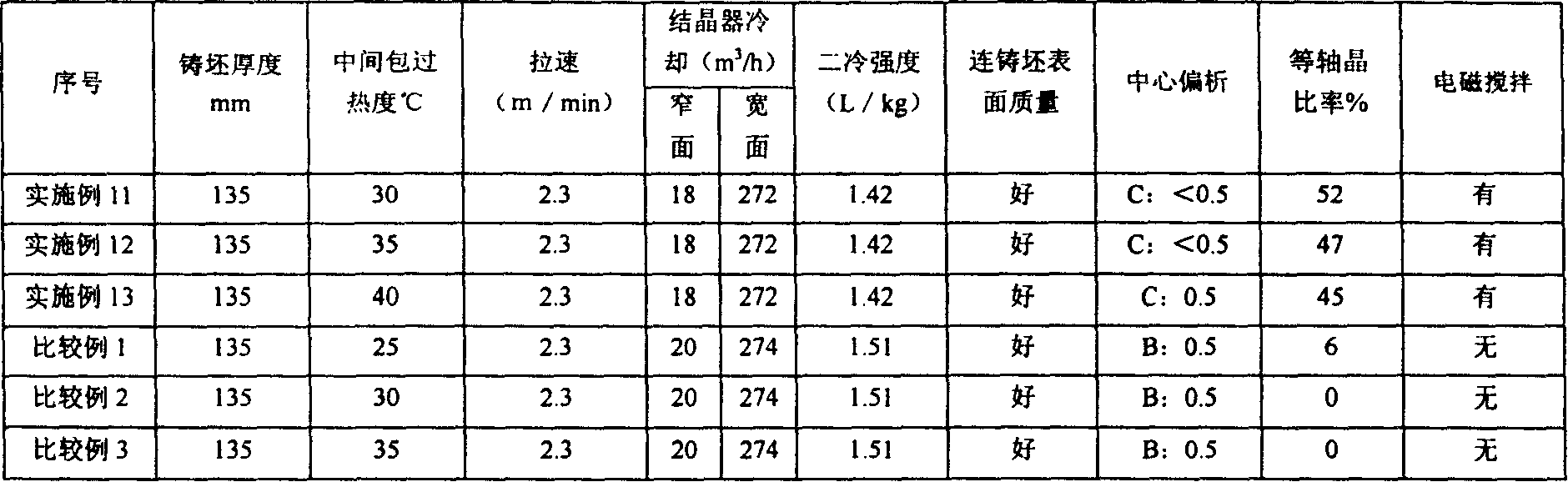

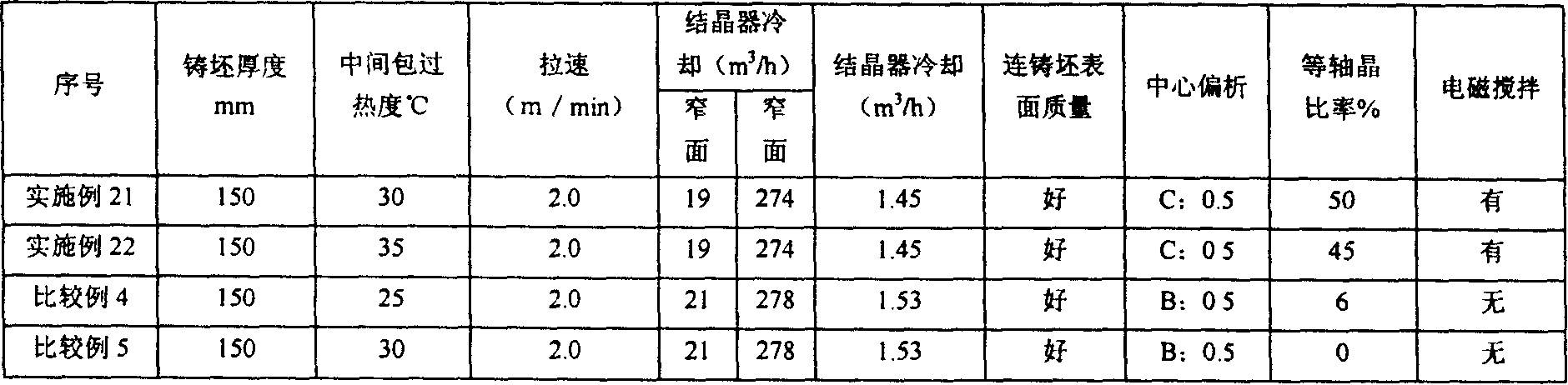

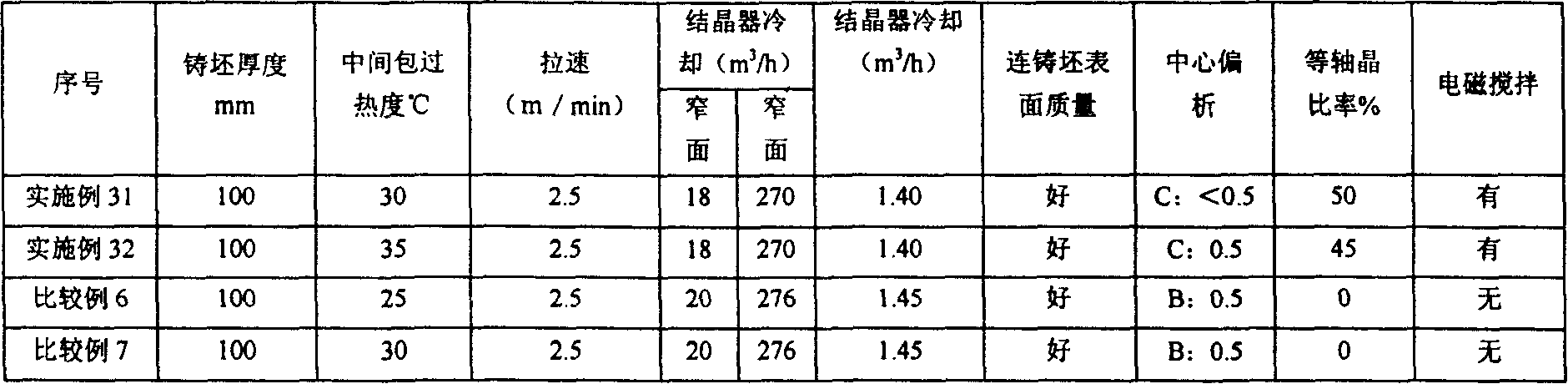

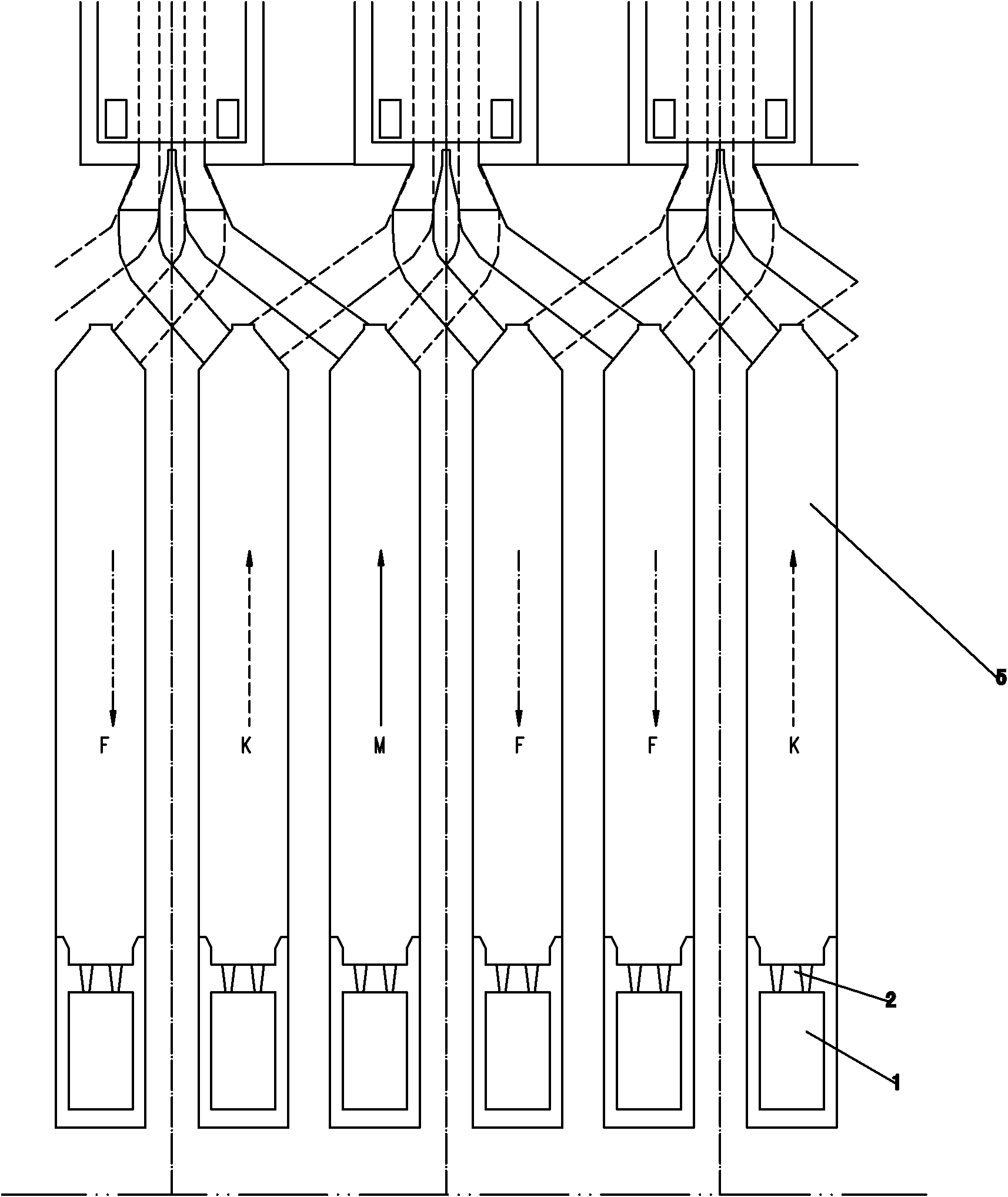

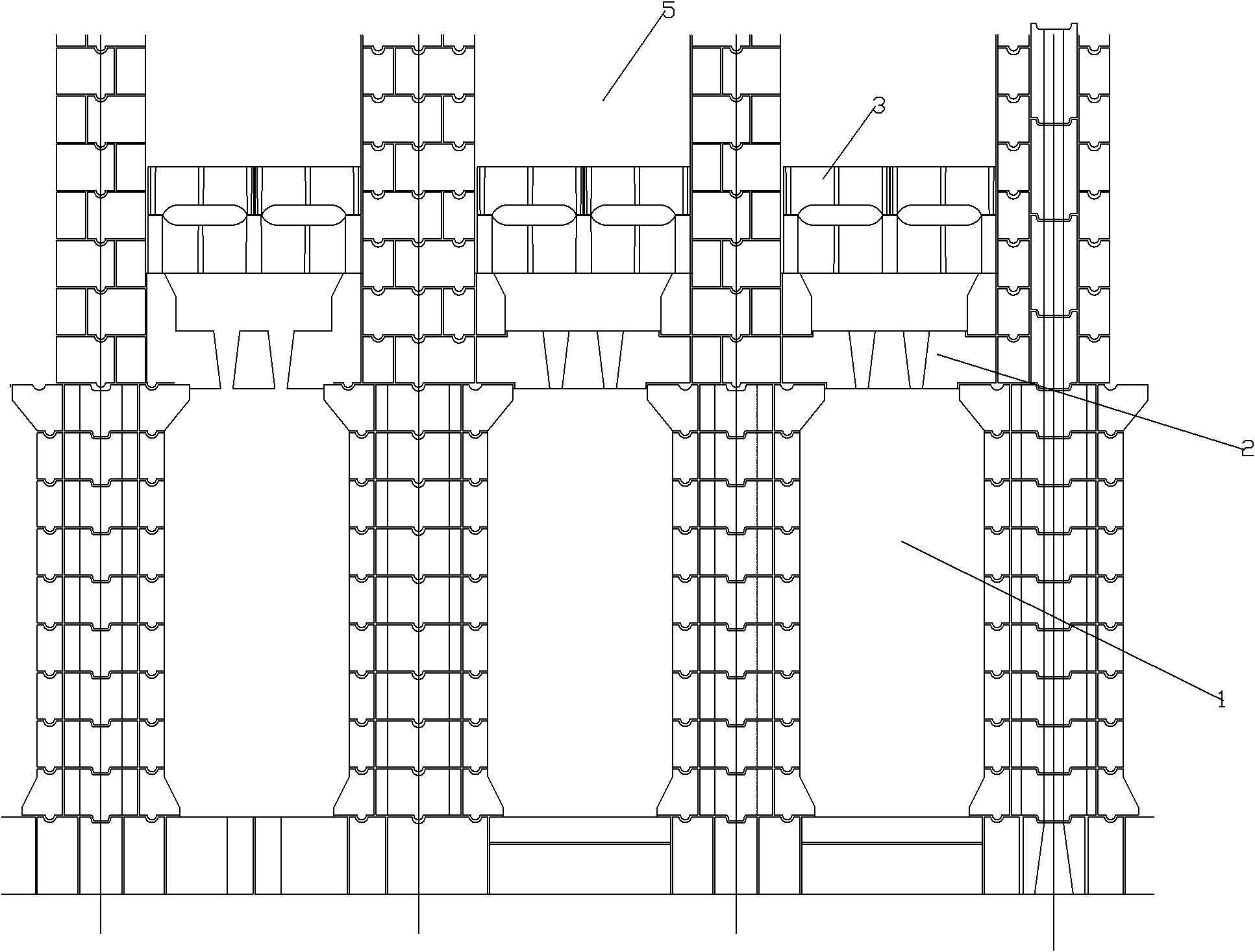

Continuous casting method for increasing equal thickness continuous casting plate billet equal axial crystal rate in non-oriented silicon steel

InactiveCN101164720AImprove mechanical propertiesImprove dynamic conditionsSiliconElectromagnetic stirring

The present invention provides a continuous casting method capable of increasing non-oriented silicon steel medium-thickness continuous cast slab equiaxial crystal rate. It is characterized by that it adopts a medium-thickness slab continuous casting machine, in the continuous casting second cooling zone it adopts a roller electromagnetic stirring equipment. The casting billet size of continuous casting machine is 100-150mmX850-1550mm, pouring speed is 1.5-3.5m / min, the cooling pattern: the narrow edge of crystallizer is 14-25m3 / h, the wide edge of crystallizer is 250-290m3 / h and second cooling intensity is 1.3-1.8L / kg. The described electromagnetic stirring equipment includes 2-4 pairs of introroller built-in traveling wave magnetic field type electromagnetic stirring devices which are assembled into two groups and mounted.

Owner:ANGANG STEEL CO LTD

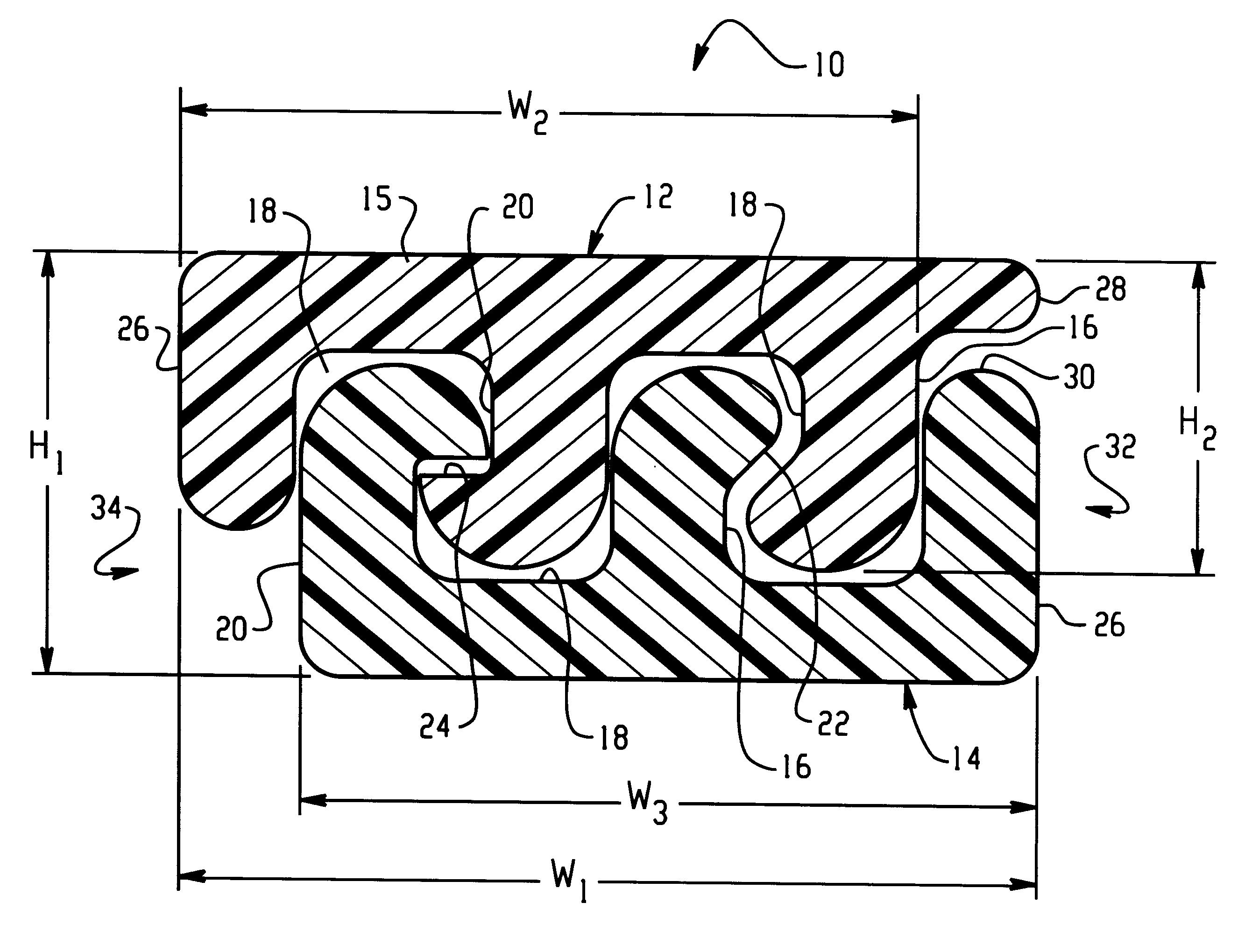

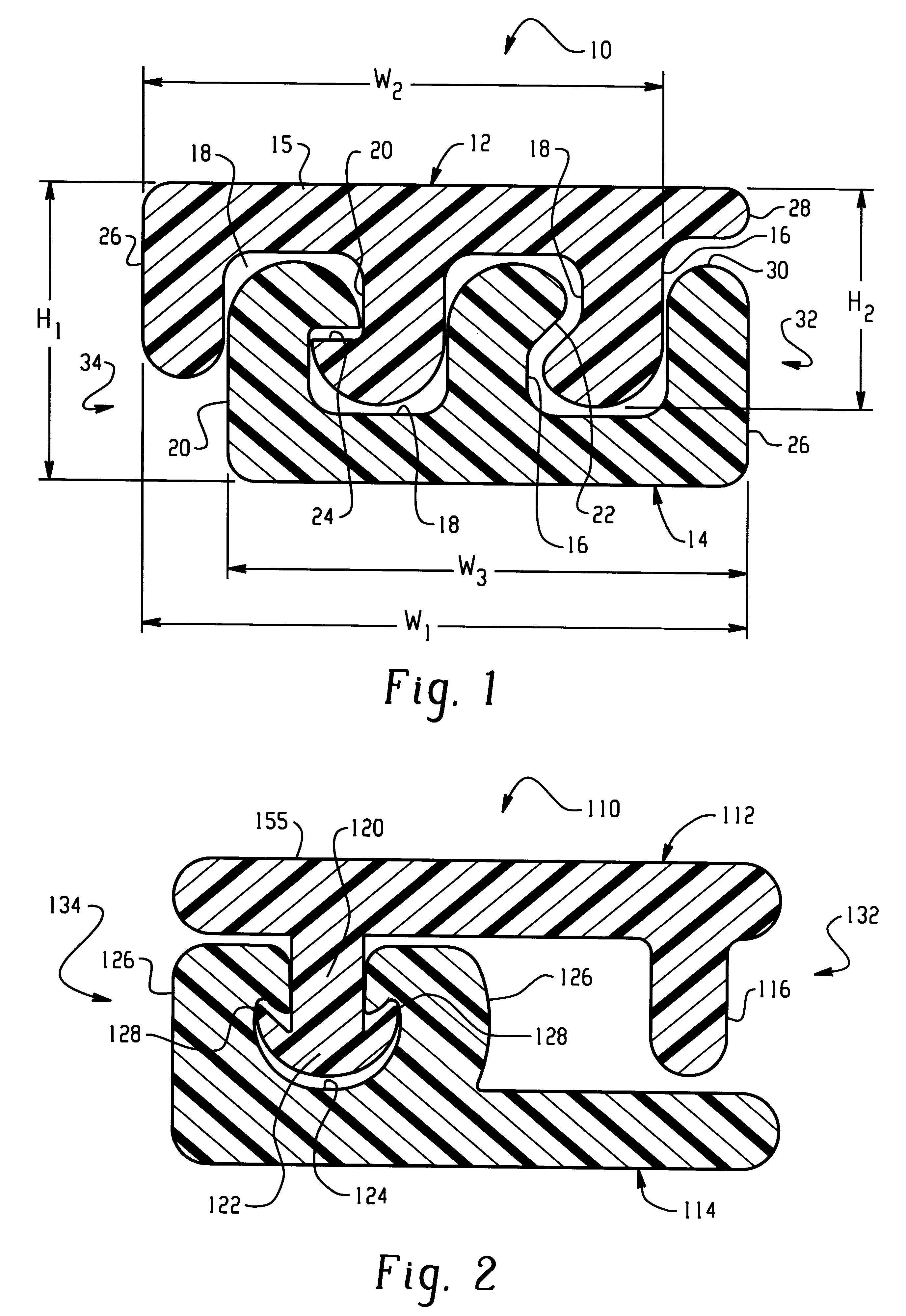

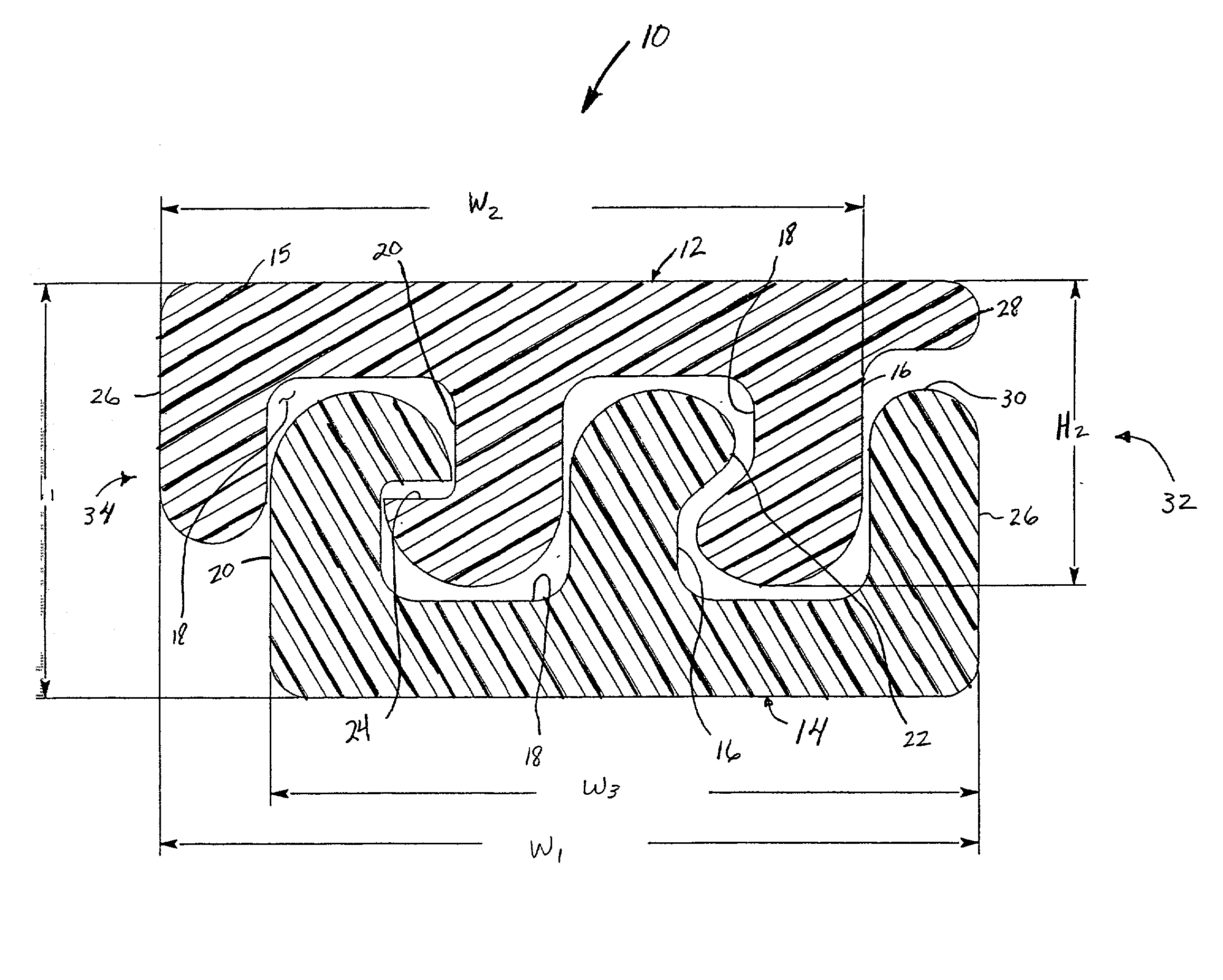

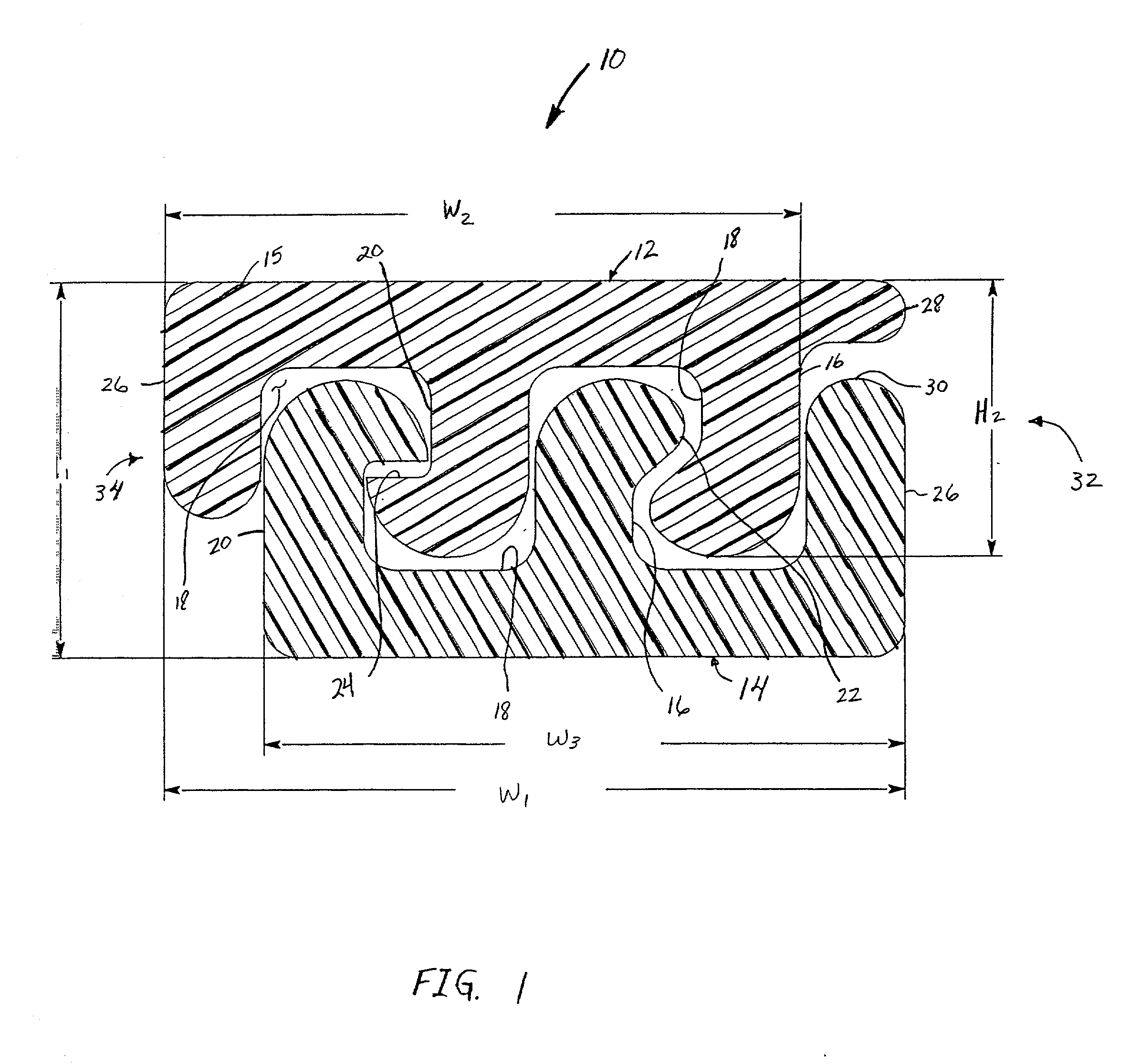

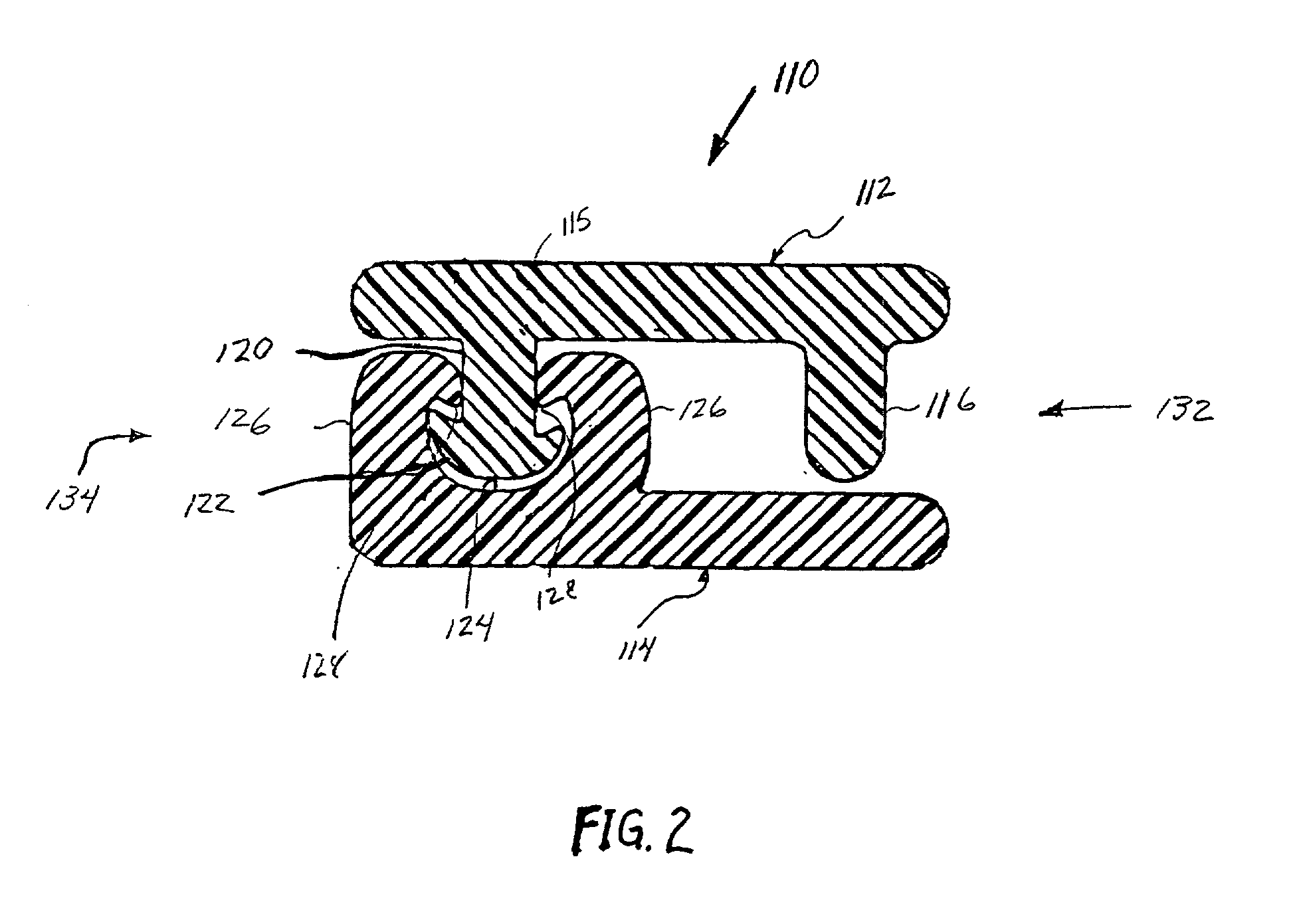

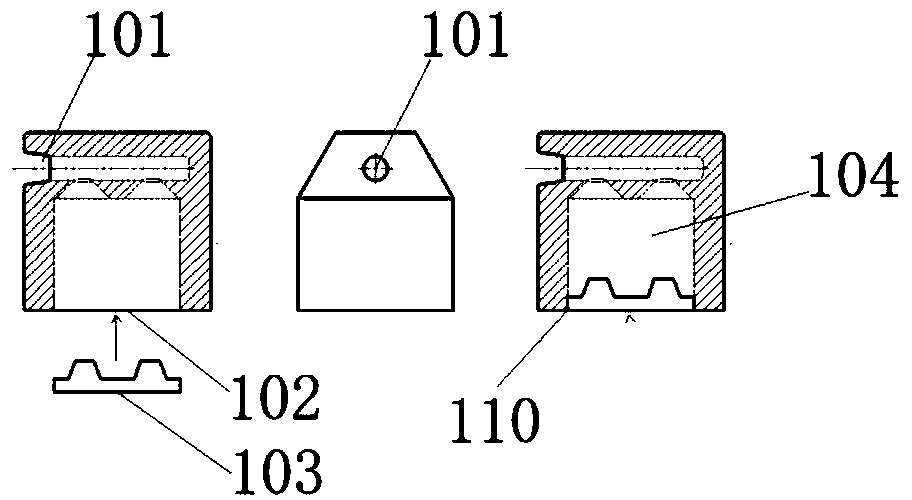

Polypropylene recloseable zipper

InactiveUS6487758B2Sufficient flexibilityReasonable temperatureSlide fastenersBagsEngineeringPolypropylene

A polypropylene closure arrangement for flexible packages comprises a blend having a polypropylene random copolymer as a base resin with a flexible modifier, and a slip component. The polypropylene closure arrangement 10, 110 is sufficiently flexible to be extruded and coiled around guide wheels similar to the fusion process of a polyethylene closure arrangement. The polypropylene closure arrangement in accordance with the present invention has the ability to be fusibly attached to a polypropylene film or other fusibly compatible thermoplastic material launch conditions.

Owner:EATON INTELLIGENT POWER LTD

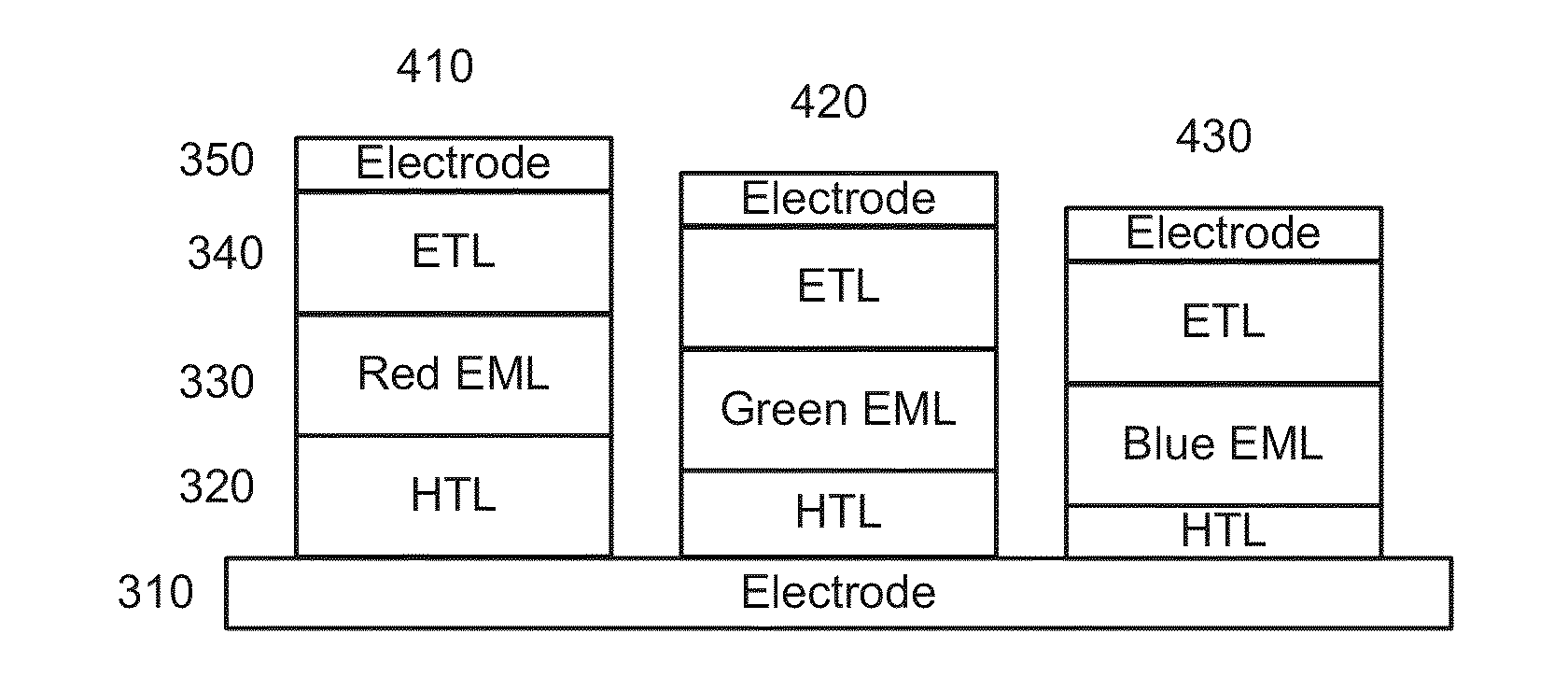

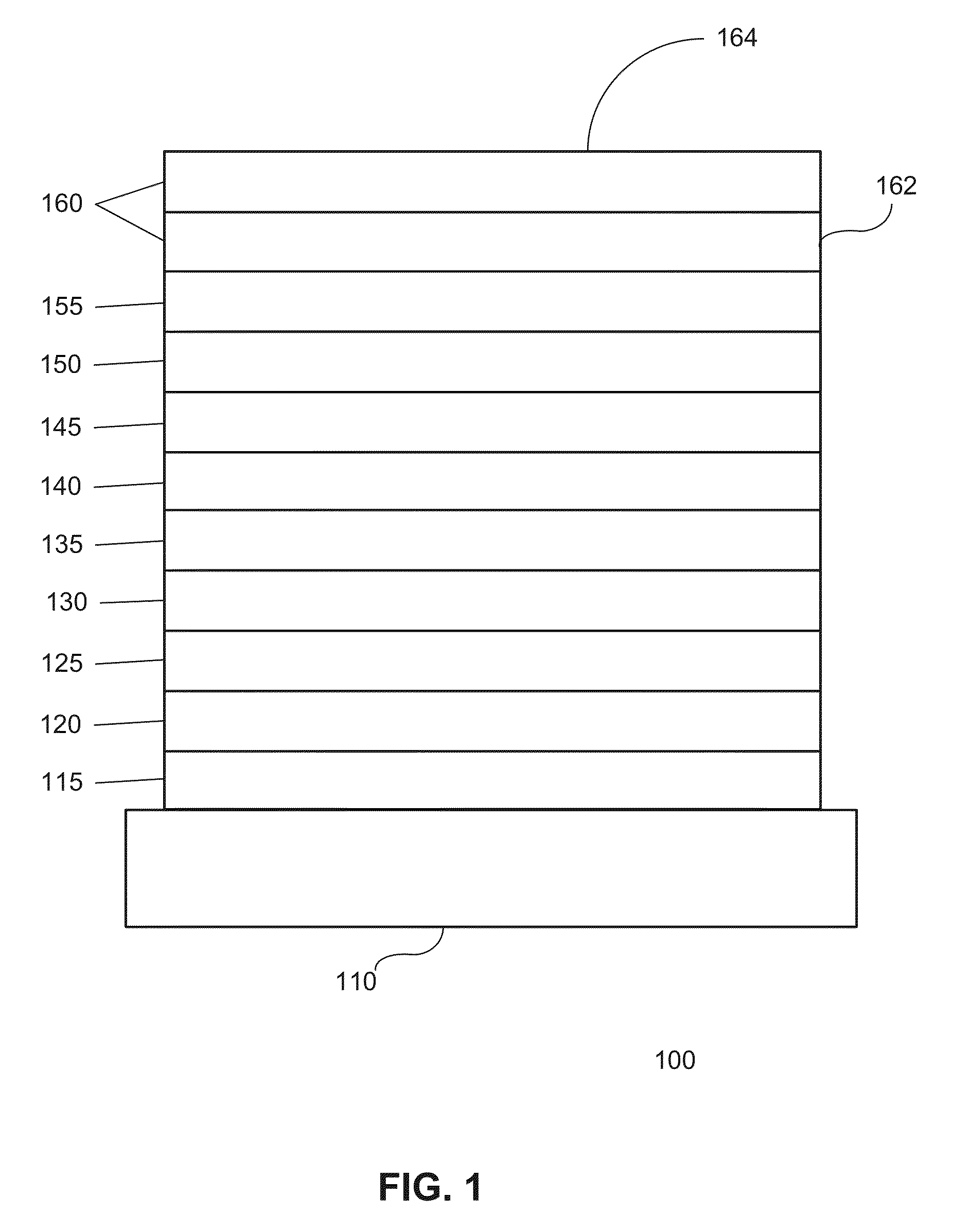

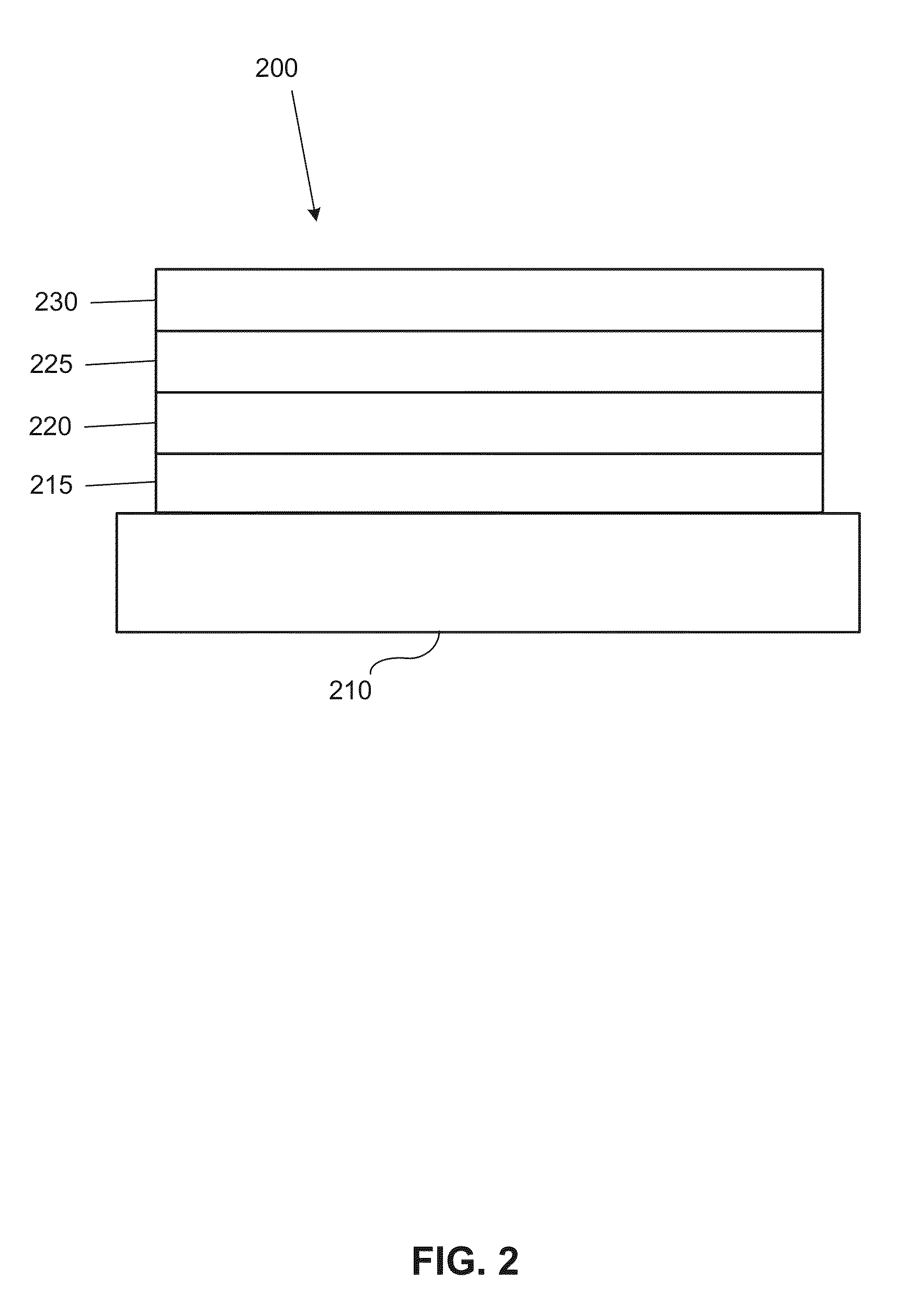

Patterning method for OLEDs

ActiveUS8940568B2Increased process windowUltra-rapid growthSemiconductor/solid-state device manufacturingOrganic layerOrganic vapor

Owner:UNIVERSAL DISPLAY

Growing method of large-size flaky sapphire crystals

InactiveCN101857970APolycrystallineReduce defect densityPolycrystalline material growthSingle crystal growth detailsManufacturing technologyControl system

The invention relates to a manufacture technology of sapphire crystals, in particular to a growing method of large-size flaky sapphire crystals. A crystal growing process of the method is carried out in a single-crystal growing furnace internally provided with a crucible and a guide mould, wherein the crystal growing process sequentially comprises the following steps of: sapphire raw material heating, seeding, shouldering, constant-diameter lifting and cooling. The single-crystal growing furnace is internally provided with a protective gas inlet and outlet system capable of introducing and exhausting protective gas and a pressure control system capable of controlling the pressure in the furnace, wherein the protective gas is introduced into the furnace in the steps of sapphire raw material heating, seeding, shouldering and constant-diameter lifting and is formed into flowing gas in the furnace through the protective gas inlet and outlet system, and the gas inlet flow of the protective gas is 0.1-50slpm; and meanwhile, the pressure in the furnace is controlled to be 100pa-90kpa through the pressure control system. The method can be directly used for growing the flaky sapphire crystals with a larger size and has simple manufacture procedure, high material utilization ratio and low manufacture cost.

Owner:镇江市丹徒区黄墟润蓝晶体制造厂

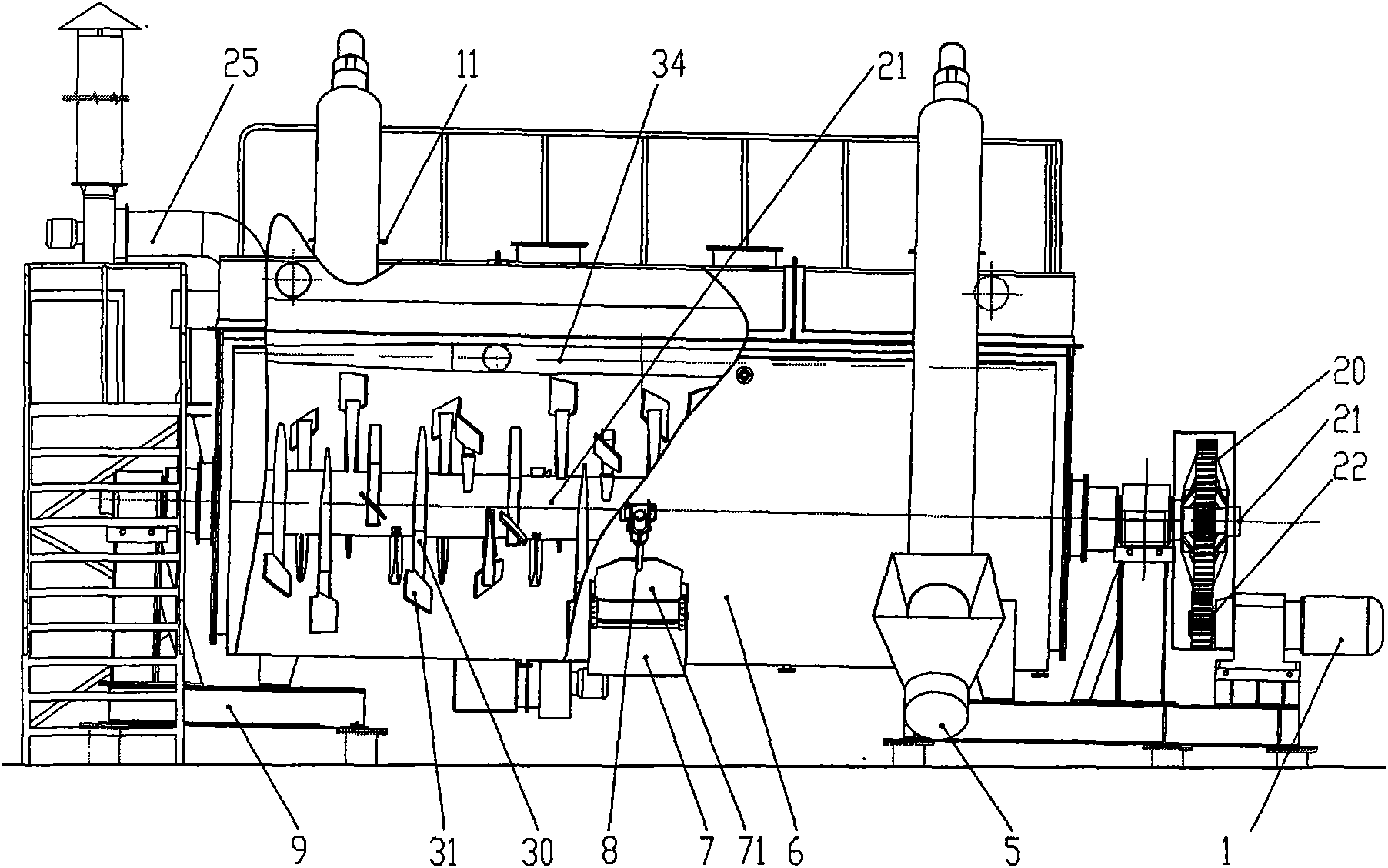

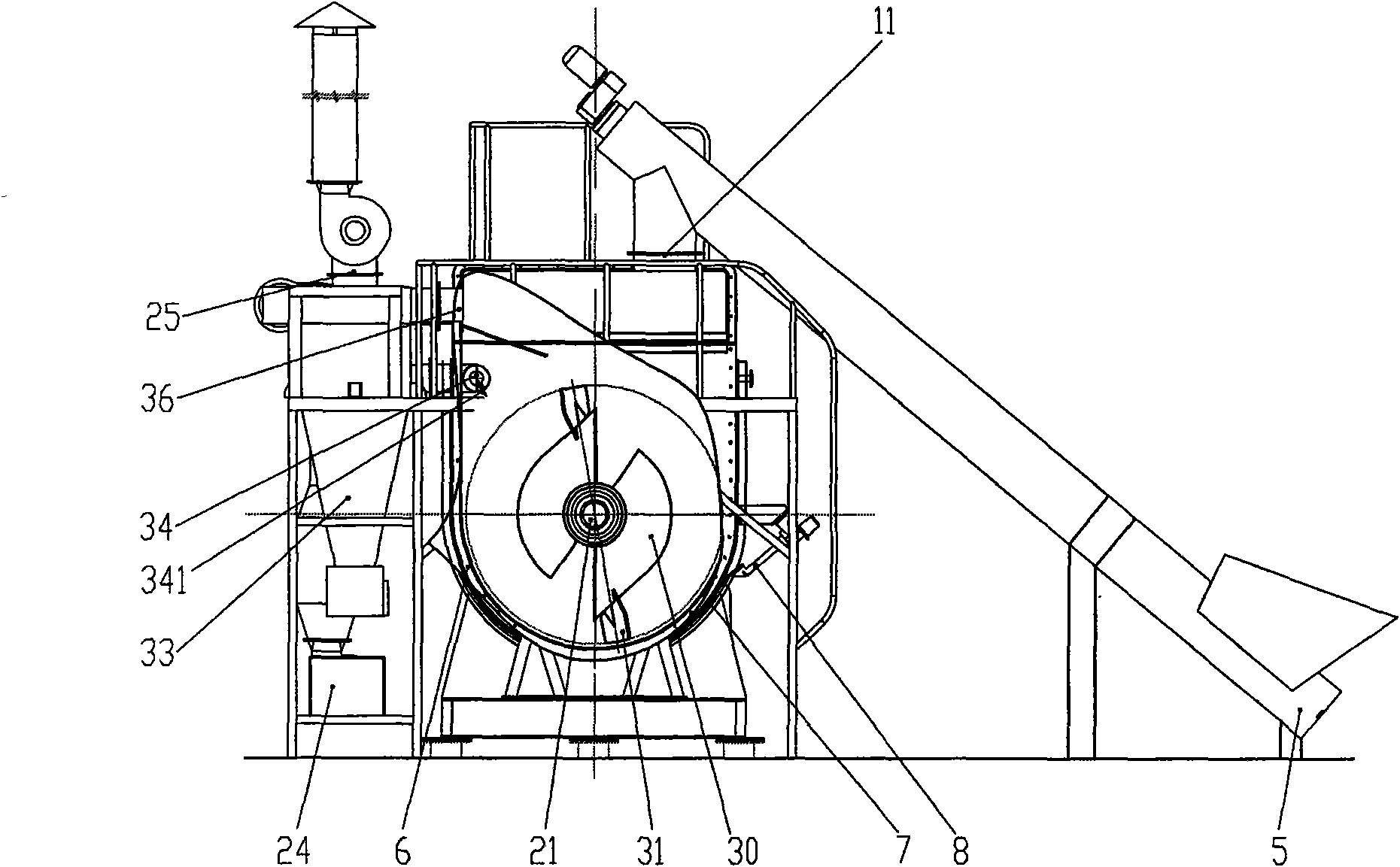

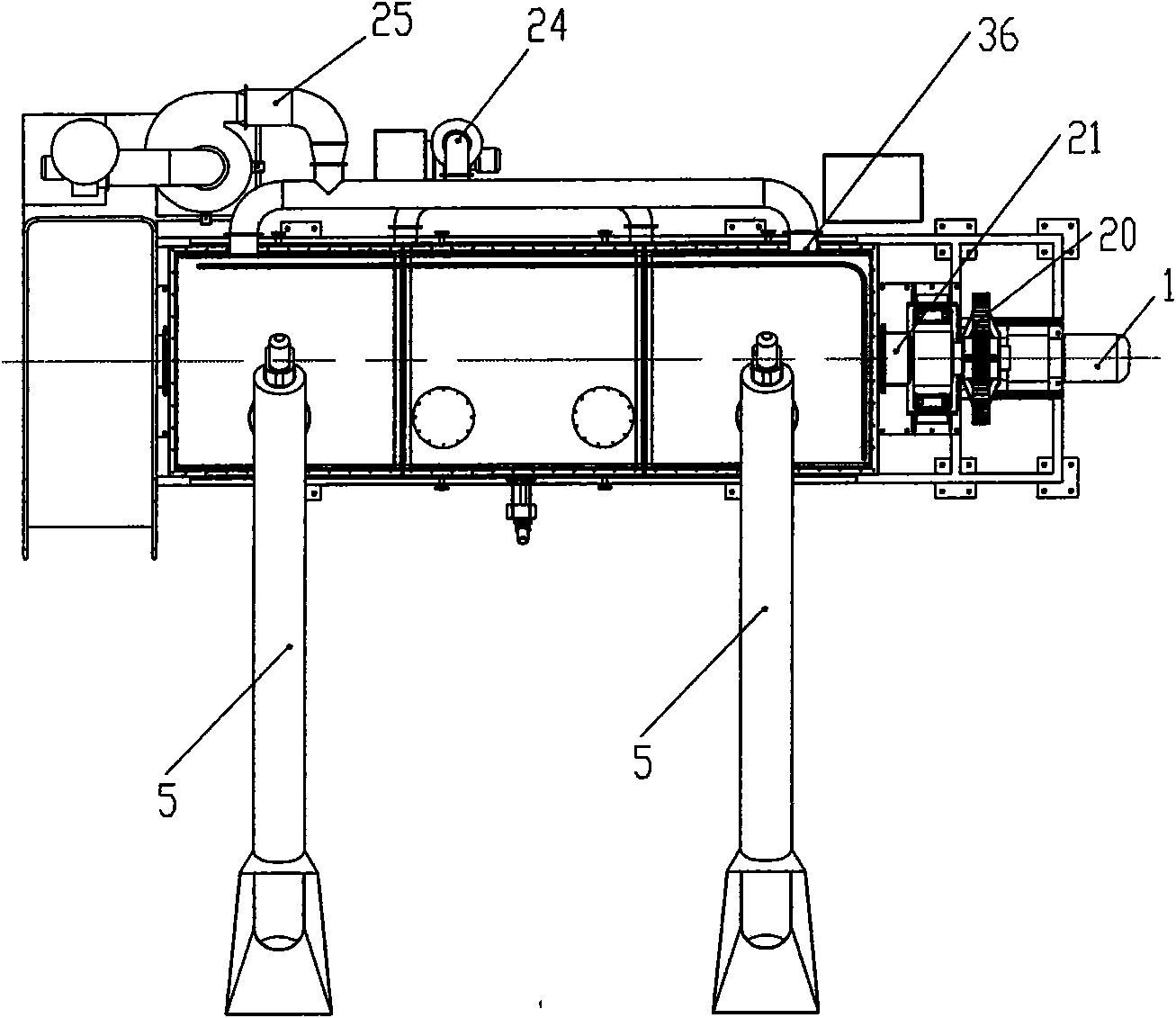

Organic waste biochemical processor

ActiveCN101632997ADecompose fullyIncrease the heat exchange areaBio-organic fraction processingSolid waste disposalOxygenPollution

The invention relates to an organic waste biochemical processor comprising a fermenting and drying chamber with a U-shaped cross section, wherein the upper end of the fermenting and drying chamber is provided with a feeding hole, and the lower end of the fermenting and drying chamber is provided with a discharging hole which is sealed by a discharging hole baffle plate; a hollow mixing shaft passes through both sides of the fermenting and drying chamber, the left end and the right end of the mixing shaft are respectively connected with a steam input pipe and a condensed water outlet pipe, the right end of the mixing shaft is connected with a reducing motor by a driving device, a hollow mixing blade is arranged on the mixing shaft, a cavity of the mixing blade is communicated with a cavity of the mixing shaft, the inner upper part of the fermenting and drying chamber is provided with an air distributing pipe, an air inlet of the air distributing pipe is communicated to an air outlet of a heat exchanger outside the fermenting and drying chamber, an air outlet of the air distributing pipe is positioned into the fermenting and drying chamber, and the upper part of the fermenting and drying chamber is provided with a humidity discharging hole which is communicated to an inlet of a dust collector of a waste gas processing device by a humidity discharging duct. The organic waste biochemical processor has low pollution and can sufficiently ferment and dry the organic waste by oxygen.

Owner:BEIJING GOLDENWAY BIO TECH

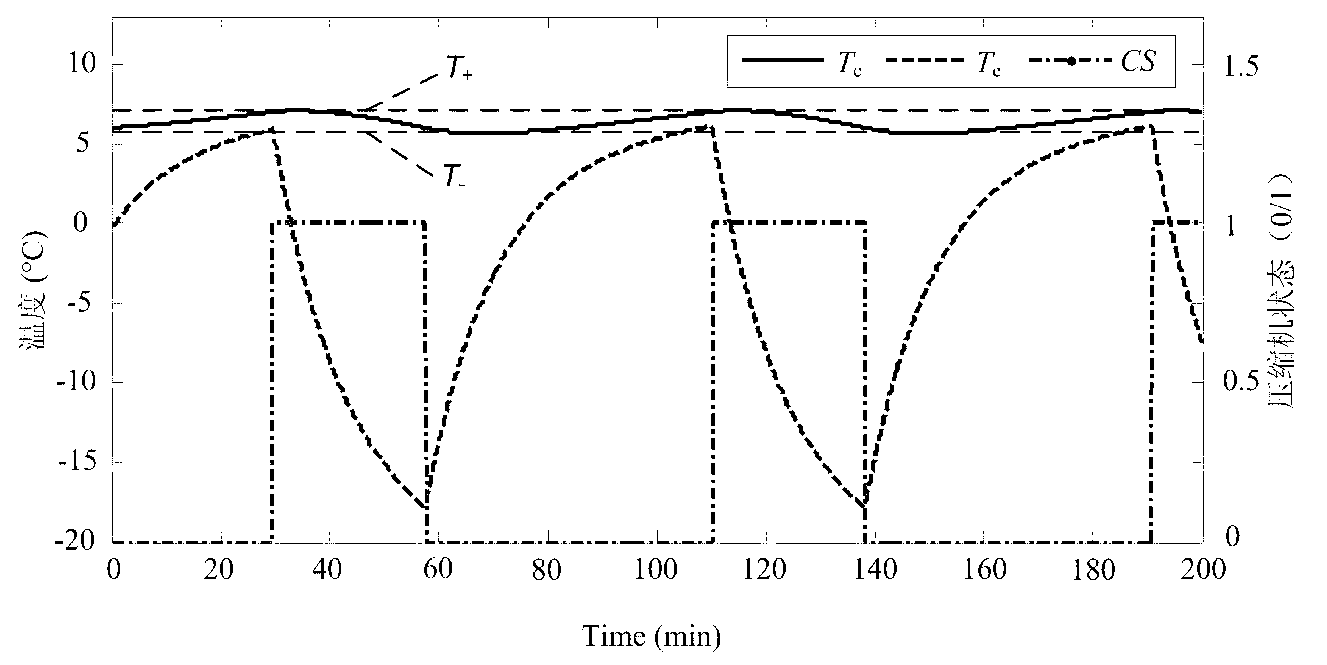

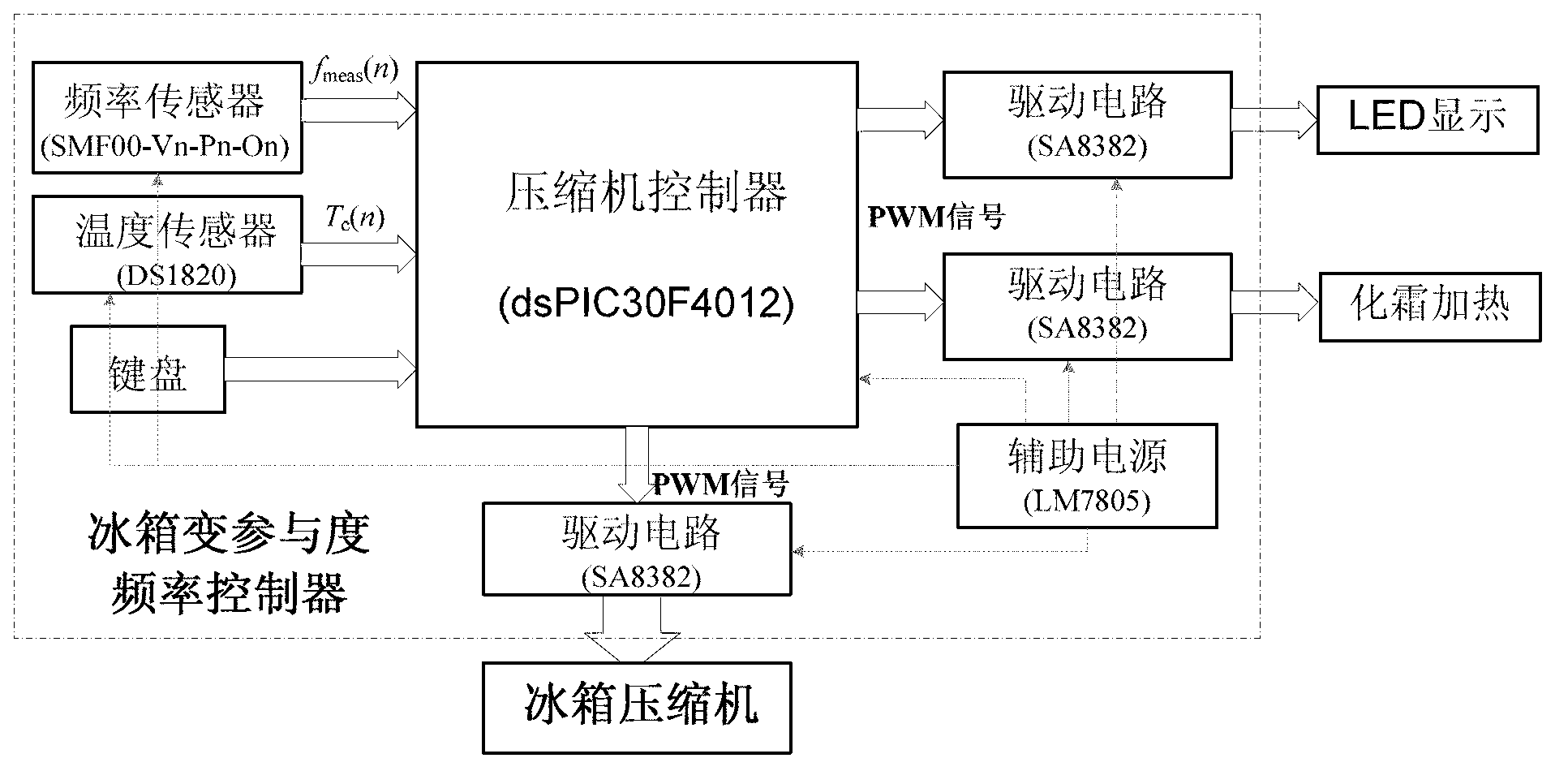

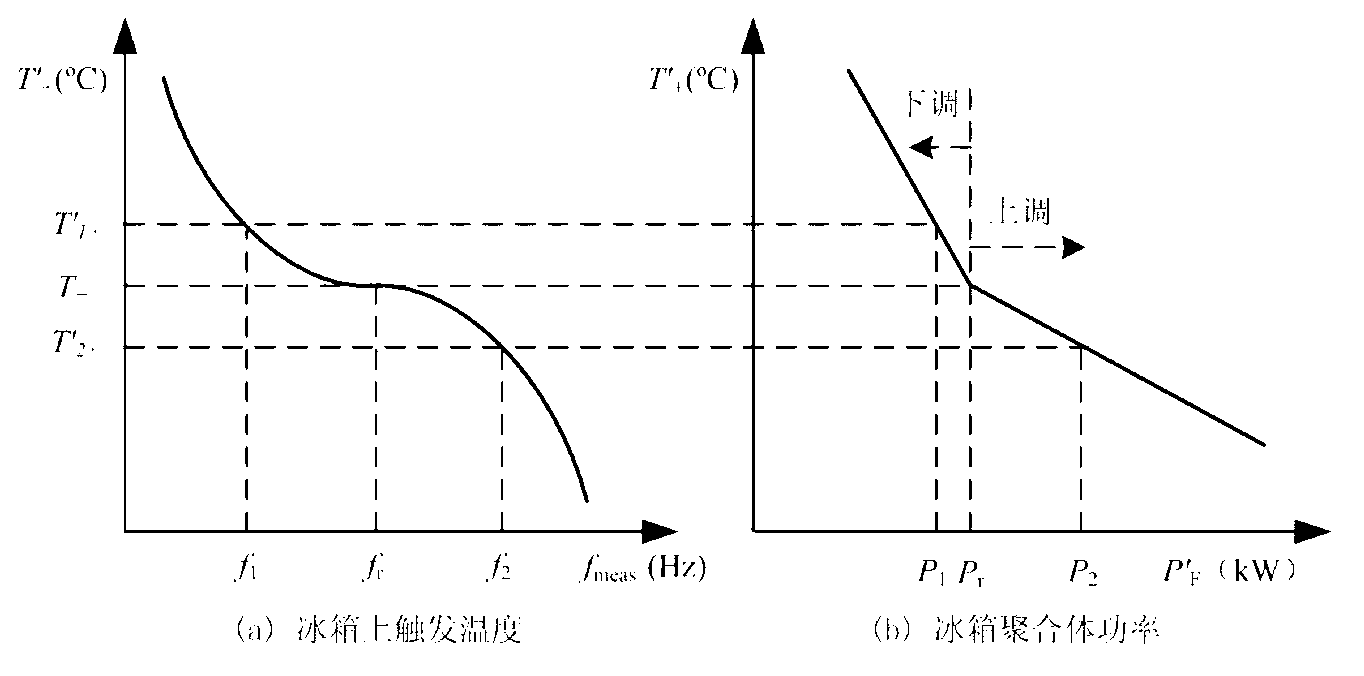

Controlling method and controller for variable participation frequency of temperature control load

InactiveCN103178533AReduce capacityReduce dependenceDomestic cooling apparatusLighting and heating apparatusPower gridReducing capacity

The invention belongs to the technical field of frequency control and relative technical field of demand side response in an intelligent power grid, aims at reducing capacity requirements on a spare generator unit and an energy storage device from system frequency control requirements, saves corresponding investment, and simultaneously avoids the problem about system 'secondary disturbance' prone to occurring during a conventional frequency controlling process. The technical scheme includes that a controlling method for variable participation frequency of temperature control load includes the steps of: (1) collecting current power grid frequency fmeas (advising a refrigerating chamber temperature Tc (n) for refrigerating equipment); (2) designing pf into a piecewise linear function in positive proportion to power grid frequency deviation; (3) calculating according to data of the step (1) and the step (2); (4) determining the next operation of a compressor of the refrigerating equipment according to the calculating result of the step (3); and (5), n=n+1, returning to the step (1) and starting the next cycle. The controlling method and a controller for the variable participation frequency of the temperature control load are mainly applied to manufacture of the refrigerating equipment.

Owner:TIANJIN UNIV

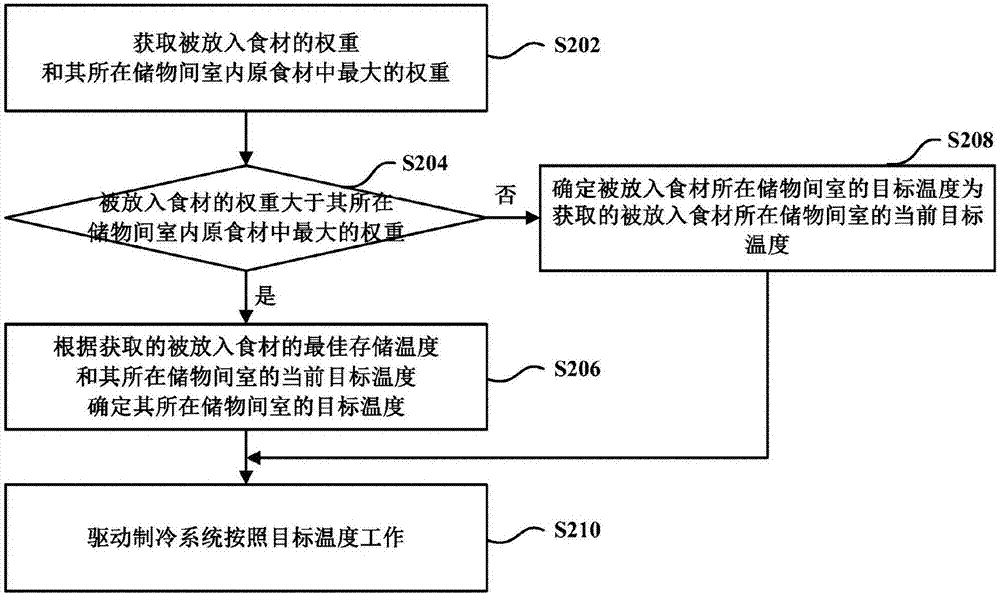

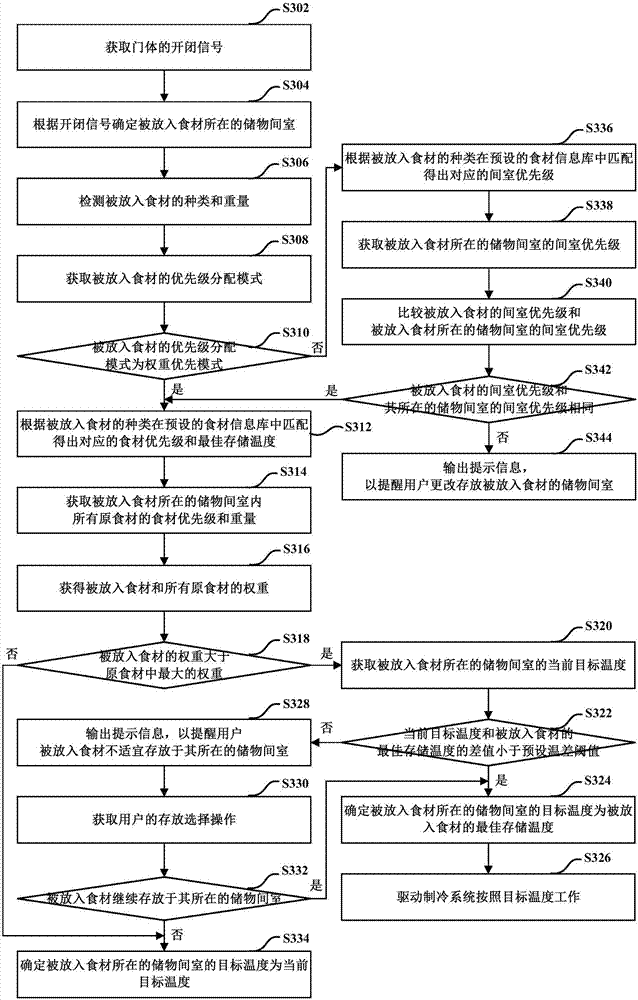

Refrigerant temperature control method based on food materials and computer storage medium

ActiveCN106979659AMeet needsGuaranteed storage effectDomestic cooling apparatusLighting and heating apparatusTemperature controlFood material

The invention provides a refrigerator temperature control method based on food materials and a computer storage medium. The refrigerator temperature control method based on the food materials includes the steps that the weight of put food materials and the maximum weight of raw food materials in a storage chamber of the food materials are obtained; whether the weight of the put food materials is higher than the maximum weight of the raw food materials in the storage chamber of the put food materials or not is judged; if the weight of the put food materials is higher than the maximum weight of the raw food materials in the storage chamber of the put food materials, the target temperature of the storage chamber of the put food materials is determined according to the best storage temperature of the put food materials and the current target temperature of the storage chamber of the put food materials, and if the weight of the put food materials is not higher than the maximum weight of the raw food materials in the storage chamber of the put food materials, the target temperature of the storage chamber of the put food materials is confirmed to be the obtained current target temperature of the storage chamber of the input food materials; and a refrigerating system is driven to work according to the target temperature. By means of the scheme, the storage effect of the newly-put food materials and the storage effect of the original food materials in the storage chamber can be taken into consideration, and the practical needs of users are met.

Owner:QINGDAO HAIER SPECIAL REFRIGERATOR CO LTD +1

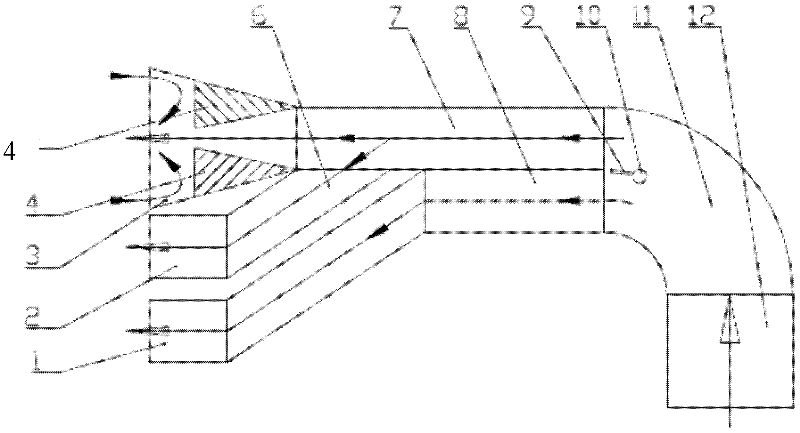

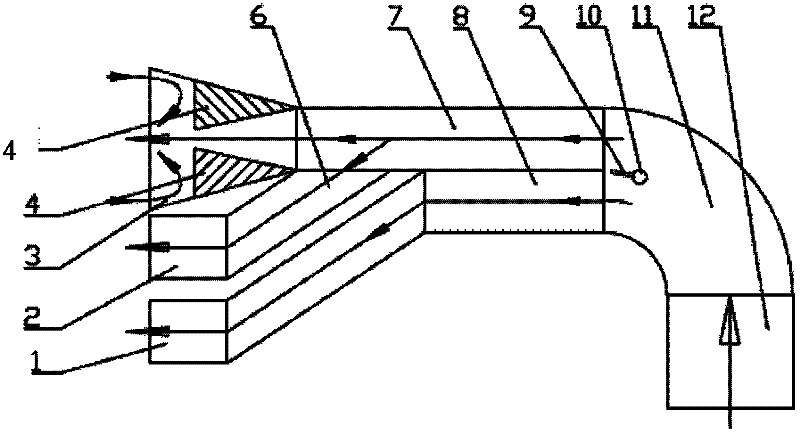

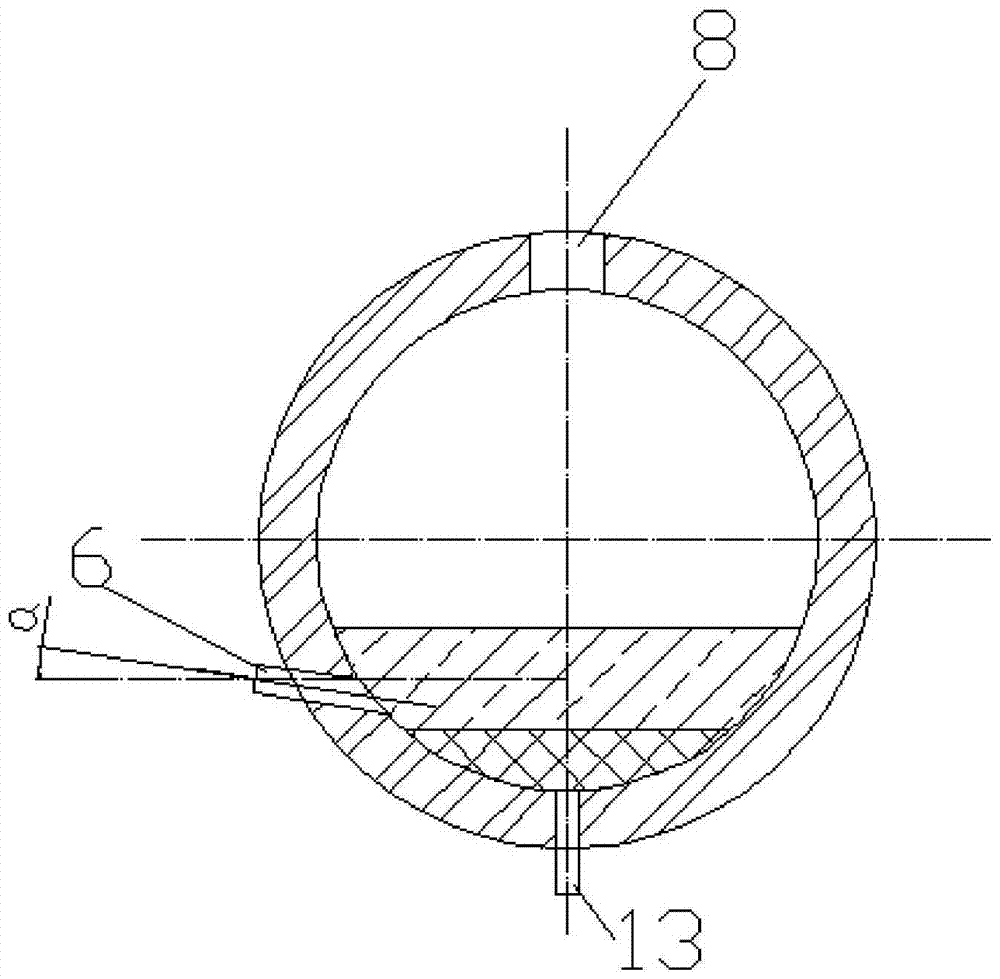

Pulverized coal decoupling combustor and decoupling combustion method thereof

InactiveCN102297425AMeet or exceed concentration efficiencyOver concentration efficiencyPulverulent fuel combustion burnersCombustorGuide tube

The invention relates to a pulverized coal decoupling combustor and a decoupling combustion method thereof. The decoupling combustor comprises a first-stage air duct (12), an inertia separator (11), air current conduits and a spout which are sequentially connected along the air current direction, wherein the air current conduits comprise a dense side air current conduit (7) and a fresh side air current conduit (8); the fresh side air current conduit (8) is communicated with a third-stage spout (1); the dense side air current conduit (7) is connected with a first-stage spout (3); a second-stage spout conduit (6) communicated with the dense side air current conduit (7) is led out of a pipeline between the dense side air current conduit (7) and the first-stage spout (3) on the dense side aircurrent conduit (7); the second-stage spout conduit (6) is communicated with a second-stage spout (2); the first-stage spout (3) is a gradually-increasing spout; a pair of pulverized coal collecting flame stabilizing devices (4) is oppositely arranged at the upper side and the lower side inside the front end of the first-stage spout (3); the cross sections of the pulverized coal collecting flame stabilizing devices (4) along the air current direction is gradually increased; and the area of the cross section of an air current channel is decreased along the air current direction, thus the coupling combustion is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for manufacturing glazed tile with glaze three-dimensional effect

InactiveCN103193457AAchieve three-dimensional effectUnique effectDecorative surface effectsClaywaresTexture gradientCeramic glaze

The invention relates to a method for manufacturing a glazed tile with a glaze three-dimensional effect. The method comprises a printing process of printing on an unglazed biscuit through a relief silk screen plate with a certain thickness and a relief roller with a certain depth, so as to form texture patterns with a variable concave-convex effect, and a once-firing process, thus preparing the glazed tile with a glaze three-dimensional effect. The glazed tile manufactured by the invention can generate a concave-convex texture gradient effect, and is good in decoration effect, high in durability, good in antifouling performance, variable in patterns, and can well reflect change of the natural color of stone.

Owner:MONALISA GRP CO LTD

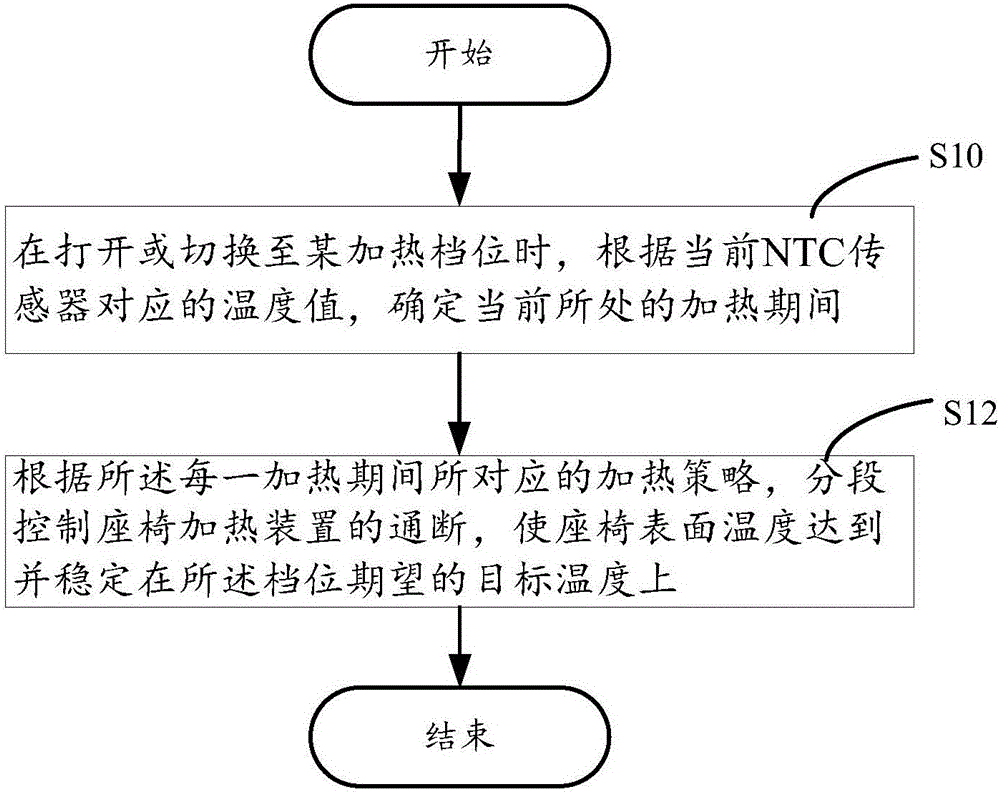

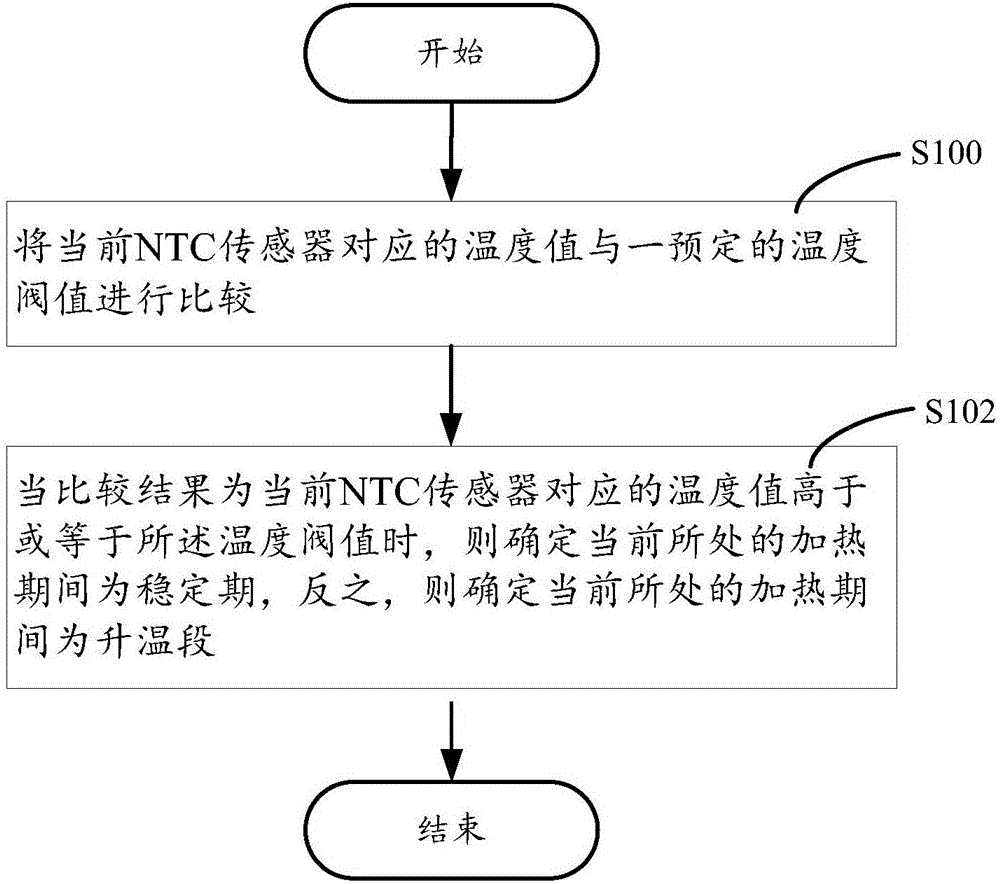

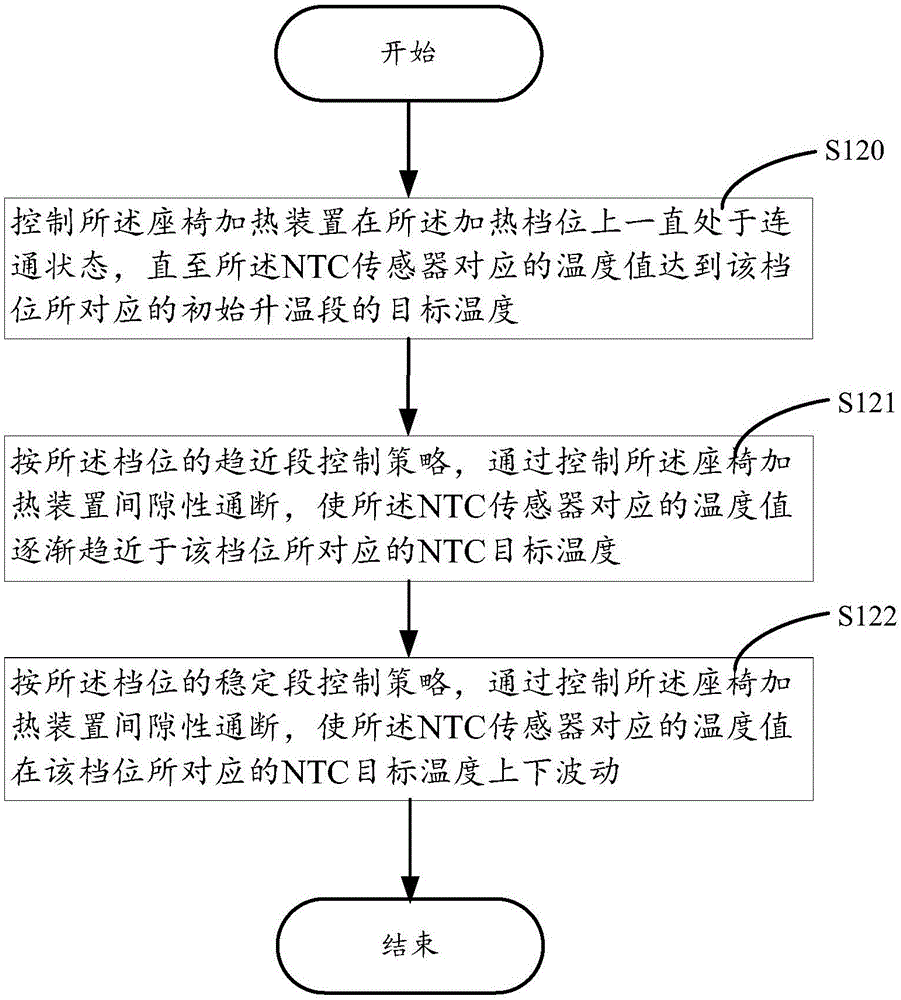

Vehicle seat heating temperature control method, device and system

ActiveCN106740341AReasonable temperatureReasonable controlSeat heating/ventillating devicesTemperatue controlTemperature controlEngineering

The invention discloses a vehicle seat heating temperature control method. The method includes the following steps that when a certain heating gear is turned on or switched to, a current heating period is determined according to the temperature value corresponding to a current NTC sensor, wherein the heating period includes an initial temperature increasing stage, an approaching stage and a stable stage; according to heating strategies corresponding to each heating period, and the on-off state of a seat heating device is controlled stage by stage, so that the temperature of the surface of a seat reaches and is stabilized at an expected target temperature of the gear. The invention further discloses a corresponding device and system. By means of the method, device and system, the temperature of the surface of the seat can quickly reach and be stabilized at the expected temperature value, and the use experience is improved for users.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Production process of sofa fabric

InactiveCN105667061AAppropriate weight ratioImprove performanceTransfer printingLamination ancillary operationsAdhesiveEngineering

The invention provides a production process of a sofa fabric and belongs to the technical field of textile fabrics.The production process includes the following steps of 1, selection of base cloth, wherein chamois flannel, knitted cloth and single-face flannel which are flat in surface are selected; 2, transfer printing of the chamois flannel; 3, gold stamping of the chamois flannel; 4, coating adhesive; 5, attachment of the knitted cloth, wherein the upper surface of the knitted cloth with weaved patterns is attached to the bottom face of the chamois flannel; 6, secondary compounding, wherein the single-face flannel is compounded to the bottom face of the knitted cloth; 7, washing with water, wherein the fabric is subjected to water processing; 8, drying, wherein the washed fabric is subjected to drying.By means of the production process, it is beneficial to improve soft handfeel of the fabric, the production process is more stable, and natural texture is formed.

Owner:TONGXIANG LONGXIANG TEXTILE

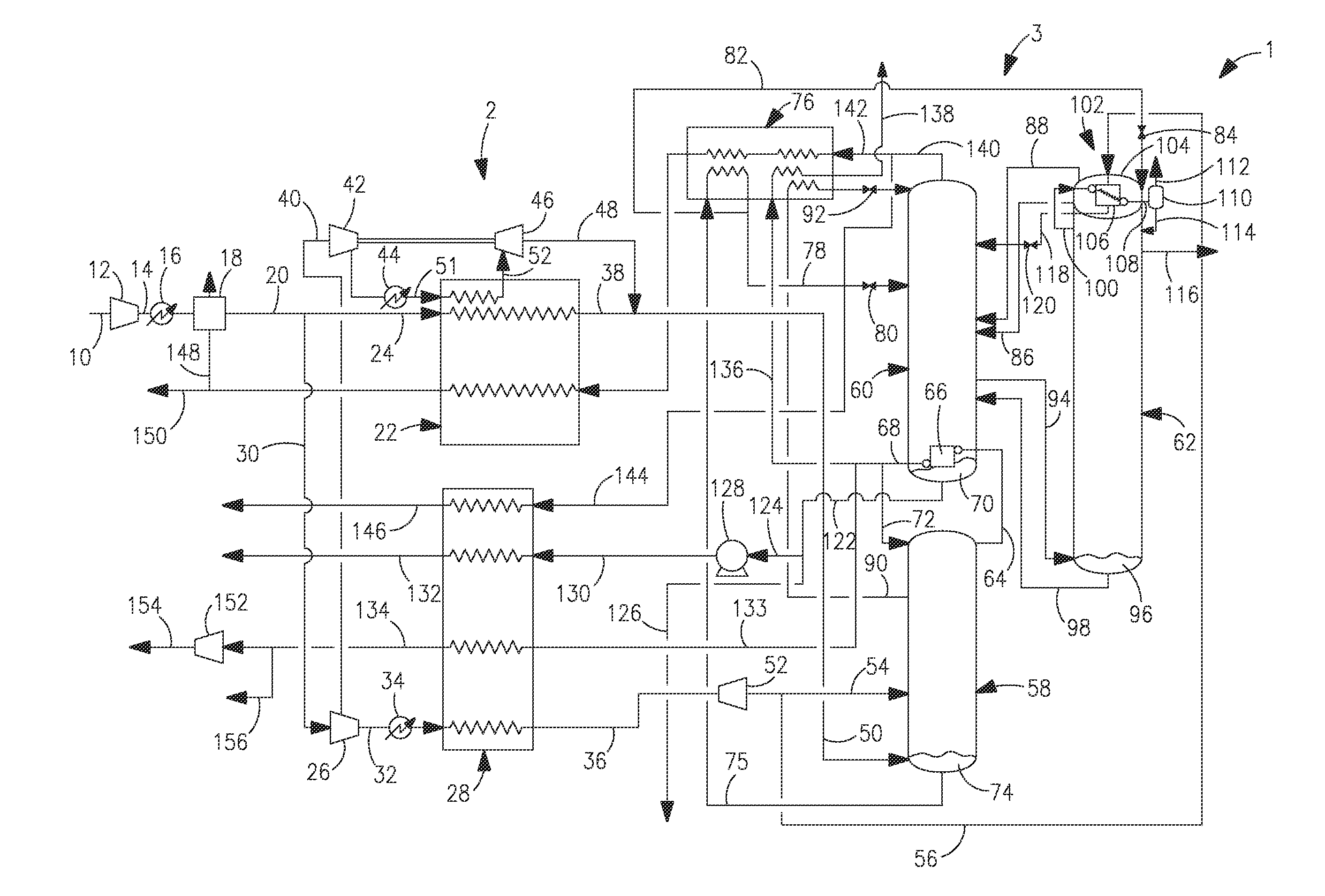

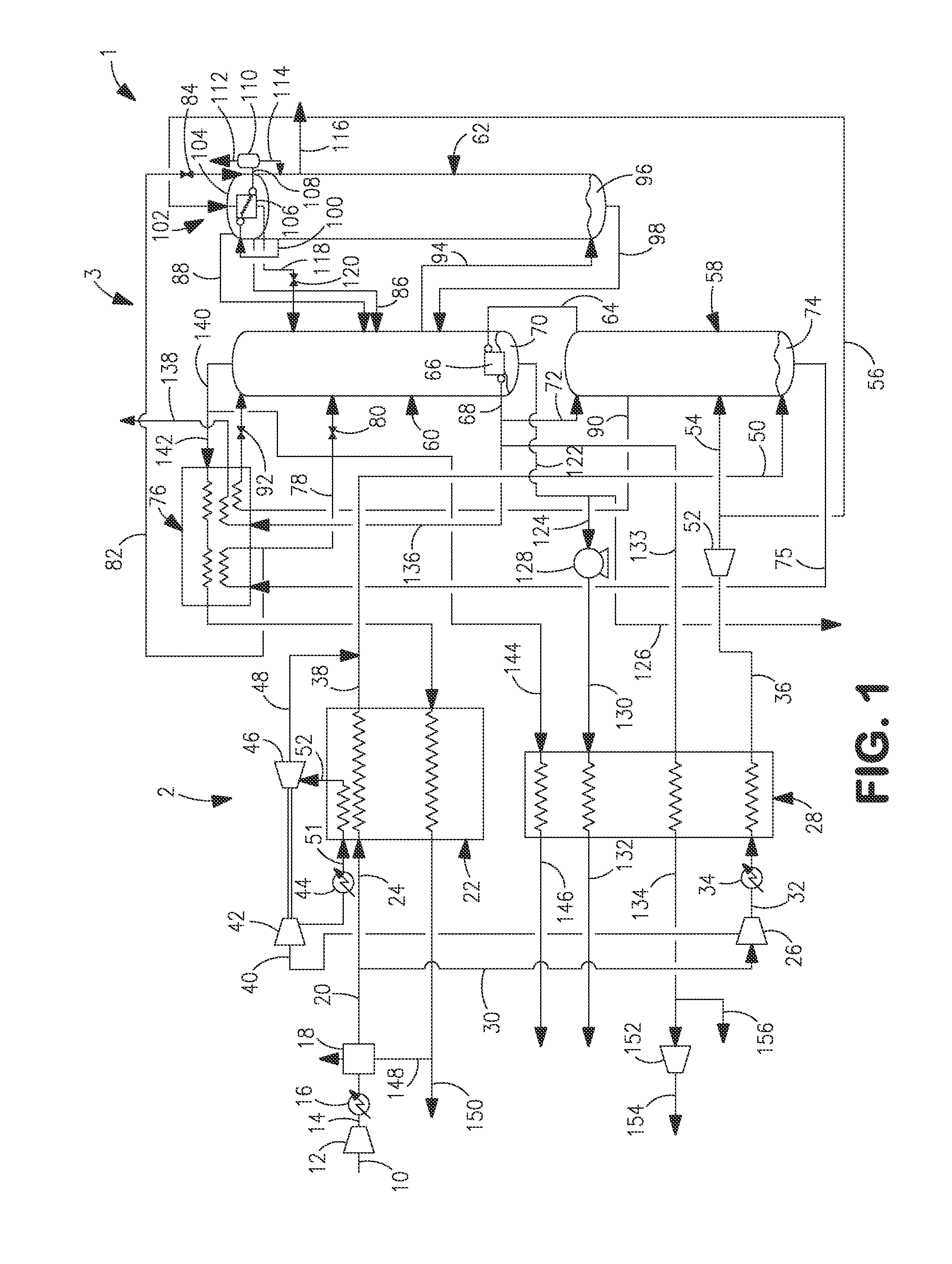

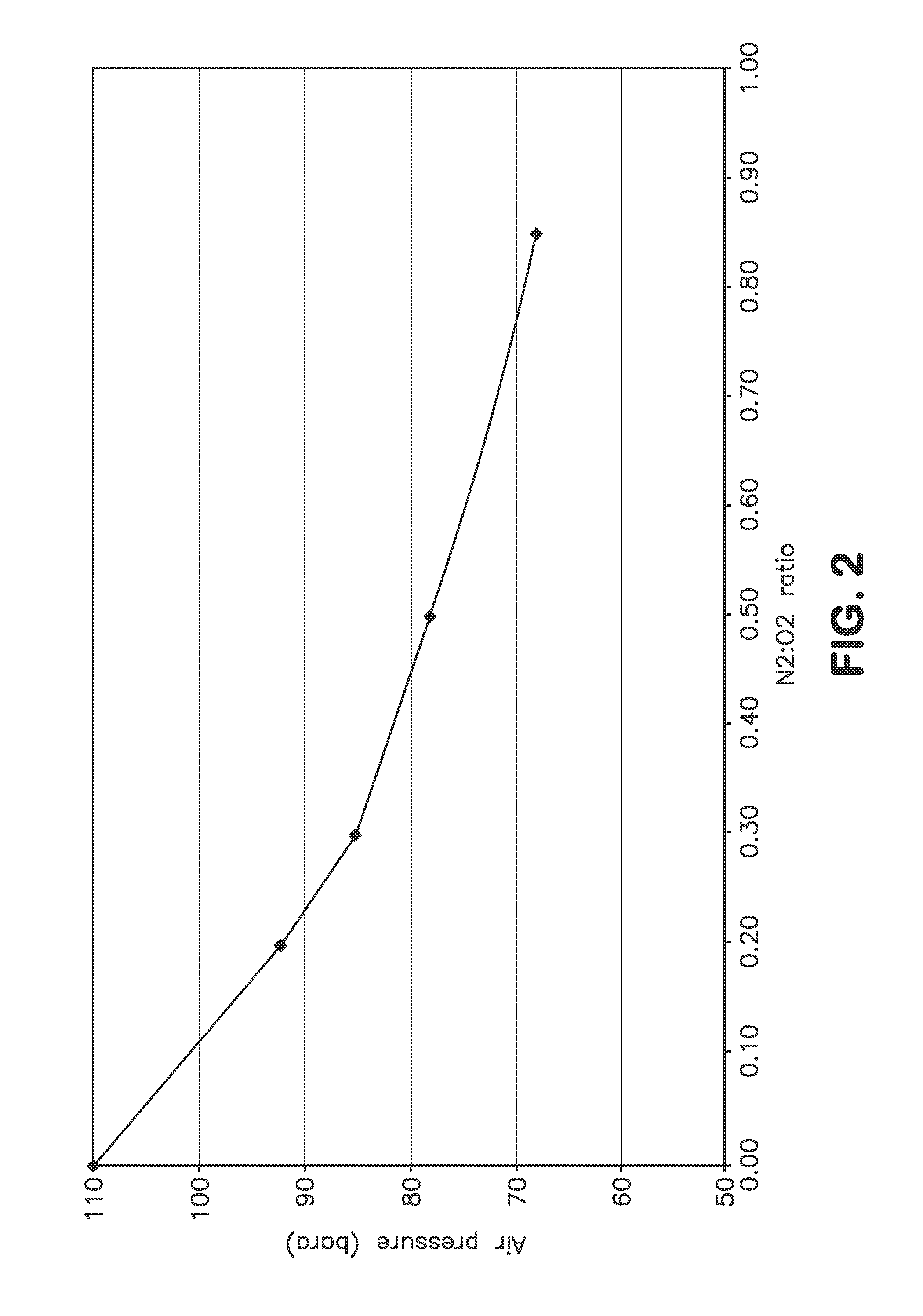

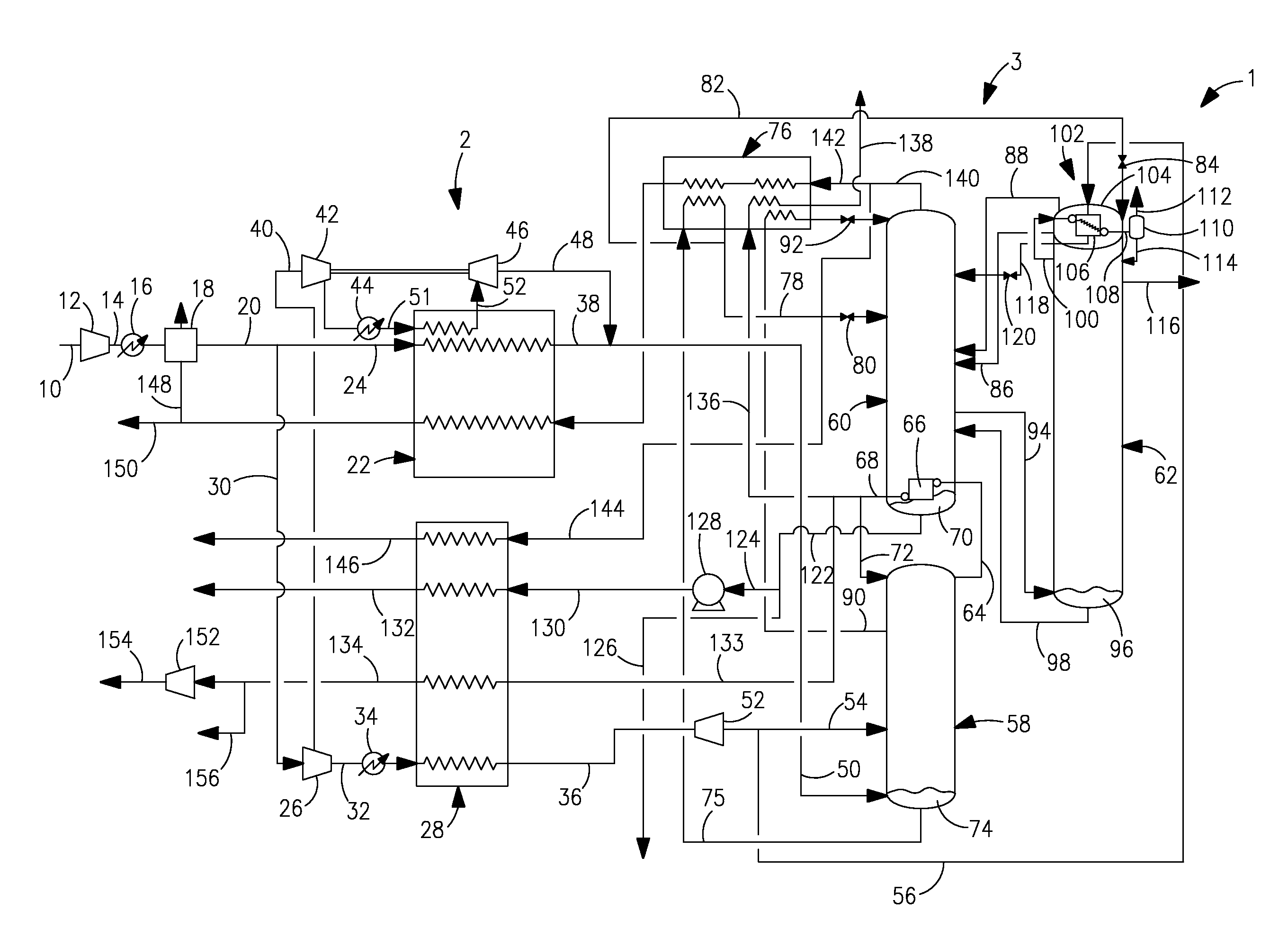

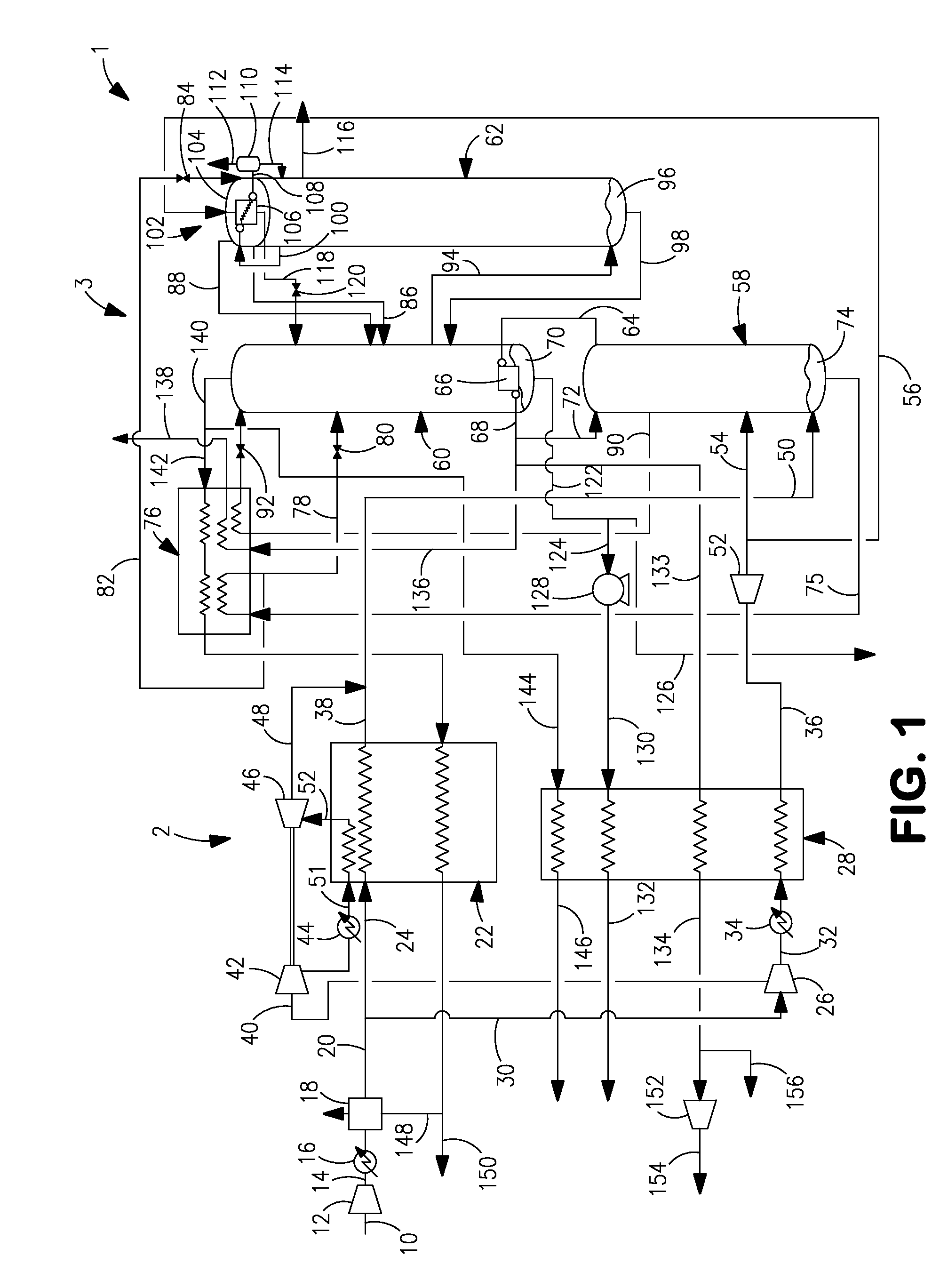

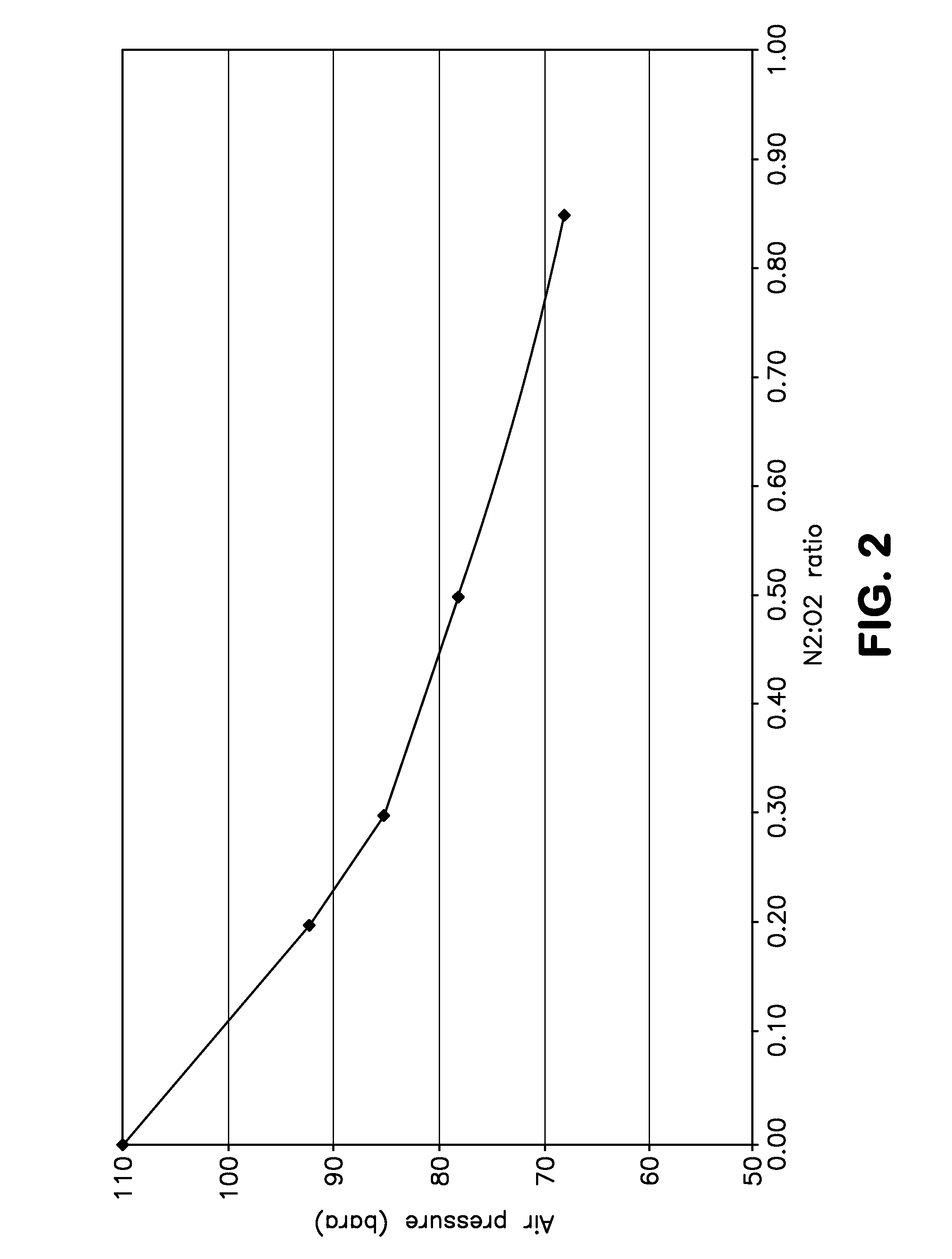

Air separation method and apparatus

An air separation method and apparatus in which a supercritical oxygen product is produced by heating a pumped liquid oxygen stream having a supercritical pressure, through indirect heat exchange with a boosted pressure air stream. The indirect heat exchange is conducted within a heat exchanger and a liquid nitrogen stream is vaporized in the heat exchanger to depress the pressure that would otherwise be required of the boosted pressure air stream to heat the pumped liquid oxygen stream. The pumped liquid oxygen stream constitutes 90 percent of the oxygen-rich liquid removed from an air separation unit in which the air is rectified, the liquid nitrogen constitutes at least 90 percent of the liquid nitrogen that is not used as reflux and a flow-rate ratio between the liquid nitrogen stream and the oxygen-rich liquid is between about 0.3 and 0.90.

Owner:PRAXAIR TECH INC

Polypropylene recloseable zipper

InactiveUS20020133919A1Cost advantage and flexibility in packaging size designSmall dimensionSlide fastenersBagsEngineeringPolypropylene

A polypropylene closure arrangement for flexible packages comprises a blend having a polypropylene random copolymer as a base resin with a flexible modifier, and a slip component. The polypropylene closure arrangement 10, 110 is sufficiently flexible to be extruded and coiled around guide wheels similar to the fusion process of a polyethylene closure arrangement. The polypropylene closure arrangement in accordance with the present invention has the ability to be fusibly attached to a polypropylene film or other fusibly compatible thermoplastic material launch conditions.

Owner:EATON INTELLIGENT POWER LIMITED

Production process for medium-high carbon steel through thin slabs

InactiveCN105543646AReduce contentReduce segregationFurnace typesHeat treatment furnacesThin slabManganese

The invention discloses a production process for medium-high carbon steel through thin slabs. The medium-high carbon steel comprises, by weight, 0.5%-0.88% of carbon, 0.15%-0.68% of silicon, 0.65%-1.55% of manganese, 0-0.025% of phosphorus, 0.002%-0.0025% of sulfur, 0.09%-0.22% of chromium, 0.08%-0.12% of nickel, 0.02%-0.035% of arsenic, 0.18%-0.20% of copper, 0-0.02% of aluminum and the balance iron. According to the production process for the medium-high carbon steel through the thin slabs, the medium-high carbon steel is produced through the thin slab continuous casting and rolling process, the production requirements are met by controlling process parameters of each procedure, and the problems existing in the background art are solved.

Owner:ANHUI CHUJIANG SPECIAL STEEL CO LTD

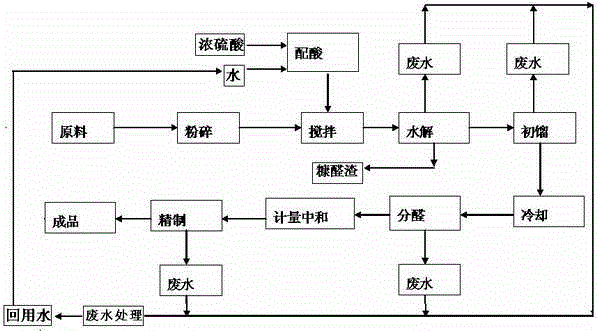

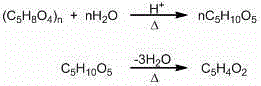

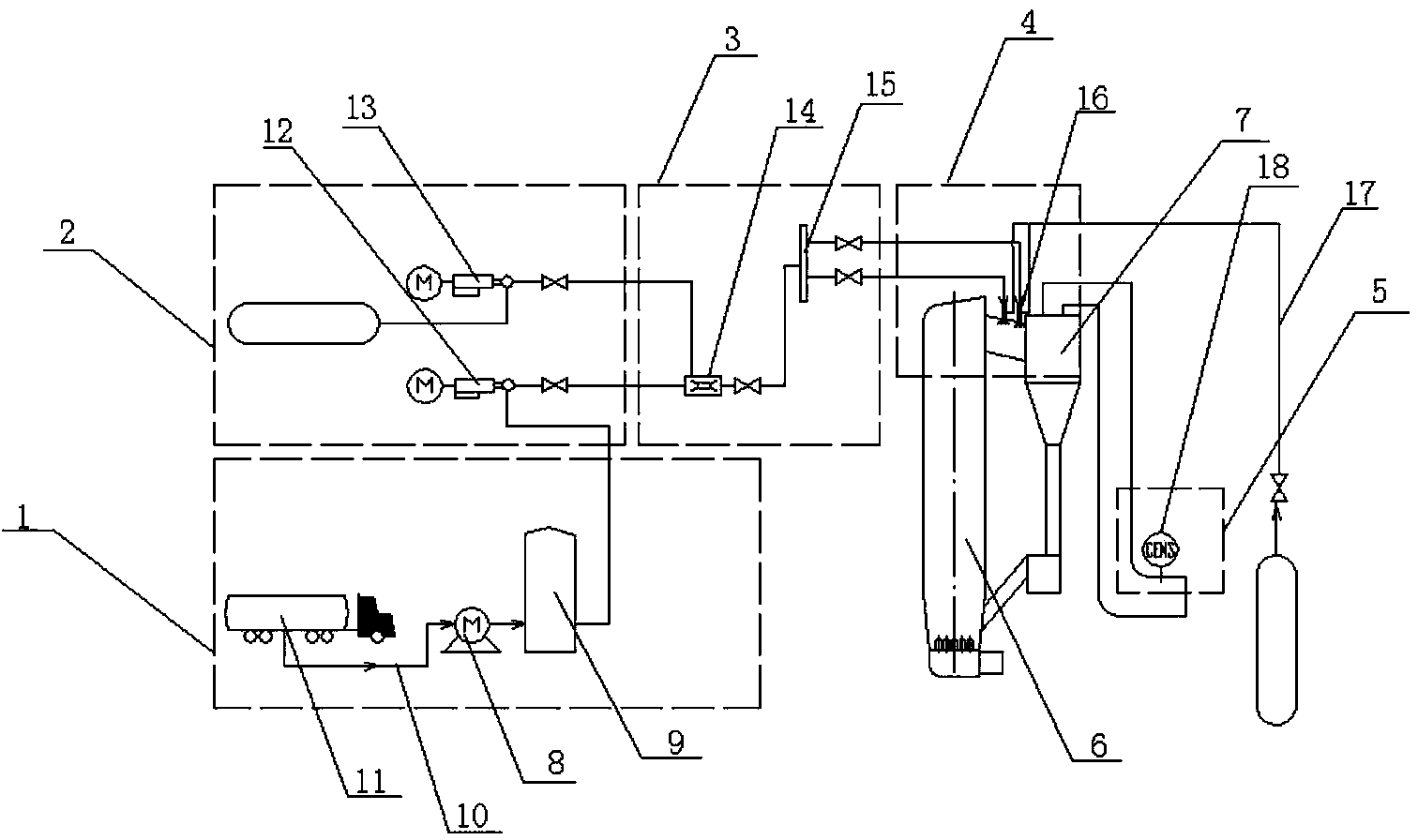

Clean production line for furfural and production method of furfural

The invention discloses a clean production line for furfural and a production method of the furfural. The clean production line comprises process facilities for sieving, crushing, acid preparation, hydrolysis, prefractionation, separation, rectification and the like and also further comprises treatment facilities for waste gas, wastewater and waste slag. The hydrolysis refers to charging corncobs mixed with acid to a hydrolysis pot at a charging density of 0.18 to 0.2t / m<3>, wherein the steam pressure is 0.5 to 1.0 MPa and the steam temperature is 140 to 180 DEG C in the hydrolysis pot; the tower top temperature is 94 to 97 DEG C and the tower bottom temperature is 98 to 108 DEG C in a prefractionation tower, furfural-containing water vapor is discharged from the tower top, and is condensed into liquid through a condenser, the liquid then enters a furfural separation tank to be subjected to water-furfural separation, and furfural liquid about 90 to 93% at the bottom automatically flows to a raw furfural tank. The clean production line disclosed by the invention can be used for scale processing of corncobs, and a separation effect of acetic acid and water can reach an international advanced level.

Owner:SHANGHAI YIZHI INDAL

Rice seed cold storage method

ActiveCN104126661ASolve dehydrationSolve agingSeed preservation by freezing/coolingSeed preservation by dryingGas compositionProduction chain

The present invention discloses a rice seed cold storage method, and relates to a field of agricultural product fresh keeping storage. The method includes the following steps: cleaning and selecting, pre-cooling, sterilization, spraying of a fresh-keeping agent, loading of a moisture bag, warehouse disinfection, controlling of the temperature, controlling of the content of oxygen and carbon dioxide, controlling of the moisture of warehouse and ex-warehousing. The method of the present invention has the following advantages that the cold storage method determines appropriate conditions for the rice seed storage, ensures reasonable temperature, moisture and gas composition inside the warehouse, solves the problems of water losing, aging, yellowing, germination, fast decaying during the process of rice seed storage, improves the rice storage time without destroying the texture of the rice seed, promotes the development of the rice industry, increases the added value and promotes the construction of an agricultural production chain demonstration mode.

Owner:巢湖春友种业科技有限公司

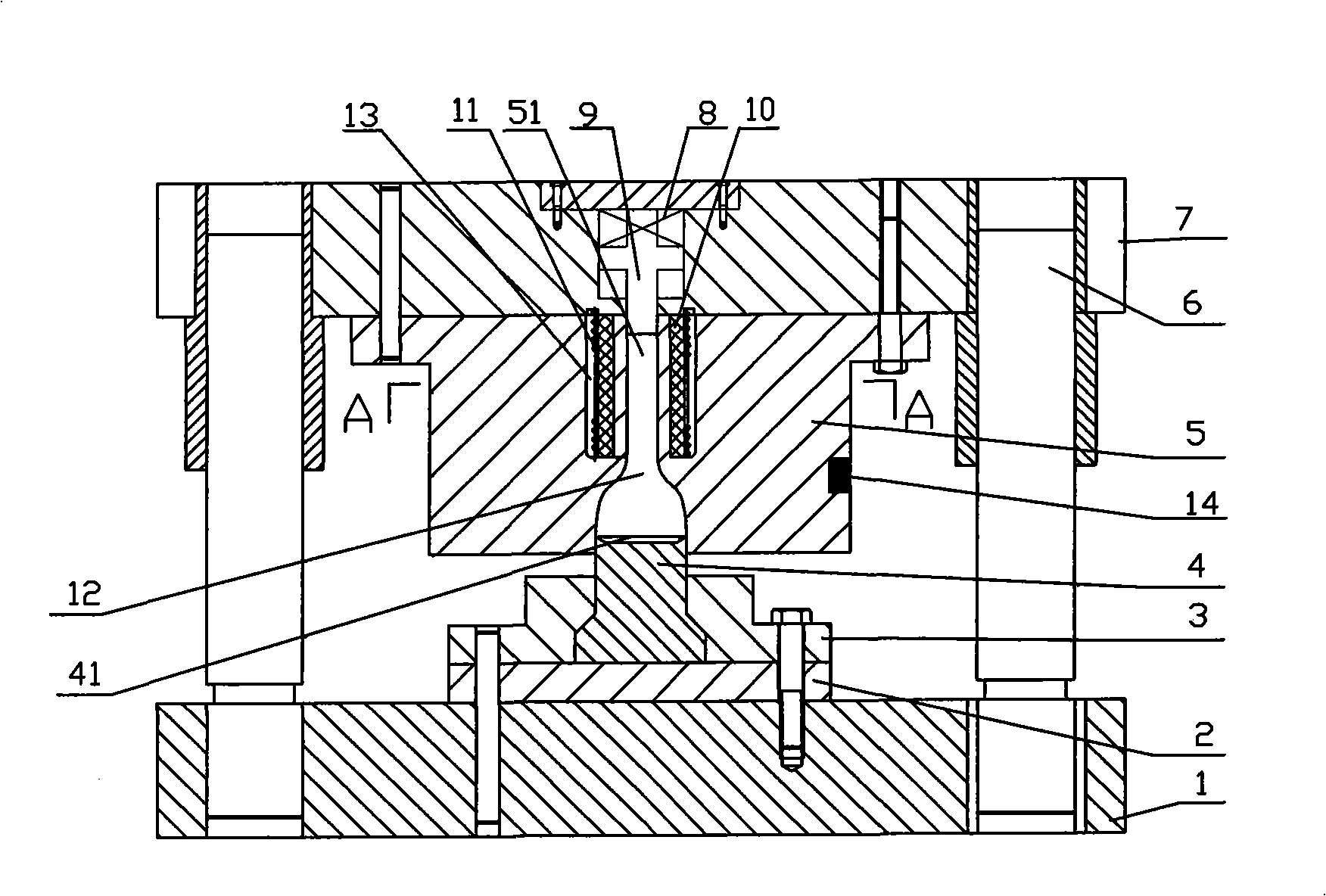

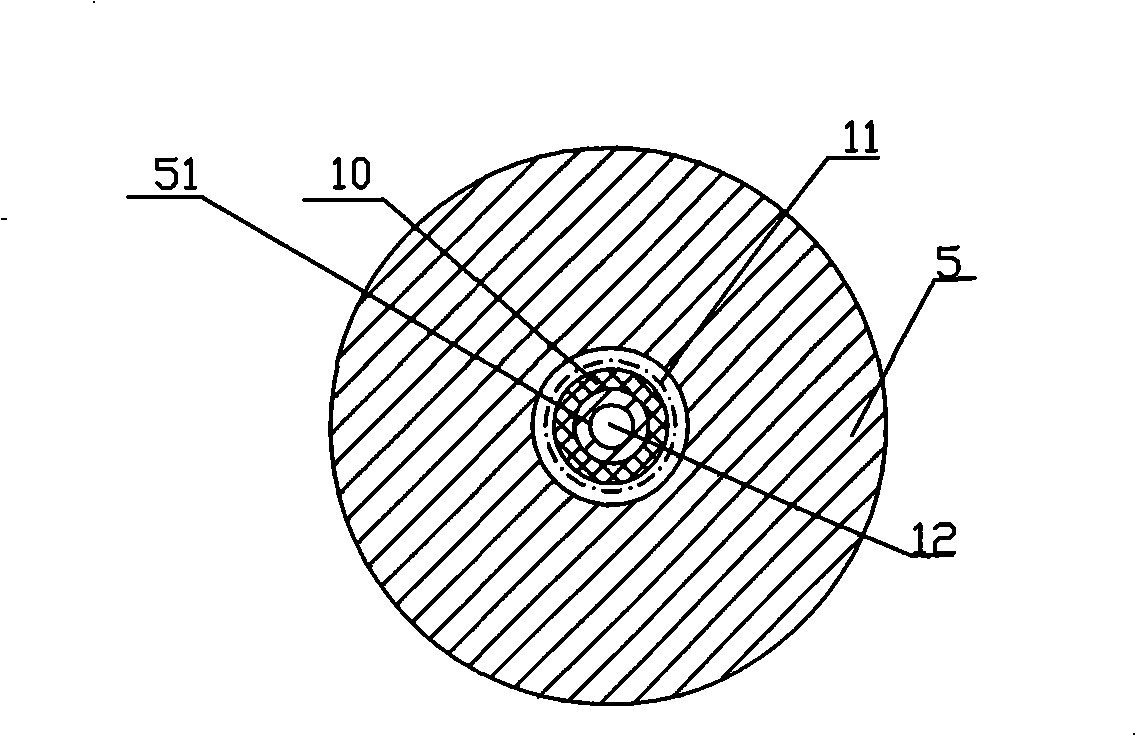

Automobile out star wheel isothermal extrusion preliminary shaping device

InactiveCN101264489AReduce temperature gradientReduce lossExtrusion diesPass rateMechanical engineering

The invention discloses a pre-forming device of automobile external star wheel by isothermal extrusion, which comprises a punch and a female die, the punch and the female die are laterally fixed and vertically movably matched by means of a guide pillar. The female die is provided with a die cavity, and a heating device is arranged at the periphery of the die cavity. The heating unit is arranged at the die cavity of the invention to maintain the outer layer temperature of the mold. The pre-forming device has the advantages of greatly reducing the geothermal gradient of blank and mold, effectively lessening the thermal dispersion of blank in the forming process, achieving the extrusion pre-forming under the isothermal condition, avoiding the situation that the die cavity can not be filled due to excessively fast temperature drop, material deformation and resistance increase, thus improving the pass rate of finished products, and reducing waste.

Owner:CHONGQING UNIV

Bottom-blowing and side-blowing molten pool reducing furnace for liquid state high lead slag

The invention discloses a bottom-blowing and side-blowing molten pool reducing furnace for liquid state high lead slag. The bottom-blowing and side-blowing molten pool reducing furnace for the liquid state high lead slag comprises a furnace body and support bases arranged on the two ends of the furnace body. The outer wall of the furnace body is fixedly provided with rolling rings. The furnace body can be rotatably installed on the support bases through the rolling rings and is driven to rotate by a driving device. The top of the furnace body is provided with a smoke outlet opening, a first material-adding opening and a second material-adding opening from left to right in sequence. The lower part of a side plate of the right end of the furnace body is provided with a slag-discharging opening. A reducing spraying gun device is arranged at the bottom, under the first material-adding opening, of the furnace body. A heating spraying gun device is arranged below the second material-adding opening. The heating spraying gun device is located on the side wall of the furnace body and arranged close to the slag-discharging opening. According to the bottom-blowing and side-blowing molten pool reducing furnace for the liquid state high lead slag, fuel and combustion improver are sprayed from a heating spaying gun into a slag layer of a molten pool, on the one hand, lead oxide of the slag layer is further subjected to reduction reaction, the lead content rate of the slag is decreased, and the direct recovery rate of lead is increased; and on the other hand, the temperature of the slag layer of the molten pool is improved, the slag is conveniently discharged, meanwhile, the distance of the spraying gun and the slag-discharging opening is shorted, the temperature of the molten poll is reduced, and the consumption of energy is reduced.

Owner:HENAN YUGUANG GOLD & LEAD

Method for producing decahydronaphthalene and tetrahydronaphthalene by naphthalene hydrogenation

InactiveCN104193578ASimple processReasonable temperatureHydrocarbon by hydrogenationChemical recyclingHydrogenTetralin

The invention discloses a method for producing decahydronaphthalene and tetrahydronaphthalene by naphthalene hydrogenation, belonging to the technical field of noncyclic or carbocyclic compounds. Under the catalytic action of Raney nickel, naphthalene is heated to react with hydrogen gas to obtain the tetrahydronaphthalene and decahydronaphthalene. The method has the advantages of simple technique, controllable and reasonable temperature and pressure, high yield and high product purity; the two products can be obtained by one hydrogenation step, so the reaction time is short; and the catalyst can be regenerated and reused, thereby greatly lowering the production cost.

Owner:邯郸惠达化工有限公司

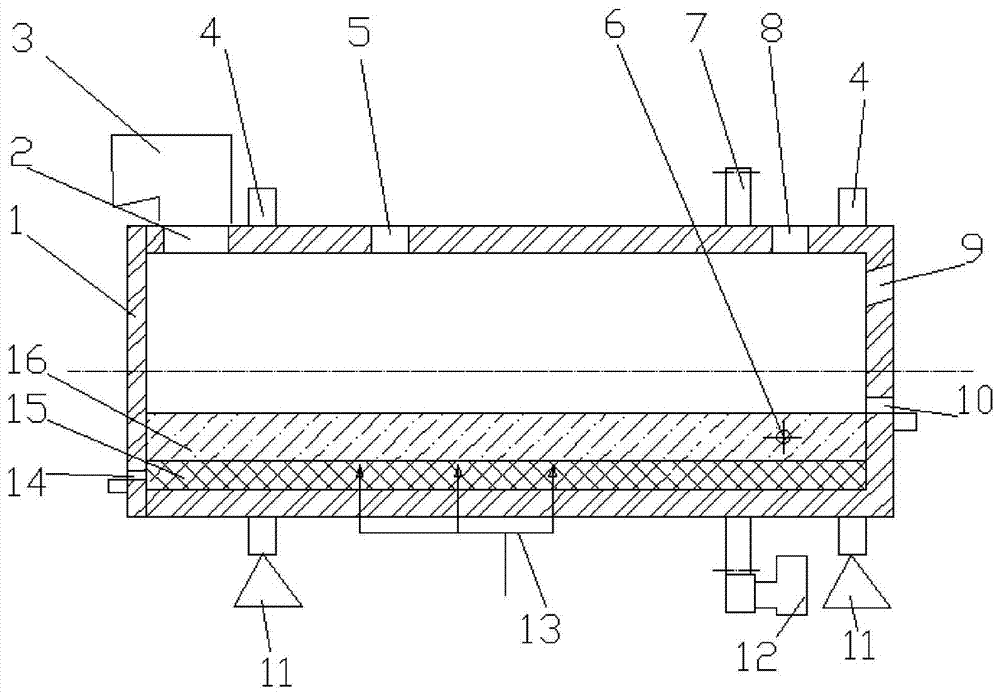

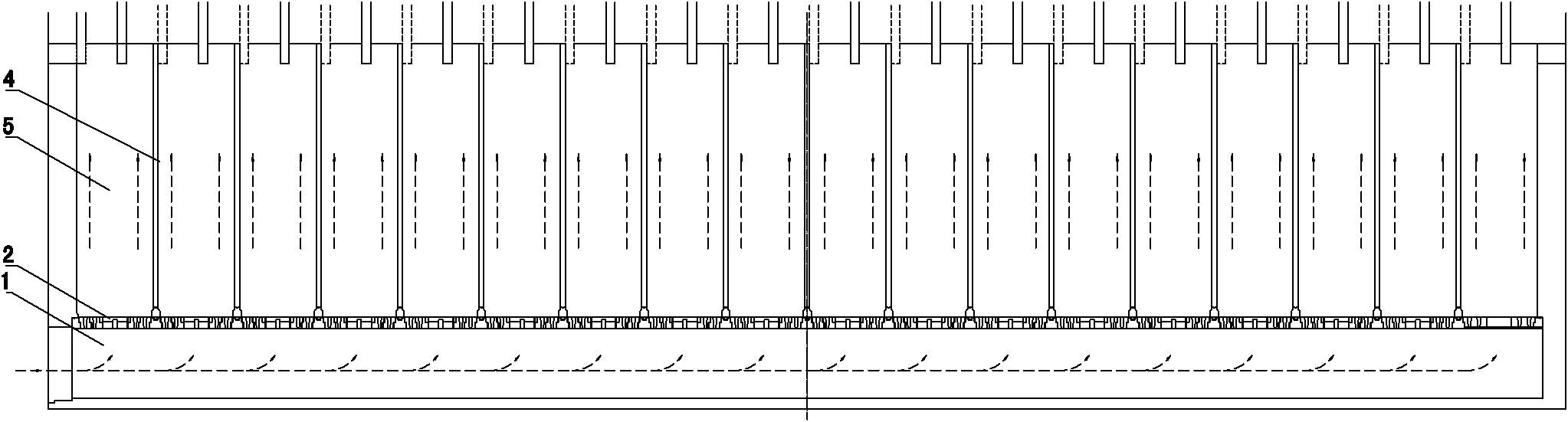

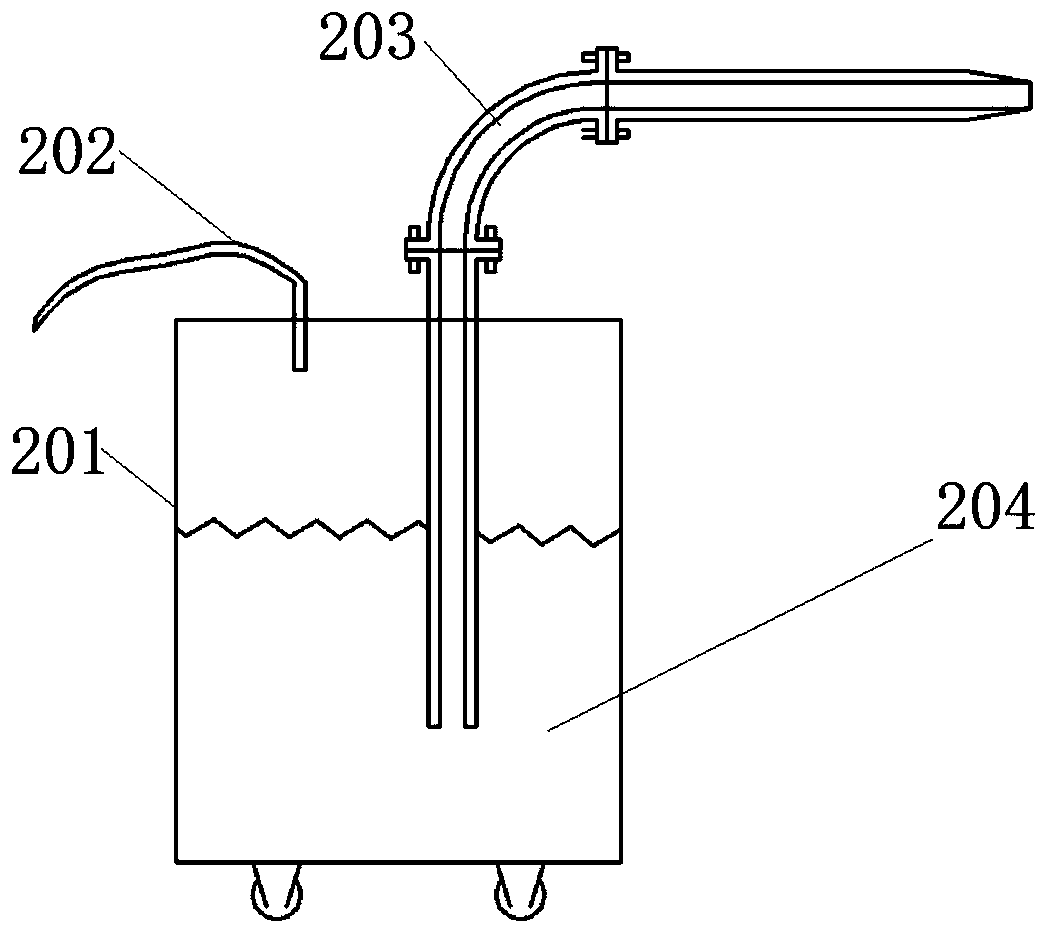

SNCR denitration system of circulating fluidized bed boiler based on flow-state reconstruction

InactiveCN103691292ASmall excess airReasonable temperatureLighting and heating apparatusDispersed particle separationFluidized bedWater storage tank

The invention belongs to the technical field of SNCR (Selective Non-Catalytic Reduction) denitration devices of circulating fluidized bed boiler equipment and particularly relates to an SNCR denitration system of a circulating fluidized bed boiler based on flow-state reconstruction. The SNCR denitration system mainly solves the problems of high investment cost and running cost and low denitration efficiency existed in the denitration of the existing boiler. The technical scheme is that the SNCR denitration system comprises a circulating fluidized bed boiler hearth and a circulating fluidized bed boiler separator, as well as an ammonia water unloading and storing system, an ammonia water diluted water delivery system, a mixing and distributing system, a spray injection system and a test system; ammonia water is delivered from a tank wagon to an ammonia water storage tank through a pipeline and an ammonia unloading pump for storing; the test system belongs to a CEMS (Continuous Emission Monitoring System) test system, and an input end of the CEMS test system is connected with the circulating fluidized bed boiler separator. The SNCR denitration system has the advantages of low cost and good denitration effect.

Owner:TAIYUAN BOILER GROUP +1

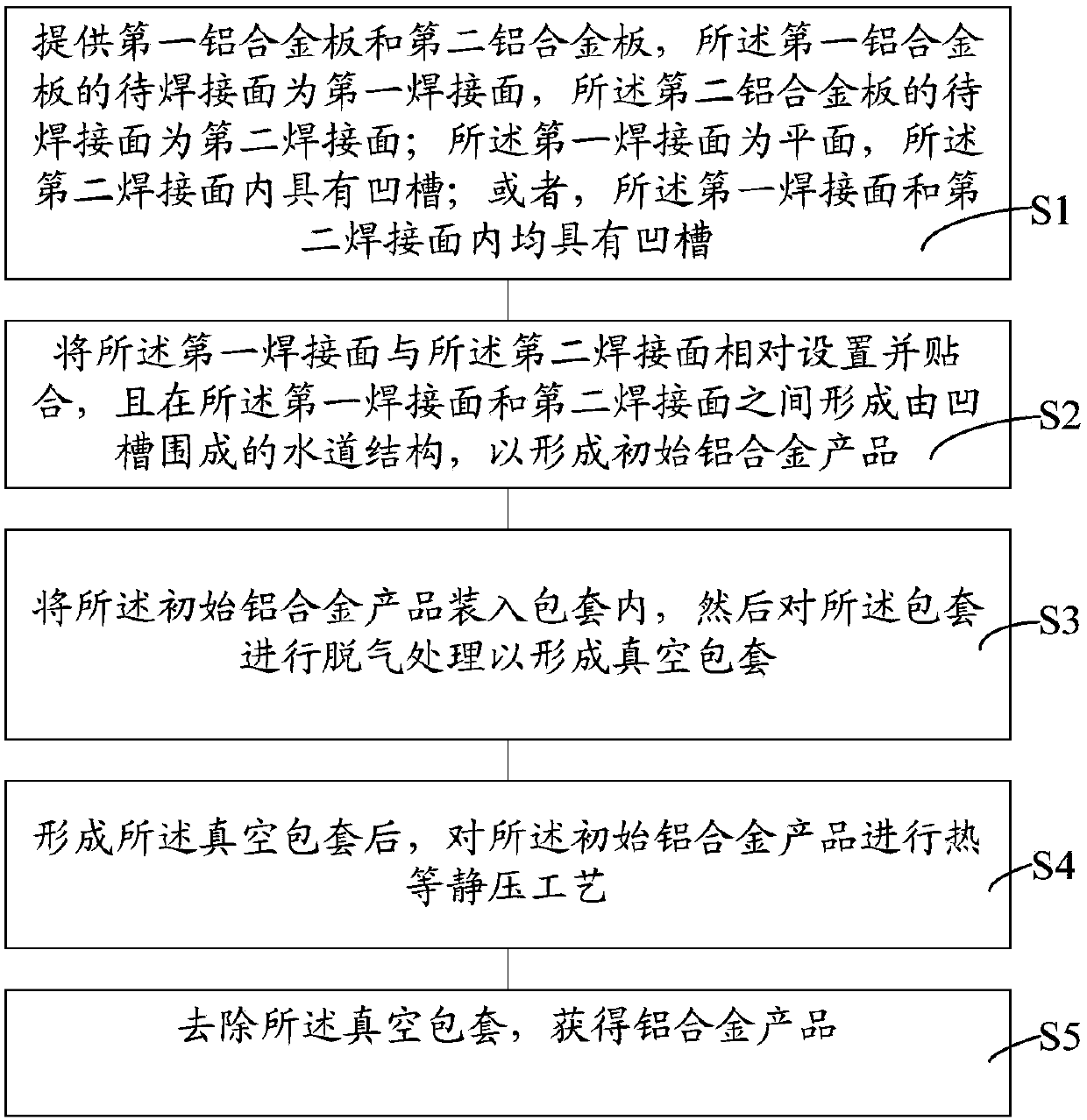

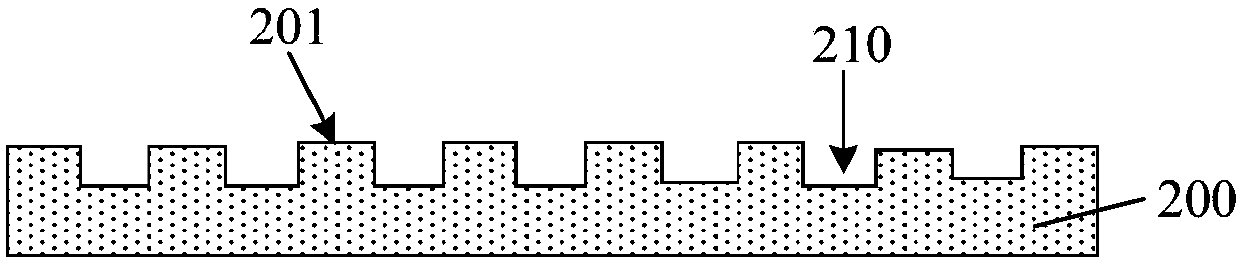

Manufacturing method of aluminum alloy product

InactiveCN107662045AImprove welding strengthAvoid deformation or even blockageNon-electric welding apparatusHot isostatic pressingWeld strength

The invention provides a manufacturing method of an aluminum alloy product. The manufacturing method of the aluminum alloy product comprises the following steps: a first aluminum alloy plate and a second aluminum alloy plate are provided, wherein a surface to be welded of the first aluminum alloy plate is a first welded surface, and a surface to be welded of the second aluminum alloy plate is a second welded surface; the first welded surface is a plane, and a groove is formed in the second welded surface; or grooves are formed in the first welded surface and the second welded surface; the first welded surface and the second welded surface are oppositely arranged and bonded, and a water way structure, surrounded by the grooves, is formed between the first welded surface and the second welded surface to form an initial aluminum alloy product; the initial aluminum alloy product is filled in a cover; the cover is degassed to form a vacuum cover; then, a hot isostatic pressing process is performed on the initial aluminum alloy product; and the vacuum cover is removed to obtain the aluminum alloy product. As the hot isostatic pressing process is applied on the initial aluminum alloy product, the welding strength of the formed aluminum alloy product is improved, and meanwhile, deformation or even blockage of the water way structure is prevented.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Tomato precooling technological process

InactiveCN103478226ASolve dehydrationSolve agingFruit and vegetables preservationPreservativeAdditional values

The invention discloses a tomato precooling technological process, relating to the field of freshness retaining and storing agricultural products. The tomato refrigerating and freshness retaining technological process comprises the steps of picking, cleaning, precooling, sterilizing and disinfecting tomatoes, washing, spraying a preservative, filling the tomatoes in a breathable bag, disinfecting a storehouse, controlling the temperature, controlling contents of oxygen and carbon dioxide, controlling the humidity of the storehouse, and delivering the tomatoes from the storehouse. According to the tomato refrigerating and freshness retaining technological process, suitable conditions beneficial to storing the tomato are determined, reasonable temperature, humidity and gas components in the storehouse are ensured, the problems of water loss, ageing, yellowing and rotting in the tomato storage process are solved, the storage time of the tomato is prolonged, the color and the texture can not be damaged, the development in the vegetable industry is promoted, the additional value is increased, and the building of a demonstrative mode in a high-efficiency agriculture industry chain is promoted.

Owner:怀远县兴达蔬菜有限公司

Method for preparing DTY (drawn textured yarn) polyester super-bright flat yarn by POY (polyester pre-oriented yarn) polyester yarn

InactiveCN102534898AThe process steps are simpleSoft touchTextiles and paperPolyesterPolymer chemistry

The invention discloses a method for preparing a DTY (drawn textured yarn) polyester super-bright flat yarn by a POY (polyester pre-oriented yarn) polyester yarn, belonging to the field of knitting / spinning raw material processing technologies. According to the method, the POY yarn is rolled after passing through a first roller, an upper heating box, a cooling plate, a false twister, a second roller, a lower heating box and a third roller, and then the DTY polyester super-bright flat yarn is obtained, wherenin the linear velocity of the first roller is 410-450m / min; the linear velocity of the second roller is 690-720m / min; a temperature of the upper heating box is 193-196 DEG C; and a temperature of the lower heating box is 135-145 DEG C. The method has the advantages that the processing steps are simple and the industrial large-scale production can be satisfied; and as the linear velocities of the first and second rollers as well as the temperatures of the upper and lower heating boxes are selected reasonably, fleece-faced fabrics processed from the obtained DTY polyester super-bright flat yarn has smooth and soft handfeel as well as fluffy and vivid texture, which is markedly superior to that of the prior art.

Owner:江苏东方阳光科技有限公司

Preparation method of seasoned poached eggs

InactiveCN106036545AGreat tasteRich structureFood thermal treatmentFood ingredient as flavour affecting agentFood flavorPoached egg

A preparation method of seasoned poached eggs comprises the following steps: (1) eggs are graded according to the quality standard; (2) a heat transfer medium is heated to 80-95 DEG C; (3) the eggs are totally immersed in the heat transfer medium and boiled for 7-10 min; (4) the boiled eggs are cooled in water at 10-20 DEG C; (5) the cooled eggs are totally immersed in a prepared seasoning liquid, the mixture is placed in vacuum decompression equipment for 2-4 days, the vacuum degree is kept from subzero 0.09 Mpa to subzero 0.1 Mpa, and the temperature is set to be 25 DEG C; (6) the poached eggs prepared through the steps are subjected to cold storage in a low-temperature environment at 0-10 DEG C. The egg white of the prepared poached eggs is denaturalized completely, and the hardness and the elasticity reach the states of normal hard boiled eggs; while the texture of yolk is in a soft sate and colloidal, the yolk is in bright deep yellow and tastes fine and soft, and small-molecular flavor substances of the prepared seasoning liquid enter the eggs completely without damaging the inside forms of the poached eggs, so that the poached eggs are good in color, flavor and taste.

Owner:SICHUAN UNIV

Method capable of adjusting heating uniformity of coke oven in length direction from lower portion and oven body structure

InactiveCN102146293AReasonable structureUniform and reasonable fire path temperatureCombustible gas coke oven heatingCoke oven detailsFlueProcess engineering

The invention relates to a method capable of adjusting heating uniformity of a coke oven in a length direction from a lower portion and a novel oven body structure. The invention is characterized in that a grate brick capable of adjusting gas passing section area is arranged at the bottom of a top heat storage chamber of a small flue and the sizes of holes of the grate brick are adjusted by adding or subtracting adjusting bricks to or from the holes of the grate brick at a cellar. Each heat storage chamber is divided into a plurality of unit cells along the length direction; and each heat storage chamber is divided into multiple gas channels in the length direction. Coal gas and air are supplied from the same side of the small flue of the heat storage chamber; namely, the coal gas and the air are both supplied from a small flue at a coke side or a small flue at a machine side. The invention has the advantages that the problem of heating uniformity in the length direction of the coke oven is solved and the temperature of a flame path is more uniform and reasonable because the structure is reasonable and the grate brick capable of adjusting the gas passing section area is arranged at the bottom of the top heat storage chamber of the small flue; and the heat storage chamber which is in a cellular structure is more beneficial to distribution of gas quantity, avoids local high temperature caused by unreasonable distribution of the gas quantity and is capable of effectively increasing the product quality of the coke oven.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

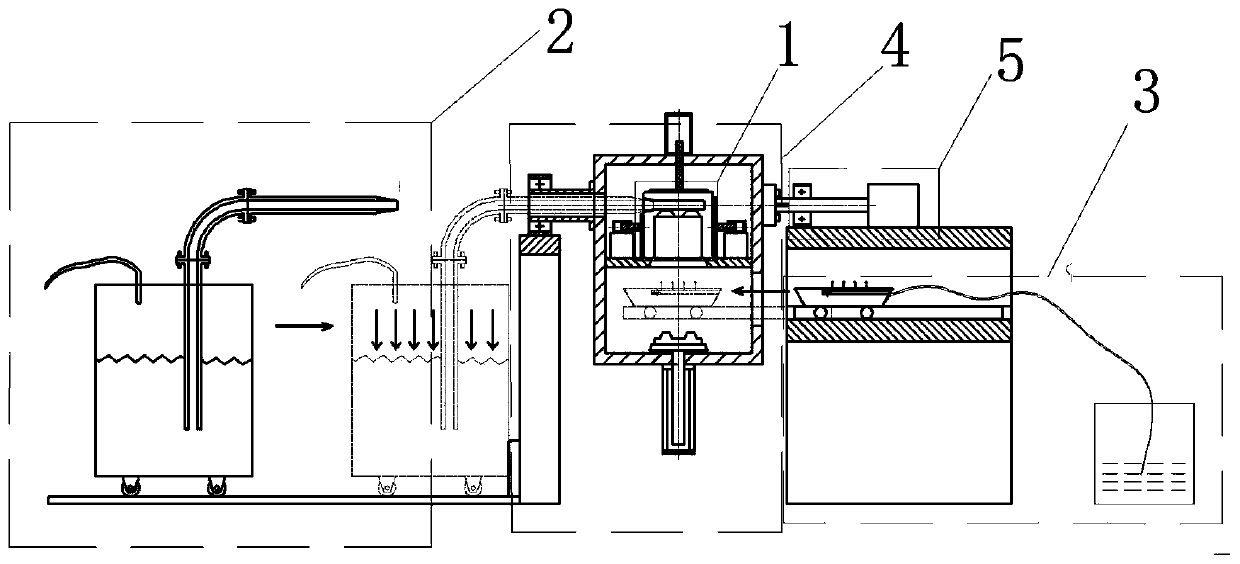

Casting forming system with turnover directional cooling function and using method thereof

PendingCN110202120AReasonable filling flow fieldReasonable temperatureMould handling equipmentsMaterial structureMolten metal

The invention discloses a casting forming system with turnover directional cooling function and a using method thereof. The system comprises a sand mold, a molten metal conveying system, an external directional cooling system, a casting mold turnover system and a turnover power system. According to the casting forming system with the turnover directional cooling function, the internal defects of castings caused by contradictions, between a molten metal flowing state and a temperature field in a solidification process, generated during mold filling in traditional casting engineering can be reduced or eliminated, the material structure is refined, the performance of the castings is improved; and meanwhile, the production period is shortened, and the production efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV +1

Air separation method and apparatus

An air separation method and apparatus in which a supercritical oxygen product is produced by heating a pumped liquid oxygen stream having a supercritical pressure, through indirect heat exchange with a boosted pressure air stream. The indirect heat exchange is conducted within a heat exchanger and a liquid nitrogen stream is vaporized in the heat exchanger to depress the pressure that would otherwise be required of the boosted pressure air stream to heat the pumped liquid oxygen stream. The pumped liquid oxygen stream constitutes 90 percent of the oxygen-rich liquid removed from an air separation unit in which the air is rectified, the liquid nitrogen constitutes at least 90 percent of the liquid nitrogen that is not used as reflux and a flow-rate ratio between the liquid nitrogen stream and the oxygen-rich liquid is between about 0.3 and 0.90.

Owner:PRAXAIR TECH INC

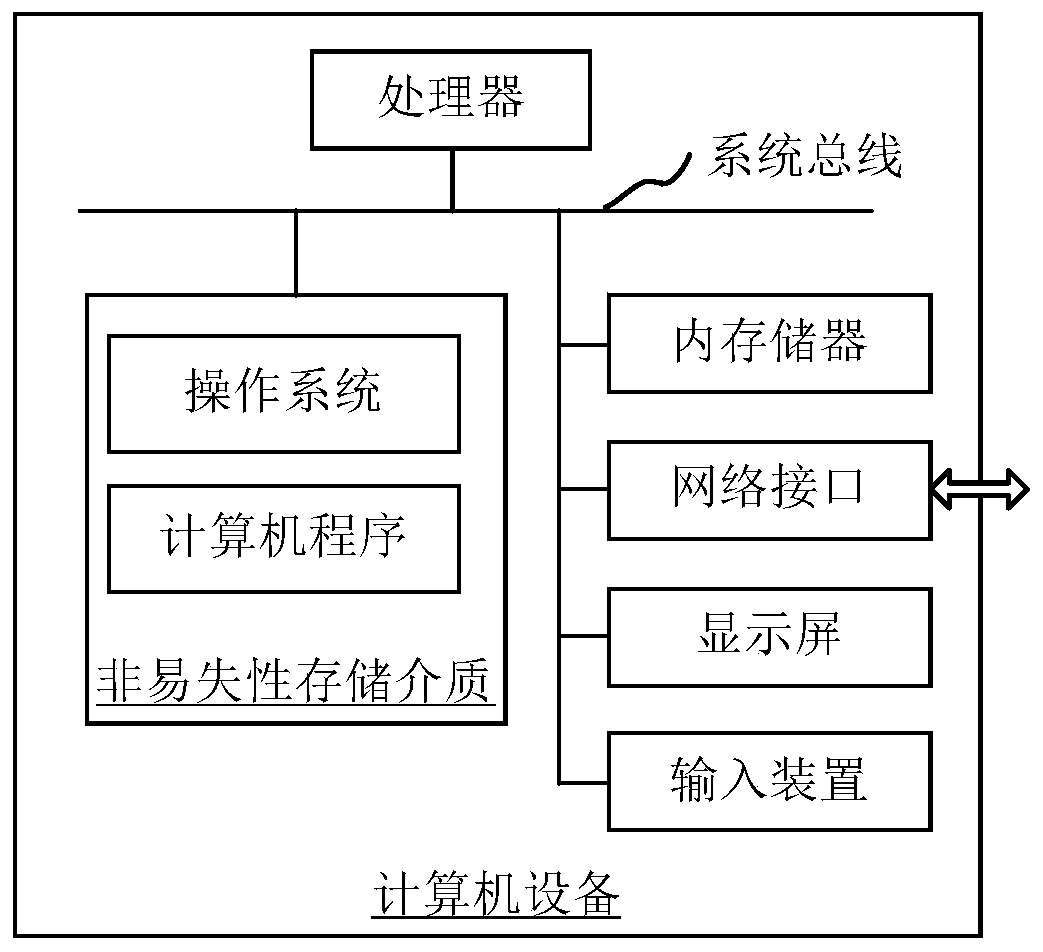

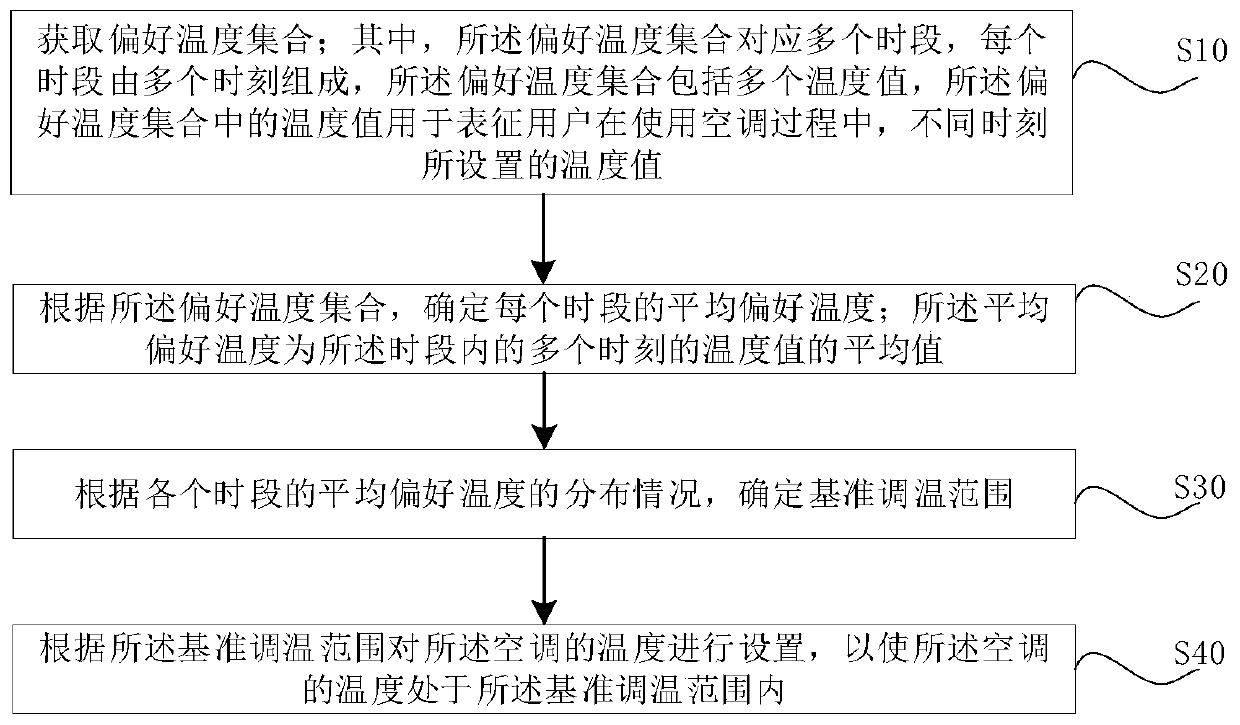

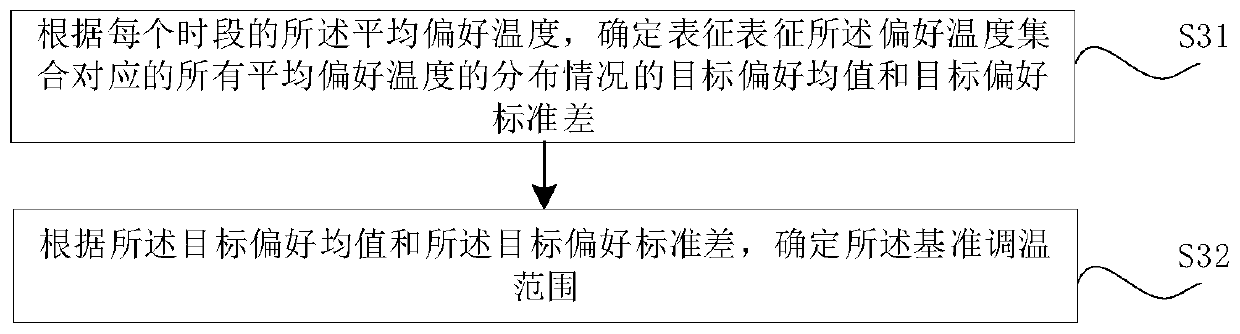

Air conditioner temperature setting method and device, computer equipment and storage medium

ActiveCN110595017AReasonable temperatureMechanical apparatusSpecial data processing applicationsValue setEngineering

The invention relates to an air conditioner temperature setting method and device, computer equipment and a storage medium. The method comprises the following steps that a preference temperature set is obtained; an average preference temperature of each time period is determined according to the preference temperature set; a reference temperature adjustment range is determined according to the distribution condition of the average preference temperature of each time period; and the temperature of an air conditioner is set according to the reference temperature adjustment range, so that the temperature of the air conditioner is within the reference temperature adjustment range, wherein the preference temperatures set corresponds to the plurality of time periods, each time period consists ofa plurality of time instants, the preference temperature set comprises a plurality of temperature values, the temperature values in the preference temperature set are used for representing the temperature values set by a user at different time instants in the air conditioner using process, and the average preference temperatures represent the averages of the temperature values of the plurality oftime instants within the time periods. The method is wide in application range and flexible in application scene.

Owner:深圳数联天下智能科技有限公司

Method for preparing cellulose-based composite film with high strength

The invention discloses a method for preparing cellulose-based composite film with high strength. The method comprises the steps that cellulose, IO4-donor are added into deionized water, then a certain amount of isopropanol, phenol or benzenediol are added, light avoiding reaction is carried out to prepare dialdehyde cellulose, then a transparent dialdehyde cellulose aqueous solution is prepared,sorbitol and glycerinum are added into the aqueous solution, and cellulose film is prepared through the processes of casting, soaking and drying processes on a flat plate. The method for preparing thecellulose-based composite film with the high strength has the advantages that cheap wood pulp, bamboo pulp, cotton and other biomass cellulose serve as cellulose suspension liquid raw materials, theuse value of biomass waste is fully improved, and a new prospect for the application of the cellulose as a packing material and a functional material is opened up.

Owner:XIAMEN UNIV

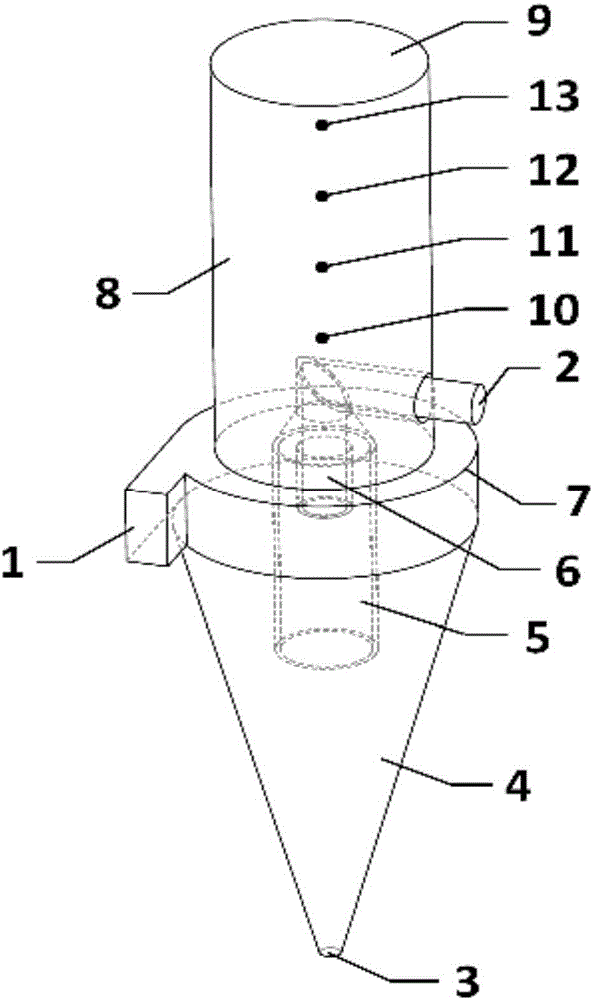

Method for preparing magnesium oxide through spray pyrolysis and spray pyrolysis furnace used therein

The invention provides a method and apparatus for preparing magnesium oxide through spray pyrolysis of a magnesium chloride solution. The apparatus comprises a cylindrical furnace chamber, a cylindrical rotation chamber arranged at the lower side of the cylindrical furnace chamber, a conical cyclone structure arranged below the cylindrical rotation chamber, a primary drum arranged in the center of the cylindrical rotation chamber and coaxial with the cylindrical rotation chamber and a secondary drum arranged in the primary drum and having a small diameter, wherein the cylindrical rotation chamber rotates under the action of tangentially-blown hot air; nozzles in the cylindrical furnace chamber spray the magnesium chloride solution for contact with hot air and a drying and pyrolysis reaction is carried out; and after sufficient drying and pyrolysis of the magnesium chloride solution, 90% or more than 90% of a solid magnesium chloride raw material is discharged from a cone-base discharge outlet (3) and then collected. According to the invention, miniaturization of a spray pyrolysis furnace is realized; reverse reactions are reduced; sufficient pyrolysis of materials is guaranteed; and gas-solid separation can be carried out in the furnace chamber, so subsequent separation operation is simplified.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com