Steel pipe concrete segment type coat node and its construction method

A technology for CFST and CFST columns is applied in the field of CFST segmented jacket joints and their construction, which can solve the problems of unsatisfactory mechanical properties, poor working performance, limited joint stiffness, etc., and achieves simple and convenient processing and production, joint stiffness. Large, high-capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

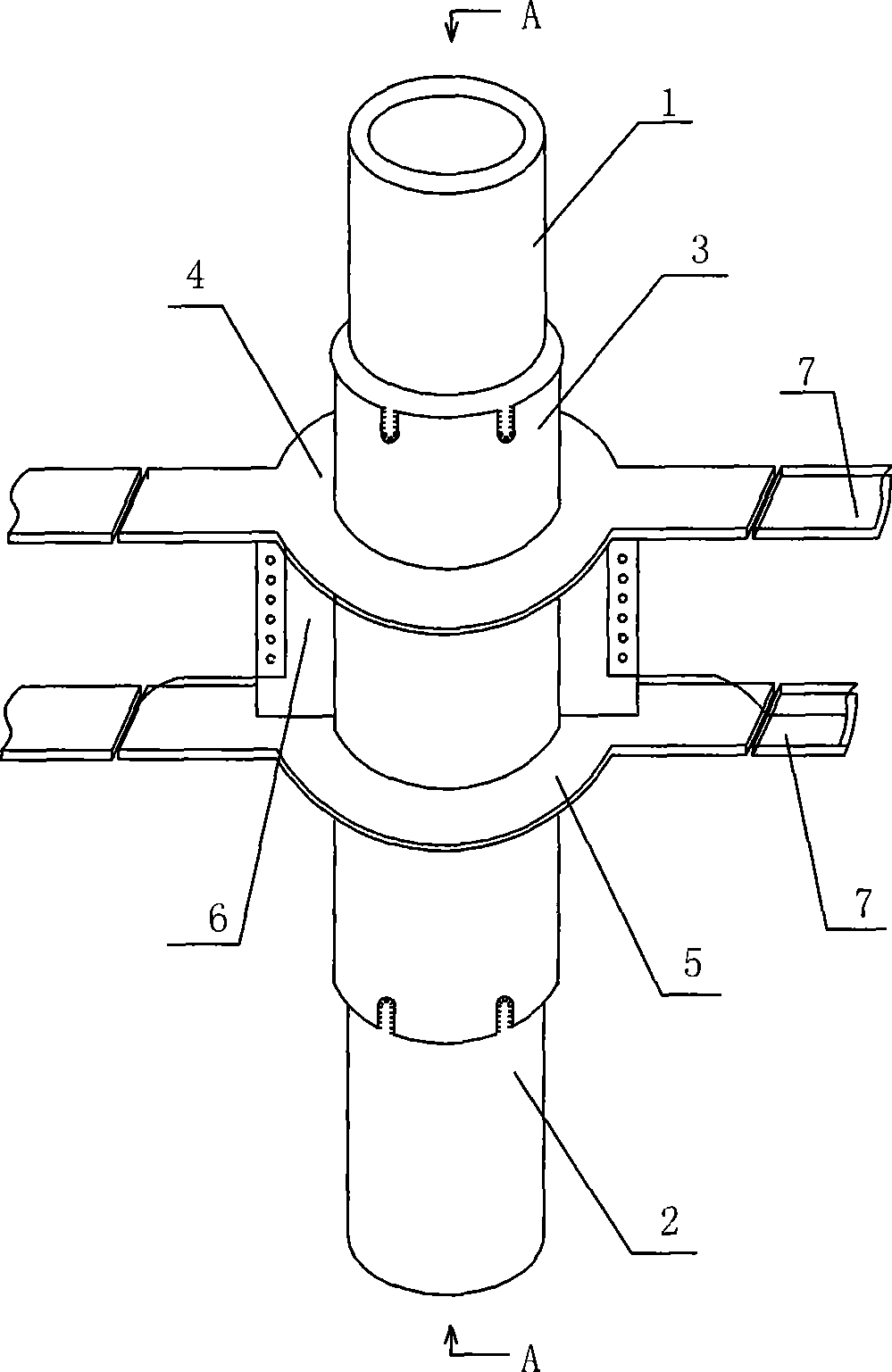

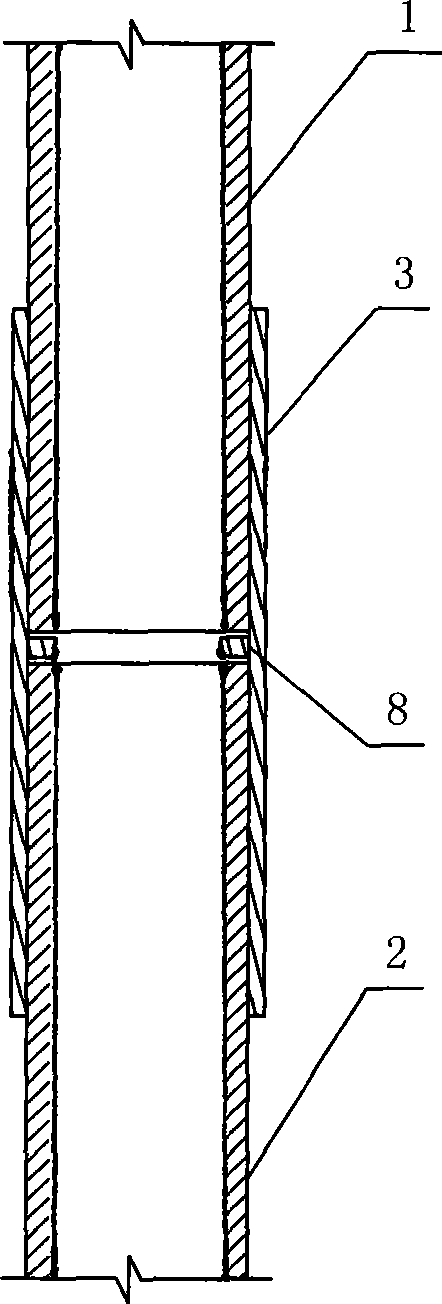

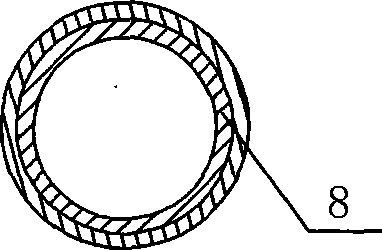

[0019] Such as figure 1 As shown, this concrete-filled steel pipe segmental jacket node includes a concrete-filled steel pipe column and a steel beam 7 connected to the column. The concrete-filled steel pipe column is formed by filling concrete into a steel pipe. The cross-section of the steel pipe is circular. The cross-sectional dimensions of the upper column steel pipe 1 and the lower column steel pipe 2 are equal to those of the lower column steel pipe 2, and the two steel pipes are connected together through the connecting sleeve 3, which is cylindrical, and the connecting sleeve 3 and the lower column steel pipe 2 are separated The outer upper part of the connecting sleeve 3 is installed with the upper reinforcing ring plate 4, the outer lower part of the connecting sleeve 3 is installed with the lower reinforcing ring plate 5, and the left and right sides of the reinforcing ring plate extend horizontally outward to form connecting ears, which are used for fixing with the...

Embodiment 2

[0023] Such as figure 2 As shown, this kind of concrete-filled steel pipe segmental jacket node includes a concrete-filled steel pipe column and a steel beam 7 connected to the column. The concrete-filled steel pipe column is formed by filling concrete into a steel pipe. The cross-section of the steel pipe is square. The steel pipe 2 of the lower column, the steel pipe 1 of the upper column and the steel pipe 2 of the lower column have the same cross-sectional size, and the two steel pipes are connected together through the connecting sleeve 3, which is also square, and it is separated from the steel pipe 2 of the lower column, and connected The outer upper part of the sleeve 3 is installed with the upper reinforcing ring plate 4, and the outer lower part of the connecting sleeve 3 is installed with the lower reinforcing ring plate 5. The reinforcing ring plate is also square. The left and right sides of the reinforcing ring plate extend horizontally outward to form connecting...

Embodiment 3

[0026] Such as image 3 As shown, this concrete-filled steel pipe segmental jacket node is in the form of variable cross-section, and it includes a steel pipe concrete column and a steel beam 7 connected to the column. The steel pipe concrete column is formed by filling concrete into a steel pipe, and the steel pipe section is rectangular. It includes the upper column steel pipe 1 and the lower column steel pipe 2. The cross-sectional dimensions of the upper column steel pipe 1 and the lower column steel pipe 2 are not equal, the upper column steel pipe 1 is thin, and the lower column steel pipe 2 is thick. 3 is separated from the lower column steel pipe 2, and the cross-sectional dimensions of the upper and lower ends of the connecting sleeve 3 are not equal, see image 3 , the connection sleeve 3 is thinner at the top and thicker at the bottom, and the middle is a transition section of variable diameter. The upper outer part of the connection sleeve 3 is installed with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com