Patents

Literature

105results about How to "Reduce penetration rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

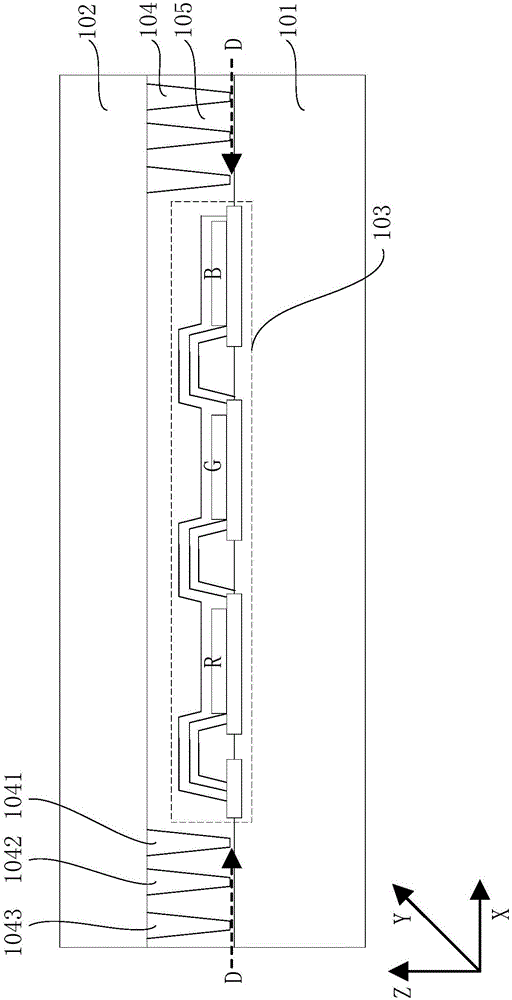

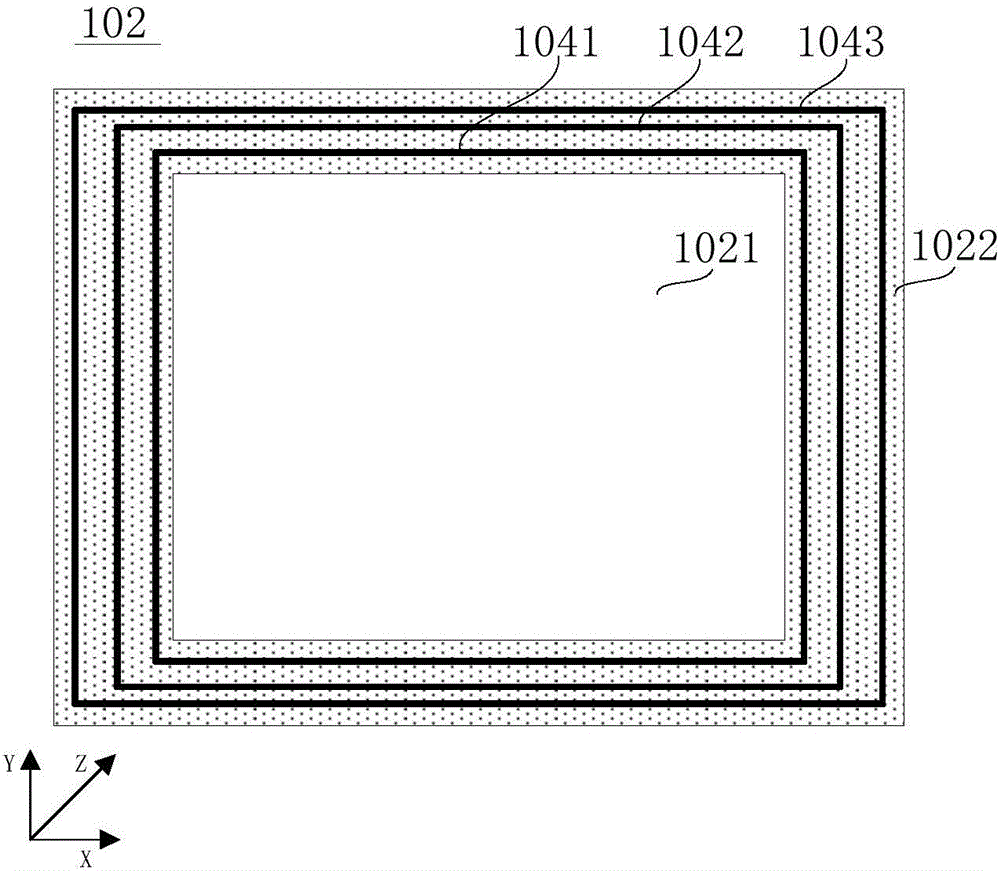

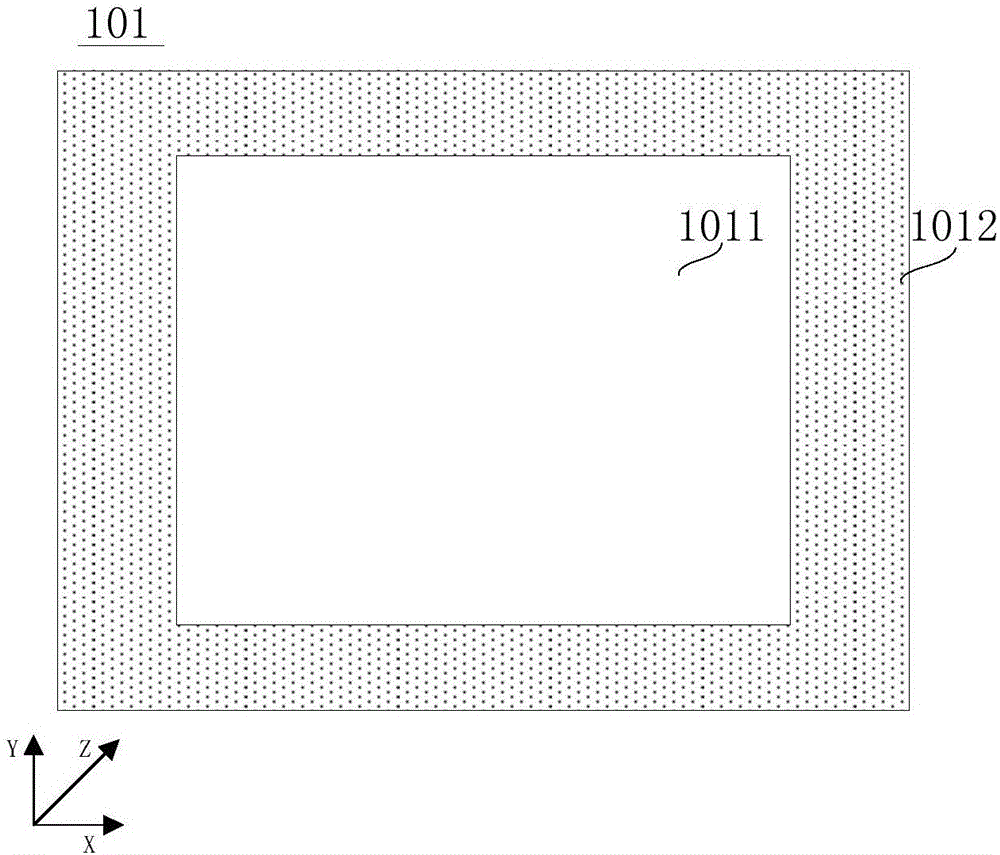

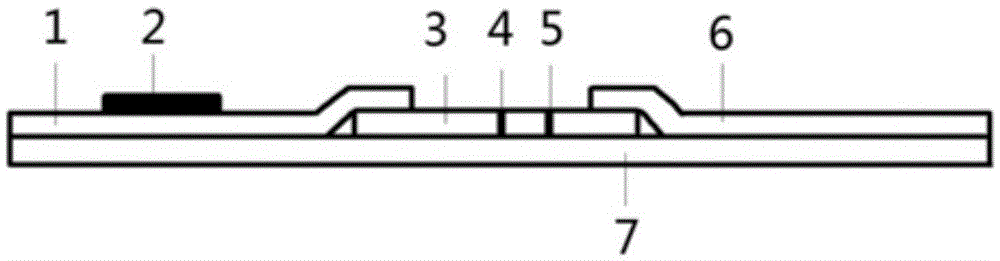

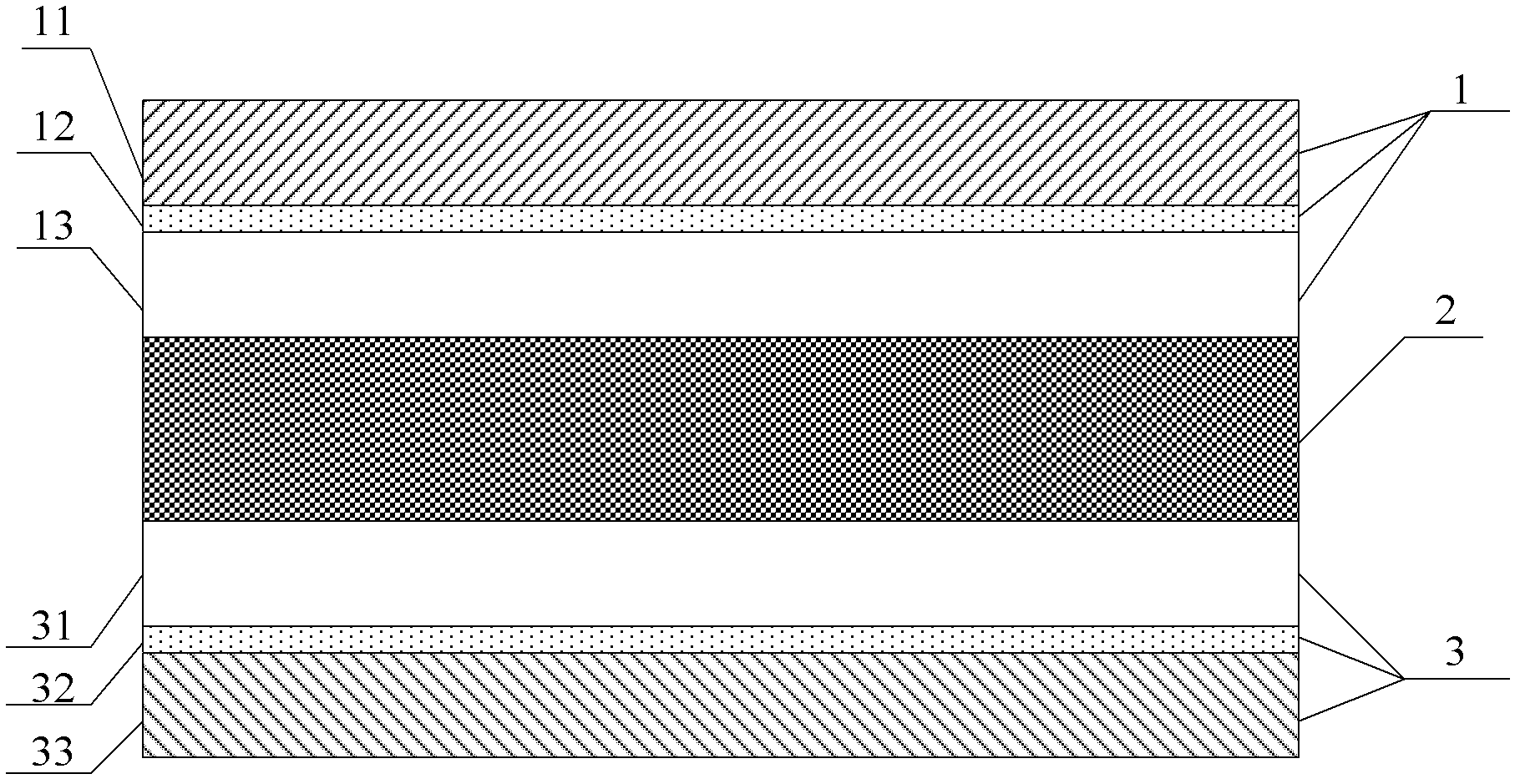

Display panel, manufacturing method thereof and display device

ActiveCN106450038AIncrease the lengthReduce penetration rateSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a display panel, a manufacturing method thereof and a display device, and relates to the technical field of display. The display panel comprises a substrate, a water and oxygen barrier layer and a light-emitting device, wherein the substrate comprises a display area and a non-display area enclosing the display area, the water and oxygen barrier layer comprises a display area and a non-display area enclosing the display area and is opposite to the substrate, and the light-emitting device is arranged between the display area of the substrate and the display area of the water and oxygen barrier layer. The non-display area of the substrate is provided with at least one retaining wall projecting towards the water and oxygen barrier layer, the non-display area of the water and oxygen barrier layer is provided with a second retaining wall projecting towards the substrate, and the first retaining wall and the second retaining wall respectively enclose the light-emitting device. By adjusting the mutually matching structure of lateral retaining walls, the length of a lateral water and oxygen infiltration path is increased, water and oxygen permeation rate is slowed down, and accordingly, stability of an OLED (organic light emitting diode) device is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Air-permeability aluminum foil and preparation method thereof

ActiveCN101628644AGood corrosionGood corrosion resistanceFlexible coversWrappersMaximum diameterCorrosion

The invention relates to an air-permeability aluminum foil and a preparation method thereof, wherein the aluminum foil is mainly suitable for air-permeability packaging in requirements of agricultural production and daily life. The aluminum foil is characterized by being made of 3003 alloy, the thickness of the aluminum foil is 0.03-0.05 mm, pinholes which can reach more than 10,000 every square meter are densely distributed on the surface of the aluminum foil, and the maximum diameter of each pinhole is not more than 0.05 mm. The preparation method comprises the following process steps: batching, smelting, cast-rolling, cold-rolling, interannealing, cold-rolling, and foil-rolling to reach the finished thickness, slitting into a finished specification, and finished annealing. The invention has the advantages of good air permeability, strong corrosion resistance and strong oxidation resistance.

Owner:新疆生产建设兵团第八师天山铝业有限公司

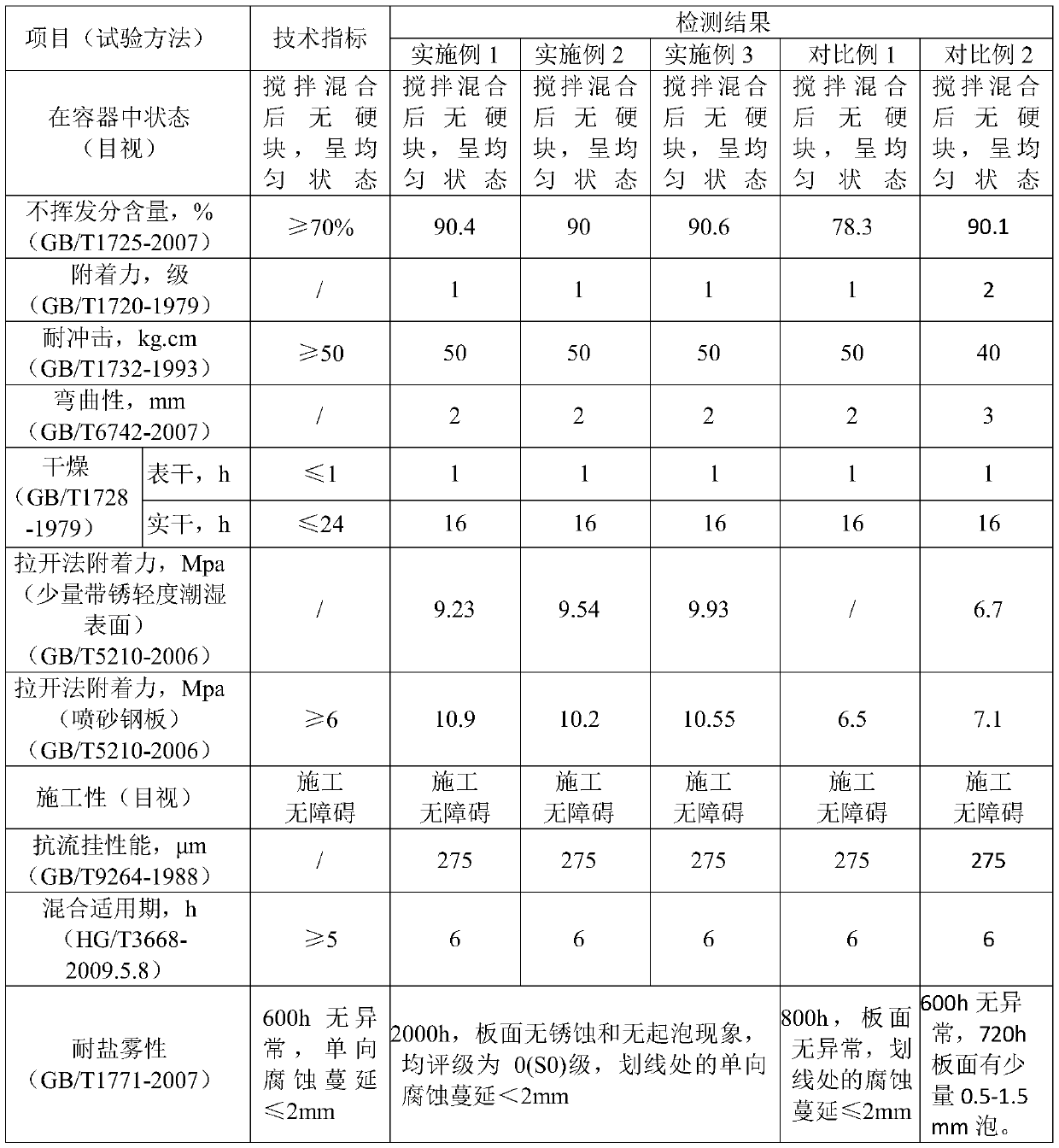

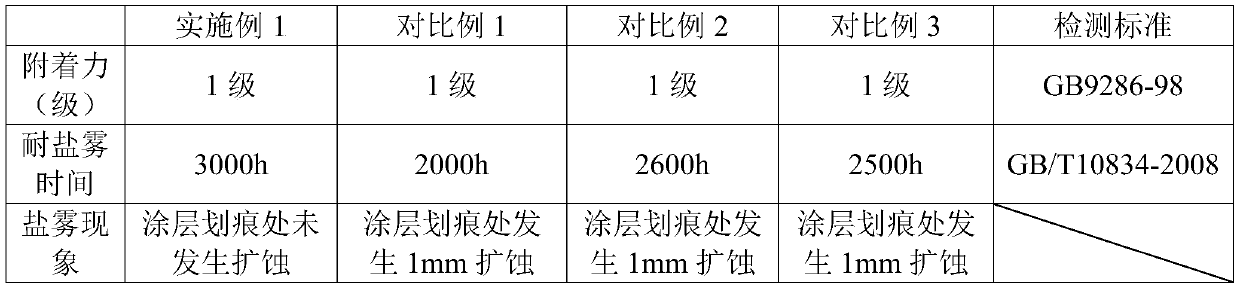

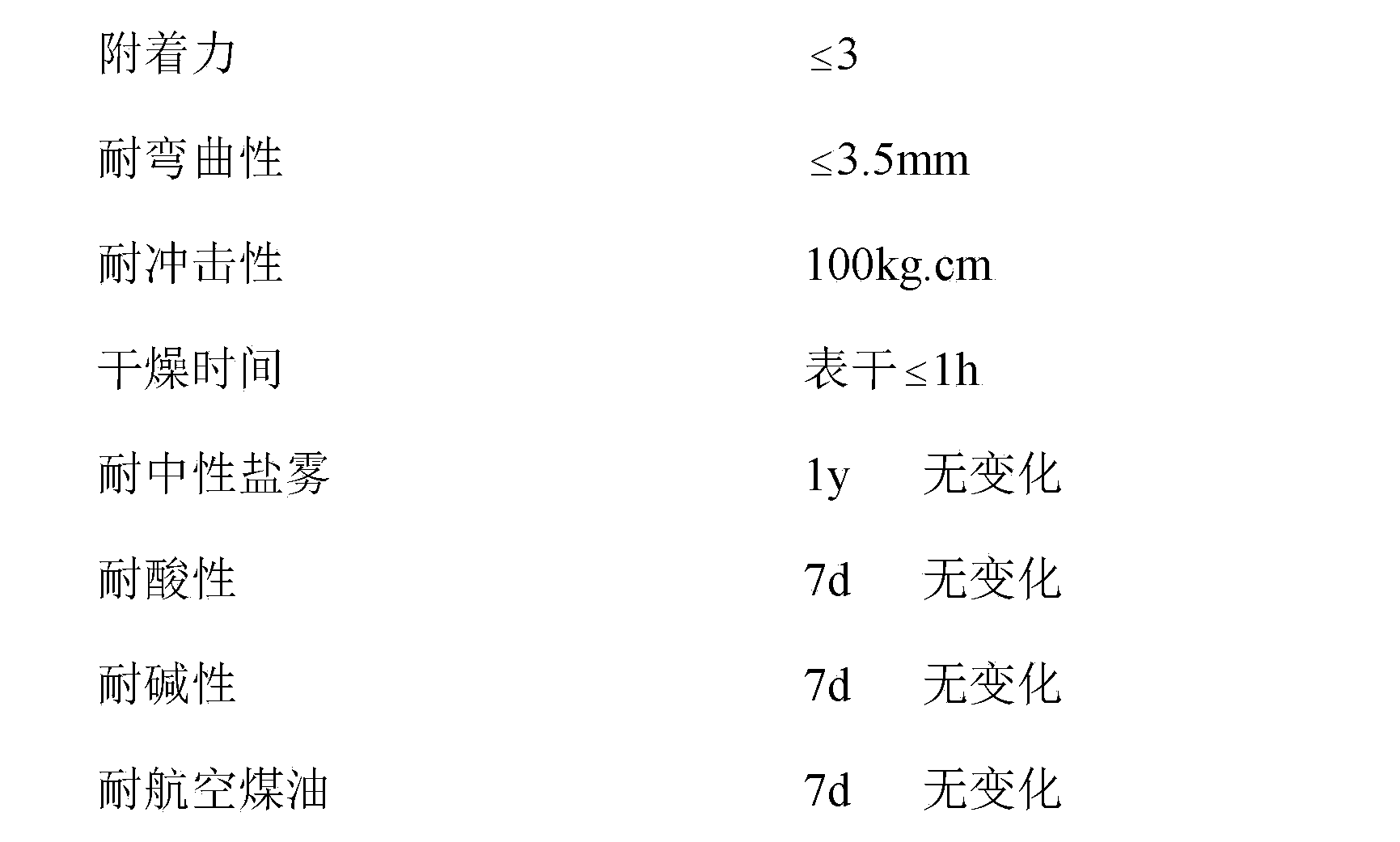

High-solid surface-tolerant epoxy zinc-rich primer and preparation method and application thereof

ActiveCN110144160AIncrease crosslink densityImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsChemical industryEpoxy

The invention relates to a high-solid surface-tolerant epoxy zinc-rich primer. The primer is prepared from a component A and a component B according to a weight ratio of (16-20):1; the component A comprises the following components in parts by weight: 5-9 parts of liquid phenolic epoxy resin, 6-15 parts of E20 solid epoxy resin, 0.5-1.5 parts of an active diluent, 0.1-0.3 part of a dispersing agent, 70-80 parts of main rust-proof pigment, 2-6 parts of chemical anti-rust pigment, 1.5-2.5 parts of an anti-settling agent and 3-4 parts of an organic mixed solvent; and the component B comprises thefollowing components in parts by weight: 1.5-2.5 parts of a polyamide curing agent, 2-3 parts of a Mannich base curing agent, 0.3-0.6 part of a silane coupling agent and 0.2-0.6 part of an organic mixed solvent. The invention also relates to a preparation method of the primer and a coating film. The primer is high in solid content and low in VOC content, is resistant to corrosion, has a long effect, has good adhesive force and salt fog resistance, and is particularly suitable for repairing and maintaining equipment in industries such as chemical industry, thermoelectricity, machinery and thelike.

Owner:江阴市大阪涂料有限公司

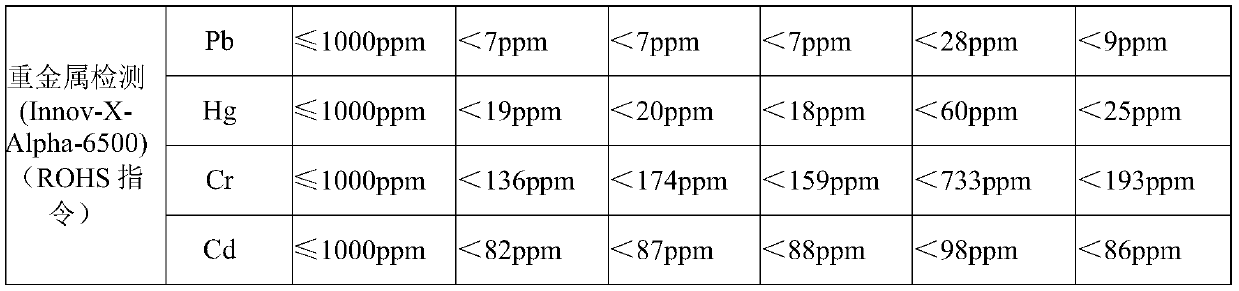

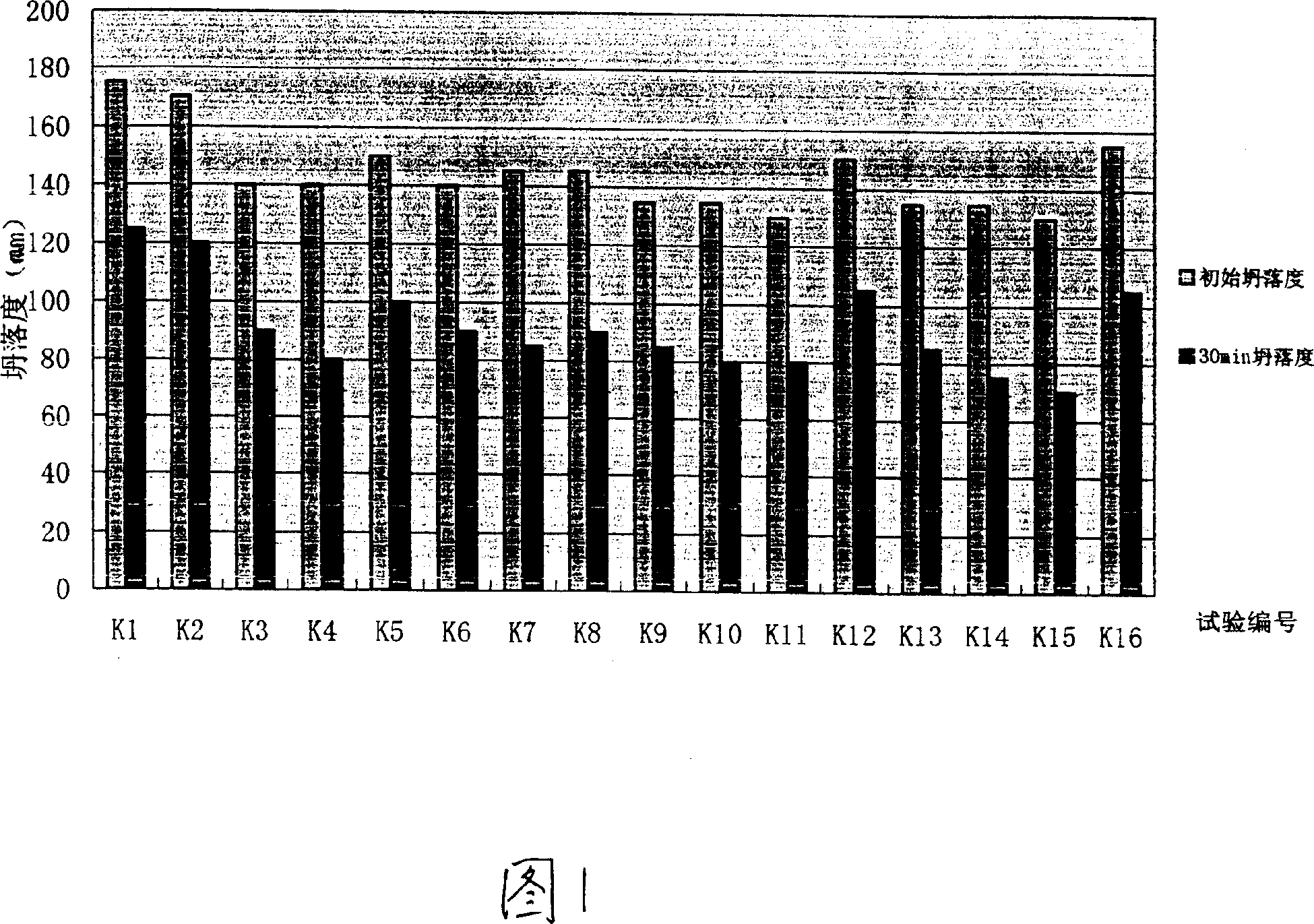

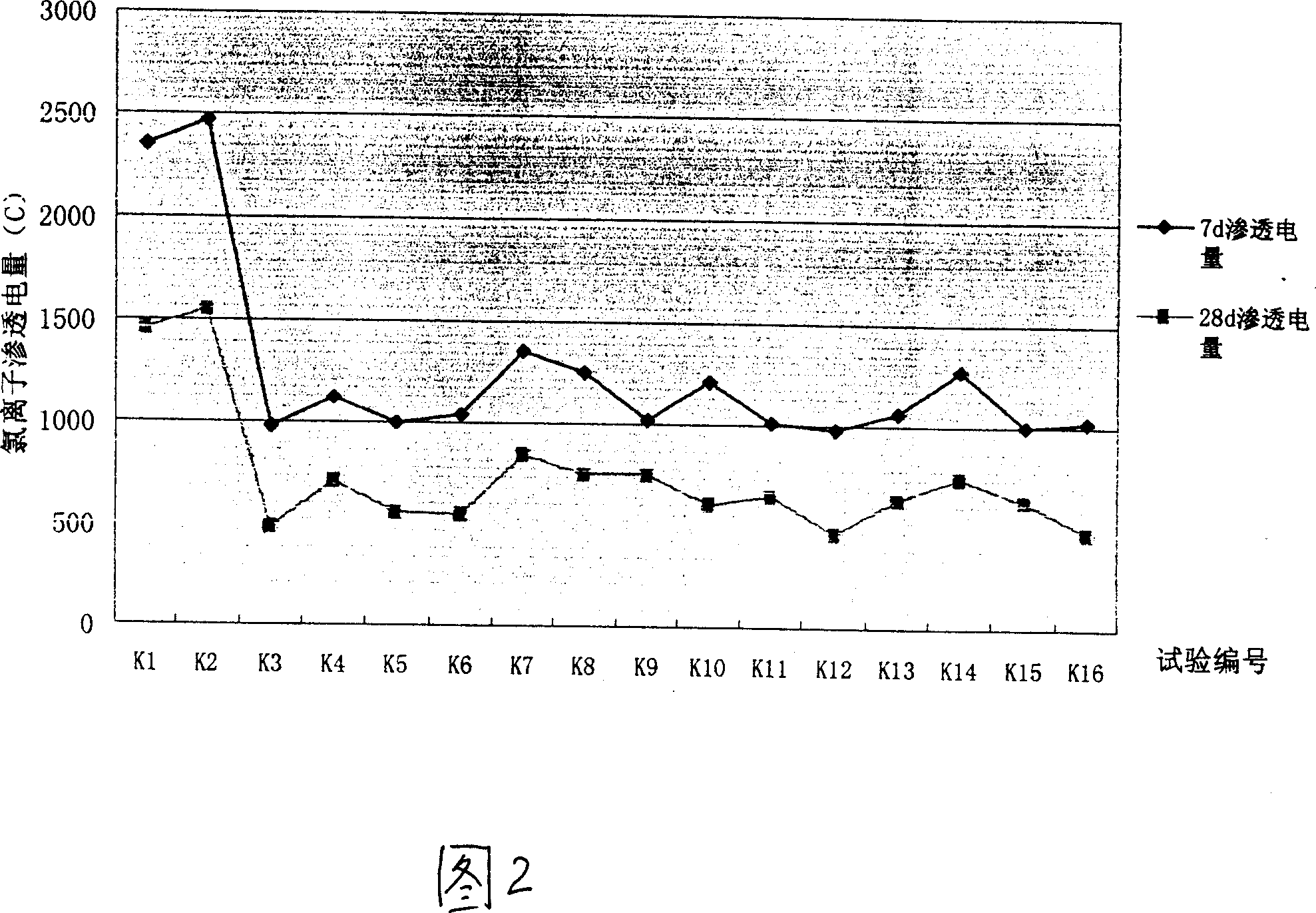

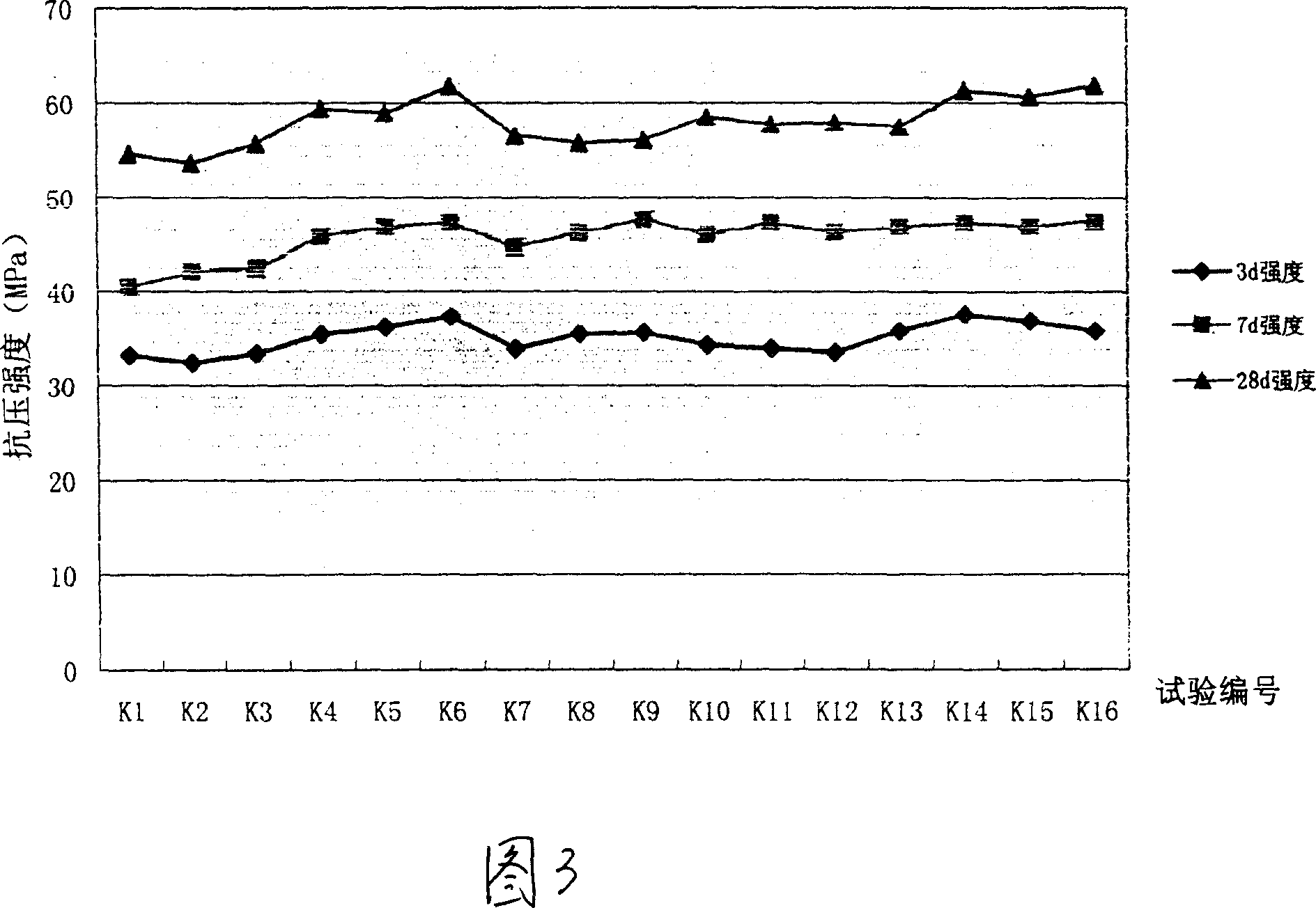

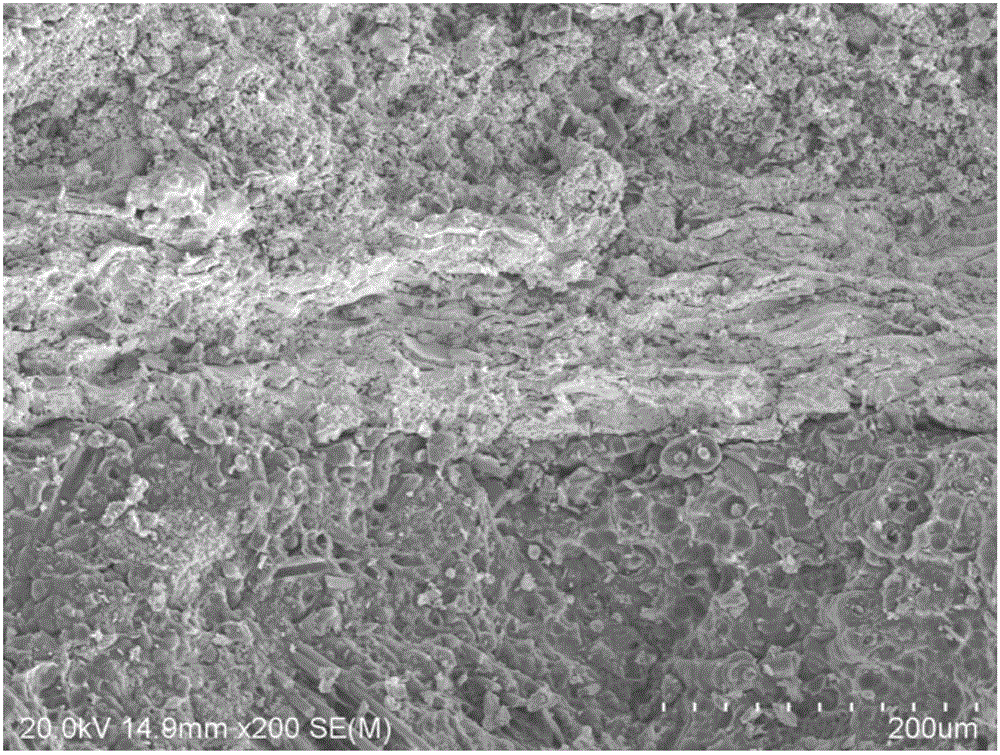

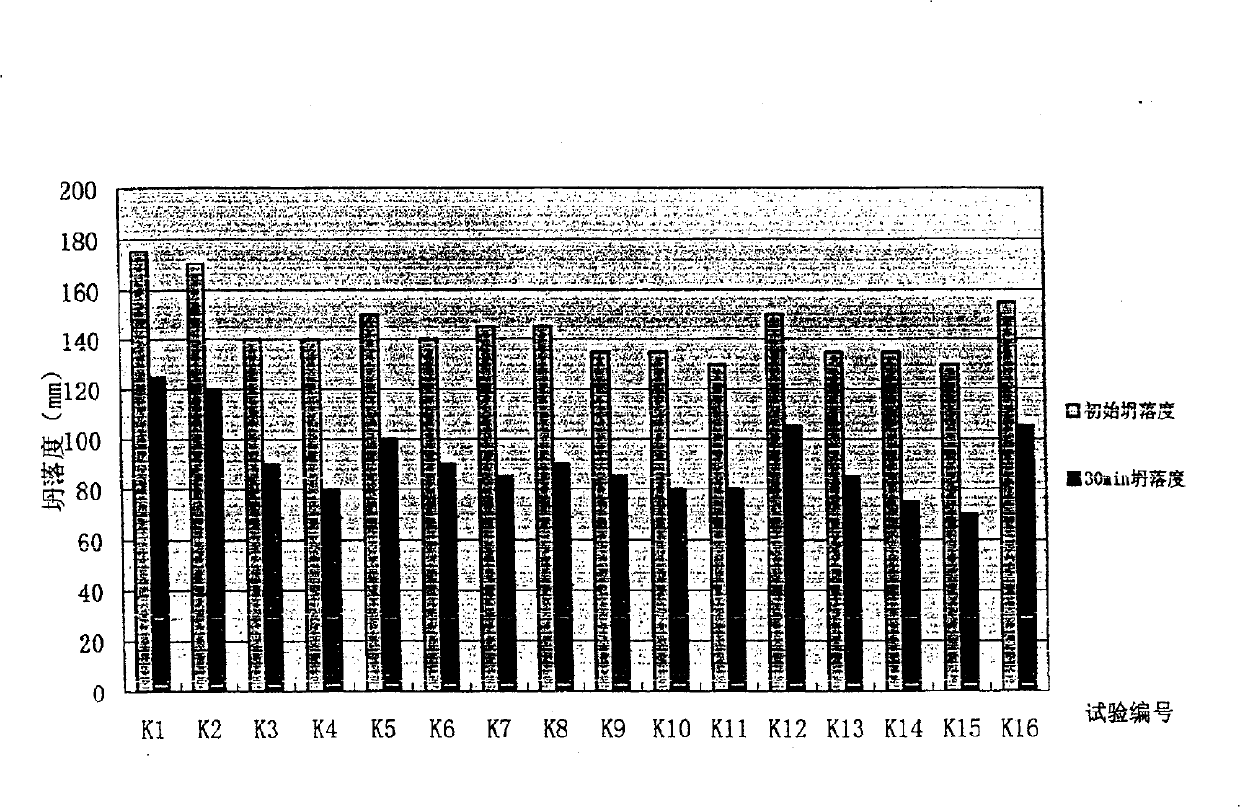

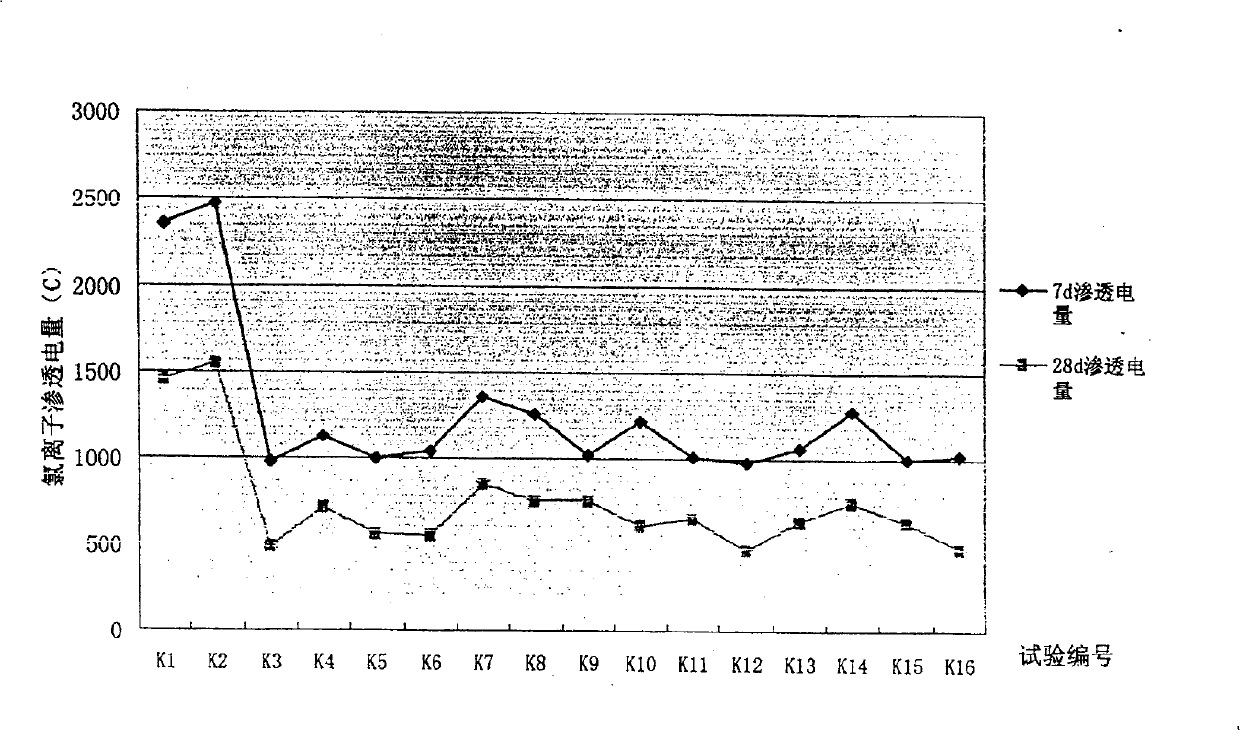

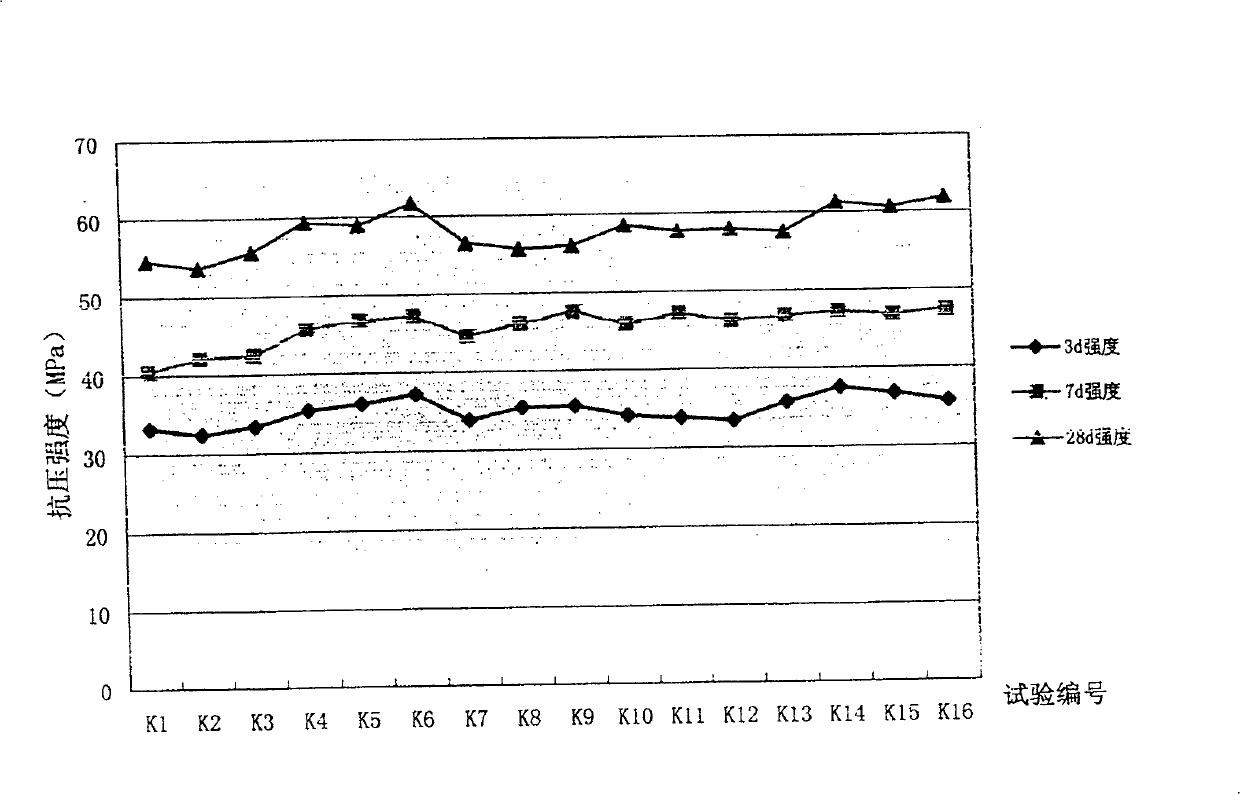

Formula of seaport engineering concrete chloride ion penetration resistant reinforcing agent

InactiveCN101134649AImprove permeabilityReduce penetration rateSolid waste managementFiberMicro structure

The present invention provides the recipe of chlorine ion penetration resisting reinforcer for concrete in harbor engineering. The chlorine ion penetration resisting reinforcer consists of superfine silica powder 15-20 wt%, washed and calcined kaolin 20-25 wt%, high grade fly ash 20-25 wt%, ground blast furnace slag 20-25 wt%, nanometer fiber 5-10 wt%, superplasticizer 6 wt%, slump keeping agent 0.09 wt%, air entraining agent 0.09 wt%, and organic active excitant 0.12 wt%. The chlorine ion penetration resisting reinforcer has inorganic components as main functional materials dispersed homogeneously in concrete cementing material, and can improve the micro structure and hydration product composition inside concrete, raise compactness, adsorb and fix chlorine ion and lower the penetration of chlorine ion in hardened concrete, so as to improve the chlorine ion penetration resisting capacity of hardened concrete.

Owner:LETS HLDG GRP CO LTD +1

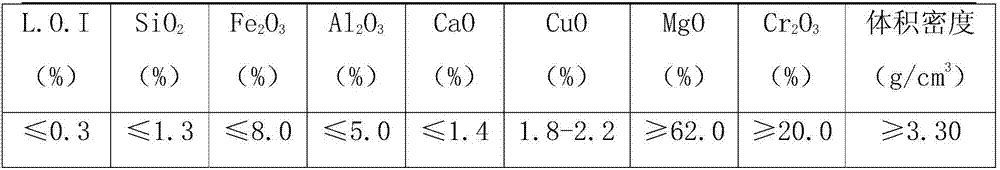

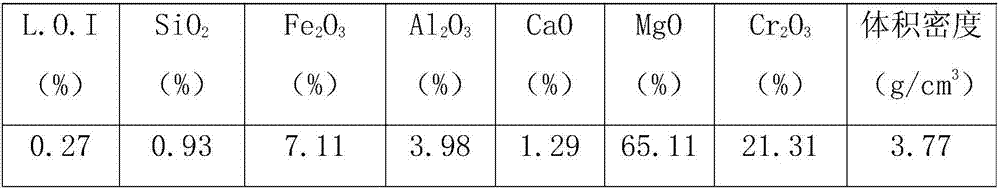

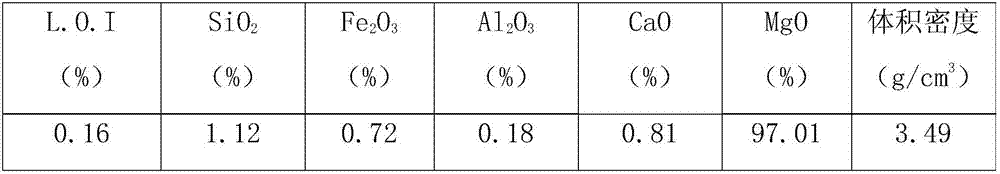

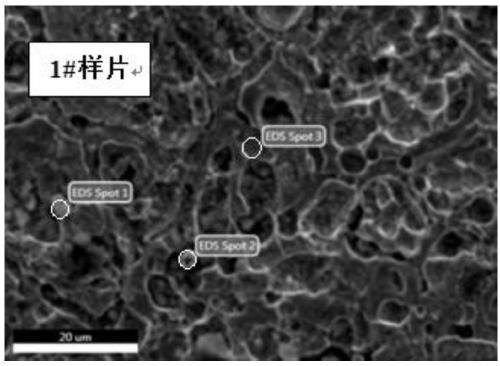

Copper composite high-performance magnesia-chrome brick and manufacturing method thereof

The invention belongs to the technical field of refractory materials, especially refractory materials for nonferrous smelting, and especially relates a copper composite high-performance magnesia-chrome brick and a manufacturing method thereof. The brick comprises 1-10 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 3-5 mm, 10-35 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 1-3 mm, 10-25 wt% of copper composite magnesia-chrome synthetic sands with the particle size being 0.088-1 mm, 1-5 wt% of fused magnesia-chrome sands with the particle size being 3-5 mm, 1-15 wt% of fused magnesia-chrome sands with the particle size being 1-3 mm, 2-13 wt% of fused magnesia-chrome sands with the particle size being 0.088-1 mm, 5-20 wt% of fused magnesia-chrome sands with the particle size being not more than 0.088 mm, 1-5 wt% of fused magnesia with the particle size being 3-5 mm, 1-15 wt% of fused magnesia with the particle size being 1-3 mm, 2-13 wt% of fused magnesia with the particle size being 0.088-1 mm, 5-20 wt% of fused magnesia with the particle size being not more than 0.088 mm, 2-10 wt% of chromium concentrate with the particle size being not more than 0.088 mm, 1-6 wt% of a composite additive and 3-5 wt% of an (externally added) binder. Magnesia-chrome brick wastes generated by the nonferrous smelting can be fully used reasonably and effectively in the invention.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

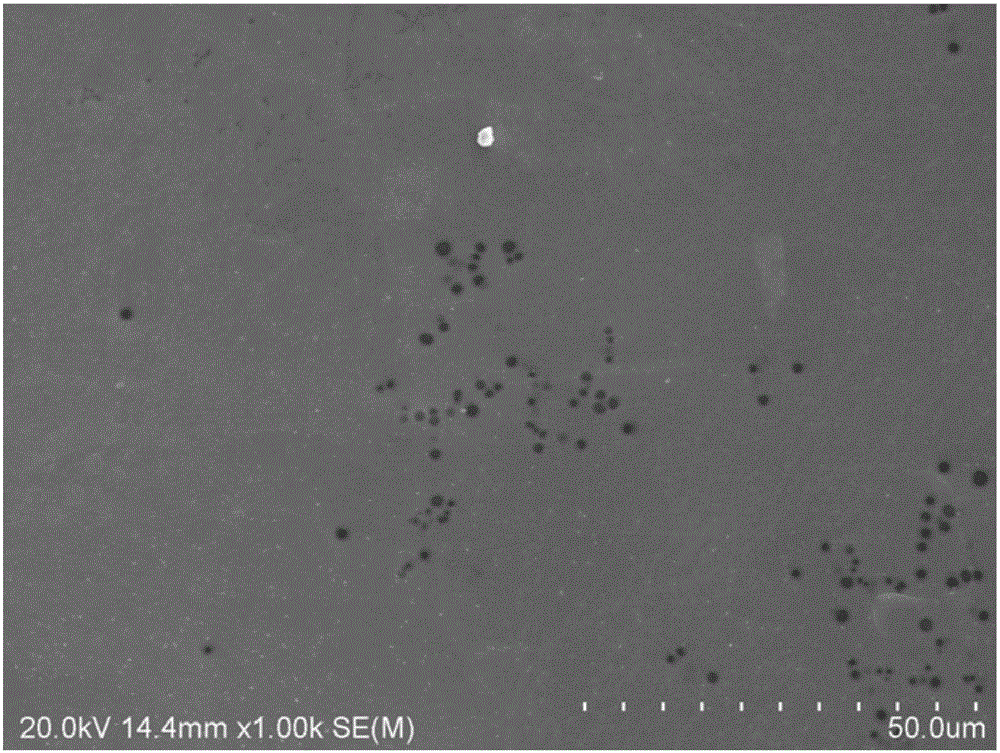

An NGAL time-resolved fluoroimmunoassay nanometer immunochromatographic quantitative detection test paper strip and a preparing method thereof

InactiveCN105527439AReduce penetration rateGuaranteed accuracyMaterial analysisFluorescenceRadioactive contamination

The invention discloses an NGAL time-resolved fluoroimmunoassay nanometer immunochromatographic quantitative detection test paper strip and a preparing method thereof. The test paper strip comprises a backing substrate plate. The backing substrate plate is provided with a nitrocellulose membrane, a sample combining pad and a water absorbing membrane. The sample combining pad and the water absorbing membrane are respectively laminated on two ends of the nitrocellulose membrane. The sample combining pad is covered with an NGAL monoclonal antibody labeled with a time-resolved fluorescent substance. The nitrocellulose membrane is provided with a detection line and a quality control line. The detection line is covered with an NGAL monoclonal antibody of another epitope. The quality control line is covered with goat anti-rat IgG. The test paper strip and the method are characterized by high sensitivity, high specificity, good stability, no radioactive contamination, and the like and can be widely applied to NGAL clinical immunoassay and scientific research.

Owner:XIAMEN YIKELISI MEDICAL TECH CO LTD

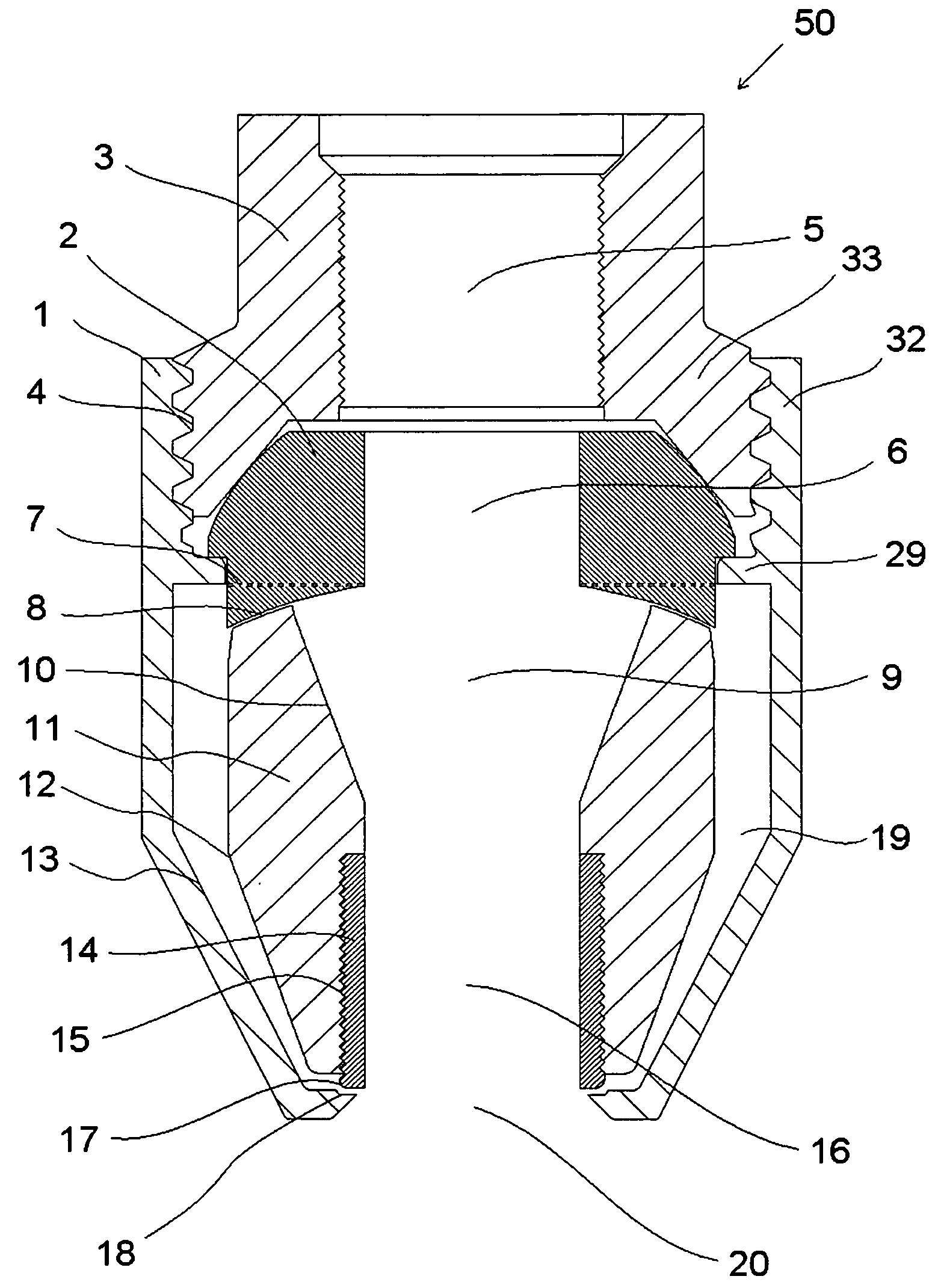

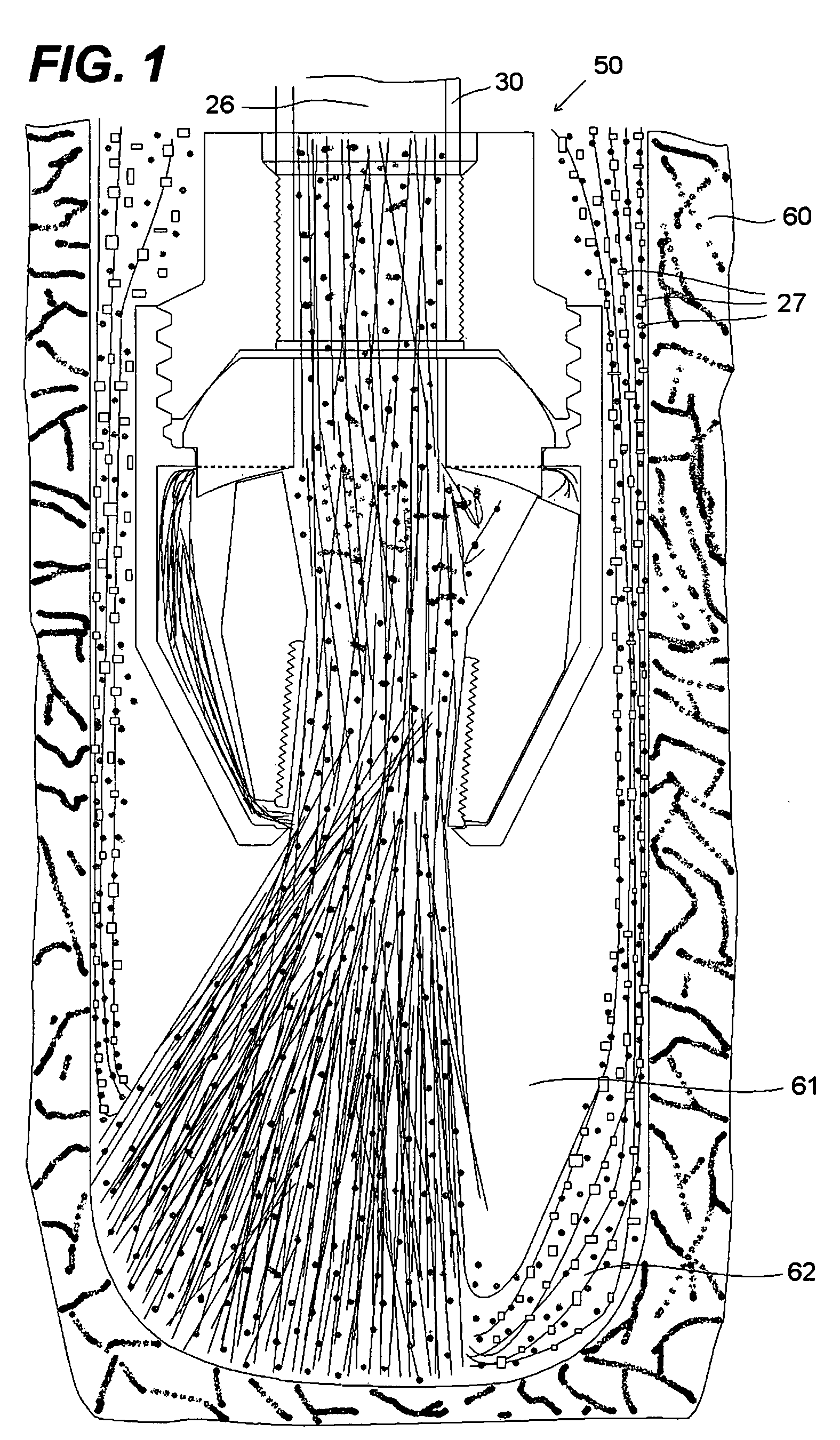

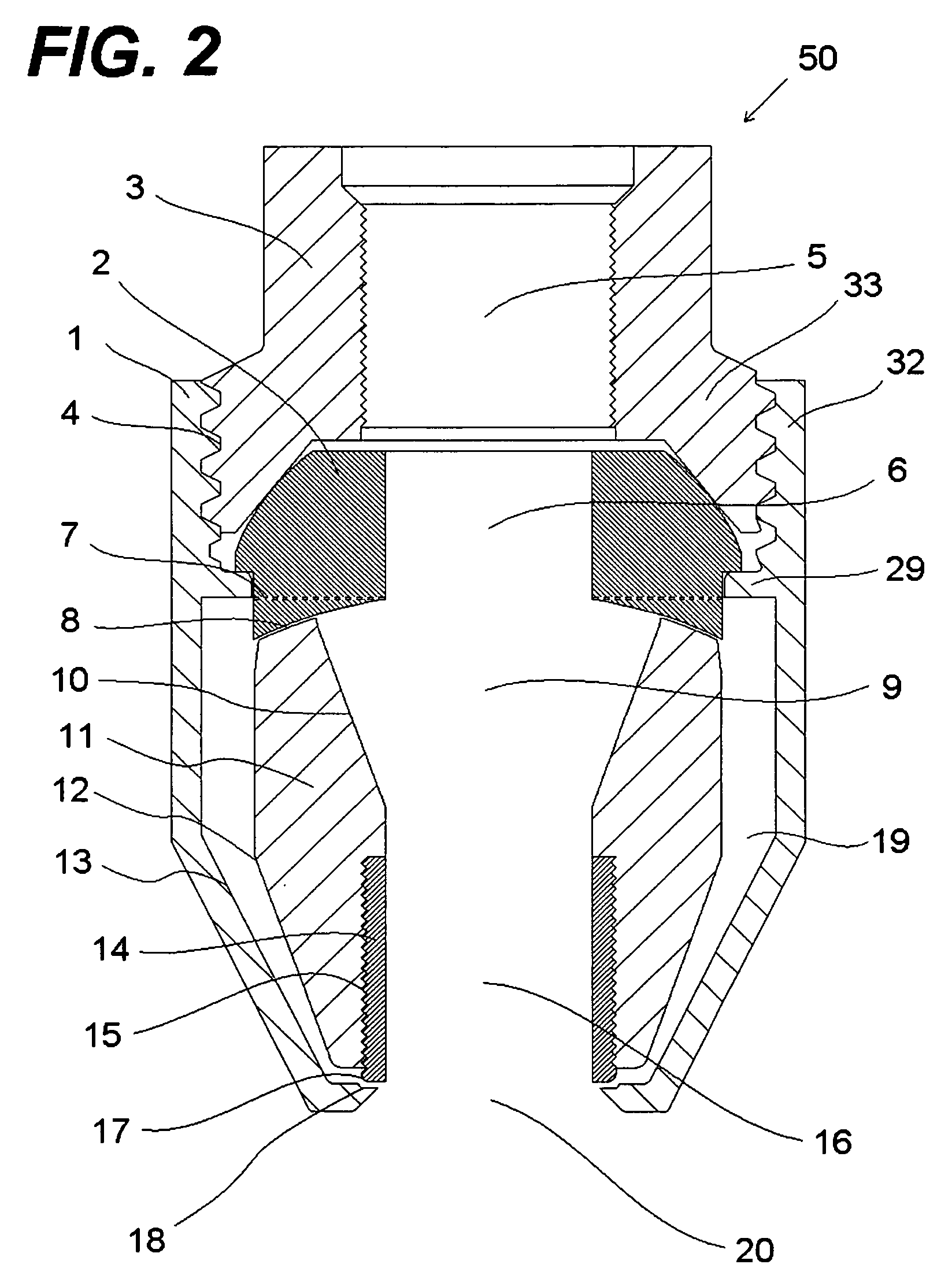

Tool and method for drilling, reaming, and cutting

InactiveUS20050183891A1Reduce penetration rateIncrease ROPDrill bitsDrilling rodsInjectorEngineering

An orbital tool apparatus and method of using the apparatus for boring, drilling, reaming, and cutting having a tool housing, a tool collar located within the housing, the tool housing having the ability to couple to a conduit structure, fluid orbiting jets within the tool collar, and a tool funnel located below the tool collar and within a lower portion of the tool housing. The orbital tool creating a bore in a surface, when fluid flowing into the orbital tool via a conduit is directed out of the orbital tool towards the structure, a portion of the fluid flowing within the orbital tool being diverted through the fluid orbiting jets causing the diverted fluid to impinge against the tool funnel, causing the tool funnel to oscillate creating a sweeping flow towards the surface.

Owner:CHRISMAN DAVID SCOTT

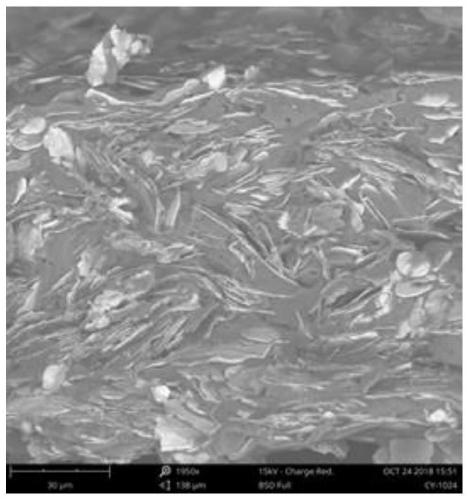

Water-based inorganic zinc-rich anticorrosive paint and preparation method thereof

InactiveCN110437654AGuaranteed anti-corrosion performanceAdd lessAlkali metal silicate coatingsAnti-corrosive paintsWater basedGraphene

The invention discloses water-based inorganic zinc-rich anticorrosive paint and a preparation method thereof. The water-based inorganic zinc-rich anticorrosive paint comprises 30-50 wt% of a silicate,45-70 wt% of a two-dimensional barrier material and 0-5 wt% of a paint assistant, wherine the modulus of a silicate solution is greater than or equal to 4.0, the two-dimensional barrier material comprises modified flaky zinc powder, modified sericite and graphene, the modified flaky zinc powder is prepared by modifying flaky zinc powder through a surface modifier, the modified sericite is prepared by modifying sericite through a surface modifier, and the surface modifier is an organosilane coupling agent. The compact two-dimensional barrier layer is formed under the combined action of the modified sericite and the graphene, and the corrosion resistance of the paint can be remarkably improved, so that the use amount of zinc powder can be reduced on the premise of ensuring the corrosion resistance of the paint, and the paint achieves the effects of low zinc powder addition amount and excellent corrosion resistance.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

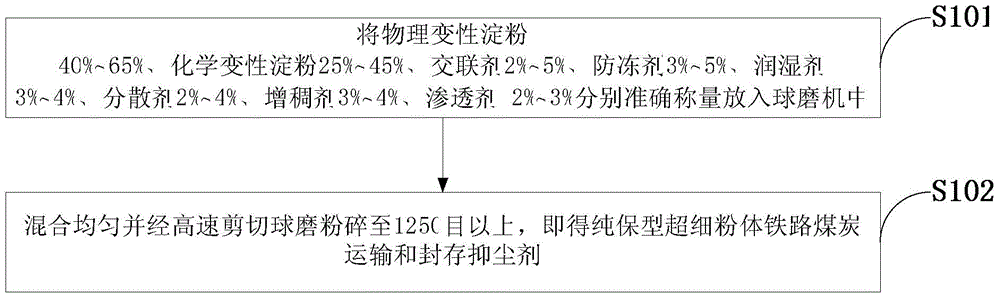

Environment-friendly superfine powder railway coal transportation and storage dust suppressant and preparation method

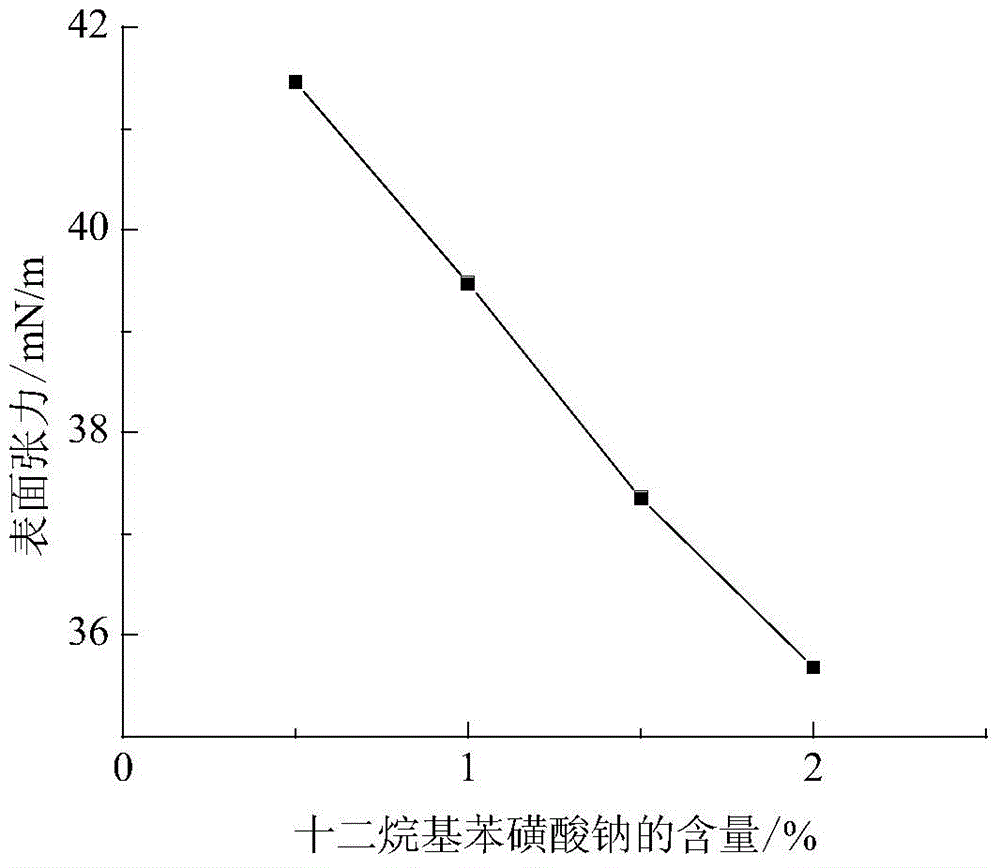

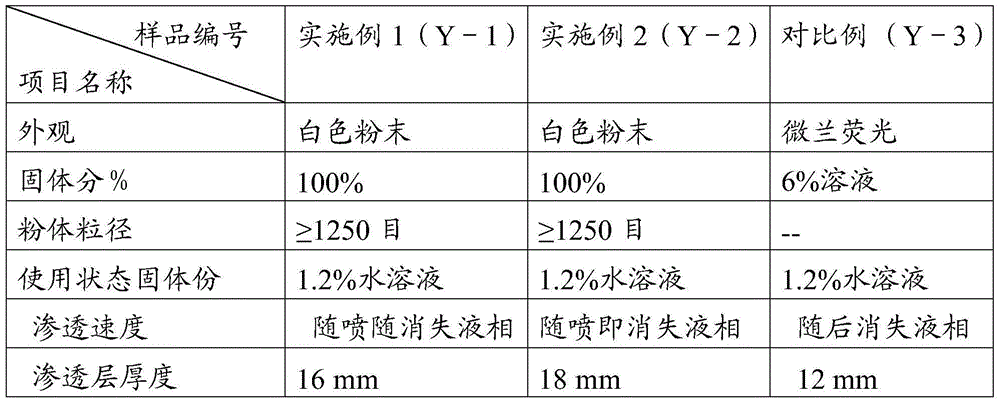

InactiveCN103980860ASuppress flyingImprove wettabilityOther chemical processesAnti freezingCross linker

The invention discloses an environment-friendly superfine powder dust suppressant for railway coal transportation and storage and a preparation method. The environment-friendly superfine powder dust suppressant for railway coal transportation and storage comprises the following components in percentage by weight: 40-65% of physical modified starch, 25-45% of chemical modified starch, 2-5% of cross linker, 3-5% of anti-freezing agent, 3-4% of wetting agent, 2-4% of dispersant, 3-4% of thickener and 2-3% of penetrating agent. The preparation method for the environment-friendly superfine powder dust suppressant for railway coal transportation and storage comprises: weighing the components of the dust suppressant in percentage by weight respectively and putting the components into a ball mill; and mixing uniformly and performing high-speed shear ball milling to above 1,250 meshes, thus obtaining the environment-friendly superfine powder dust suppressant for railway coal transportation and storage. The superfine powder material is prepared by compounding the physical modified starch and the chemical modified starch, adding an inorganic gel material and adding multiple aids, and has the construction effects of good coal bed wetting effect, thick pervious bed, high curing speed, large setting strength of the pervious bed and good dust suppression effect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

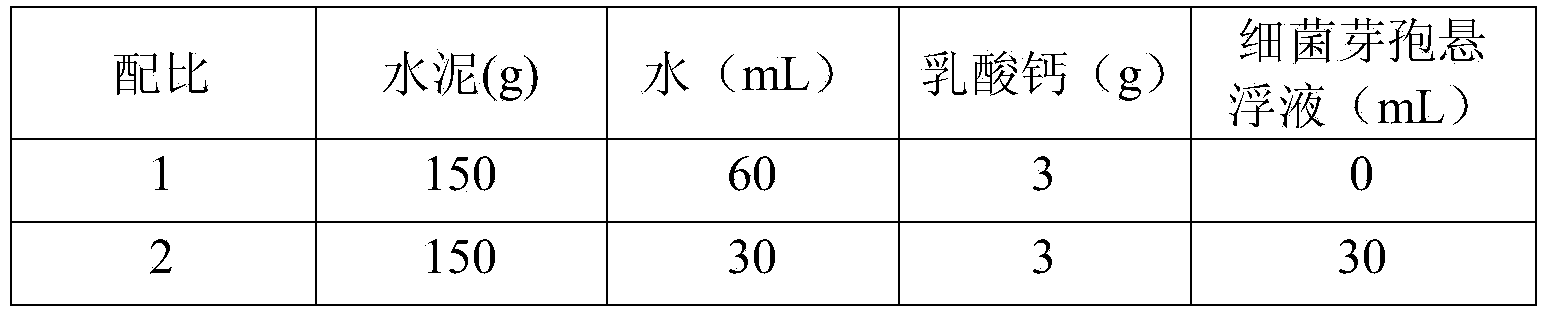

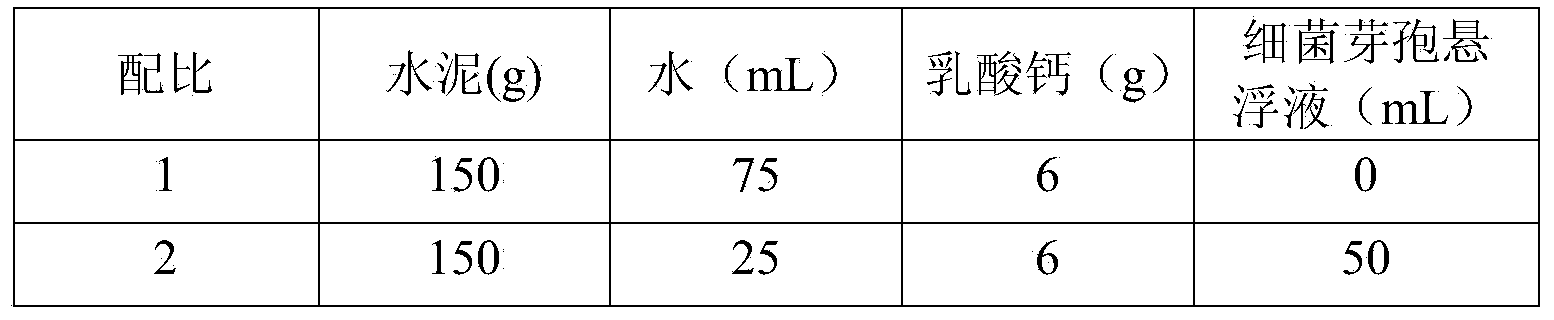

Self-healing cement-based material containing bacterial spores and preparation method thereof

The invention relates to a self-healing cement-based material containing bacterial spores and a preparation method thereof. The self-healing cement-based material consists of cement, water, calcium lactate and bacterial spores, wherein the mass ratio of the water to cement is 0.3-0.5, the mass of calcium lactate accounts for 1%- 5% of the mass of cement, 10<6>-10<9> spores are added into 1cm<3> of cement-based material. The preparation method comprises the steps of: inoculating alkali-resistant Bacillus, culturing to obtain strain solution having a high spore forming rate, heating the strain solution in a 80 DEG C water bath for 20min, centrifugally cleaning to obtain a spore suspension; weighing the required cement, proportionally weighing and adding calcium lactate, stirring until calcium lactate is evenly distributed in the cement; mixing the spores suspension which is used for replacing a part of mixing water with the rest water evenly in a shaking manner and pouring into the cement and calcium lactate, and stirring evenly, and pouring into a mold for forming.

Owner:SOUTHEAST UNIV

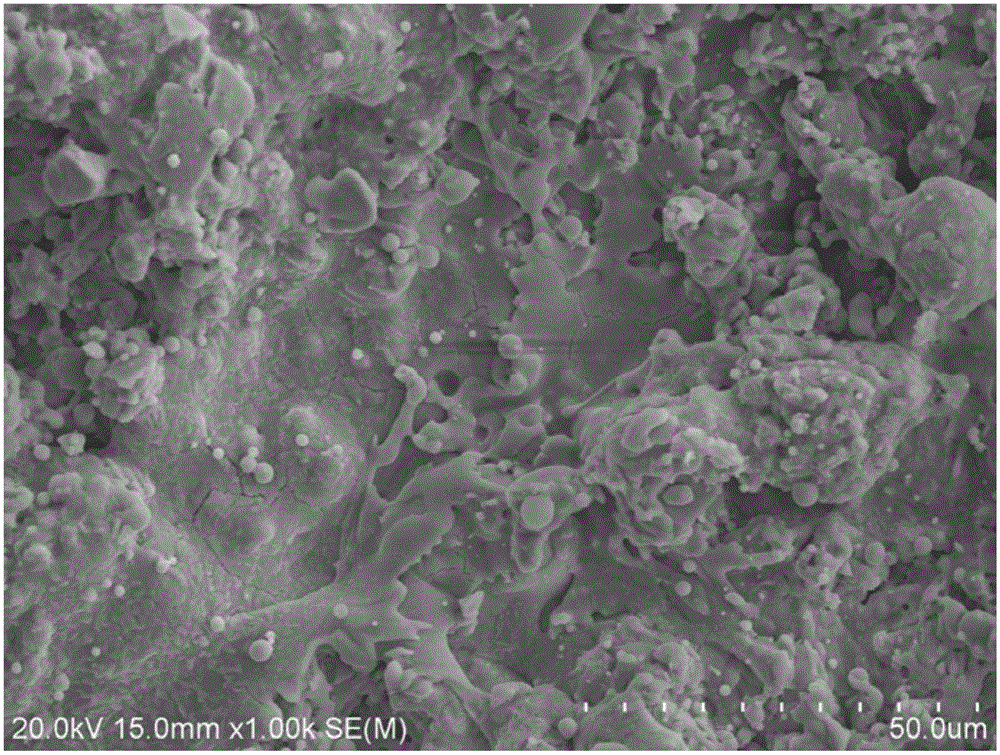

Heavy anti-corrosion paint made of epoxy resin and basalt scales

InactiveCN103627294APrevent penetrationReduce penetration rateAnti-corrosive paintsPolyamide coatingsEpoxyPolyamide

The invention discloses a heavy anti-corrosion paint made of epoxy resin and basalt scales. The paint comprises a component A and a component B, and is characterized in that: the component A comprises the following components in parts by weight: 20 to 40 parts of epoxy resin, 25 to 38 parts of dibutyl phthalate, 15 to 35 parts of dispersant, 20 to 40 parts of antifoaming agent, 20 to 39 parts of levelling agent, 10 to 25 parts of pigment zinc phosphate, and 12 to 78 parts of basalt scales; and the component B comprises the following components in parts by weight: 20 to 40 parts of polyamide and 25 to 40 parts of solvent. Basalt scales are adopted as the filling material, because of the labyrinth effect of the basalt scales, penetration of corrosive mediums is effectively prevented, the penetration rate is reduced by 8 to 9 times, and the paint has the advantages of high adhesive force, corrosion resistance, good penetration resistant property, low coating contracting rate, small thermo-expanding coefficient, low curing residual stress, wear resistance, simpleness for construction, and easy repairing.

Owner:哈尔滨功成科技创业投资有限公司

Zircon mullite brick for cement kiln and preparation method thereof

The invention relates to a zircon mullite brick for a cement kiln and a preparation method thereof. According to the technical scheme, by weight, 58-75% of particles, 3-20% of zircon mullite fine powder, 3-10% of Guangxi white clay fine powder, 1-3% of Ti3AlC2 / Ti3SiC2 composite powder, 2-7% of monatomic silicon fine powder, 3-15% of raw bauxite micro powder and 0.5-1.0% of zirconium boride fine powder are adopted as a raw material A, cerium chloride accounting for 0.5-2% of the raw material A by weight and sulfite lye accounting for 3-8% of the raw material A by weight are additionally added,stirring, forming and drying are performed, the temperature of 1,400-1,600 DEG C is kept constant for 2-8 h, and the zircon mullite brick for the cement kiln is obtained. According to the particles, kyanite tailing fine powder or gangue fine powder are adopted as a raw material B, yttrium oxide fine powder accounting for 0.5-2% of the raw material B by weight and sulfite lye accounting for 4-6% ofthe raw material B by weight are additionally added, uniform mixing, forming and drying are performed, the temperature of 1,300-1,500 DEG C is kept constant for 3-9 h, and cooling and breaking are performed to obtain the particles. The cost is low, and the prepared zircon mullite brick for the cement kiln is good in abrasion resistance, low in heat conductivity coefficient, good in thermal shockresistance and good in corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

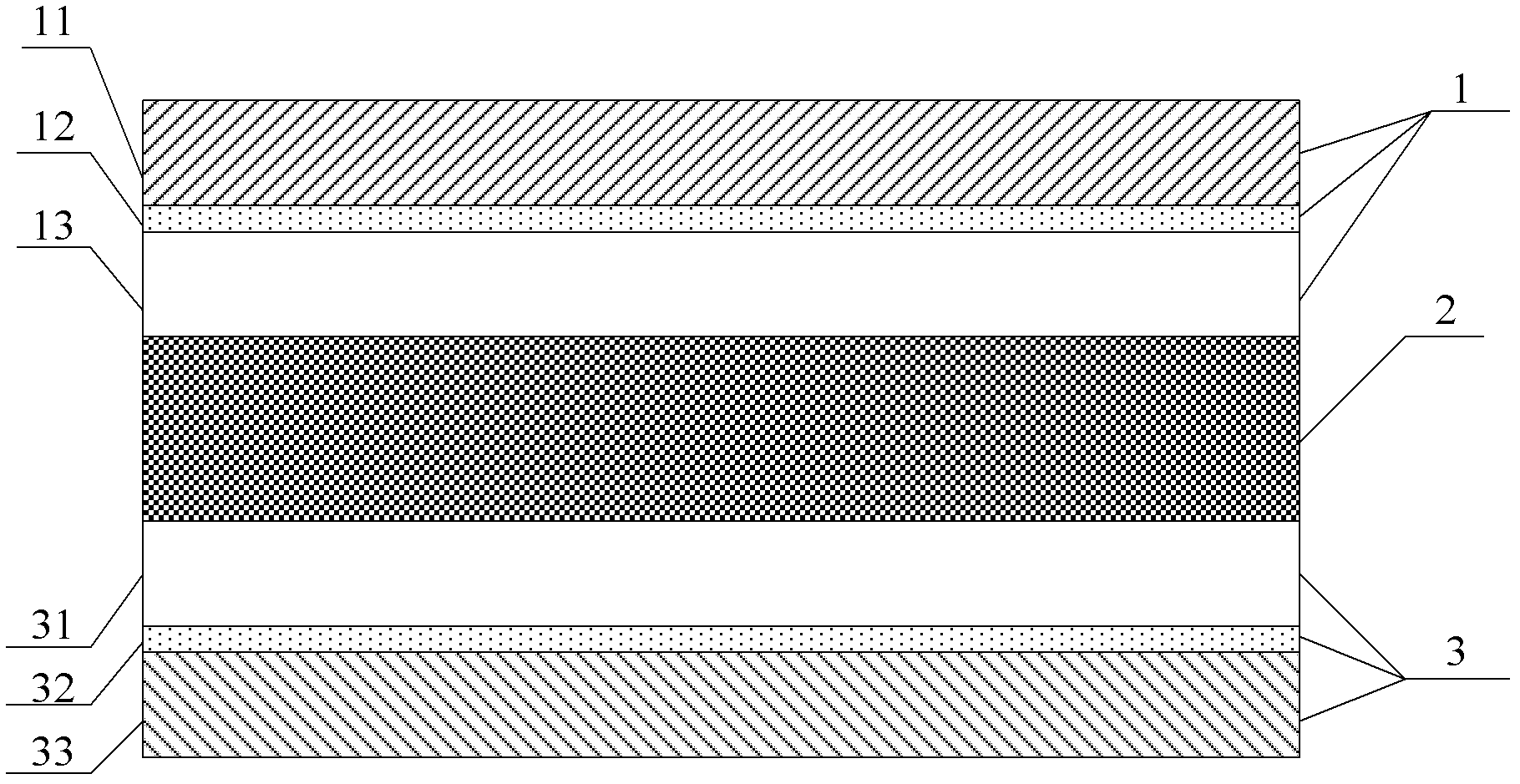

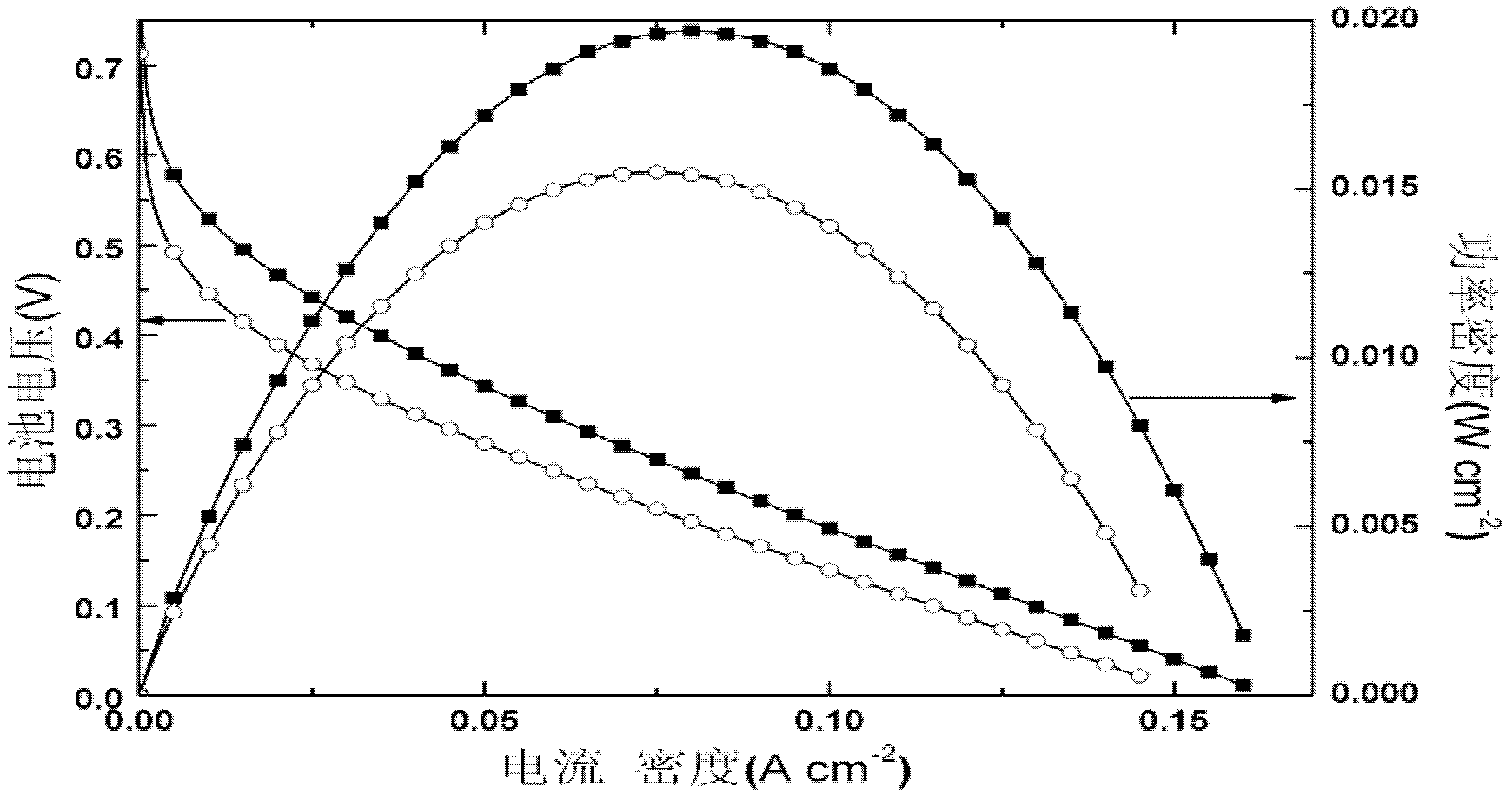

Membrane electrode complex of direct methanol fuel cell and preparation method and direct methanol fuel cell thereof

InactiveCN102361088AIncrease energy densityIncrease profitCell electrodesSolid electrolyte fuel cellsFuel cellsHigh energy

The invention provides a membrane electrode complex of a direct methanol fuel cell and a preparation method and a direct methanol fuel cell thereof. The membrane electrode complex of a direct methanol fuel cell comprises an anode composite membrane layer, a liquid electrolyte layer and a cathode composite membrane layer which are orderly arranged; the anode composite membrane layer comprises an anode diffusion layer, an anode catalytic layer and an anode proton exchange membrane which are orderly arranged; the liquid electrolyte layer comprises: a porous material and liquid electrolyte adsorbed on the porous material; the cathode composite membrane layer comprises a cathode diffusion layer, a cathode catalytic layer and a cathode proton exchange membrane which are orderly arranged. The membrane electrode complex of a direct methanol fuel cell provided by the invention has a low methanol permeation rate and high proton conductivity, is applicable to a high methanol concentration, thus provides higher energy density for the methanol fuel cell, and increases the fuel utilization rate.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Anti-oxidation coating and preparation method thereof

ActiveCN105755423AImprove antioxidant capacityImproves ablation resistanceMolten spray coatingCarbon fibersOxidation resistant

The invention relates to anti-oxidation coating and a preparation method thereof.The anti-oxidation coating comprises an adhering layer and a ceramic layer which are sequentially prepared on a base, wherein the adhering layer is made of W, the ceramic layer is made of Yb2SiO4, the adhering layer is 0.05-0.15mm in thickness, and the ceramic layer is 0.15-0.3mm in thickness.The preparation method includes the steps of firstly, preheating the base, and controlling the temperature of the base to be 100-200 DEG C; secondly, using a plasma spraying method to sequentially prepare the adhering layer and the ceramic layer on the preheated base.The anti-oxidation coating and the preparation method thereof have the advantages that the coating is prepared by the single plasma spraying process; the preparation method is simple in process, low in cost and high in efficiency; the technical difficulties that traditional coating preparation technologies of carbon-fiber-reinforced ceramic-based composite materials are complex and the prepared coating is weak in steam corrosion resistance.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

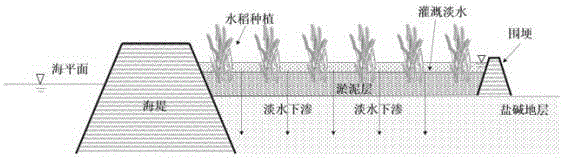

Method for quickly desalinizing mud flat saline and alkaline land by laying sludge on surface layer

InactiveCN105144895ASimple structureImprove fertilityRice cultivationSoil-working methodsAlkali soilSurface layer

The invention relates to the technical field of desalinization of mud flat saline and alkaline lands, particularly a method for quickly desalinizing a mud flat saline and alkaline land by laying sludge on a surface layer. The method comprises the steps: circularly building ridges 30-40 cm high around a paving range, and distributing an irrigation and drainage system; uniformly paving river and lake dredging sludge 30 cm thick on the surface of the mud flat saline and alkaline land; irrigating fresh water on the surface of sludge and maintaining 10-15 cm of a water layer; directly planting rice on the surface of sludge; and carrying out irrigation according to the growing requirement of rice, and in a water requiring stage for rice growth, ensuring that the water layer is properly 10-15 cm. Rice is planted in the sludge layer, the purpose of washing salt and pressing alkali is achieved by virtue of continuous infiltration of irrigation water for rice, the desalinizing speed of the mud flat saline and alkaline land is accelerated, the quality of mud flat soil is improved, and the mud flat soil is quickly reclamated to be used.

Owner:HOHAI UNIV

Cool and refreshing toilet water capable of relieving itching and expelling mosquito

ActiveCN101780020AReduce penetration rateLow toxicityCosmetic preparationsAntipyreticIrritationPeppermints

The invention discloses a cool and refreshing toilet water capable of relieving itching and expelling mosquito, comprising the following components in percentage by weight: 40-75% of edible alcohol, 0.1-2% of peppermint derivative, 0.1-2% of salicylic acid derivative, 1-20% of humectant, 1-15% of plant mosquito repellent, 1-10% of synthesized mosquito repellent, and water as the rest. The toilet water has the effect of slowly releasing refrigerant and is capable of keeping cool for a long time and diminishing inflammation without stimulating skin by reducing the permeation rate of salicylic acid, thereby avoiding irritant effect for skin and improving the comfort when in use; and the artificially synthesized mosquito repellent is complexly used with natural mosquito repellent, thereby improving the mosquito repelling effect and prolonging the mosquito repelling time and decreasing the toxicity of synthesized mosquito repellent with relatively higher safety.

Owner:广东名臣日化有限公司

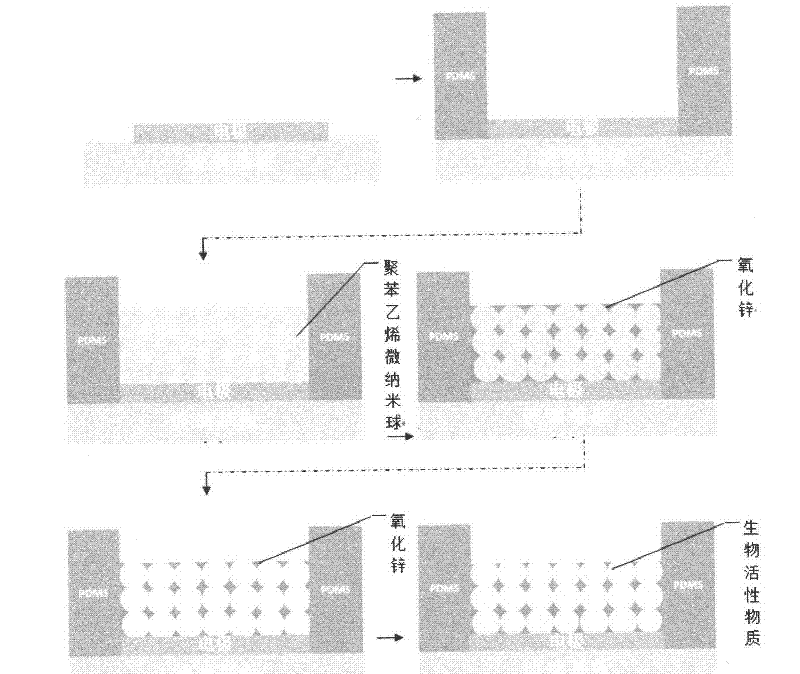

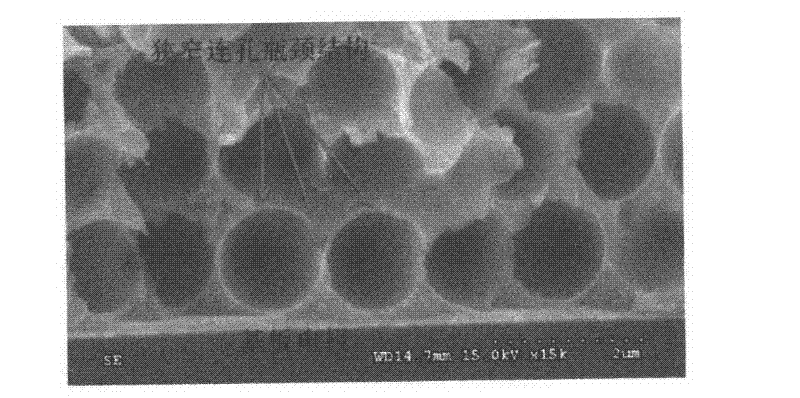

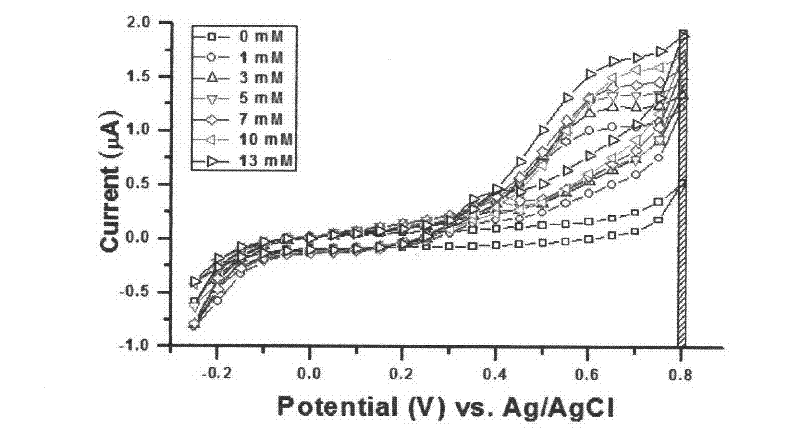

Porous biosensor and making and application methods

InactiveCN102590308ARemarkable effectKeep aliveMaterial analysis by electric/magnetic meansElectricityPolymer thin films

The invention discloses a porous biosensor and making and application methods. The porous biosensor is characterized by sequentially comprising a substrate, an electrode layer and a polymer film layer. A polymer film in a substrate electrode sensing region is removed, and the exposed substrate electrode region and the edge of the polymer film layer form a well-like structural region array; a zinc oxide coating with a porous structure is filled in each well-like structural region; and bioactive substance molecules with negative electricity are adsorbed in a porous zinc oxide structure under the action of static electricity, and a nano-scale narrow bottleneck structure is adopted between inner holes of each coating with the porous structure.

Owner:厦门思明银河整形外科门诊部有限公司

Fertilizer for repairing soil polluted by manganese ore

The invention discloses fertilizer for repairing soil polluted by manganese ore. The fertilizer is prepared from, by weight, 7-8 parts of peat soil, 31-33 parts of plant ash, 15-16 parts of beer residues, 22-25 parts of chicken feather, 4-6 parts of chitosan, 3-4 parts of humic acid iron, 2-3 parts of calcium sulfate, 30-32 parts of palm leaves, 14-16 parts of siderite slag, 14-16 parts of limonite slag, 65-70 parts of orange peel, 4-6 parts of EM compound microorganism bacterium agent and an appropriate amount of water. For the characteristics that soil polluted by manganese ore is low in fertility, poor in water-retaining property and high in heavy metal content, through the collaborative complexing and degrading effects of biochar immobilized microorganisms and lots of humus, on one hand, the water permeation speed is decreased, the water-retaining potential of soil is increased and the water-retaining property is enhanced by increasing the porosity of soil, and on the other hand, the content of organic carbon and humus in soil is increased and the fertilizer retention capacity is improved.

Owner:MAANSHAN XINZHOU GRAPES PROFESSIONAL COOP

High-temperature molding method for nutritive block

InactiveCN103385363AImprove bindingHigh mechanical strengthAnimal feeding stuffCompression moldingAdhesive

The invention relates to the field of forages, and specifically relates to a high-temperature molding method for a nutritive block. The molding method comprises: respectively crushing the raw materials comprising corn, wheat bran and rapeseed meal, uniformly mixing to form a solid mixture according to a ratio; also heating molasses, adding urea, heating and thawing to form a molasses-urea liquid mixture; and mixing the solid mixture and the molasses-urea liquid mixture, heating, performing compression molding in a mold and drying. By employing a high-temperature molding technology, the starch in wheat bran and corn flour are gelatinized at a high temperature to form a high-viscosity starch adhesive, the adhesive and the molasses are adsorbed to the surface of solid particles together, and thus strong chemical bonds are formed. The improvement of the binding force between the particles is beneficial to improving mechanical strength of the block; because the starch adhesive is hard after cooling, the hardness of the block is enhanced, and the enhancement of the hardness is beneficial to controlling intake; and also the alleviation of the water penetration speed helps to improve water proofness of the block.

Owner:SICHUAN AGRI UNIV

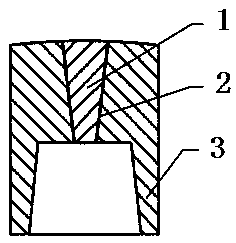

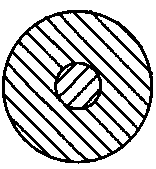

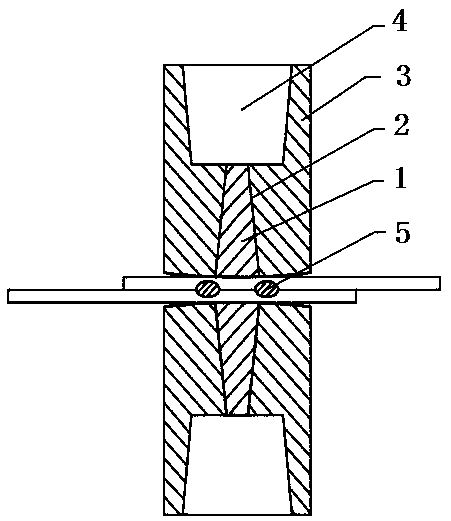

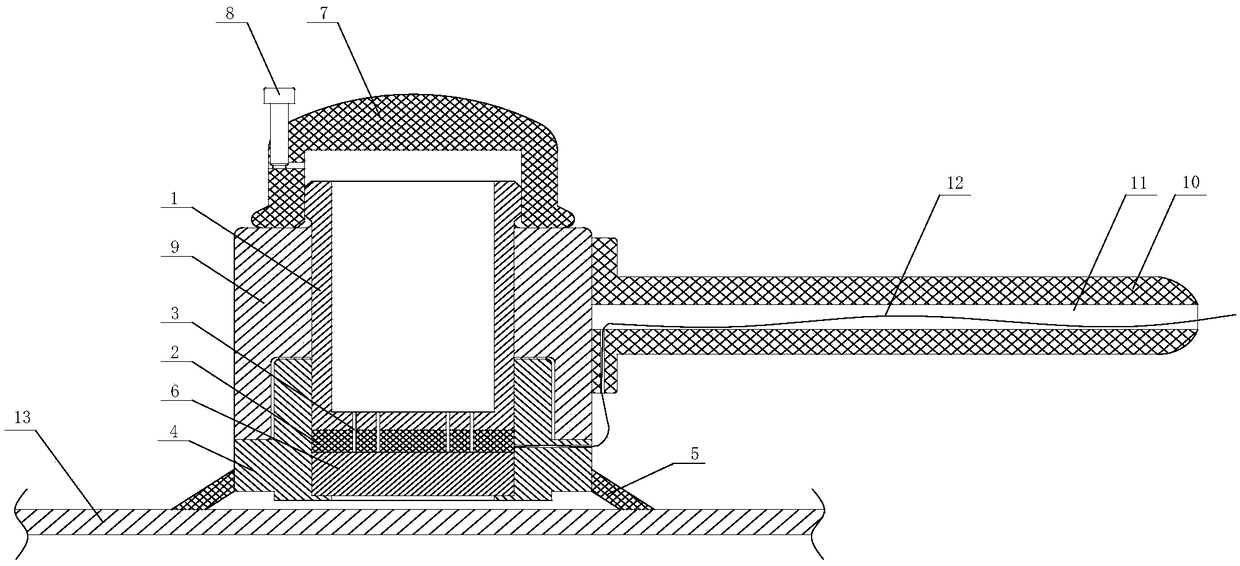

Thin film insulating core non-conducting electrode cap and annular nugget resistance spot welding method

InactiveCN110814497AImprove distributionSolve the problem of concentrationElectrode featuresElectrical resistance and conductanceCurrent distribution

The invention relates to a thin film insulating core non-conducting electrode cap and an annular nugget resistance spot welding method, and belongs to the technical field of resistance spot welding. The thin film insulating core non-conducting electrode cap comprises an electrode cap core part and an electrode cap peripheral part, wherein the two parts are made of homogeneous materials with good thermal conductivity; a layer of thin film insulating material is sprayed on the outer side surface of the electrode cap core part; and the electrode cap core part with a thin film insulating layer isin interference fit with the electrode cap peripheral part. The electrode cap core part and the electrode cap peripheral part have the same spherical radius, and the two parts are in smooth transitionat the junction of the end faces. In the welding and electrifying process, due to the existence of the insulating layer, current can circulate in the peripheral area of the contact surface of the electrode cap and a workpiece, and annular current distribution is formed. Under the action of annular heat distribution, an annular nugget is formed between workpieces, and the reduction of the penetration rate under the condition of the same connecting area is realized, so that the joint strength is guaranteed under the condition that the welding heat input is reduced, the indentation and deformation are reduced, and the joint performance of resistance spot welding is further improved.

Owner:JILIN UNIV

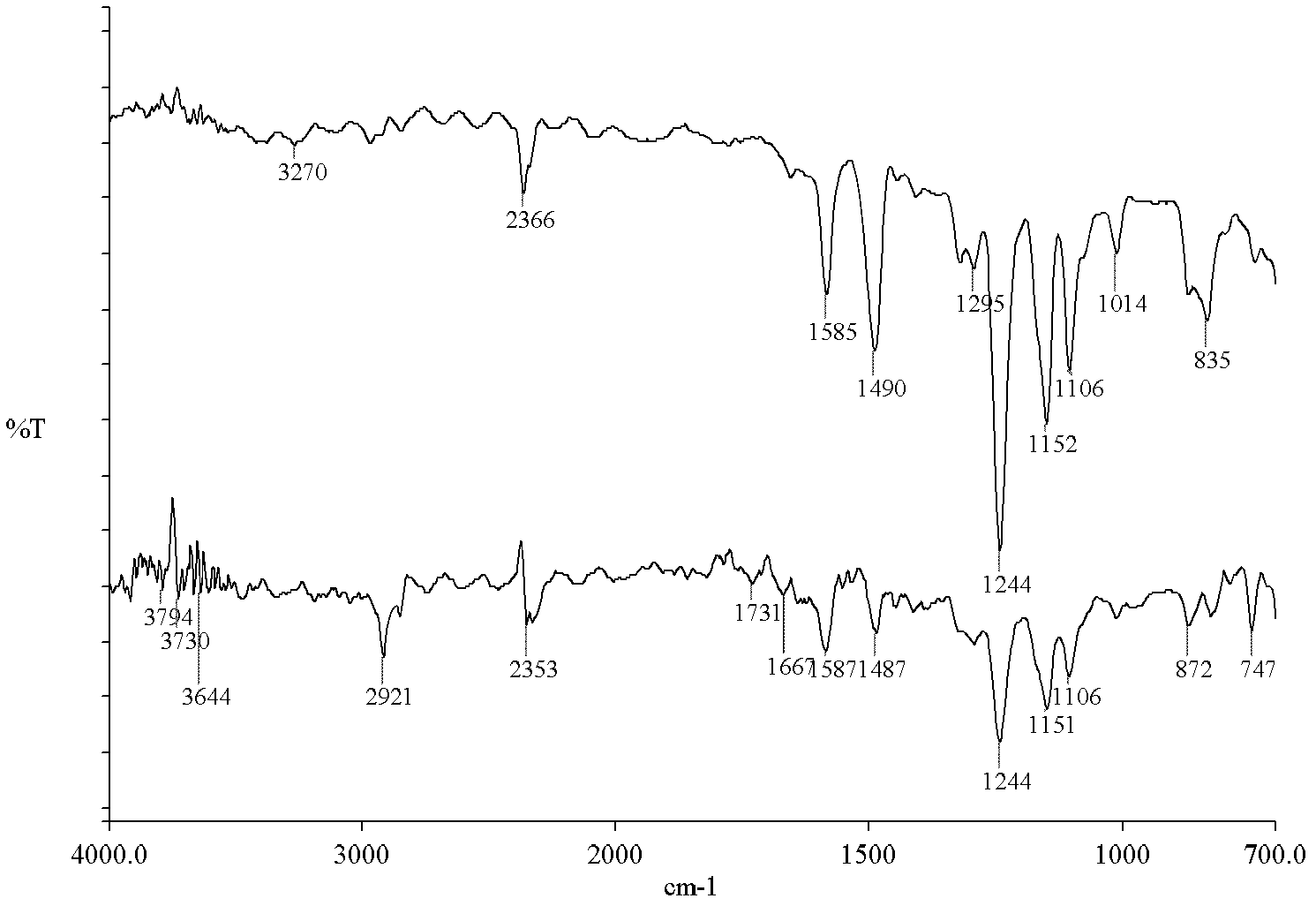

A method for preparation of enantioselective composite membrane

InactiveCN102438734AHigh mechanical strengthReduce penetration rateSemi-permeable membranesOrganic compound preparationOptical resolutionChemistry

The present invention provides an enantioselective composite membrane useful for separation of optical isomers and the process for the preparation thereof. The invention further provides a membrane based pressure driven separation process for separation of enantiomers from their mixture to obtain optical pure isomers. The present invention also provides a membrane based method for optical resolution of racemic mixtures of amino acids to obtain optically pure amino acids.

Owner:COUNCIL OF SCI & IND RES

Large-scale cultivation method of pumpkin seedlings

InactiveCN107172909AReduce penetration rateEffective corrosionBiocideDead animal preservationPumpkin seedPest control

The invention relates to a large-scale cultivation method of pumpkin seedlings. The method includes the steps of firstly, preprocessing seeds; secondly, processing before sowing; thirdly, performing spaced sowing, and performing daily weeding and pest control. Experiments show that the method can effectively avoid diseased and weak seedlings, the cultured seedlings can be sold, and the method is of great significance to the large-scale cultivation of the pumpkin seedlings.

Owner:安徽祥飞枞阳媒鸭养殖有限公司

Air-permeability aluminum foil and preparation method thereof

ActiveCN101628644BImprove corrosion resistanceDecreased corrosion resistanceFlexible coversWrappersMaximum diameterAlloy

The invention relates to an air-permeability aluminum foil and a preparation method thereof, wherein the aluminum foil is mainly suitable for air-permeability packaging in requirements of agricultural production and daily life. The aluminum foil is characterized by being made of 3003 alloy, the thickness of the aluminum foil is 0.03-0.05 mm, pinholes which can reach more than 10,000 every square meter are densely distributed on the surface of the aluminum foil, and the maximum diameter of each pinhole is not more than 0.05 mm. The preparation method comprises the following process steps: batching, smelting, cast-rolling, cold-rolling, interannealing, cold-rolling, and foil-rolling to reach the finished thickness, slitting into a finished specification, and finished annealing. The invention has the advantages of good air permeability, strong corrosion resistance and strong oxidation resistance.

Owner:新疆生产建设兵团第八师天山铝业有限公司

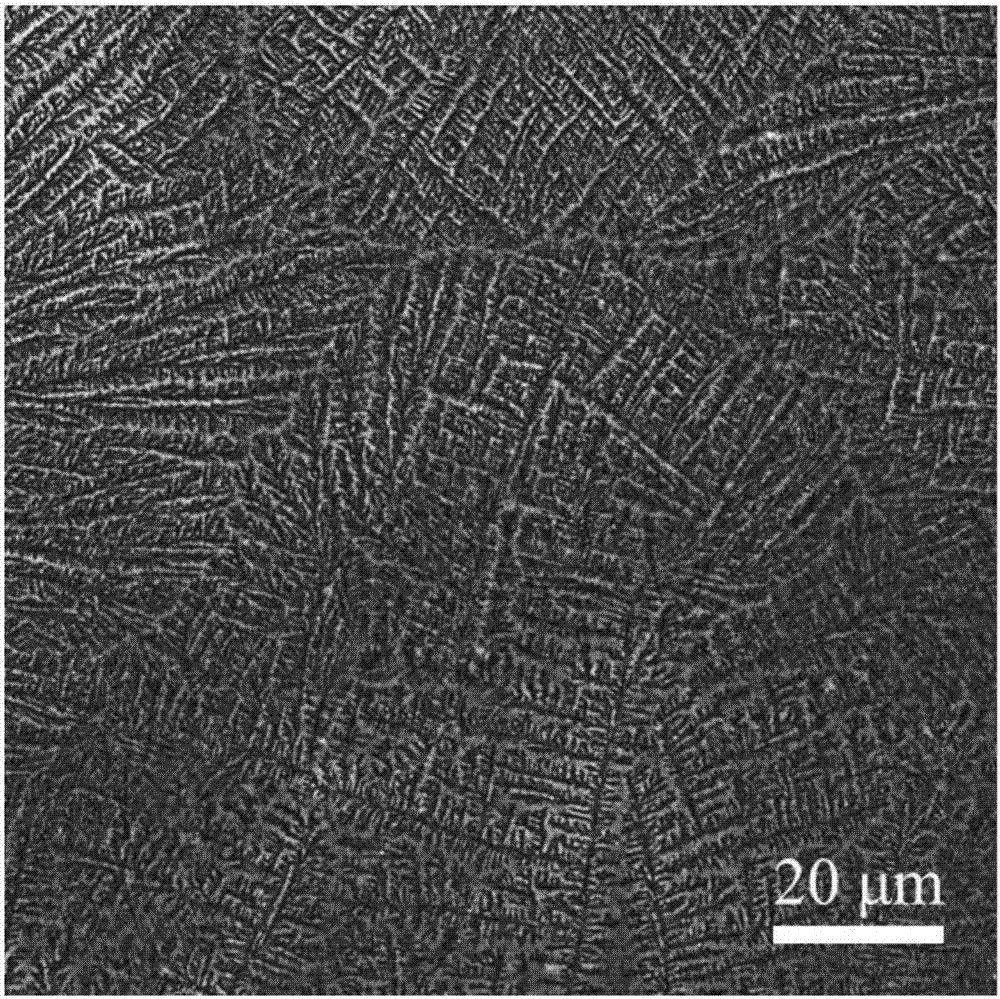

Desulfurization/vermiculization/inoculation-integrated vermicular cast iron modifier and preparation technique thereof

InactiveCN104164532ASolve the problem that the amount of addition is not easy to controlReduce the impact of volatilityAdhesiveRare earth

The invention relates to a desulfurization / vermiculization / inoculation-integrated vermicular cast iron modifier and a preparation technique thereof. The modifier is mainly composed of the following components in percentage by weight: 6-10% of limestone flour, 76-80% of rare-earth magnesium alloy particle, 13-16% of flake high-purity graphite powder and the balance of adhesive. The preparation technique comprises the following steps: by using the limestone flour as the desulfurizer, the rare-earth magnesium alloy as the vermiculizer, the flake high-purity graphite powder as the retarder and inoculator and the water glass as the adhesive, crushing the alloy, carrying out primary mixing and secondary mixing, naturally setting, and drying. The modifier can complete the desulfurization, vermiculization and inoculation operations in one vermicular cast iron production process, and can stably obtain the vermicular cast iron with the vermicular ratio of higher than 85%.

Owner:李明弟

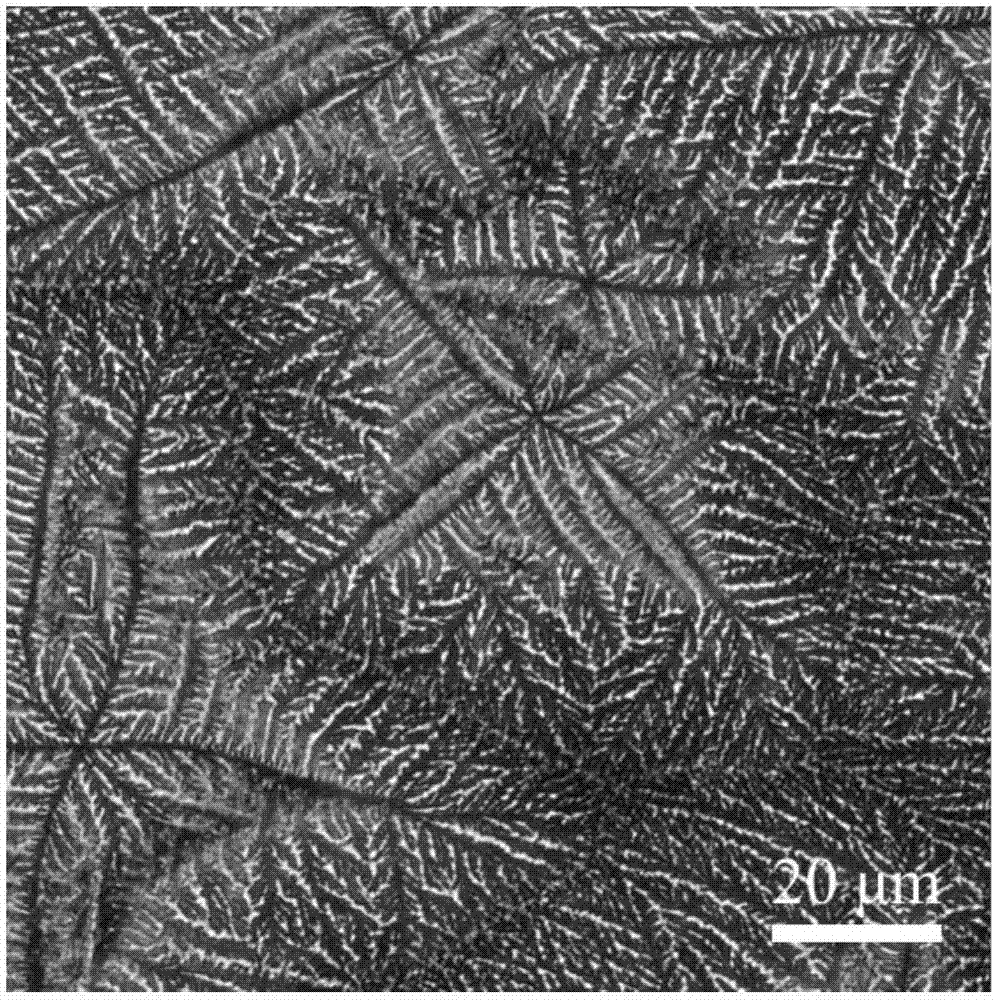

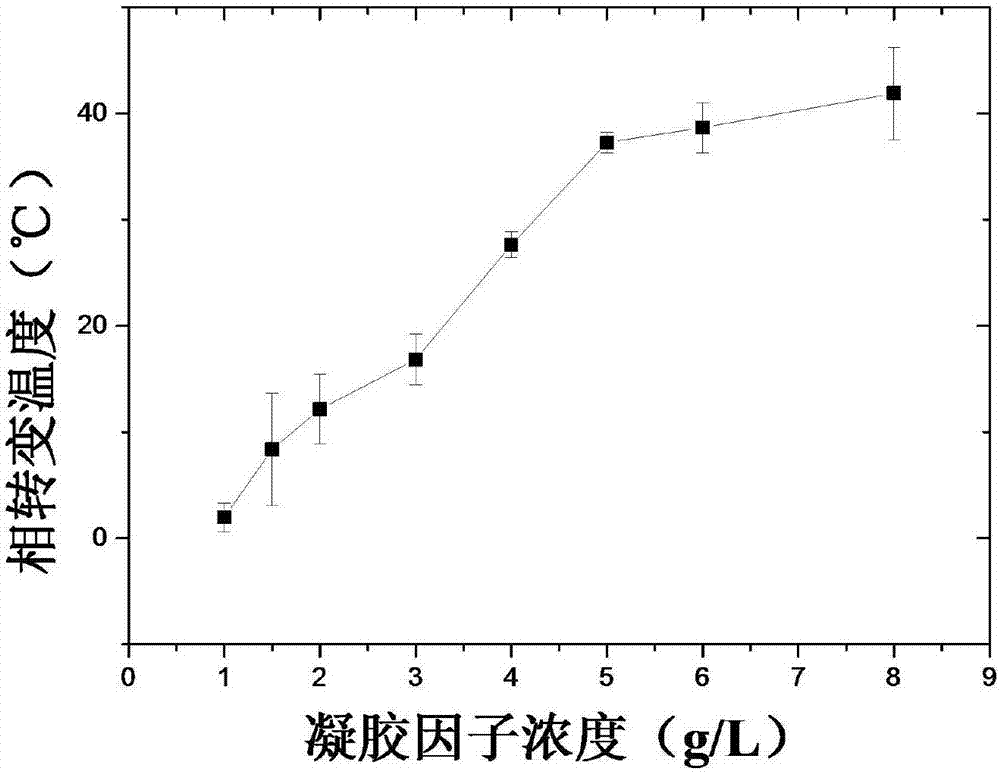

Method of freezing Schwann cells by compound low-temperature cryopreserving system

ActiveCN106982820AReduce osmotic damageLow permeability coefficientDead animal preservationCell culture mediaLiquid nitrogen

The invention discloses a method of freezing Schwann cells by a compound low-temperature cryopreserving system. The method comprises the following steps of: heating amino acid gel factors and dissolving the same in a cell culture medium, filtering and degerming the cell culture medium, and preparing a cell suspension liquid with the cell culture medium containing the gel factors; dropwise adding a cell culture medium containing a compound freezing protecting agent into the cell suspension liquid at 0-4 DEG C and uniformly mixing the mixture, wherein the compound freezing protecting agent is prepared by mixing a permeable freezing protecting agent and a non-permeable freezing protecting agent; and putting a cryopreserving tube in a programmed cryopreserving box to be frozen for 24h at 80 DEG C below and then transferring the cryopreserving tube to liquid nitrogen to be cryopreserved. The supermolecular gel formed by self-assembling the amino acid gel factors has a unique three-dimensional netty structure. When the freezing protecting agent is dropwise added, cells are coated by the supermolecular gel, so that the permeating damage of the freezing protecting agent is reduced; in temperature-reducing and restoring processes, damage of ice crystals is reduced as the three-dimensional netty structure of the supermolecular gel limits growth and recrystallization of the ice crystals.

Owner:WUHAN UNIV OF TECH

Electrochemistry in-situ dirt removing method of radioactive contaminant on surface of metal

ActiveCN109295493AWon't wasteHigh decontamination precisionElectrolysis componentsLiquid wasteLiquid storage tank

The invention discloses an electrochemistry in-situ dirt removing method of radioactive contaminant on the surface of metal. A liquid storage tank is involved in the method. A cathode plate is installed below the liquid storage tank. A guide wire is connected to the cathode plate. A through hole is formed in the bottom of the liquid storage tank. The bottom of the through hole penetrates through the liquid storage tank and the cathode plate sequentially. An anode contactor is detachably connected to the exterior of the liquid storage tank. The anode contactor is provided with a storing cavityused for storing the cathode plate. The anode contactor is provided with a ring-shaped sealing part. The interior of the ring-shaped sealing part and the bottom face of the anode contactor form a washing cavity. An opening is formed in the bottom of the anode contactor. The opening communicates with the storing cavity and the washing cavity. According to the method, for the small contaminant area,fixed-point in-situ dirt removing can be carried out on the radionuclide area by means of the washing cavity formed by the anode contactor and the ring-shaped sealing part, the dirt removing precision is high, the dirt removing effect is good, the electrolyte solution is prevented from being wasted on the surface of the metal which does not need to be washed, the washing cost is saved, and the amount of second-time waste liquid is small.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Seaport engineering concrete chloride ion penetration resistant reinforcing agent

InactiveCN100515973CImprove permeabilityReduce penetration rateSolid waste managementMicro structureFiber

The present invention provides the recipe of chlorine ion penetration resisting reinforcer for concrete in harbor engineering. The chlorine ion penetration resisting reinforcer consists of superfine silica powder 15-20 wt%, washed and calcined kaolin 20-25 wt%, high grade fly ash 20-25 wt%, ground blast furnace slag 20-25 wt%, nanometer fiber 5-10 wt%, superplasticizer 6 wt%, slump keeping agent 0.09 wt%, air entraining agent 0.09 wt%, and organic active excitant 0.12 wt%. The chlorine ion penetration resisting reinforcer has inorganic components as main functional materials dispersed homogeneously in concrete cementing material, and can improve the micro structure and hydration product composition inside concrete, raise compactness, adsorb and fix chlorine ion and lower the penetration of chlorine ion in hardened concrete, so as to improve the chlorine ion penetration resisting capacity of hardened concrete.

Owner:LETS HLDG GRP CO LTD +1

Special vermiculizer for non-magnetic vermicular graphite cast iron, and preparation technology thereof

The invention relates to a special vermiculizer for non-magnetic vermicular graphite cast iron, and a preparation technology thereof, which belong to the technical field of non-magnetic vermicular graphite cast iron production. By weight percent, the vermiculizer comprises the following constituents: 75-85% of rare earth magnesium alloy, 12-20% of high-purity graphite powder and 3-5% of sodium silicate binder, wherein the rare earth magnesium alloy comprises 4-5% of Mg, 1.0-1.5% of Re, 1-1.5% of Al, at most 40% of Si and the rest of Fe. The vermiculizer integrates vermicularizing treatment and inoculation treatment together, and by adopting a graphite moderation technology, seepage velocity of molten iron to the vermiculizer is reduced, a layer-by-layer reaction state is formed, vermicularizing reaction speed and time can be controlled effectively, and alloy absorption rate is improved; by adopting the graphite inoculation technology, an inoculation fade phenomenon is avoided under the efficient inoculation effect of the graphite forming a lot of non-spontaneous crystal nucleus, and non-magnetic vermicular graphite cast iron material with the vermicularizing rate of more than 80% can be obtained steadily.

Owner:SHANDONG JIANZHU UNIV +1

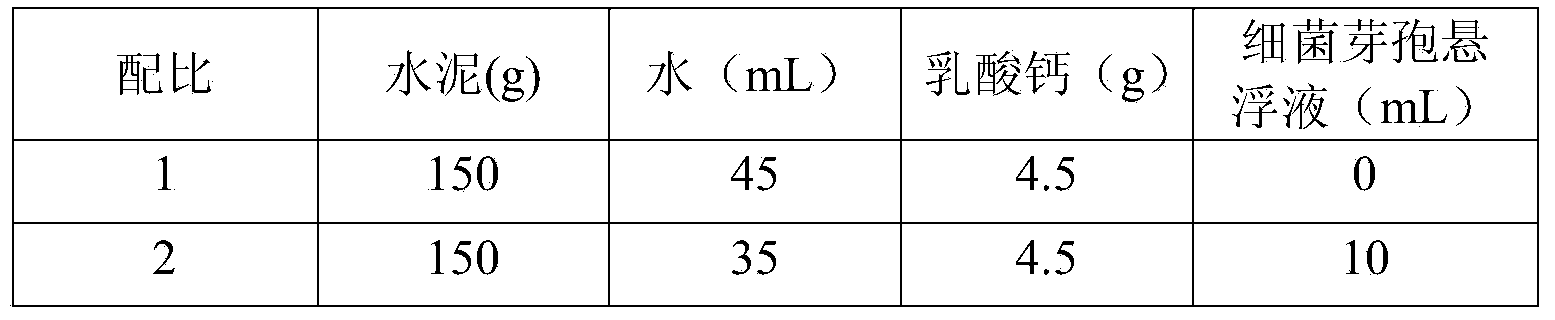

Waste alkaline residue recycling method and alkaline residue self-repairing cement-based material prepared by same

ActiveCN111848048AReduce processing costsChanging the method of landfillingSolid waste managementSteelmakingEnvironmental engineering

The invention discloses a waste alkaline residue recycling method and an alkaline residue self-repairing cement-based material prepared by the same. The method comprises the following steps: firstly,weighing the following components in parts by mass: 1-1.1 parts of cement, 0.30-0.45 part of spore solution and 0.35-0.4 part of alkaline residue, then uniformly mixing and stirring the alkaline residue and the cement, then adding the spore solution, and uniformly stirring to obtain the alkaline residue self-repairing cement-based material, wherein the number of the bacillus in each milliliter ofthe alkaline residue self-repairing cement-based material is 10<6>-10<9>. According to the invention, industrial waste residue-alkaline residue is used as a cement-based material additive, the problemof overhigh cost of a calcium source in a self-repairing cement-based material is perfected, the problem of insufficient utilization of the calcium source is balanced by using steelmaking industrialwaste residue blast furnace slag powder, and the cement-based material with self-repairing performance is prepared.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

Ecological water-retention and fertilizer-conservation soil configuration modifier on aeolian sandy soil, and use method thereof

InactiveCN107011915AReduce penetration rateEase of implementation in the fieldOther chemical processesOrganic fertilisersPolyacrylamideCrop yield

The invention belongs to a sandy soil improvement technology, concretely relates to an ecological water-retention and fertilizer-conservation soil configuration modifier on aeolian sandy soil, and a use method thereof. A sandy soil, montmorillonite powder and anionic polyacrylamide mixture is added to the bottom of the plough layer of the sandy soil to keep the water content of the bottom layer of the soil being 70-80% of the field water capacity; and an organic fertilizer and a small amount of a chemical fertilizer are added to the plough layer in order to reduce the seepage of soil rainfall and irrigation water, prevent the nutrient loss of the soil and improve the water-retention and fertilizer-conservation ability of the soil. The ecological water-retention and fertilizer-conservation soil configuration modifier on aeolian sandy soil, and the use method thereof have the advantages of improvement of the profile construction of soil in the sandy soil, increase of the water holding capacity and the fertilizer conservation ability of the soil, improvement of the physical properties of the soil, increase of the water retention and the fertilizer conservation of the soil, facilitation of the growth of crops, and increase of the yield of the crops.

Owner:内蒙古自治区土地整治中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com