Automobile out star wheel isothermal extrusion preliminary shaping device

A technology of isothermal extrusion and extraterrestrial wheel, which is applied in the direction of metal extrusion molds, etc., can solve the problems of rapid temperature drop of the workpiece, increase of hardness, and plastic deformation that cannot fill the cavity, so as to achieve uniform heating temperature, reasonable temperature, and eliminate artificial The effect of subjective influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

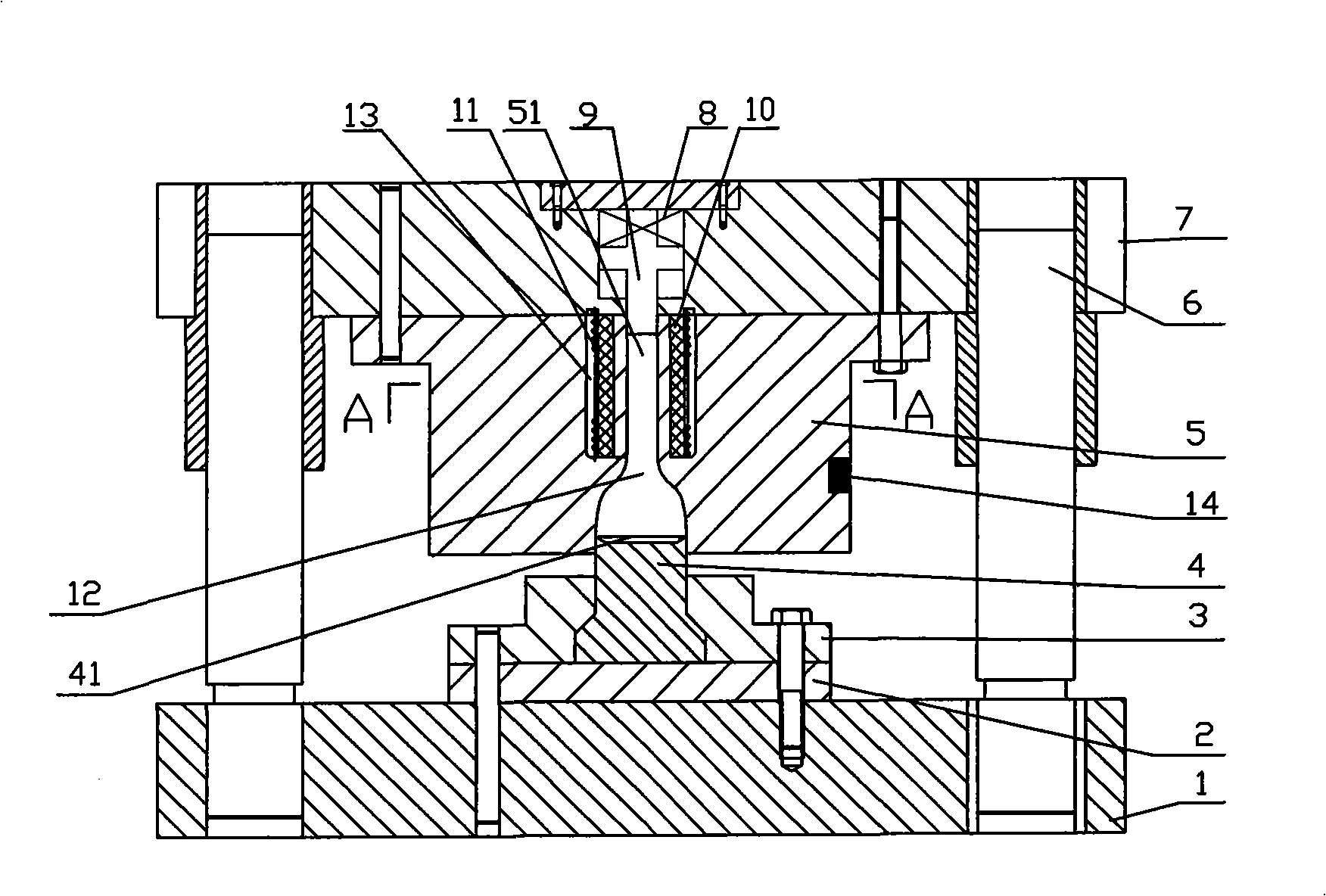

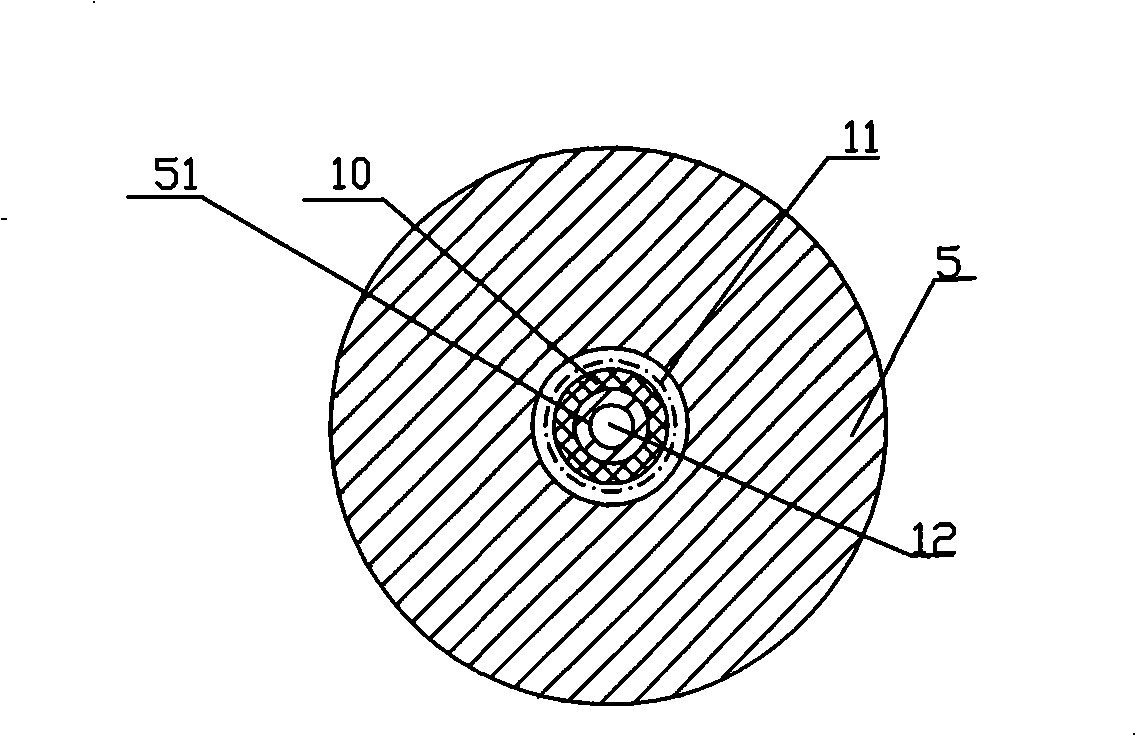

[0021] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 A sectional view along A-A, as shown in the figure: the isothermal extrusion preforming device for the automotive outer planetary wheel of the present embodiment includes a punch 4 and a die 5, and a positioning groove 41 is set at the contact position between the punch 4 and the workpiece 12; 4 and the die 5 are horizontally fixed and vertically movable through the guide post 6, and the die 5 is fixed on the die base 7; the punch 4 is fixed on the punch base 1 through the positioning block 3 and the base 2; the die 5 Set the cavity 51, and process the annular heating cavity 13 around the cavity 51 corresponding to the rod of the workpiece 12. The distance between the inner ring surface of the annular heating cavity 13 and the outer wall of the cavity 51 is 0.8 times the diameter of the cavity cross section. A heating device 11 is arranged in the chamber 13; the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com