Polycarboxylate superplasticizer for ceramics and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of polycarboxylic acid water reducing agent for ceramics and its preparation, can solve the problems of low water reduction rate, general reduction effect, and high energy consumption of spray drying tower, so as to reduce drying energy consumption , Good water-reducing effect and shortening grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

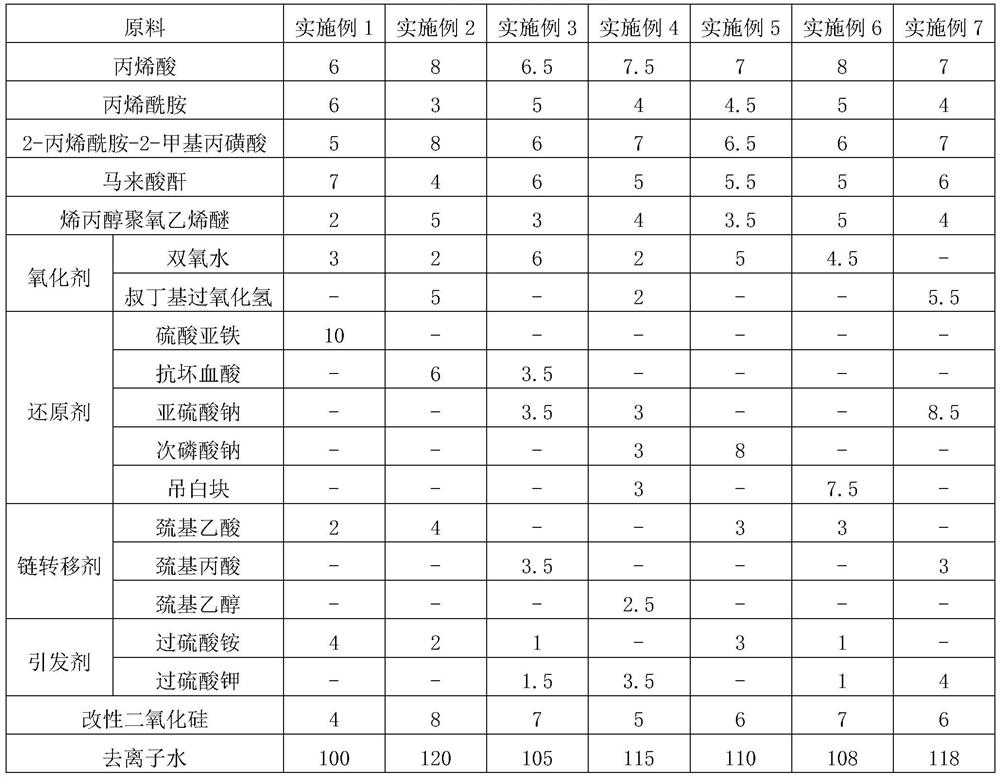

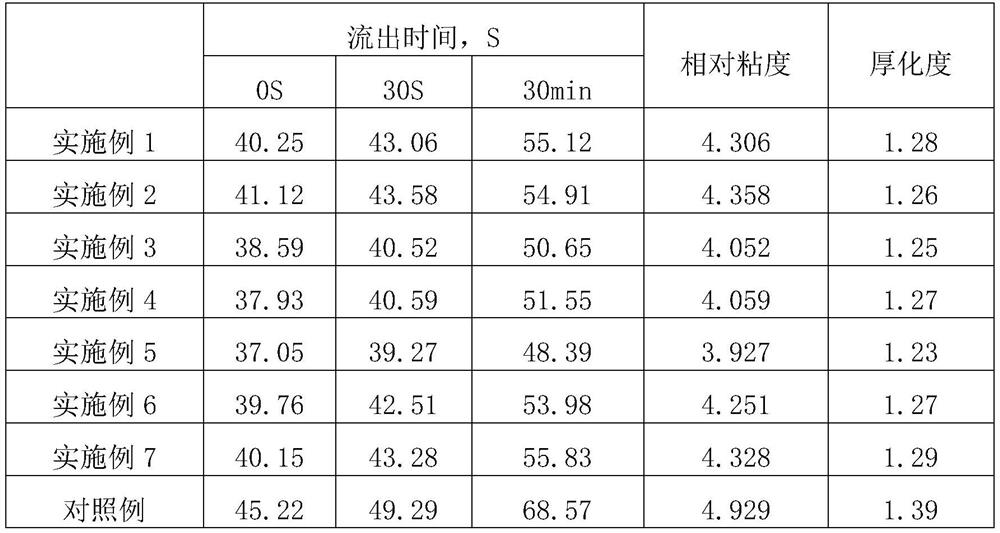

Examples

Embodiment 1

[0032] Include the following steps:

[0033] S1. Uniformly disperse the modified silicon dioxide in deionized water to obtain liquid A;

[0034] S2, diluting acrylic acid with deionized water to obtain liquid B;

[0035] S3, diluting the reducing agent and the chain transfer agent with deionized water to obtain liquid C;

[0036] S4, add acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, maleic anhydride, allyl alcohol polyoxyethylene ether, oxidizing agent, initiator and remaining deionized water (preparation A liquid, B liquid and the remaining deionized water after liquid C), and stir evenly, be warmed up to reaction temperature 40 ℃;

[0037] S5. Keep the reaction temperature at 40°C, slowly add liquid B and liquid C dropwise to the reaction vessel under stirring, and complete the dropwise addition of liquid B and liquid C within 2.5 hours; after the liquid B and liquid C are added dropwise, Insulation reaction for 2.5h;

[0038] S6. Add liquid A to the reaction ve...

Embodiment 2

[0041] Include the following steps:

[0042] S1. Uniformly disperse the modified silicon dioxide in deionized water to obtain liquid A;

[0043] S2, diluting acrylic acid with deionized water to obtain liquid B;

[0044] S3, diluting the reducing agent and the chain transfer agent with deionized water to obtain liquid C;

[0045] S4, add acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, maleic anhydride, allyl alcohol polyoxyethylene ether, oxidizing agent, initiator and remaining deionized water (preparation A liquid, B liquid and the remaining deionized water after liquid C), and stir evenly, be warmed up to reaction temperature 20 ℃;

[0046] S5. Keep the reaction temperature at 20°C, slowly add liquid B and liquid C to the reaction vessel under stirring, and complete the addition of liquid B and liquid C within 3 hours; after the addition of liquid B and liquid C is completed, keep warm Reaction 3h;

[0047] S6. Add liquid A to the reaction vessel under stirring a...

Embodiment 3

[0050] Include the following steps:

[0051] S1. Uniformly disperse the modified silicon dioxide in deionized water to obtain liquid A;

[0052] S2, diluting acrylic acid with deionized water to obtain liquid B;

[0053] S3, diluting the reducing agent and the chain transfer agent with deionized water to obtain liquid C;

[0054] S4, add acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, maleic anhydride, allyl alcohol polyoxyethylene ether, oxidizing agent, initiator and remaining deionized water (preparation A liquid, B liquid and the remaining deionized water after liquid C), and stir evenly, be heated up to reaction temperature 60 ℃;

[0055] S5. Keep the reaction temperature at 60°C, slowly add liquid B and liquid C to the reaction vessel under stirring, and complete the addition of liquid B and liquid C within 2 hours; after the addition of liquid B and liquid C is completed, keep warm Reaction 2h;

[0056] S6. Add liquid A to the reaction vessel under stirring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com