Down-hole liquid release device and method for oil and gas fields

A release device, oil and gas field technology, applied in earth-moving drilling, wellbore/well components, cleaning appliances, etc., can solve the problems of difficult to control the release speed, difficult to ensure uniform release of drugs, etc., to achieve the effect of continuous release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

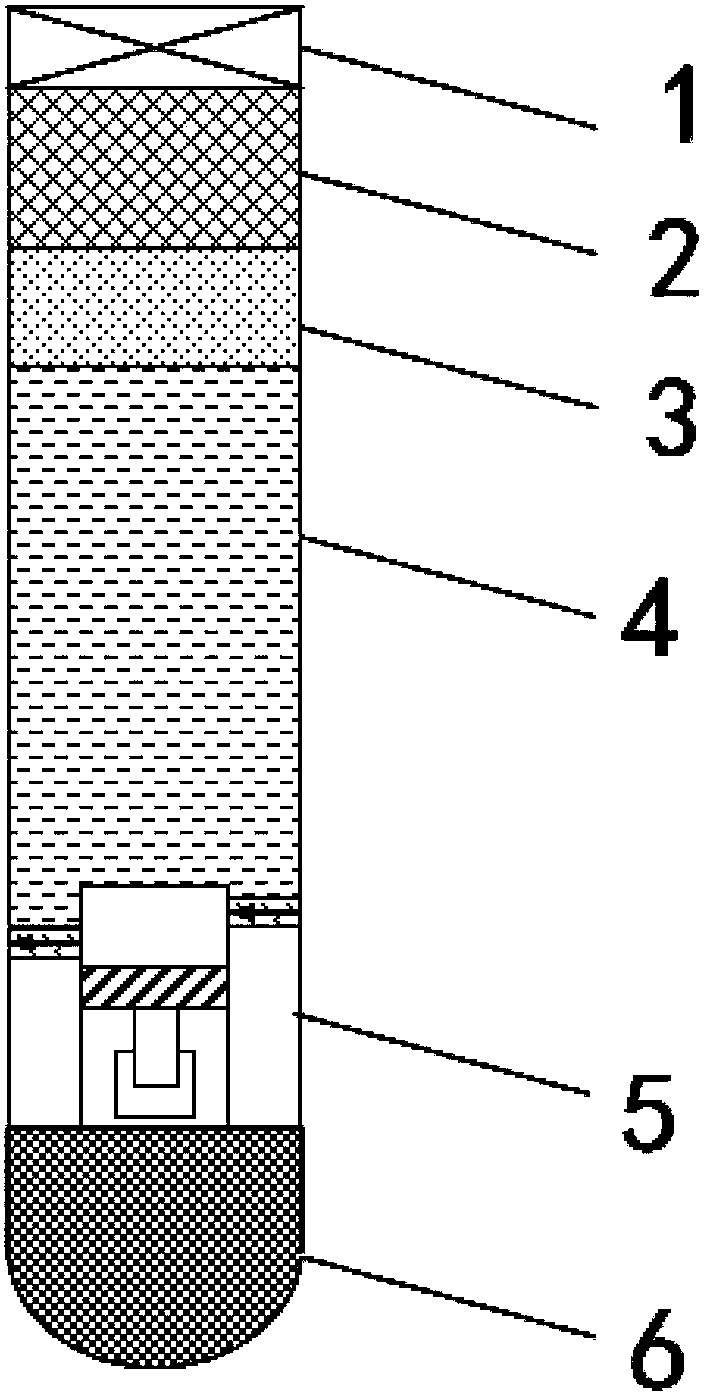

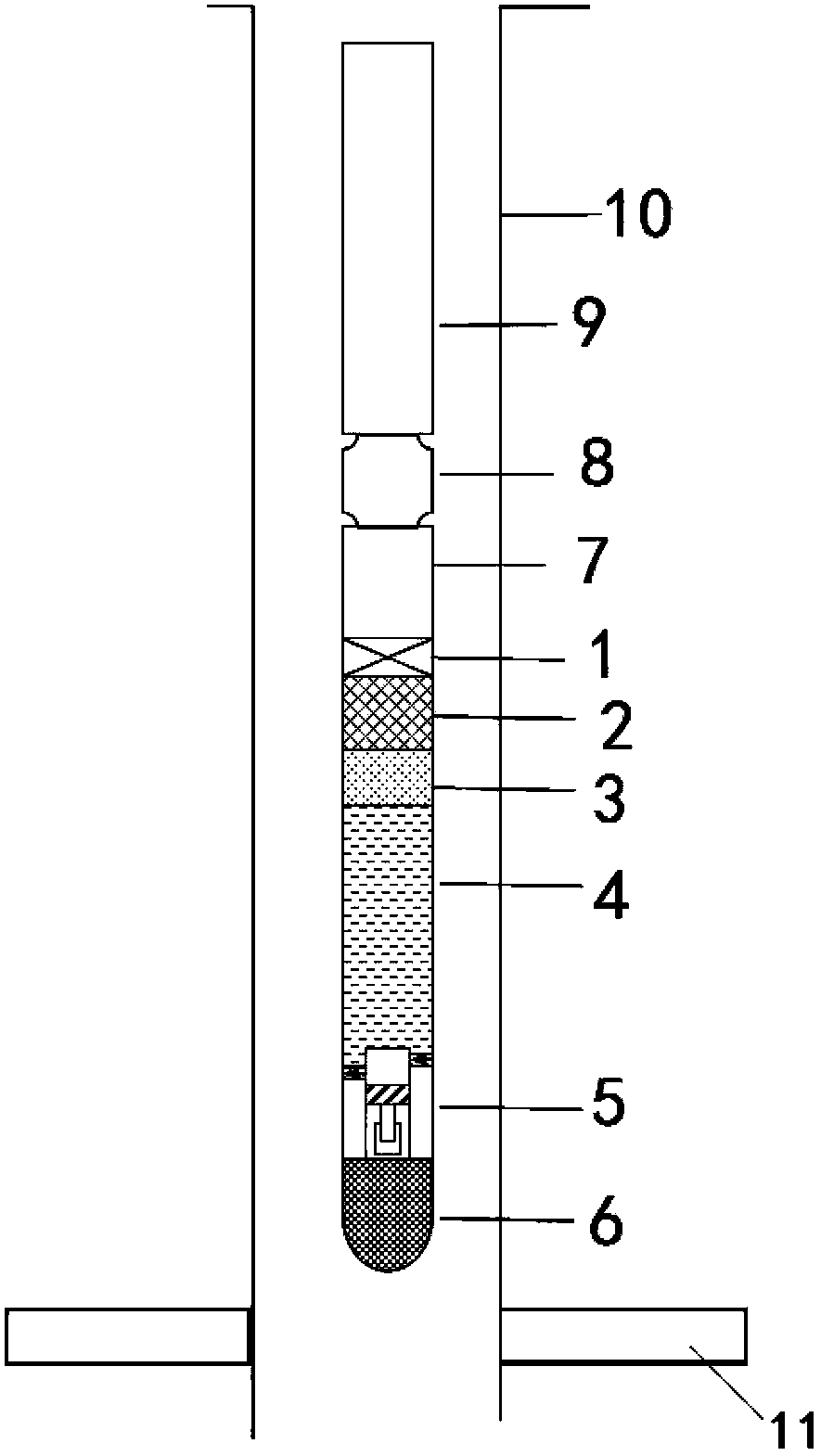

[0019] Embodiment 1: as figure 1 , figure 2 as shown,

[0020] In the figure, 01 plug, 02 liquid inlet pipe, 03 separation liquid, 04 liquid storage pipe, 05 piston pump, 06 battery nipple

[0021] 01 Plug, 02 Inlet pipe, 03 Partition liquid, 04 Storage pipe, 05 Piston pump, 06 Battery nipple

[0022] A downhole liquid release device for oil and gas fields, consisting of a plug 1, a liquid inlet pipe 2, a separation liquid 3, a liquid storage pipe 4, a piston pump 5, and a battery nipple 6; the battery nipple 6 is connected to the piston through a collar and a thread The pump 5 and the piston pump 5 are connected to the liquid storage pipe 4 through a coupling and a threaded thread, the liquid storage pipe 4 is connected to the liquid inlet pipe 2 through a coupling and a threaded thread, the liquid inlet pipe 2 is connected to the plug 1 through a coupling and a threaded thread, and the storage There is a separation liquid 3 or a separation liquid layer between the liquid...

Embodiment 2

[0025] Taking an oil well as an example, the well casing is API standard 5 1 / 2 Well Production Tubing is API Standard 2 7 / 8 Oil pipe, the average pump inspection cycle is 1 year, the daily liquid production volume is 50 cubic meters, and the liquid production density is 0.92g / cm 3 , in order to ensure the normal production of the oil well, it is necessary to continuously add 20ppm of oil with a density of 1.2g / cm2 to the well every day 3 Drug A.

[0026] Calculate and set the release speed of the piston pump to 0.58ml / min based on the above data. When the oil well is completed, connect the battery nipple to the piston pump and 11 2 7 / 8 Liquid storage tube, add 365 kg (about 304 liters) of drug A to the liquid storage tube, and then add 3 kg 3 separator fluid. Connect the inlet tube and plug. Finally, the device is connected to the lowermost end of the production tubing through a coupling. Since the plug is at the uppermost end, the device is not directly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com