Metal cleaning agent and preparing method thereof

A metal cleaning agent and builder technology, applied in the field of oil cleaning agent, can solve the problems of precision components processing confusion, poor rinsing performance, long cleaning time, etc., achieve excellent metal corrosion resistance, strong ability to remove heavy oil, and use The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

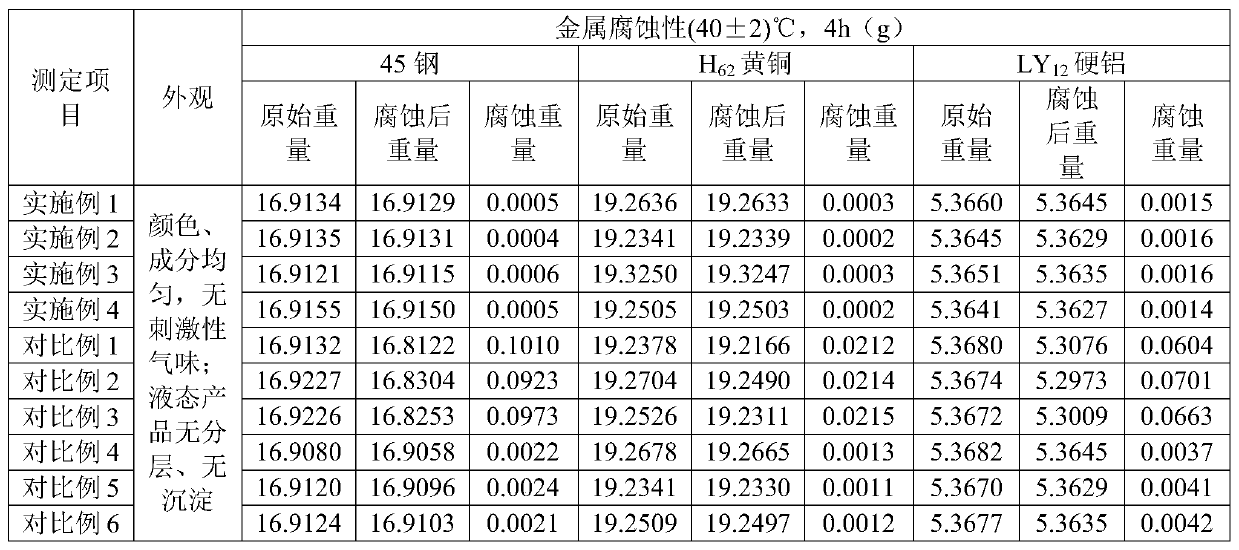

Embodiment 1

[0026] Preparation of builder: disperse graphene oxide in a mixed solution containing ethylene glycol and water to obtain a dispersion of graphene oxide, and the dispersion of graphene oxide is mixed with 4 under the conditions of pH 9 and temperature 100°C -Amination reaction of aminophenylboronic acid, heat preservation reaction for 2 hours, washing with ethanol aqueous solution, and drying to obtain the builder. Wherein, the weight ratio between the amount of graphene oxide and the amount of 4-aminophenylboronic acid is 1:0.7.

[0027] The function of the mixed solution of ethylene glycol and water is to disperse the graphene oxide, and dissolve the 4-aminophenylboronic acid in the dispersion of the graphene oxide, and carry out an amination reaction between the graphene oxide and the 4-aminophenylboronic acid; The total amount of the mixed liquid of ethylene glycol and water and the weight ratio of the amount of ethylene glycol and water can be used as long as the above pu...

Embodiment 2

[0030] Preparation of builder: disperse graphene oxide in a mixed solution containing ethylene glycol and water to obtain a dispersion of graphene oxide, and the dispersion of graphene oxide is mixed with 4 -Amination reaction of aminophenylboronic acid, heat preservation reaction for 3.5 hours, washing with ethanol aqueous solution, and drying to obtain the builder. Wherein, the weight ratio between the amount of graphene oxide and the amount of 4-aminophenylboronic acid is 1:0.8. In this embodiment, a mixture of ethylene glycol and water with a weight ratio of 1:1 is selected, and the weight ratio of the total amount of the mixture of ethylene glycol and water to graphene oxide is 5:1.

[0031] Preparation of metal cleaning agent: In terms of weight percentage, mix 4% of builder and 15% of diethylene glycol monobutyl ether evenly, then add 2% of Gray lan826 corrosion inhibitor, 2% of diethanolamine, isooctyl alcohol Polyoxyethylene polyoxypropylene ether 2%, sodium lauryl s...

Embodiment 3

[0033] Preparation of builder: disperse graphene oxide in a mixed solution containing ethylene glycol and water to obtain a graphene oxide dispersion, and the graphene oxide dispersion is mixed with 4 under the conditions of pH 11 and temperature 90°C -Amination reaction of aminophenylboronic acid, heat preservation reaction for 5 hours, washing with ethanol aqueous solution, and drying to obtain the builder. Wherein, the weight ratio between the amount of graphene oxide and the amount of 4-aminophenylboronic acid is 1:0.9. In this embodiment, a mixture of ethylene glycol and water with a weight ratio of 1:1 is selected, and the weight ratio of the total amount of the mixture of ethylene glycol and water to graphene oxide is 5:1.

[0034] Preparation of metal cleaning agent: by weight percentage, mix builder 3% and dipropylene glycol monobutyl ether 5% evenly, then add imidazoline 2.5%, triethanolamine 2.5%, lauryl alcohol atactic polyether 3% , sodium lauryl sulfate 2%, sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com