Preparation method of aluminum oxide metal ceramic reinforced iron-based composite

A technology of iron-based composite materials and alumina ceramics, which is applied in the field of preparation of alumina cermet-reinforced iron-based composite materials, can solve problems such as environmental pollution, achieve reduced production costs, uniform structure and components, and good high-temperature mechanical mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

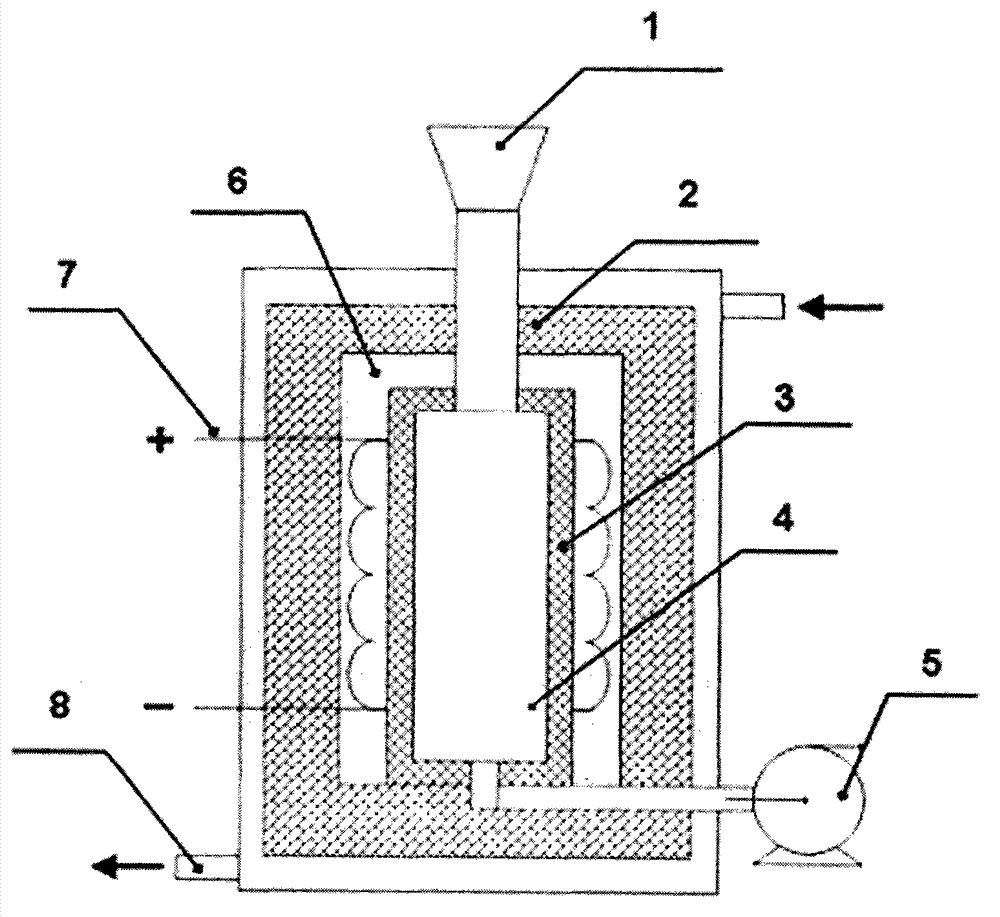

[0018] Preferably, the technical solution of the present invention is implemented according to the following steps to prepare an alumina cermet reinforced iron-based composite material.

[0019] Step 1. Preparation of alumina cermet preform

[0020] The alumina cermet skeleton green body prefabricated with the active Si element is sintered at a high temperature of 800-850° C. for 30 minutes to produce a surface-modified alumina cermet preform 4 with mesh-like pores. Among them, the porosity of the cermet prefabricated part 4 is about 45% vol%, and the shape is determined by the shape and size of the final required composite material parts and tooling molds.

[0021] Step 2. Prepare casting sand mold

[0022] Coated lining: prepare a polypropylene plastic mandrel similar in shape to the gating system, cover the side of the mandrel with 1-3 layers of newspaper or straw paper; then wrap the alumina-based metal with 1-3 layers of newspaper or straw paper The outer side of the ce...

Embodiment 2

[0032]Preferably, the technical scheme of the present invention is implemented according to the following steps to prepare a No. 45 steel-based composite material that is tightly bonded with alumina cermet by two media.

[0033] The steps are basically the same, the difference is that: step 1, the alumina corundum sand with an average particle size of 1.5mm prefabricated by the active Si element is used as a ceramic skeleton body, and the surface is modified by sintering to form a mesh-like pore. The alumina ceramic preform 4 has a porosity of about 55 vol%. In the third step, No. 45 steel is melted into a steel metal liquid at 1500-1550 °C, and pouring is started, that is, an alumina-based cermet reinforced No. steel composite.

[0034] The alumina cermet-reinforced steel-based composite material prepared by the above-mentioned embodiment has uniform distribution of ceramic particles, and the metal phase fills and penetrates the mesh-like pores of the entire cermet prefabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com