Casting materials and casting method for 35kV-grade large-capacity dry main transformer coil

A pouring method and large-capacity technology, which is applied in coil manufacturing and other directions, can solve problems such as glass fibers are easy to fly with the wind, affect the health of workers, and coils are easy to crack, so as to avoid harm to the human body, extend the pouring time, and prolong The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The formula and pouring method used in the pouring ingredients of the 35kV class large-capacity dry-type main transformer provided in this example are as follows:

[0020] Select 45 parts of resin, 45 parts of curing agent, and 90-110 parts of microsilica powder according to the ratio of parts by weight; first, mix 45 parts of resin and 45-55 parts of microsilica powder and stir until uniform; 45-55 parts of curing agent mixed with the remaining 45-55 parts of silicon powder, and stirred until uniform; then the above-mentioned resin silicon powder mixture and curing agent silicon powder mixture were mixed, and degassed while stirring. The stirring and degassing process was about 30 minutes; finally, pour the stirred and degassed mixture into the mold to realize the coil casting of the dry main transformer.

Embodiment 2

[0022] The formula and pouring method used in the pouring ingredients of the 35kV class large-capacity dry-type main transformer provided in this example are as follows:

[0023] Select 55 parts of resin, 55 parts of curing agent, and 90 parts of microsilica powder according to the proportioning by weight; first, mix and stir 55 parts of resin and 45 parts of microsilica powder; simultaneously mix 55 parts of curing agent with Mix and stir the remaining 45 parts of microsilica powder; then mix the above resin microsilica powder mixture with the curing agent microsilica powder mixture, and degas while stirring. The stirring and degassing process is about 30 minutes; finally, stir and degas The final mixture is poured into the mold to realize the coil casting of the dry main transformer.

Embodiment 3

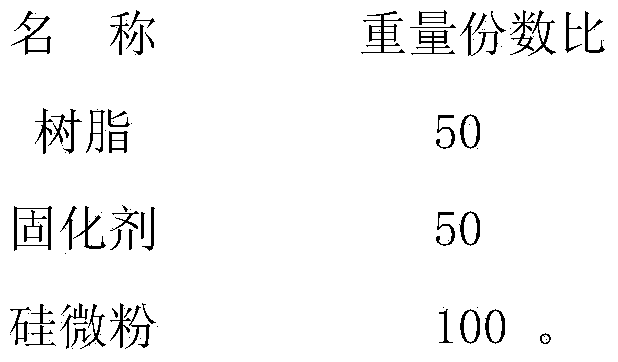

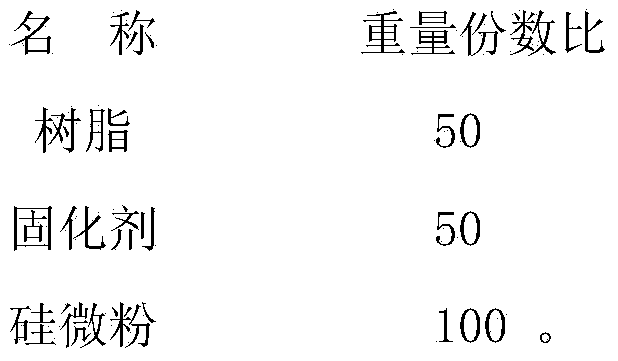

[0025] The formula and pouring method used in the pouring ingredients of the 35kV class large-capacity dry-type main transformer provided in this example are as follows:

[0026] Select 50 parts of resin, 50 parts of curing agent, and 100 parts of microsilica powder according to the ratio of parts by weight; first, mix and stir 50 parts of resin and 50 parts of microsilica powder; simultaneously mix 50 parts of curing agent with Mix and stir the remaining 50 parts of microsilica powder; then mix the above resin microsilica powder mixture with the curing agent microsilica powder mixture, and degas while stirring. The stirring and degassing process is about 30 minutes; finally, stir and degas The final mixture is poured into the mold to realize the coil casting of the dry main transformer.

[0027] In the above three embodiments, the set value of the resin degassing vacuum degree is not higher than 133Pa, and the vacuum degree after inputting the curing agent is not higher than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com