Patents

Literature

104results about How to "Automation reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

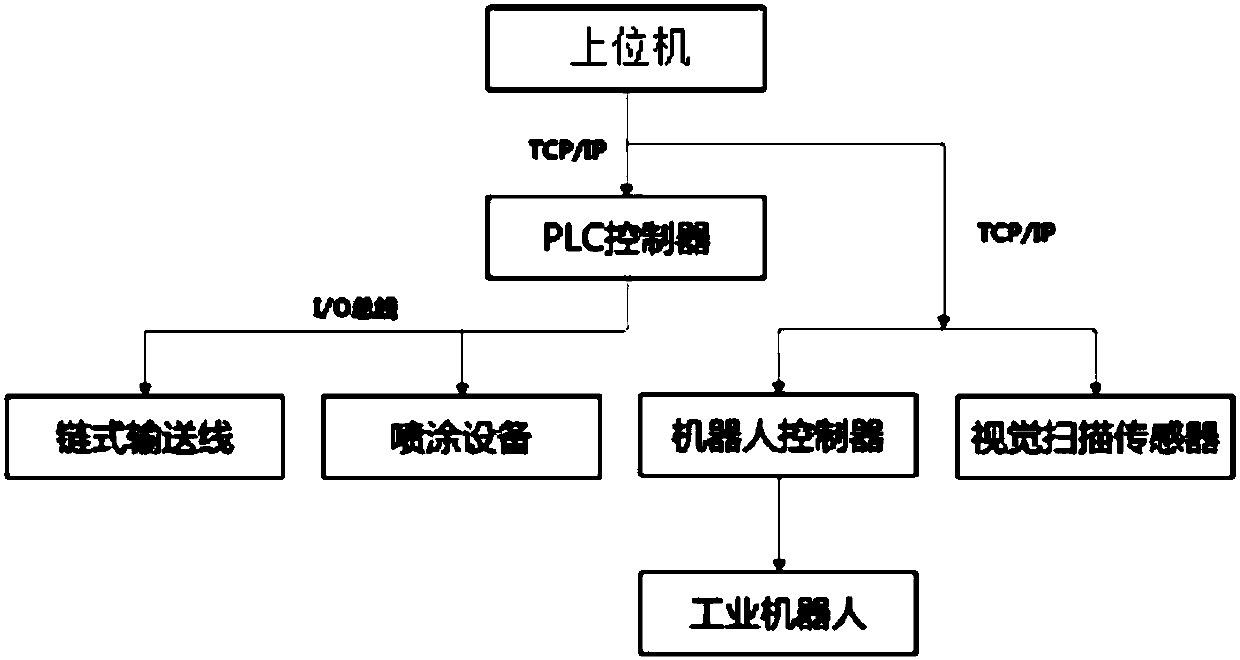

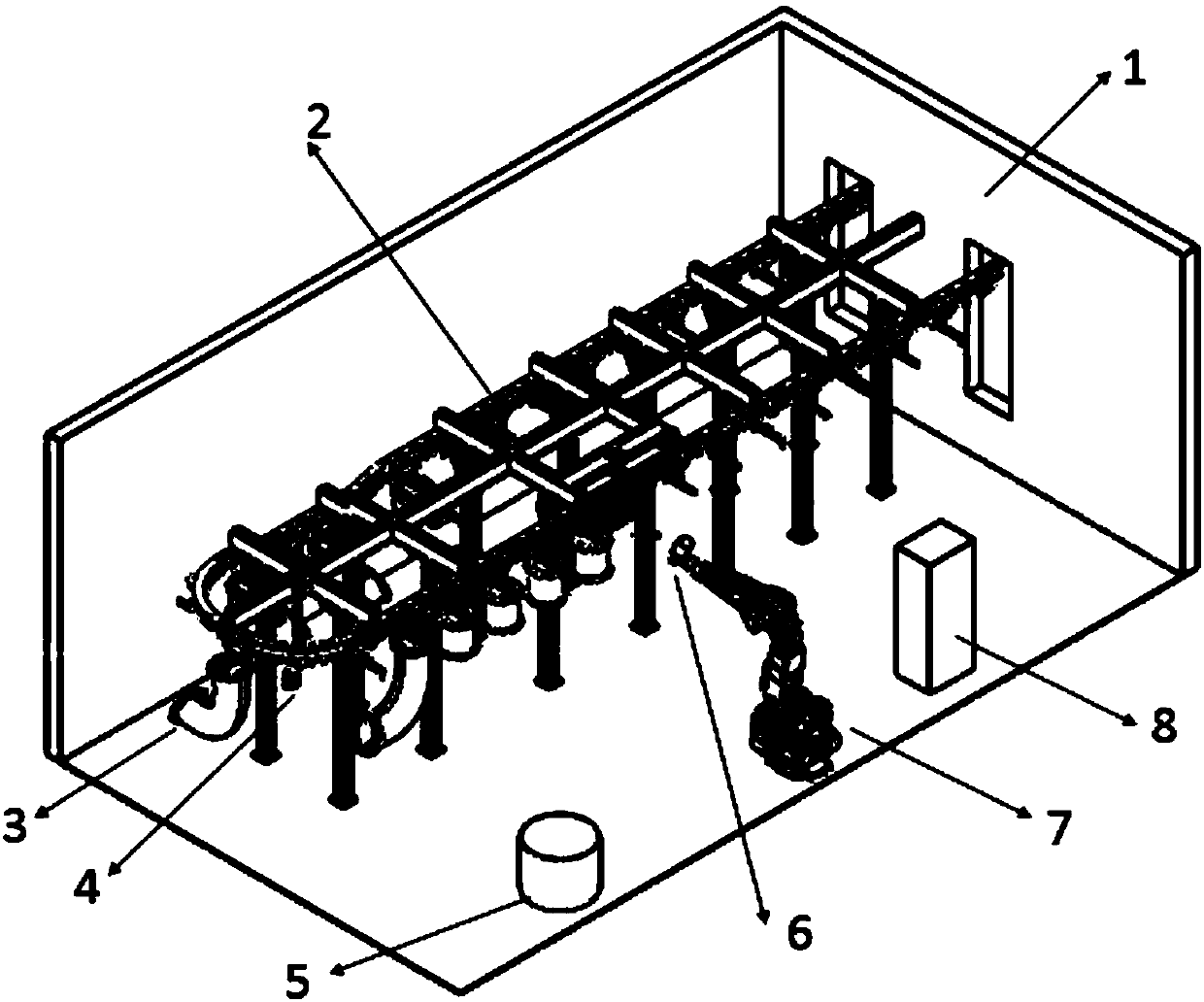

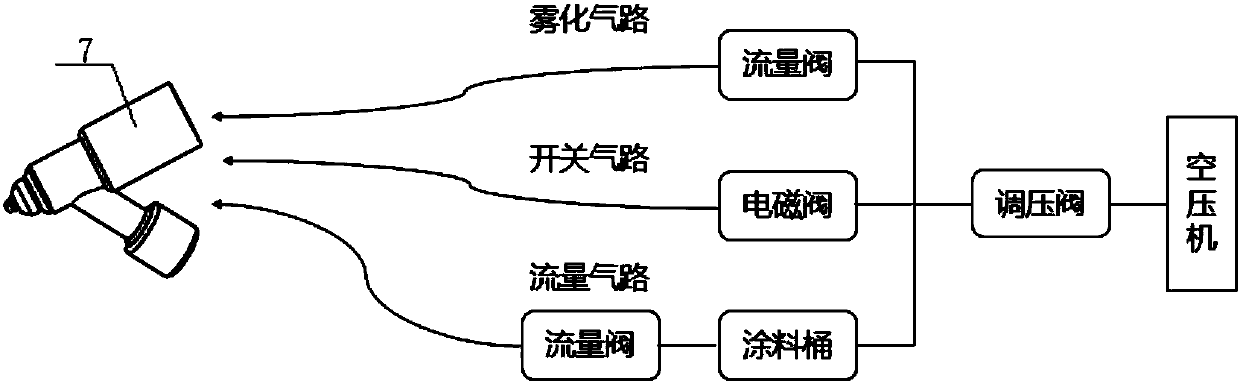

Robot spraying system and control method thereof

InactiveCN107899814AImprove spraying accuracyReduce teaching workloadSpraying apparatusChain typeEngineering

The invention discloses a robot spraying system. The system is provided with a chain type conveying line for conveying a to-be-sprayed workpiece. The chain type conveying line conveys the workpiece tosequentially pass through a vision scanning area and a spraying area. The vision scanning area is provided with a vision sensor used for conducting three-dimensional scanning on the workpiece. The spraying area is provided with an industrial robot. A spray gun is fixed to the end portion of the industrial robot and connected with spraying equipment. The vision sensor outputs signals to an upper computer. The upper computer outputs spraying track signals to a robot controller. The robot controller drives the industrial robot to execute the spraying track. The upper computer outputs the controlsignals to a PLC. The PLC drives the chain type conveying line and the spraying equipment to work. The robot spraying system has the beneficial effects that automatic complex hook face spraying trackplanning can be achieved, and the spraying precision is improved; and the offline programming technology is utilized, the demonstration workload of the robot is reduced to the maximum degree, and productivity can be rapidly achieved.

Owner:WUHU HIT ROBOT TECH RES INST

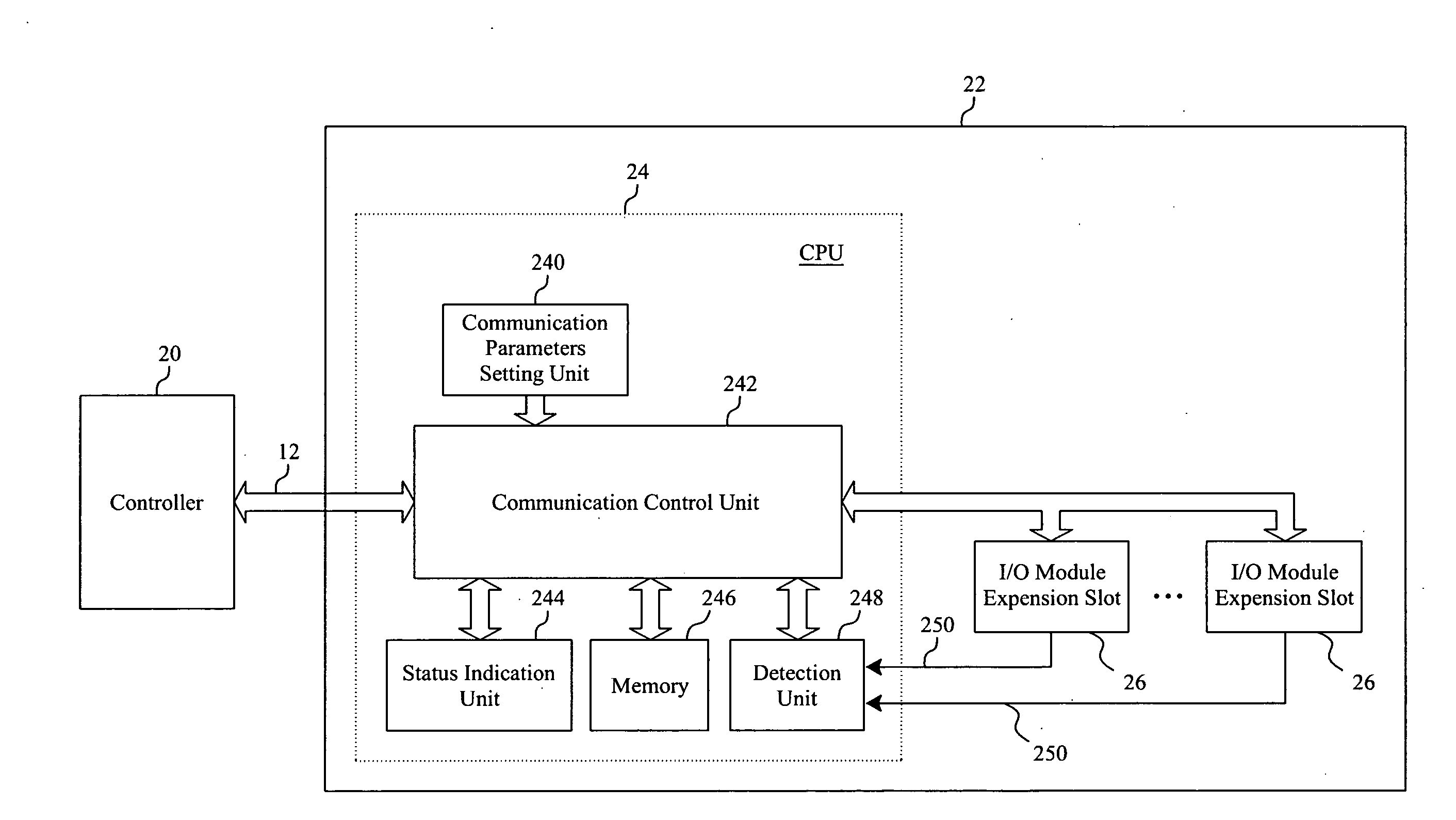

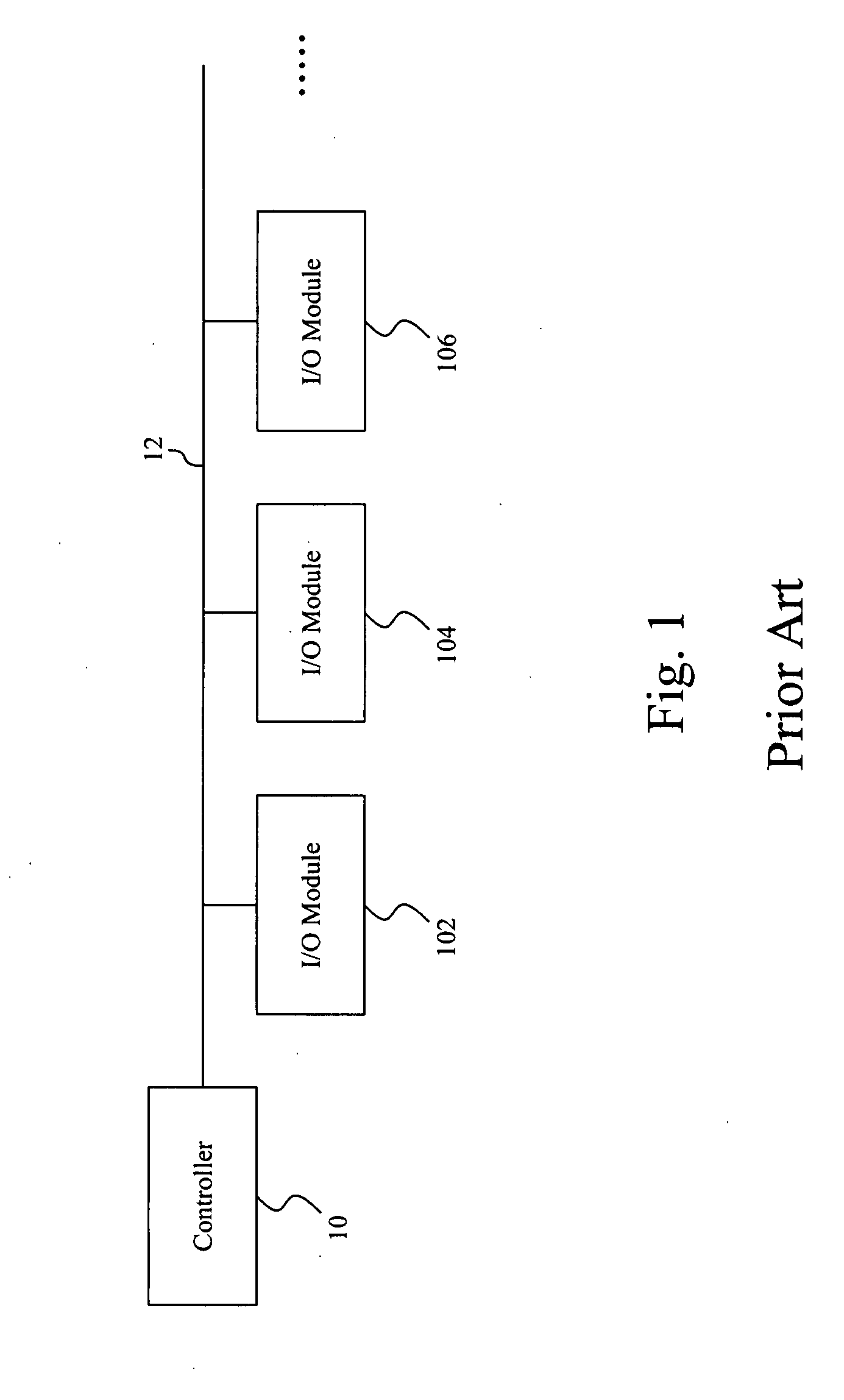

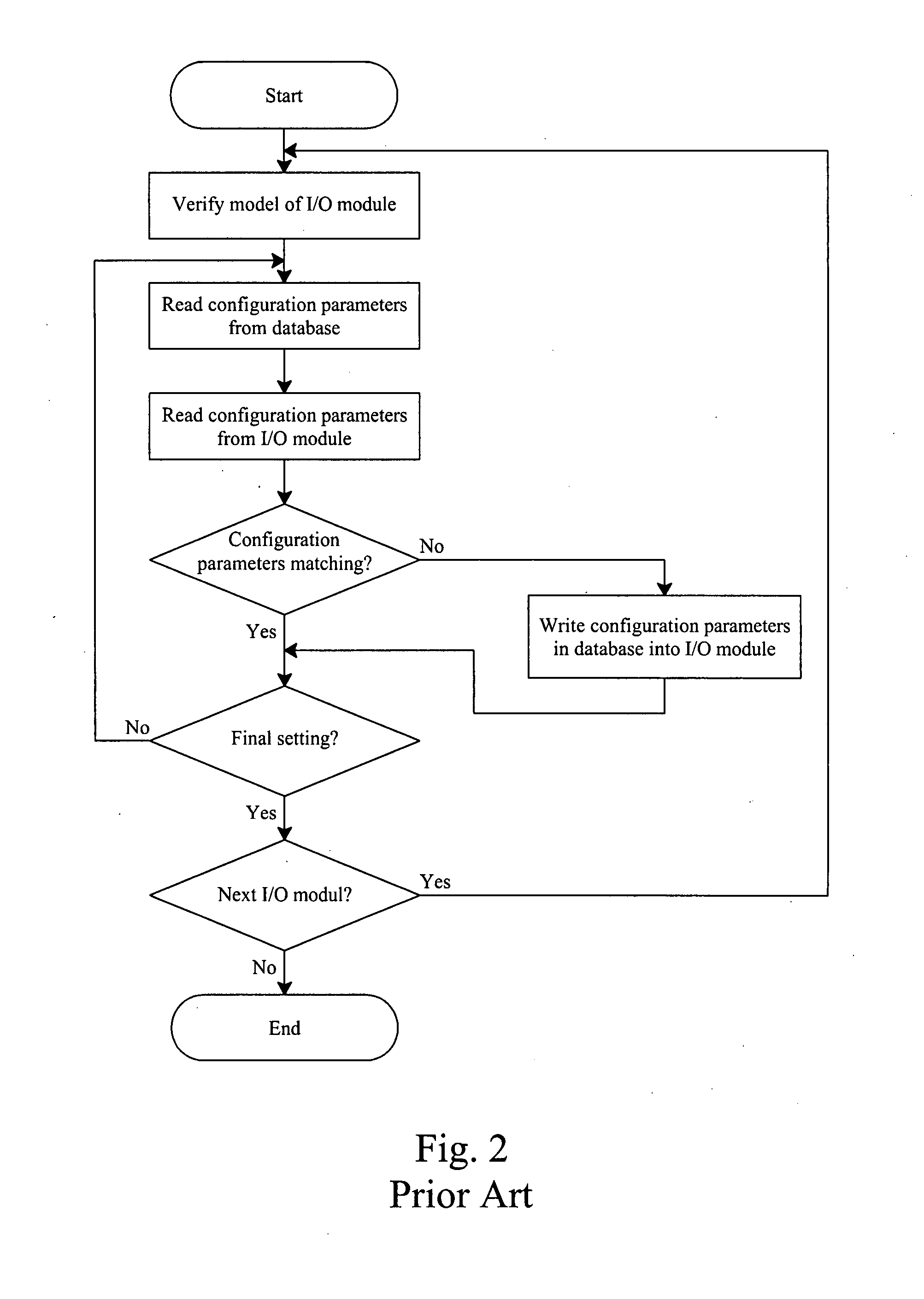

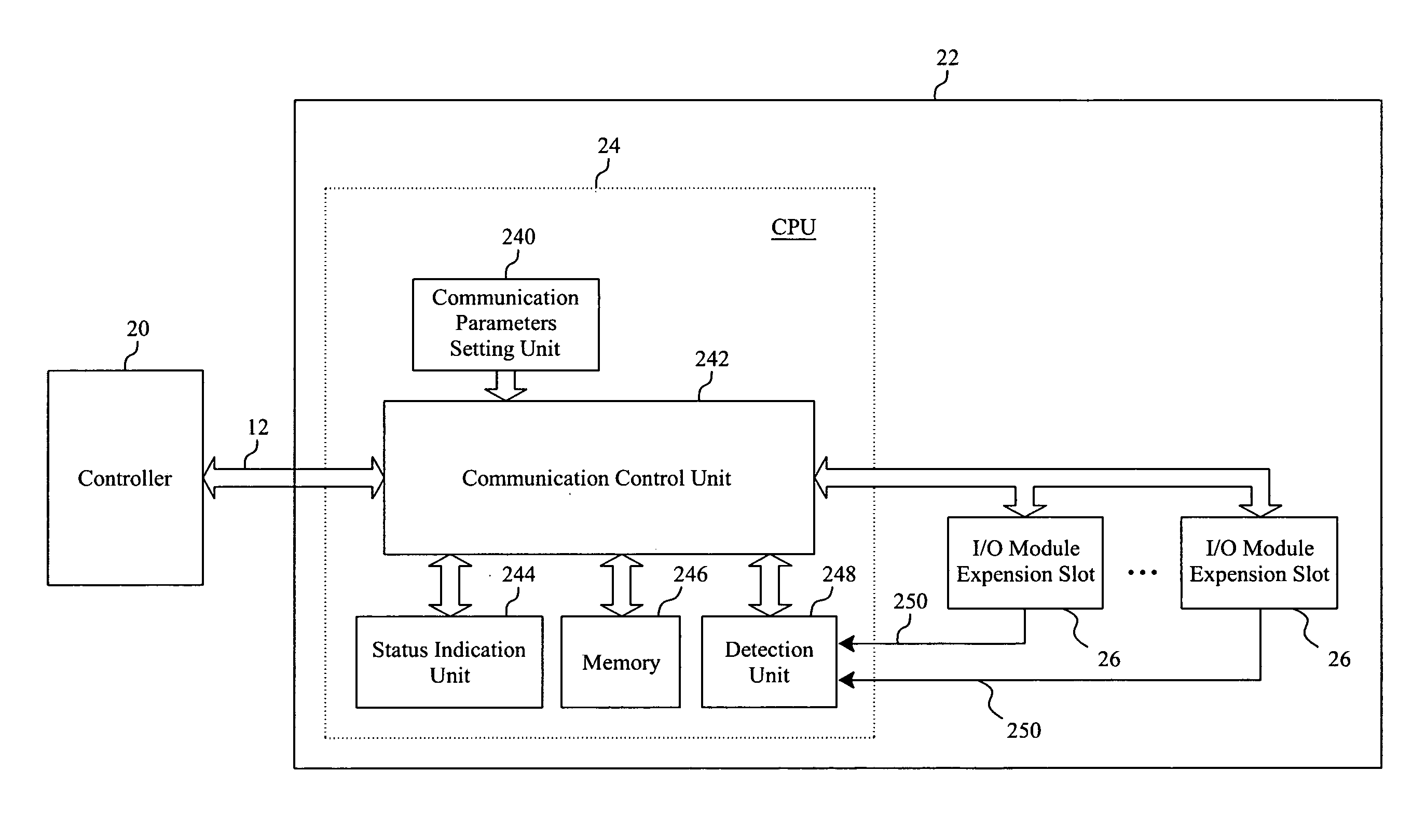

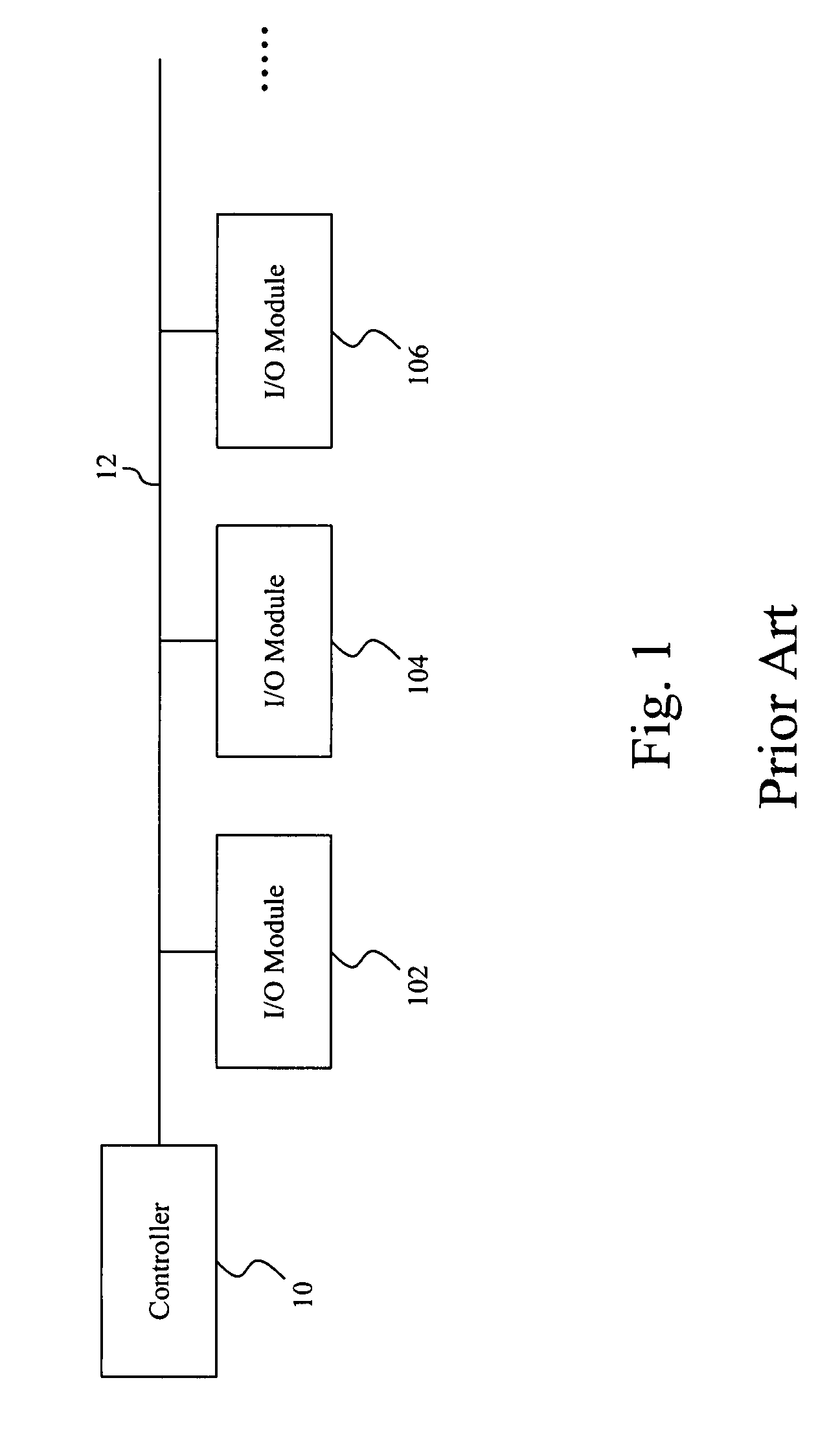

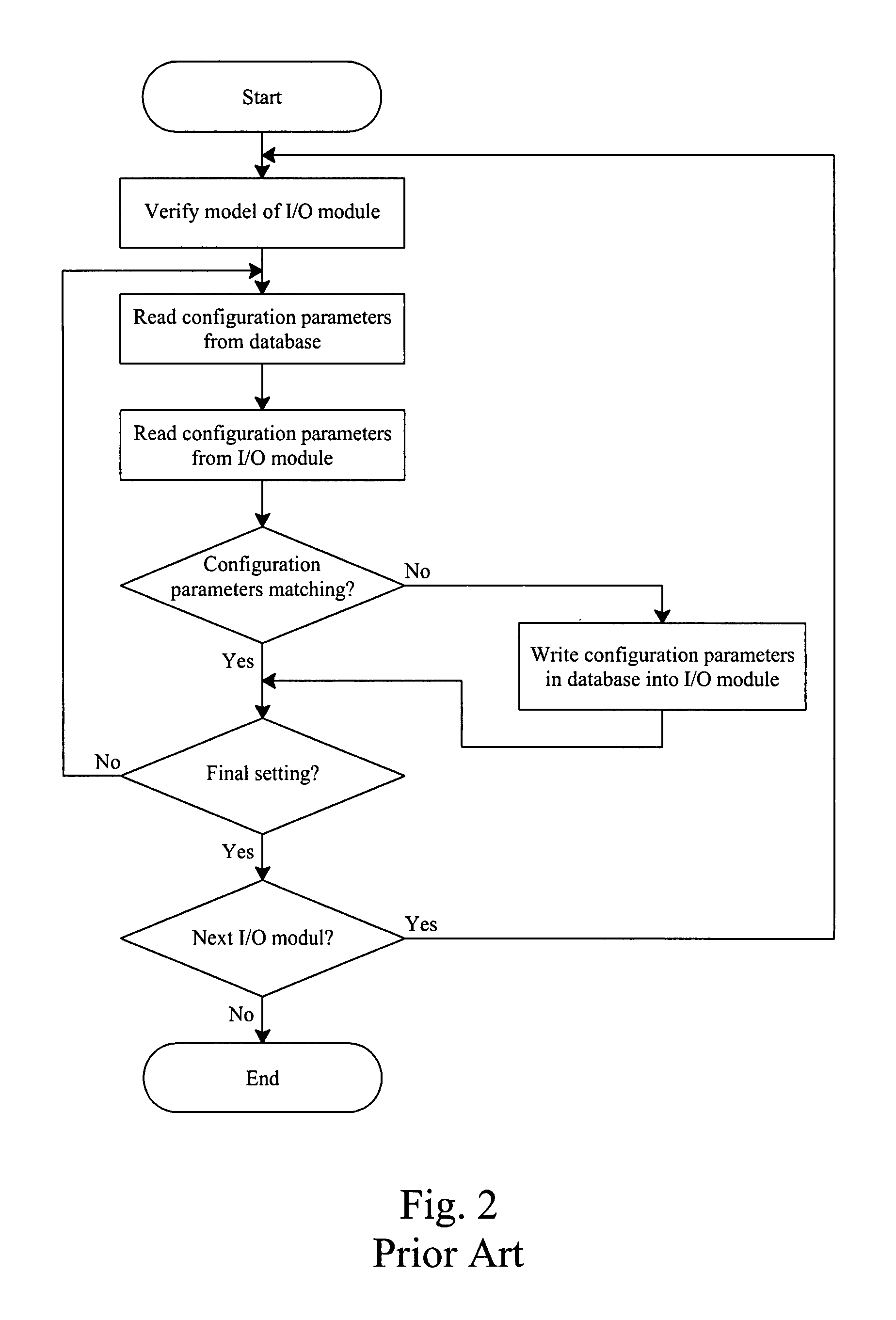

I/O module expansion unit and distributed automation system

InactiveUS20090077270A1Quick SetupQuick changeProgramme controlInput/output processes for data processingComputer architectureChecksum

An I / O module expansion unit having slots to install I / O modules thereon is provided for a distributed automation system. With the I / O module expansion unit, storing the configuration checksums generated with an algorithm from the software and hardware information of I / O modules, the distributed automation system can simplify the identification of an I / O module. By directly writing the configuration parameters stored in the I / O module expansion unit into the installed I / O module, the distributed automation system can simplify the setting and replacement of an I / O module. The I / O module expansion unit may also fast detect a hot-swap of an I / O module by wiring to the slots.

Owner:RICHTEK TECH +1

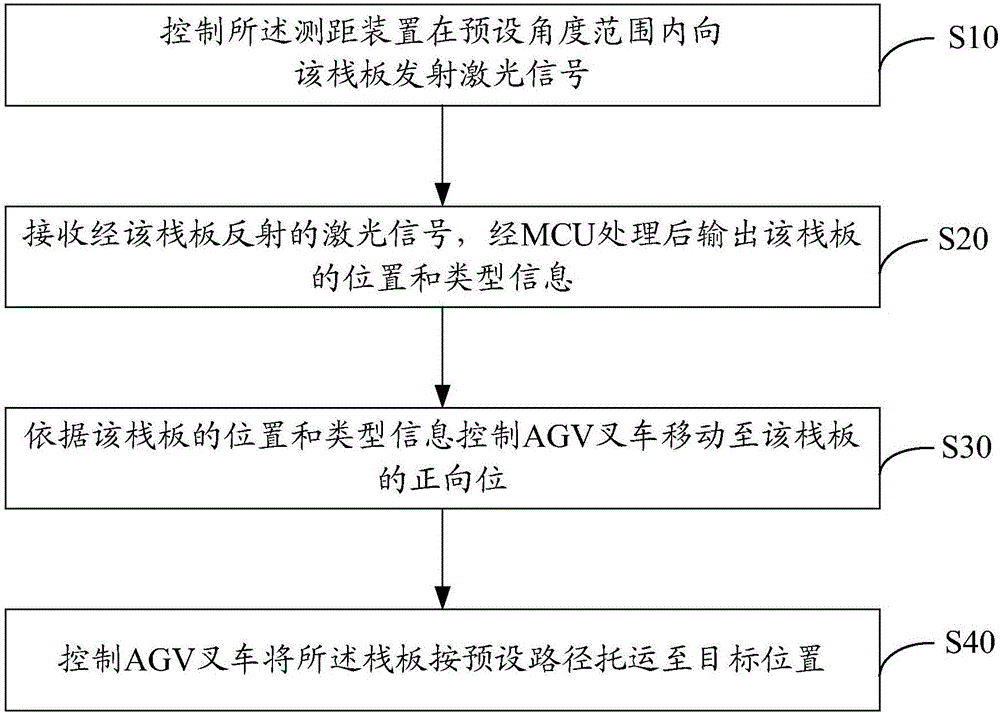

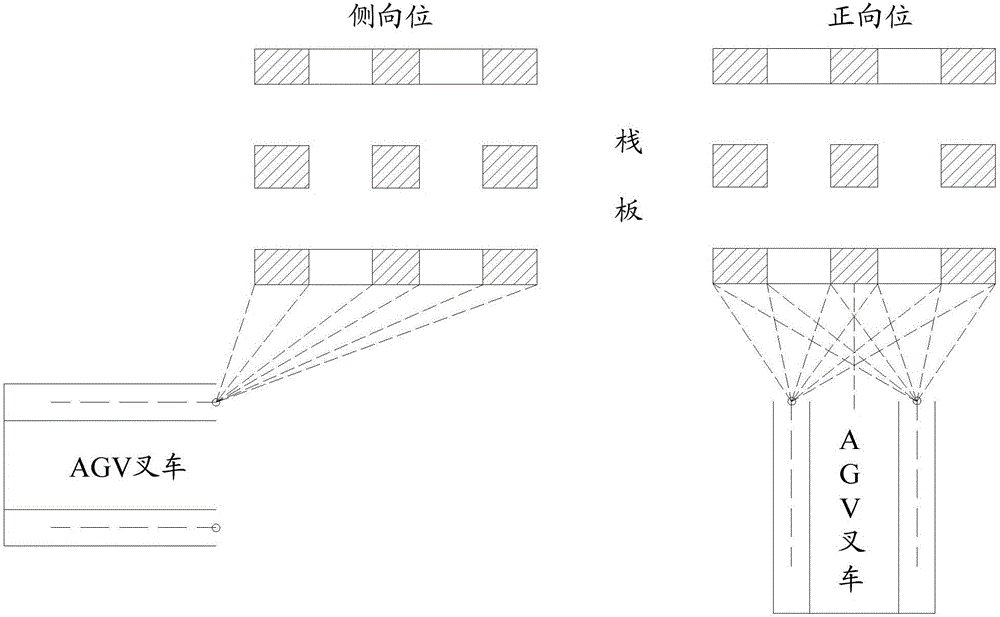

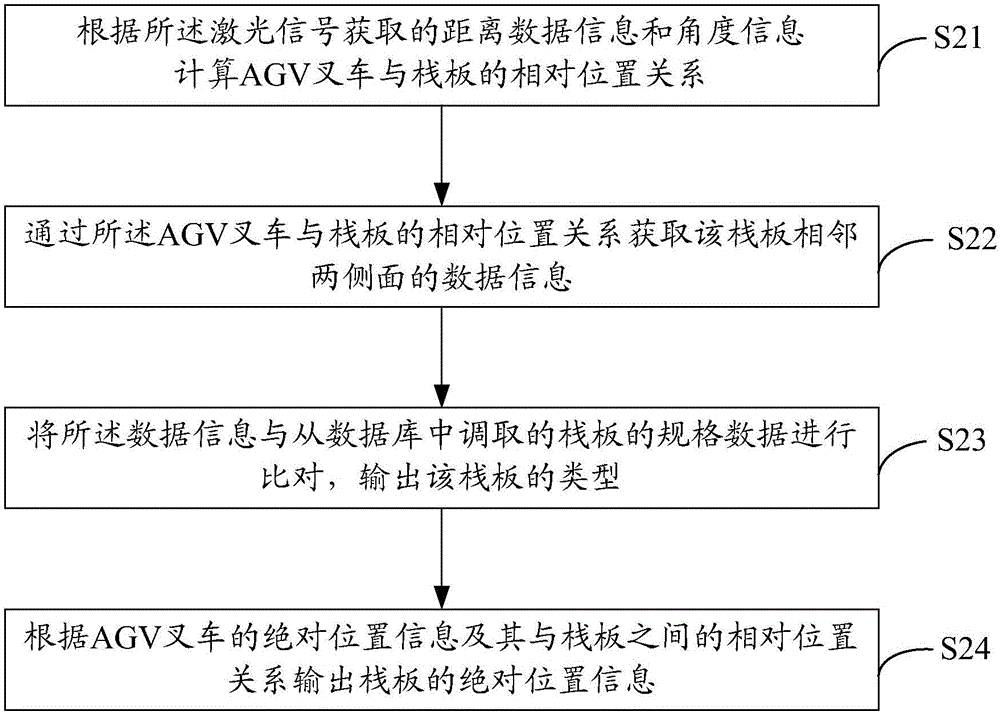

AGV (automated guided vehicle) forklift control method and device and AGV forklift

ActiveCN106671906AAutomation reductionLow costLifting devicesTarget-seeking controlOptoelectronicsAutomated guided vehicle

The invention discloses an AGV (automated guided vehicle) forklift control method and device and an AGV forklift; the AGV forklift is provided with a ranging device for transmitting a laser signal; in use of the control method, the ranging device is controlled to transmit a laser signal to a pallet within a preset angle range, the laser signal is reflected back after touching the pallet, a distance from the ranging device to a pallet touch point can be acquired according to the transmitted laser and the reflected laser, serial data received can be processed by a microprocessor to obtain positional and type information of the pallet, the AGV forklift is controlled to move to a positive position for the pallet, two arms are aligned to two receiving ports of the pallet, the AGV forklift is finally controlled and inserted into the receiving ports to raise the pallet, and the pallet is conveyed to a target position according to a preset path. The automation and intelligence cost of the AGV forklift is reduced, and the AGV forklift is simple to operate and highly practical.

Owner:唐山宏正机械设备有限公司

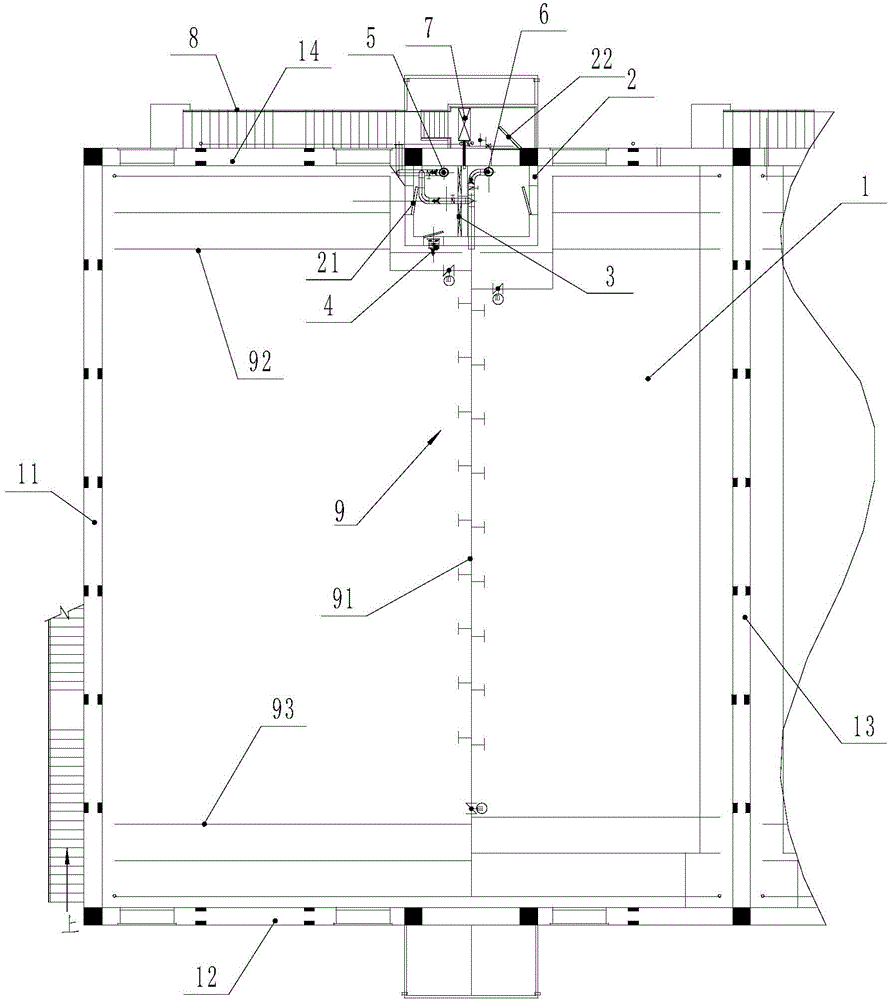

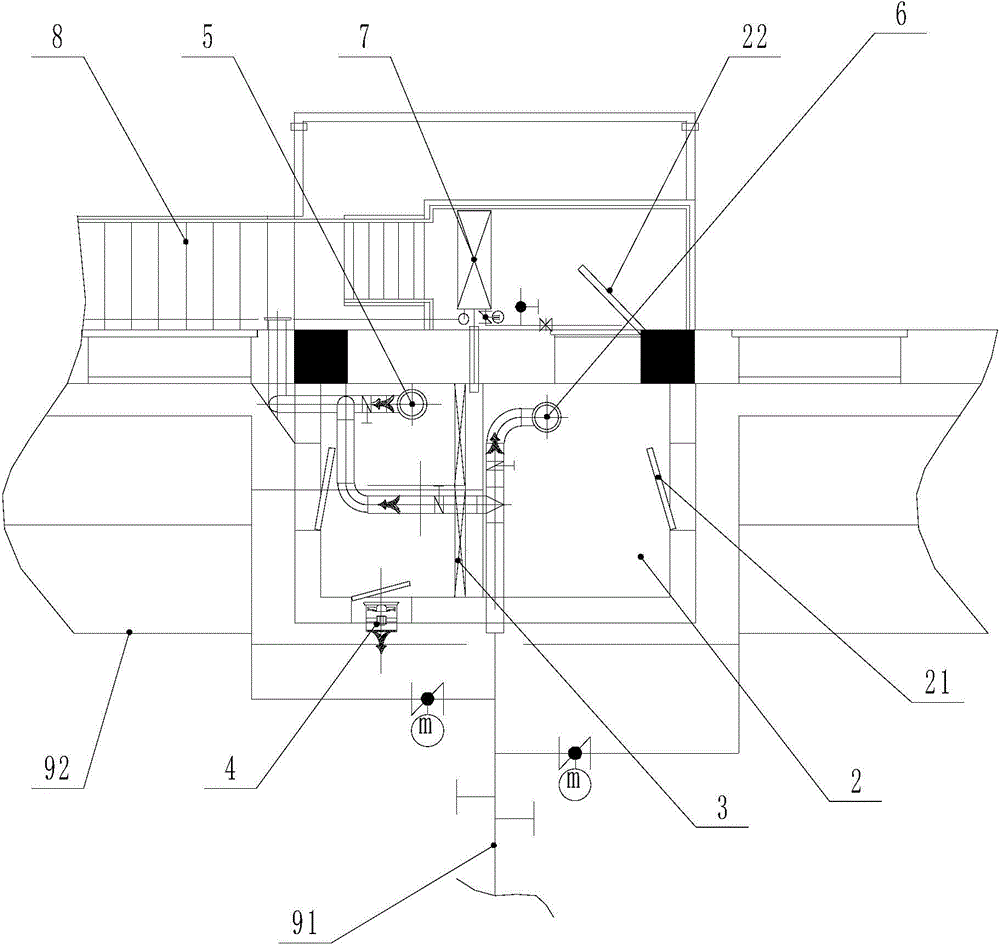

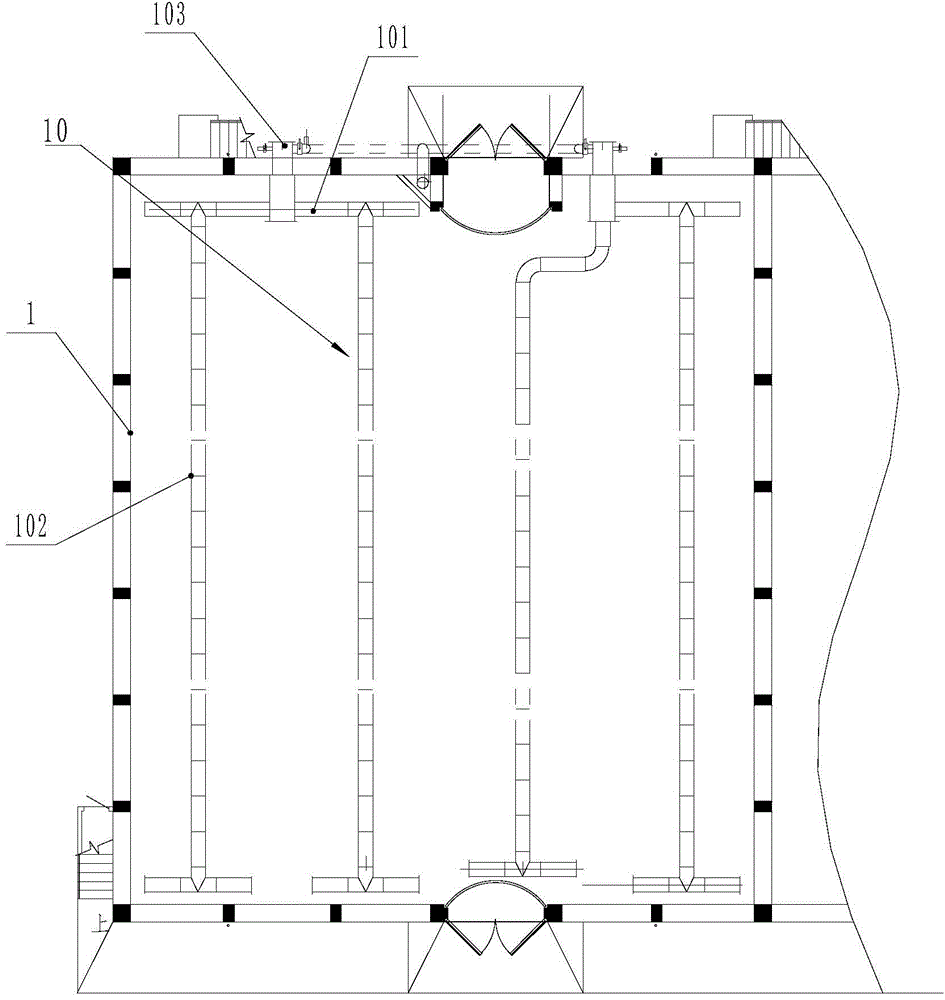

Low-temperature grain storage method for low-temperature barn

InactiveCN104871747AAchieving ventilation circulationReduce energy consumptionAgriculture tools and machinesHarvested fruit hanging devicesPositive pressureAgricultural engineering

The invention discloses a low-temperature grain storage method for a low-temperature barn. A ground cage ventilation pipeline is paved on the ground of the barn; an under-film ventilation pipeline is arranged on the middle part of the barn; grains are piled in the barn in such a manner that a grain pile covers the under-film ventilation pipeline, and a grain mask covers the grain pile; the under-film ventilation pipeline is communicated with a grain pile negative-pressure circulating fan; the ground cage ventilation pipeline is connected with a grain pile positive-pressure circulating fan; when the temperature of air outside the barn is lower than the upper temperature limit value Tmax of grain low-temperature storage, natural air outside the barn is used for cooling; when the temperature outside the barn is higher than the upper temperature limit value Tmax of grain low-temperature storage, a refrigeration room is used for refrigerating in order that the temperature in the refrigeration room is lower than the Tmax, low-temperature air is supplied into the grain pile through the ground cage ventilation pipeline, and the low-temperature air flows through the under-film ventilation pipeline from bottom to top and enters the refrigeration room to be circulated continually. By adopting the low-temperature grain storage method, the low-temperature barn can be refrigerated more intelligently, the existing barn cooling machine is replaced, the refrigeration efficiency is increased, and the energy consumption is lowered.

Owner:ZHANGJIAGANG SHUANGLING REFRIGERATION EQUIP CO LTD

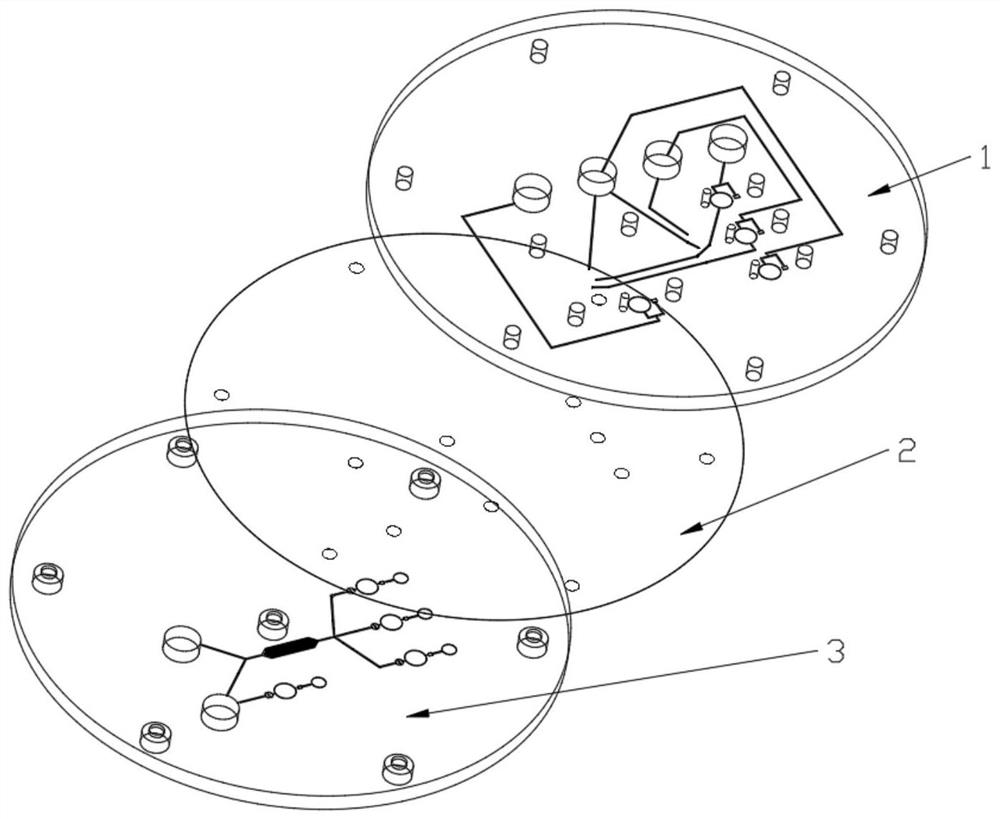

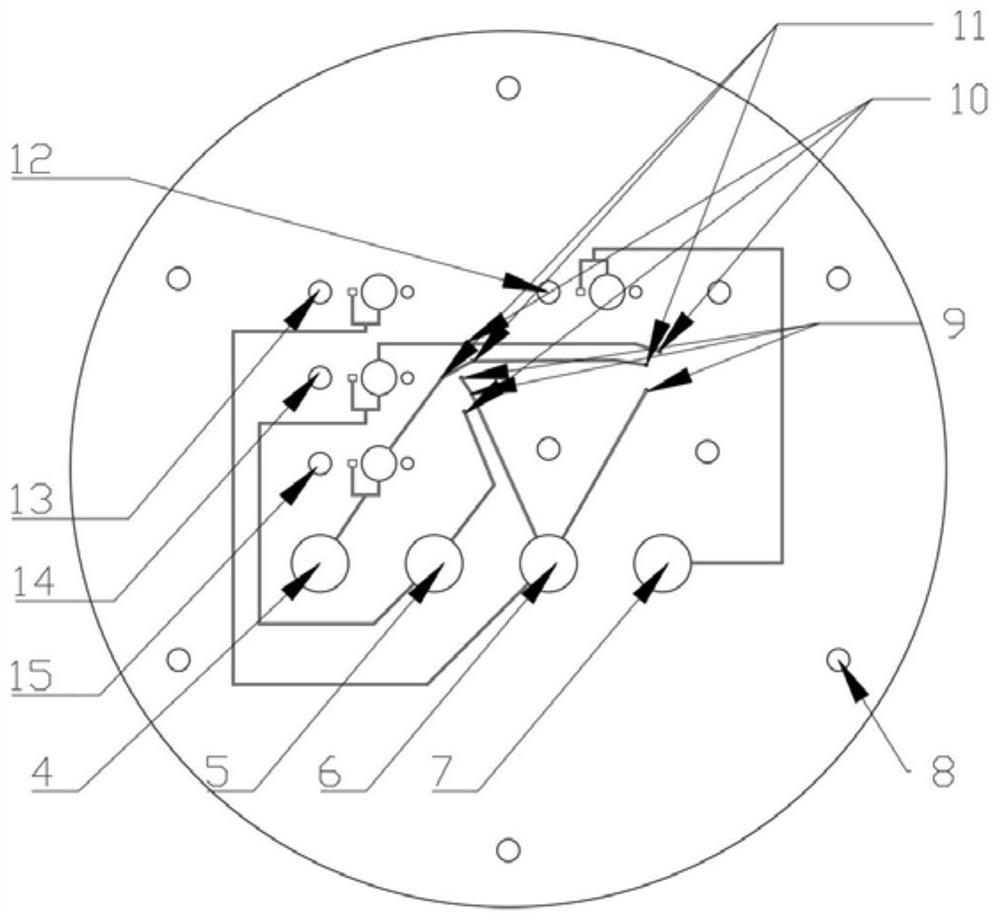

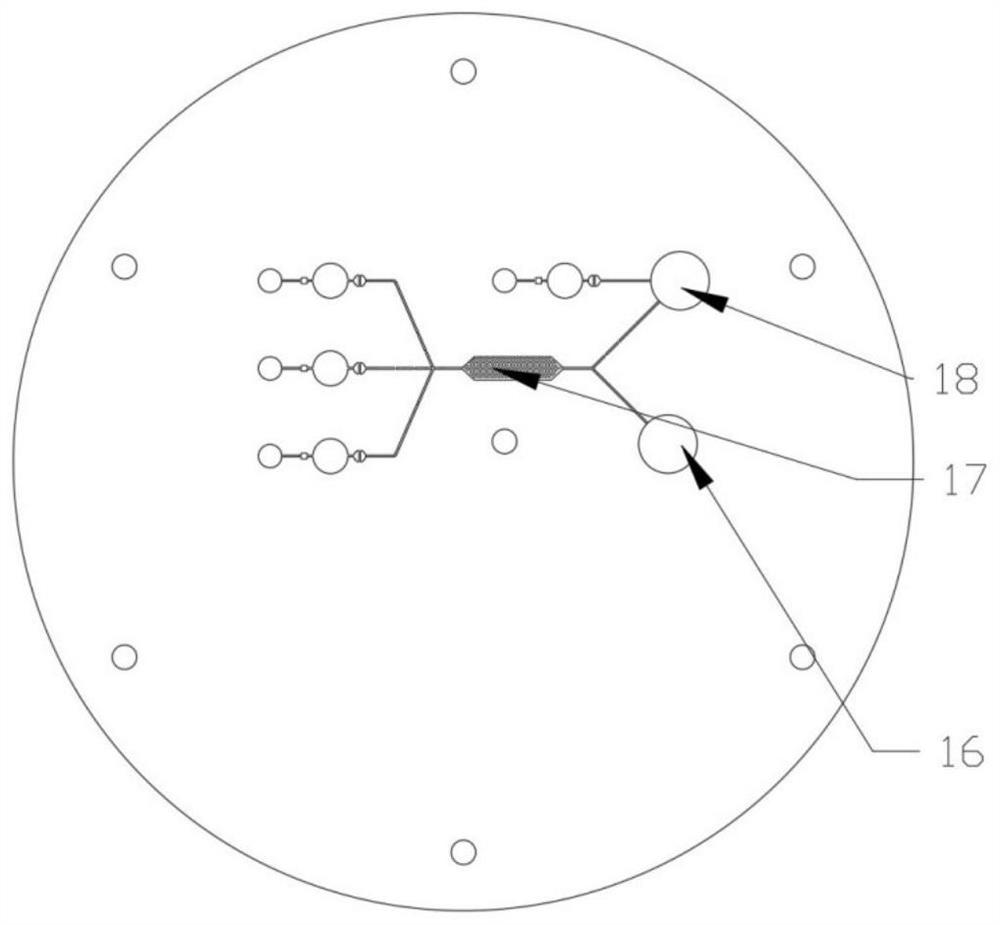

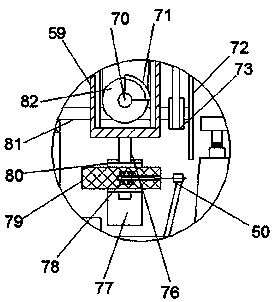

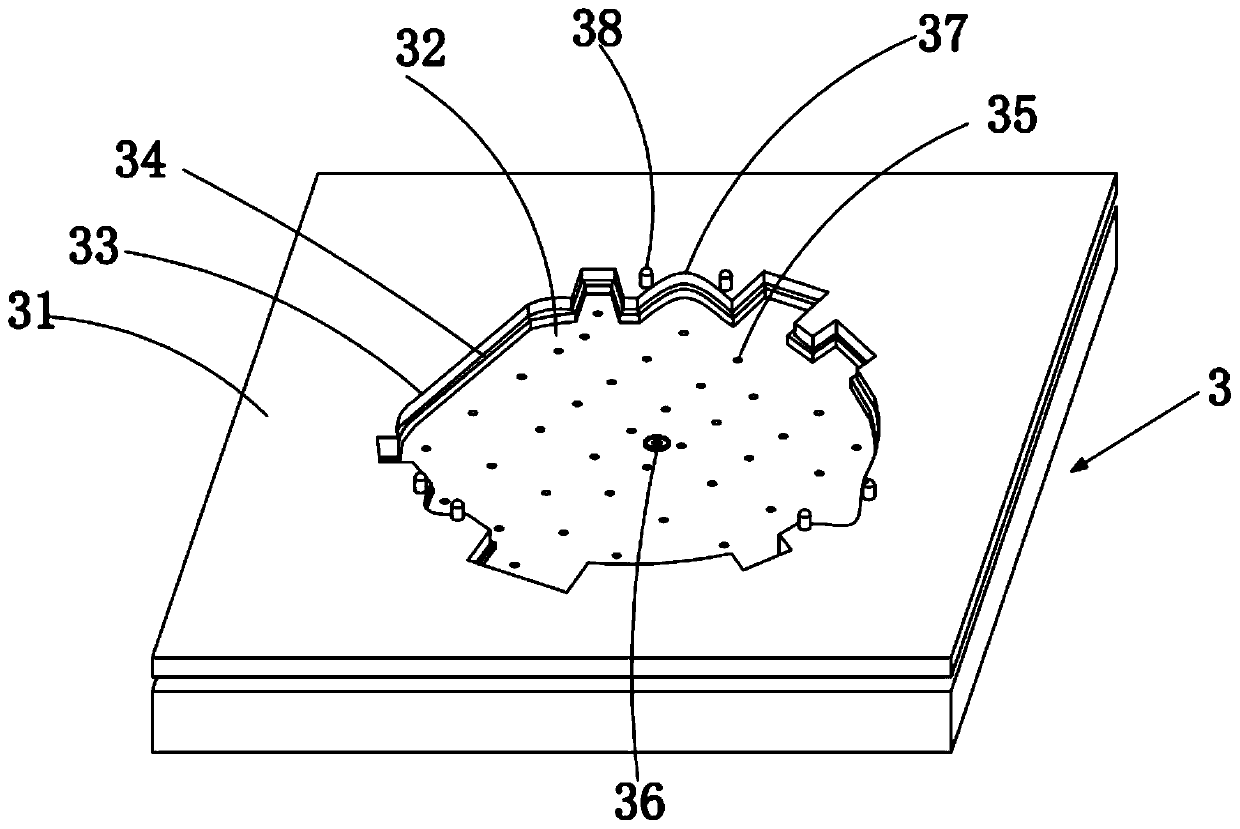

Micro fluidic chip for nucleic acid detection

ActiveCN112195099AConvenient amountConvenient and accurate dosageBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acid detectionLiquid storage tank

The invention discloses a micro fluidic chip for nucleic acid detection use. The micro fluidic chip for the nucleic acid detection use comprises an air passage layer, an interface layer, and a flow passage layer; the air passage layer consists of buttons one to four as well as air passages thereof, a reaction liquid storage tank, an eluent storage tank, a cleaning liquid storage tank, and a sampleliquid storage tank; the interface layer is an elastic film; the flow passage layer consists of a waste liquid tank, a nucleic acid purification and concentration chamber, a reaction chamber, and a plurality of flow passages; the reaction liquid storage tank, the eluent storage tank, the cleaning liquid storage tank and the sample liquid storage tank are respectively connected with flow passagesone to four on the flow passage layer via through holes in the film; four micro pumps are separately arranged on the flow passages one to four; the flow passages one to three are connected with an inlet of the nucleic acid purification and concentration chamber; the nucleic acid purification and concentration chamber is separately connected with the waste liquid tank and the reaction chamber through flow passages five to six; the reaction liquid storage tank is connected with the reaction chamber through the flow passage four; the buttons one to four are respectively connected with the micro pumps through the air passages; and liquid is pumped out of the liquid storage tank through the corresponding micro pumps when being pressed, thereby realizing quantitative flow of liquid.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

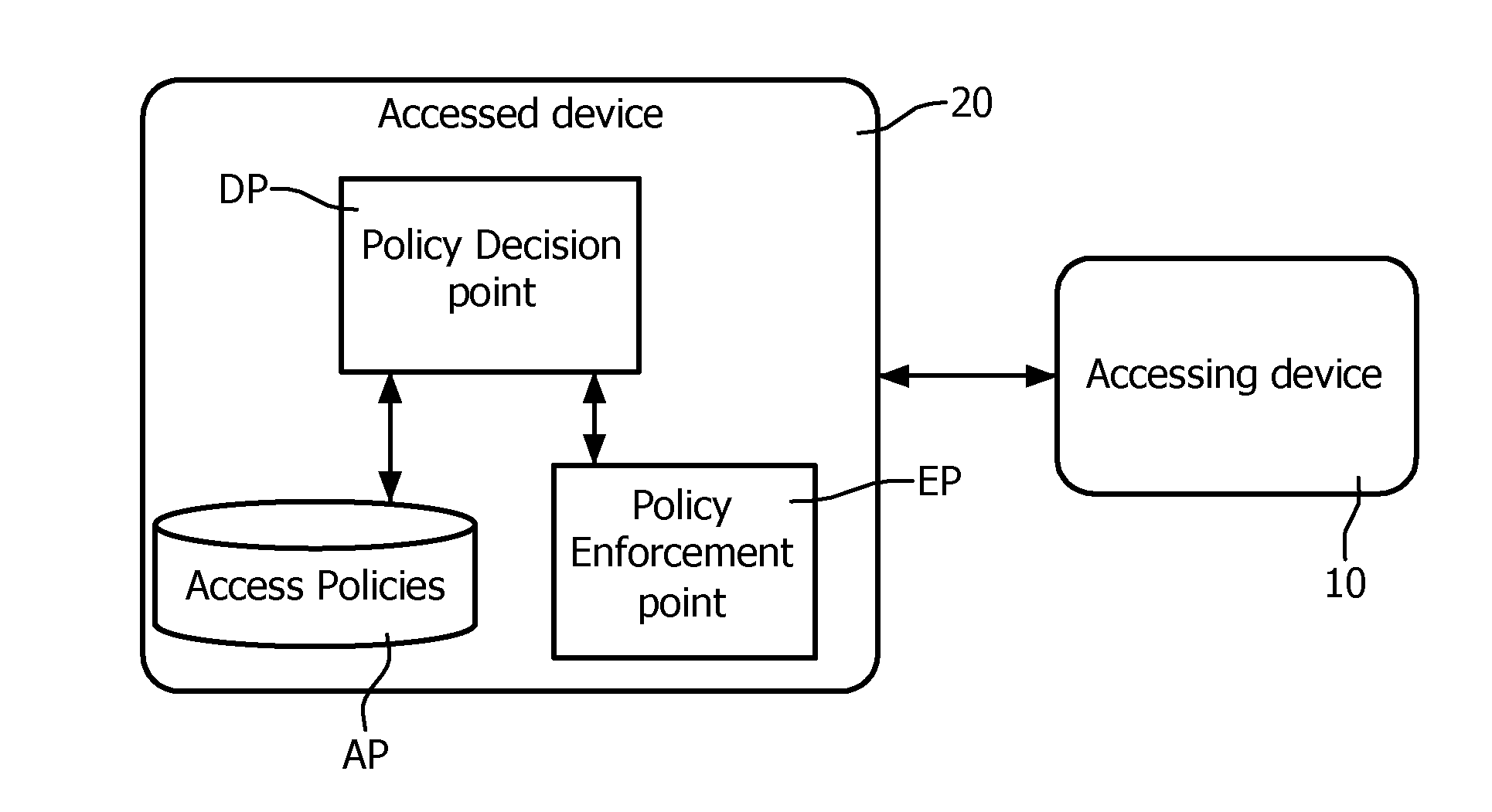

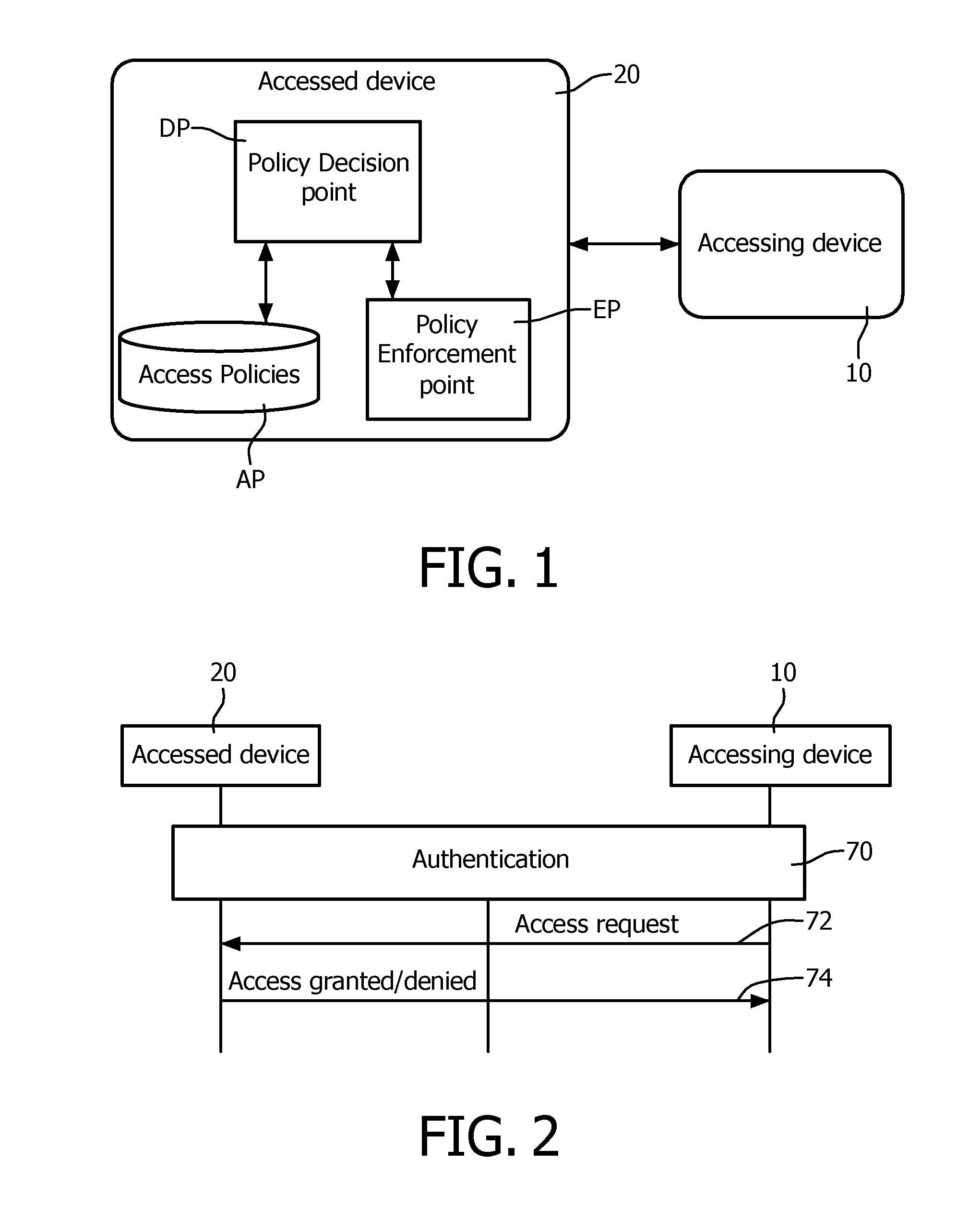

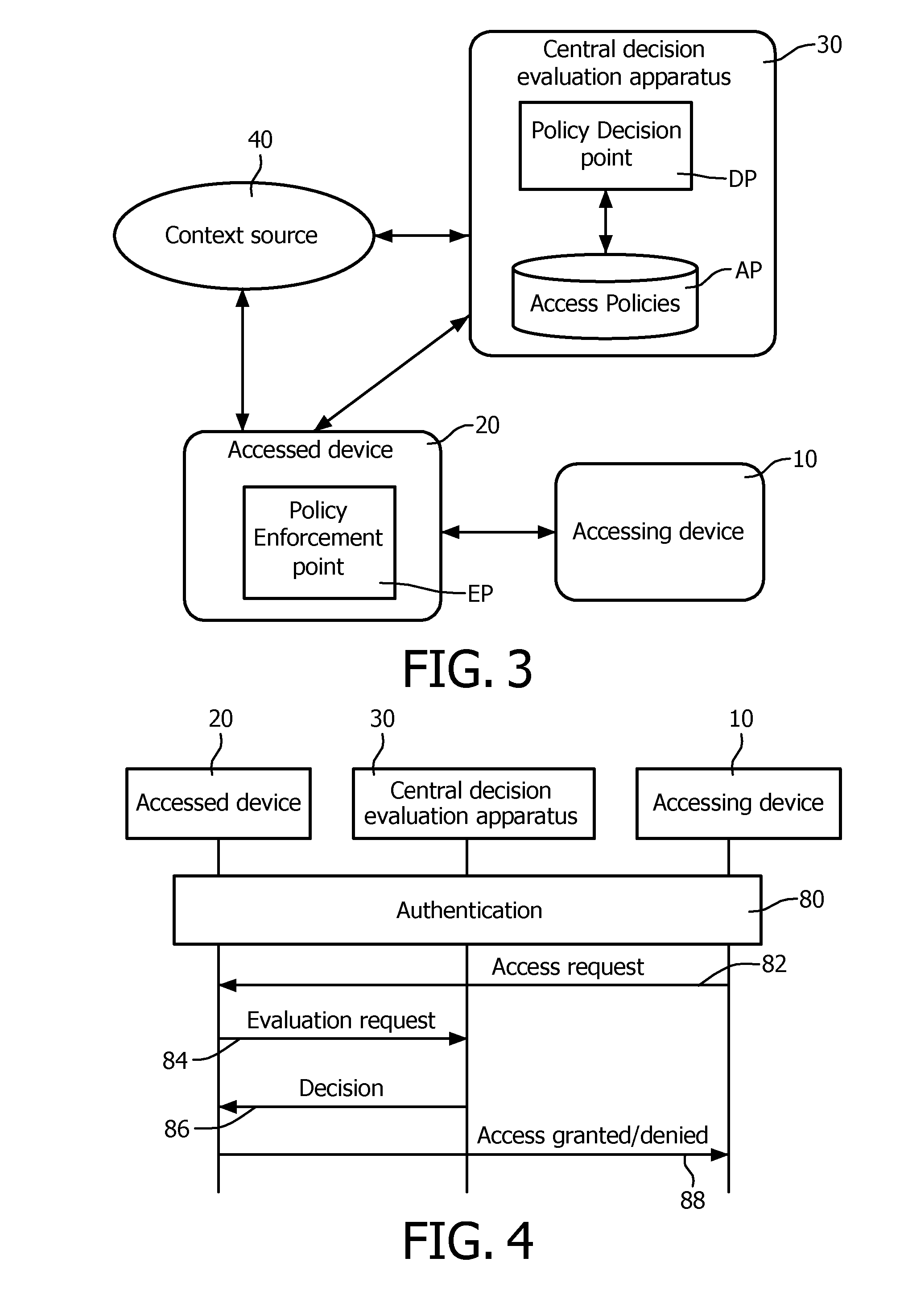

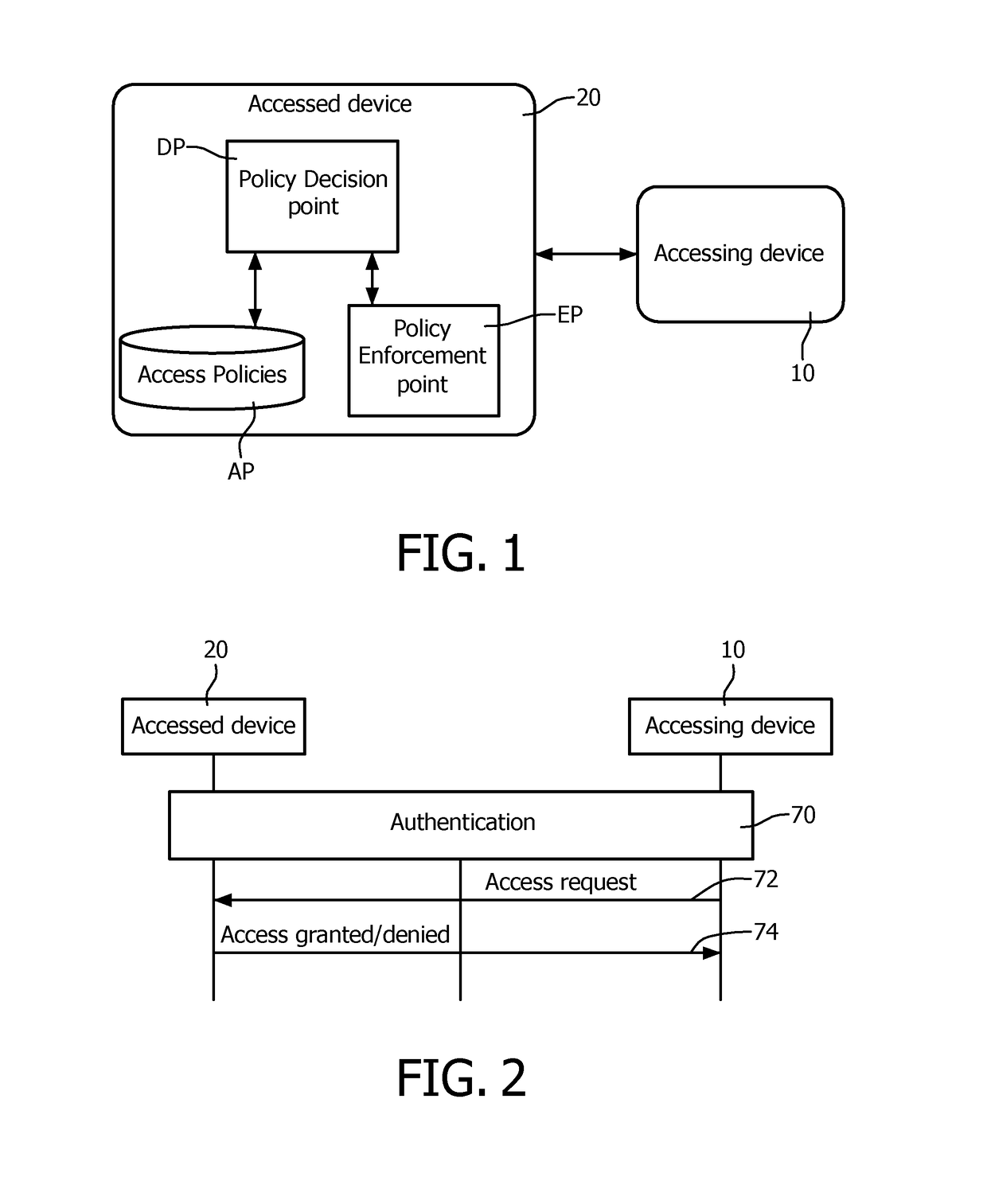

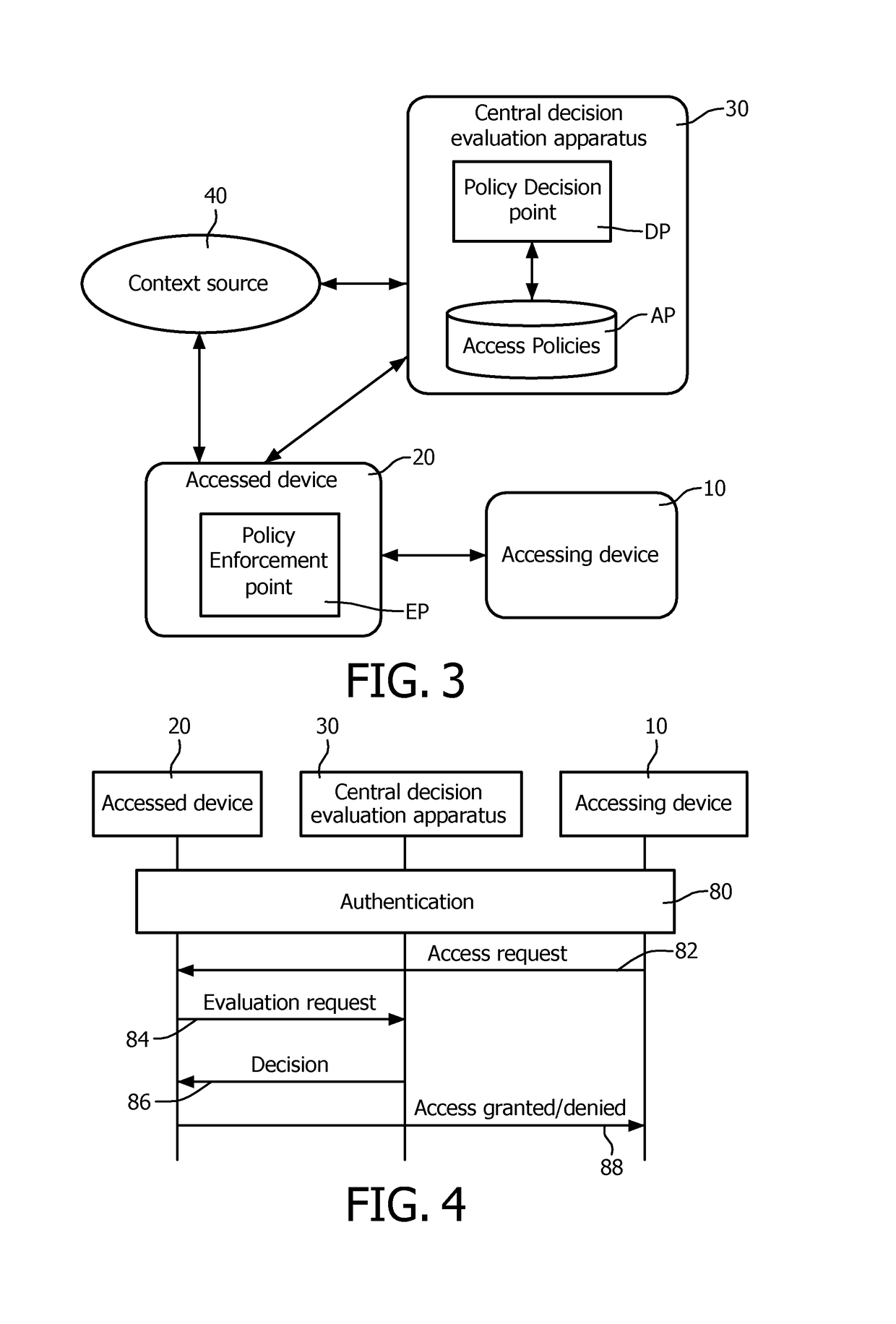

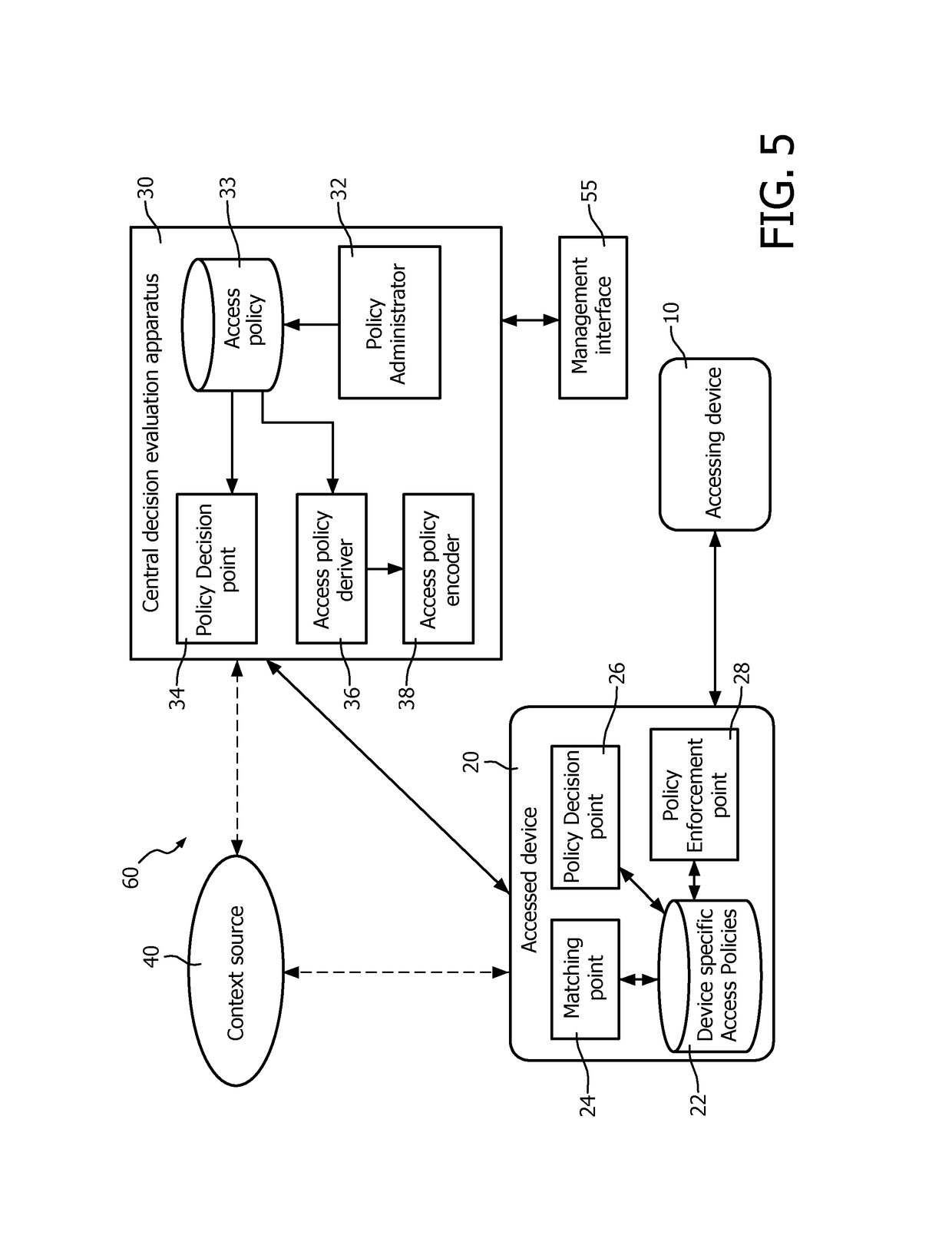

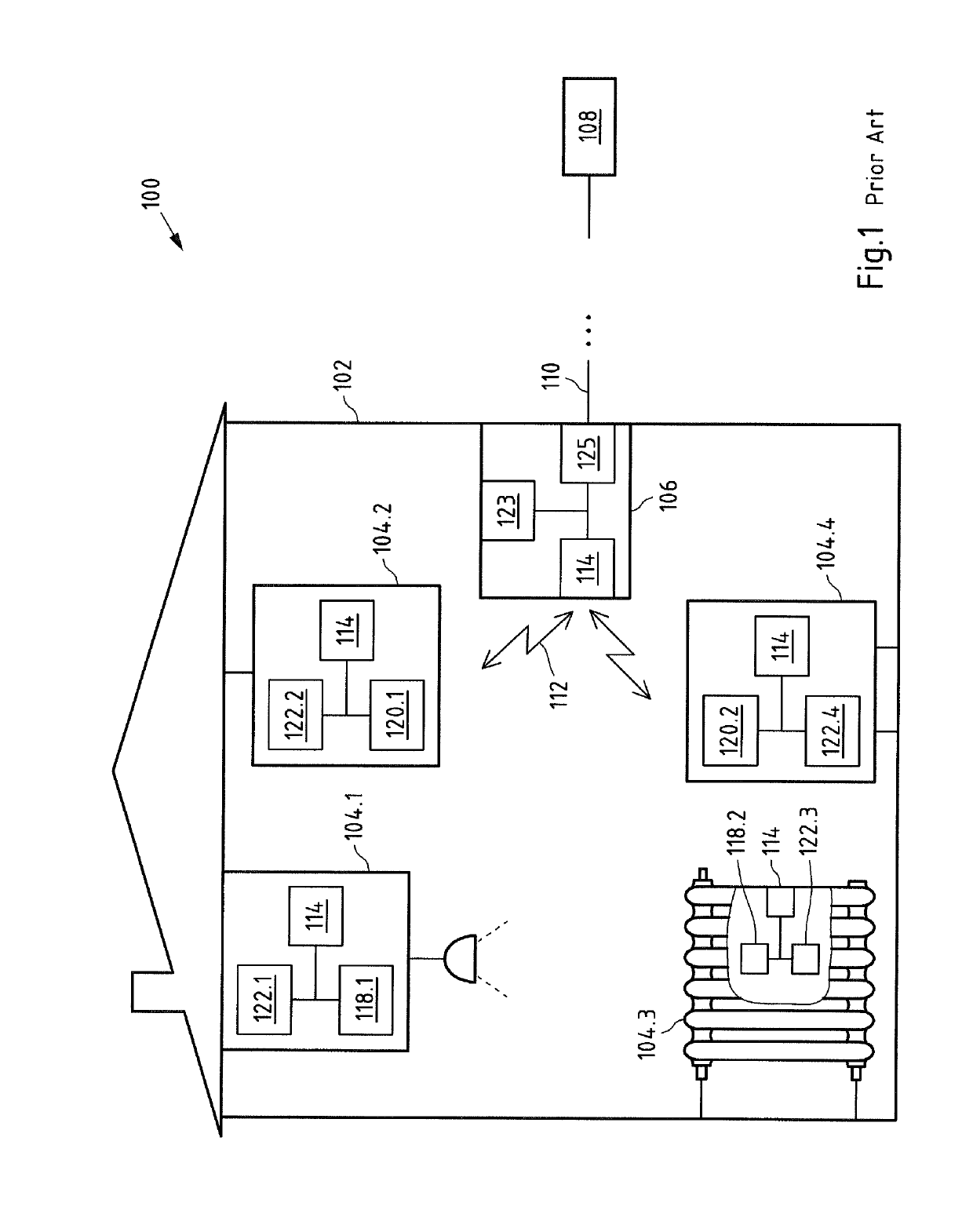

System and method for access decision evaluation for building automation and control systems

ActiveUS20160139573A1Reduce the amount requiredMinimize accessProgramme controlSampled-variable control systemsControl systemBuilding automation

The present invention relates to a method for access decision evaluation in a building automation and control system, the method comprising: sending, from an accessing device (10) to an accessed device (20), an access request, sending, from the accessed device (20) to a central decision evaluation apparatus (30), an evaluation request asking if the access request is granted or denied, evaluating, at the central decision evaluation apparatus (30), the evaluation request using one or more central access control policies in order to reach a decision on if the access request is granted or denied, deriving, at the central decision evaluation apparatus (30), the one or more central access control policies that was used for evaluation into a device specific access policy, sending, from the central decision evaluation apparatus (30) to the accessed device (20), the decision and the device specific access policy, and storing, at the accessed device (20), the device specific access policy.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

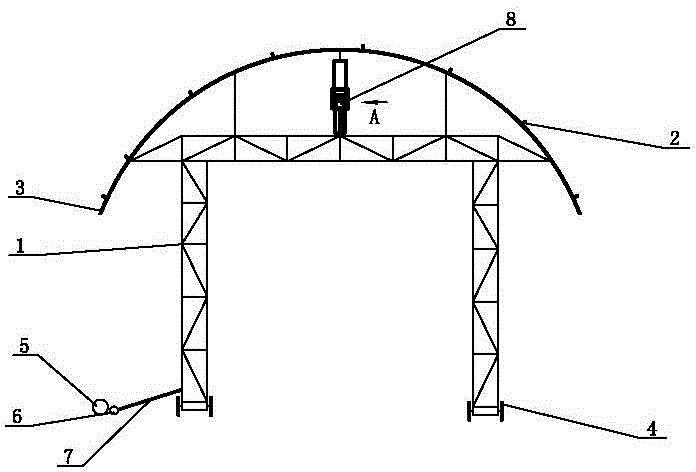

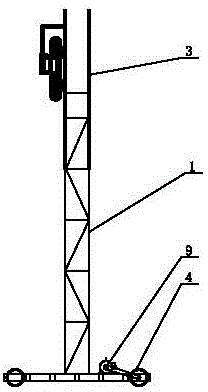

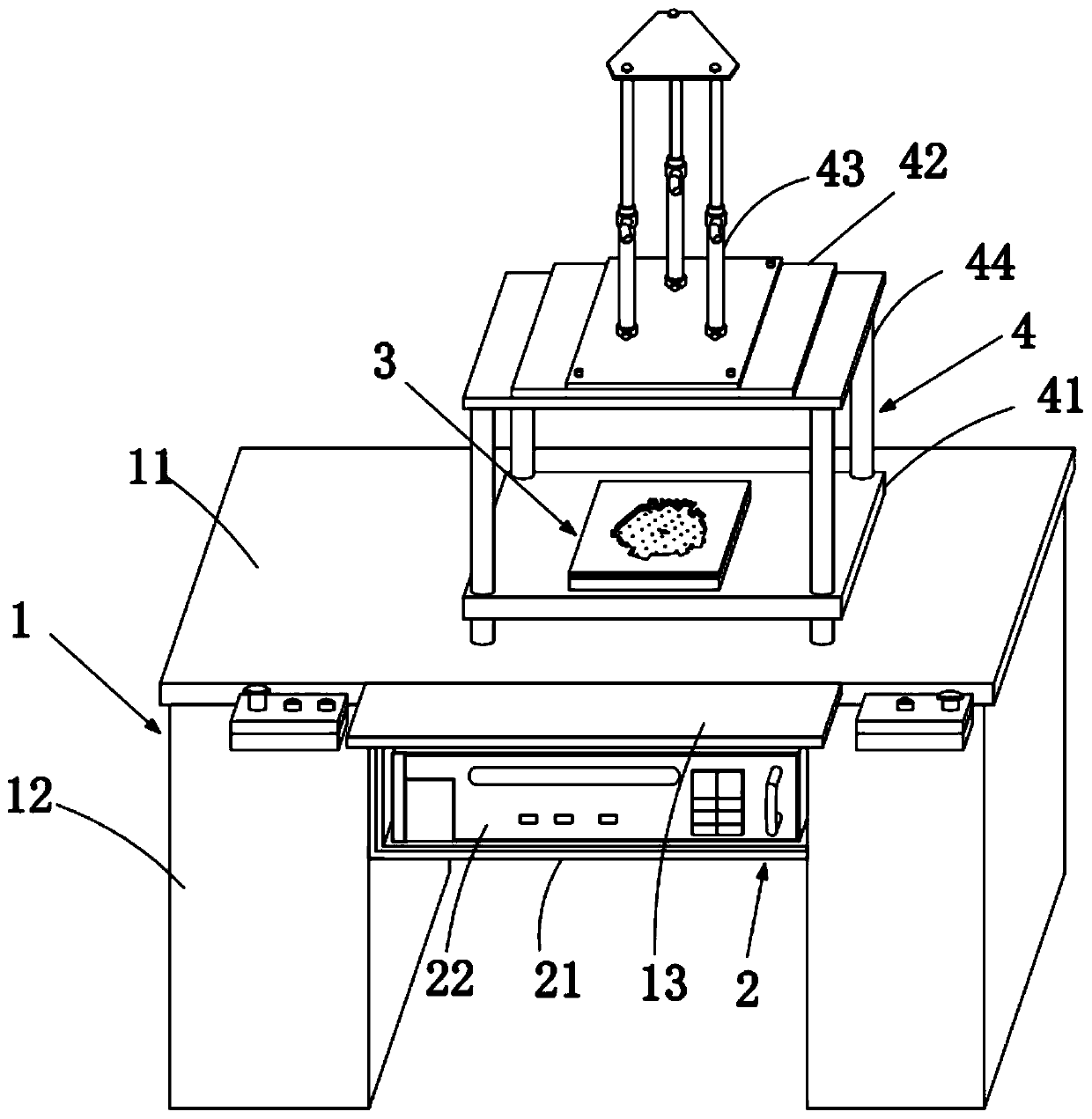

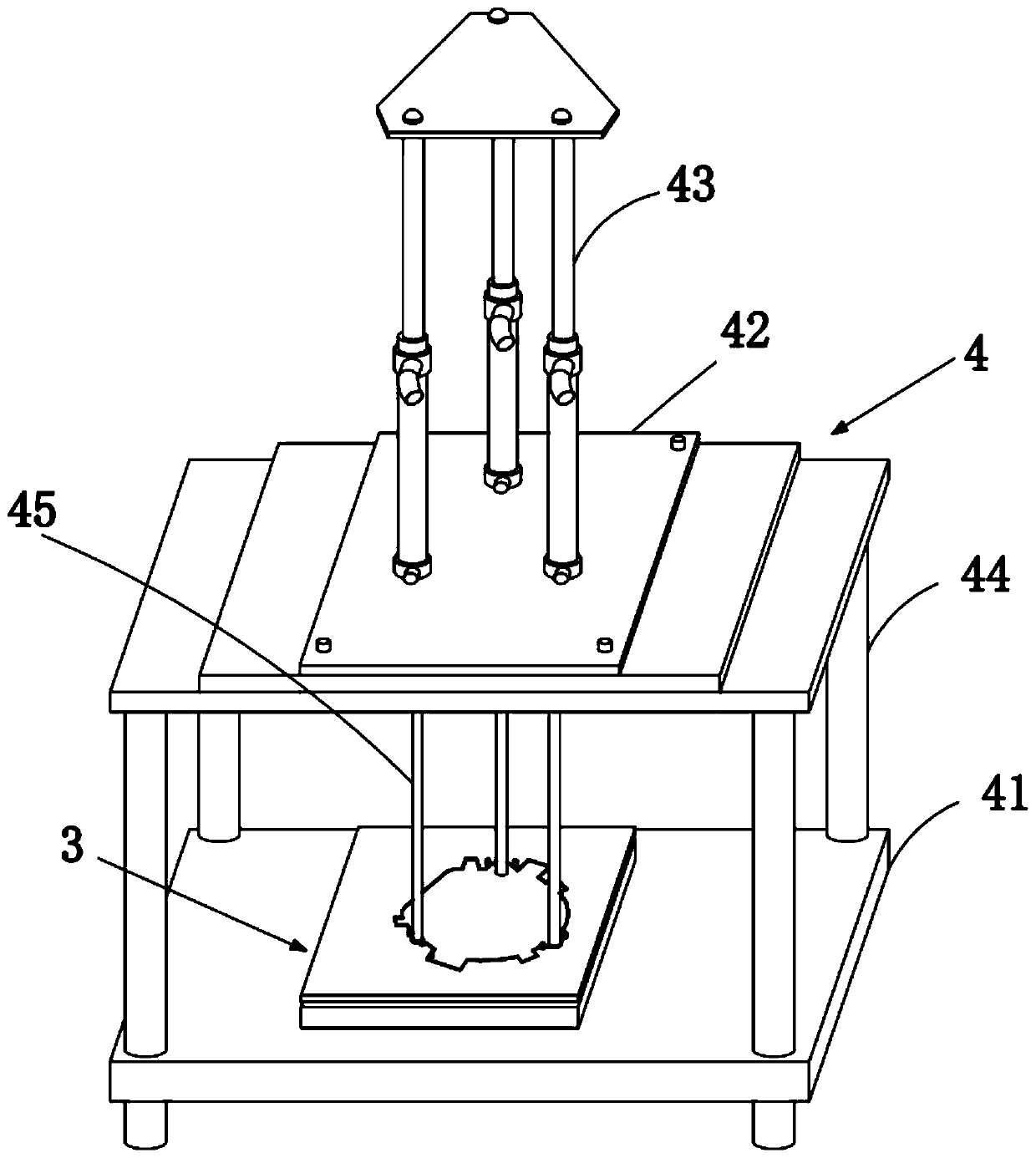

Full-automatic tunnel concrete lining maintenance device and use method thereof

ActiveCN104975862AAchieve crackReduce crackingMining devicesUnderground chambersAutomatic controlAtomizer nozzle

The invention provides a full-automatic tunnel concrete lining maintenance device comprising a maintenance rack, a controller, a water spraying device and a power distribution box. The water spraying device is composed of a pressurizing pump, two rows of arc water spraying pipes and atomizing nozzles. The lower portion of the maintenance rack is provided with a walking device and the controller. The upper portion of the maintenance rack is provided with the two rows of parallel arc water spraying pipes. The full-automatic tunnel concrete lining maintenance device is easy to operate, achieves automatic maintenance, can automatically walk and spray water and effectively reduces cracks on the surface of lining concrete, the walking speed of the full-autonomous tunnel concrete lining maintenance device can be automatically controlled through a remote controller, the strength and the durability of a concrete lining are guaranteed, and indirect economic benefits are generated; the full-automatic tunnel concrete lining maintenance device is suitable for maintenance of all kinds of tunnel lining concrete, improves construction efficiency, lowers the maintenance process cost, improves the appearance quality of concrete, purifies air in a tunnel, and shortens ventilation time. Remarkable economic benefits are created for construction. The full-automatic tunnel concrete lining maintenance device further has the advantages of being simple and compact in structure, low in manufacturing cost and easy and convenient to use.

Owner:CHINA RAILWAY SHISIJU GROUP CORP +2

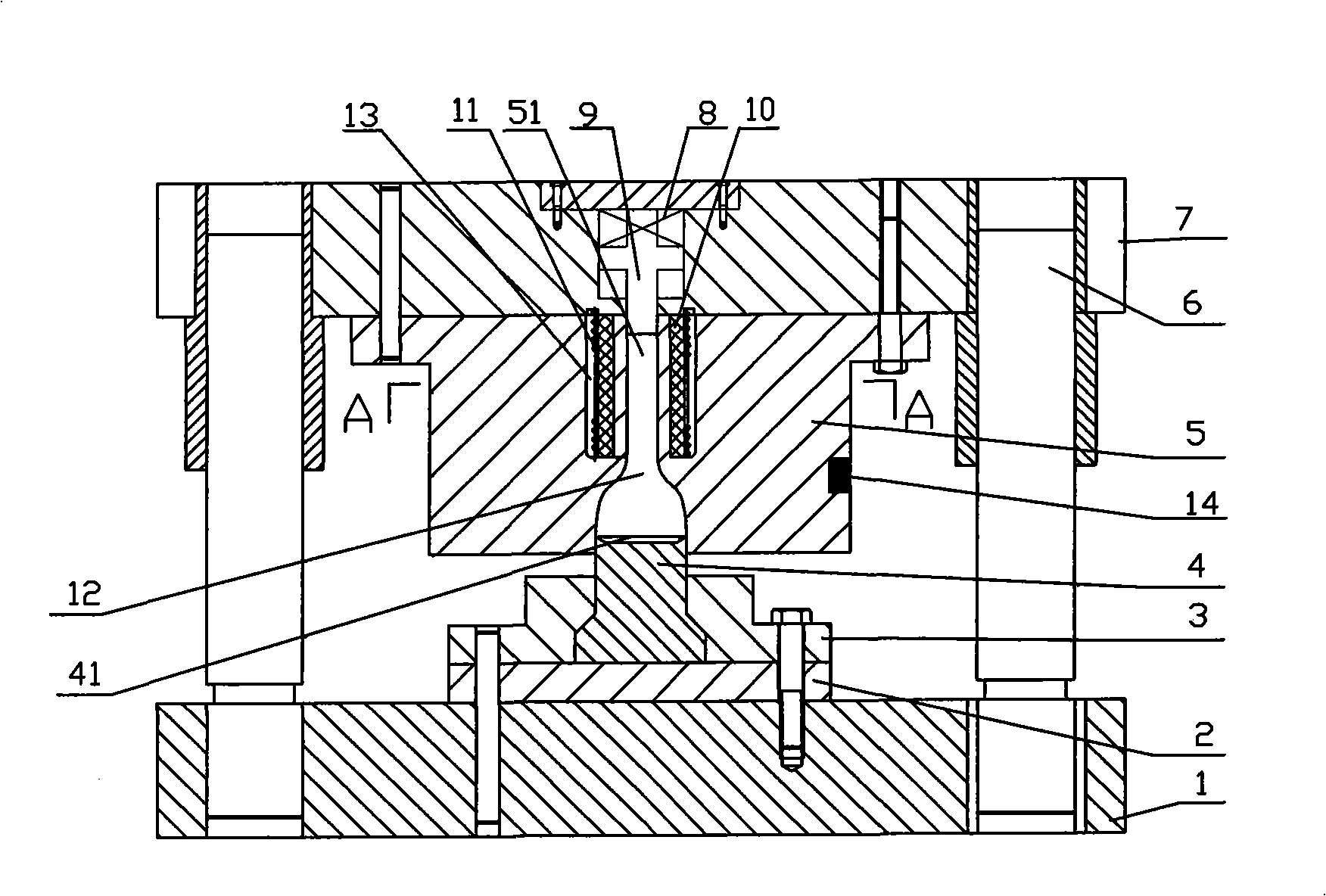

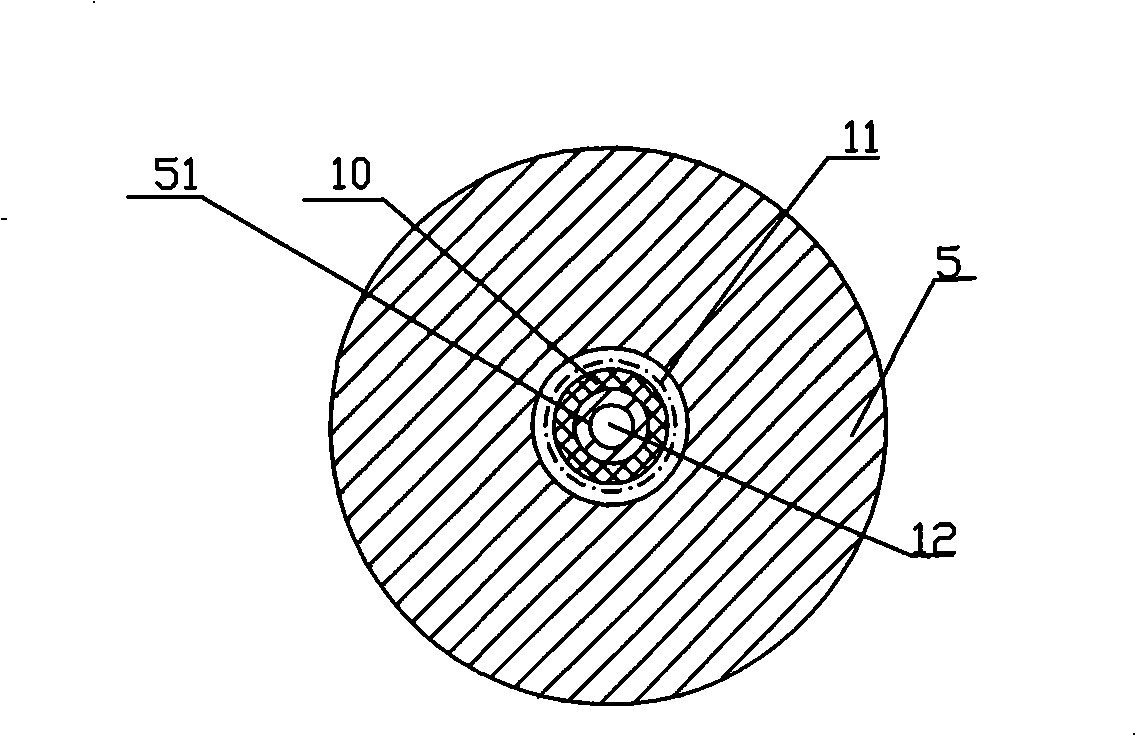

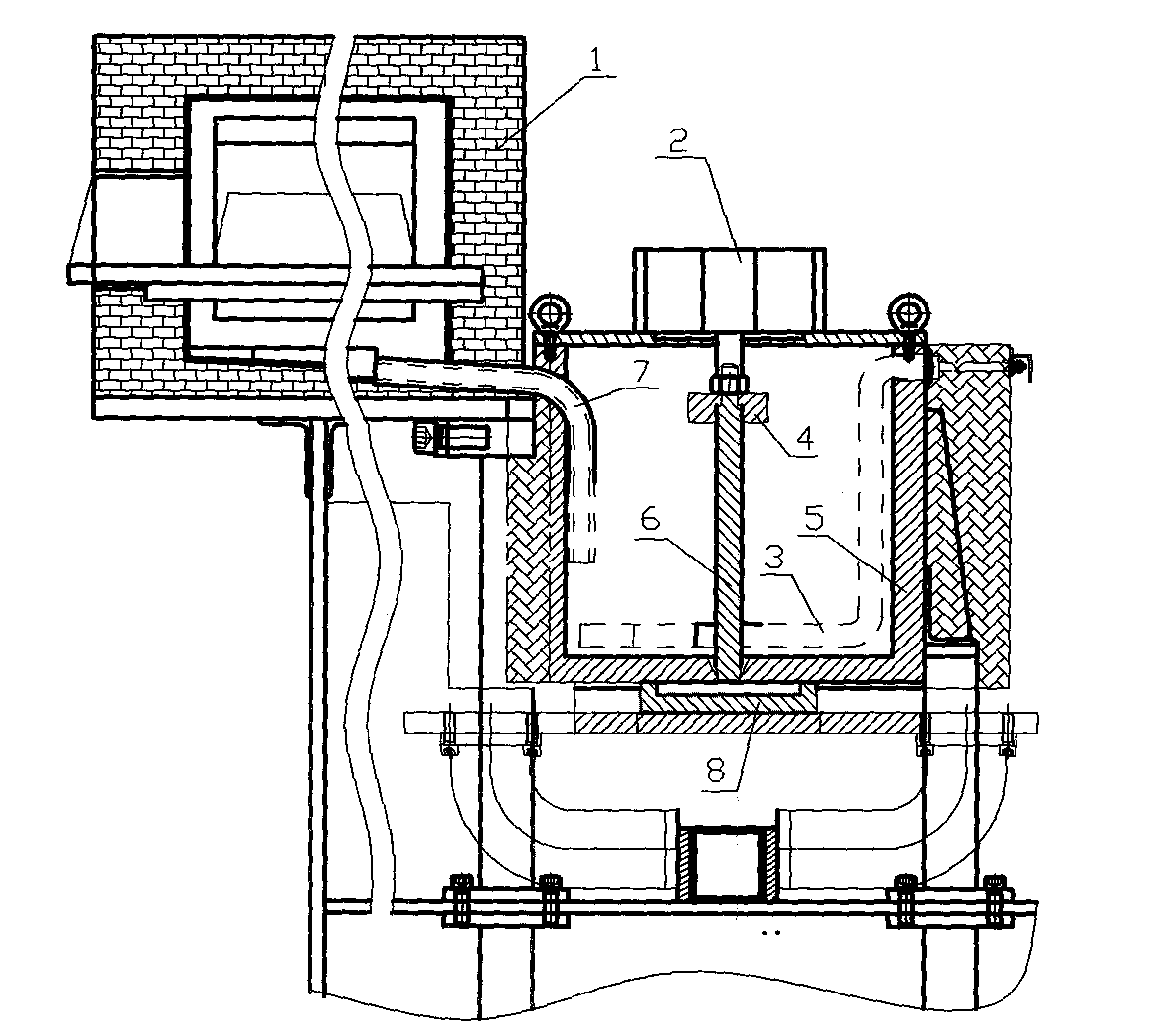

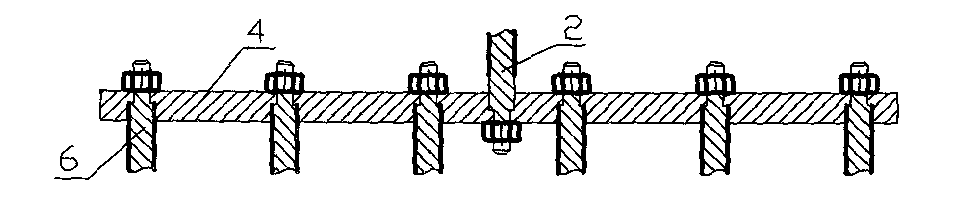

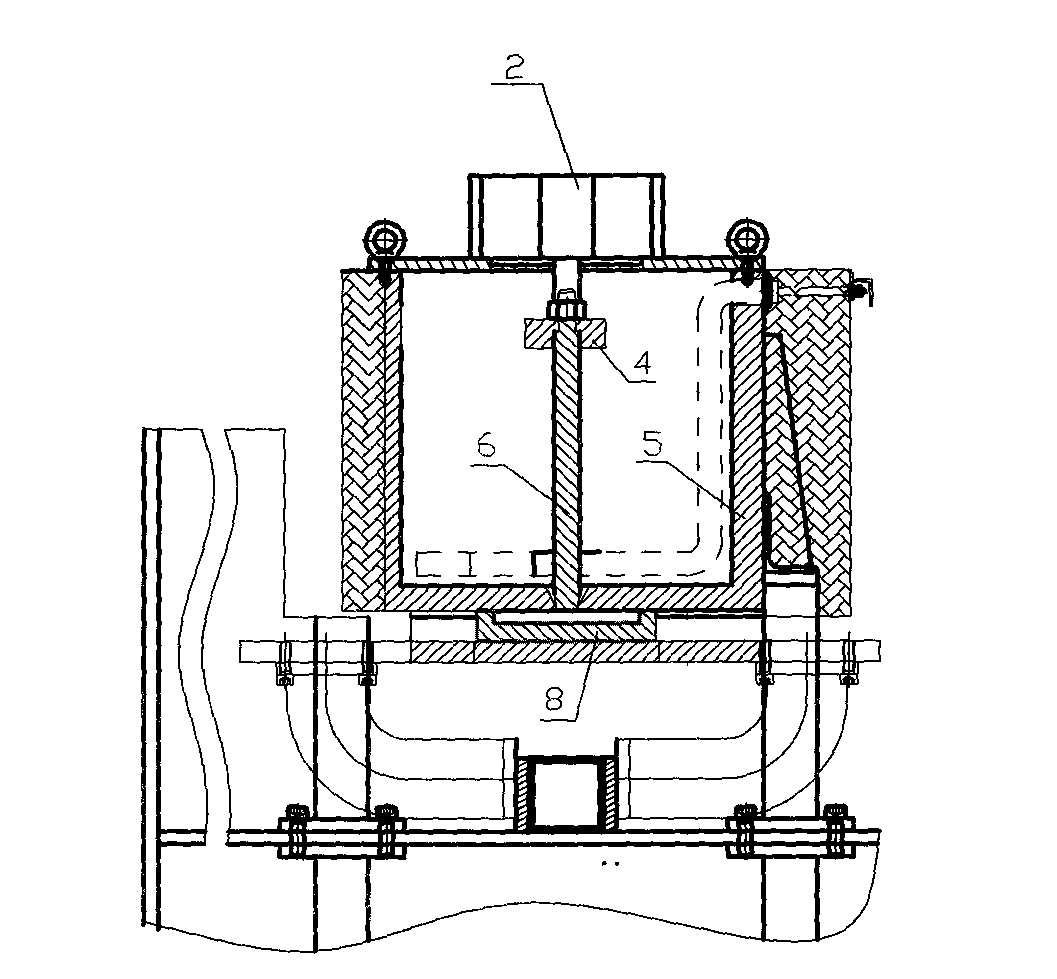

Method for low-pressure casting thin-wall long-sized castings and equipment used by same

The invention relates to a method for low-pressure casting thin-wall long-sized castings and equipment used by the same, wherein metal materials are firstly smelted, a furnace body is closed, a mould is prepared, dry compressed air is filled into an airtight container, under the action of gas pressure, liquid metal rises along a multitube and multi-sprue riser tube and stably enters a mould cavity through a sprue, and the gas pressure on the liquid level in a crucible is kept; and after the casting is completely solidified, the gas pressure on the liquid level is relieved to enable the unsolidified liquid metal in the riser tube to flow back into the crucible, and then the casting is taken out. The method for producing the thin-wall long-sized casting has the advantages that mold-filling is stable, a product is well molded, the mold-filling of liquid metal is carried out under the pressure, the liquid metal has good liquidity and is convenient to cast the thin-wall casting of the kind the casting is crystallized and solidified under the pressure and has a compact structure, so the mechanical property is improved, a pouring system is simple, casting heads are reduced, mechanization and automation are realized, the labor intensity of workers is reduced, a mould with multi-cavities is realized, the production efficiency is improved and the like.

Owner:烟台路通精密科技股份有限公司

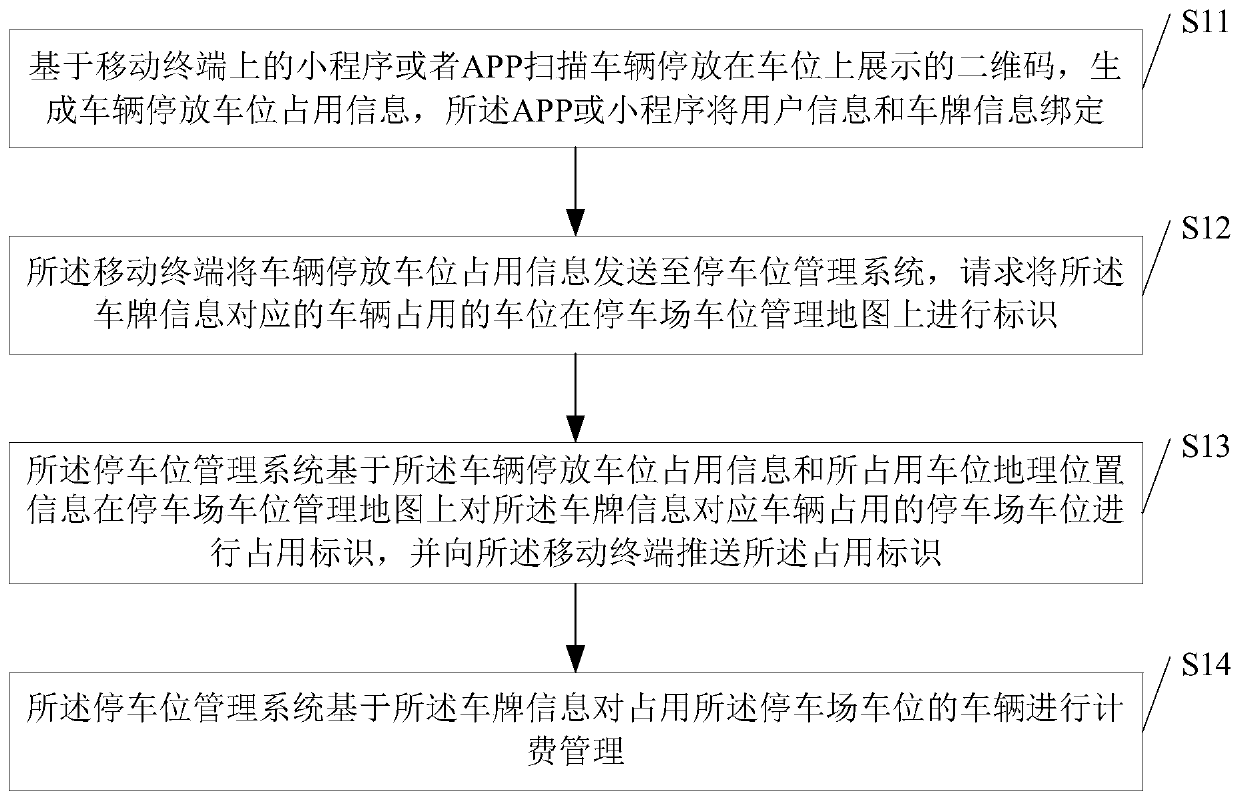

Parking space management method based on parking space 2D code identification

InactiveCN110136474ARealize remote managementEasy to findTicket-issuing apparatusIndication of parksing free spacesParking areaParking space

The invention discloses a parking space management method based on parking space 2D code identification. The method comprises steps of: scanning a 2D code shown in a vehicle parking space based on anapplet on a mobile terminal or an APP, and generating occupation information of the vehicle parking space; and sending the occupation information of the vehicle parking space to a parking space management system, and requesting to mark a parking space used by a vehicle corresponding to license plate information on a parking lot parking space management map; and marking, by the parking space management system based on the occupation information of the vehicle parking space and geographical position information of the used parking space, the parking space used by the vehicle corresponding to thelicense plate information on the parking lot parking space management map, and sending an occupation marker to the mobile terminal; and charging the vehicle using the parking space of the parking lotby the parking space management system based on the license plate information. Through adoption of the method, the user spends less time in searching the vehicle in the parking lot, the parking lot is managed in a manner of 2D code, and the management cost is saved.

Owner:舒维黎

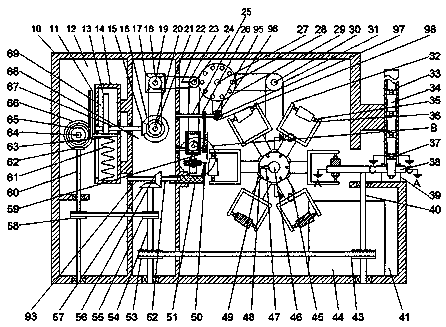

Automobile out star wheel isothermal extrusion preliminary shaping device

InactiveCN101264489AReduce temperature gradientReduce lossExtrusion diesPass rateMechanical engineering

The invention discloses a pre-forming device of automobile external star wheel by isothermal extrusion, which comprises a punch and a female die, the punch and the female die are laterally fixed and vertically movably matched by means of a guide pillar. The female die is provided with a die cavity, and a heating device is arranged at the periphery of the die cavity. The heating unit is arranged at the die cavity of the invention to maintain the outer layer temperature of the mold. The pre-forming device has the advantages of greatly reducing the geothermal gradient of blank and mold, effectively lessening the thermal dispersion of blank in the forming process, achieving the extrusion pre-forming under the isothermal condition, avoiding the situation that the die cavity can not be filled due to excessively fast temperature drop, material deformation and resistance increase, thus improving the pass rate of finished products, and reducing waste.

Owner:CHONGQING UNIV

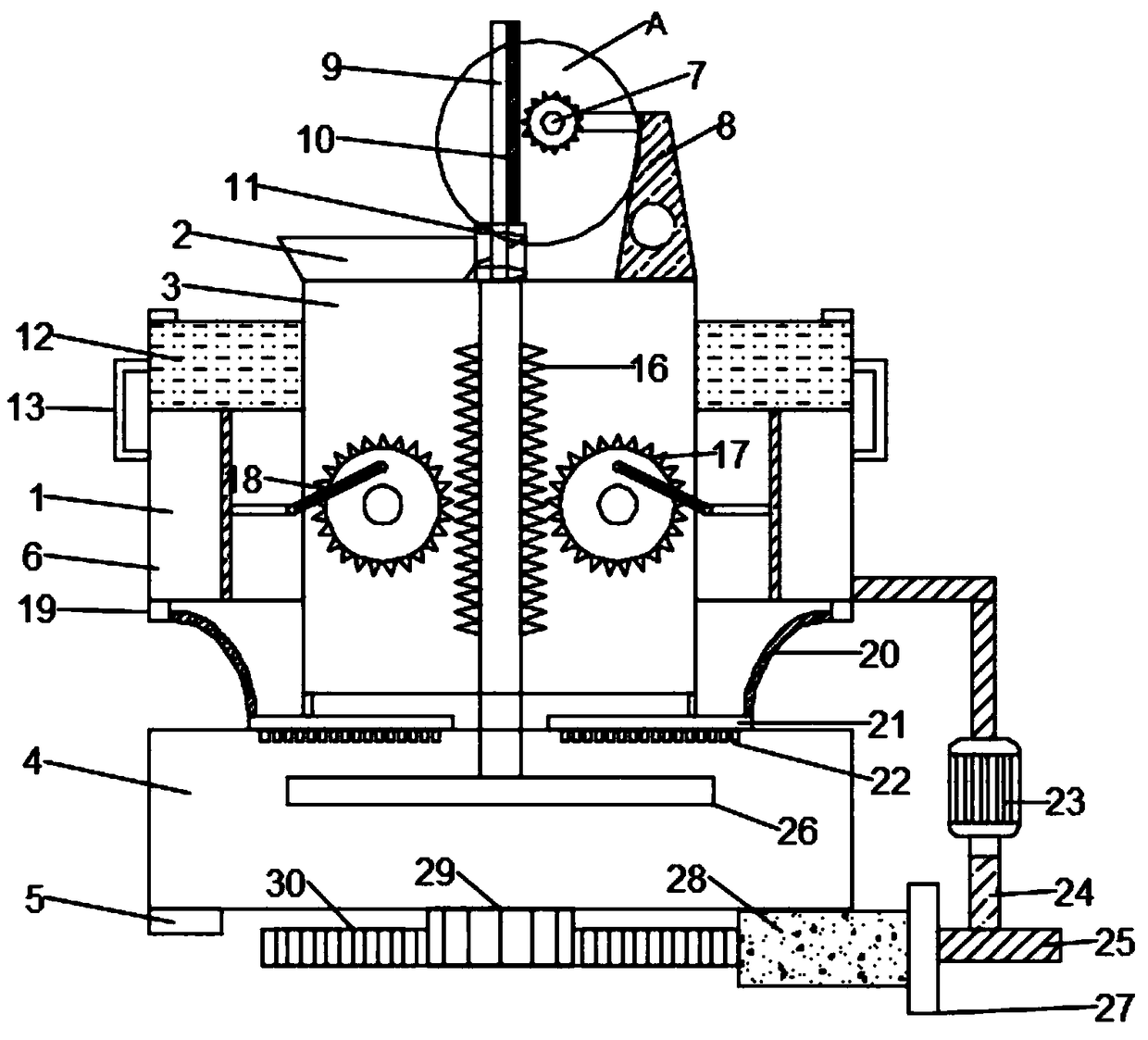

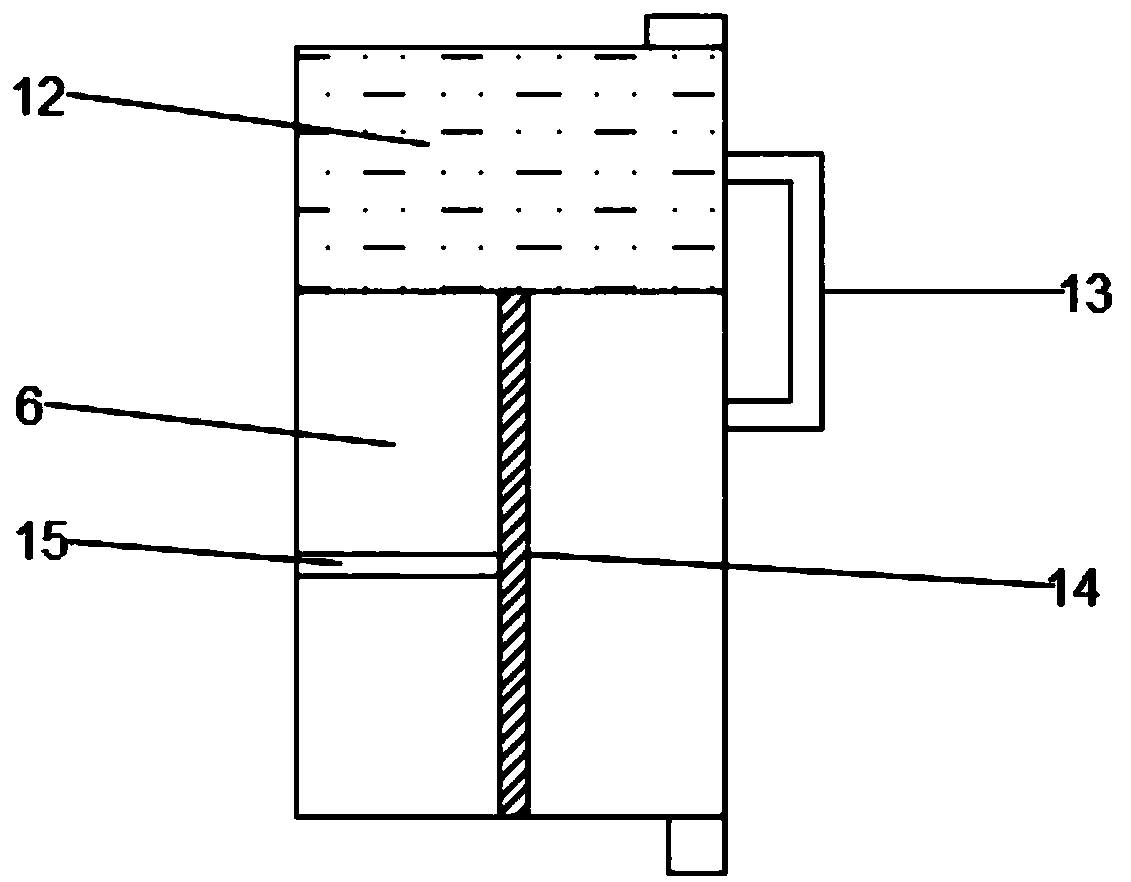

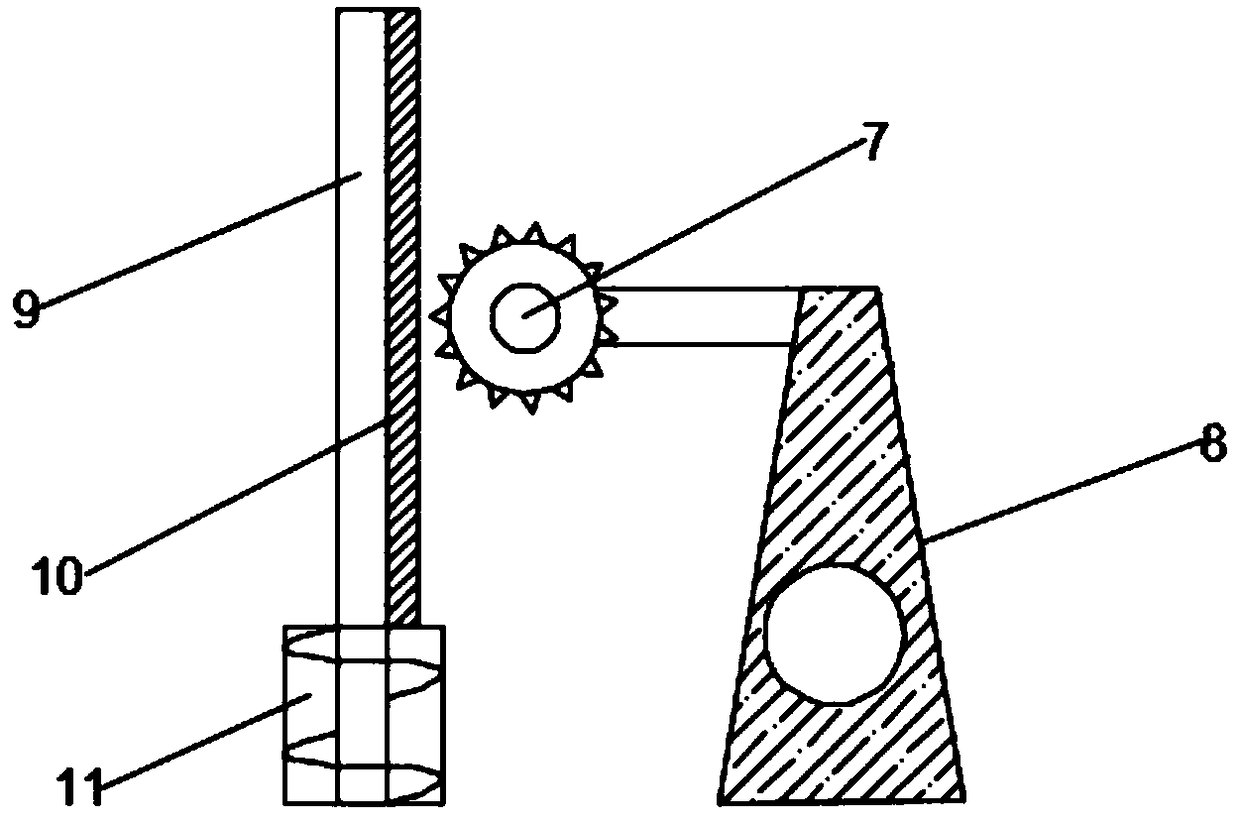

Automatic soil repairing equipment for soil pollution treatment

ActiveCN108637002AImprove governanceImprove crushing efficiencyContaminated soil reclamationGrain treatmentsEnergy consumptionPolluted soils

The invention discloses automatic soil repairing equipment for soil pollution treatment. The automatic soil repairing equipment comprises a machine body, a pulverizing cavity, a liquid chemical spraying cavity and liquid chemical mixing cavities. The upper portion of the left side of the machine body is provided with a feeding port, the lower portion of the feeding port is connected with the pulverizing cavity, and the liquid chemical mixing cavities are symmetrically welded to the two sides of the pulverizing cavity. The upper side of each liquid chemical mixing cavity is fixedly provided with a liquid chemical storage cavity, wherein the liquid chemical storage cavity is connected with the liquid chemical mixing cavity through a first liquid chemical guide pipe. The liquid chemical spraying cavity is formed below the pulverizing cavity and internally provided with a grinding plate. A discharging port is formed in the left side position of the bottom of the liquid chemical spraying cavity. The automatic soil repairing equipment has the beneficial effects that efficiency is high, and energy consumption is low; workers are prevented from making direct contact with polluted soil, andlife safety and health of maintenance personnel are guaranteed; and meanwhile, manual operation is not needed in the soil treatment process, the whole treatment work process is automatic, and the burden of the workers is relieved.

Owner:CHINA CONSTR FIRST BUREAU GRP INTERIOR FITOUT ENG

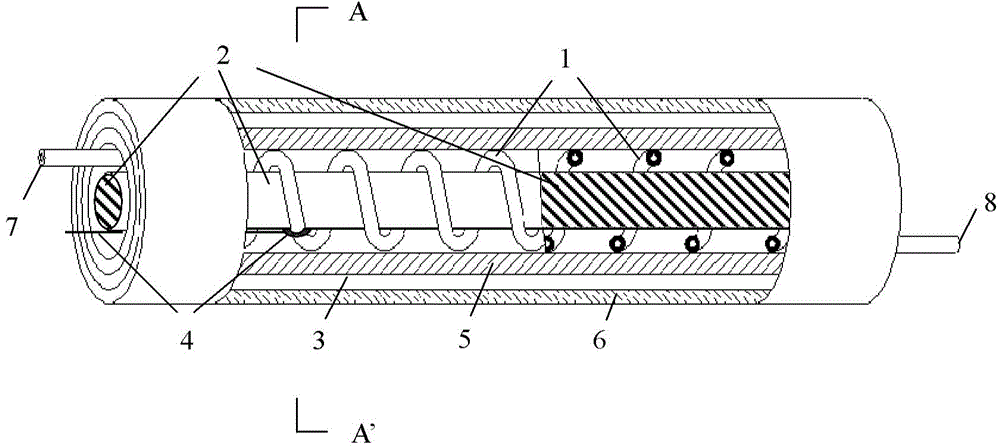

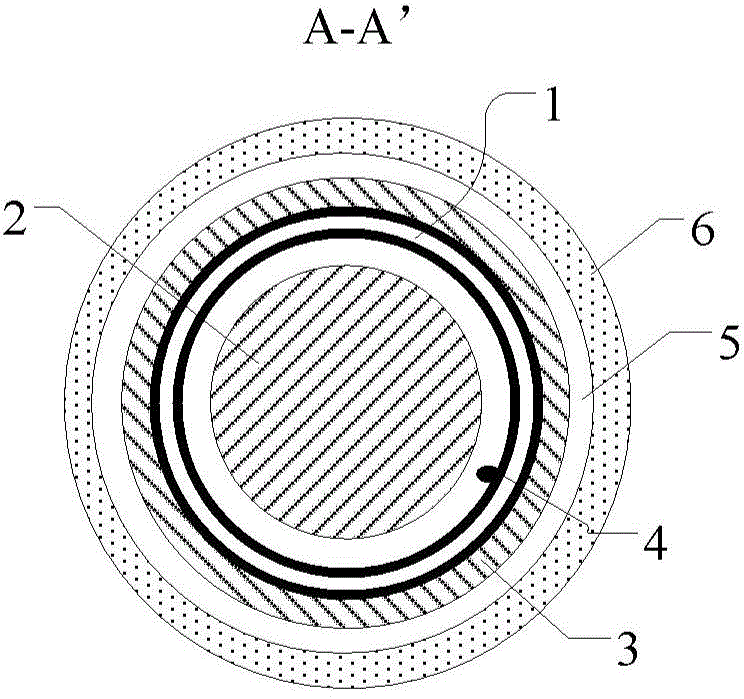

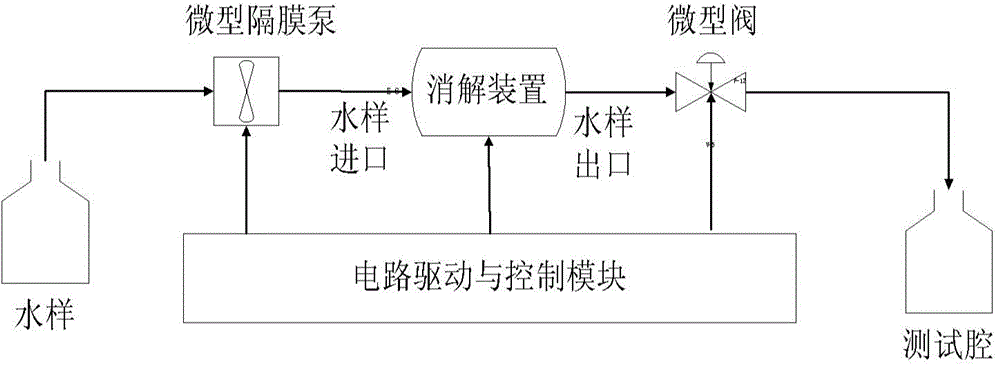

Digestion method and digestion apparatus of total phosphorus of water quality

InactiveCN104819890ARealize automatic controlMiniaturizationPreparing sample for investigationUltraviolet lightsWavelength

The invention discloses a digestion method and a digestion apparatus of total phosphorus of water quality. In the digestion method, the total phosphorus in a thin-layer water sample is subjected to combined digestion with a short-wave-length ultraviolet light being 254 nm in wave length and heat energy without addition of any oxidizing agent. The digestion apparatus is in a roll-type structure, wherein a high-transmittance ultraviolet light spiral quartz tube being 1 mm in internal diameter is employed as a digestion tube to form a thin-layer solution. A short-wave-length cold-cathode ultraviolet light tube being 254 nm in wave length is used as an ultraviolet light source and a flexible heating sheet is employed as a heating part, wherein the cold-cathode ultraviolet light tube is positioned at the center of the spiral digestion tube and the flexible heating sheet wraps the spiral digestion tube externally. The digestion method and a digestion apparatus simplify the digestion process of the total phosphorus, can achieve miniaturization, low power consumption and automation of a digestion device of total phosphorus, and provides a strong technical support for on-line monitoring the total phosphorus.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

I/O module expansion unit and distributed automation system

InactiveUS7818465B2Quick verificationLess timeProgramme controlInput/output processes for data processingComputer architectureChecksum

An I / O module expansion unit having slots to install I / O modules thereon is provided for a distributed automation system. With the I / O module expansion unit, storing the configuration checksums generated with an algorithm from the software and hardware information of I / O modules, the distributed automation system can simplify the identification of an I / O module. By directly writing the configuration parameters stored in the I / O module expansion unit into the installed I / O module, the distributed automation system can simplify the setting and replacement of an I / O module. The I / O module expansion unit may also fast detect a hot-swap of an I / O module by wiring to the slots.

Owner:RICHTEK TECH +1

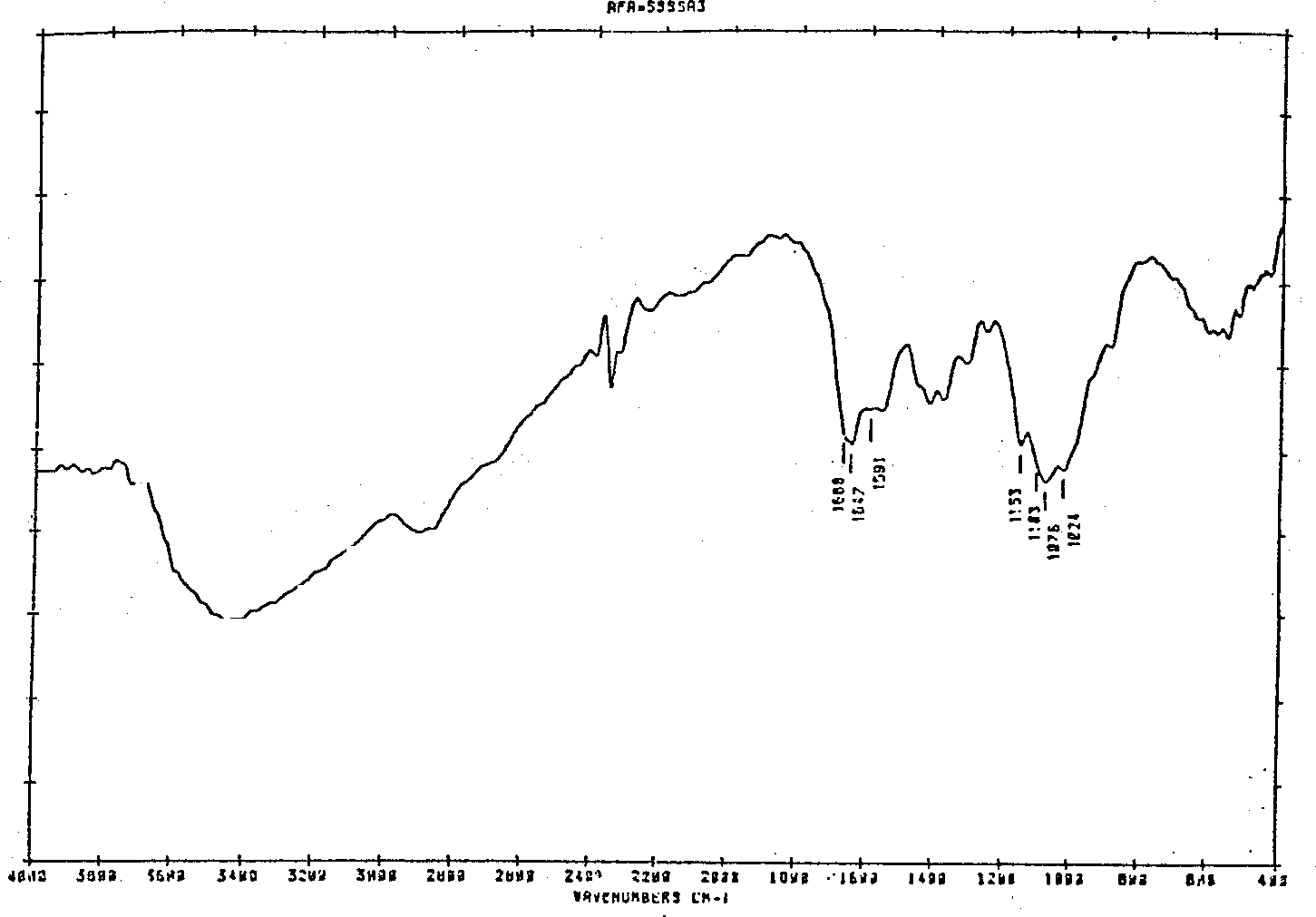

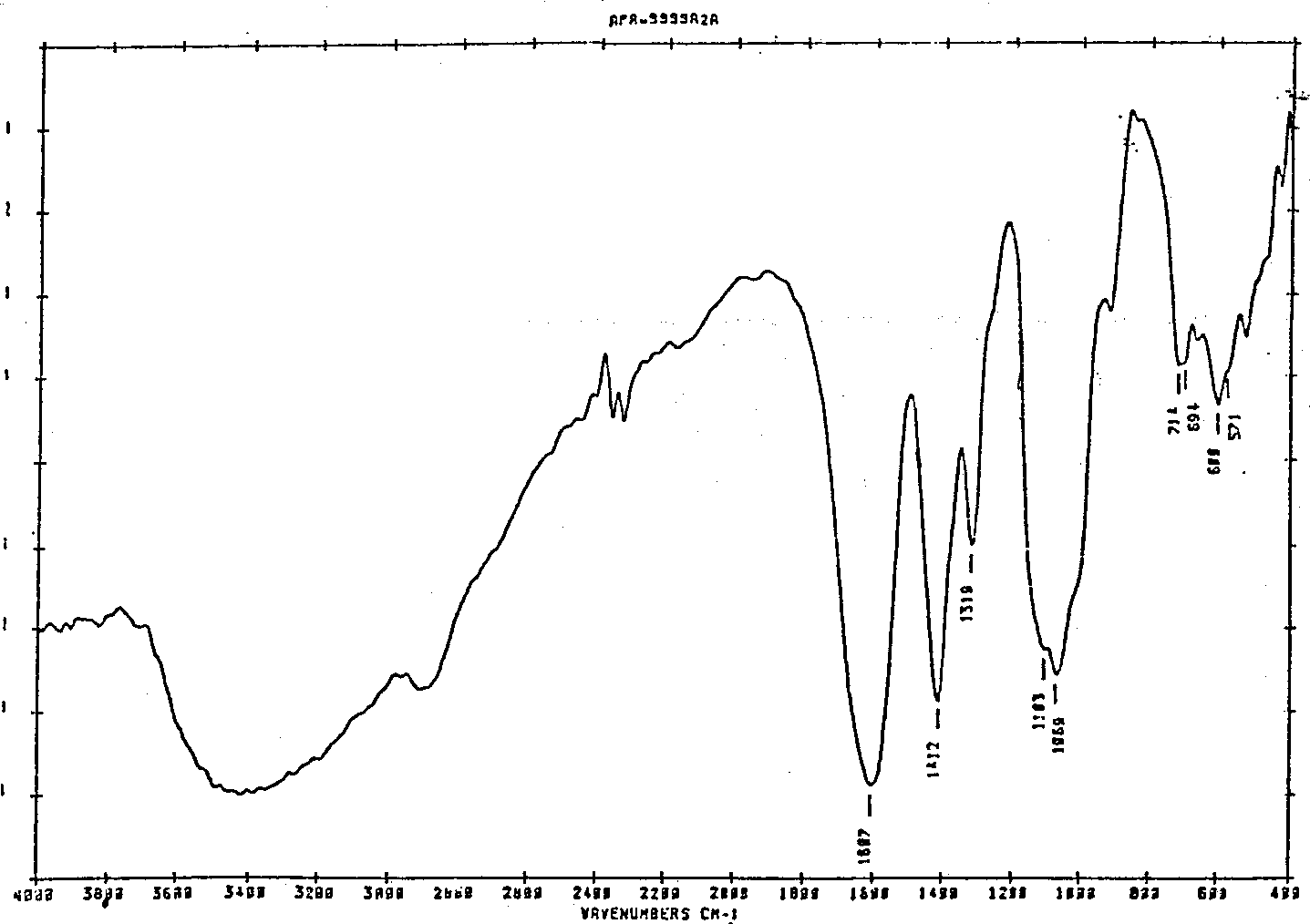

Semi-dry microwave synthesis of carboxymethyl chitosan

The present invention relates to a new process for synthesizing carboxymethyl chitosan by using semi-dry microwave method under the condition of having no organic solvent, and the said process includes the following steps: using purified ultramicro-pulverized chitosan 20-50 weight portions, adding 35% sodium hydroxide solution 50-500 weight portions, adding activating agent 30% hydrogen peroxide 0.1-0.8 weight portion, uniformly mixing them and placing them into a reactor, adopting 100-300 W microwave for 5-10 min., cooling below 10 deg.C, defreezing and then adding 30% sodium hydroxide and microwave treatment for three times, cooling, further adding sodium hydroxide, microwave treatment, cooling so as to obtain the finished product, then using methyl alcohol and ethyl alcohol to remove excess chloroacetic acid and sodium hydroxide so as to obtain pure product.

Owner:唐梓进 +1

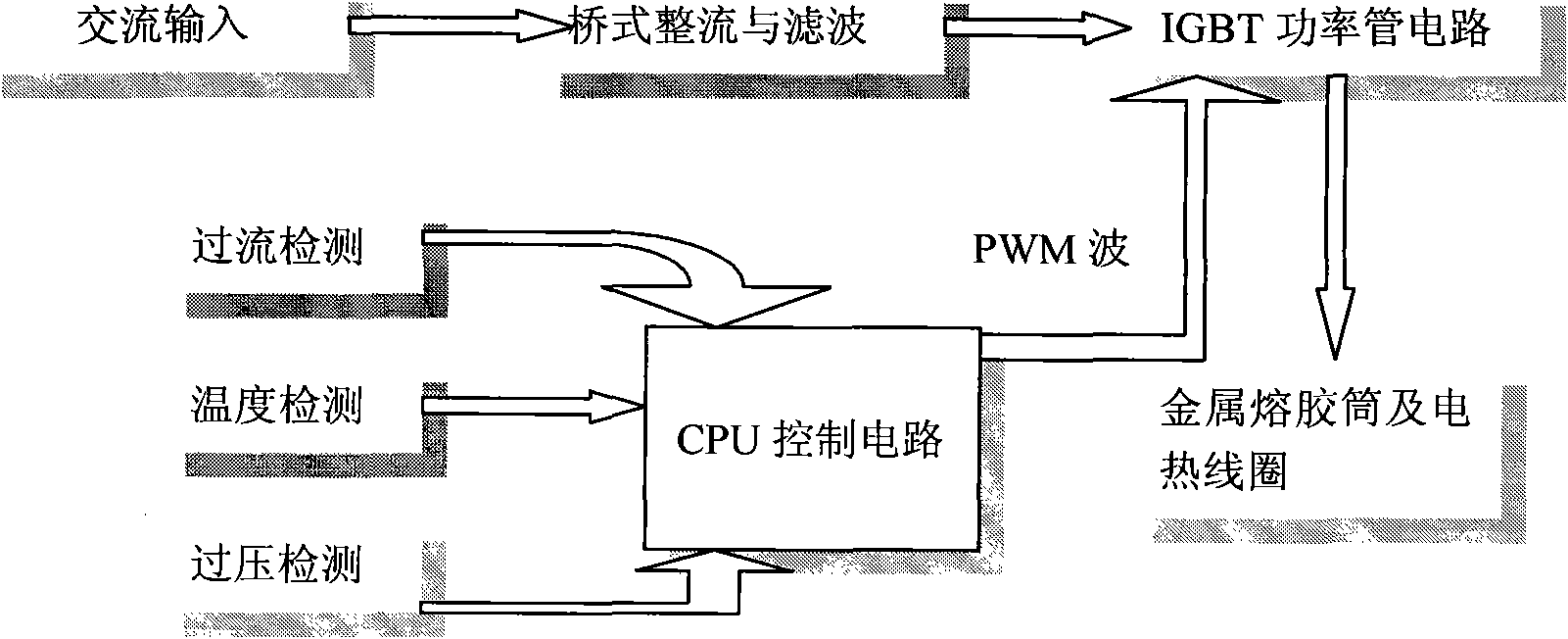

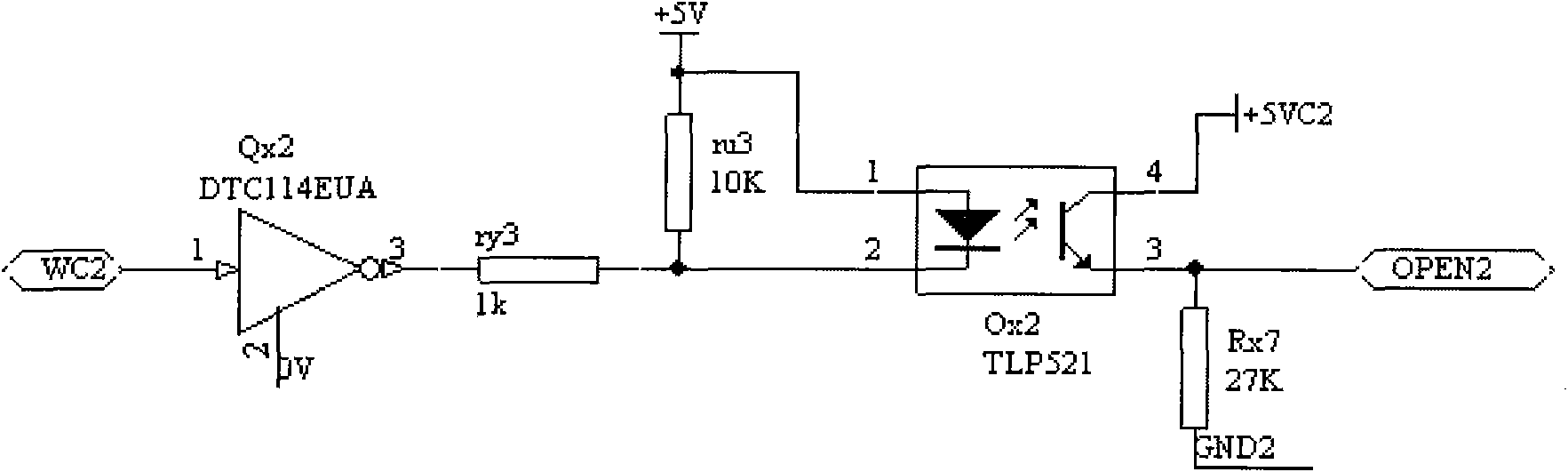

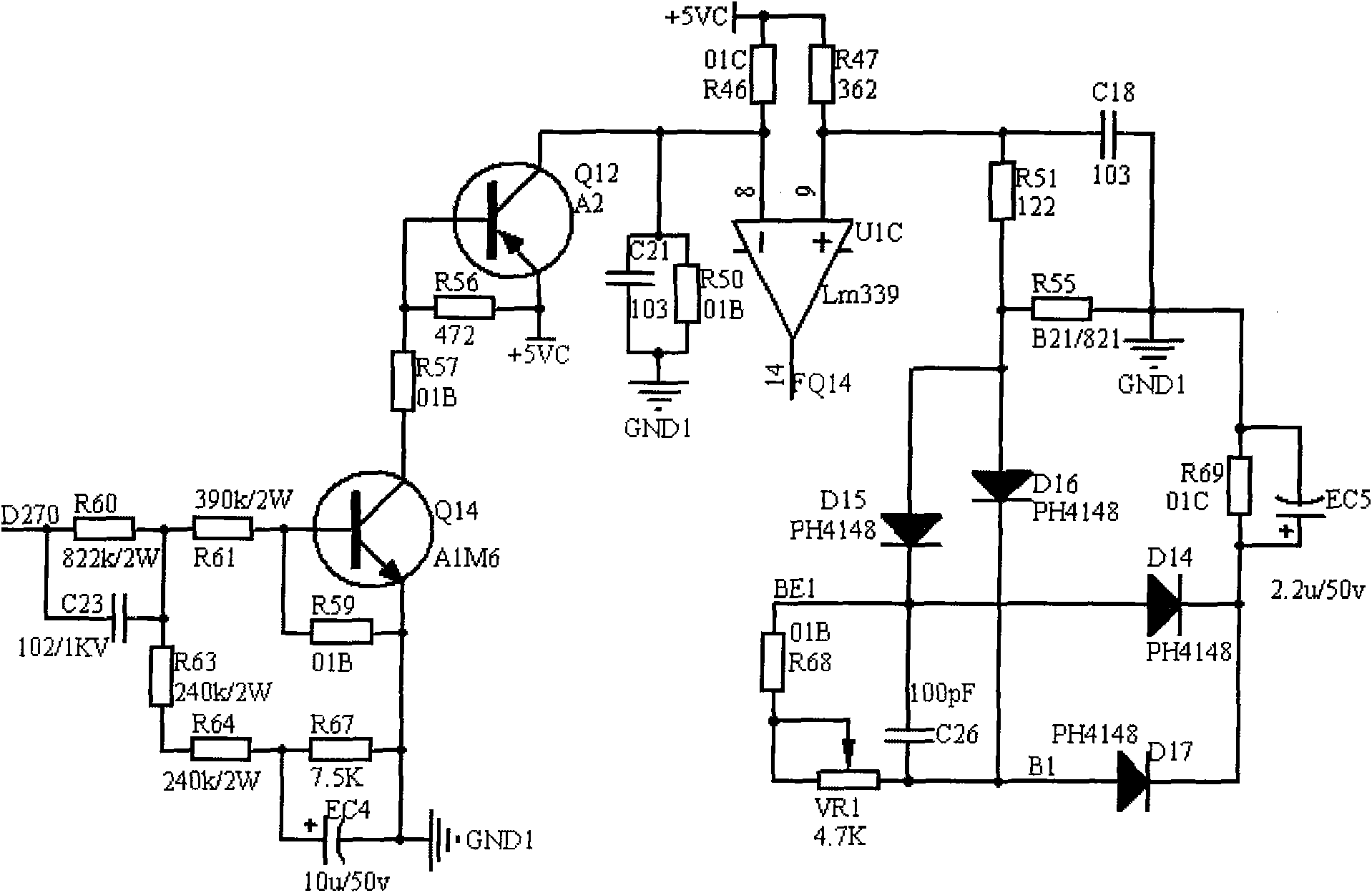

Electromagnetic heating system

InactiveCN101568205AControl leakageHigh precisionConversion with intermediate conversion to dcInduction current sourcesLow noiseInternational market

The invention relates to an electromagnetic heating system, comprising an alternating power supply, an over-current detection device, a temperature detection device, an over-voltage detection device and an electric heating coil; the alternating current power supply generates a direct current high voltage of more than 300V by a bridged rectifier and filter; the direct current voltage is connected with the electric heating coil of a metal glue-melting cylinder by an IGBT power tube; the over-current detection device, the temperature detection device, the over-voltage detection device are connected with a CPU control circuit (namely a microprocessor); the PWM wave generated by the microprocessor directly controls the G-pole control pin of the IGBT; the direct current voltage of 300V is inverted to the alternating current voltage; and the alternating current voltage generates a magnetic field in the electric heating coil. The electromagnetic heating system can achieve the technical characteristics of high precision, high efficiency, low energy dissipation, low noise, high automation, and the like, has wide prospect, can replace the traditional resistance-type heating injection machine, prompt the progress of the injection machine industry and improve the competitiveness capability to the international market.

Owner:NINGBO ZHIXIANG MOTOR DEVICE

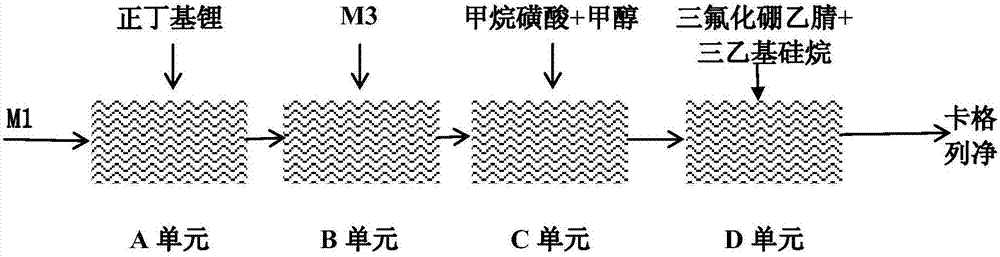

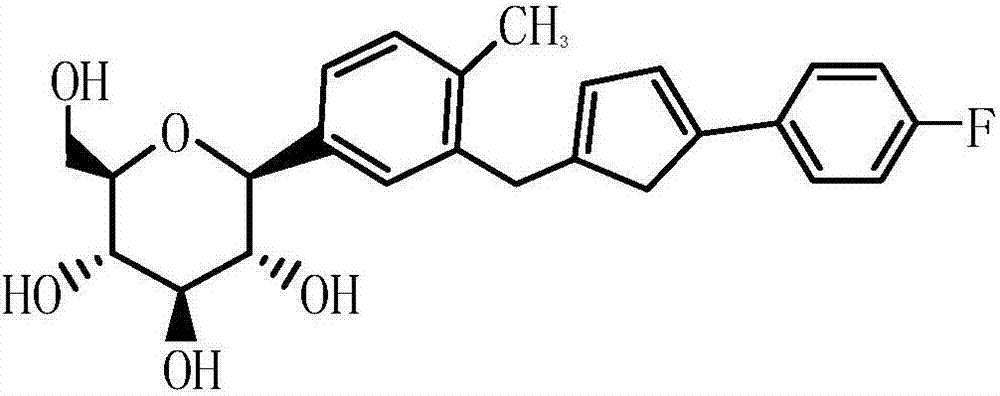

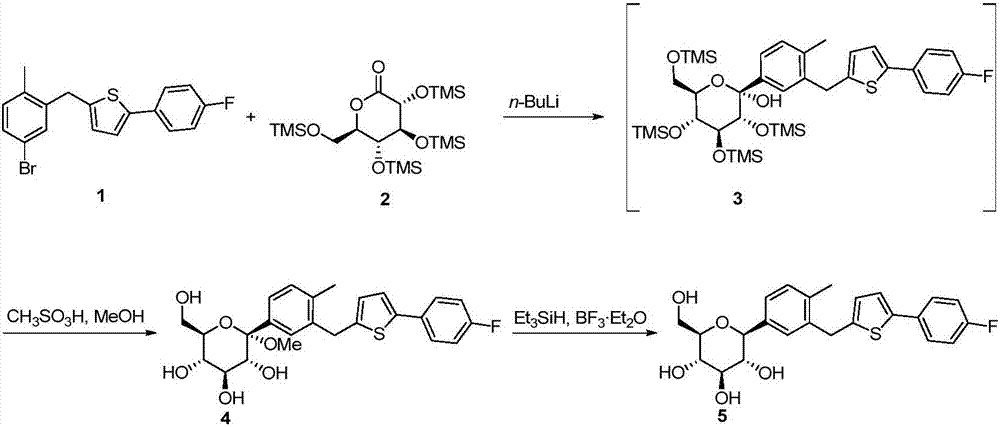

Method for continuously preparing canagliflozin by using microreactor one-pot method

ActiveCN106866645AWell mixedReduce the production of by-productsOrganic chemistryBulk chemical productionSolventButyl lithium

The invention discloses a method for continuously preparing canagliflozin by using a microreactor one-pot method. The method is used for continuously preparing the canagliflozin by using the microreactor one-pot method, and microreactors are divided into a unit A, a unit B, a unit C and a unit D. The method comprises the steps of mixing a solution of M1 with n-butyl lithium in the unit A for carrying out a reaction; after the reaction is finished, enabling the reaction product to enter the unit B together with a solution of M3, and carrying out a reaction at the temperature of -15 to -5 DEG C to obtain an intermediate A; enabling reaction liquid containing the intermediate A to enter the unit C together with a methanol solution of methane sulfonic acid, and carrying out a reaction to obtain an intermediate B; enabling reaction liquid containing the intermediate B to directly react with boron trifluoride and triethyl silicane in the unit D to obtain the canagliflozin. The method greatly simplifies the operation steps, shortens the reaction time, greatly reduces the use of various solvents, lowers the production cost, improves the production safety, can realize continuous and automatic production, and is high in product purity and yield, thus being suitable for industrial production.

Owner:山东安信制药有限公司

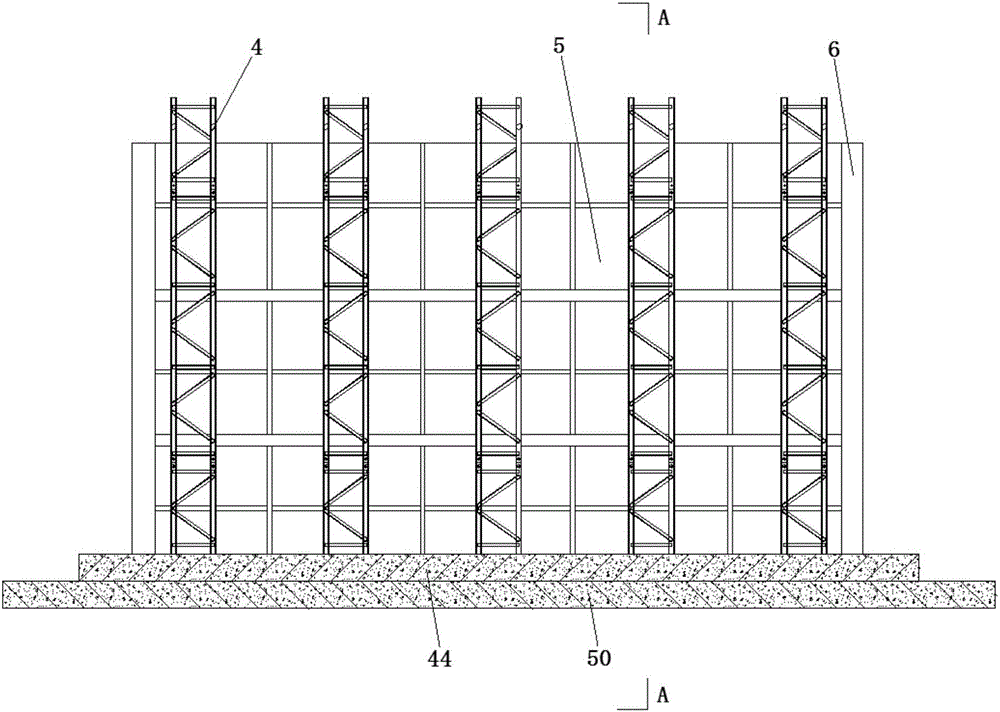

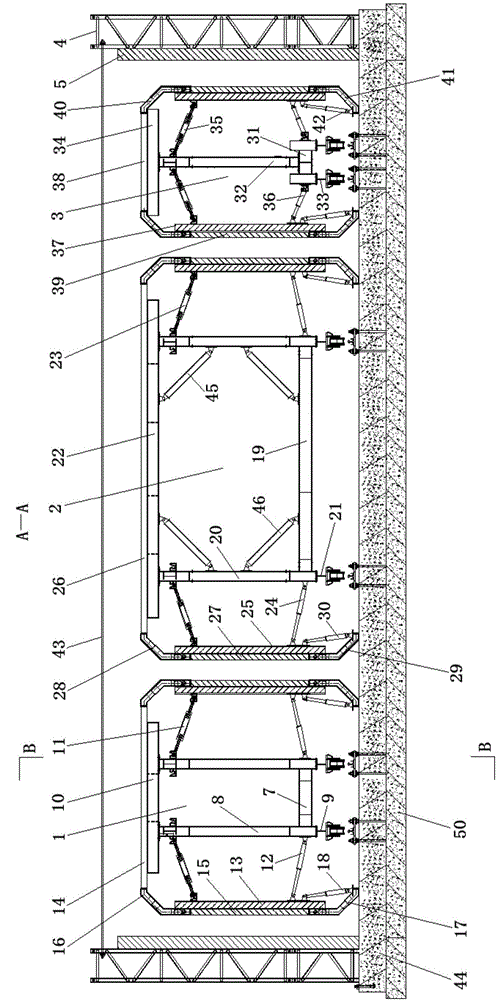

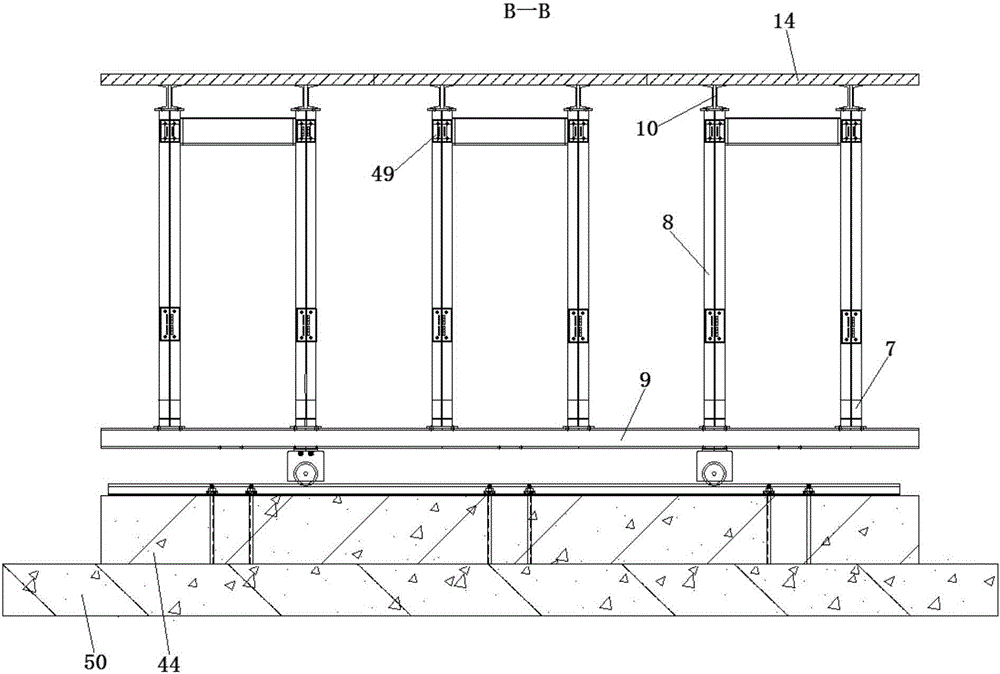

Multiple-opening box type culvert making mold and method for making box type culverts by three-opening box type culvert mold

ActiveCN106827193AShort manufacturing cycleGuaranteed manufacturing accuracyDischarging arrangementMouldsEngineeringCulvert

The invention relates to a multiple-opening box type culvert making mold and belongs to the technical field of box type culverts engineering, aiming to solve the problems of difficult manufacture, long construction cycle and high production cost of the existing box type culvert and the multiple-opening box type culvert. A first inner form board supporting device, a second inner form board supporting device and a third inner form board supporting device are sequentially arranged from left to right on base plate of the box culvert; two rows of support truss are arranged on the base plate of the box culvert of both sides of the first inner form board supporting device and the third inner form board supporting device; the supporting trusses are relatively arranged and parallel, and the upper ends of each of the two supporting trusses arranged in each set are connected by a connecting rod; the inner sides of the two rows of supporting trusses are all provided with outer form boards, and both ends of the outer form boards are provided with end sealing form boards. The multiple-opening box type culvert making mold can be prefabricated, assembled and reused on the spot, and the inner mold can be automatically supported; after the box culvert is finished, the inner mold is automatically released and is moved to the next station to manufacture the box type culverts.

Owner:HEILONGJIANG ZHONGXIN ROAD & BRIDGE MATERIAL CO LTD

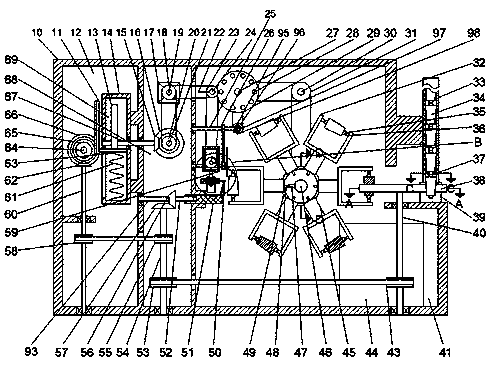

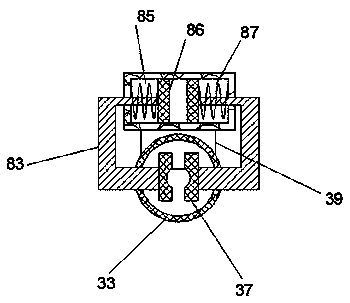

Method and special device for performing fusion welding on electrode lead plate of energy-saving environment-friendly type lead-acid battery

InactiveCN102581264AAvoid dripping accidentsReduce oxidation lossManufacturing technologyEngineering

The invention provides a method and a special device for performing fusion welding on an electrode lead plate of an energy-saving environment-friendly type lead-acid battery, relating to the manufacturing technology of lead-acid batteries. The method provided by the invention comprises the following steps: (1) heating and melting solid lead for being infused into a lead storage tank or a lead injection tank to melt the lead, and preheating a melting template; (2) shifting the melting template to tightly cling to the lead storage tank, driving plunger rods to raise through the action of a cylinder on the lead storage tank or the lead injection tank, infusing liquid lead into a rectangular groove of the melting template, and closing taper holes through the plunger rods; (3) shifting the melting template to a station for fusion welding, pushing a tooling box to lead the lower surface of the tooling box to stick on the upper surface of the melting template, and inserting a small rectangular relief block in the liquid lead inside the rectangular groove of the melting template for 2-10seconds; (4) cooling the melting template; and (5) separating a box body of the tooling box from the melting template and then taking out a product. The device provided by the invention consists of a lead melting furnace, the lead storage tank or the lead injection tank; an electric heating induction coil is fixed on the lead melting furnace; the lead storage tank is provided with an electric heating pipe, the taper holes, a cylinder piston rod and a linkage plate; and a liquid inlet pipe arranged on the side wall of the upper part of the lead storage tank is communicated with a liquid outlet pipe of the lead melting furnace. The method and the special device provided by the invention have the advantage that: little liquid lead is used so as to meet the energy-saving requirement during the process of lead injection.

Owner:FUAN GUANGYUAN ELECTROMECHANICAL

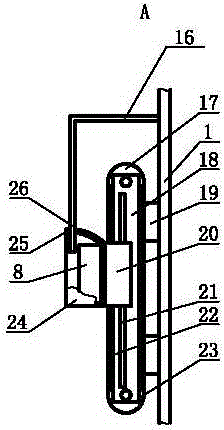

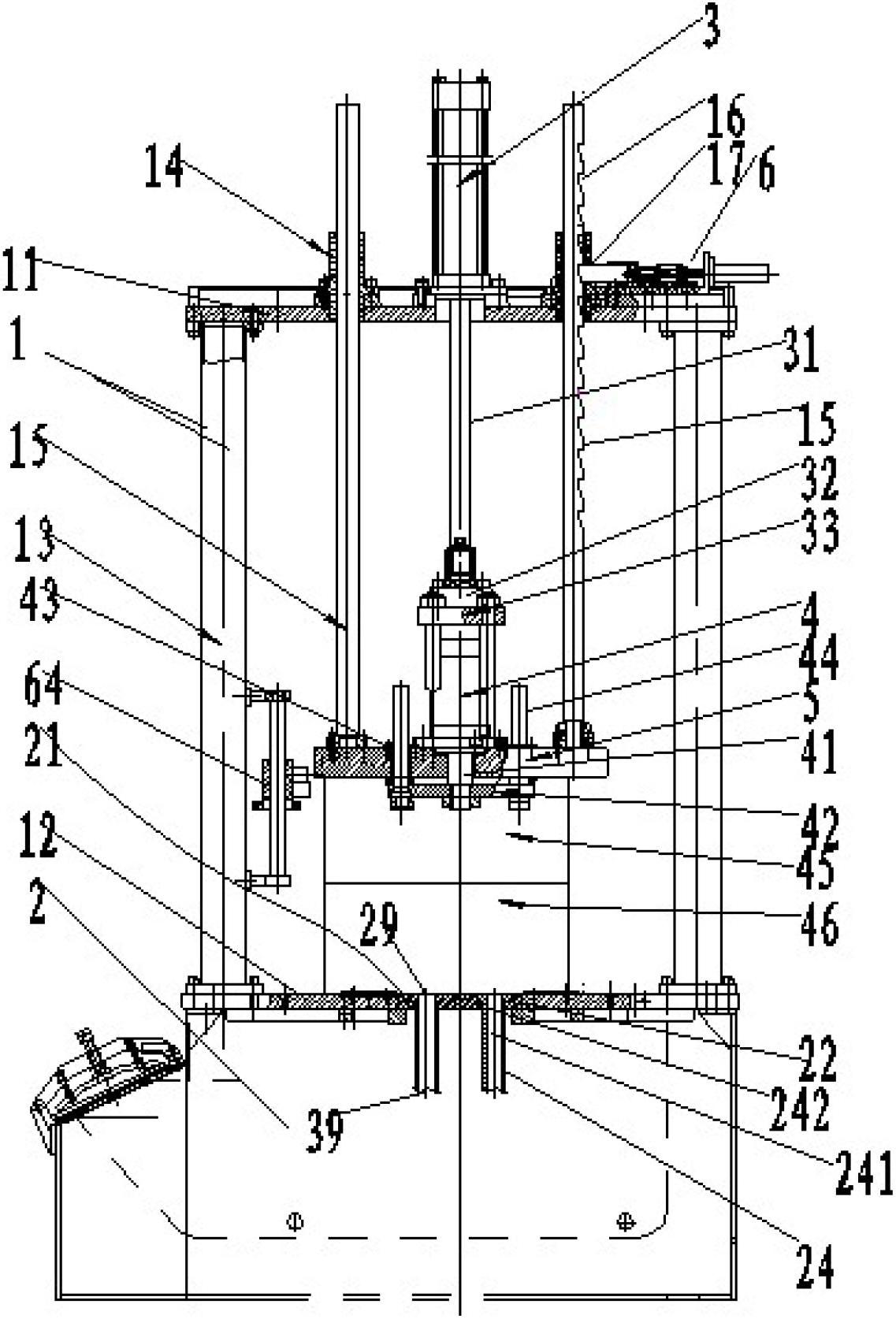

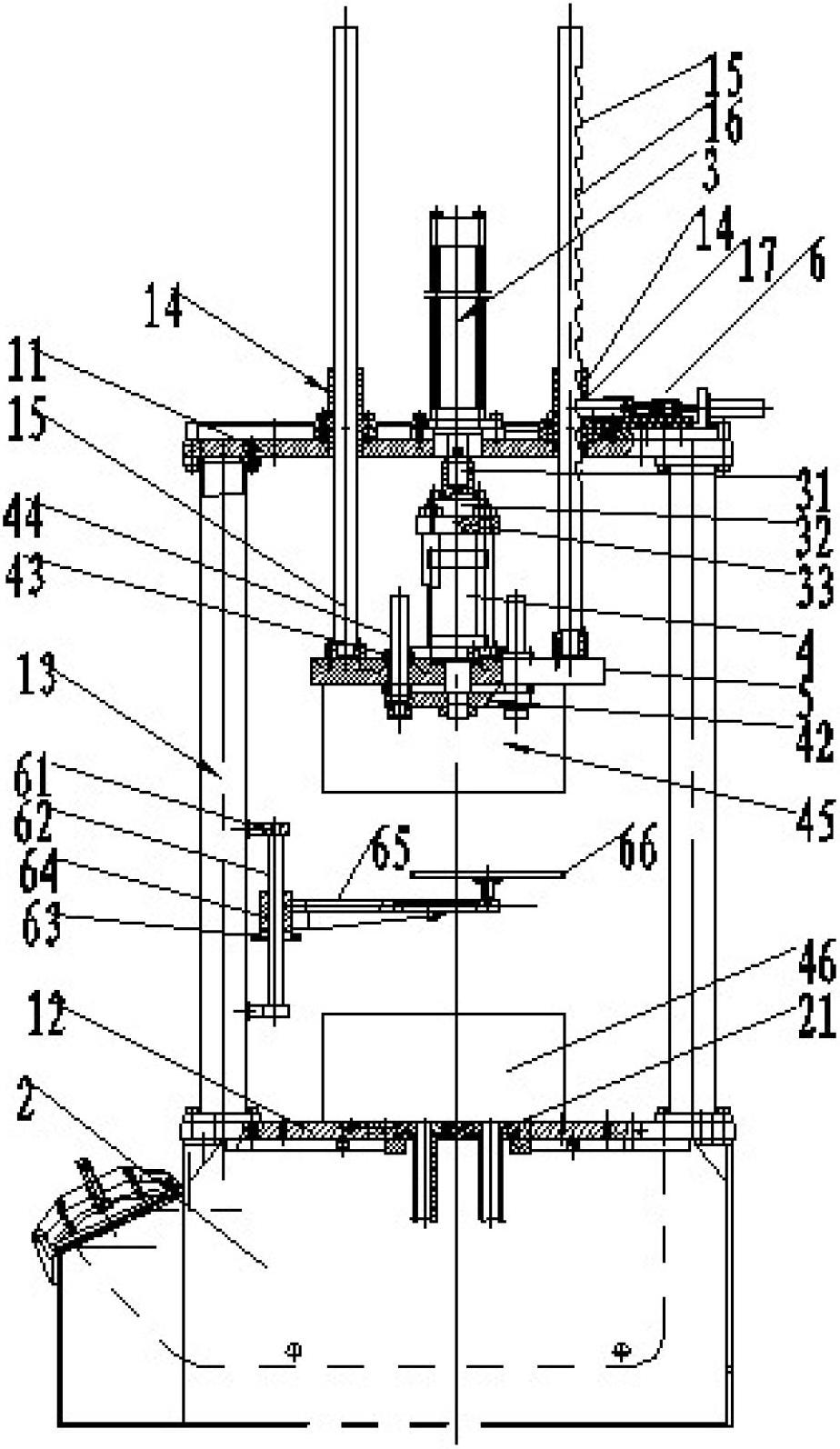

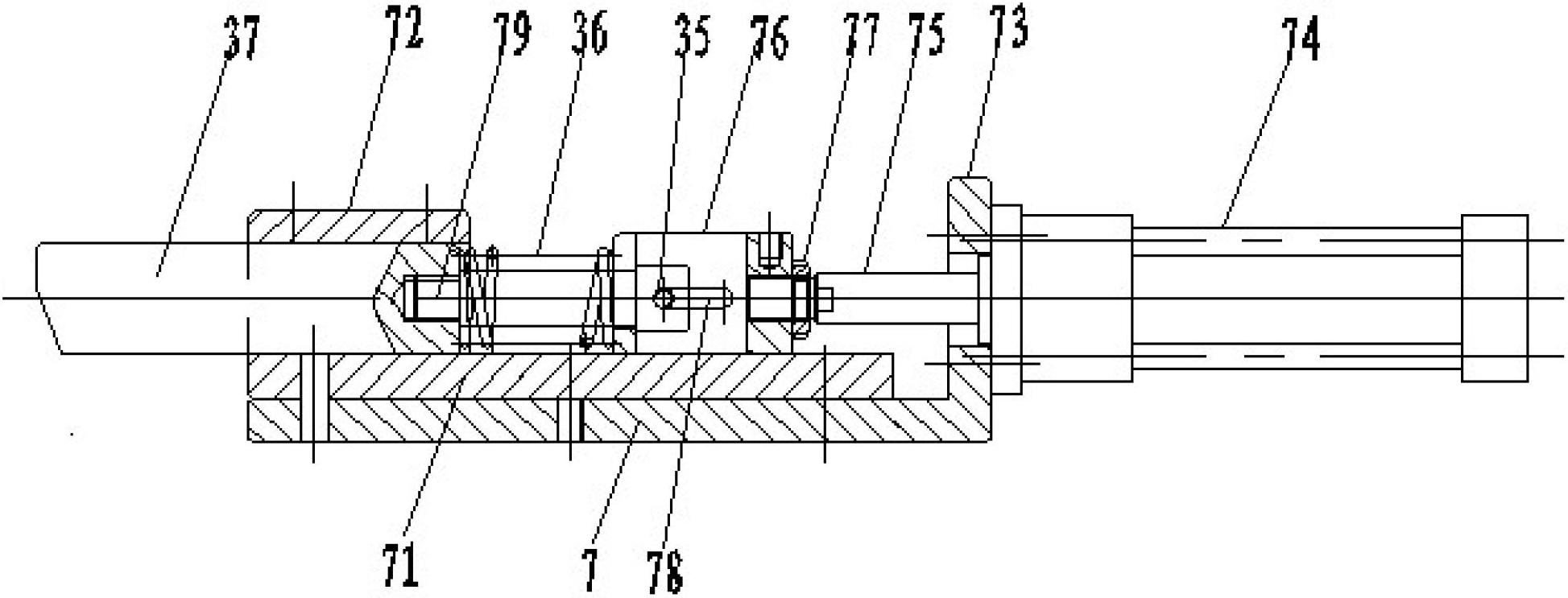

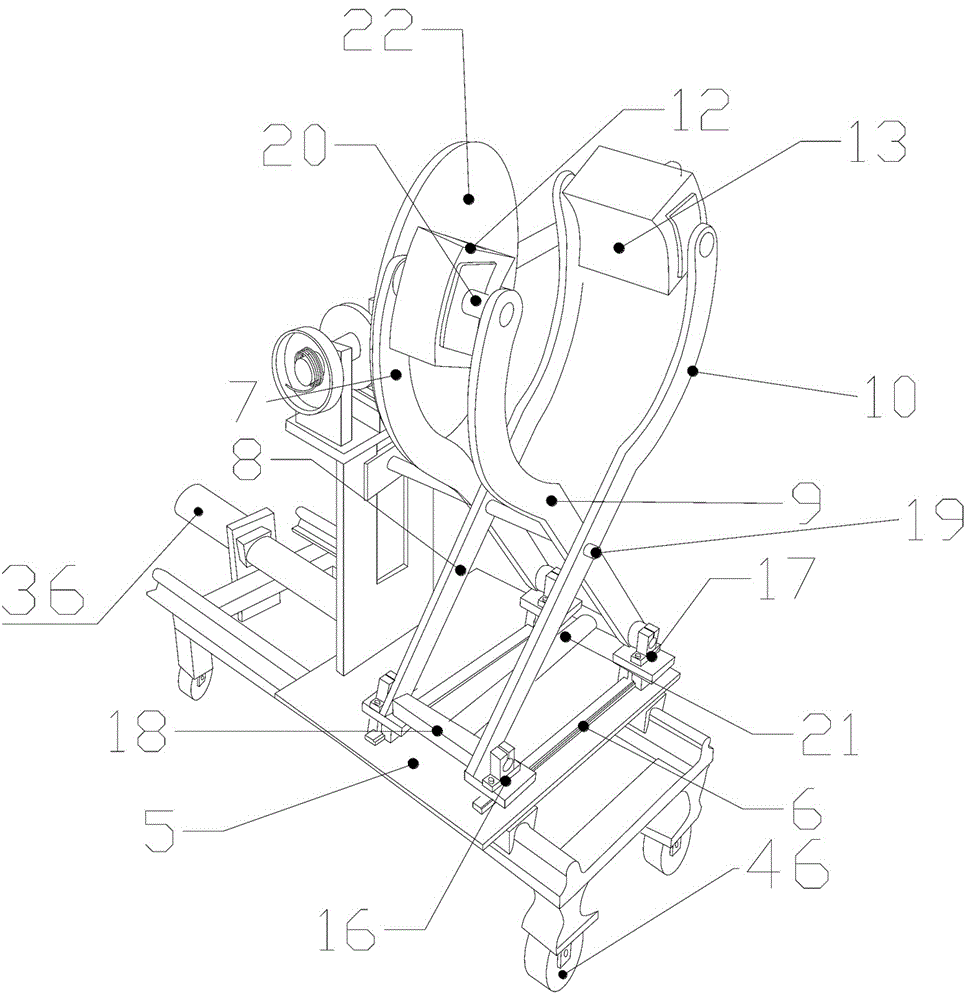

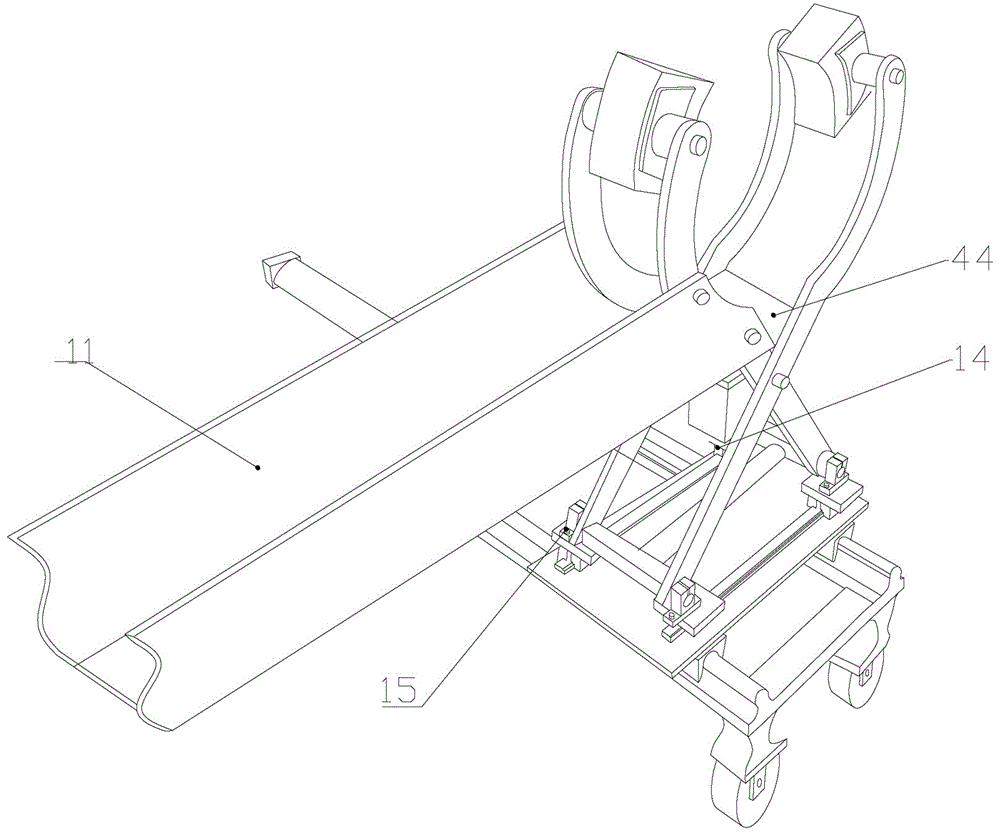

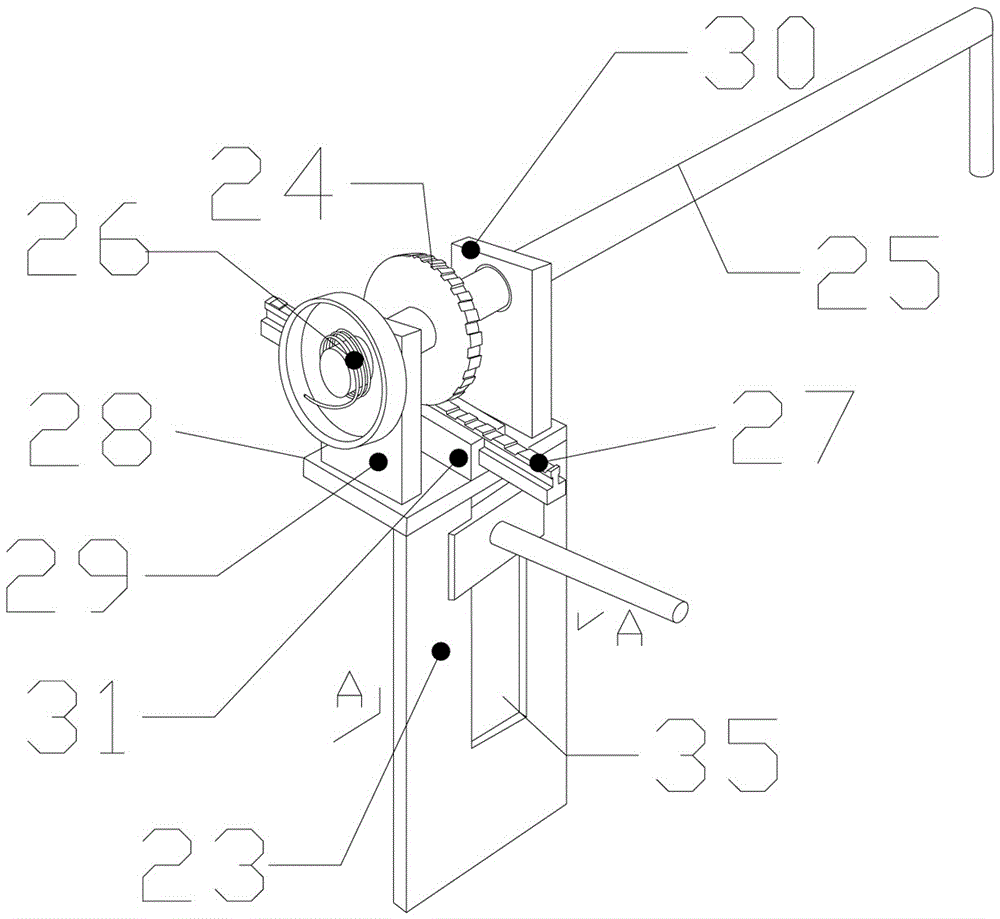

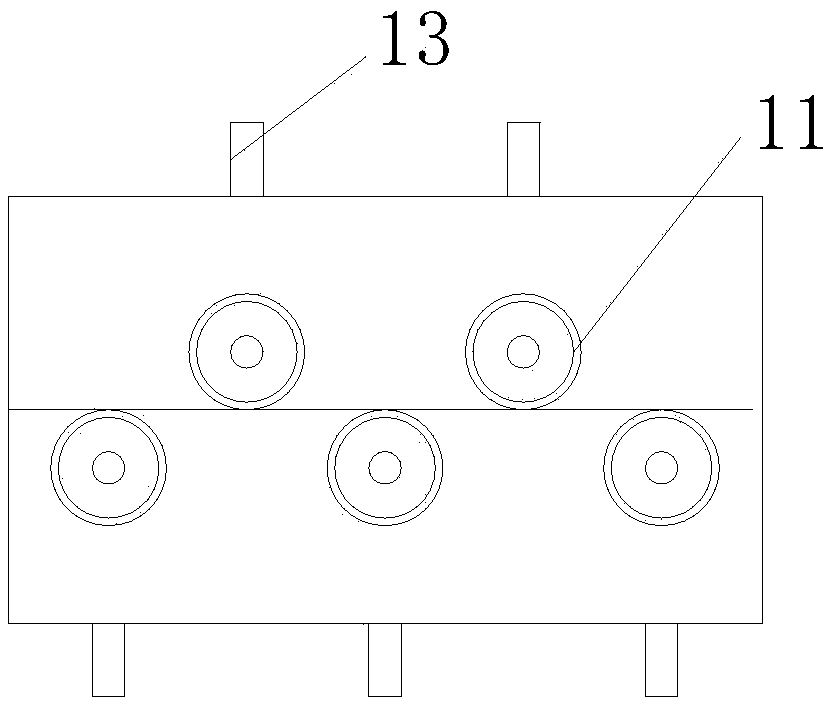

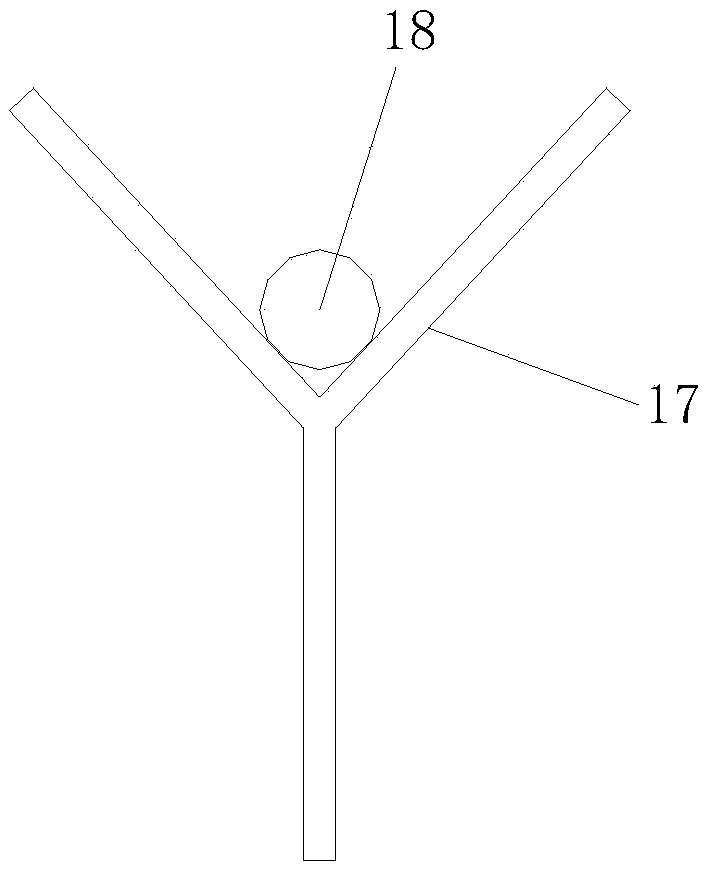

Winding mechanism and operating method thereof

InactiveCN109250569ARealize windingAutomation reductionFilament handlingEngineeringMechanical engineering

Owner:余名宪

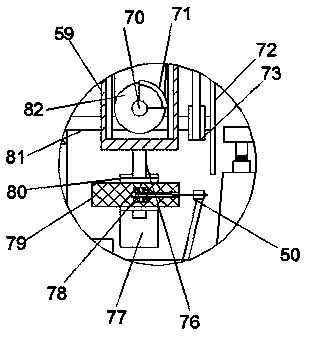

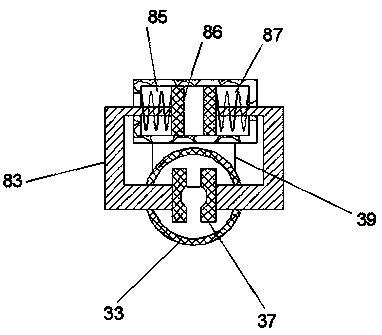

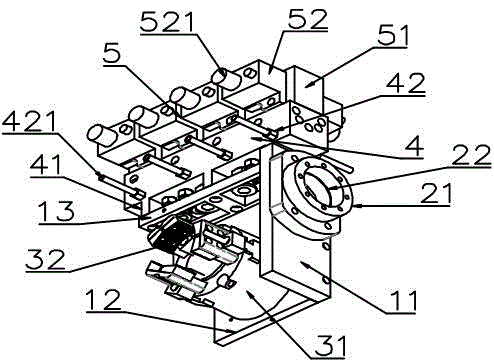

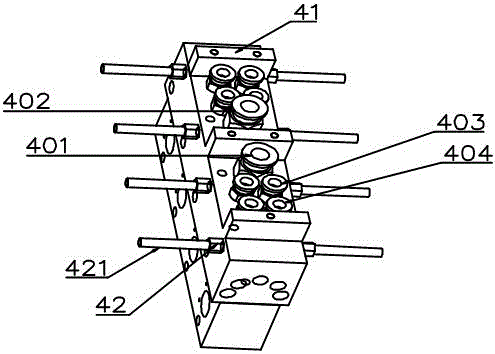

Part taking, spraying and stamping integrated device of intelligent die casting robot

A part taking, spraying and stamping integrated device of an intelligent die casting robot comprises a fixed plate, a clamping device, a blowing device and an atomizing device. The fixed plate is composed of a bottom plate, a first side plate and a second side plate, wherein the first side plate and the second side plate are adjacent, the clamping device is fixed to the bottom plate, a mounting position is arranged on the first side plate, the blowing device is fixed to the second side plate, and the atomizing device is fixed to the blowing device; a plurality of sets of gas paths and a plurality of sets of water paths are arranged in the blowing device, the gas inlet ends of the multiple sets of gas paths are correspondingly connected with a plurality of sets of gas inlet connectors on the surface of the blowing device, and the gas outlet ends of the multiple sets of gas paths are connected with the atomizing device; and the water paths supply water to same water inlet connectors from the surface of the blowing device, and are connected with the atomizing device; and resources are effectively integrated, the labor cost is reduced, automation of a die casting system is achieved, the die casting production efficiency is improved, and the good market application value is achieved.

Owner:深圳市日昭自动化设备有限公司

Winding mechanism

InactiveCN109230826ARealize windingAutomation reductionFilament handlingConductor CoilMechanical engineering

Owner:余名宪

Preparation method of low-viscosity cassava composite modified starch

The invention relates to cassava starch, and particularly relates to low-viscosity composite modified starch, belonging to the technical field of weaving. The preparation method of the low-viscosity cassava composite modified starch comprises the following steps of carrying out esterification reaction on cassava starch and an esterifying agent under the effect of catalysts so as to obtain esterification starch, and irradiating the esterification starch, thereby obtaining the low-viscosity cassava composite modified starch. The esterified starch is irradiated, and other indexes are all not affected except the reduction of the viscosity. Products with different viscosities can be obtained by controlling the irradiation condition. The technique provided by the invention has the advantages of simple process, low energy consumption, few public hazards, easiness in automation, safety, reliability and the like.

Owner:GUANGXI HONGHAO STARCH DEV

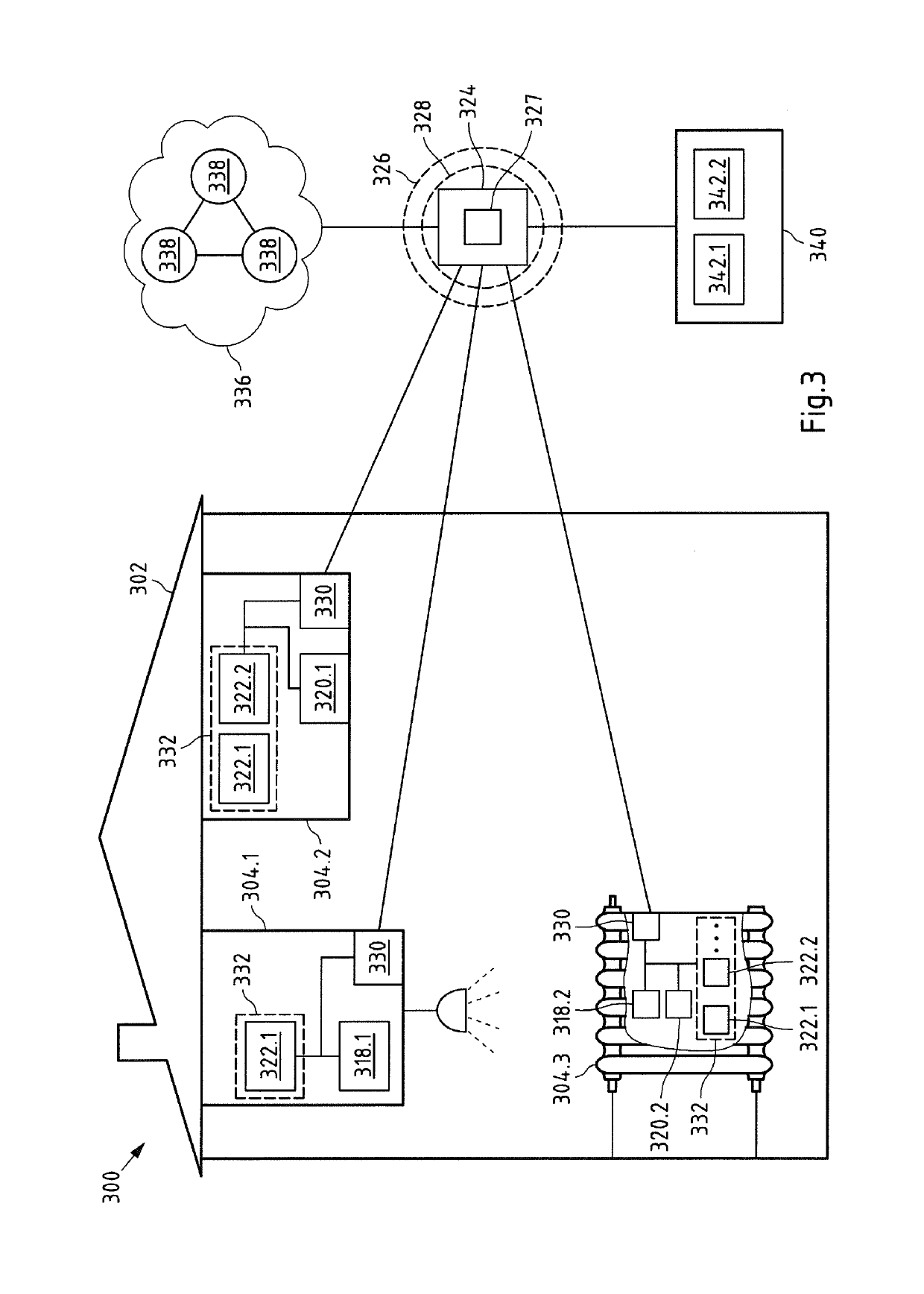

System and method for access decision evaluation for building automation and control systems

ActiveUS10139789B2Minimize accessReduce the amount requiredProgramme controlComputer controlControl systemBuilding automation

The present invention relates to a method for access decision evaluation in a building automation and control system, the method comprising: sending, from an accessing device (10) to an accessed device (20), an access request, sending, from the accessed device (20) to a central decision evaluation apparatus (30), an evaluation request asking if the access request is granted or denied, evaluating, at the central decision evaluation apparatus (30), the evaluation request using one or more central access control policies in order to reach a decision on if the access request is granted or denied, deriving, at the central decision evaluation apparatus (30), the one or more central access control policies that was used for evaluation into a device specific access policy, sending, from the central decision evaluation apparatus (30) to the accessed device (20), the decision and the device specific access policy, and storing, at the accessed device (20), the device specific access policy.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

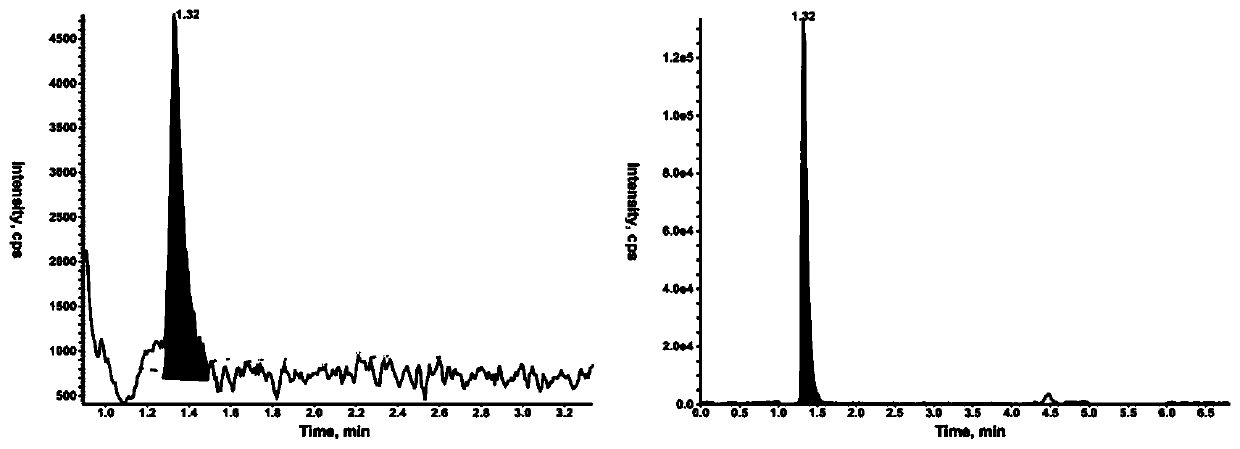

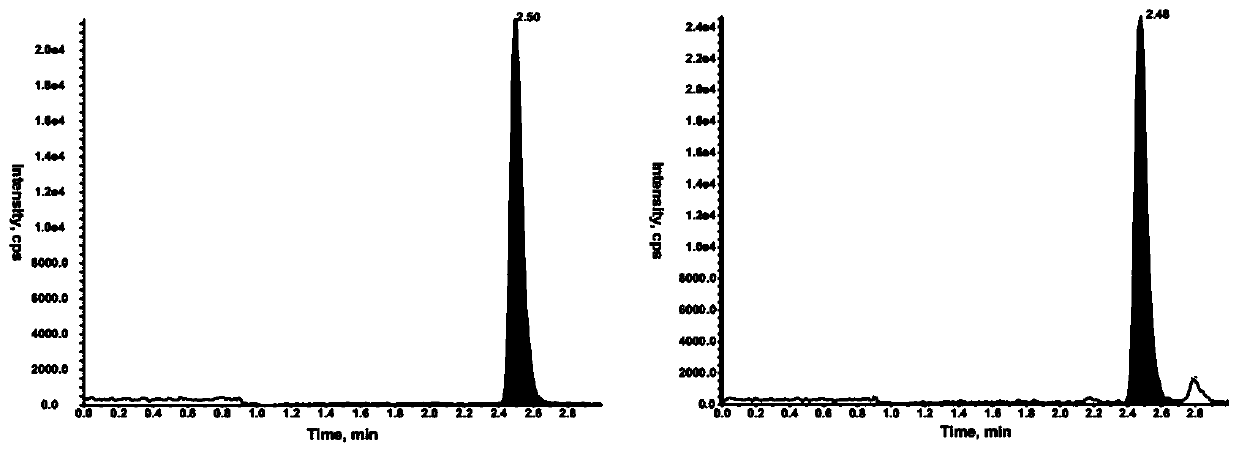

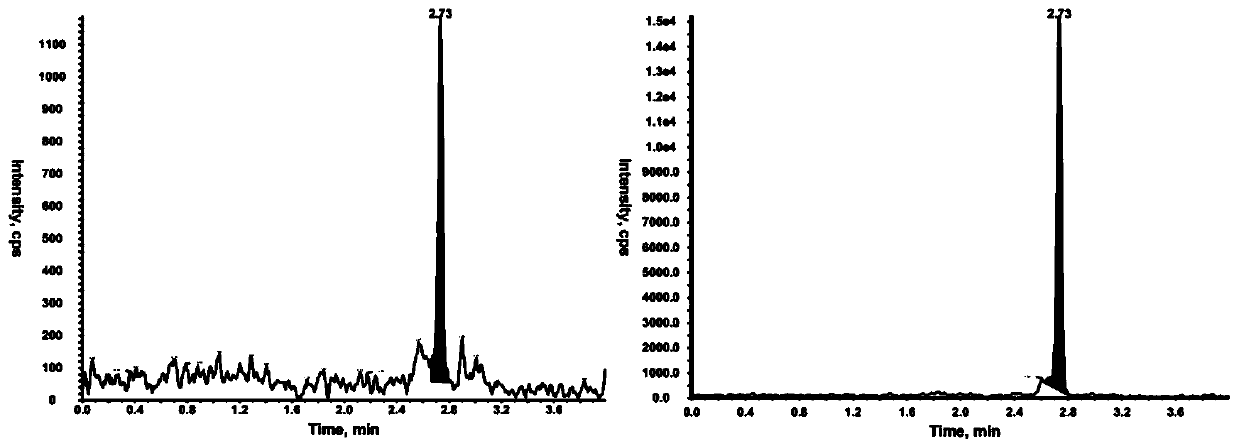

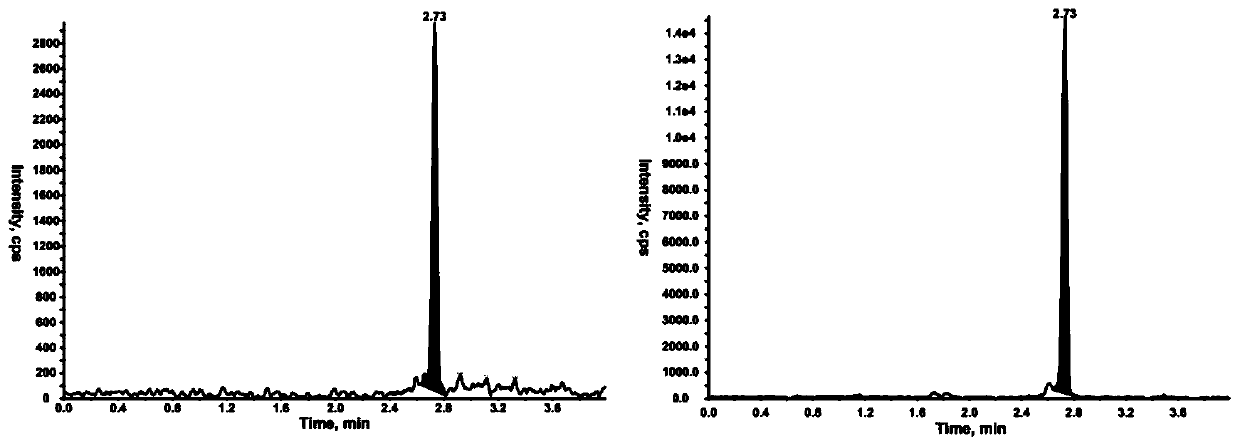

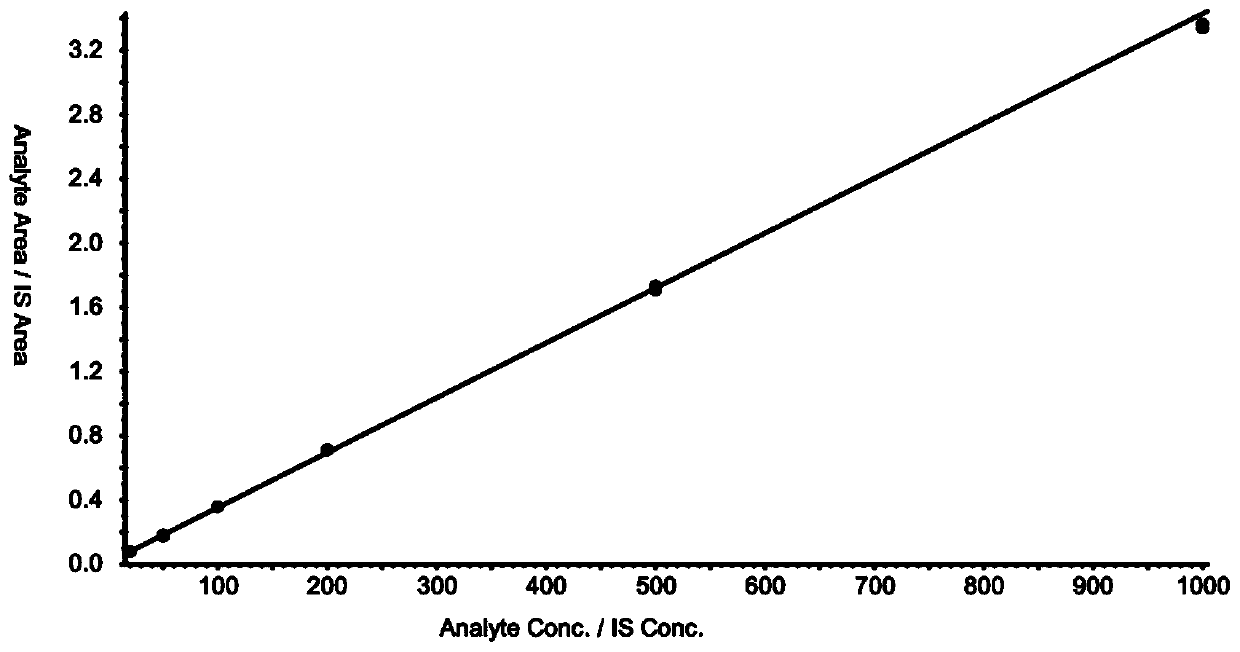

High performance liquid chromatography tandem mass spectrum detection method of free catecholamine and metabolites in human urine

PendingCN109709255AHigh specificityReduce Disruption and ImpactComponent separationTandem mass spectrometryChemistry

The invention discloses a high performance liquid chromatography tandem mass spectrum detection method of free catecholamine and metabolites in human urine. The method comprises the following steps of(1) preprocessing a sample, successively adding urine samples in an internal standard working solution and a phosphoric acid solution, and carrying out vortex mixing; (2) carrying out weak cation exchange solid phase extraction 96-well plate (SPE96 well plate) activation; (3) carrying out solid phase extraction processing, after step (1) processing, loading the samples to the SPE 96-well plate after step (2) activation, carrying out formic acid methanol solution elution, and drying eluant with nitrogen; and (4) redissolving and using a high performance liquid chromatography tandem mass spectrometry to carry out analysis detection. The method has the advantages of high accuracy, high reproducibility, high sensitivity, high specificity, high efficiency, high flux, low cost, simple and rapidoperation and the like.

Owner:杭州凯莱谱精准医疗检测技术有限公司

Locking and self-discharging mechanism for wire reels

The invention relates to a winding mechanical device, in particular to a locking and self-discharging mechanism for wire reels. The locking and self-discharging mechanism comprises a locking mechanism and a reel discharging mechanism. The locking mechanism comprises a box body and a fixing disc; the fixing disc is movably arranged on the box body; and a spindle used for being sleeved with a wire reel is perpendicularly arranged in the center of the fixing disc. The locking and self-discharging mechanism is not only suitable for the automation of winding equipment, with further exploitation, by applying a modern control technology to the automated manufacturing filed, the theoretical method of the patent technology can be popularized and applied to the manufacturing of other automated mechanical equipment so as to manufacture other mechanical equipment. The locking and self-discharging mechanism for the wire reels is simple and reasonable in structure, high in precision, safe and reliable.

Owner:ZHENGZHOU TECHN COLLEGE

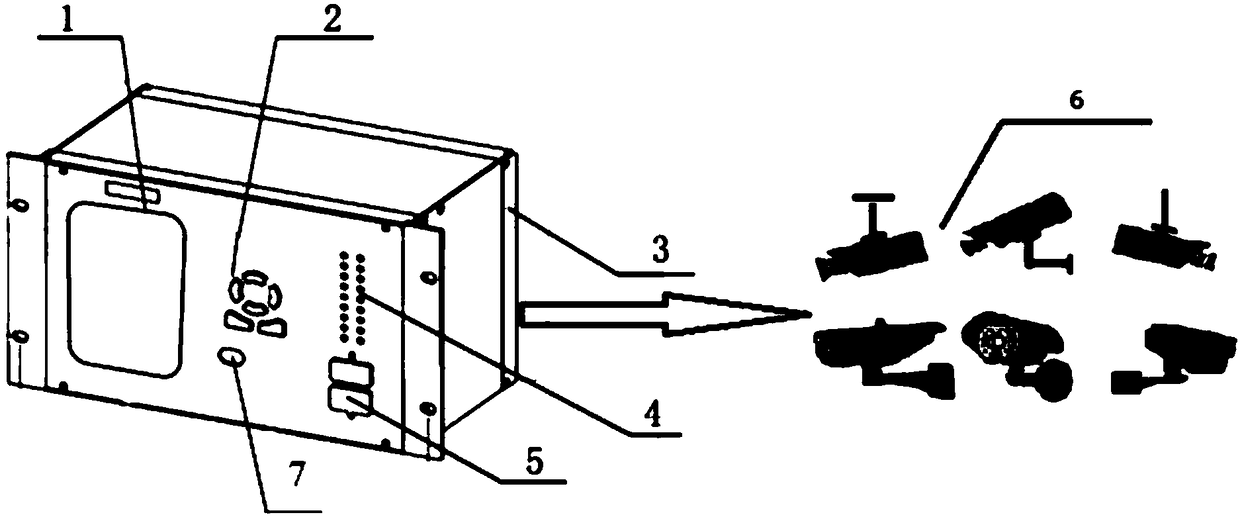

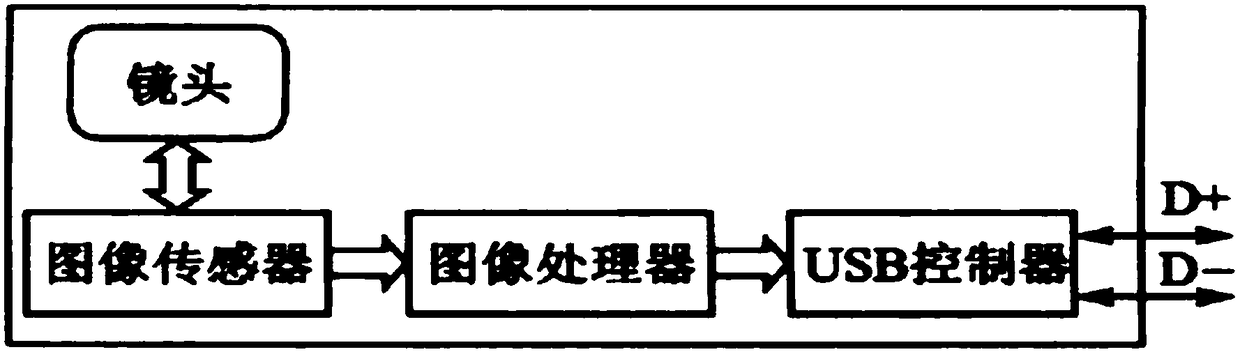

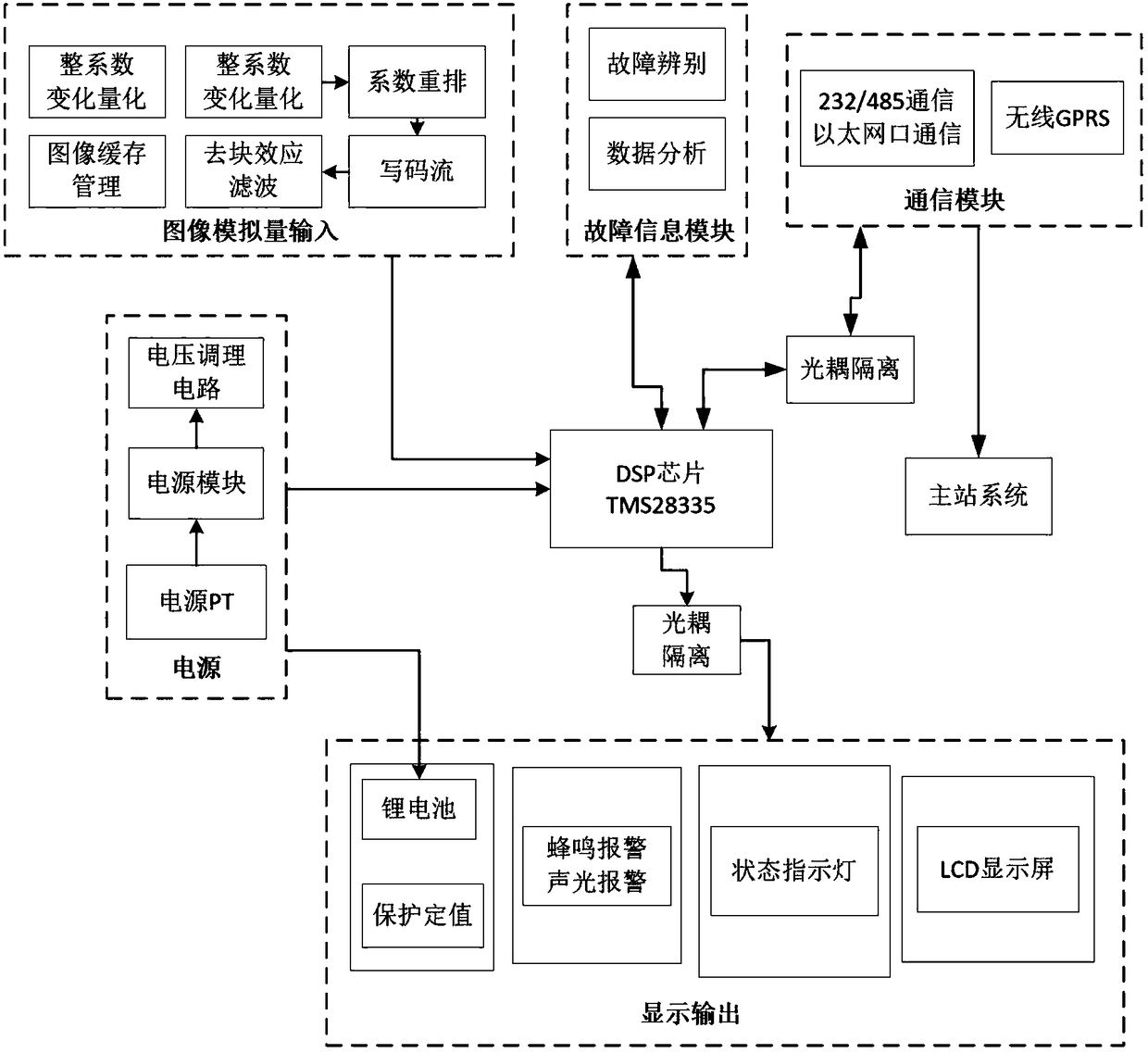

Power distribution terminal for image automatic recognition of power equipment, and control method

PendingCN108288877AReduce power consumptionAutomation reductionCircuit arrangementsCharacter and pattern recognitionKey pressingData information

The invention relates to a power distribution terminal for image automatic recognition of power equipment, and a control method. The power distribution terminal comprises a power distribution terminalbody, an image collection module, an image data processing module, and a fault information module, wherein the power distribution terminal body comprises a power distribution terminal front panel anda power distribution terminal back panel; the power distribution terminal front panel is provided with a display screen; the power distribution terminal front panel is provided with indicator lamps,communication interfaces and operation keys; the image collection module enables the collected image information to be processed by the image data processing module and then transmits the processed image information to a central processing unit of the power distribution terminal; the output interface of the central processing unit of the power distribution terminal is connected with the display screen; the central processing unit of the power distribution terminal displays data information on the display screen; and the fault information module performs data fault analysis on the collected data information and transmits to the central processing unit of the power distribution terminal, and the display screen displays the real-time data information and the fault information. The power distribution terminal for image automatic recognition of power equipment has low power consumption, automation and high intelligent degree.

Owner:北京合锐清合电气有限公司

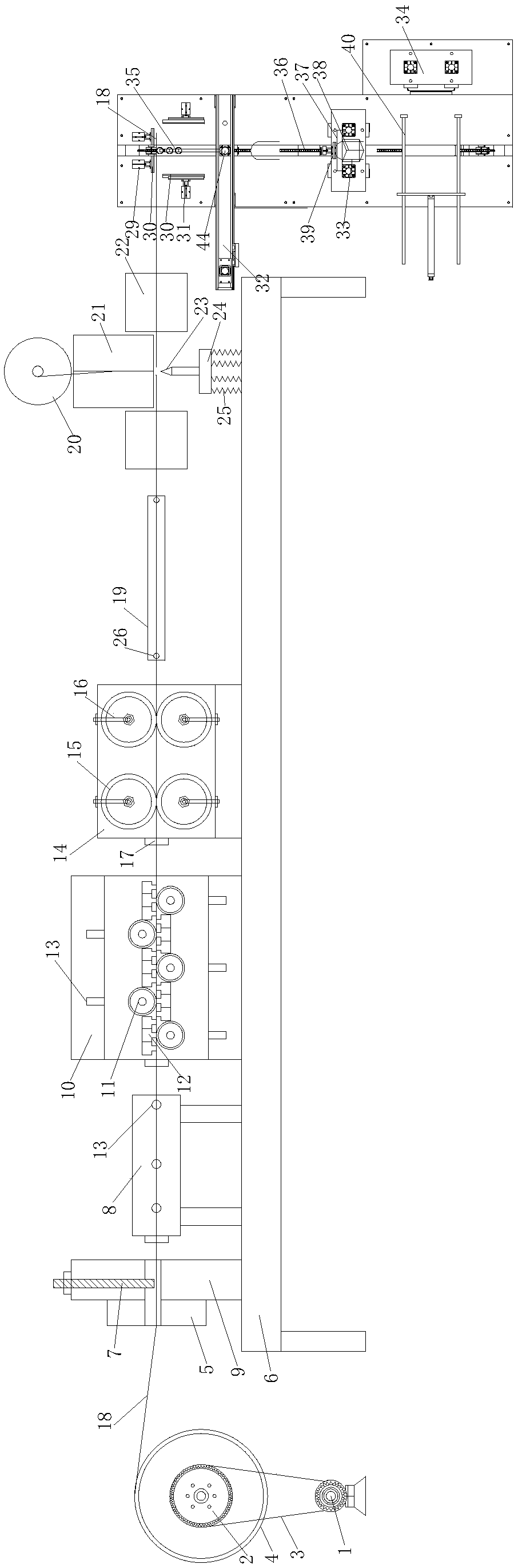

Metal wire drawing, shearing and bending integrated machine and machining process thereof

PendingCN109175151AIncrease productivityReduce labor intensityMetal working apparatusEngineeringMachining process

The invention belongs to the technical field of integrated machines and particularly relates to a metal wire drawing, shearing and bending integrated machine. The metal wire drawing, shearing and bending integrated machine comprises shearing equipment, drawing equipment and bending equipment which are installed on a frame in sequence, wherein the drawing equipment comprises a wire feeding structure, a positioning device, drawing devices and a rolling compaction straightening device, the drawing devices comprise the first drawing device and the second drawing device, and the first drawing device comprises a bottom plate, upper and lower two sets drawing idler wheel sets which are in misalignment arrangement and installed on the bottom plate and adjusting screw rods adjusting positions of drawing idler wheels correspondingly. By means of a machining process of the metal wire drawing, shearing and bending integrated machine disclosed by the invention, shearing, drawing and bending are integrated into a whole, full automation and integration are realized, straightening of metal wires is realized by integrating drawing deformation and plastic deformation, then the shearing and bending are performed on the metal wires through the shearing equipment and the bending equipment, the product qualified rate is high, and the technical benefits are obvious.

Owner:浙江步丹工贸有限公司

Part cracking inspection device

PendingCN110530585AImprove applicabilityImprove detection efficiencyMeasurement of fluid loss/gain rateAlarmsProduction scheduleEngineering

The invention discloses a part cracking inspection device. The device comprises a supporting mechanism used for supporting and fixing parts, a detection mechanism used for providing pressure stabilizing gas, a detection tool used for receiving the parts and forming a closed space, and a fixing mechanism used for fixing the parts. The detection mechanism, the detection tool and the fixing mechanismare supported and detected by the supporting mechanism. The detection mechanism inflates and measures pressure during detection. The detection tool clamps the parts, and then the fixing mechanism presses the parts on a top of the detection tool. A relatively closed space is formed between the parts and the tool, whether gas leakage exists in the space or not is judged through inflation, pressuremaintenance and measurement by the detection mechanism, and therefore, the detection of cracks of the parts is achieved. The device has the advantages of high applicability and high detection efficiency, and the lag of a production schedule caused by product replacement is greatly reduced.

Owner:苏州市格范五金塑胶工业有限公司

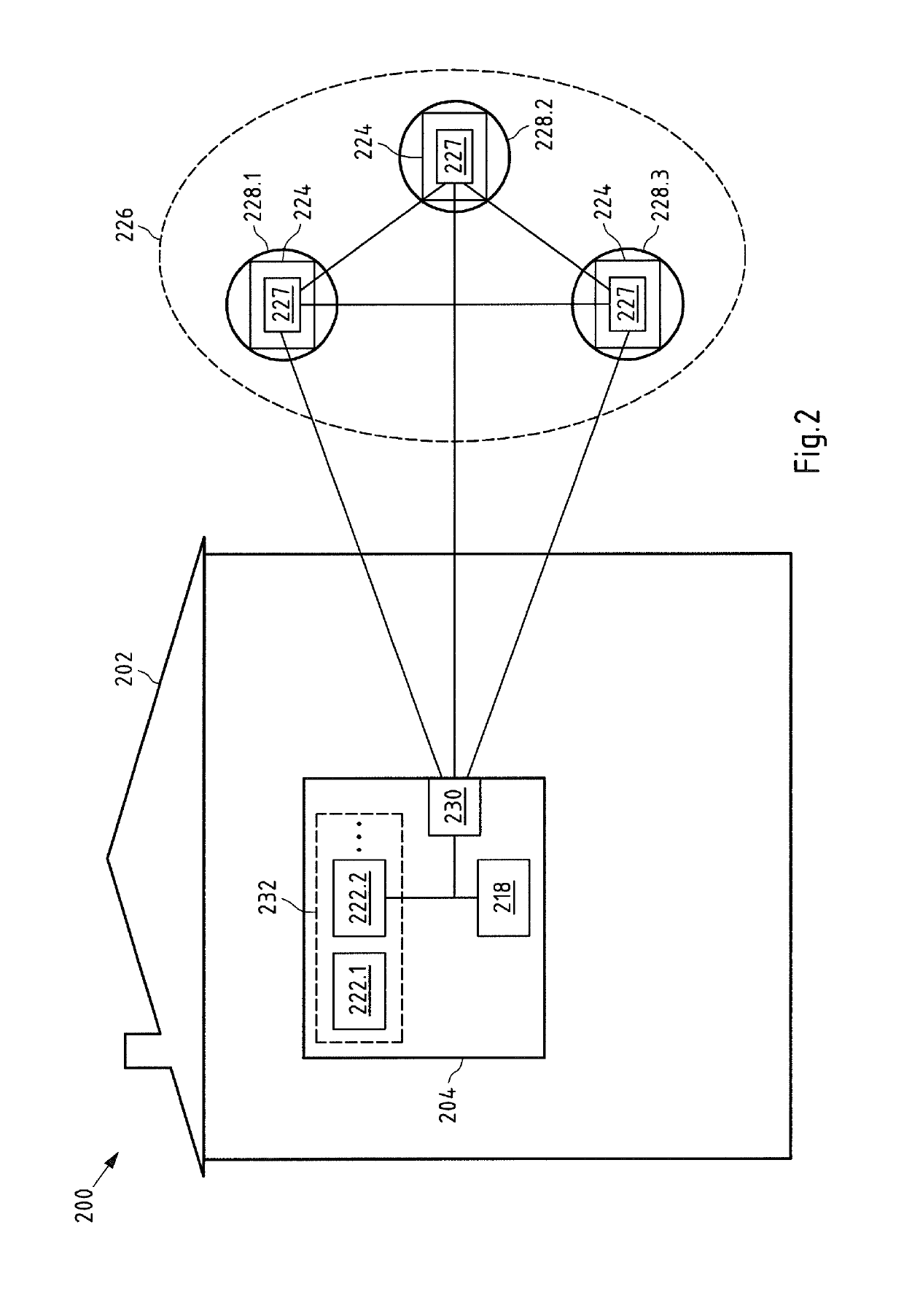

Building automation system

ActiveUS20190190742A1Easy to implementReduce transaction costsProgramme controlComputer controlEngineeringBuilding automation

Disclosed herein are embodiments of a building automation system. The building automation system includes at least one first appliance device having an actor and / or a sensor. The first appliance device includes a first function module and is configured to operate in accordance with the first function module in order to provide a first function. The building automation system also includes a peer-to-peer network with a peer-to-peer application and a peer-to-peer module assigned to the first appliance device and configured to communicate with the peer-to-peer application. The peer-to-peer application includes a controlling means configured to provide a second function module to the first appliance device by means of the peer-to-peer module assigned to the first appliance device, and the first appliance device is configured to operate in accordance with the second function module in order to provide at least one second function.

Owner:INNOGY INNOVATION GMBH

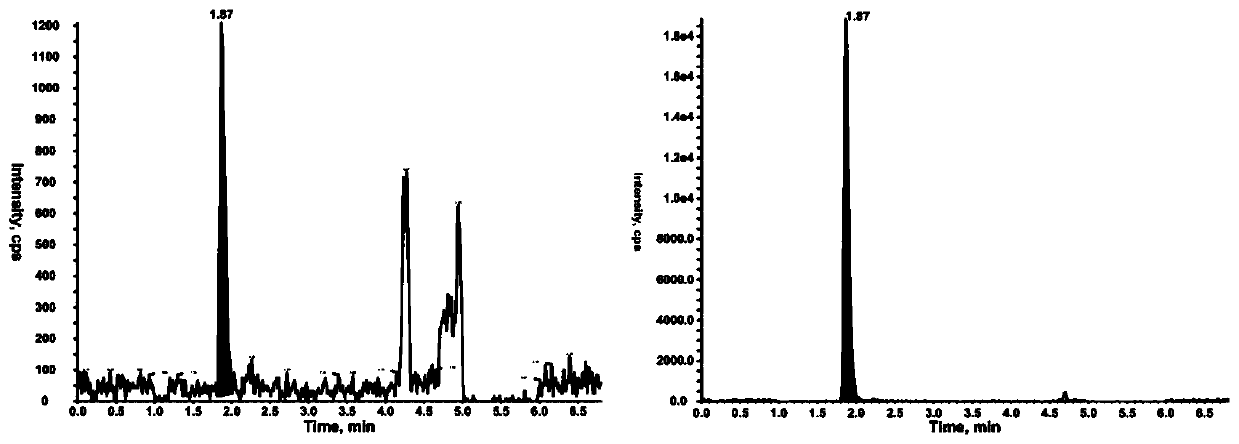

High performance liquid chromatography detection method of free methoxy group noradrenaline and methoxy group in human plasma

PendingCN109725079AReduce distractionsReduce the impactComponent separationIon exchangeSolid phase extraction

The invention discloses a high performance liquid chromatography detection method of free methoxy group noradrenaline and methoxy group in human plasma. The high performance liquid chromatography detection method of the free methoxy group noradrenaline and the methoxy group in the human plasma comprises the following steps that: (1) sample pre-treatment is conducted, interior label working solution and spiritus mindereri are successively added into a plasma sample, vortex is mixed, and centrifugation is conducted; (2) weak positive ion exchange solid phase extraction 96 pore plate (SPE 96 poreplate) is activated; (3) solid phase extraction treatment is conducted, after the step (1) is conducted, the sample is loaded into the treated SPE 96 pore plate, a formic acid acetonitrile solution is eluted, and eluent is dried by nitrogen; and (4) redissolution is conducted, analysis and detection are conducted by the high performance liquid chromatography detection method. The high performanceliquid chromatography detection method of the free methoxy group noradrenaline and the methoxy group in the human plasma has the advantages that accuracy is high, reproducibility is high, sensitivityis high, specificity is high, the efficiency is high, flux is high, the cost is low, and the operation is easy, convenient and fast.

Owner:杭州凯莱谱精准医疗检测技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com