Patents

Literature

31results about How to "Easy pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

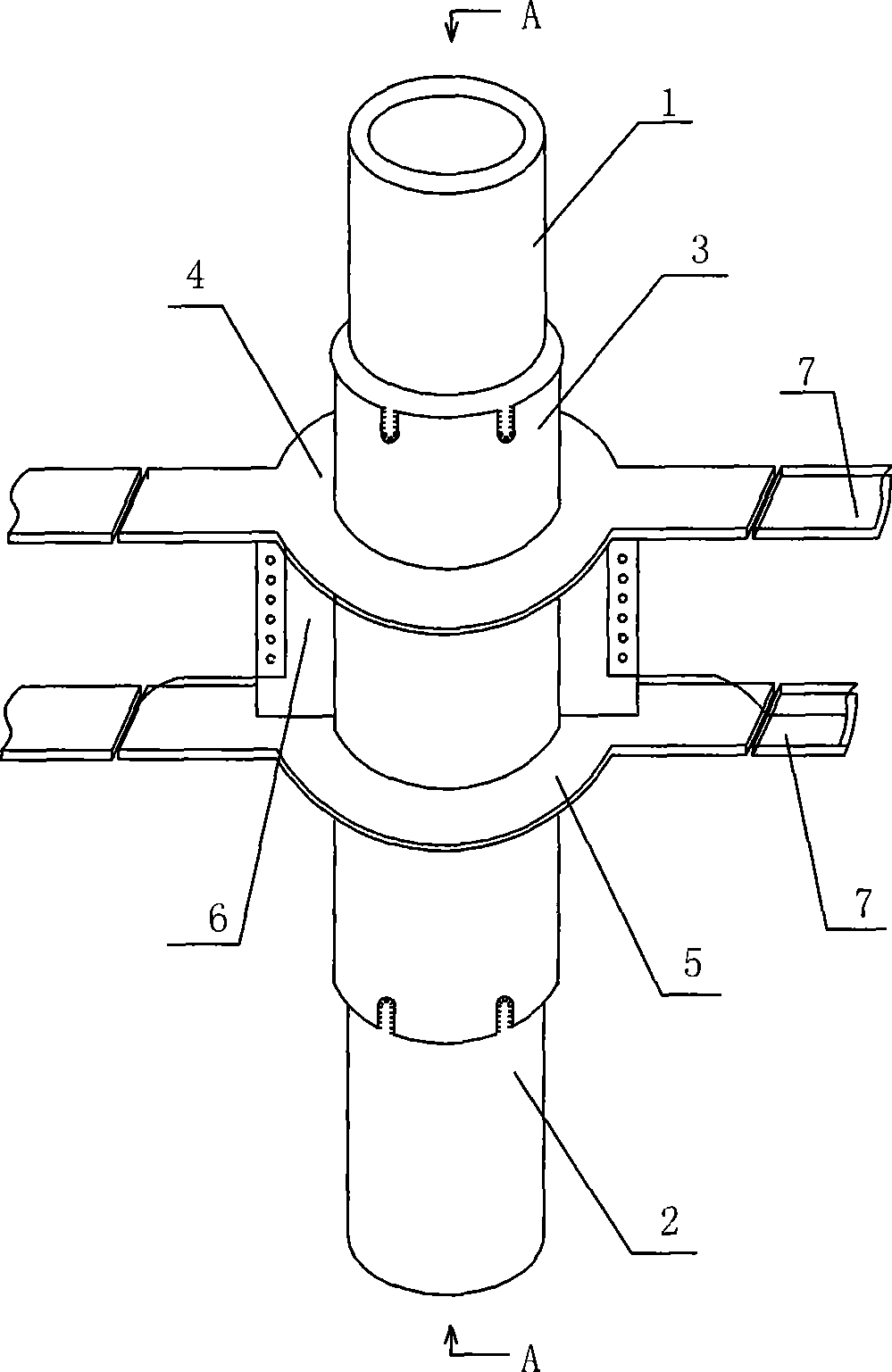

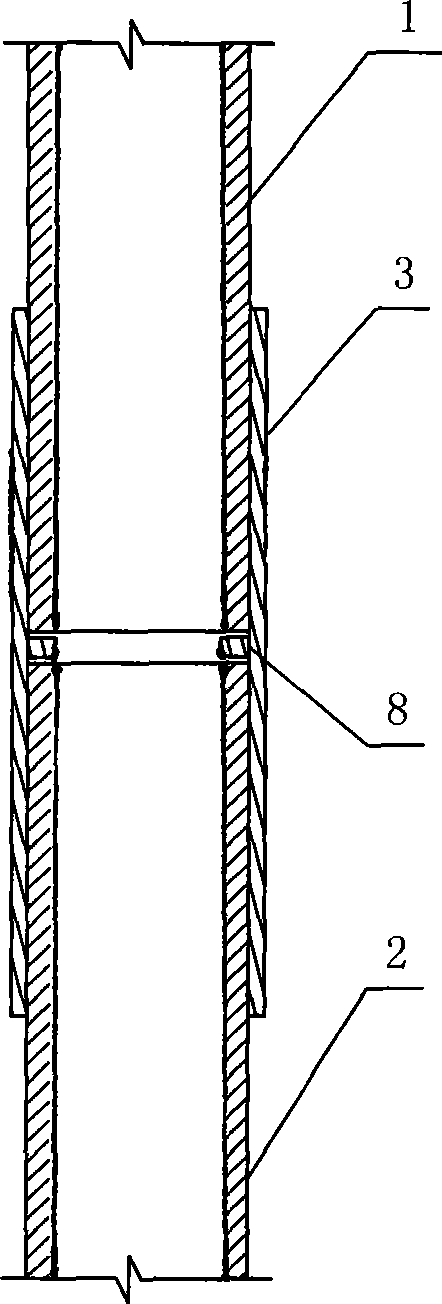

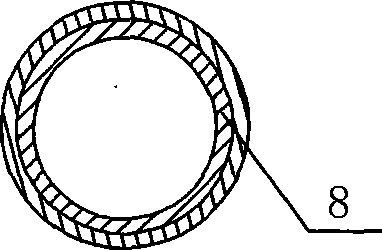

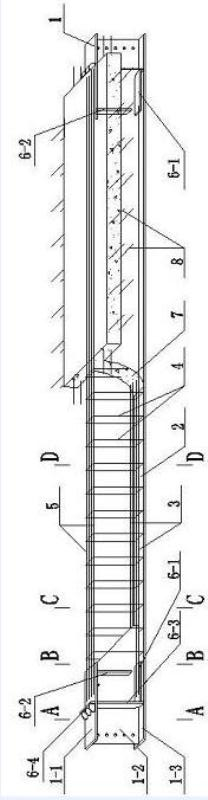

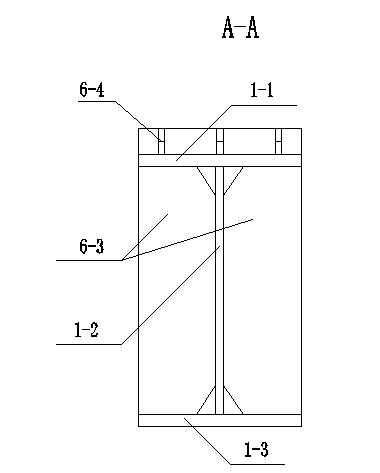

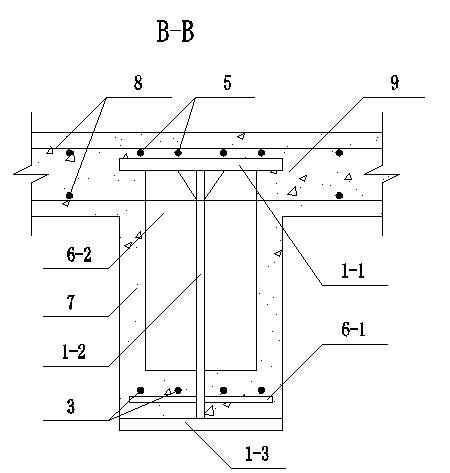

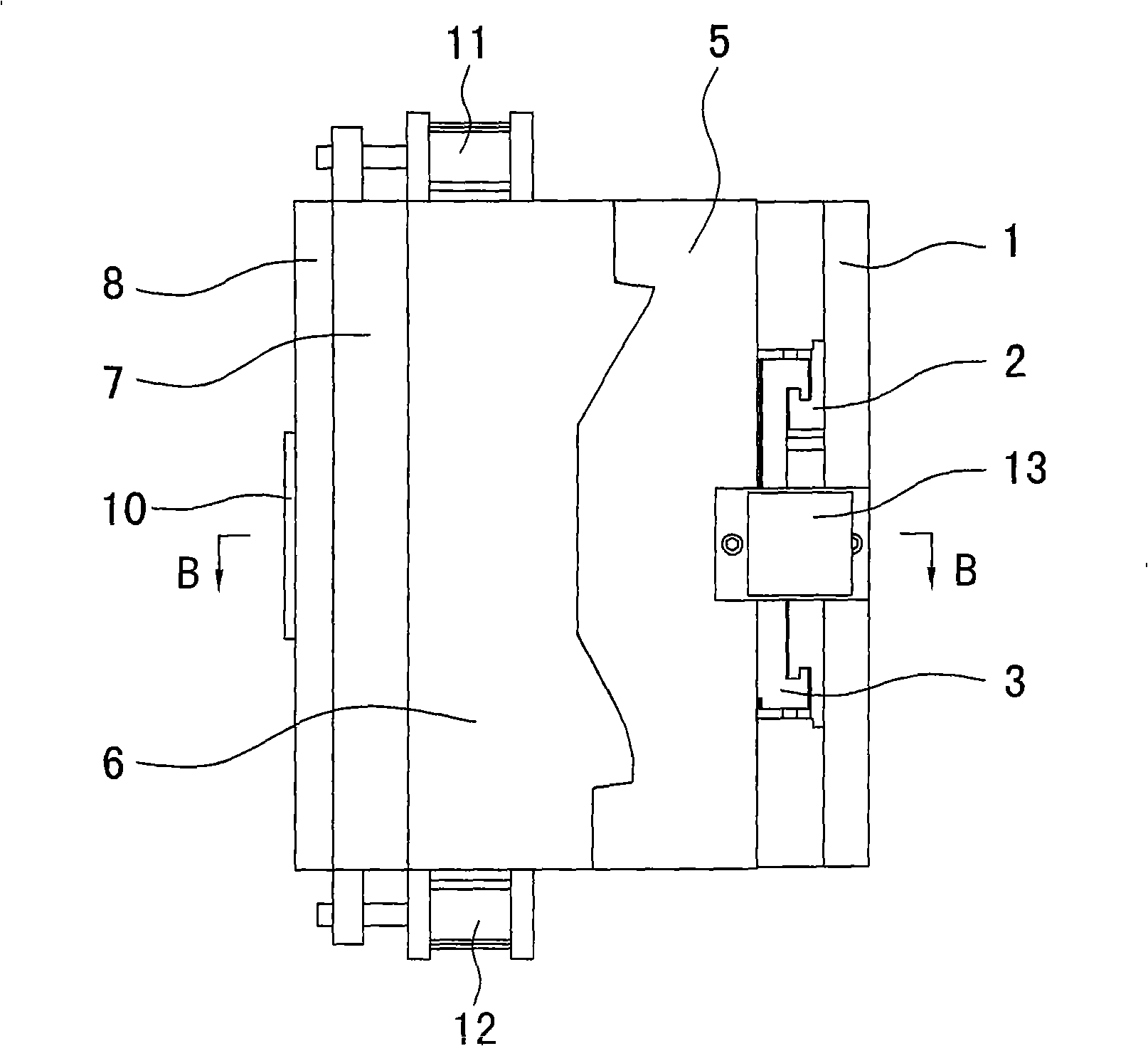

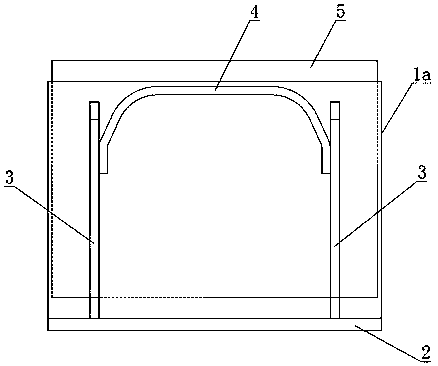

Steel pipe concrete segment type coat node and its construction method

InactiveCN101476348AMeet the needs of strong nodes and weak membersIncrease stiffnessBuilding constructionsUltimate tensile strengthMechanical property

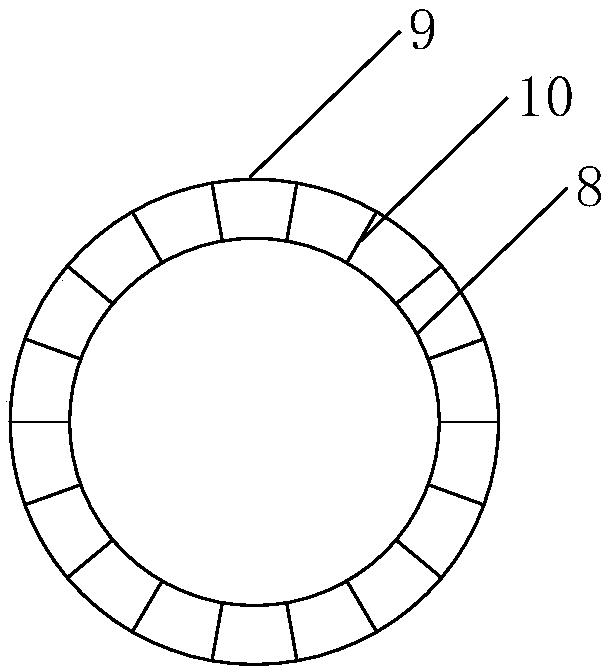

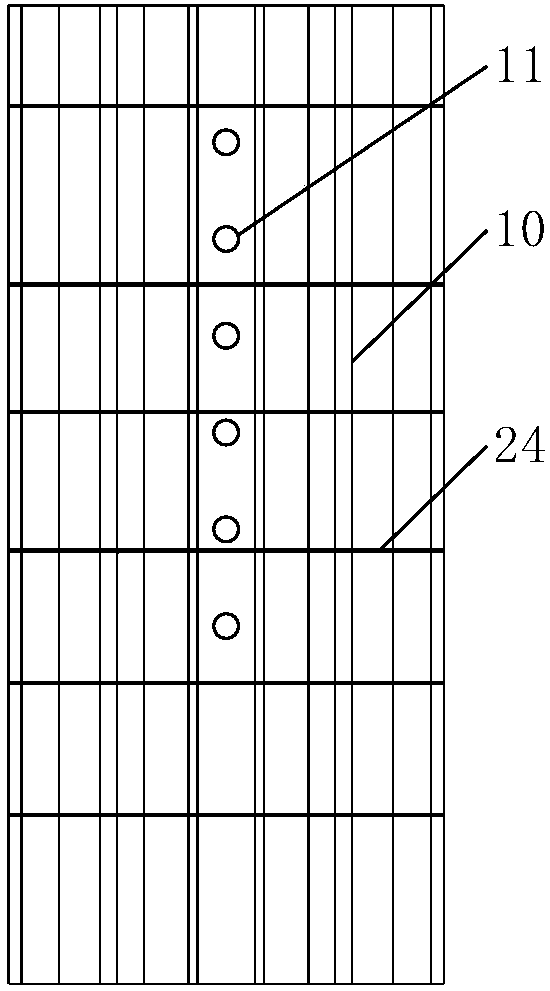

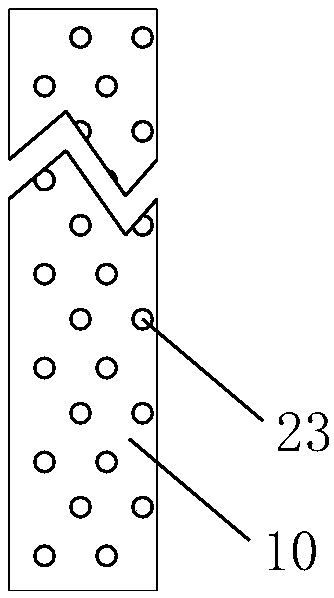

The invention relates to a concrete-filled steel tube sectional type sleeve gusset and a construction method thereof, which relate to a connecting gusset for connecting a concrete-filled steel tube column and a girder in civil engineering and a construction method thereof. The concrete-filled steel tube sectional type sleeve gusset comprises the concrete-filled steel tube column and the steel girder which is connected with the column, wherein the concrete-filled steel tube column is formed by filling concrete into a steel tube; the steel tube is formed by connecting an upper column steel tube and a lower column steel tube through a connecting sleeve; the connecting sleeve and the lower column steel tube are in split type; an upper reinforcement ring plate and a lower reinforcement ring plate are arranged outside the connecting sleeve; and a vertical connecting plate is arranged between the upper reinforcement ring plate and the lower reinforcement ring plate. The connecting sleeve and the lower column steel tube in the concrete-filled steel tube sectional type sleeve gusset are in split type, so that the concrete casting strength of the lower column steel tube and the upper column steel tube can be different under the condition of construction, thereby the requirement of strong gussets and weak members can be met. Moreover, the concrete-filled steel tube sectional type sleeve gusset has the advantages of concise and definite force transferring path, large gusset rigidity, high bearing capacity, superior mechanical property, good anti-seismic performance and simple and convenient processing and manufacture.

Owner:DAQING GASOLINEEUM INST

Preparation method of aluminum oxide metal ceramic reinforced iron-based composite

The invention relates to a preparation method of aluminum oxide metal ceramic reinforced iron-based composite, namely, aluminum-oxide-based metal ceramic is used as a structural framework and one of effective components to prepare metal ceramic iron-based composite, which is consistent in structure, even in metal phase distribution, high in mechanical performance, and high in wear resistance, under certain pressure by melt casting and further processing. The preparation method includes the steps of firstly, preparing aluminum oxide metal ceramic framework base pretreated by activated Si into surface-modified prefabricated ceramic part with a silk-screen-shaped pore structure by high-temperature sintering; secondly, preparing a pouring sand module; thirdly, placing the pouring sand module into a casting sand box for pretreating, pouring, vacuumizing, and allowing iron-based molten metal to fully permeate into pores of the prefabricated ceramic part to form a rigid integrity; and fourthly, performing heat treatment and air cooling to obtain the iron-based composite with closely combined aluminum oxide metal ceramic and iron base.

Owner:北京康盛宏达科技有限公司

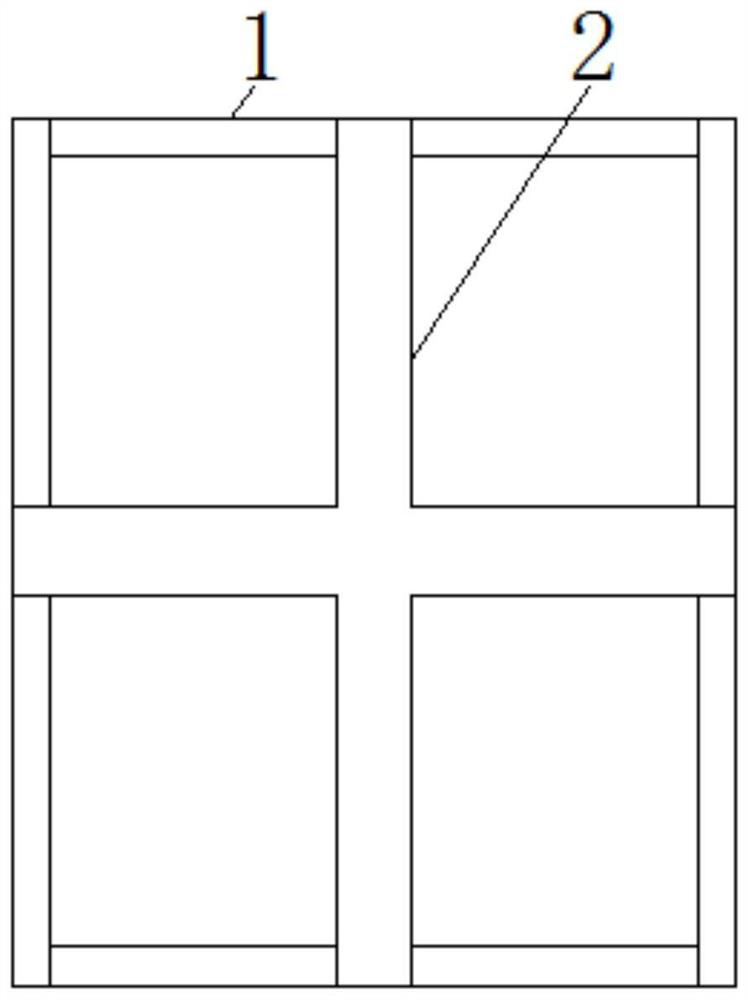

Cast-in-place steel-concrete composite beam

ActiveCN101845871AFast constructionFast integrityLoad-supporting elementsFloor slabReinforced concrete

The invention discloses a cast-in-place steel-concrete composite beam, which relates to a composite beam. The cast-in-place steel-concrete composite beam solves the problems that a reinforced concrete beam and a column connection node in the existing steel structure and the existing steel-concrete composite structure have complex structures and are difficult to construct, the problems that a common composite beam has a large steel consumption and a high structure manufacturing cost, and the problems that a composite beam of which the publication number is CN101215855 is complex in operation and is inconvenient to construct when connected with a reinforced concrete wall column, and has low bearing capacity, small rigidity, weak spanning capacity, large fracture width for tensile region concrete and small application range. Bottom flanges of two I-shaped steel beam sections of the cast-in-place steel-concrete composite beam and a tensile region steel plate are made into an integral body; a longitudinal steel plate ribbed stiffener is connected through a fire-resisting longitudinal bar; top flanges of the two I-shaped steel beam sections are connected through a tensile region longitudinal bar; stirrups are uniformly arranged along the longitudinal direction of the fire-resisting longitudinal bar; floor steel bars are paved on a stiffening framework of the composite beam; and concrete is poured on the floor steel bars and the stiffening framework of the composite beam. The cast-in-place steel-concrete composite beam is applied to civil engineering constructions.

Owner:HARBIN INST OF TECH

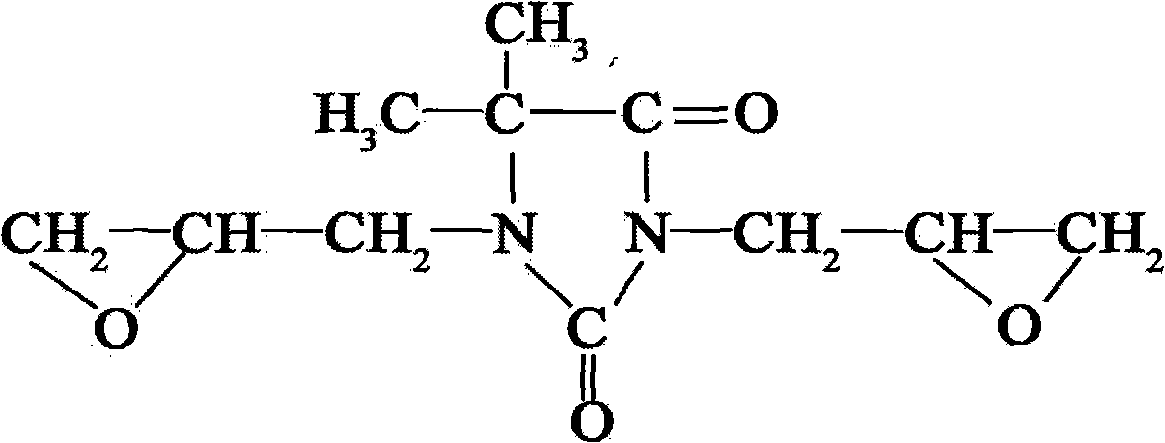

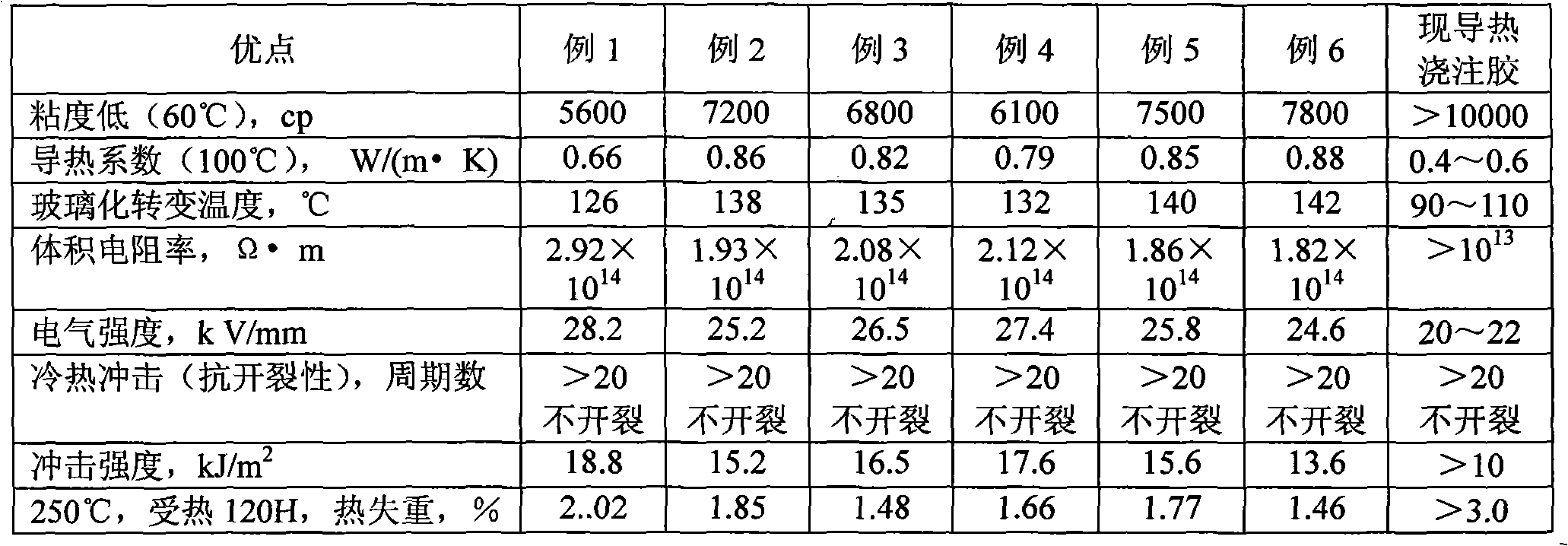

Heat conduction insulating casting glue and preparation method thereof

ActiveCN102093665ALow viscosityGood workmanshipInorganic insulatorsHeat-exchange elementsEpoxyTetrahydrophthalamic acid

The invention relates to a heat conduction insulating casting glue and a preparation method thereof. The casting compound comprises the following main components in parts by weight: (A) 100 parts of hydantoin epoxy resin, (B) 60-120 parts of anhydride curing agent, and (C) 200-400 parts of inorganic heat conductive filler, wherein the component A (per 100 weight parts) contains 10-15 weight partsof alcohol plasticizer; the component B is one or more of hexahydrophthalic anhydride, tetrahydrophthalic anhydride, methyltetrahydrophthalic anhydride, methylhexahydrophthalic anhydride and methylnadic anhydride; and the component C is one or more of silica micropowder, aluminum oxide, aluminum nitride and boron nitride in 300-900 meshes. The preparation method of the casting compound comprises the following steps: mixing A and B proportionally; soaking C in ethanol solution of silane coupling agent, dispersing at a high speed, filtering, and oven-drying; heating the mixture of A and B, adding C, mixing, and debubbling; and casing, and curing. The casting compound provided by the invention has low viscosity, greatly improved heat-conducting property and improved mechanical properties, and is convenient in casting. The preparation method of the casting compound is solvent-free, and has no pollution to the environment.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

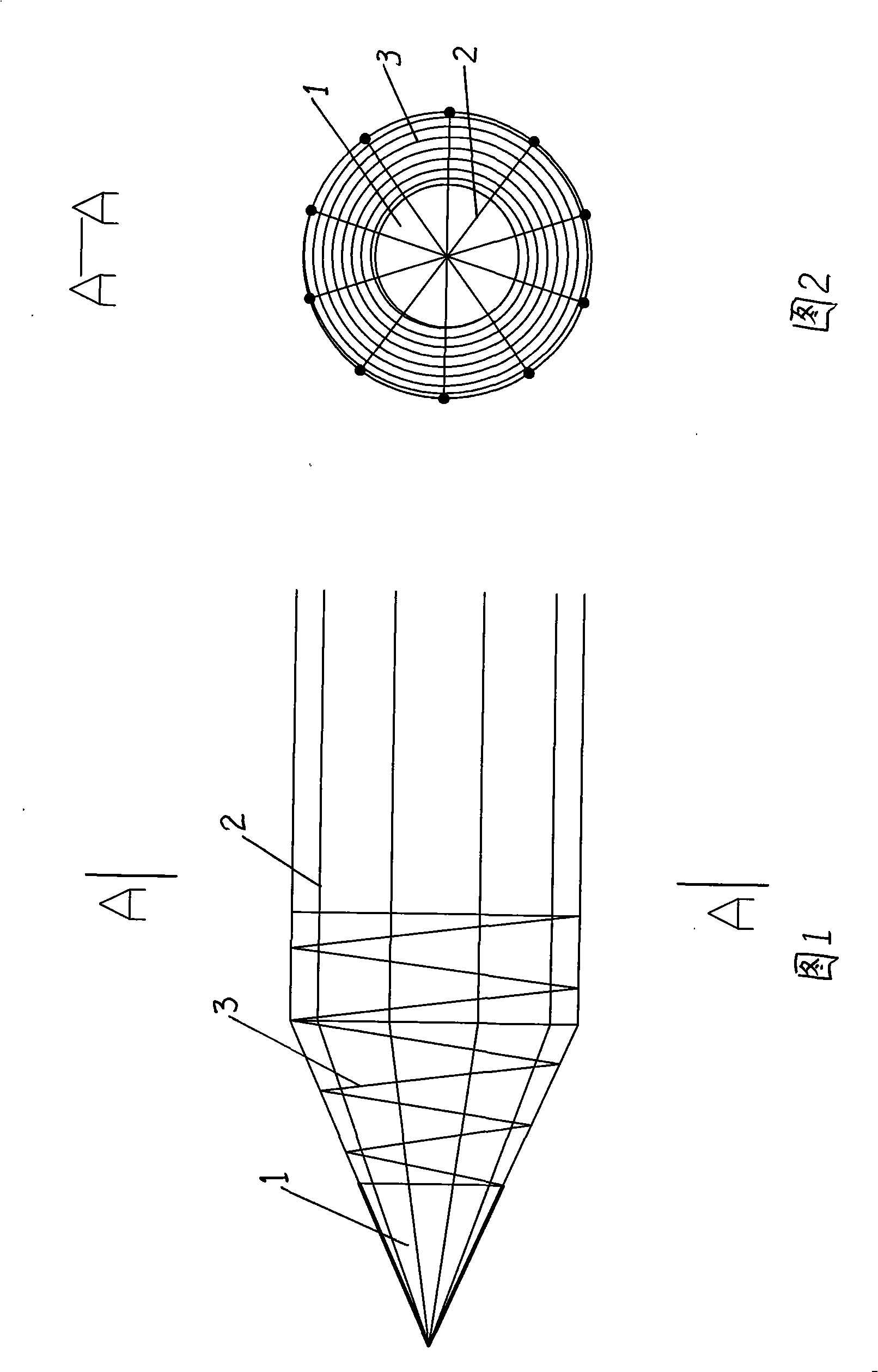

Prestressing force pipe pile precast pile tip and its production process

InactiveCN101307597AEasy pouringGuarantee product qualityBulkheads/pilesFoundation engineeringEngineering

The invention relates to the architecture field and relates to a preformed pile point for a prestressed tubular pile, wherein, anchor bars are welded continuously on the inner circumference of the steel point; the outer layers of the anchor bars are bound and fastened by annular spirally reinforced columns; and prestressing tendon hole sites are preserved on a placing concrete body. The preformed pile point for the prestressed tubular pile is a unique preformed pile point with the prestress performance; the pile point is integrated into a whole with a square pile; the bearing capacity of a pile point part is improved; and the pile point is difficult to break and maintains the same service life with the pile. The method for producing the pile point guarantees the product quality, saves the labor and a great number of steel products, is safe and reliable, improves the durability and the earthquake resistance, and meets the demand of architectural pile foundation engineering.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

Method for low-pressure casting thin-wall long-sized castings and equipment used by same

The invention relates to a method for low-pressure casting thin-wall long-sized castings and equipment used by the same, wherein metal materials are firstly smelted, a furnace body is closed, a mould is prepared, dry compressed air is filled into an airtight container, under the action of gas pressure, liquid metal rises along a multitube and multi-sprue riser tube and stably enters a mould cavity through a sprue, and the gas pressure on the liquid level in a crucible is kept; and after the casting is completely solidified, the gas pressure on the liquid level is relieved to enable the unsolidified liquid metal in the riser tube to flow back into the crucible, and then the casting is taken out. The method for producing the thin-wall long-sized casting has the advantages that mold-filling is stable, a product is well molded, the mold-filling of liquid metal is carried out under the pressure, the liquid metal has good liquidity and is convenient to cast the thin-wall casting of the kind the casting is crystallized and solidified under the pressure and has a compact structure, so the mechanical property is improved, a pouring system is simple, casting heads are reduced, mechanization and automation are realized, the labor intensity of workers is reduced, a mould with multi-cavities is realized, the production efficiency is improved and the like.

Owner:烟台路通精密科技股份有限公司

Processing die of dual-color plastic chair and its processing method

InactiveCN101288992AIncreasing the thicknessClear color boundariesDomestic articlesEngineeringMechanical engineering

A processing die for a double-color plastic chair is provided with a casting system, a die cavity, a mold core and a demoulding system; a product mould cavity is arranged between the die cavity and the mold core. The processing die of the invention is characterized in that the mold core is provided with a movable embedded block which is connected with an inclined slide block A; the inclined slide block A is contacted with an inclined slide block B; the slide block B is driven by a pushing air cylinder; the die cavity is provided with two pouring heads; an opening of the first pouring head is arranged on the back surface of the die cavity and the outer layer of an injection plastic chair; an opening of the second pouring head is arranged on the end surface of the die cavity and the inner layer of the injection plastic chair. A seat plate and a backrest of the plastic chair manufactured by the die of the invention are compounded by the inner layer and the outer layer with two different colors; the limit of the colors is clear; compared with a single color chair, the appearance of the invention is beautiful; the product grade is high; the thickness of a manufactured product is large; the mechanical intensity is high and the invention can be applied to work in an office and daily life.

Owner:STARWAY INTERNATIONAL HOME LIVING CO LTD

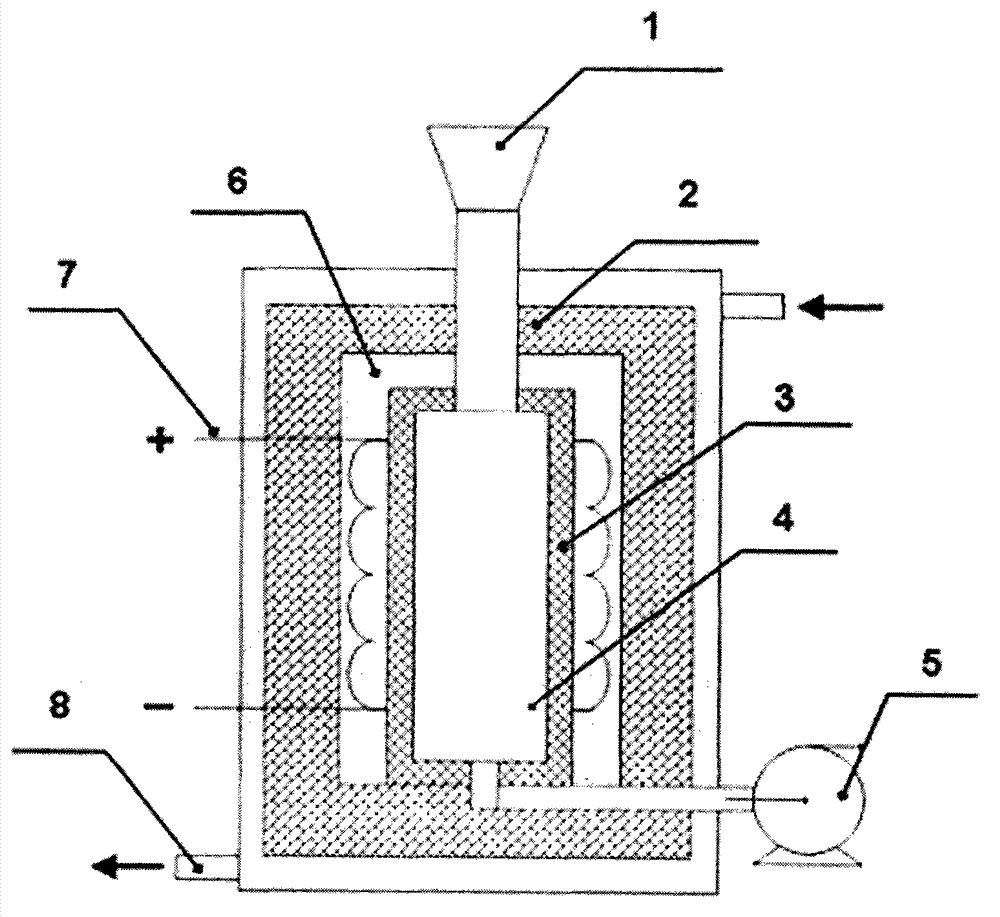

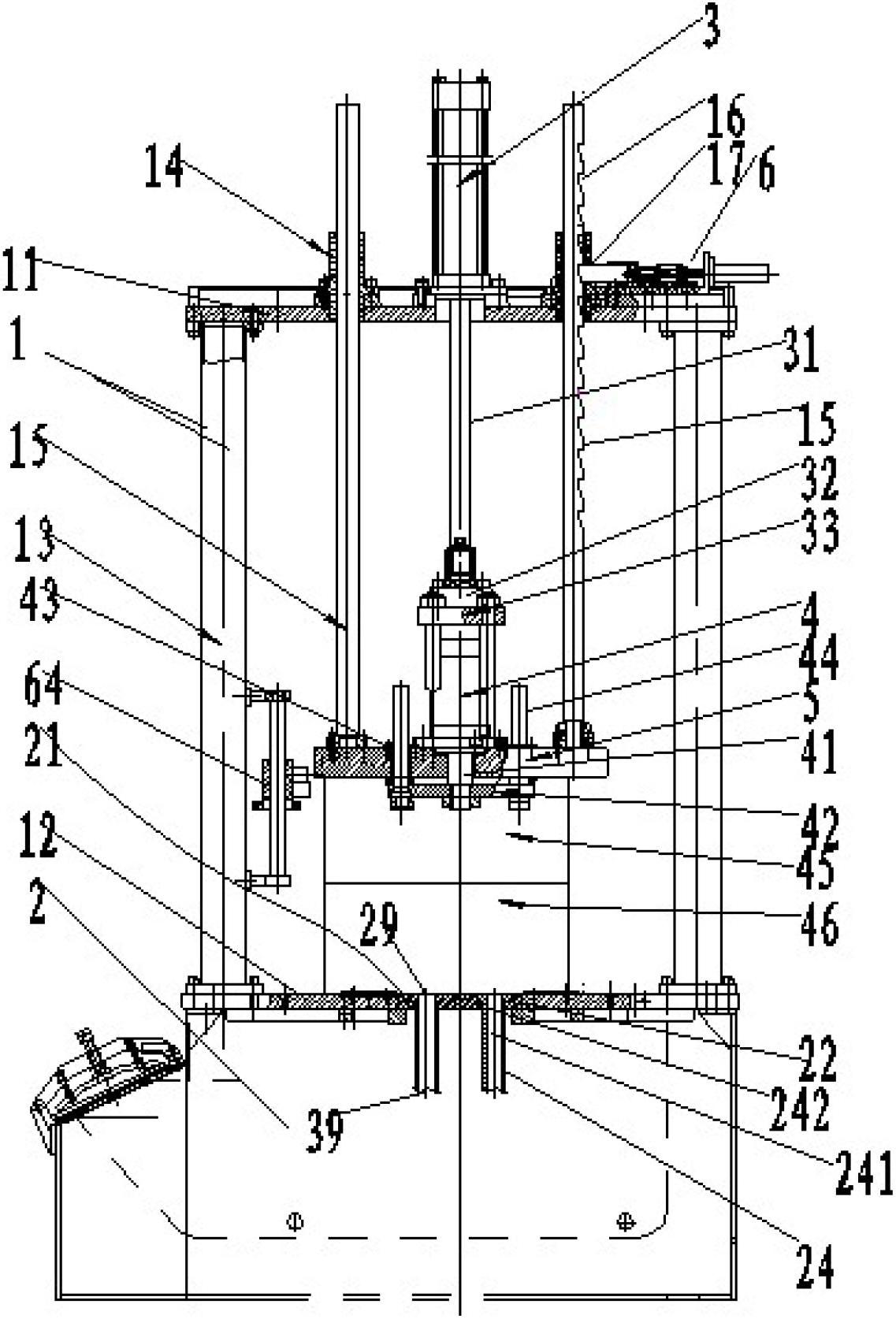

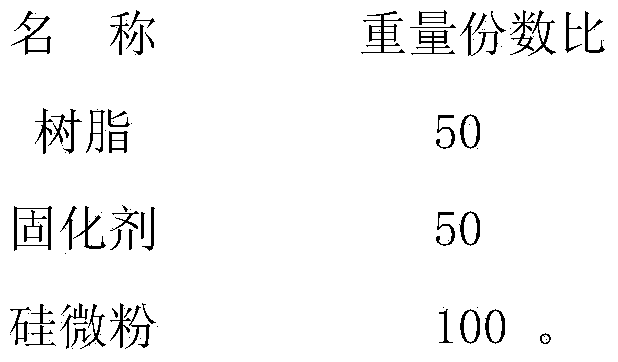

Casting materials and casting method for 35kV-grade large-capacity dry main transformer coil

The present invention discloses casting materials and a casting method for a 35kV-grade large-capacity dry main transformer coil. The casting materials comprise a resin, a curing agent, and silicon micro-powder, wherein a weight part ratio of the resin to the silicon micro-powder is 45-55:90-110, and a weight part ratio of the resin to the curing agent is 1:1. The method comprises: pre-mixing the resin and the silicon micro-powder, and pre-mixing the curing agent and the silicon micro-powder, wherein the weights of the resin and the curing agent are the same; mixing the resin-silicon micro-powder mixture and the curing agent-silicon micro-powder mixture, stirring, and degassing; and finally pouring the stirred and degassed mixture into a mold to achieve the dry main transformer coil casting. According to the present invention, the casting of the 35kV-grade large-capacity dry main transformer coil can be achieved, the coil formed by using the materials and the casting method has the high strength and does not crack; and the glass fibers are not adopted, such that the damage of the glass fibers on human body is effectively avoided.

Owner:JIANGSU HUACHEN TRANSFORMER

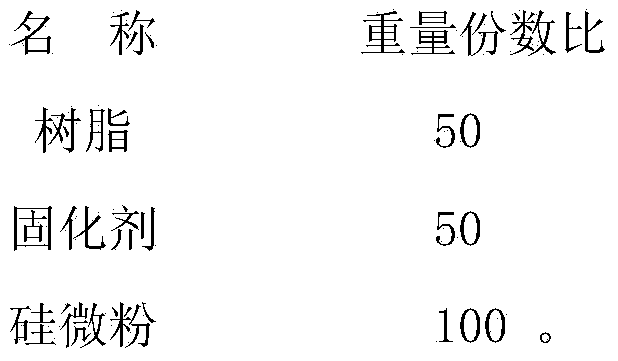

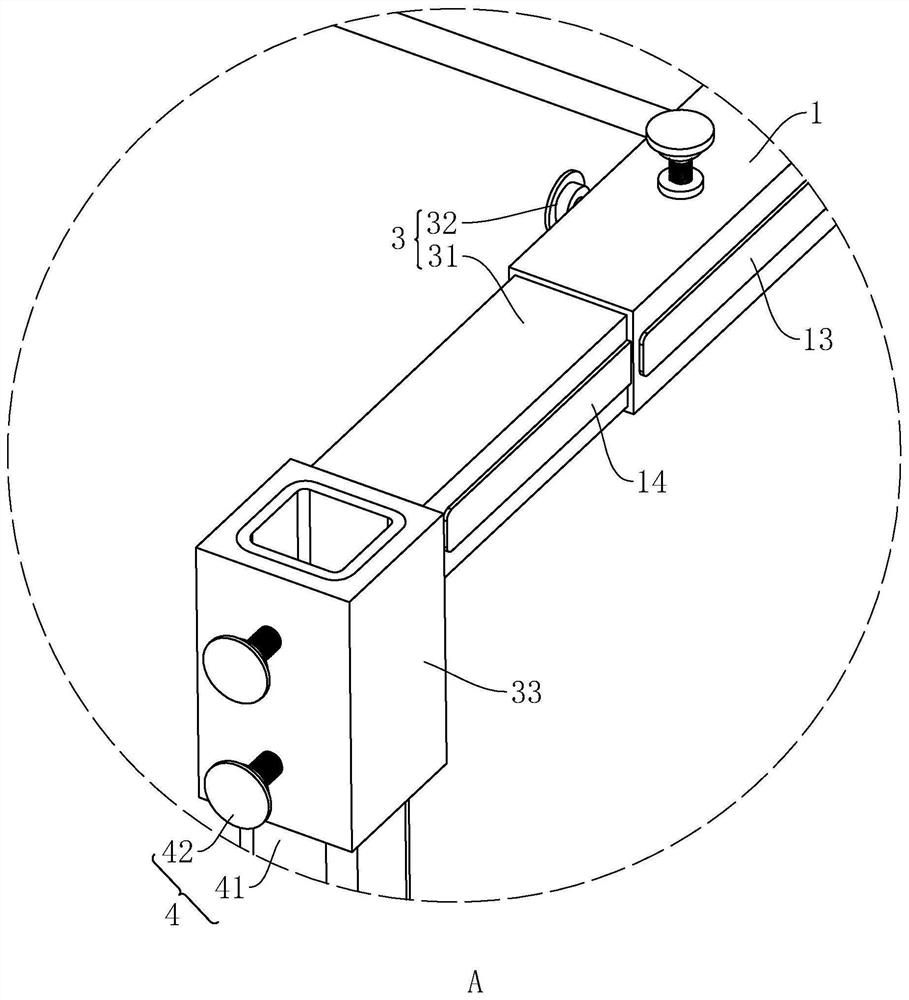

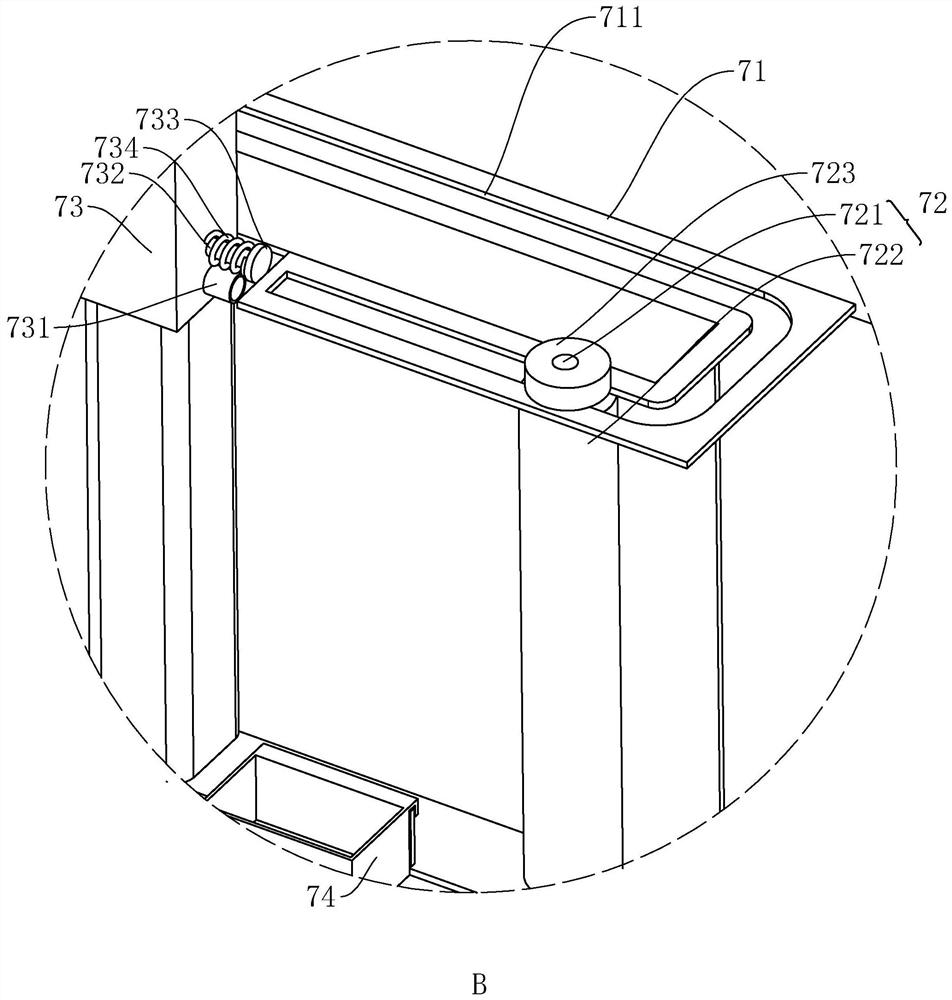

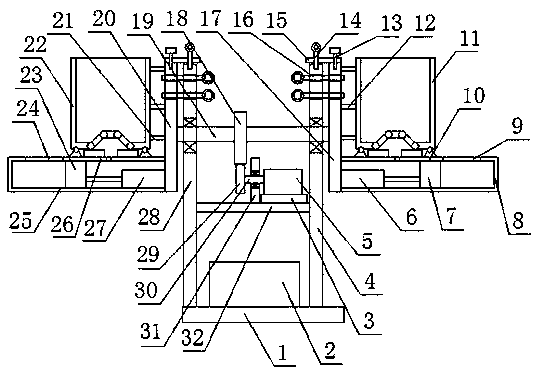

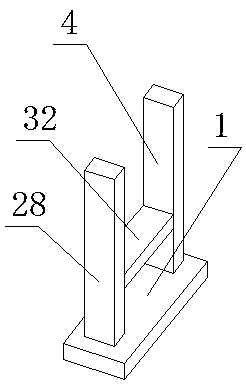

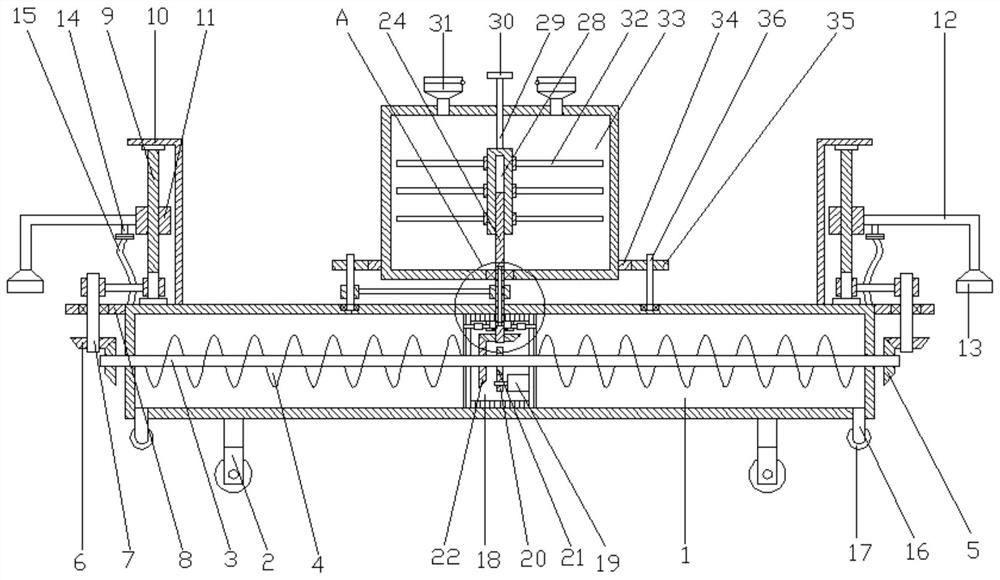

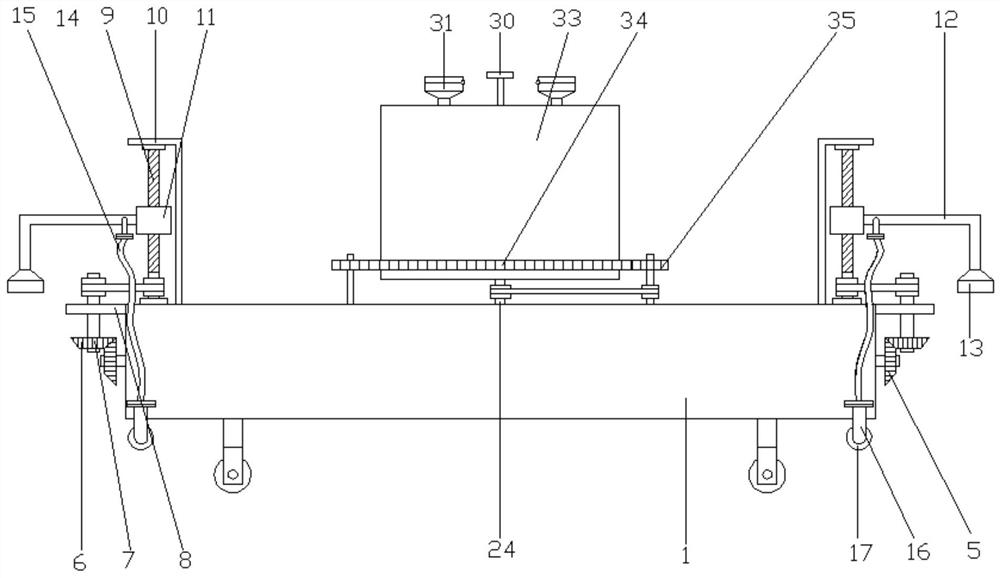

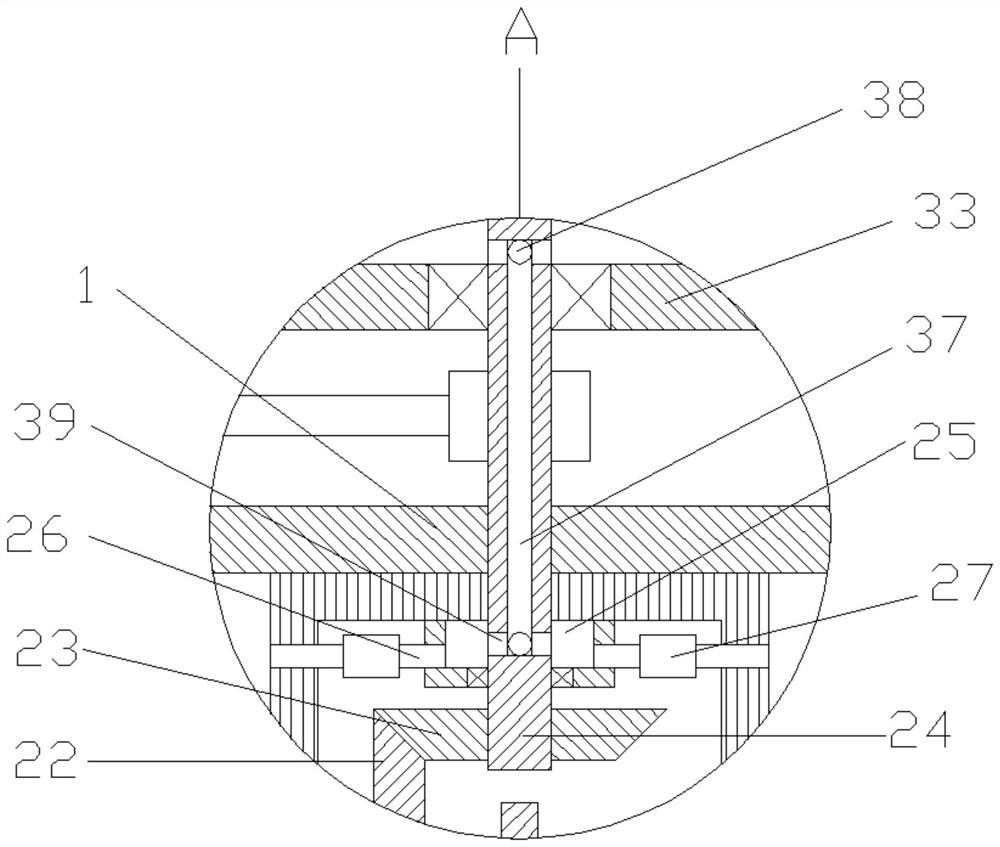

Curbstone back plain concrete efficient construction method

ActiveCN113737613AEasy pouringImprove construction efficiencyPaving gutters/kerbsRoads maintainenceArchitectural engineeringBuilding construction

The invention relates to a curbstone back plain concrete efficient construction method and relates to the field of building construction. The curbstone back plain concrete efficient construction method comprises steps that curbstone pretreatment is conducted, specifically, the curbstone back is cleaned; pouring is conducted, specifically, a movable construction tool is adopted for construction, the construction tool comprises a fixing frame, the fixing frame is in sliding connection with the curbstone, a formwork is arranged on the fixing frame, a pouring area is arranged between the formwork and the curbstone, concrete is poured into the pouring area, and after the concrete is initially set, the concrete is poured into the pouring area; and the construction tool is moved to the next construction position, pouring is continued, and the steps are repeated till pouring of the plain concrete on the back of the curbstone is completed. The construction method has advantages of being convenient to use, high in construction efficiency and capable of saving materials and cost.

Owner:JIANGSU CHENGDONG CONSTR ENG CO LTD

Preparation method of novel high-strength self-compacting concrete

InactiveCN105330217AImprove tensile propertiesIncreased shear strengthSolid waste managementSuperplasticizerStearic acid

The invention discloses a preparation method of novel high-strength self-compacting concrete. The novel high-strength self-compacting concrete comprises raw materials in parts by weight as follows: 3 parts of basalt fiber, 4 parts of glass fiber, 100 parts of cement, 160 parts of fly ash, 800 parts of rubble with the particle size of 10-15 mm, 250 parts of rubble with the particle size of 15-20 mm, 500 parts of sand, 150 parts of water, 10 parts of bentonite, 0.5 parts of a super plasticizer, 1 part of an air entraining agent, 0.1 parts of a defoaming agent, 0.4 parts of a rosin thermopolymer, 0.02 parts of a tackifier, 0.4 parts of lauryl sodium sulfate and 0.4 parts of calcium stearate. The preparation method of the novel high-strength self-compacting concrete is simple and convenient, characteristics of the raw materials can be fully used, the strength of the prepared concrete is greatly improved and is improved by more than 50% than that of concrete in the prior art, and the single-pile bearing force of a square pile prepared with the method is higher.

Owner:扬州康龙环保工程有限公司

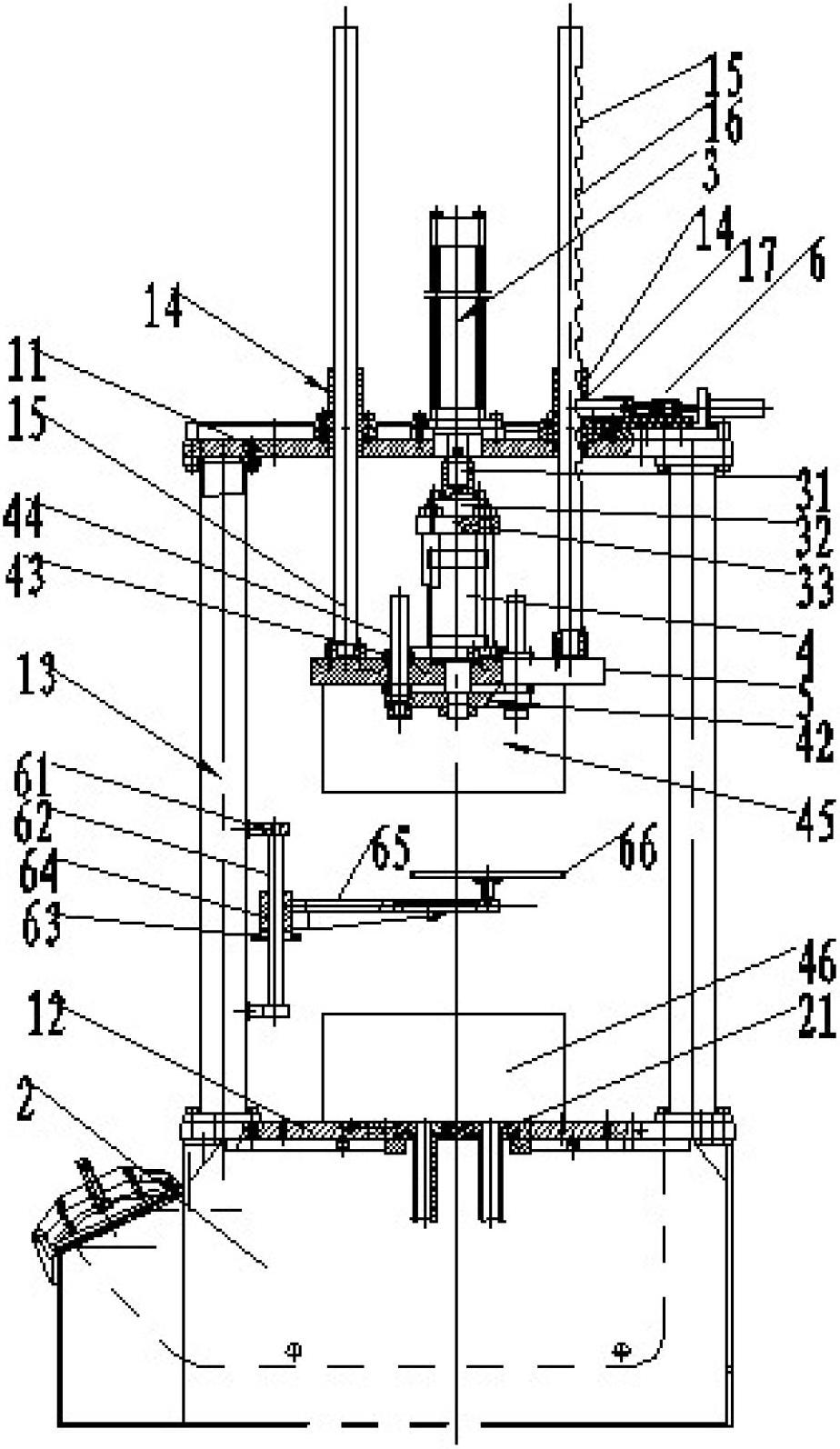

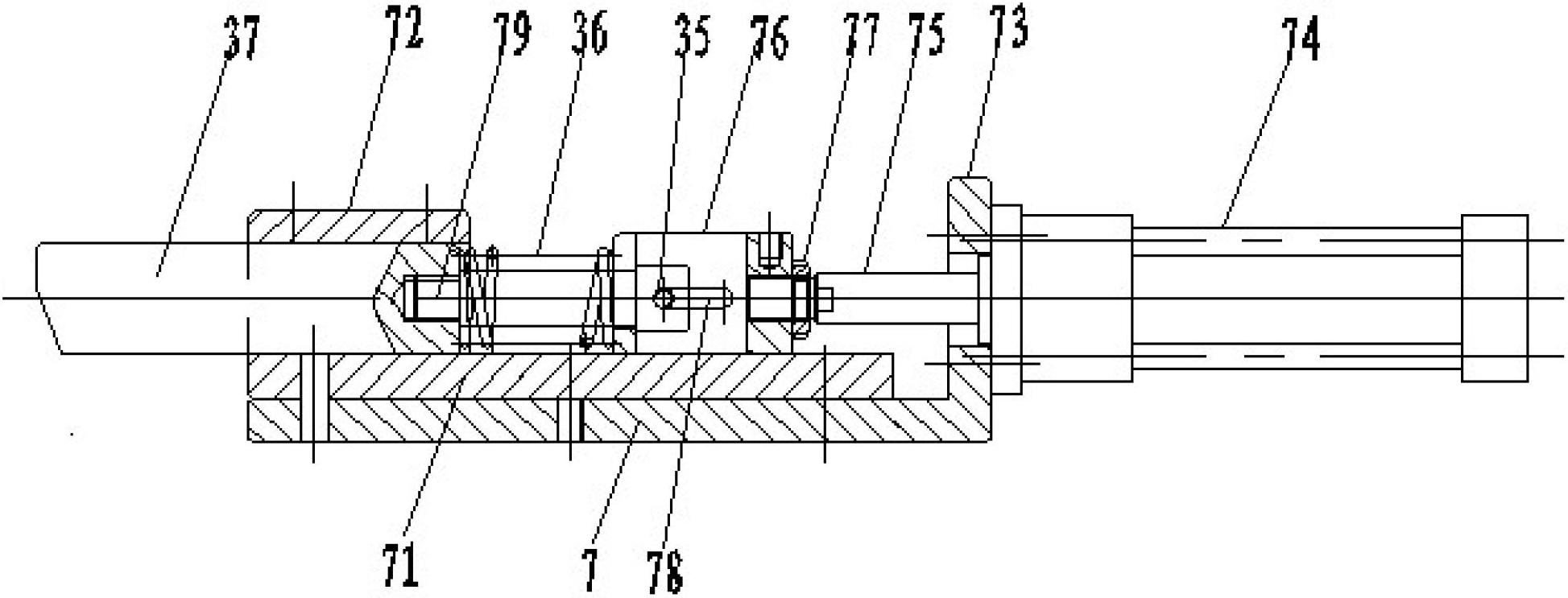

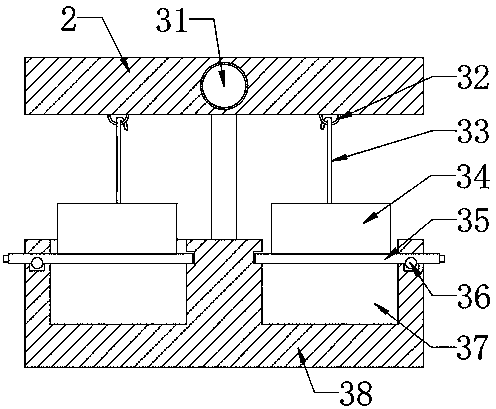

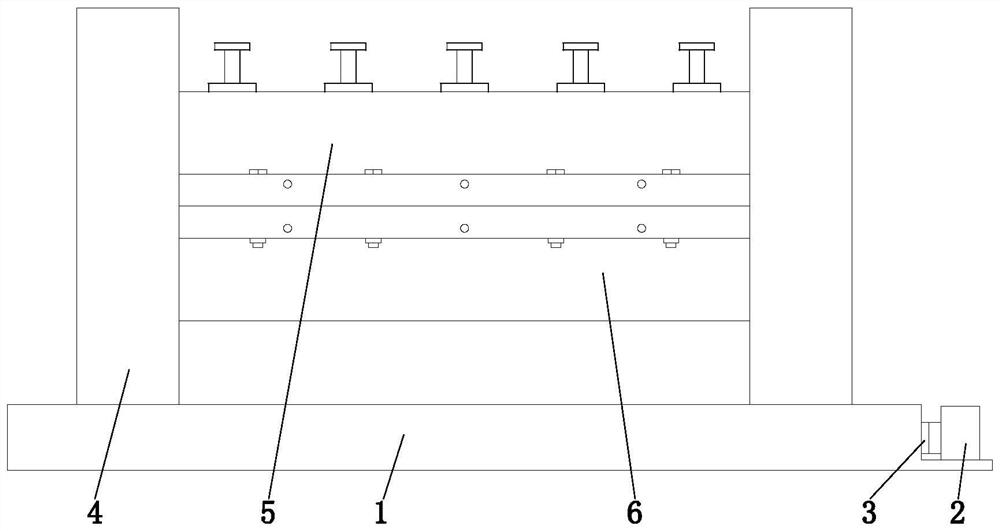

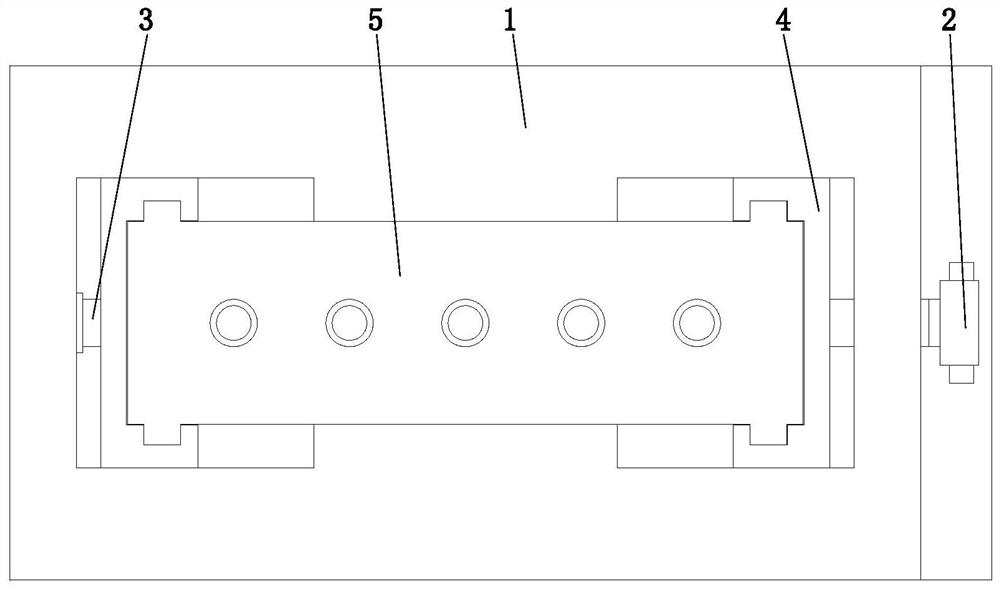

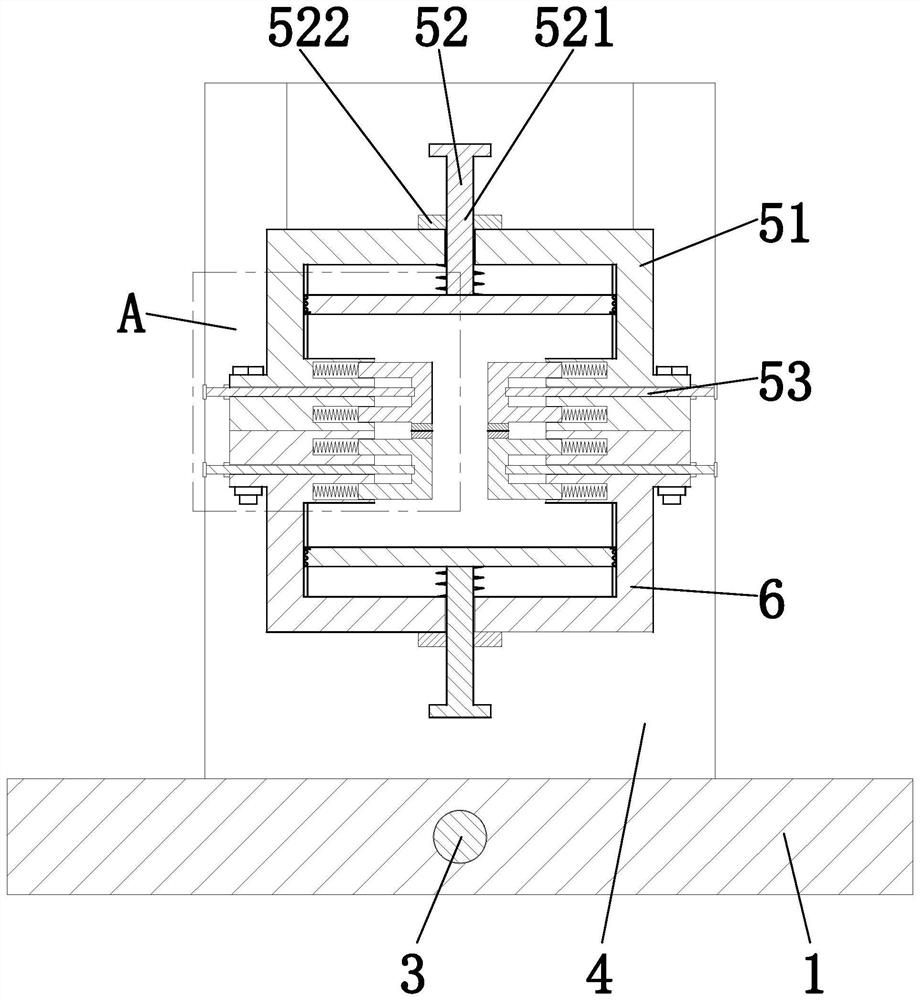

Metal casting demolding and discharging system

The invention relates to a metal casting demolding and discharging system. The system comprises an installation base plate, a left installation stand column and a right installation stand column are fixedly arranged on the left side and the right side of the upper part of the installation base plate respectively, and a stand column connecting plate is fixedly connected to the middle position between the left installation stand column and the right installation stand column; a rotating shaft is arranged at the upper position between the left installation stand column and the right installationstand column; and the two ends of the rotating shaft are fixedly connected with a left fixing installation plate and a right fixing installation plate respectively, the left fixing installation plateand the right fixing installation plate are arranged on the outer side of the left installation stand column and the outer side of the right installation stand column respectively. In the system, a motor is used for controlling the rotation of a casting cavity, moreover, electric push rods are used for controlling the movement of the side surfaces of the cavity, so that the cavity can be adjustedconveniently for pouring, moreover, after the bottom plate of the cavity is raised, demolding of a molding sand cavity with solidified metal solid is convenient after the molding sand cavity is loosened, under the rotation of the motor, the demolding treatment can be better performed after the opening direction of the cavity body is adjusted, and the using effect is good.

Owner:龚灿锋

Chloride-free early-strength water-reducing agent capable of improving concrete workability

Owner:滁州京安工贸有限责任公司

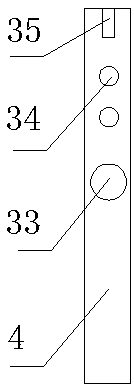

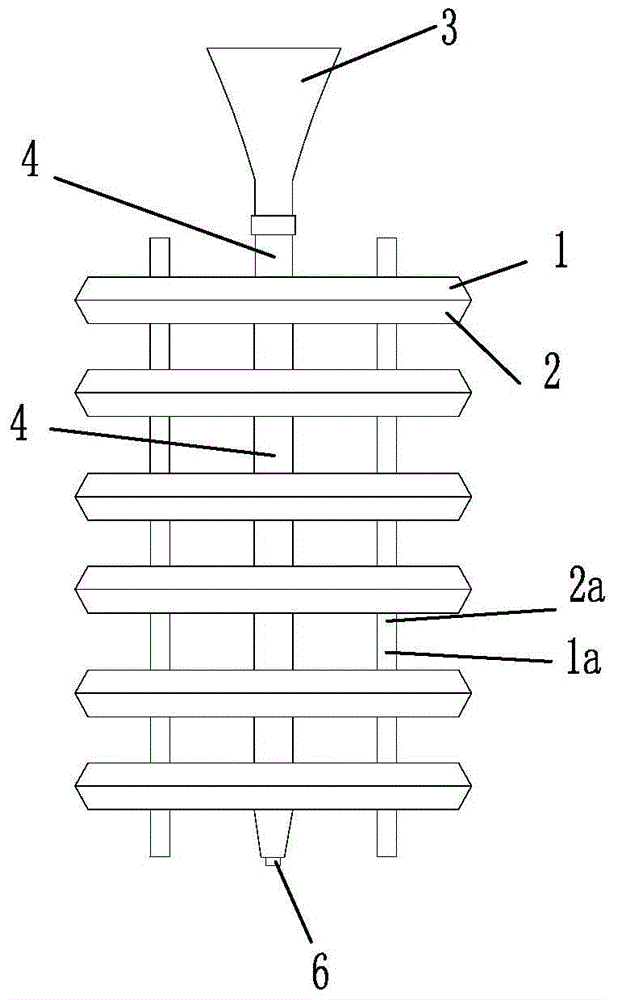

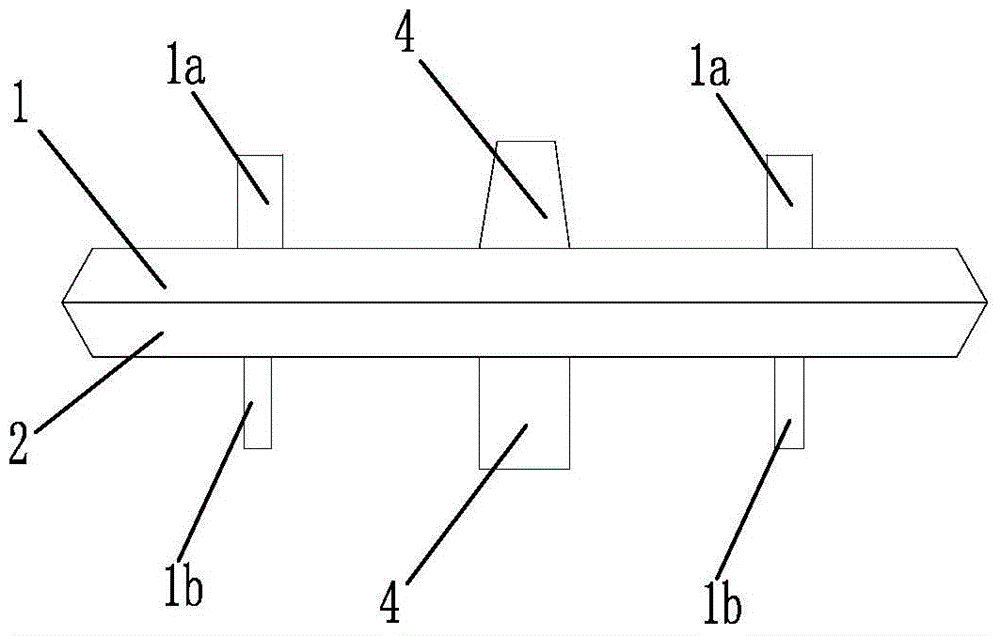

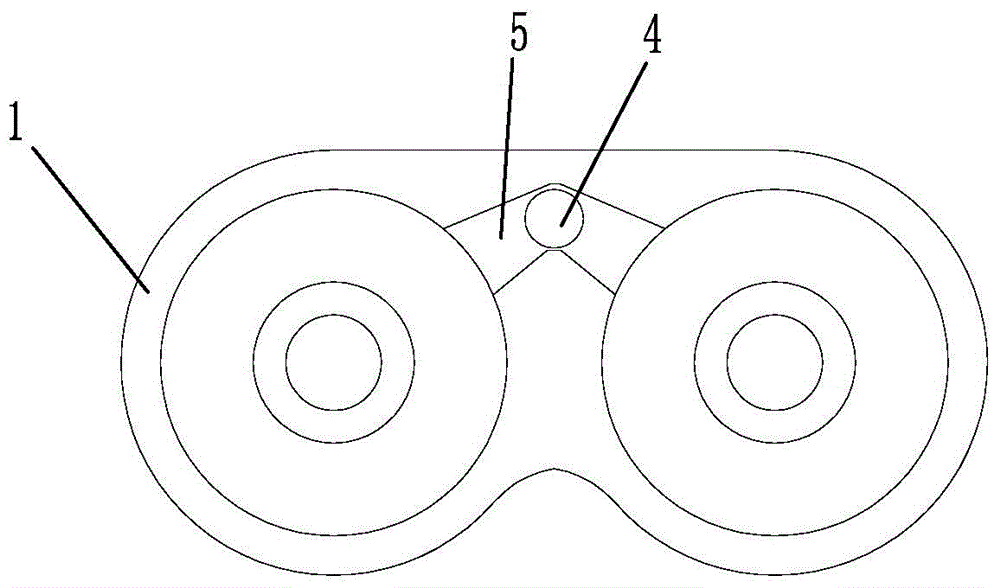

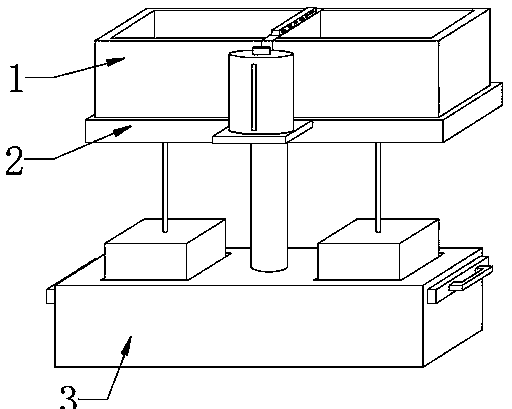

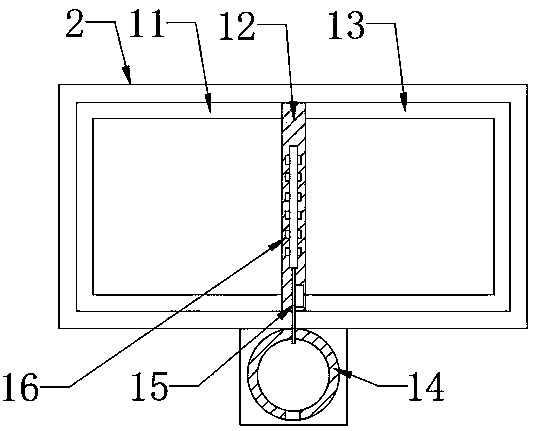

Single-row type disc piece pouring combination mold

InactiveCN105215283ANo misalignmentEasy pouringFoundry mouldsFoundry coresMaterials scienceSingle row

The invention discloses a single-row type disc piece pouring combination mold. The single-row type disc piece pouring combination mold comprises an upper sanding shell, a lower sanding shell and a sprue which are all made of precoated sand on a core shooting machine; the upper sanding shell and the lower sanding shell are buckled together to form two independent cavities matched with a disc piece in outline; the sprue comprises a feeding opening and a discharging opening, the feeding opening is in a hopper shape, and the upper sanding shell and the lower sanding shell are buckled together to form a pouring mold; a plurality of pouring molds are sequentially connected in series through pouring risers to form a row of pouring molds with through cavities; adjacent pouring molds are positioned through an upper positioning column and a lower positioning column, the discharging opening of the sprue is connected with the first pouring mold, the discharging opening of the sprue and the pouring riser of the first pouring mold are assembled to achieve leakage prevention through bonding, and the pouring risers of the adjacent pouring molds are assembled to achieve leakage prevention through bonding; and the idle pouring riser on the last pouring mold is sealed through a plug. A plurality of disc piece blanks can be poured at a time, and the production efficiency is improved.

Owner:CHONGQING HANGFENG MACHINERY CO LTD

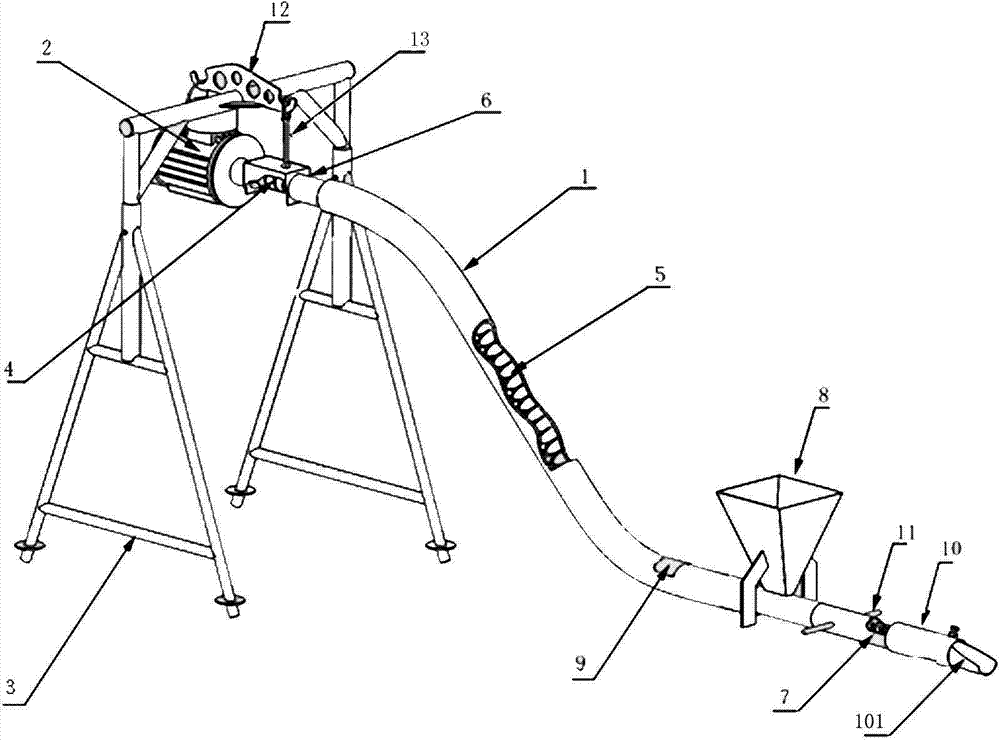

Automatic proportioning conveying device

InactiveCN104511972ALow input costHigh strengthMixing operation control apparatusFeeding arrangmentsDrive shaftSpiral blade

An automatic proportioning conveying device comprises a conveying pipe, a motor, and a portal frame. The motor is fixed on the beam of the portal frame; a transmission shaft drives rotation of a soft auger in the conveying pipe; one end of the conveying pipe is provided with a discharging port, and the other end is a reducing pipe; the reducing pipe is provided with a sandstone mixture inlet; the sandstone mixture inlet is provided with an adjusting cap sliding along the conveying pipe; sliding of the adjusting cap adjusts the cover range of the sandstone mixture inlet cover, so as to adjust the opening size of the sandstone mixture inlet; a cement hopper and a water inlet are arranged between the sandstone mixture inlet and outlet on the conveying pipe; a stirring ridge rises at the middle of the soft auger spiral blade surface along the spiral direction, and a plurality of protrusions are arranged on the stirring ridge; and blades are arranged on both sides of the spiral blade edges. The invention can realize the mixing and conveying lifting of concrete by one device, reduces the investment of the equipment and saves the engineering cost.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

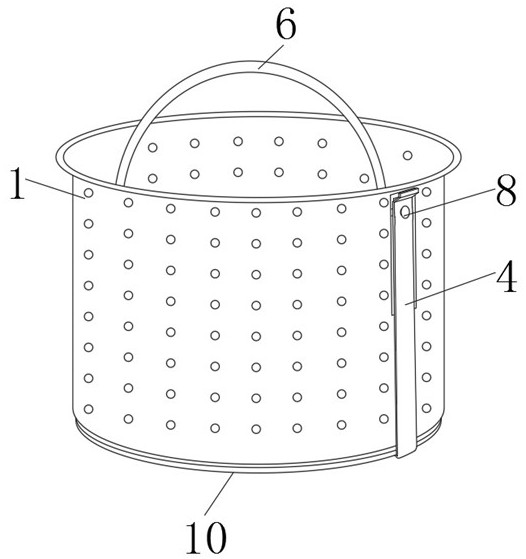

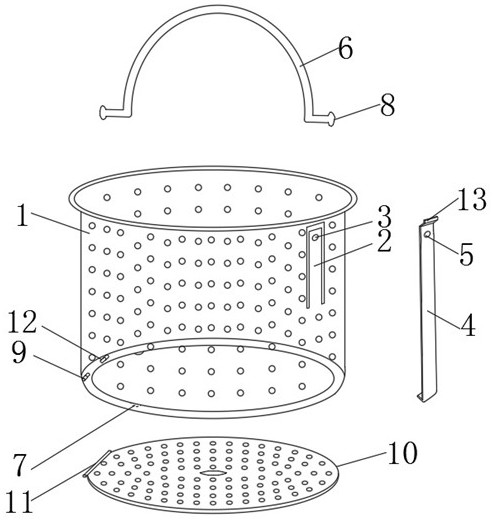

Residue filtering basket of water tank drainer

PendingCN112575851AEasy pouringEasy to cleanDomestic plumbingStructural engineeringMechanical engineering

Owner:丁功伟

Barreled water carrying rack

InactiveCN109399531AEasy to openEasy pouringBottle/container closurePower operated devicesEngineeringSmall arms

Owner:韩金轩

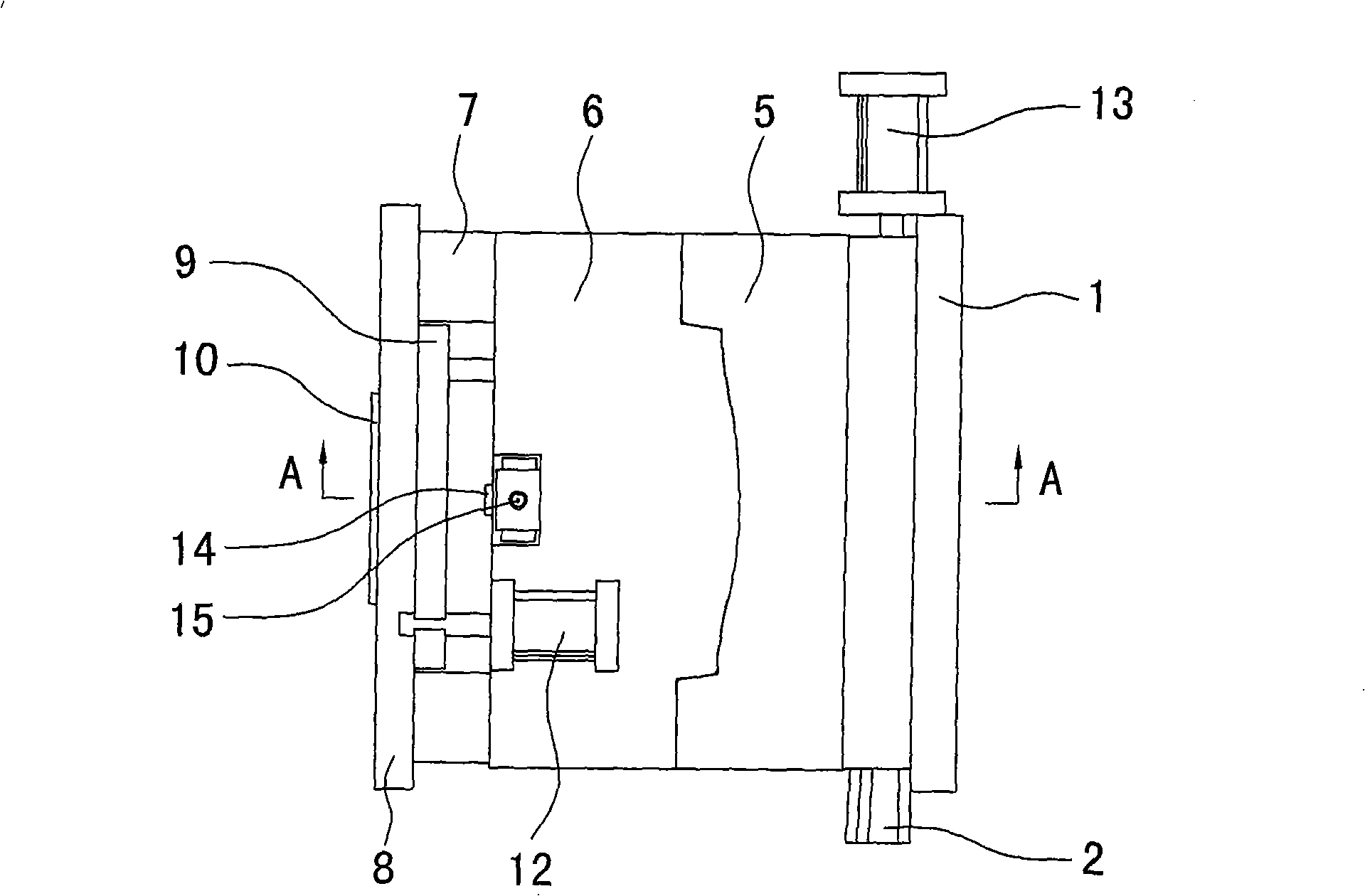

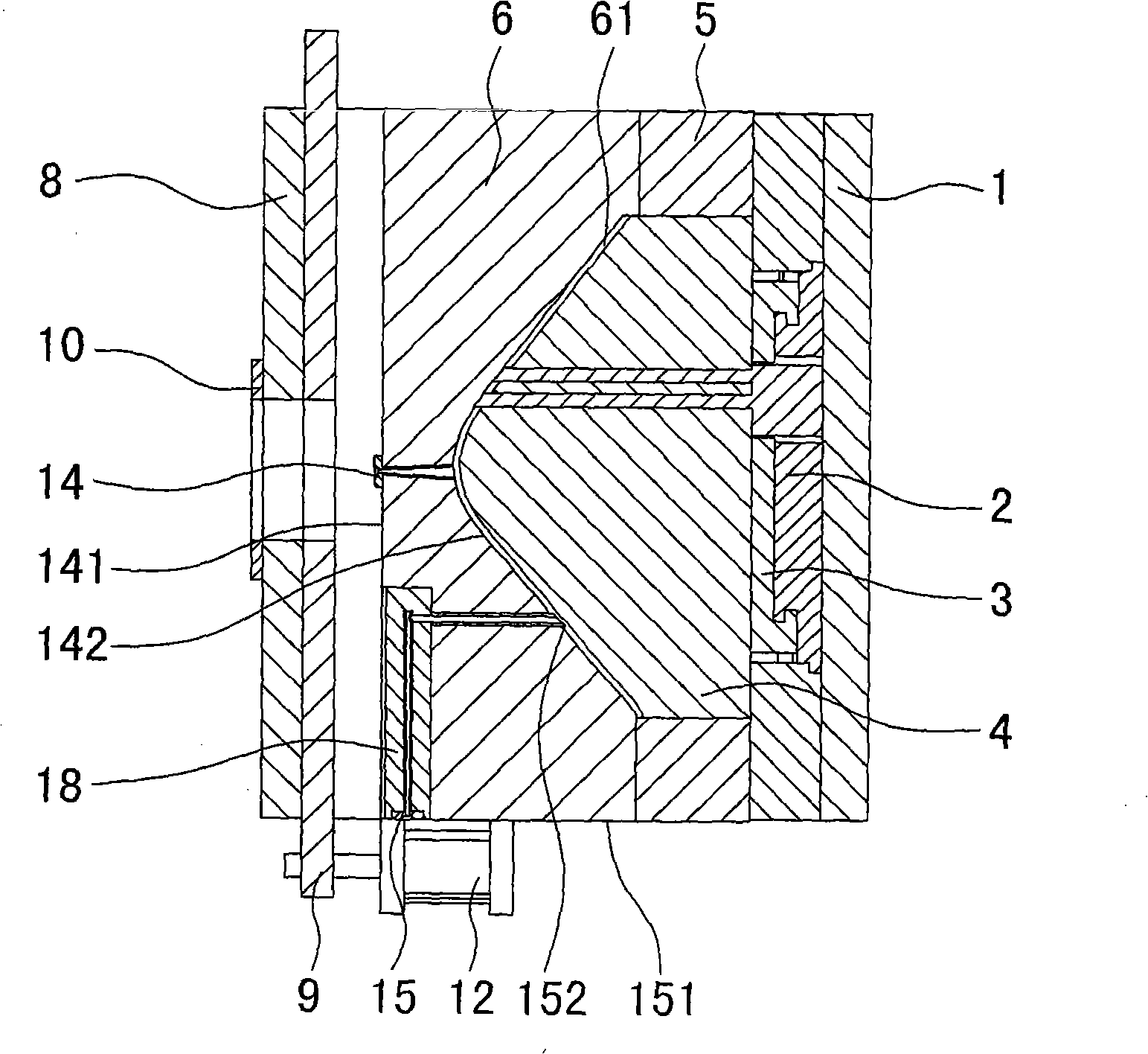

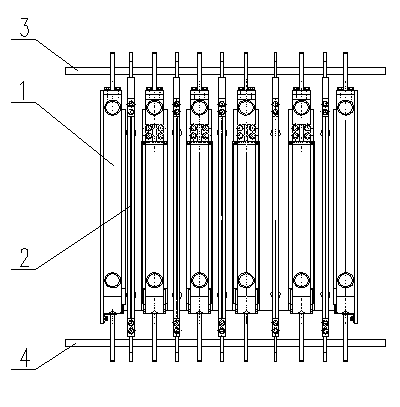

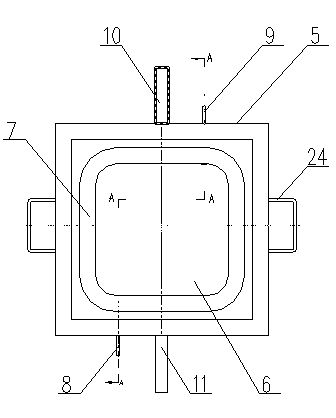

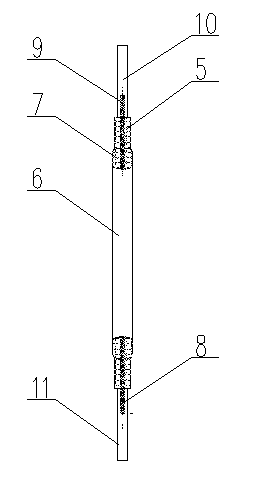

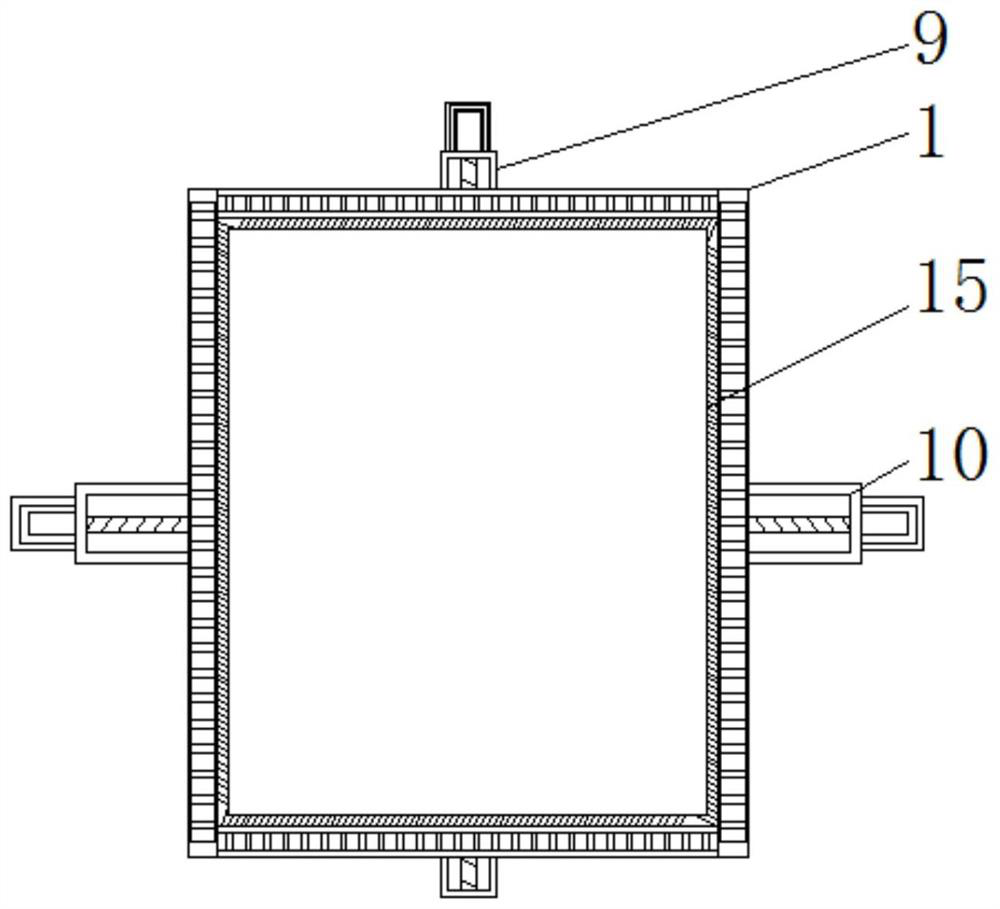

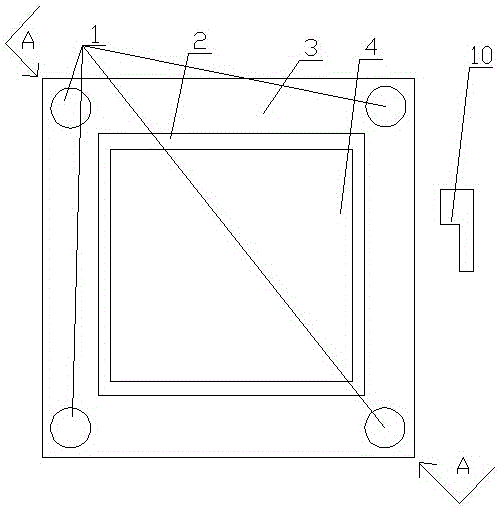

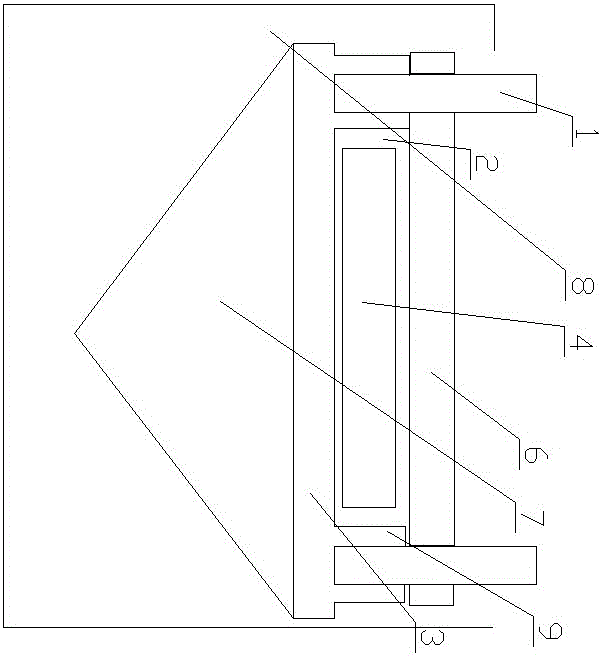

Mold for vertical pouring of organic glass and method for vertically pouring organic glass by the mold

The invention relates to a mold for vertical pouring of organic glass and a method for vertically pouring organic glass by the mold. The mold comprises multiple adhesive tape frames and multiple water tanks. Each one of the adhesive tape frames is vertically arranged between corresponding two of the multiple water tanks at an interval in a seal clamping state. Each one of the adhesive tape frames is vertically arranged between corresponding two of the multiple water tanks at an interval in a seal clamping state and different reaction heat sources are provided to the water tanks so that polymerization molding temperature requirements of raw materials in the adhesive tape frames are satisfied and thus vertical pouring and integrated curing molding of organic glass are realized. The mold has a simple and compact structure, is convenient for use, saves time and labor, can effectively guarantee molding quality, production efficiency and a production cost, and can be widely used for pouring polymerization molding of acrylic acid and acrylates.

Owner:TAIXING TOMSON ACRYLIC CO LTD

Casting production technology of right hinged support

InactiveCN104624957AGood slag blocking effectReduce consumptionFoundry mouldsFoundry coresSlagMachining

The invention discloses a casting production technology of a right hinged support. The above casting is a small casting, has a complex structure and is not symmetric, so an integral sand core is selected. A closed casting system is adopted after casting system analysis, and has the advantages of good slag resistance, difficult air entry, easy cleaning of an ingate, less metal consumption, stable metal casting, no injection and difficult oxidation. A sprue is arranged at a position close to the inner wall of a sandbox, so casting is convenient; an overlapping mode selected in the invention has excellent slag resistance in order to further avoid slag inclusion generation and other defects, so the raw material utilization rate is high, and the production cost is reduced; and the caliber dimension of the bulb tube of a cast finished product is accurate, and no machining is needed, so the quality of the casting is effectively guaranteed.

Owner:青岛齐力铸钢有限公司

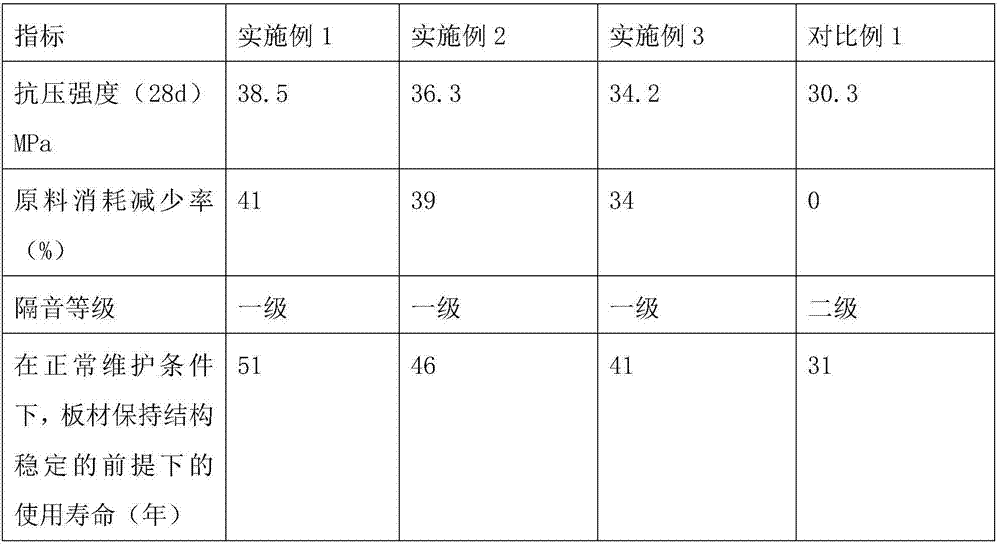

Energy-saving material for setting up building construction wall and preparation method thereof

InactiveCN106957165AHigh compressive strengthSolve environmental problemsSolid waste managementFiberPolyester

The invention provides an energy-saving material for setting up a building construction wall and a preparation method thereof, and relates to the field of building materials. The energy-saving material for setting up a building construction wall is prepared from the following raw materials in parts by weight: 12-24 parts of fine sand, 22-26 parts of gravel, 15 -25 parts of cement, 21-29 parts of waste foamed cement, 15-20 parts of waste gypsum plate, 10-15 parts of waste soft wood board, 12-24 parts of ferro-alloy residue, 3-5 parts of coal ash, 20-25 parts of mineral cotton, 35-40 parts of polyester fiber sound-absorbing board, 0.8-1.4 parts of water reducing agent, and 3-5 parts of water. The preparation method of the energy-saving material for setting up a building construction wall comprises the following steps: weighing raw materials, crushing, stirring, pouring, demoulding and curing. The invention solves the problem of shortage of a building partition wall material having the characteristics of energy conservation and environmental friendliness, high compressive strength, good durability and good soundproofing effectiveness in the market of building wall materials at present.

Owner:合肥天沃能源科技有限公司

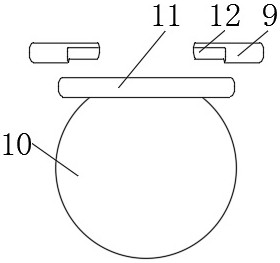

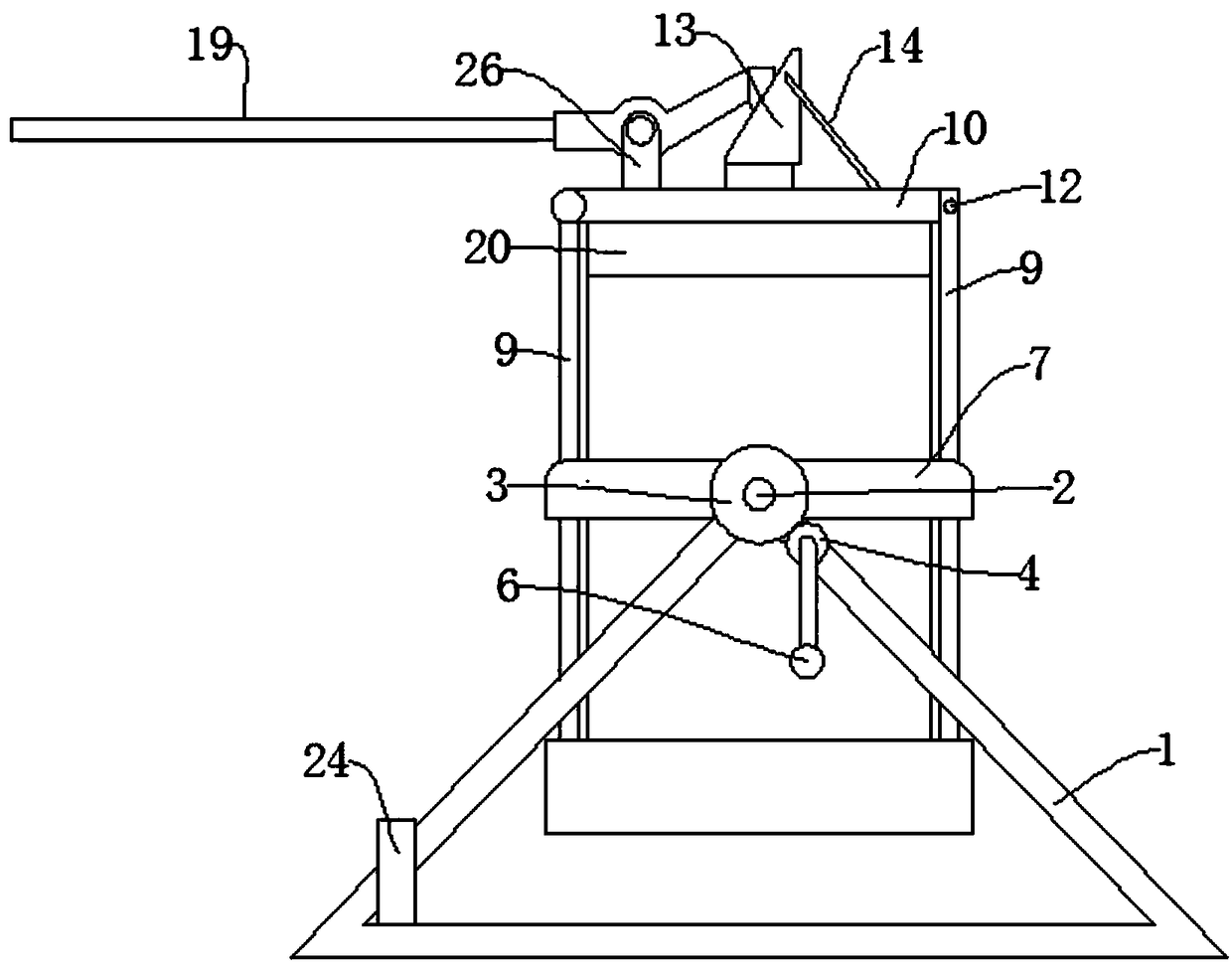

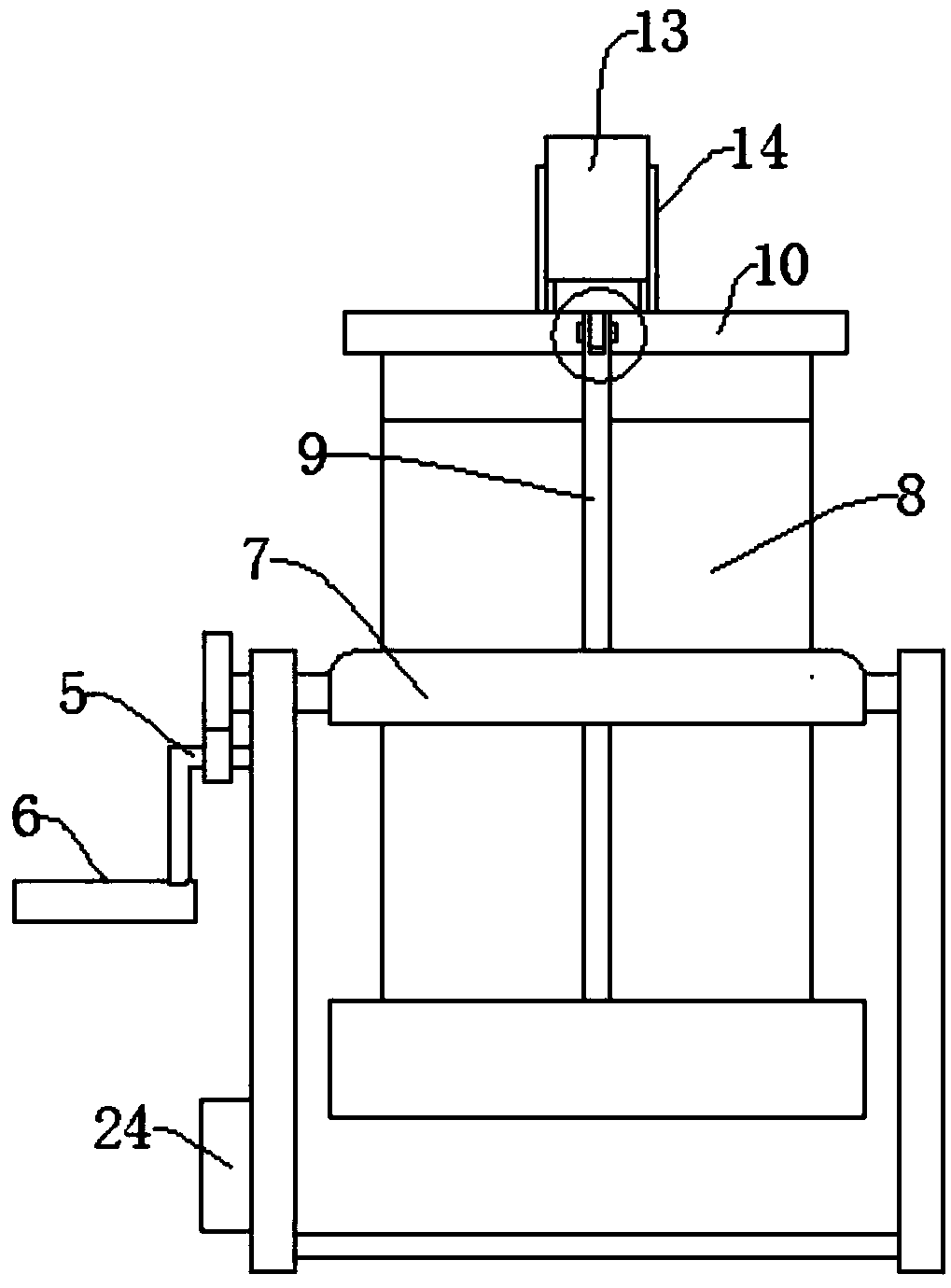

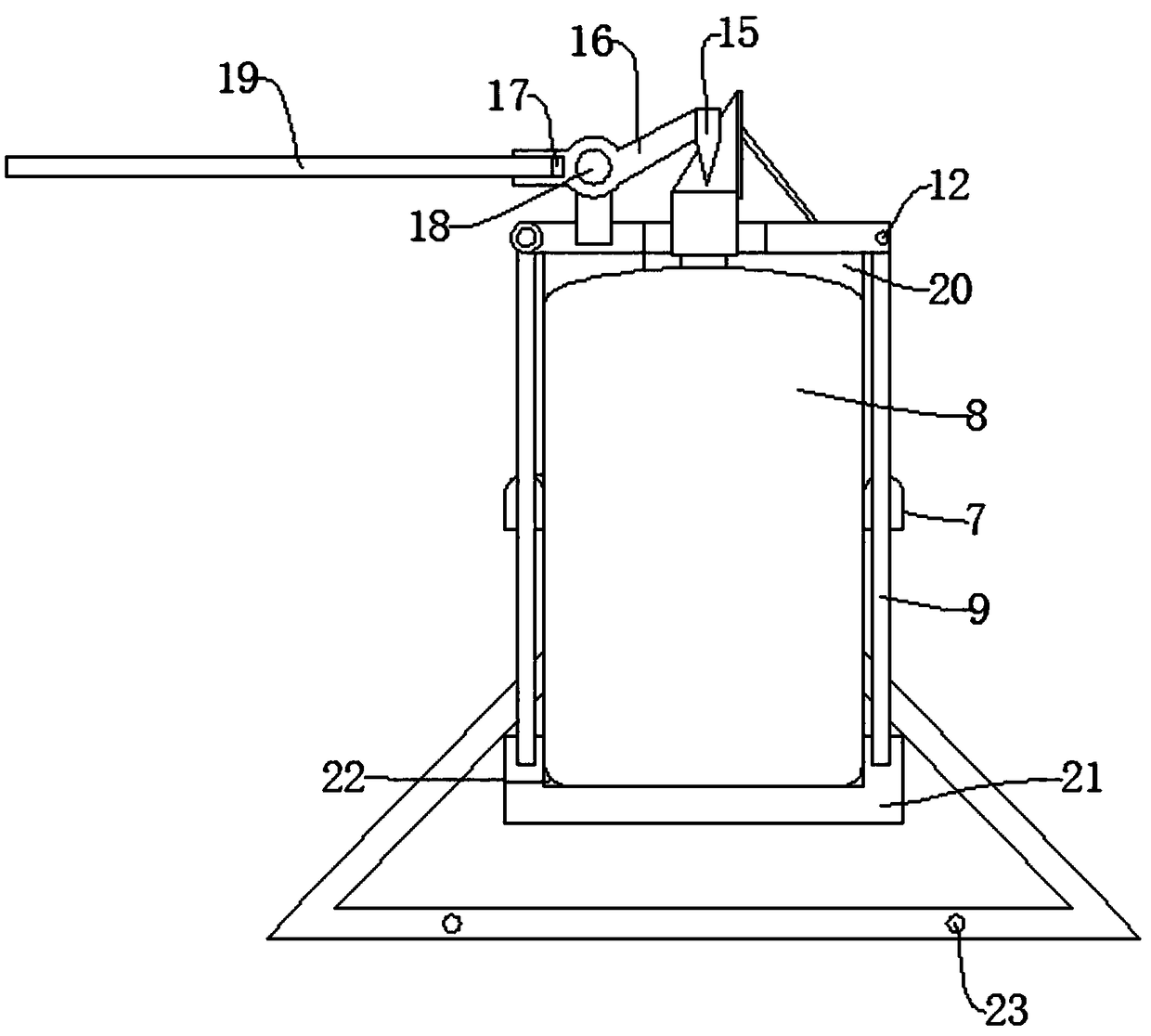

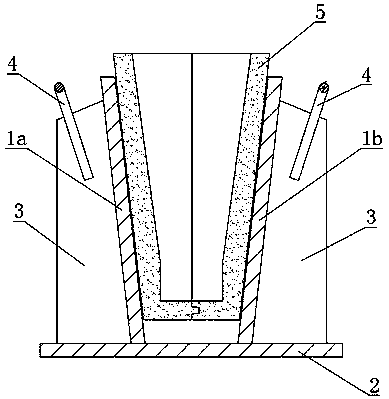

Conical shell type water tower cast-in-situ supporting structure

The invention relates to a cast-in-place supporting structure of a conical shell water tower, which includes a support tube, steel bars, ring supports, hangers, suspensions, supporting steel beams, derricks, water tank templates, and ring plates; the ring support and the top of the support tube pass through The steel bar is fixed, the section of the ring support is inverted L-shaped, the ring plate is fixed on the support tube under the ring support, the ring support and the ring plate are fixed and supported by reinforcing ribs, the hanger and the top of the ring support are welded and fixed, and the suspension It is fixedly connected with the hanger; the support steel beam is fixed to the inner wall of the support tube, the bottom of the support steel beam is supported and fixed by a reinforcing plate, and the bottom of the derrick is fixed to the support steel beam; the support tube includes an inner steel tube, an outer sleeve, a rib plate, and Ribs, welded ribs are uniformly distributed radially on the outside of the inner steel cylinder; the outer sleeve is assembled longitudinally and layered by a circular steel structure, and the circular steel structure is spliced by several arc-shaped plates. The advantages are: it can realize the in-situ concrete pouring operation of the water tank, reduce the danger of high-altitude operation, shorten the construction period and reduce the cost.

Owner:CHINA THIRD METALLURGICAL GRP

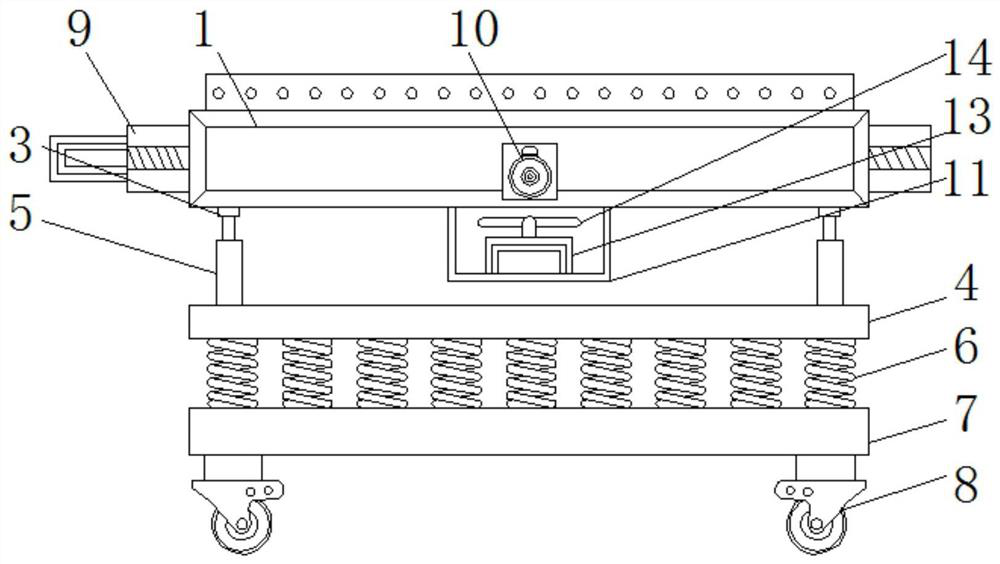

Device facilitating mold stripping for fabricated building

InactiveCN113510833AImprove efficiencyHigh speedDischarging arrangementHydraulic cylinderElectric machine

The invention discloses a device facilitating mold stripping for a fabricated building. The device comprises a mounting table, a bearing plate, a vertical mold stripping device, a transverse mold stripping device, a through frame, a rotating motor and an anti-sticking plate, wherein a mounting groove is formed in the bottom of the mounting table in a penetrating mode, and the top end of the bearing plate is fixedly connected with the bottom of a hydraulic cylinder. The device facilitating mold stripping for the fabricated building is provided with movable wheels, the mounting table is pushed to drive the movable wheels to move so as to move an overall prefabricated part mold outdoors for prefabricated part pouring treatment, thus, the circumstance that the overall prefabricated part mold is fixed at the same position for a long time, so that the overall drying period is long and the drying efficiency is low after the prefabricated part is poured is avoided, meanwhile, through external air drying and sunlight irradiation, the drying period of the prefabricated part is shortened, the drying efficiency of the prefabricated part mold is improved, and the production efficiency of the prefabricated part is sequentially improved.

Owner:徐州中煤汉泰建筑工业化有限公司

Combined flower shelf for domestic use

InactiveCN108741995ASolve the problem of insufficient wateringEasy to waterSelf-acting watering devicesFlower tablesEngineeringA-weighting

The invention provides a combined flower shelf for domestic use. The combined flower shelf for domestic use comprises a flower shelf main body, a first planting groove, a second planting groove, nozzles, a hinge, a hanging ring, a hanging rod, a weighting block, a load-bearing plate, guide rails and a fixed block, wherein the first planting groove is formed in the left side of the upper end face of a partition plate, the second planting groove is formed in the right end face of the partition plate, and the nozzles are symmetrically arranged on the left end face and the right end face of the partition plate; due to the design, the defect of the combined flower shelf for domestic use in the watering aspect is overcome. The hinge is arranged at the middle position of the internal part of theflower shelf main body, the hanging ring is arranged on the left side and the right side of the lower end face of the flower shelf main body, the hanging rod is arranged on the lower side of the hanging ring, the weighting block is arranged on the lower end face of the hanging rod, the load-bearing plate is arranged on the upper side of the internal part of a movable cavity, the fixed block is arranged on the lower side of the flower shelf main body, and the guide rails are symmetrically arranged on the front end face and the back end face of the load-bearing plate; due to the design, the defect of the combined flower shelf for domestic use in the aspect of angle adjustment is overcome. The combined flower shelf for domestic use is reasonable in structure, convenient to water, high in adjusting property and high in reliability.

Owner:王小莉

High-hardness emulsion explosive and preparation technology thereof

InactiveCN108586167AHigh hardnessIncreased sensitivityExplosive working-up apparatusPlasticizerEmulsion explosive

The invention discloses a high-hardness emulsion explosive. The high-hardness emulsion explosive comprises the following components: ammonium nitrate, sodium nitrate, a surfactant, a flame inhibitor,a plasticizer, an enhancer, an adhering improving agent and a curing agent. The invention further designs a preparation technology of the high-hardness emulsion explosive. The preparation technology is simple, and easy to carry out; the prepared explosive is high in hardness and high in explosion transfer stability, and high in adaptability in high temperature and underwater environments and otherenvironments; in addition, the raw materials do not include heavy metal and heavy metal oxide; the demand of special explosion work on high-hardness explosive is met.

Owner:宜兴市阳生化工有限公司

Prestressed precast concrete pipe pile pouring steel formwork

The invention provides a prestressed precast concrete pipe pile pouring steel formwork. The steel formwork comprises a bottom plate, an adjusting motor, an adjusting lead screw, a sliding side plate,an upper module unit and a lower module unit. The problems that in the using process of an existing H-shaped concrete pipe pile pouring steel formwork, mainly, H-shaped pipe piles with various wall thicknesses cannot be adjusted and poured in the pouring process of the H-shaped concrete pipe pile pouring steel formwork; and therefore the using effect of the H-shaped concrete pipe piles is low, concrete easily overflows and leaks in the concrete pouring process of the existing H-shaped concrete pipe pile pouring steel formwork, then the pouring effect of the concrete pipe piles is affected, theoverflowing and leaking concrete and the pouring steel formwork are mutually condensed, and therefore drawing is affected are solved.

Owner:浙江顺邦工程机械设备有限公司

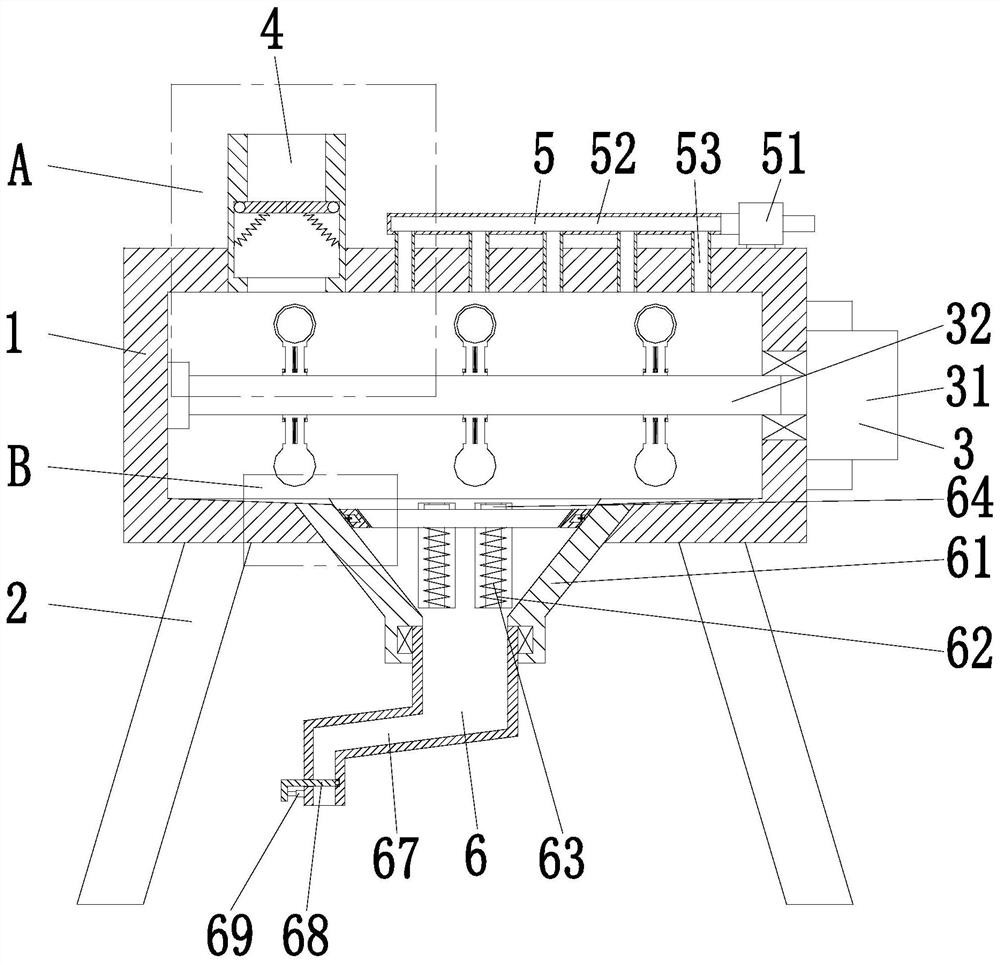

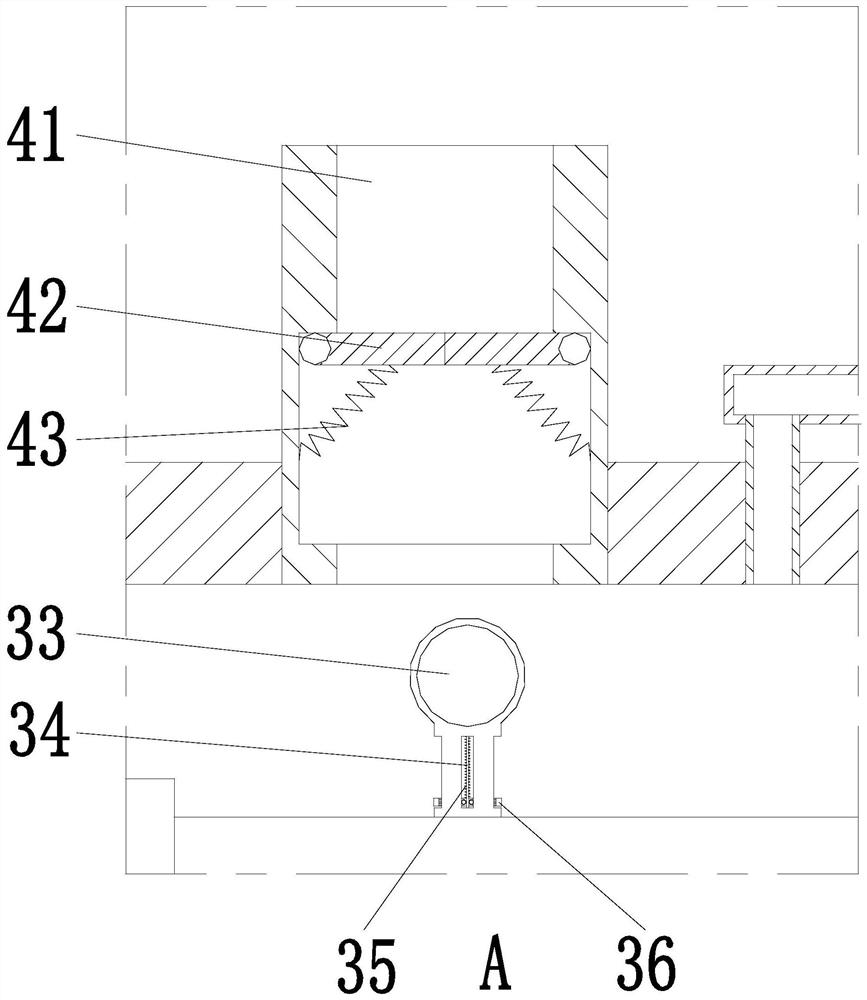

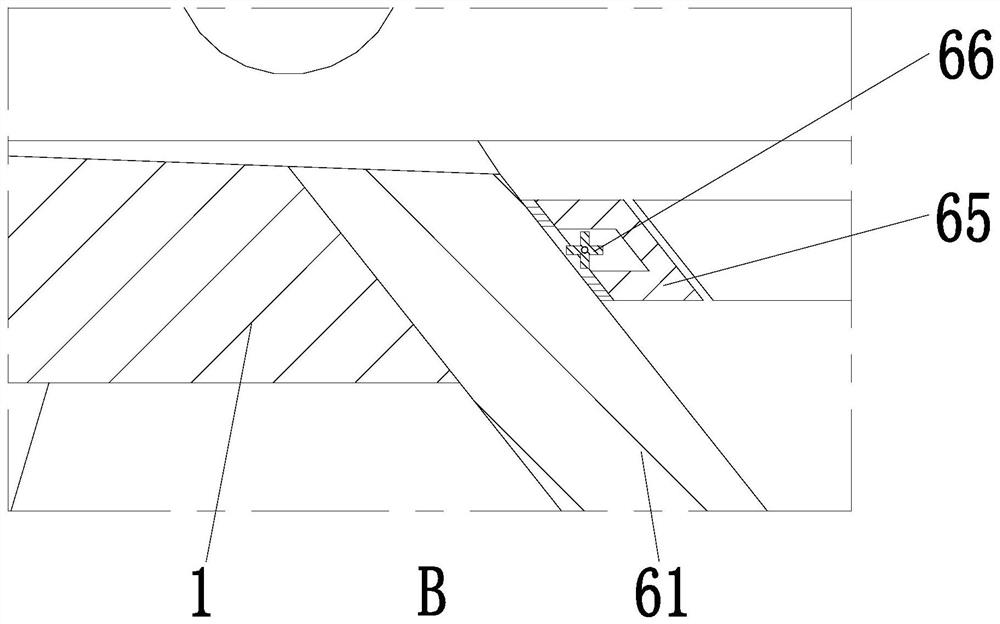

Polyurethane elastic sponge body casting molding equipment

InactiveCN112157855AImprove cleanlinessEasy to squeeze out and emptyHollow article cleaningMechanical engineeringChemistry

The invention provides polyurethane elastic sponge body casting molding equipment which comprises a reaction box, supporting legs, a stirring device, a feeding unit, a pneumatic control unit and a discharging device, wherein the supporting legs are uniformly arranged at the lower end of the reaction box; the stirring device is transversely arranged in the reaction box through a bearing; the feeding unit is arranged on the outer wall of the left side of the upper end of the reaction box and communicates with the interior of the reaction box;the pneumatic control unit is arranged on the outer wall of the right side of the upper end of the reaction box and communicates with the interior of the reaction box; and the discharging device is arranged in the middle of the lower end of the reactionbox. The problem that in the existing polyurethane elastic sponge body casting molding process,casting molding equipment is difficult to adjust a casting opening, and consequently casting is carried out inconveniently is solved; and the problem that after pouring, mixed raw materials in the reaction box are difficult to empty, so that part of the mixed raw materials remain in the reaction box, andthe cleanness in the reaction box is influenced is solved.

Owner:杭州乐杰新型材料科技有限公司

Y-type test block shell mold pouring fixture

The invention discloses a Y-type test block shell mold pouring fixture. The pouring fixture is simple in structure, facilitates pouring and improves the production and sampling efficiency. The problemthat cleaning inconvenience is caused due to the fact that an existing Y-type test block shell mold is clamped through bolts or buried in a sand mold to conduct molding is solved. A wedge-shaped space formed by two beveled clamping plates and the wedge-shaped outer surface of a Y-type test block shell mold are in close fit, so that the shell mold is seated between the clamping plates to be clamped to protect the shell mold against swelling or leakage, and the pouring quality of the Y-type test block is guaranteed.

Owner:溧阳市联华机械制造有限公司

Concrete preparation and pouring all-in-one machine for municipal construction

InactiveCN112459491AConvenient discharge and transportationEasy pouringDischarging apparatusBuilding material handlingAugerThreaded pipe

The invention relates to the field of municipal administration, in particular to a concrete preparation and pouring all-in-one machine for municipal construction. The machine comprises a conveying cavity, a conveying shaft is arranged in the middle of the conveying cavity, a conveying auger is arranged on the conveying shaft, a first bevel gear is installed on the conveying shaft, a second bevel gear is meshed with the upper end of the first bevel gear, and a first rotating shaft is arranged at the upper end of the second bevel gear. The upper end of the first rotating shaft is connected witha first threaded rod through a belt, a sliding block is connected to the first threaded rod, a first connecting pipe is arranged on the outer side of the sliding block, a pouring nozzle is installed at the outer end of the first connecting pipe, a sealing cavity is formed in the conveying cavity, a third bevel gear is installed in the sealing cavity, and a fourth bevel gear is meshed with the upper end of the third bevel gear. A second threaded rod is arranged at the upper end of the fourth bevel gear, the upper end of the second threaded rod is arranged in the stirring cavity, the upper end of the second threaded rod is connected with a threaded pipe, and stirring rods are installed at the two ends of the threaded pipe.

Owner:徐天元

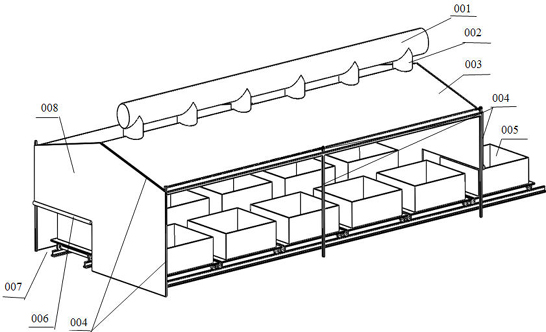

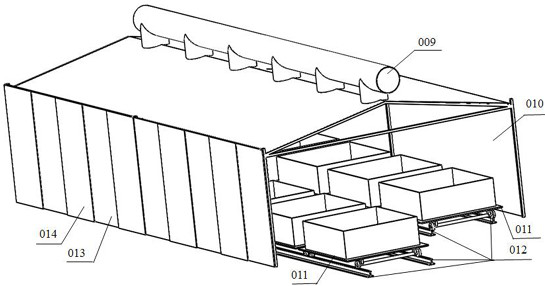

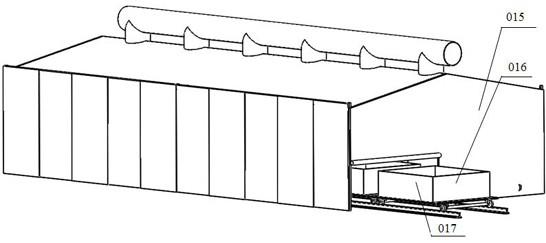

Closed dust removal room in molten metal pouring production line

A closed dust removal room in a molten metal pouring production line belongs to the field of casting, a plurality of rails are arranged on the ground of the dust removal room, trolleys are arranged on the rails in a rolling mode, an inlet and an outlet are formed in the two ends of the dust removal room respectively, and the trolley rails on the inlet side and the outlet side are communicated with a molding workshop and a box opening workshop respectively. The side face of the dust removal room is communicated with a metal melting workshop, a pouring side is arranged on the side face of the dust removal room, the periphery of the dust removal room is closed, and opening and closing door curtains are arranged on an inlet, an outlet and the pouring outlet side of the dust removal room. An exhaust pipe is arranged outside a roof of the dust removal room and communicated with the interior of the dust removal room. The environment pollution generated in the pouring process can be reduced, the body health of workers is protected, and an efficient and practical dust removal measure is provided for a metal casting in a pouring forming production line.

Owner:河南旭锐合金新材料制造有限公司

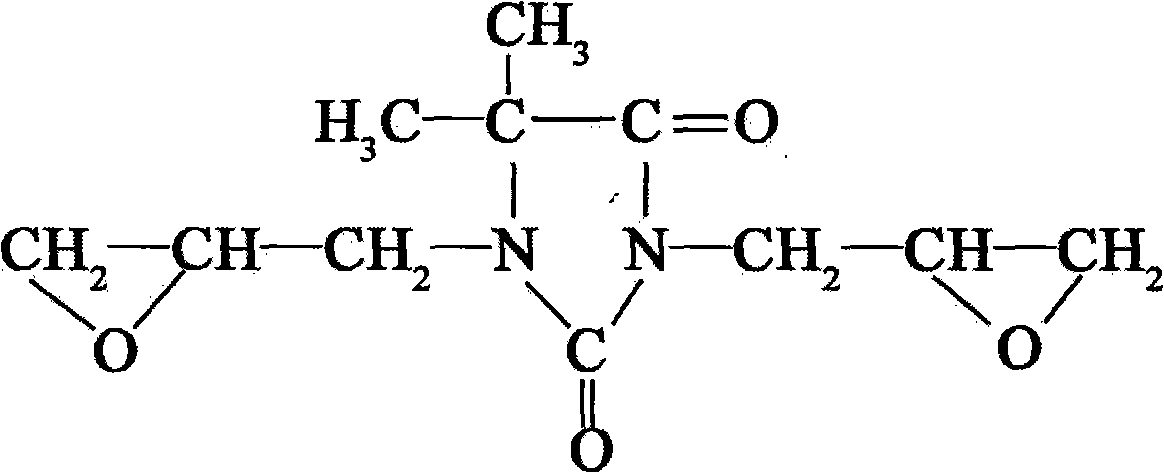

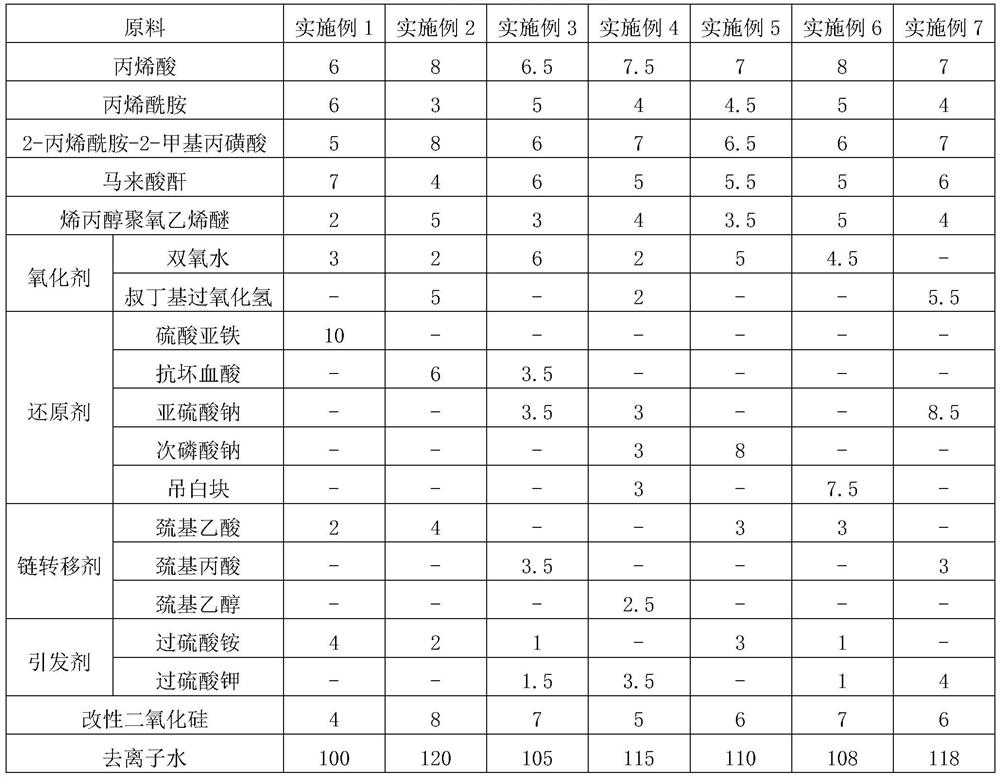

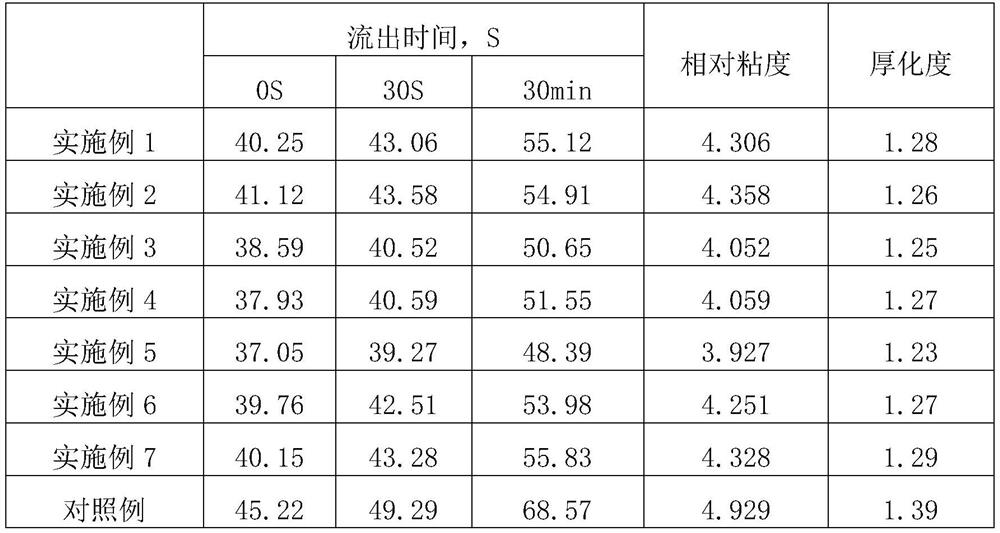

Polycarboxylate superplasticizer for ceramics and preparation method thereof

The invention discloses a polycarboxylic acid water reducing agent for ceramics and a preparation method thereof, and solves the technical problems that when a water reducing agent in the prior art is applied to the ceramic industry, the water reducing rate is relatively low, the reducing effect is general, and the energy consumption is relatively high when a spray drying tower is used for drying. The water reducer is prepared from the following raw materials in parts by weight: 6-8 parts of acrylic acid; 3 to 6 parts of acrylamide; 5 to 8 parts of 2-acrylamide-2-methylpropanesulfonic acid; 4-7 parts of maleic anhydride; 2 to 5 parts of allyl alcohol polyoxyethylene ether; 3-7 parts of an oxidant; 6-10 parts of a reducing agent; 2-4 parts of a chain transfer agent; 2-4 parts of an initiator; 4-8 parts of modified silicon dioxide; and 100 to 120 parts of deionized water. When the water reducing agent is applied to the ceramic industry, the water reducing rate is high, the dispersion effect of ceramic slurry is good, and the energy consumption of a spray drying tower during drying is greatly reduced.

Owner:SICHUAN SEDAR CHEM

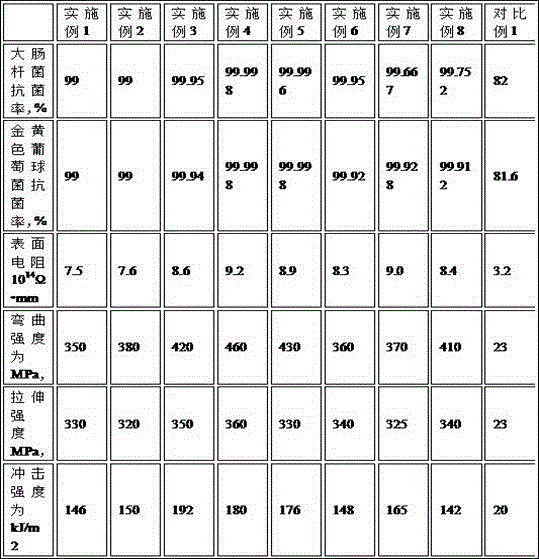

PC product information recognition system

InactiveCN106118007AImprove tensile propertiesIncreased shear strengthEngineeringStyrene maleic anhydride

The invention discloses a PC product information identification system, which includes a PC product pillar, a housing arranged inside the PC product pillar, several positioning rods arranged on the side wall of the housing, and a chip scanning gun for scanning chips. The casing has a groove, and a chip is arranged in the groove, and a sealing plate for sealing the groove of the casing is arranged on the casing. The PC product pillar is composed of the following components in parts by weight: 100-120 parts of PC resin, poly 10-12 parts of imide, 4-8 parts of graphite, 2-5 parts of antibacterial agent, 5-10 parts of nylon, 10-12 parts of steel fiber, 15-22 parts of gravel, 6-8 parts of basalt fiber, styrene ‑Maleic anhydride random copolymer 3-5 parts. The invention has the advantages of convenient installation, firm structure, good insulation performance and long service life.

Owner:HENAN DINGLI POLE TOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com