Bimetallic composite steel pipe and production method thereof

A technology of composite steel pipe and production method, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of difficult welding of bimetal mechanical composite pipes, uneven performance of composite pipes, and low welding qualification rate, etc. To achieve the effect of bonding strength guarantee, simple manufacturing process and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

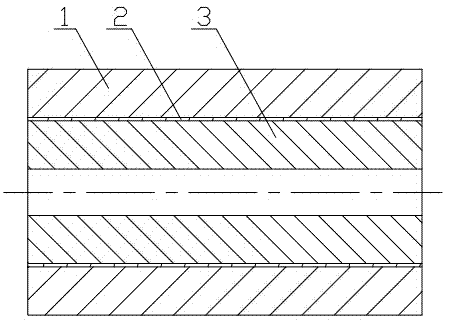

[0030] A bimetal composite steel pipe, the outer layer is austenitic stainless steel pipe 1, the material of austenitic stainless steel pipe 1 is 304 austenitic stainless steel; the inner layer is carbon steel pipe 3, and the material of carbon steel layer 3 is 20G Carbon steel, the outer surface of the carbon steel pipe 3 is surfacing with a nickel-based alloy bonding layer 2 for interference fit.

[0031] The production method for manufacturing the bimetal clad steel pipe comprises the following steps:

[0032] 1) Select the outer tube and inner bar: the outer tube is made of 304 austenitic stainless steel, and the inner bar is made of 20G carbon steel. Let the outer diameter of the outer tube be a and the inner diameter be b, and the outer diameter of the inner bar stock be c.

[0033] 2) Surfacing and turning nickel-based alloy layer: the outer surface of the inner bar is surfacing with a nickel-based alloy bonding layer with a thickness greater than 2mm, and turning the ...

Embodiment 2

[0039] A bimetal composite steel pipe, the outer layer is austenitic stainless steel pipe 1, the material of austenitic stainless steel pipe 1 is TP310 austenitic stainless steel; the inner layer is carbon steel pipe 3, and the material of carbon steel pipe 3 is T11 carbon The outer surface of plain steel and carbon steel pipe 3 is surfacing with a nickel-based alloy bonding layer 2 for interference fit.

[0040] The production method for manufacturing the bimetal clad steel pipe comprises the following steps:

[0041] 1) Select the outer tube and the inner tube: the material of the outer tube is TP310 austenitic stainless steel, and the material of the inner tube is T11 carbon steel.

[0042] 2) Surfacing and turning nickel-based alloy layer: Surfacing a nickel-based alloy layer with a thickness greater than 2mm on the outer surface of the inner tube, and turning the nickel-based alloy layer, the thickness of the nickel-based alloy layer after turning 1mm.

[0043]3) Interf...

Embodiment 3

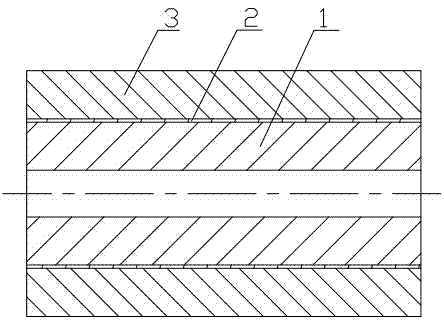

[0047] A bimetal composite steel pipe, the outer layer is carbon steel pipe 3, the material of carbon steel pipe 3 is T11 carbon steel; the inner layer is austenitic stainless steel pipe 1, and the material of austenitic stainless steel pipe 1 is TP310 austenitic Body stainless steel, the inner surface of the carbon steel pipe 3 is surfacing with a nickel-based alloy bonding layer 2 for interference fit.

[0048] The production method for manufacturing the bimetal clad steel pipe comprises the following steps:

[0049] 1) Select the outer tube and inner bar: the outer tube is made of T11 carbon steel, and the inner bar is made of TP310 austenitic stainless steel.

[0050] 2) Surfacing and turning nickel-based alloy layer: Surfacing a nickel-based alloy bonding layer with a thickness greater than 3mm on the inner surface of the outer tube, and turning the nickel-based alloy bonding layer, the nickel-based alloy bonding layer after turning The thickness is 3mm.

[0051] 3) Int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com