AGV (automated guided vehicle) forklift control method and device and AGV forklift

A control method and control device technology, applied in the field of forklifts, can solve the problems that the pallet cannot be moved out of the fixed position, the cost of the positioning system is high, and the use is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0049] The invention proposes a control method of an AGV forklift, which is used for the AGV forklift to move pallets.

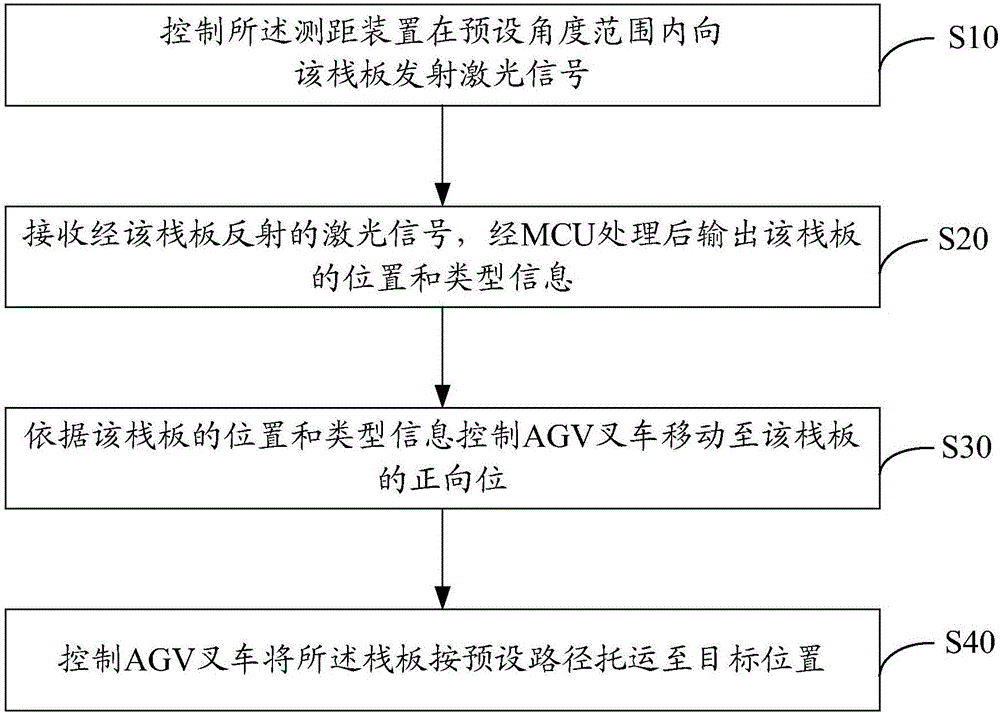

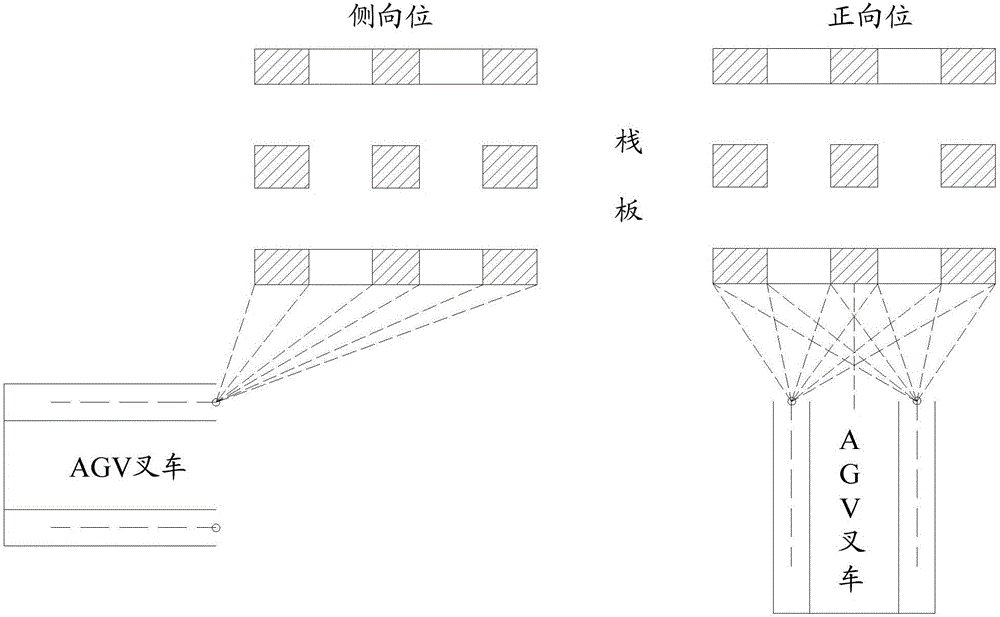

[0050] refer to figure 1 , figure 1 It is a flowchart of an embodiment of the control method of the AGV forklift of the present invention.

[0051] In this embodiment, the two fork arms of the AGV forklift are provided with distance measuring devices that emit laser signals, and the control method includes the following steps:

[0052] S10: controlling the distance measuring device to emit a laser signal to the pallet within a preset angle range;

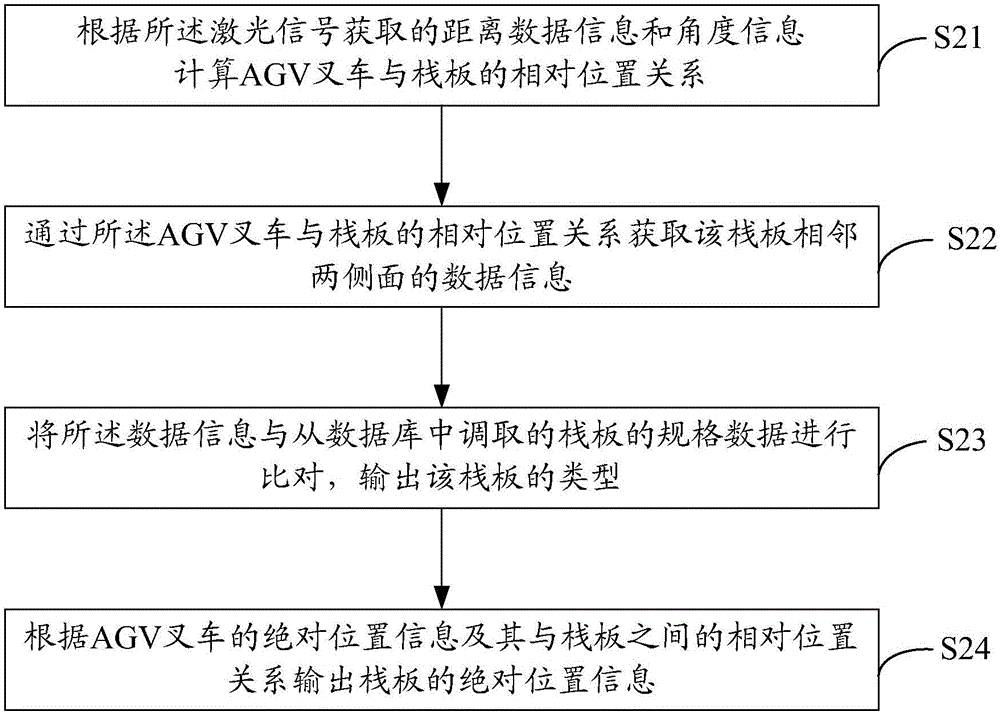

[0053] S20: Receive the laser signal reflected by the pallet, and output the position and type information of the pallet after being processed by the MCU;

[0054] S30: Control the AGV forklift to move to the positive position of the pallet according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com