Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

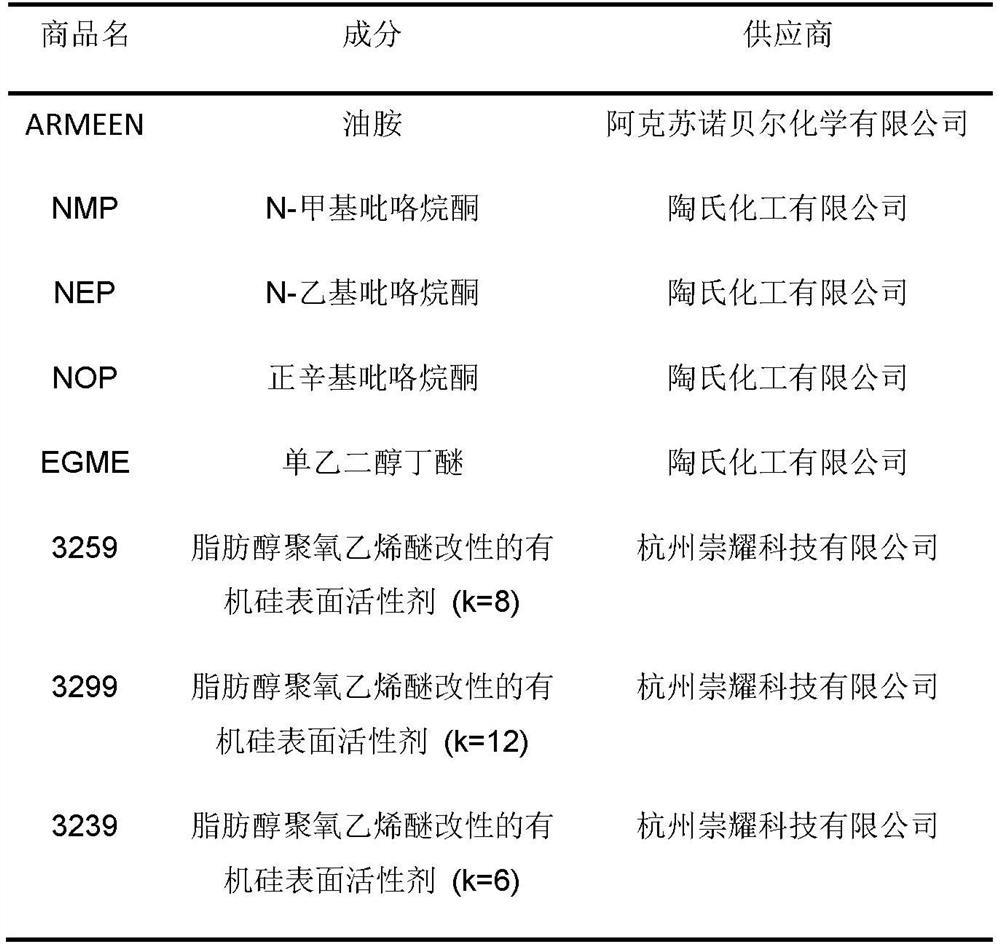

35results about How to "Excellent metal corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

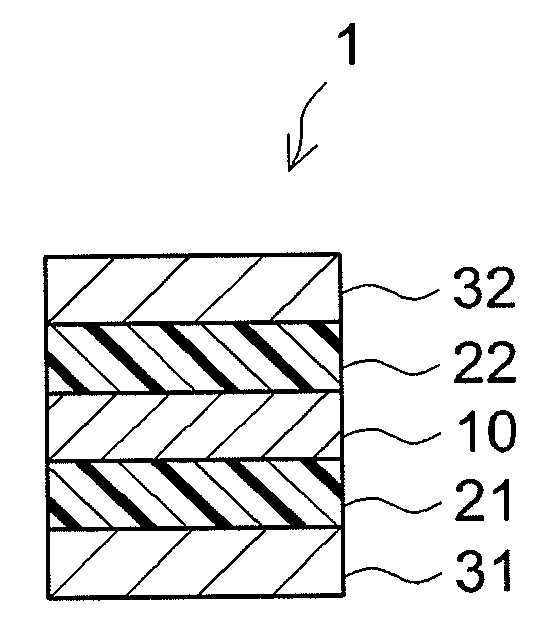

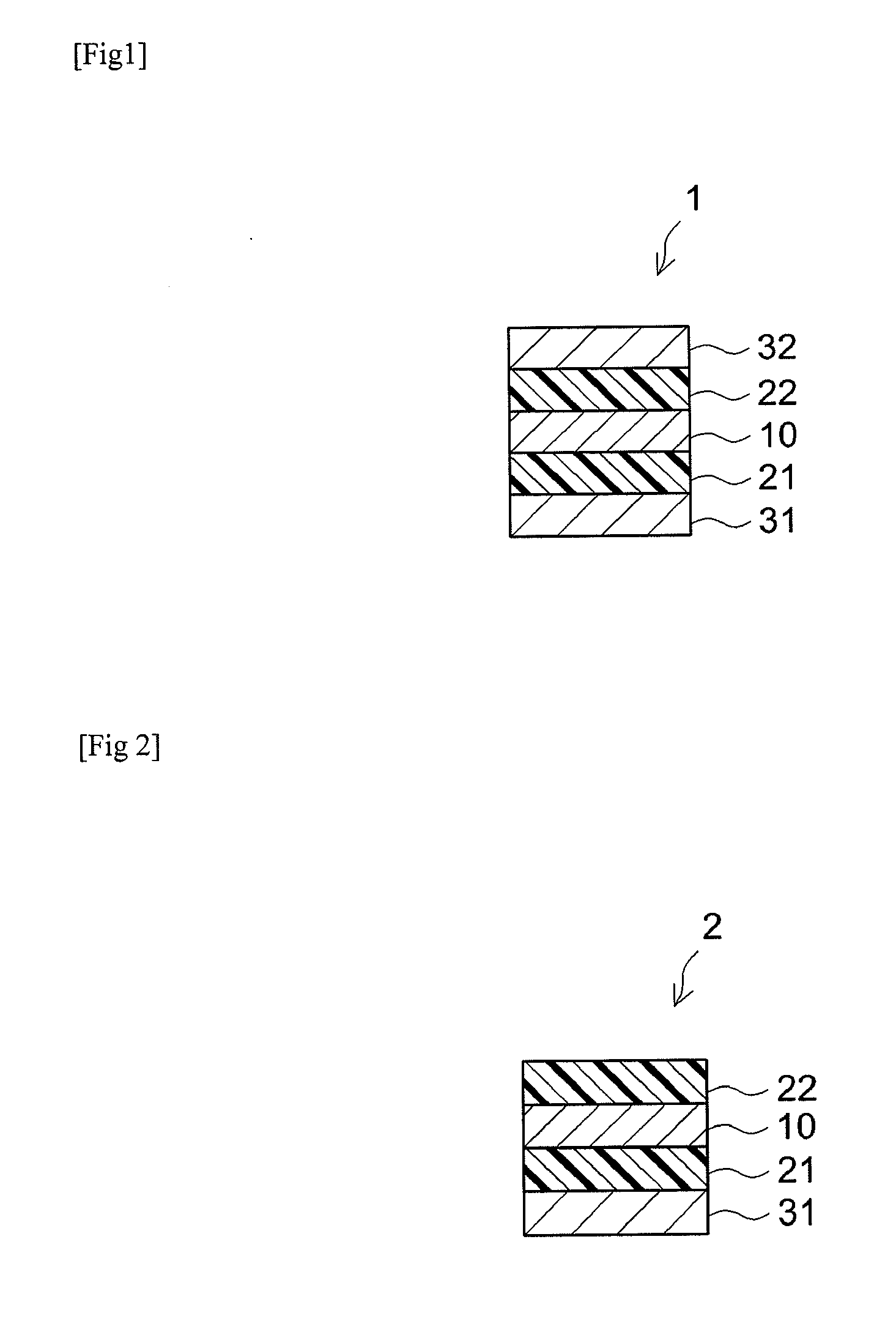

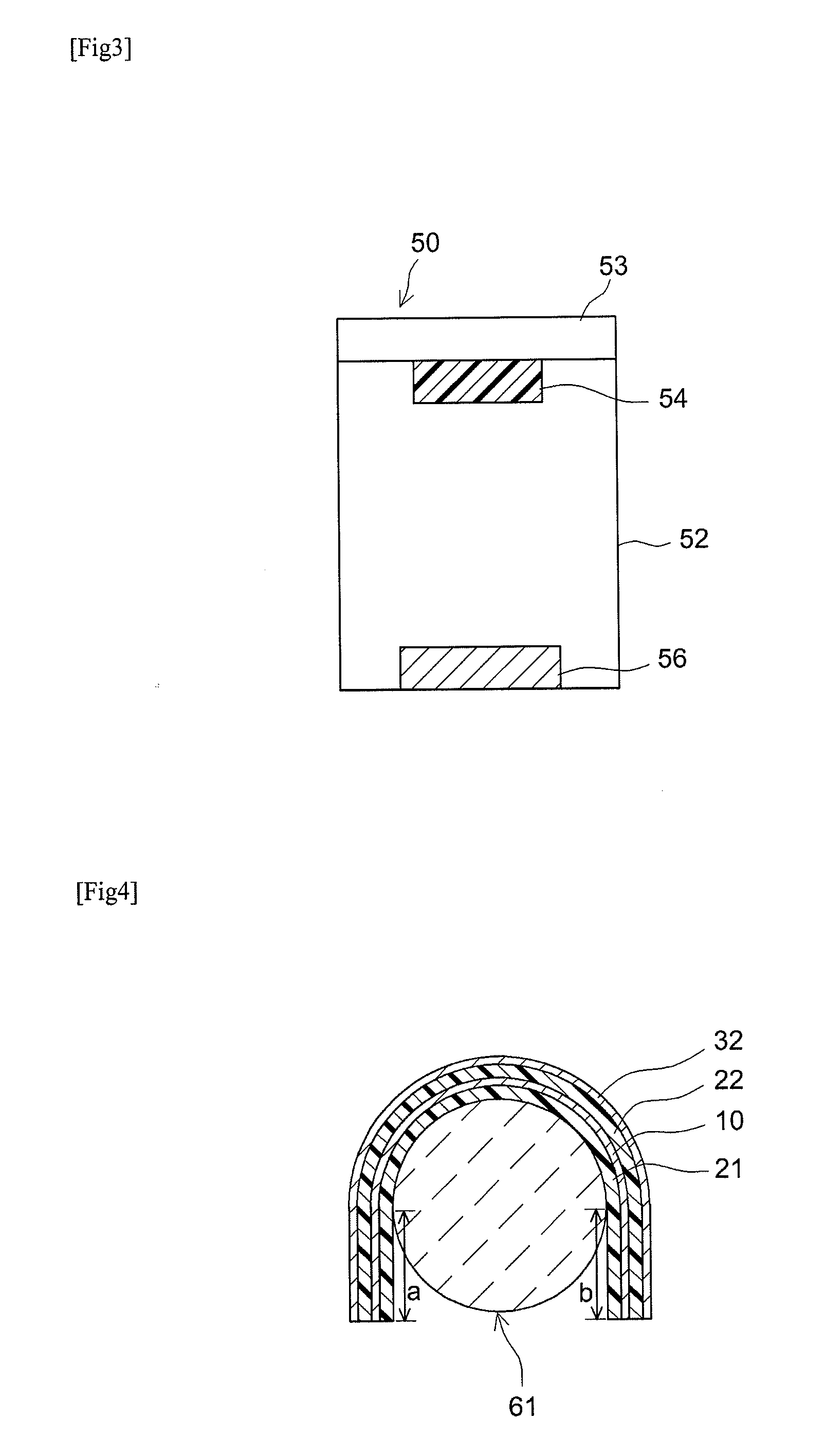

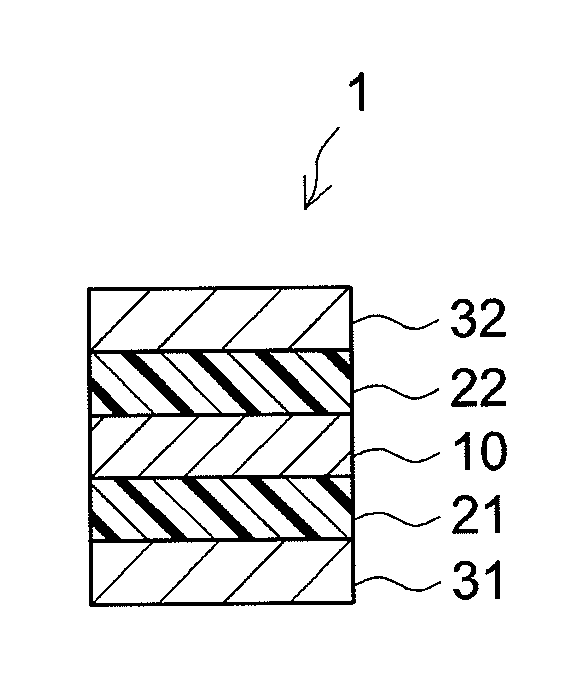

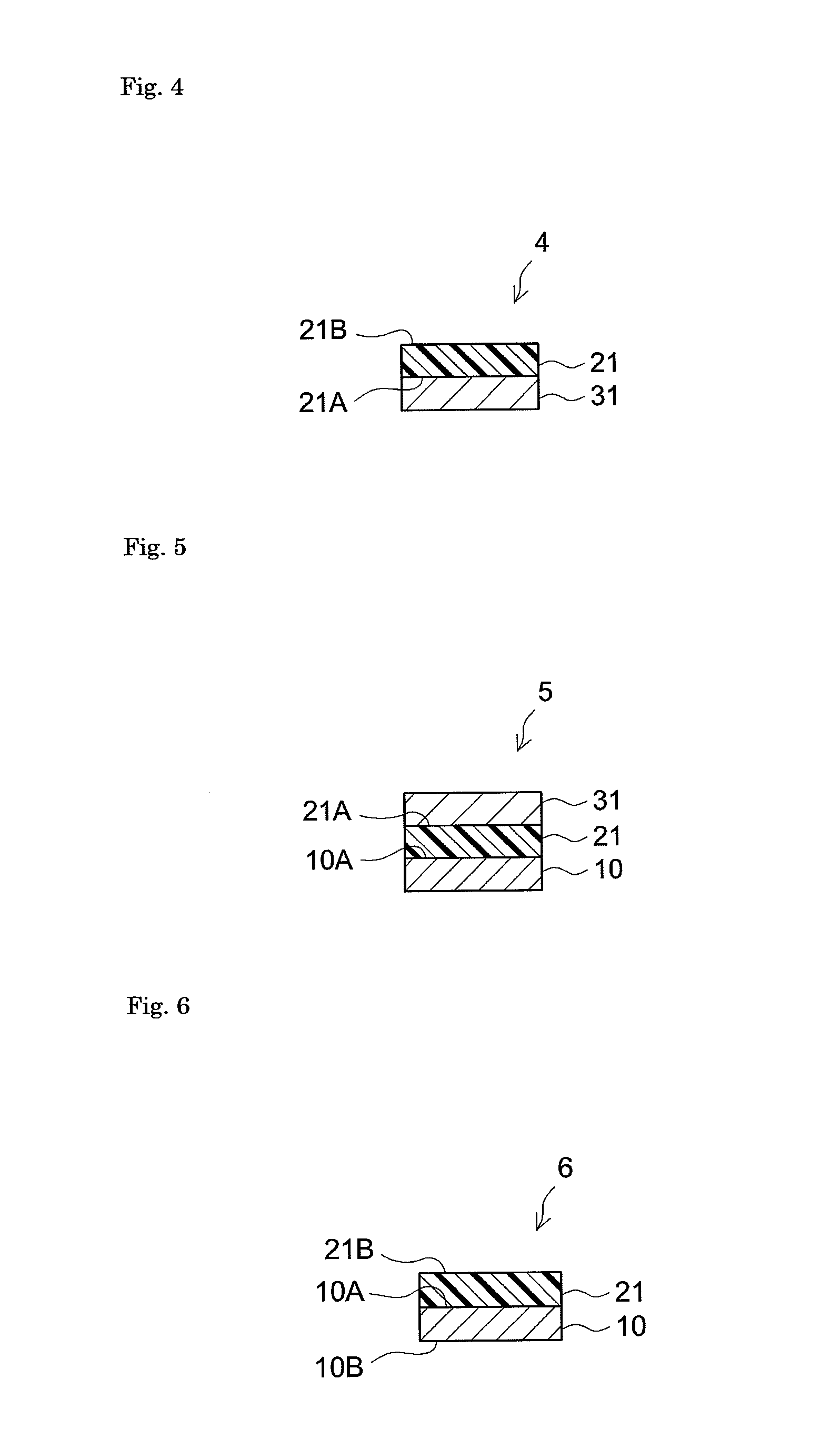

Adhesive agent composition for optical films, adhesive agent layer for optical films, optical film having adhesive agent layer attached thereto, and image display device

ActiveCN106133096AIncreased durabilityPrevent peelingNon-macromolecular adhesive additivesPolarising elementsPolymer scienceMeth-

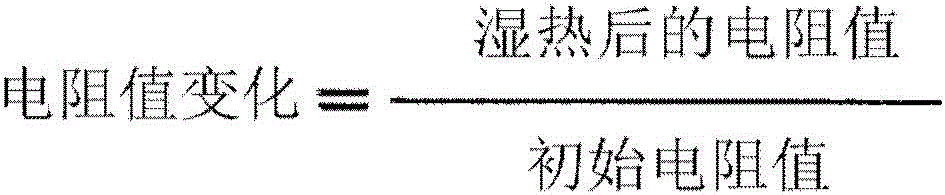

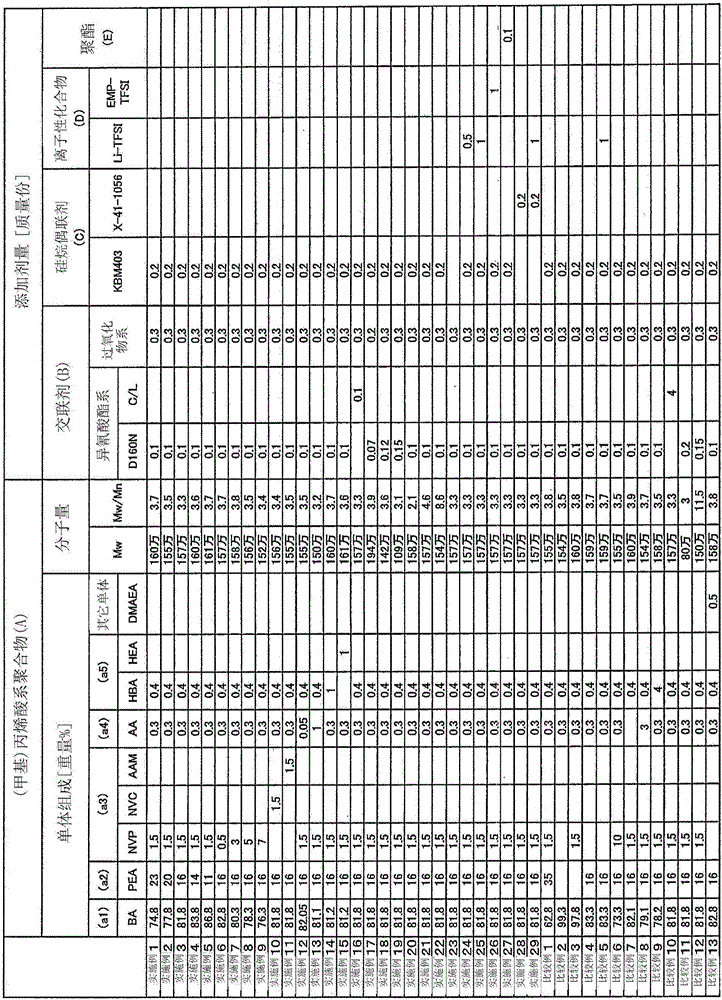

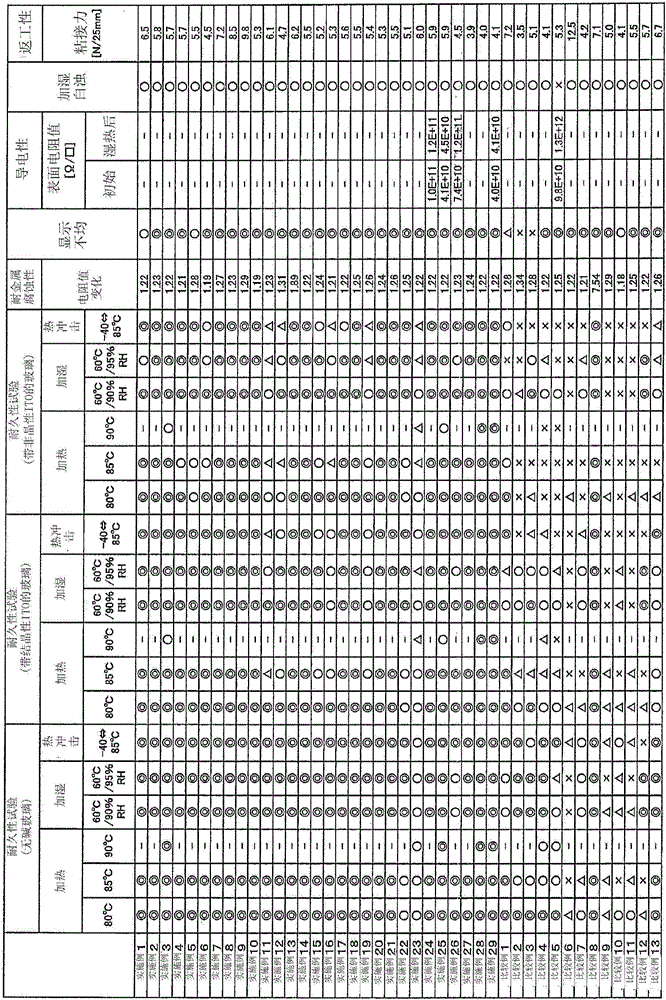

An adhesive agent composition for optical films, which comprises: a (meth)acrylic polymer (A) that contains, as monomer units, 70% by weight or more of an alkyl (meth)acrylate (a1), 3 to 25% by weight of an aromatic-ring-containing (meth)acrylate (a2), 0.1 to 8% by weight of an amide-group-containing monomer (a3), 0.01 to 2% by weight of a carboxyl-group-containing monomer (a4) and 0.01 to 3% by weight of a hydroxyl-group-containing monomer (a5) and meets such requirements that the weight average molecular weight (Mw) is 1,000,000 to 2,500,000 and the Mw / (number average molecular weight (Mn)) ratio is 1.8 to 10 inclusive; and a cross-linking agent (B) in an amount of 0.01 to 3 parts by weight relative to 100 parts by weight of the (meth)acrylic polymer (A). The adhesive agent composition can be formed into an adhesive agent layer which satisfies durability to such an extent that the adhesive agent layer does not undergo foaming, is not detached or does not get clouded under humidified conditions when applied onto a glass or a transparent conductive layer, and which can prevent the occurrence of display unevenness due to leakage of light, and which has excellent metal corrosion resistance.

Owner:NITTO DENKO CORP

Preparation method of graphene oxide/acrylate-epoxy resin composite anticorrosive paint

InactiveCN111518450AImprove anti-corrosion performanceLow corrosion current densityAnti-corrosive paintsPolymer scienceEpoxy resin composite

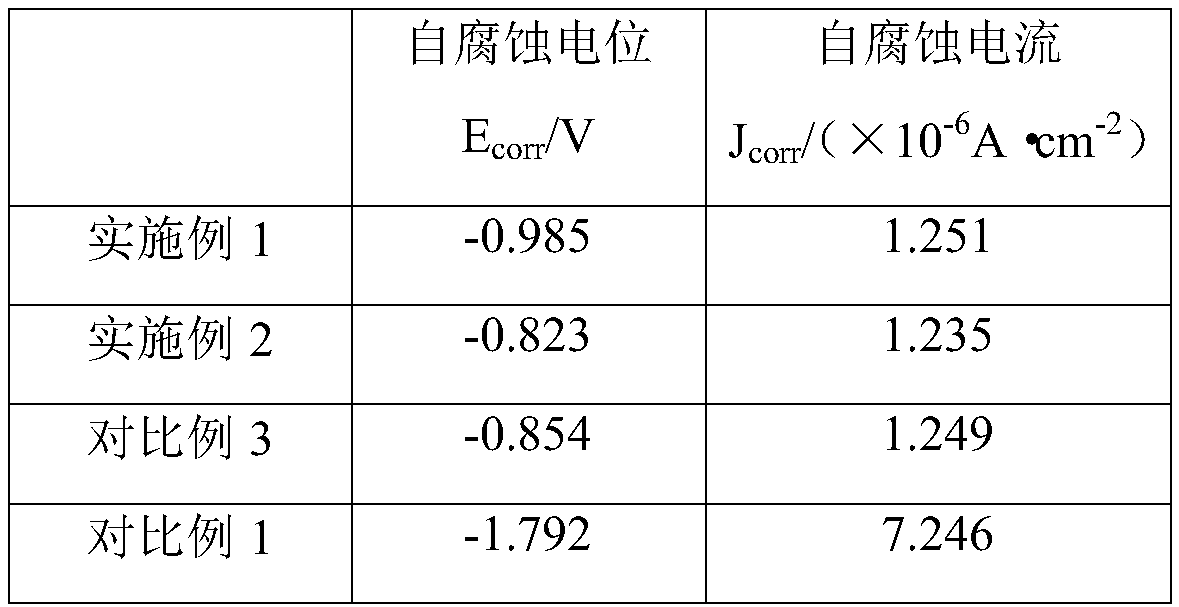

The invention discloses a preparation method of graphene oxide / acrylate-epoxy resin composite anticorrosive paint. The preparation method comprises the following steps: preparing graphene oxide, and preparing an acrylic acid modified epoxy resin intermediate from bisphenol A epoxy resin and acrylic acid; then, respectively preparing a nuclear phase monomer pre-emulsion and a shell phase monomer pre-emulsion, and carrying out core-shell reaction polymerization on the nuclear phase monomer pre-emulsion and the shell phase monomer pre-emulsion through an initiator to obtain an acrylate-epoxy resin core-shell emulsion; and finally, mixing the acrylate-epoxy resin core-shell emulsion with graphene oxide to obtain the anticorrosive paint. According to the invention, an epoxy group on the surfaceof the graphene oxide is used as a reaction active point, so the corrosion resistance of the graphene oxide / acrylate-epoxy resin composite anticorrosive paint is greatly improved. Along with the increase of the content of the graphene oxide, the corrosion potential of the paint is increased, and corrosion current density is reduced, so the paint presents excellent metal corrosion resistance.

Owner:JINLING INST OF TECH

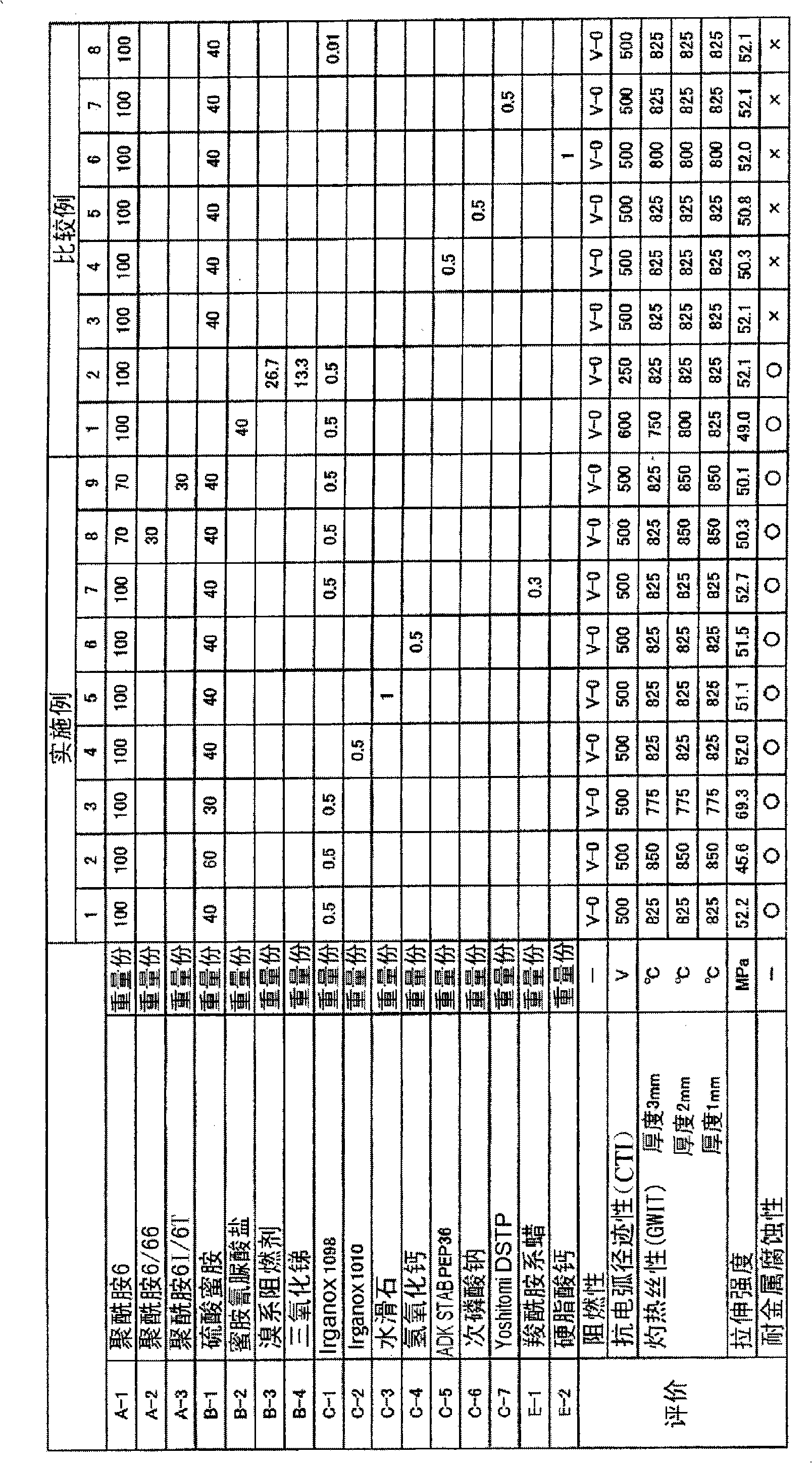

Flame retardant polyamide resin composition

ActiveCN101802098AImprove flame retardant performanceExcellent glow wire propertyOrganic sulfonic acidAlkaline earth metal

Owner:MITSUBISHI ENG PLASTICS CORP

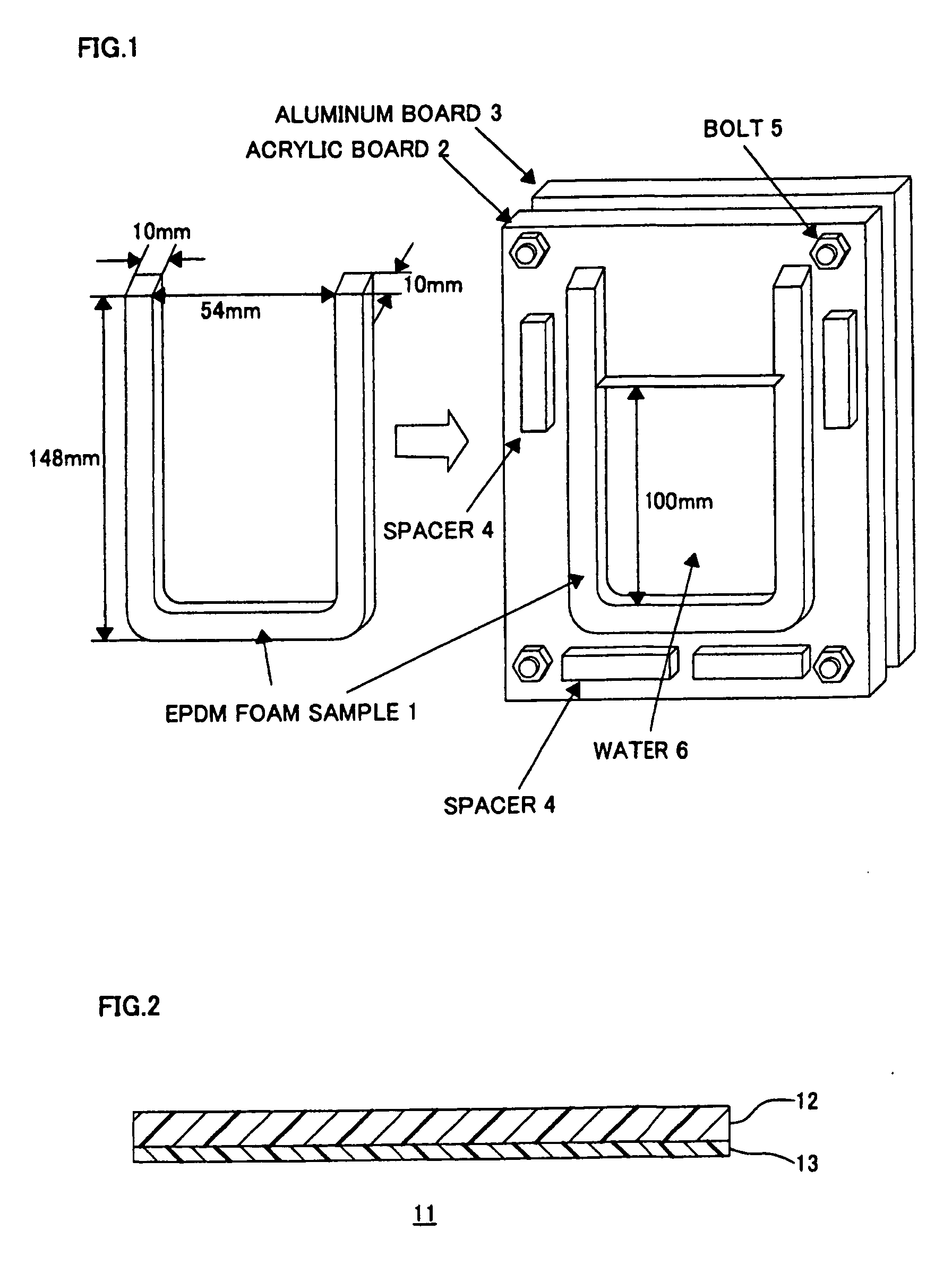

EPDM foam and adhesive sealing material

InactiveUS20120277337A1Improve the water-stop effectSame level of sealingOther chemical processesRubber derivative adhesivesMetalEPDM elastomer

Owner:NITTO DENKO CORP

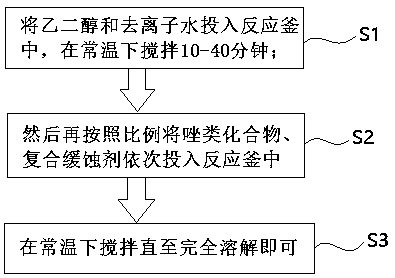

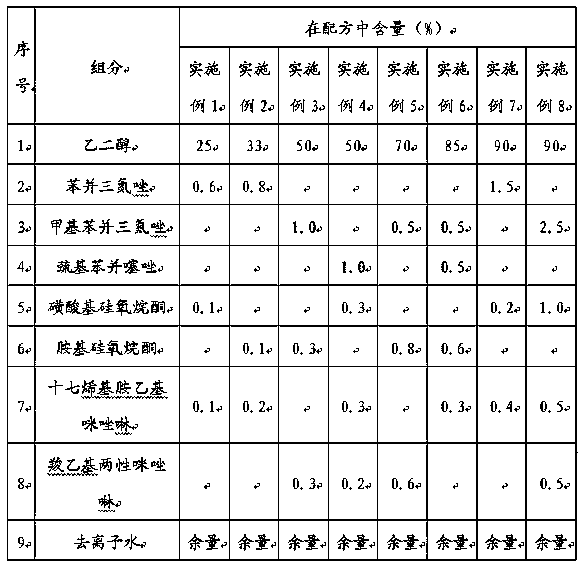

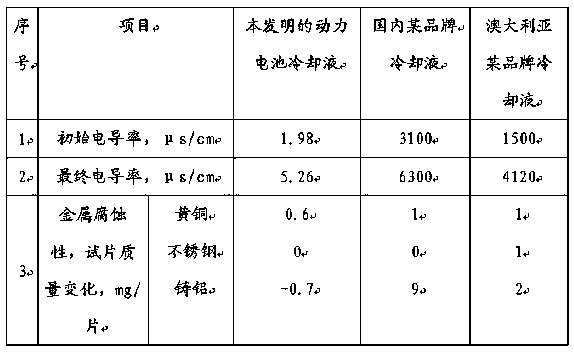

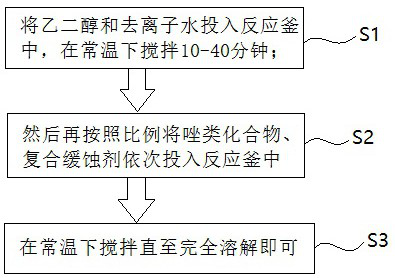

New energy automobile power battery cooling liquid and preparation method thereof

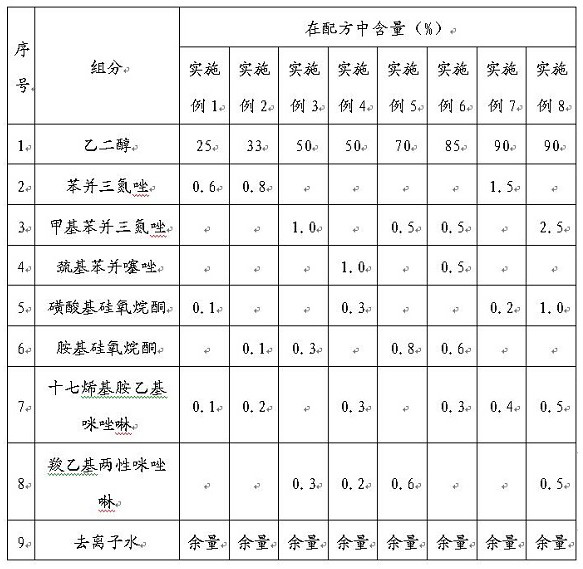

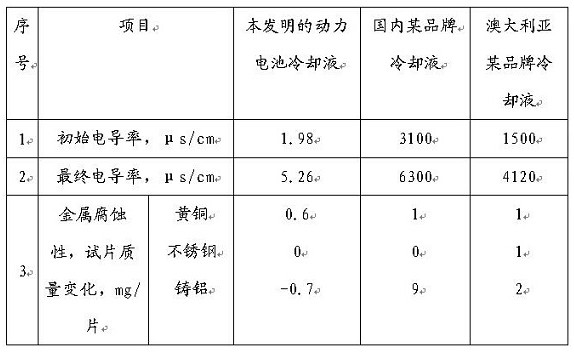

ActiveCN111218259AExcellent metal corrosion resistanceReduce conductivitySecondary cellsHeat-exchange elementsMetallurgyNew energy

The invention relates to a new energy automobile power battery cooling liquid and a preparation method thereof. The cooling liquid is prepared by mixing and stirring the following components: 25-95% of ethylene glycol, 0.5-3% of an azole compound, 0.2-2% of a composite corrosion inhibitor, and the balance of deionized water. Compared with the cooling liquid in the prior art, the cooling liquid ofthe invention has the advantages that the cooling liquid is free of inorganic salt and is compounded with an organic special-effect corrosion inhibitor, so that the power battery cooling liquid disclosed by the invention has an excellent metal anti-corrosion effect and long-acting extremely-low conductivity, and the requirements of a new energy automobile power battery cooling system on cooling, corrosion prevention, insulation, long acting and the like of the cooling liquid are met.

Owner:北京蓝星清洗有限公司

Environment-friendly, thermal-insulating and corrosion-resistant coating for metal and preparation method of coating

InactiveCN106085145AExcellent metal corrosion resistancePromote environmental protectionFireproof paintsAnti-corrosive paintsGas phaseThermal insulation

The invention discloses an environment-friendly, thermal-insulating and corrosion-resistant coating for metal. The environment-friendly, thermal-insulating and corrosion-resistant coating is characterized by being prepared from raw materials in parts by weight as follows: 60-90 parts of acrylic acid modified epoxy resin, 3-8 parts of modified polyuria, 20-35 parts of a composite thermal insulation agent, 10-20 parts of nano hydroxyapatite powder, 3-6 parts of a wet dispersant, 8-15 parts of gas-phase aluminum oxide, 2-10 parts of polyacrylate type thickeners, 1-5 parts of lower-molecular polyethylene wax, 1-2 parts of zinc dihydrogen phosphate with the concentration being 1.5%, 2-8 parts of propylene glycol, 0.5-1 part of mercaptobenzothiazole, 3-20 parts of other aids and 20-30 parts of water. The invention also discloses a preparation method of the environment-friendly, thermal-insulating and corrosion-resistant coating for the metal. The coating prepared according to the raw material formula with the preparation method has good metal corrosion resistance, environmental protection performance and thermal insulation performance.

Owner:SUZHOU HONGKE METAL PROD CO LTD

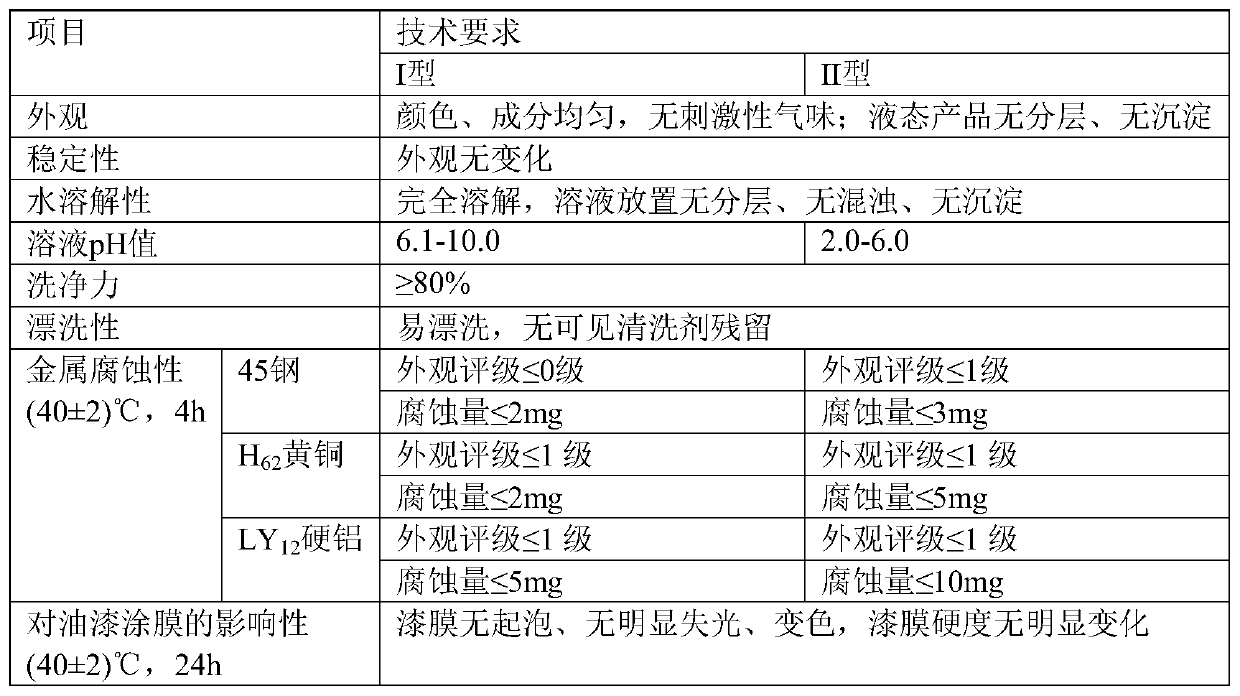

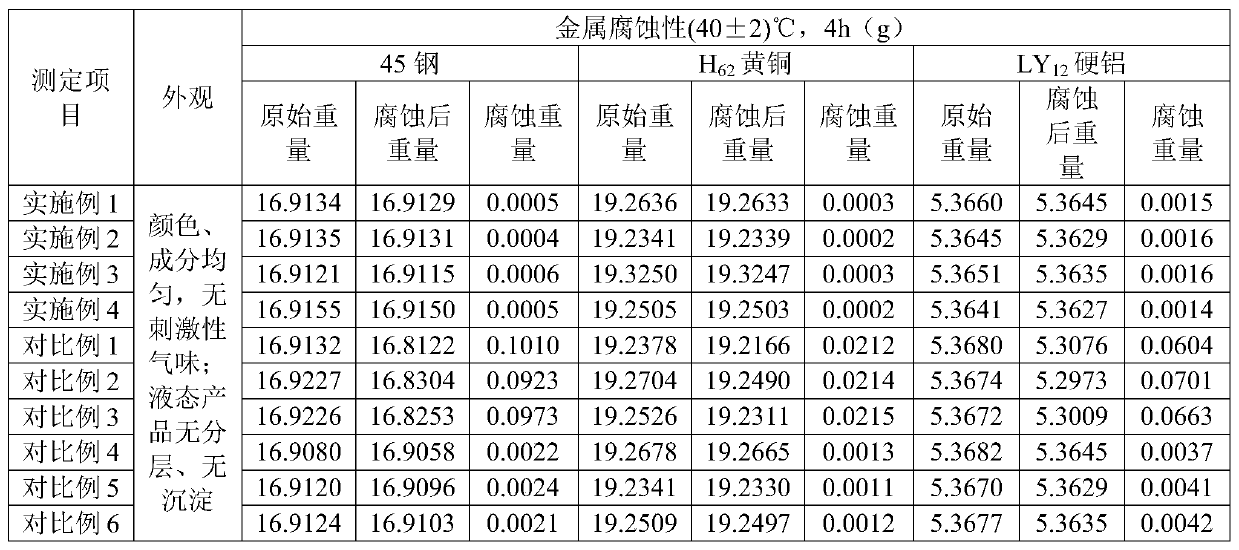

Metal cleaning agent and preparing method thereof

The invention relates to a metal cleaning agent and a preparing method thereof. Raw materials of the metal cleaning agent include 1%-20% of an organic solvent, 1%-5% of a corrosion inhibitor, 1%-7% ofan emulsifying agent, 1%-5% of a penetrating agent, 1%-10% of a dispersing agent, 1%-5% of a washing assisting agent, 1%-10% of a surface active agent, 0.5%-3% of a chelating agent and the balance water. The preparing method includes the following steps that the washing assisting agent and the organic solvent are evenly mixed, then the surface active agent, the dispersing agent, the emulsifying agent, the corrosion inhibitor, the penetrating agent, the chelating agent and the deionized water are added and evenly mixed, and the metal cleaning agent is obtained. The metal cleaning agent has thebeneficial effects that the heavy oil dirt removing capability is high, and the cleaning speed is high; and in addition, the beneficial effects that the metal corrosion resistance is good, and biodegradability is achieved are achieved.

Owner:北京净油洁宝科技有限公司

Anti-abrasive and anticorrosive paint for metal and preparation method of paint

InactiveCN105907191AExcellent metal corrosion resistancePromote environmental protectionWax coatingsConjugated diene hydrocarbon coatingsPhytic acidCarboxylic acid

The invention discloses an anti-abrasive and anticorrosive paint for metal and a preparation method of the paint. The paint is prepared from, by weight, 40-60 parts of copolymer of styrene and acrylic acid, 10-20 parts of styrene butadiene rubber, 10-15 parts of inorganic filler, 5-15 parts of EVA abrasion-resistant agent, 2-5 parts of wetting dispersant h-9040, 3-8 parts of petroleum resin modified wax emulsion, 2-10 parts of gaseous titanium dioxide, 1-4 parts of zinc oxide, 0.5-1 part of phosphonic carboxylic acid, 1-2 parts of 1.5% phytic acid, 0.5-1 part of lignosulfonate, 1-3 parts of anti-flash-rust agent, 2-6 parts of propylene glycol, 2-6 parts of film-forming agent, and 15-25 parts of water. The invention further discloses a preparation method of the anti-abrasive and anticorrosive paint for metal. The paint obtained according to the raw material formula and the preparation method has good metal anti-corrosion property, environmental friendliness, and abrasion resisting property; the service life and the anti-corrosion period of the paint are prolonged; therefore, the cost is reduced, the work intensity is lowered, and the anti-corrosion efficiency is improved.

Owner:SUZHOU HONGKE METAL PROD CO LTD

Double-sided pressure-sensitive adhesive sheet

InactiveUS20110070430A1Emission reductionExcellent metal corrosion resistanceFilm/foil adhesivesSynthetic resin layered productsPlastic filmSulfur containing

A double-sided pressure-sensitive adhesive (PSA) sheet having a plastic film as a substrate is provided, with the property of corroding a metal not in contact therewith being suppressed. This PSA sheet has a PSA layer that uses a water-dispersed acrylic PSA composition on each side of the plastic film substrate. The PSA composition contains a water-dispersed acrylic polymer synthesized using a sulfur-containing chain transfer agent. The PSA sheet has the emission of sulfur-containing gas of 0.043 μg or less per 1 cm2 surface area of the PSA sheet, when converted to SO42−, in a gas generation test under which the PSA sheet is heated at 85° C. for one hour.

Owner:NITTO DENKO CORP

Water-free cooling liquid for automobile engine

InactiveCN105505336ALowering the freezing pointHigh boiling pointHeat-exchange elementsSebacic acidBorax

The invention discloses a water-free cooling liquid for an automobile engine. The water-free cooling liquid for the automobile engine is prepared from, by weight, 40-50 parts of ethylene glycol, 30-40 parts of propylene glycol, 5-8 parts of benzotriazole, 3-5 parts of 2-mercaptobenzothiazole, 1-3 parts of sodium benzoate, 0.5-1 part of sodium sebacate, 0.5-0.8 part of cinnamic acid, 0.5-0.8 part of sebacic acid, 1-2 parts of sodium oleate, 0.5-1 part of sodium molybdate, 5-8 parts of calcium chloride, 8-10 parts of dimethyl silicone oil, 0.01-0.05 part of borax, 0.3-0.5 part of triethanolamine oleic soap and 8-10 parts of carboxymethyl cellulose. The water-free cooling liquid for the automobile engine has a lower freezing point and a higher boiling point and has better metal corrosion prevention property, cavitation prevention property and scaling prevention property and long service life.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Fluororubber composition

ActiveUS20140031461A1Excellent metal corrosion resistanceImprove corrosion resistanceOther chemical processesBuilding insulationsTetrafluoroethyleneFuel oil

A fluororubber composition comprising 100 parts by weight of a peroxide-crosslinkable tetrafluoroethylene-vinylidene fluoride-hexafluoropropene ternary copolymer rubber having a fluorine content of 64 wt. % or more, (A) 5 to 90 parts by weight of carbon black having a specific surface area of 5 to 20 m2 / g, (B) 5 to 40 parts by weight of a fine bituminous powder, (C) at least one of 1 to 20 parts by weight of hydrophilicity-imparted talc and / or 1 to 30 parts by weight of hydrophilicity-imparted clay, and (D) 0.5 to 6 parts by weight of an organic peroxide; the fluororubber composition being used as a molding material for fuel oil sealing materials to be in contact with fuel oil. The fluororubber composition provides a sealing materials having excellent metal corrosion resistance, without compounding an acid acceptor comprising a metal oxide.

Owner:NOK CORP

Pressure-sensitive adhesive sheet

InactiveUS20100178500A1Emission reductionExcellent metal corrosion resistanceFilm/foil adhesivesSynthetic resin layered productsSulfur containingAcrylic polymer

There is provided a pressure-sensitive adhesive (PSA) sheet with the property of corroding a metal not in contact therewith suppressed. This PSA sheet is provided with a PSA layer formed from a water-dispersed PSA composition. The PSA composition contains a water-dispersed acrylic polymer synthesized using a sulfur-containing chain transfer agent. Moreover, in a gas generation test whereby the PSA sheet is heated at 85° C. for one hour, the emission of sulfur-containing gas is 0.043 μg or less per 1 cm2 surface area of the sheet, when converted to SO42−.

Owner:NITTO DENKO CORP

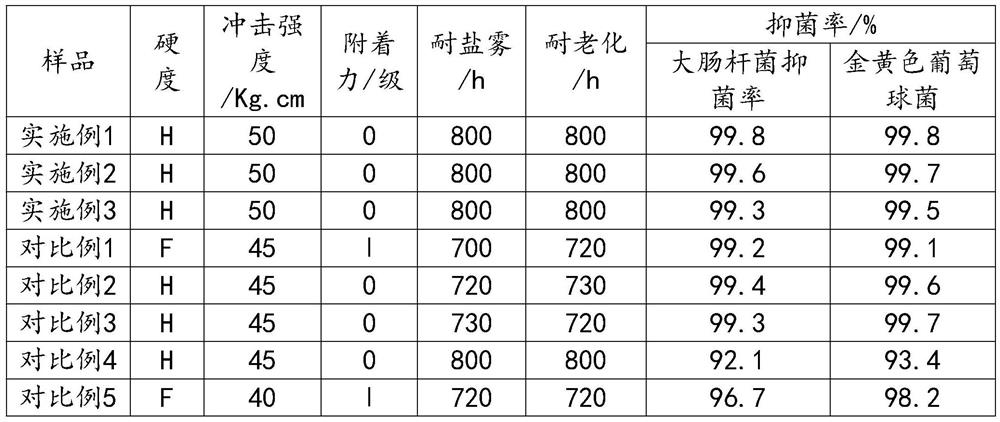

Low-carbon environment-friendly anticorrosive paint and preparation method thereof

InactiveCN111849296AImprove mechanical propertiesImprove thermal stabilityAntifouling/underwater paintsPaints with biocidesPhytic acidPolypropylene

The invention discloses a low-carbon environment-friendly anticorrosive paint which is prepared from the following raw materials in parts by weight: 25-55 parts of a composite powder, 15-30 parts of organic silicon modified polypropylene resin, 0.5-2 parts of an inorganic filler, 1-3 parts of an organic solvent, 35-45 parts of deionized water, 10-15 parts of modified attapulgite and 0.5-1 part ofa composite antibacterial agent. The invention also discloses a preparation method of the low-carbon environment-friendly anticorrosive paint. Inorganic matters such as graphene oxide, vanadium pentoxide xerogel powder and montmorillonite are used as base materials, the base materials are mixed with organic silicon modified polypropylene resin, and the other auxiliary agents are added to prepare afinished product. According to the present invention, the graphene is subjected to covalent modification, and phytic acid is grafted to the graphene, so that the corrosion ions can be effectively prevented from entering the metal surface, and slowing down of metal corrosion is realized; by selecting the raw materials, the introduction of organic matters is greatly reduced, and the low-carbon environment-friendly anticorrosive paint is environment-friendly and has excellent metal anticorrosive performance.

Owner:杭州吉邦综合服务有限公司

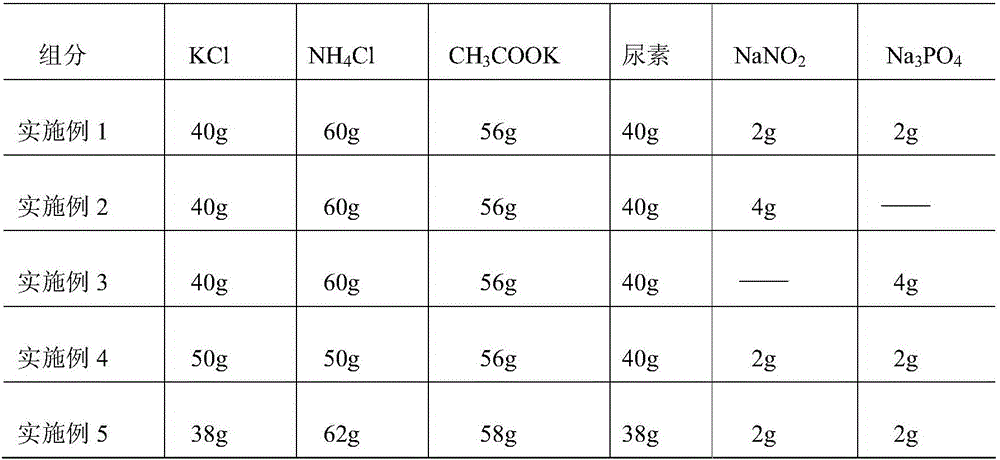

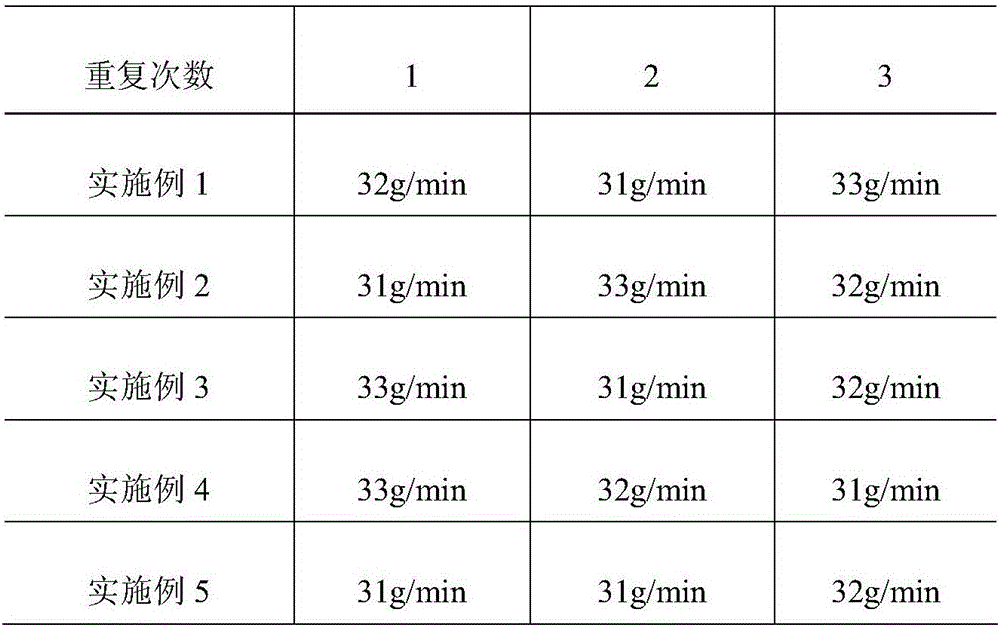

Environmentally-friendly composite type snow-melting agent and preparation method thereof

ActiveCN106634841ARaw materials are easy to getLow costOther chemical processesSodium phosphatesSnow melting

The invention relates to an environmentally-friendly composite type snow-melting agent and a preparation method thereof. The snow-melting agent is prepared from the following raw materials in parts by weight: 40 to 55 parts of chlorine salt, 45 to 55 parts of organic salt and 1 to 2 parts of a corrosion inhibitor, wherein the chlorine salt is prepared from the following raw materials in parts by weight: 15 to 20 parts of potassium chloride and 25 to 35 parts of ammonia chloride; the organic salt is prepared from the following raw materials in parts by weight: 25 to 30 parts of potassium acetate and 20 to 25 parts of urea; the corrosion inhibitor is one of or a mixture of sodium nitrite and sodium phosphate; and the snow-melting agent is prepared from the following raw materials in parts by weight: 50 parts of chlorine salt, 48 parts of organic salt and 2 parts of a corrosion inhibitor. The snow-melting agent is doped with the corrosion inhibitor; and related corrosiveness tests indicate that the snow-melting agent doped with the sodium phosphate has smallest corrosion effect on metal and can protect the surface of the metal, the metal still can maintain the original metal luster when being soaked into a salt solution, and a good metal corrosion-resistant effect is achieved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Fireproof coating for steel structures

InactiveCN103992723AGood physical and mechanical propertiesExcellent metal corrosion resistanceFireproof paintsEpoxy resin coatingsEpoxyChemical industry

The invention discloses a fireproof coating for steel structures and belongs to the technical field of chemical industry. The fireproof coating consists of the following components in parts by weight: 15-25 parts of epoxy resin, 7-13 parts of acrylic resin, 3.7-4.5 parts of No. 200 gasoline, 4-6 parts of dimethyl benzene, 5-7 parts of butyl acetate, 0.5-0.9 part of fumed silica, 0.1-0.3 part of a dispersant, 6-8 parts of pentaerythritol, 5-10 parts of acetone, 16-18 parts of ammonium polyphosphate, 5-8 parts of melamine, 10-14 parts of antimony trioxide and 2-5 parts of titanium dioxide powder. The fireproof coating disclosed by the invention has good mechanical and physicochemical performance and can form a good foam heat insulating layer in a fire, and the foam layer does not drop even at a high temperature; the fireproof coating disclosed by the invention is good in metal corrosion resistance and good in appearance decoration.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

Environment-friendly engine coolant

InactiveCN105419747ALowering the freezing pointHigh boiling pointHeat-exchange elementsCavitationSodium hydroxide

The invention discloses an environment-friendly engine coolant which is composed of following raw materials, by weight: 80-85 parts of ethylene glycol, 15-20 parts of propylene glycol, 2-5 parts of magnesium silicate, 5-10 parts of sodium silicate, 1-3 parts of potassium sorbate, 0.01-0.05 parts of sodium benzoate, 0.02-0.04 parts of decanedioic acid, 0.1-0.3 parts of benzotriazole, 0.05-0.08 parts of mercaptobenzothiazole, 0.1-0.5 parts of sodium hydroxide, 0.5-1 part of hydrolyzed polymaleic anhydride, 2-5 parts of carboxymethylcellulose, and 15-20 parts of deionized water. The engine coolant is low in freezing point and high in boiling point, is excellent in metal anti-corrosion property, anti-cavitation property and anti-scaling property, is safe and environment-friendly and is environment-friendly.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

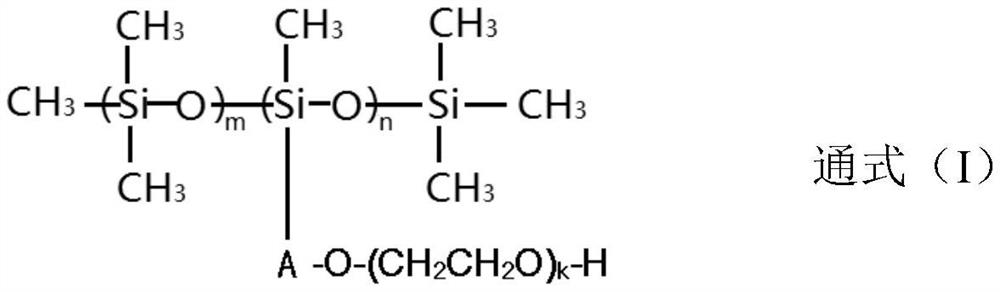

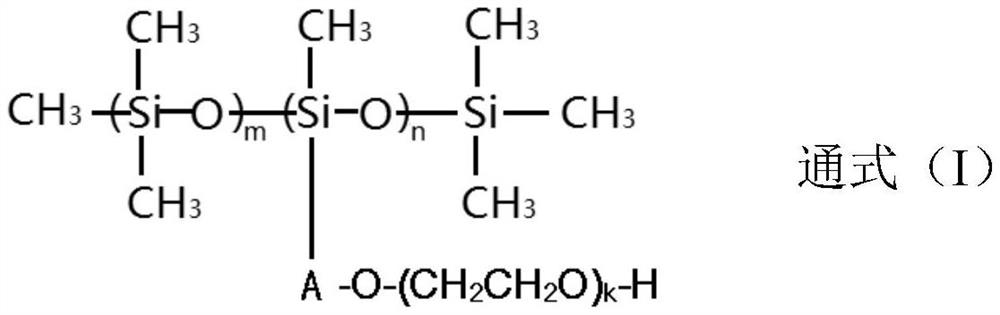

Engine carbon deposit cleaning composition, method for preparing engine carbon deposit cleaning composition, and method for cleaning engine carbon deposit

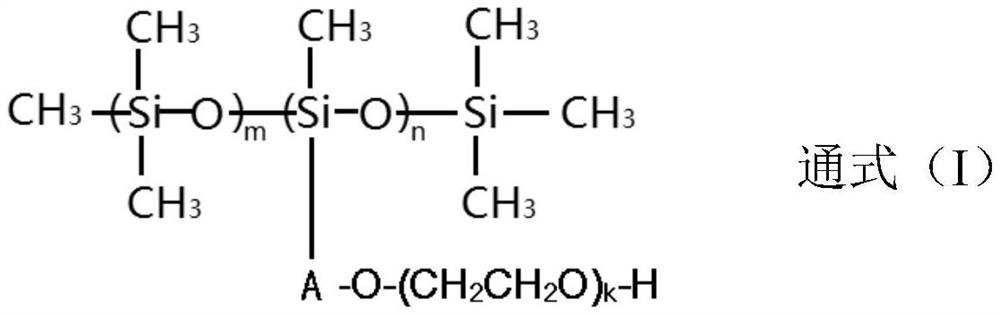

ActiveCN112251297AGood carbon cleaning abilityExcellent metal corrosion resistanceNon-ionic surface-active compoundsOrganic detergent compounding agentsActive agentPyrrolidinones

The invention provides an engine carbon deposit cleaning composition, and the composition comprises the following components in percentage by weight: (a) 3-10% of oleylamine; (b) 0-60 wt% of a fatty alcohol polyoxyethylene ether modified organosilicon surfactant; (c) 30-83% by weight of pyrrolidone; (d) 5-67 wt% of ethylene glycol butyl ether; (e) 0-20% by weight of water. The engine carbon deposit cleaning composition has good carbon deposit cleaning capacity and good metal corrosion resistance.

Owner:3M CHINA

Metal material preservative

InactiveCN103695923AGood metal corrosion resistanceExcellent metal corrosion resistanceCorrosionZinc

The invention provides a metal material preservative. The technical scheme adopted by the invention is that the metal material preservative comprises water and a benzoic acid component and is characterized by also comprising the following components in parts by mass: 2-8 parts of zeolite powder, 2-8 parts of zinc oxide, 1-8 parts of butadiene and 0.8-1.8 parts of cyproconazole. Compared with the prior art, the metal material preservative provided by the invention has the beneficial effects that by adding the zeolite powder, zinc oxide, butadiene and cyproconazole, the preservative has perfect metal corrosion resistance.

Owner:王刚

Preparation method of sulfonic acid type graphene/polyurethane-epoxy resin composite anticorrosive paint

InactiveCN111574918AImprove anti-corrosion performanceIncreased corrosion potentialAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceEpoxy resin composite

The invention discloses a preparation method of sulfonic acid type graphene / polyurethane-epoxy resin composite anticorrosive paint, which comprises the following steps: preparing graphene oxide, sulfonating the graphene oxide to obtain sulfonic acid type graphene, and preparing an acrylic acid modified epoxy resin intermediate from bisphenol A type epoxy resin and acrylic acid; respectively preparing a core phase monomer pre-emulsion and a shell phase monomer pre-emulsion, and carrying out core-shell reaction polymerization on the core phase monomer pre-emulsion and the shell phase monomer pre-emulsion through an initiator to obtain a polyurethane-epoxy resin core-shell emulsion; and finally, mixing the polyurethane-epoxy resin core-shell emulsion with the sulfonic acid type graphene to obtain the anticorrosive paint. According to the invention, the corrosion resistance of the sulfonic acid type graphene / polyurethane-epoxy resin composite anticorrosive paint is greatly improved, and the corrosion potential of the coating is increased and the corrosion current density is reduced along with the increase of the content of sulfonic acid type graphene, so that the sulfonic acid type graphene / polyurethane-epoxy resin composite anticorrosive paint has excellent metal corrosion resistance.

Owner:JINLING INST OF TECH

Metal coating and production method thereof

InactiveCN106854423AHigh strengthReduce weightAnti-corrosive paintsPolyurea/polyurethane coatingsCorrosionPOLYETHYLENE WAX

The invention discloses a metal coating and a production method thereof. The formula of the metal coating comprises, by mass, 55-75 parts of acrylic acid modified epoxy resin, 1-2 parts of a polyacrylate thickener, 2-6 parts of fumed alumina, 6-10 parts of modified polyurea, 4-6 parts of a composite heat insulation agent, 2-4 parts of caprin, 1-3 parts of low molecular polyethylene wax, 12-14 parts of hydroxyapatite nano-powder, 5-7 parts of boron carbide, 4-6 parts of mercaptobenzothiazole, 2-6 parts of zinc dihydrogen phosphate, 1-2 parts of an assistant and 1-3 parts of a wetting dispersant. The coating produced through using the formula and the production method has good metal corrosion resistance, good environmentally-friendly property and good heat insulation property.

Owner:钦州市钦南区生产力促进中心

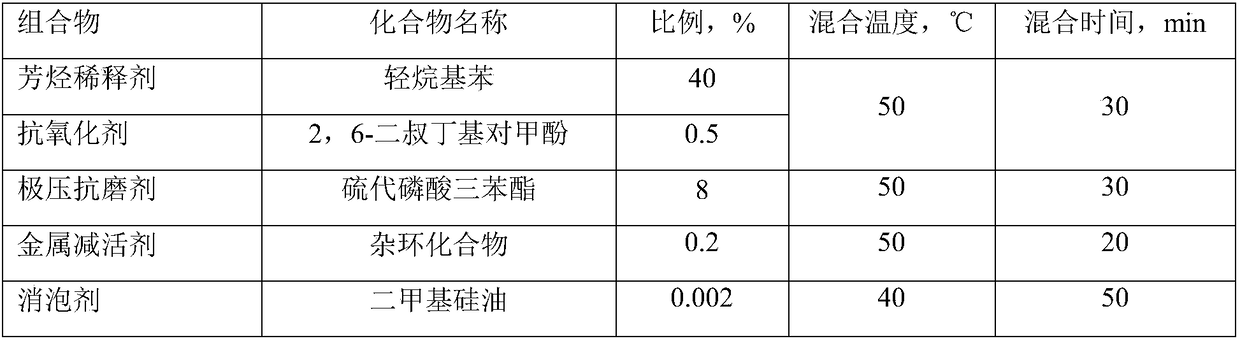

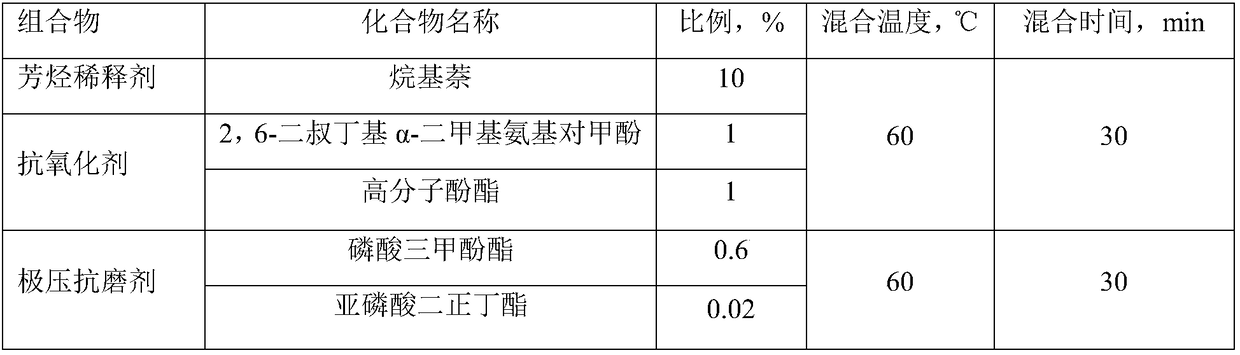

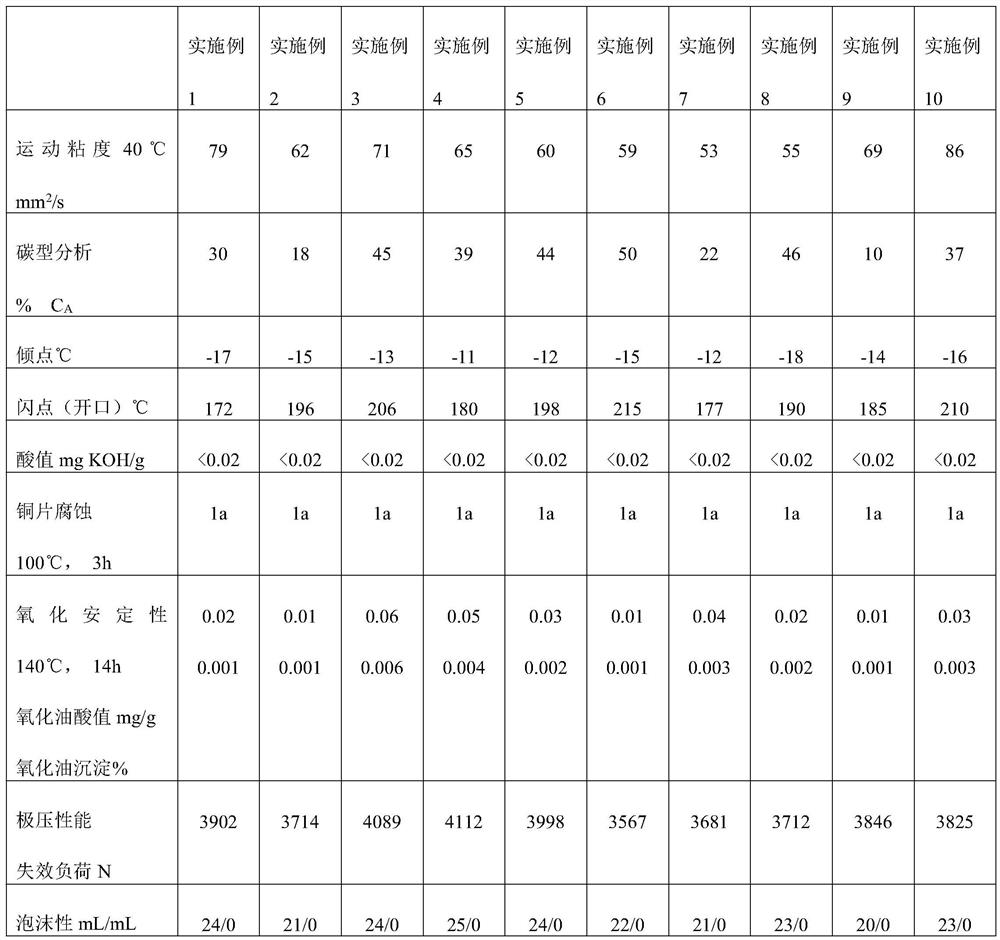

Composite additive composition for refrigerating machine oil for screw-type ammonia refrigerating compressor and preparing method thereof

InactiveCN108587738AGood fluidity at low temperatureSimple and efficient production operationAdditivesOxidation stabilityCorrosion

The invention discloses a composite additive composition for refrigerating machine oil for a screw-type ammonia refrigerating compressor. The composite additive composition is prepared from, by weight, 5%-70% of aromatic diluent, 0.1%-20% of antioxidant, 0.1%-10% of extrcme pressure anti-wear additive, 0.01%-5% of metal deactivator and 0.001%-0.2% of antifoaming agent, wherein the kinematic viscosity of the aromatic diluent at the temperature of 40 DEG C is 5 mm<2> / s to 100 mm<2> / s, and %CA is 4% to 60%. The refrigerating machine oil obtained after the composite additive composition is added for the screw-type ammonia refrigerating compressor has the excellent low temperature fluidity, oxidation stability, extreme pressure anti-wear property, metal corrosion resistance and foaming resistance, and can more efficiently and circularly work in the ammonia refrigerating compressor for a long life. In addition, through the composite additive composition, the refrigerating machine oil is moreeasy and efficient in production operation and lower in energy consumption.

Owner:CNOOC TAIZHOU PETROCHEM CO LTD +1

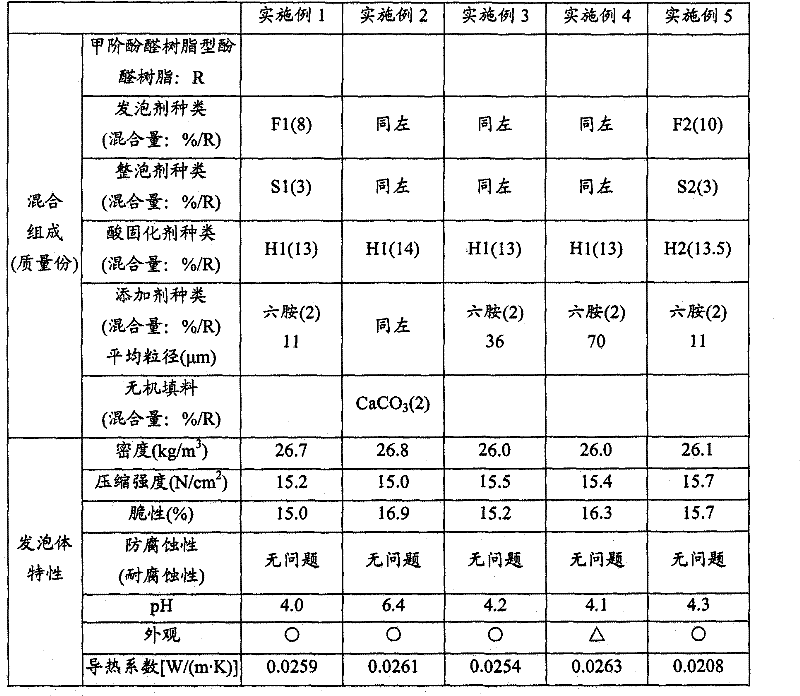

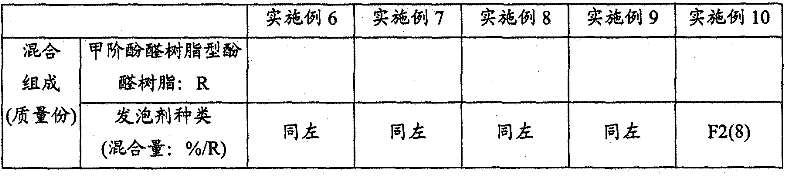

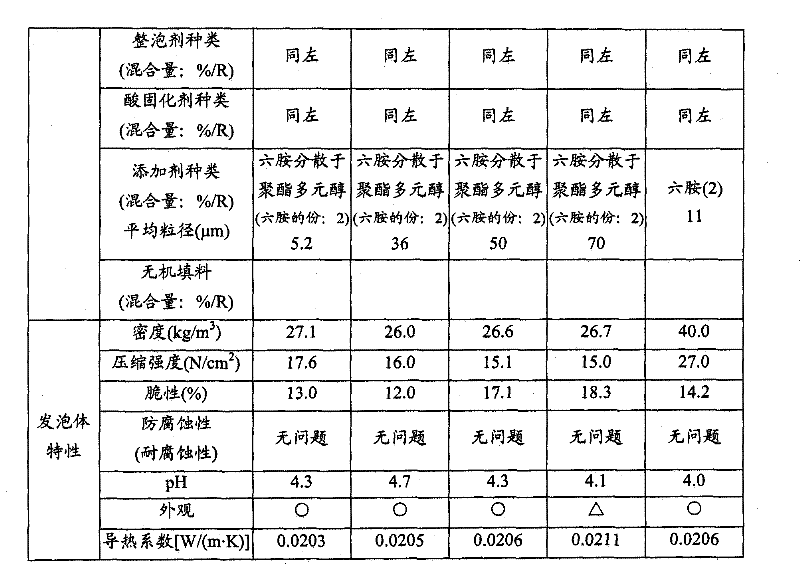

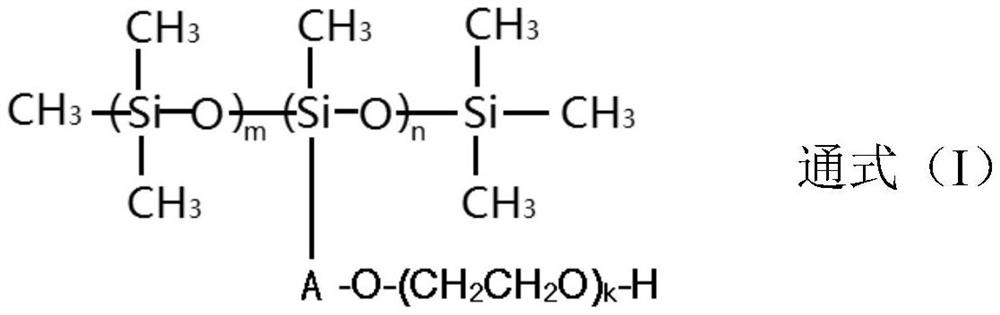

Foamable resol-type phenolic resin molding material, preparation method thereof, and phenolic resin foam

A foamable resol type phenolic resin molding or forming material comprising a liquid resol type phenolic resin, foaming agent, a foam stabilizer, an acid curing agent and an additive, the additive being a nitrogen-containing bridged cyclic compound having an average particle diameter of 80 µm or less, and a phenolic resin foamed product formed by foaming and curing the above molding or forming material.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Engine carbon deposit cleaning composition, method for preparing engine carbon deposit cleaning composition, and method for cleaning engine carbon deposit

ActiveCN112251297BGood carbon cleaning abilityExcellent metal corrosion resistanceNon-ionic surface-active compoundsOrganic detergent compounding agentsActive agentPyrrolidinones

The invention provides an engine carbon deposit cleaning composition, which comprises: (a) 3-10% by weight of oleylamine; (b) 0-60 % by weight of fatty alcohol polyoxyethylene ether modified silicone surfactant; (c) 30-83% by weight of pyrrolidone; (d) 5-67% by weight of ethylene glycol butyl ether; and (e) 0- 20% by weight of water. The engine carbon deposit cleaning composition has good carbon deposit cleaning ability and good metal corrosion resistance.

Owner:3M CHINA

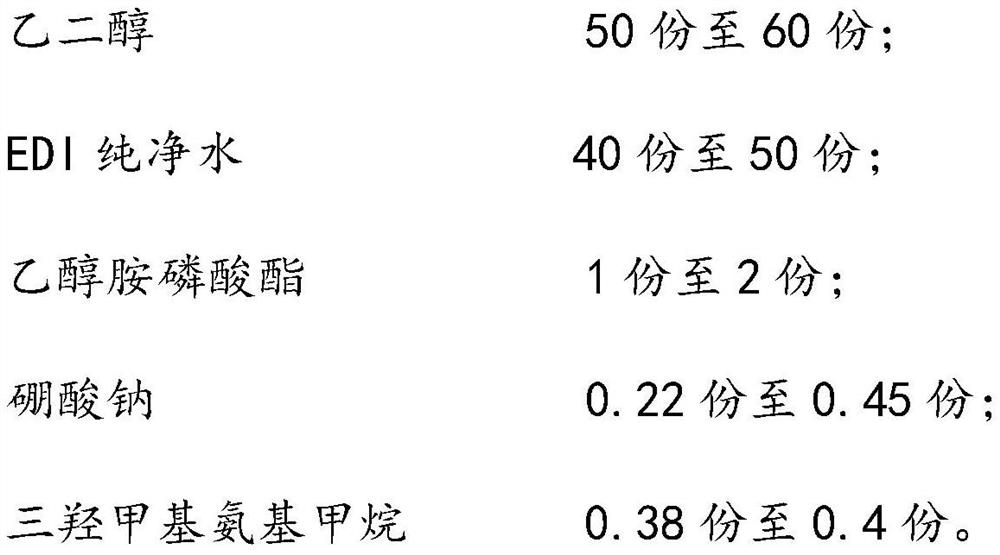

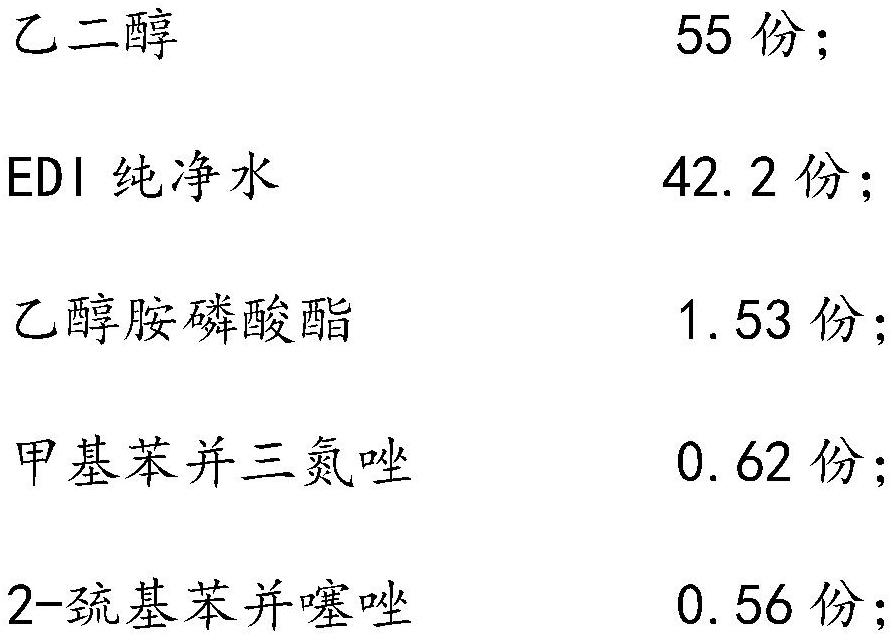

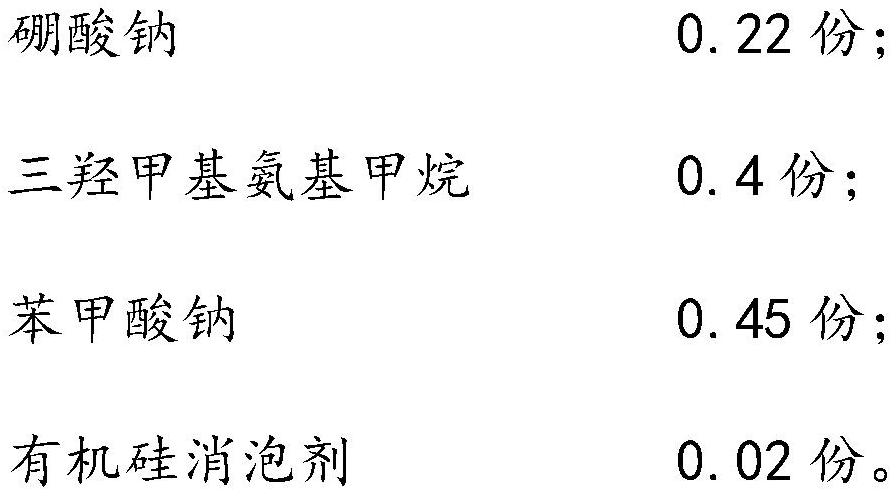

New energy automobile power battery cooling liquid, preparation method and application

PendingCN114464930AExcellent metal corrosion protectionReduce conductivitySecondary cellsCorrosion inhibitorCooling fluid

The invention discloses a cooling liquid for a power battery of a new energy automobile. The cooling liquid comprises the following substances in parts by mass: 50-60 parts of ethylene glycol; 40 to 50 parts of EDI purified water; 1 to 2 parts of ethanolamine phosphate; 0.22 part to 0.45 part of sodium borate; 0.38 to 0.4 part of tris (hydroxymethyl) aminomethane; the invention also discloses a preparation method of the cooling liquid. The metal corrosion inhibitor has the advantages of wide temperature range and slow metal corrosion.

Owner:浙江嘉富力环保科技有限公司

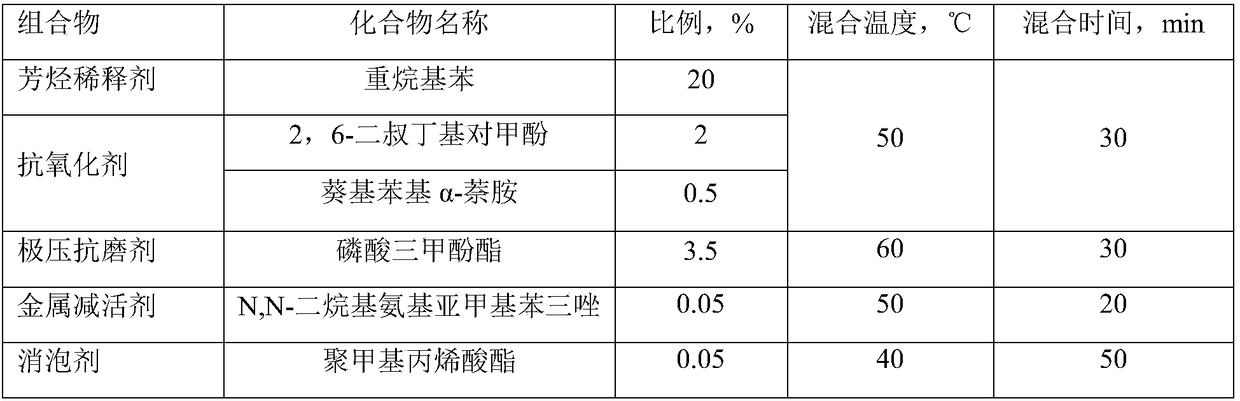

Cold work refrigerator oil additive

InactiveCN111793514AGood fluidity at low temperatureImprove Oxidation StabilityAdditivesOil additiveAniline

The invention belongs to the technical field of refrigerator oil, and provides a cold work refrigerator oil additive, which comprises the following raw materials in parts by weight: 23-40 parts of anaromatic hydrocarbon diluent, 10-15 parts of an antioxidant, 5-8 parts of an extreme pressure anti-wear agent, 1-3 parts of a metal deactivator and 0.12-0.16 part of a defoaming agent; wherein the aromatic hydrocarbon diluent is heavy alkyl benzene, the antioxidant is octyl / butyl diphenylamine, the extreme pressure anti-wear agent is triphenyl thiophosphate, the metal deactivator is benzotriazole,and the defoaming agent is polyalkylene glycol. The preparation method is simple, the proportion is reasonable, and after the additive is added into the refrigerator oil, the refrigerator oil can have the refrigerant compatibility, lubricity and low-temperature fluidity.

Owner:仝宝雄

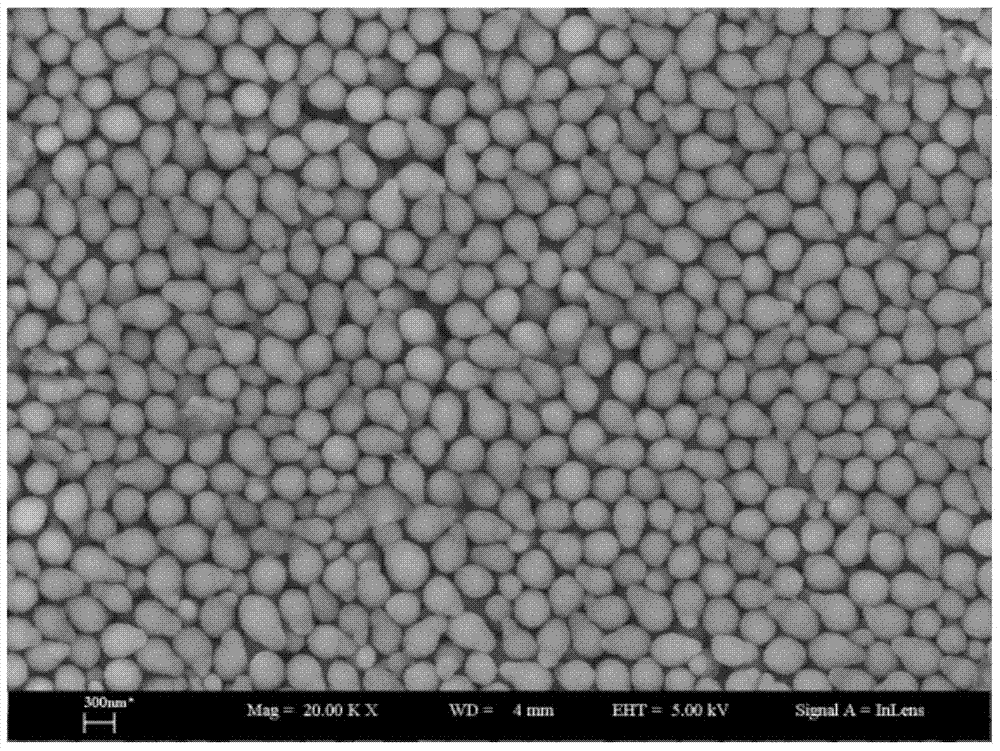

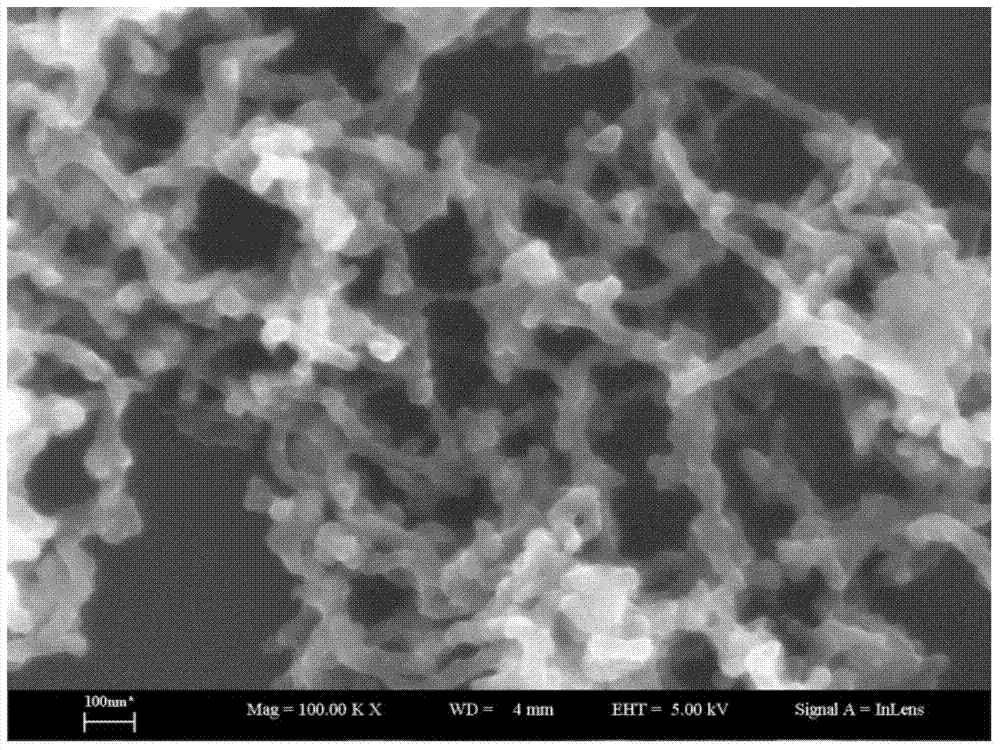

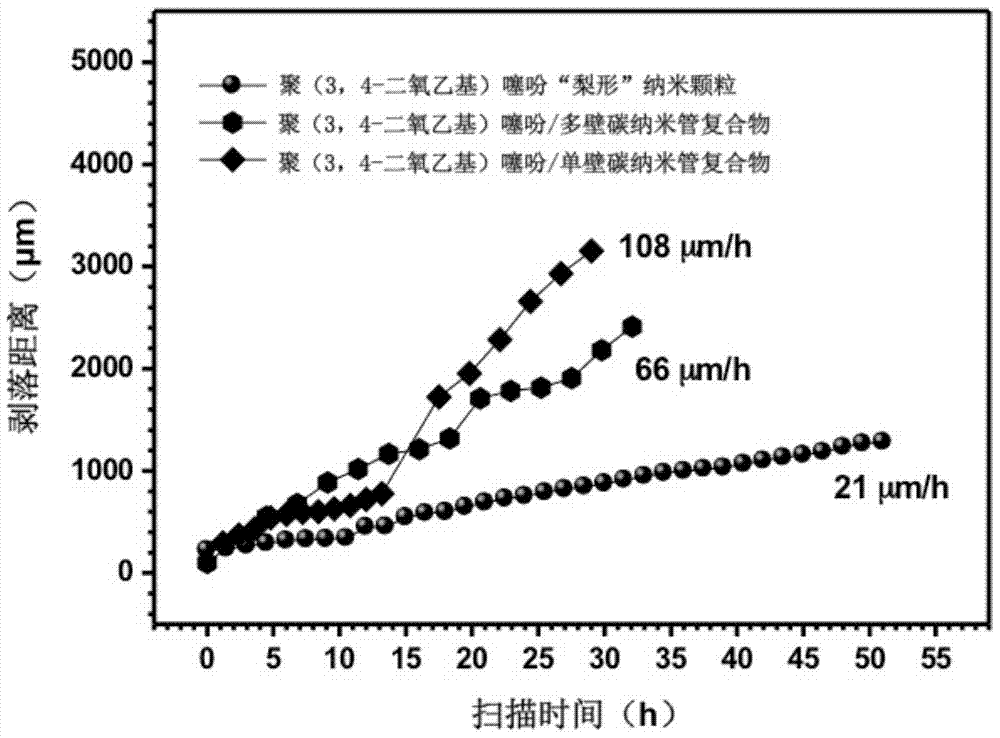

A polythiophene composite metal anti-corrosion coating influenced by morphology, preparation method and application thereof

ActiveCN105153883BEasy to prepareSimple manufacturing methodAnti-corrosive paintsFiberCarbon nanotube

The invention discloses a shape-affected polythiophene composite metal anticorrosion coating as well as a preparation method and application thereof. The composition and content of the composite anticorrosion coating of the present invention are: "pear-shaped" nanoparticles of poly(3,4-dioxyethyl)thiophene or a composite of poly(3,4-dioxyethyl)thiophene and carbon nanotubes Nanofiber: 15~110mg; polyvinyl butyral ethanol solution: 1~3mL; absolute ethanol 1~3mL. In the present invention, the "pear-shaped" nanoparticles of poly(3,4-dioxyethyl)thiophene or composite nanofibers of poly(3,4-dioxyethyl)thiophene and carbon nanotubes are firstly prepared by emulsion polymerization , and then mix it with polyvinyl butyral ethanol solution and absolute ethanol to prepare conductive composite metal anticorrosion coating and apply it to metal iron anticorrosion. The coating of the invention has low cost, little environmental pollution and good comprehensive performance. In addition, the selected scanning Kelvin probe test technology avoids damage to the coating, and can effectively monitor the corrosion resistance of the coating to the metal.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

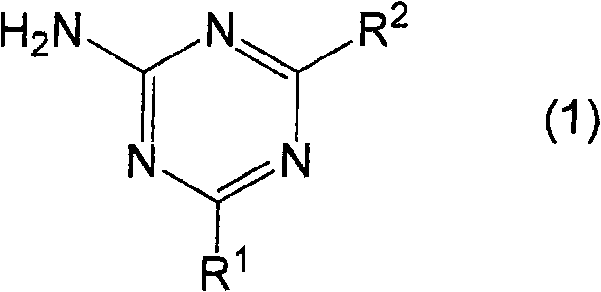

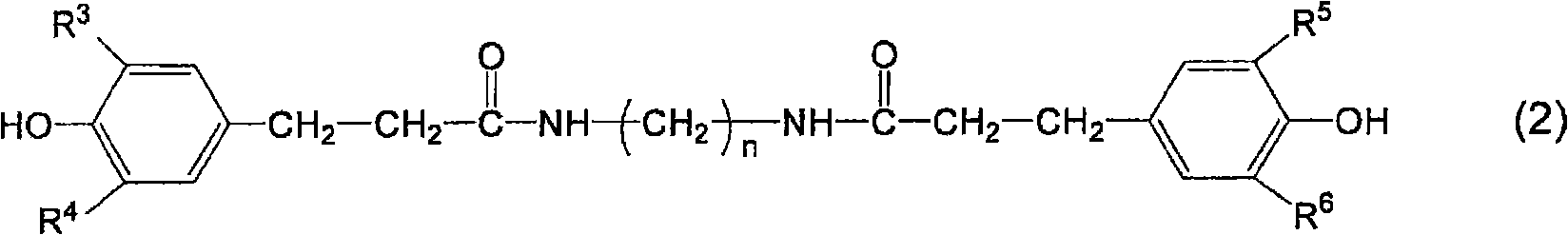

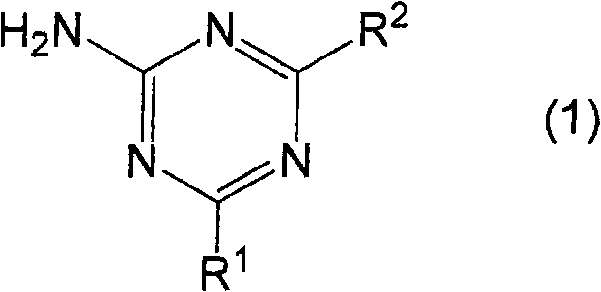

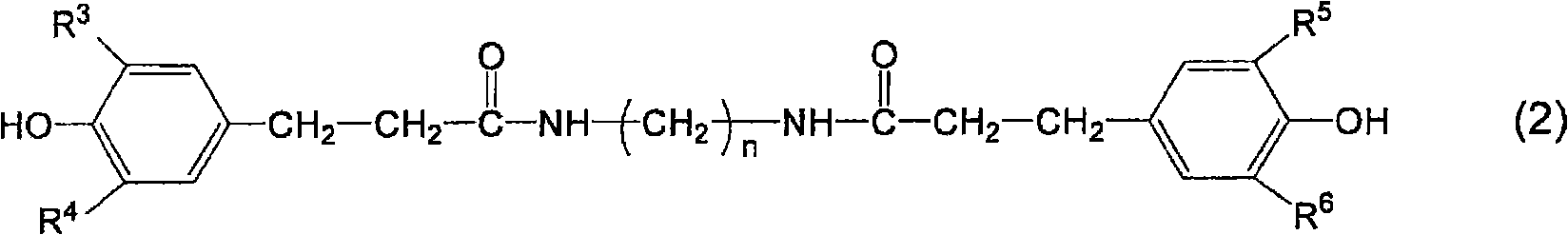

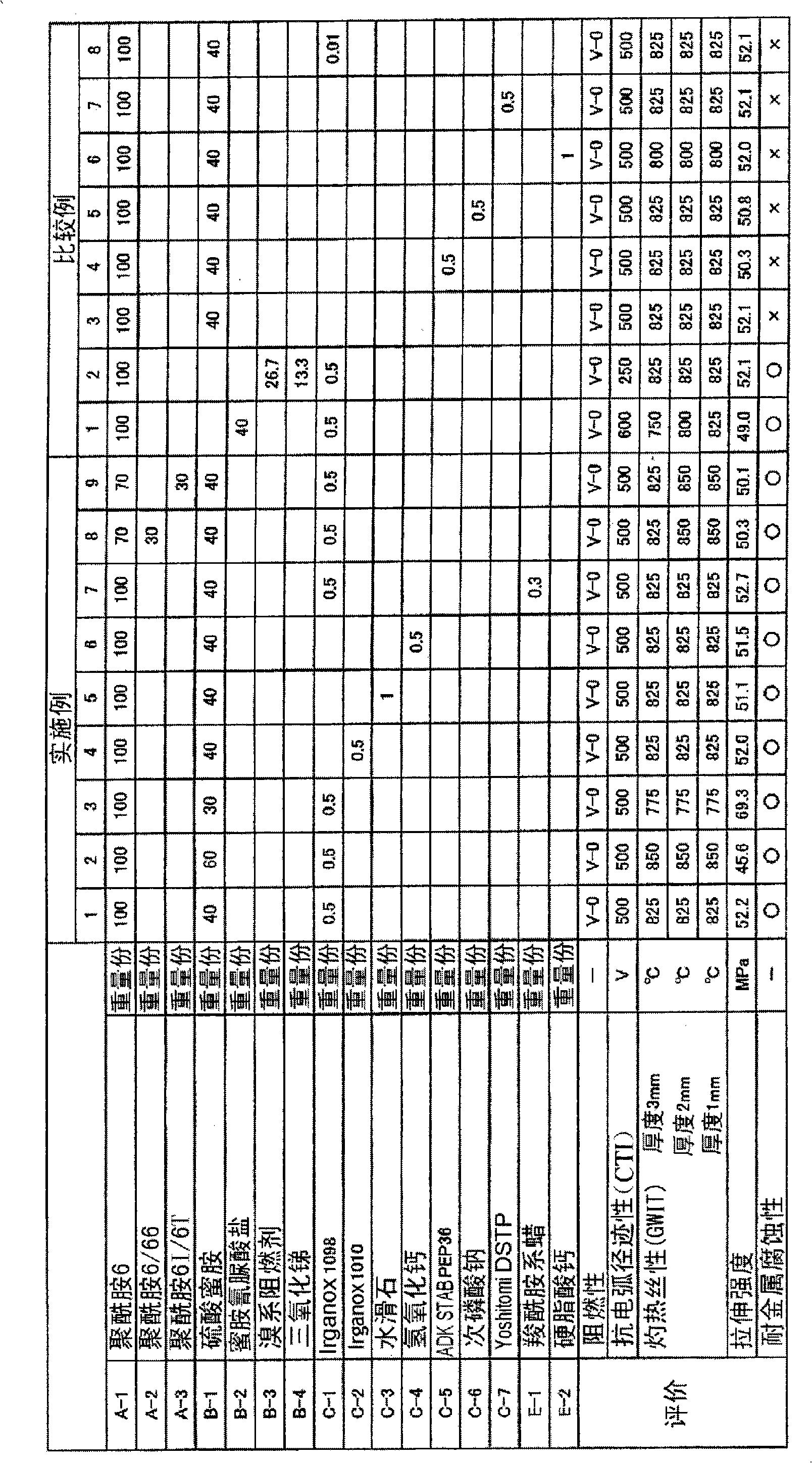

Flame retardant polyamide resin composition

ActiveCN101802098BImprove flame retardant performanceExcellent glow wire propertyAlkaline earth metalHydrotalcite

Disclosed is a flame-retardant polyamide resin composition excellent in all of flame retardation, glow-wire characteristic, tracking resistance and mechanical strength, and also in anti-corrosive performance for metals, and suitably be applied to electric / electronic components having metal contacts or metal terminals, such as connectors and so forth. A flame-retardant polyamide resin composition comprising, per 100 parts by weight of polyamide resin (A), 10 to 60 parts by weight of a salt (B) of an aminotriazine compound and at least one compound selected from the group consisting of sulfuric acid, pyrosulfuric acid and organosulfonic acid, and at least one compound (C) selected from the group consisting of hindered phenol-base compound, hydrotalcite and hydroxide of alkaline earth metal, wherein the ratio of comprising (C) / (B) by weight of the component (C) and the component (B) is 0.0005 to 0.2.

Owner:RYOGLOBAL POLYOXYMETHYLENE CO LTD

A new energy vehicle power battery coolant and preparation method thereof

ActiveCN111218259BExcellent metal corrosion resistanceReduce conductivitySecondary cellsHeat-exchange elementsCompound organicNew energy

The invention relates to a new energy vehicle power battery cooling liquid and a preparation method thereof. The cooling liquid is prepared by mixing and stirring according to the following component proportions: ethylene glycol 25%-95%; azole compounds 0.5%-3%; Corrosion agent 0.2%-2%; the balance is deionized water; compared with the cooling liquid of the prior art, the new energy vehicle power battery cooling liquid provided by the present invention does not contain inorganic salts, and is compounded with an organic special effect corrosion inhibitor, so that the The power battery cooling liquid of the present invention has excellent metal anti-corrosion effect, and has long-term and extremely low electrical conductivity, and meets the cooling, anti-corrosion, insulation, long-term and other requirements of the cooling liquid for the power battery cooling system of new energy vehicles.

Owner:北京蓝星清洗有限公司

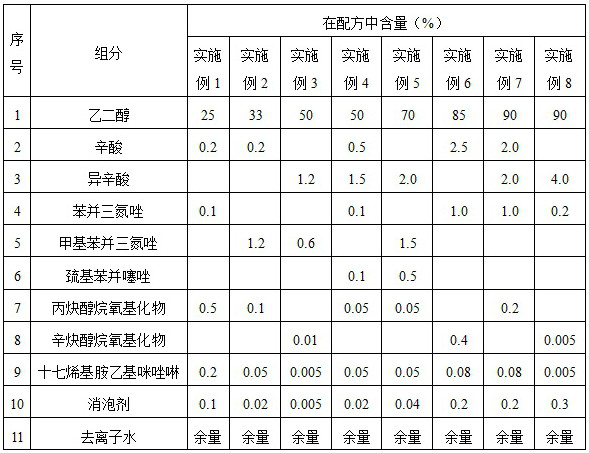

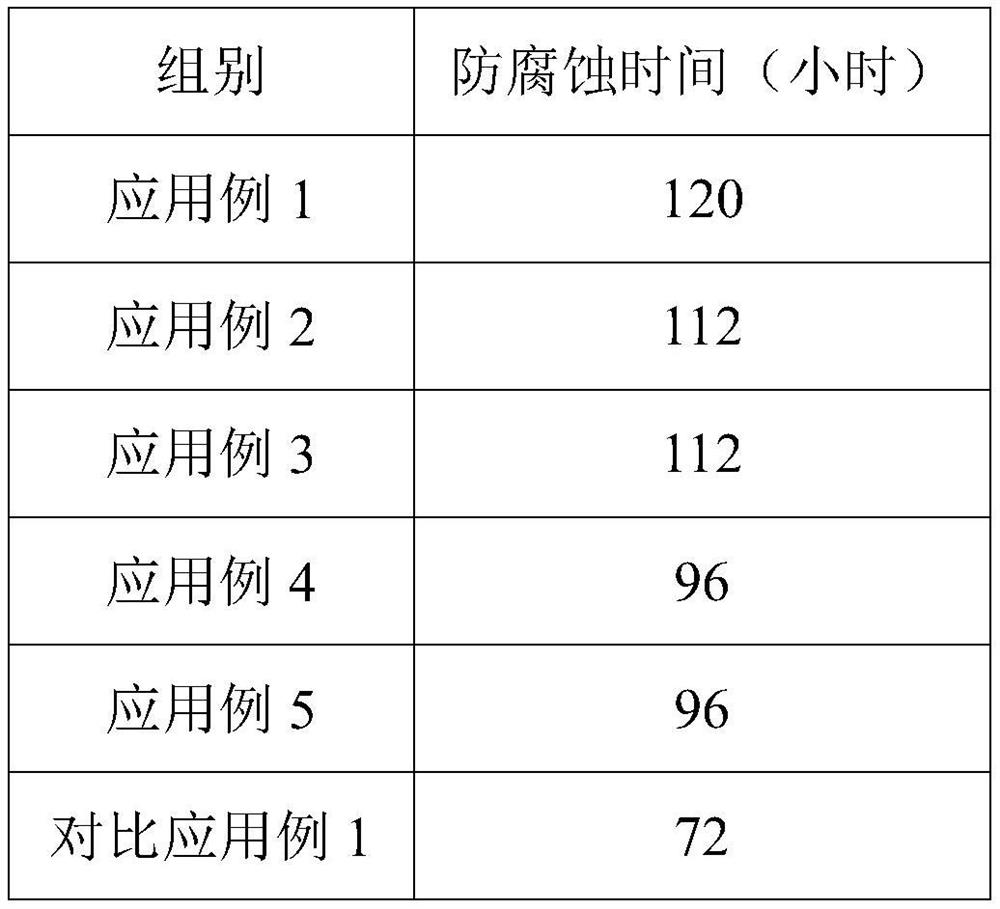

A kind of cooling liquid for wind power generating set and preparation method thereof

ActiveCN109837071BReduce contentAvoid corrosionHeat-exchange elementsCarboxylic acidGlycol synthesis

The invention provides a cooling liquid for a wind power generator set, and a preparation method thereof, wherein the cooling liquid comprises, by weight, 25-95% of ethylene glycol, 0.2-4% of aliphatic monocarboxylic acid, 0.1-2% of an azole-based compound, 0.01-1% of a composite corrosion inhibitor, 0.001-0.3% of a defoamer, and the balance of deionized water. According to the present invention,the wind power cooling liquid adopts the synergetic effect of the azole-based compound, the composite corrosion inhibitor and the low-content aliphatic monocarboxylic acid, does not contain the inorganic salt, has advantages of excellent metal anticorrosive effect and extremely low electrical conductivity, and can meet the requirements of wind power generator set cooling systems on cooling, corrosion resistance, insulation, long-acting and the like of cooling liquids.

Owner:北京蓝星清洗有限公司

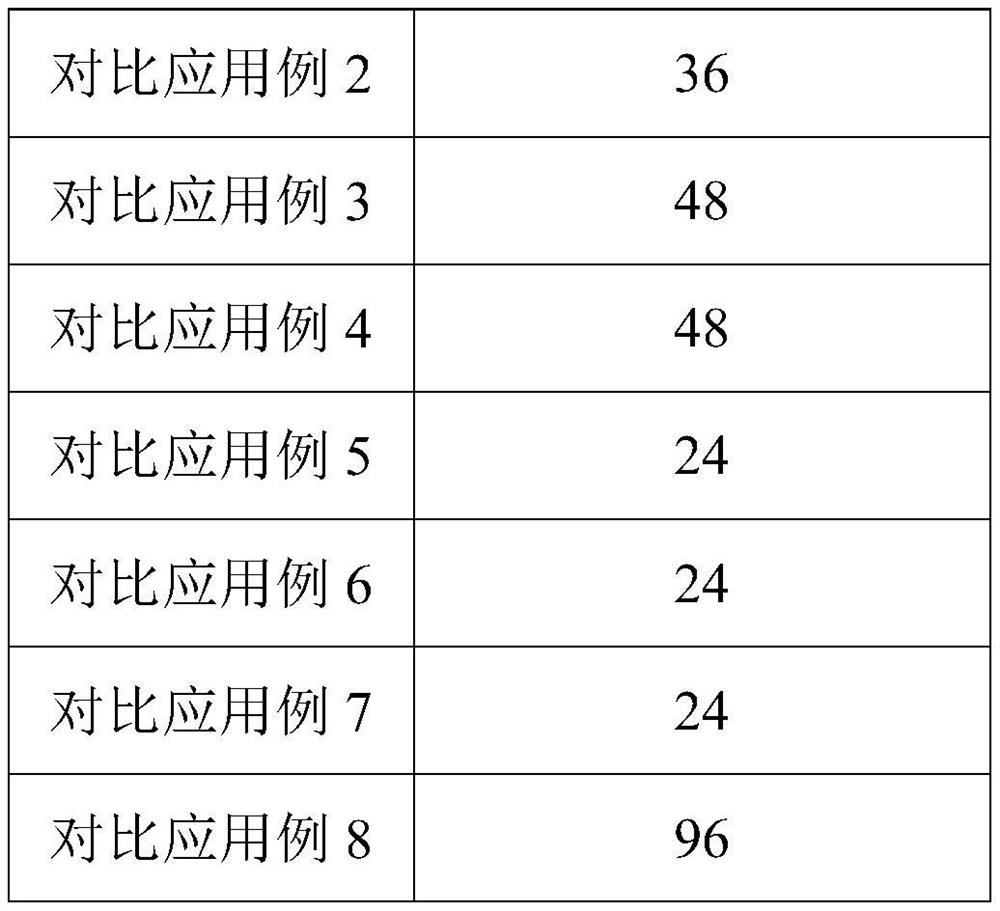

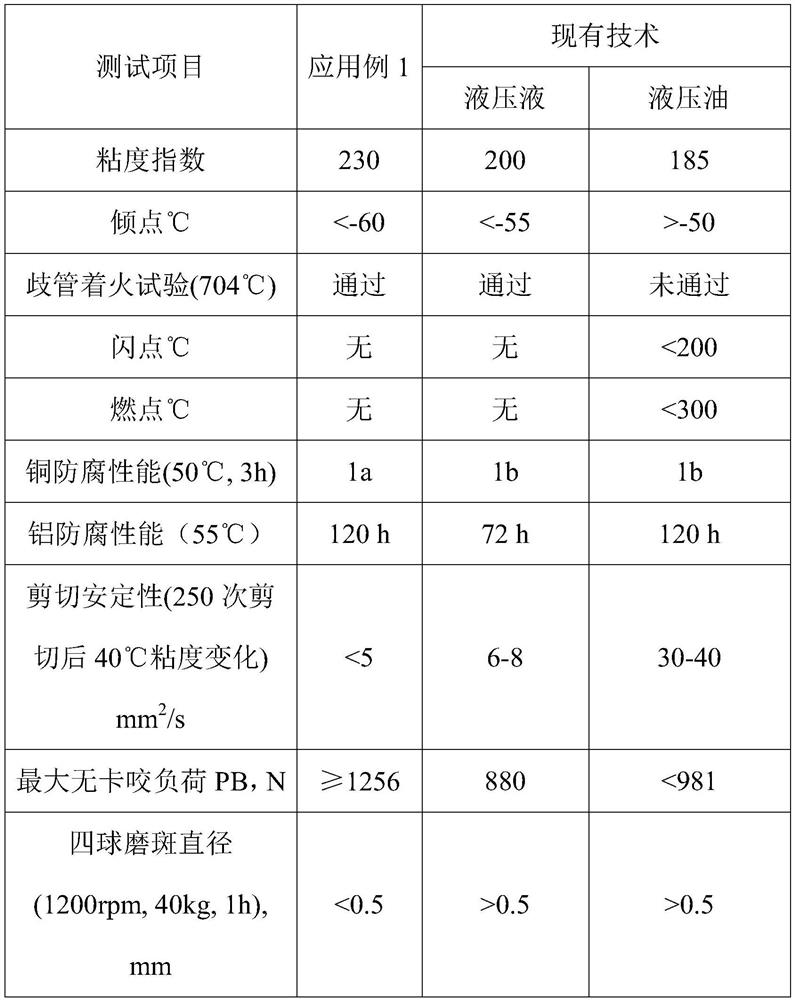

Compound preservative as well as preparation method and application thereof

ActiveCN114231336AGood anti-corrosion and anti-corrosion effectGood water solubilityAdditivesPhosphoric Acid EstersPhosphate

The invention relates to a compound preservative as well as a preparation method and application thereof. The compound preservative comprises an alcohol amine compound, a phenyl azole / thiazole compound and alkanolamide phosphate. Alcohol amine compounds, phenyl azole / thiazole compounds and alkanolamide phosphate in the compound preservative are matched with one another and have a synergistic effect on corrosion resistance and corrosion prevention of metal materials, and the hydraulic fluid prepared from the compound preservative is high in flame resistance and environment-friendly, has good metal corrosion resistance and can be applied to the field of hydraulic engineering. Particularly, the coating has good aluminum corrosion resistance, and has important application value in the fields of door closers and the like.

Owner:QUAKER CHEM CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com