Waterproof phase-change heat storing plaster wallboard formed by reinforcing straw fibers

A straw fiber, phase change heat storage technology, applied in the field of building materials, can solve the problems of poor bending resistance, poor water resistance of gypsum light wallboard, etc., and achieve the effects of excellent waterproofness, saving heating energy consumption, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The weight percent of each component of the present embodiment is:

[0039] Gypsum cementitious material 45%

[0040] Phase change heat storage microcapsules 20%

[0041] Composite water repellent 2%

[0042] Mineral powder 30%

[0044] Binder 0.9%

[0045] Stimulator 1.4%

[0046] Water reducing agent 0.4%.

[0047] The gypsum cementitious material is desulfurized gypsum, the mineral powder is iron tailings slag powder, and the activator is magnesite cement.

Embodiment 2

[0049] The weight percent of each component of the present embodiment is:

[0050] Gypsum cementitious material 35%

[0051] Phase change heat storage microcapsules 16%

[0052] Composite water repellent 4%

[0053] Mineral powder 40%

[0054] Straw fiber 0.4%

[0055] Binder 1.2%

[0056] Stimulator 2.6%

[0057] Water reducer 0.8%.

[0058] The gypsum cementitious material is building gypsum, the mineral powder is blast furnace slag powder, and the activator is sulphoaluminate cement.

Embodiment 3

[0060] The weight percent of each component of the present embodiment is:

[0061] Gypsum cementitious material 25%

[0062] Phase change heat storage microcapsules 10%

[0063] Composite water repellent 7%

[0064] Mineral powder 50%

[0065] Straw fiber 0.6%

[0066] Binder 1.5%

[0067] Stimulator 4.4%

[0068] Water reducing agent 1.5%.

[0069] The gypsum cementitious material is fluorine gypsum, the mineral powder is iron tailings slag powder, and the activator is sulphoaluminate cement.

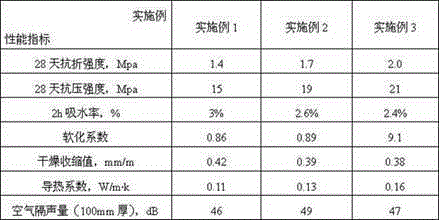

[0070]

[0071] It can be seen from the above table that the waterproof coating prepared according to the present invention has the characteristics of high strength, excellent water resistance, sound insulation and heat preservation, and high toughness. 3%, suitable for working in wet environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com