Curbstone back plain concrete efficient construction method

A construction method and technology of curbstone, applied in the direction of gutter/curb, roads, roads, etc., can solve the problems of low construction efficiency of wood formwork, achieve high construction efficiency, save materials and costs, and improve the effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

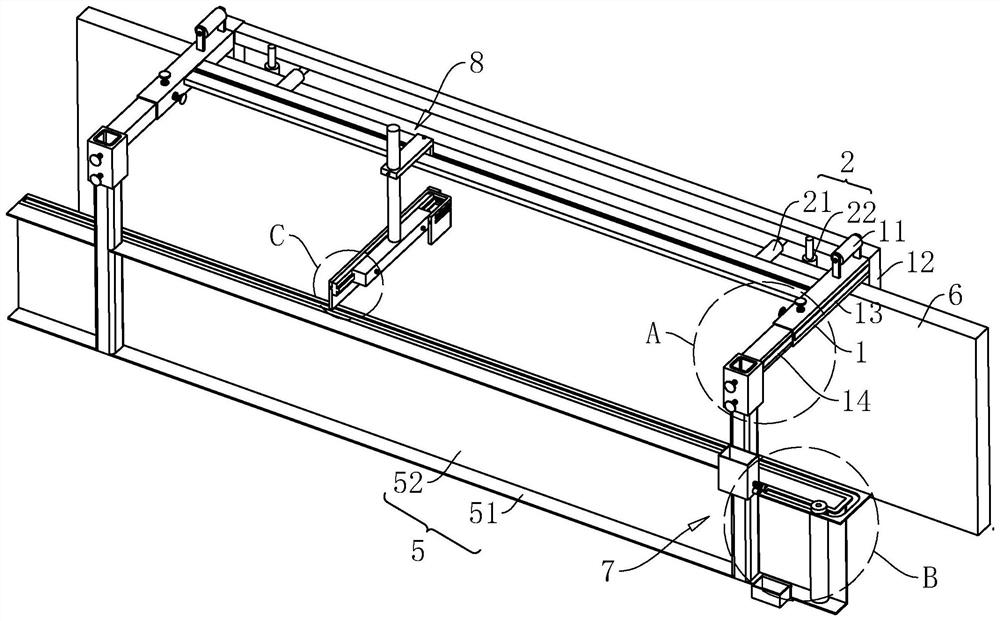

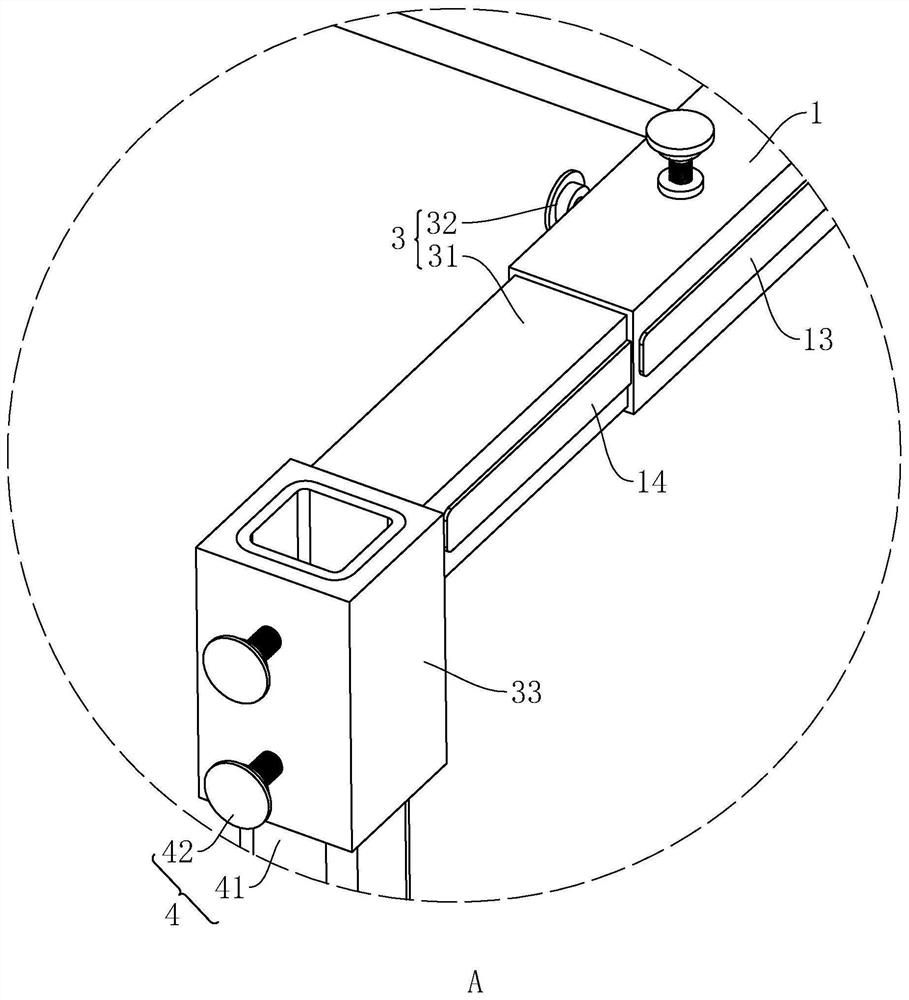

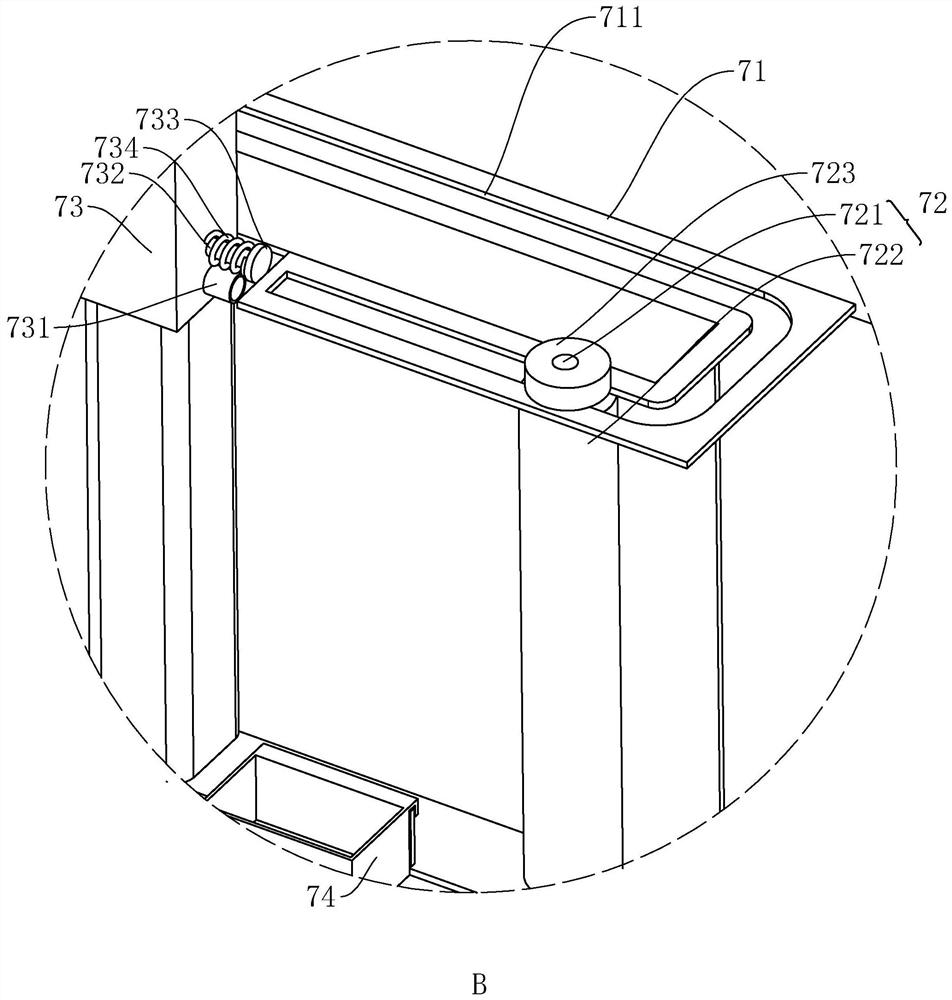

[0040] The application discloses a high-efficiency construction method for plain concrete behind curb stones. refer to figure 1 A high-efficiency construction method for plain concrete behind curbs includes construction tools, and the construction tools include a fixed frame 1. A sliding assembly 2 is arranged on the fixed frame 1, and the sliding assembly 2 is slidably connected with the curb 6, so that the fixed frame 1 can move along the The curb 6 slides in the length direction. A formwork 5 is also provided on the fixed frame 1, and a pouring area is formed between the formwork 5 and the curb stone 6, which is convenient for pouring concrete. A first adjustment assembly 3 and a second adjustment assembly 4 are arranged between the fixed frame 1 and the template 5, the first adjustment assembly 3 is used to adjust the distance between the template 5 and the fixed frame 1, and the second adjustment assembly 4 is used to adjust The height of the template 5. During work, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com