Water-based inorganic zinc-rich anticorrosive paint and preparation method thereof

An inorganic zinc-rich, anti-corrosion coating technology, applied in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of agglomeration, zinc powder dissolution, waste of resources, etc., achieve delayed electrochemical reaction, low zinc powder The effect of adding amount and reducing the amount of zinc powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

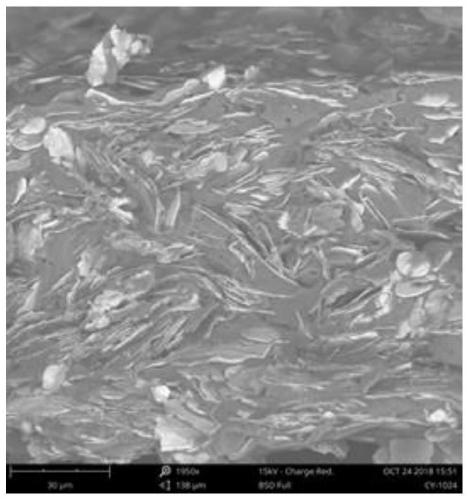

Image

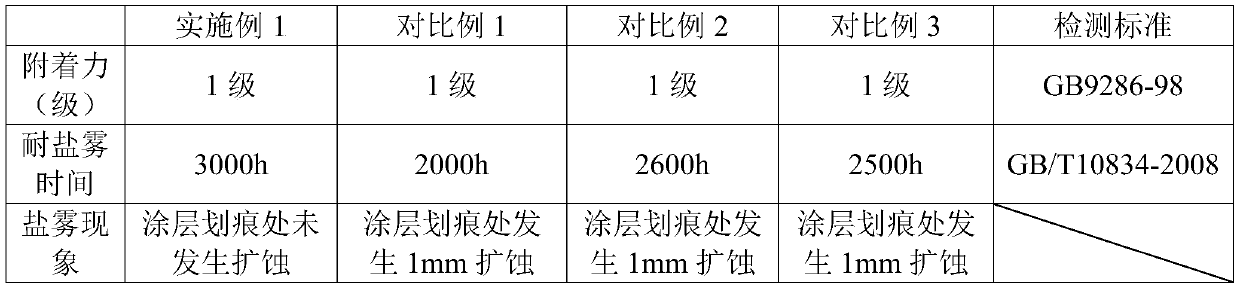

Examples

Embodiment 1

[0029] The present embodiment provides a kind of water-based inorganic zinc-rich anticorrosion coating, which is prepared according to the following steps:

[0030] (1) Preparation of silicate solution: take raw materials potassium hydroxide, silica sol and water, wherein the molar ratio of potassium hydroxide, silica sol and water is 1:8:6. Pre-mix and dissolve potassium hydroxide and water to obtain a potassium hydroxide solution, then gradually add the potassium hydroxide solution dropwise to the silica sol under rapid stirring, and react for 1 hour at a water bath temperature of 50°C to prepare a silicate Potassium silicate solution with a modulus of 4.0.

[0031] (2) Preparation of graphene aqueous dispersion: Take 0.2g of graphene dispersion aid polyethylene glycol mono-4-nonylphenyl ether and add it to 85g of pure water, stir and mix evenly with strong ultrasonic machinery, then gradually add 15g of graphite Graphene, strong ultrasonic mechanical stirring for 1 h to ob...

Embodiment 2

[0036] The present embodiment provides a kind of water-based inorganic zinc-rich anticorrosion coating, which is prepared according to the following steps:

[0037] (1) Preparation of silicate solution: take raw materials sodium hydroxide, potassium hydroxide, silica sol and water, wherein the molar ratio of sodium hydroxide, potassium hydroxide, silica sol and water is 0.3:0.7:14:10. Sodium hydroxide, potassium hydroxide and water are premixed and dissolved to obtain a mixed solution, and then, under rapid stirring, the mixed solution is gradually added dropwise to the silica sol, and the reaction time is 1 hour at a water bath temperature of 50 ° C. The prepared modulus is 6.5 Silicate solution.

[0038] (2) Preparation of graphene aqueous dispersion: Take 0.2g of graphene dispersion aid polyvinylpyrrolidone and add it to 80g of pure water, stir and mix evenly with strong ultrasonic machinery, then gradually add 20g of graphene, and stir with strong ultrasonic machinery for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com