A kind of cooling liquid for wind power generating set and preparation method thereof

A cooling liquid and wind power technology, applied in the chemical industry, can solve the problems of aging insulation pipeline, large leakage current of electrical conductivity, generator flashover, etc., to prevent metal corrosion, excellent metal corrosion resistance, and meet the cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below by embodiment:

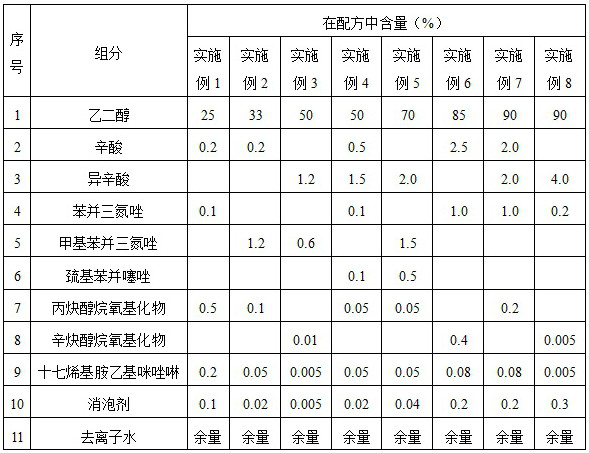

[0022] The formula of the low-conductivity wind power cooling liquid of the present invention has been subjected to a large number of screening experiments, and a formula combination with reasonable economy and excellent technology has been obtained. The specific components and ratios of each embodiment are shown in Table 1. The preparation method comprises the following steps: put ethylene glycol and deionized water into the reaction kettle according to the amount of each substance stipulated in the formula, stir at room temperature for 10 minutes, and then mix the aliphatic monobasic acid, azole compound, compound Put the corrosion inhibitor into the reaction kettle one by one, stir at room temperature for 40 minutes, then add the defoamer until it is completely dissolved.

[0023] Table 1 Composition and proportion of wind power cooling fluid

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com