A polythiophene composite metal anti-corrosion coating influenced by morphology, preparation method and application thereof

A composite metal and anti-corrosion coating technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of difficult control of stability and repeatability, inability to synthesize on a large scale, insufficient stability of performance, etc., and achieve excellent environmental and chemical stability, excellent Effect of metal anticorrosion performance and high redox potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

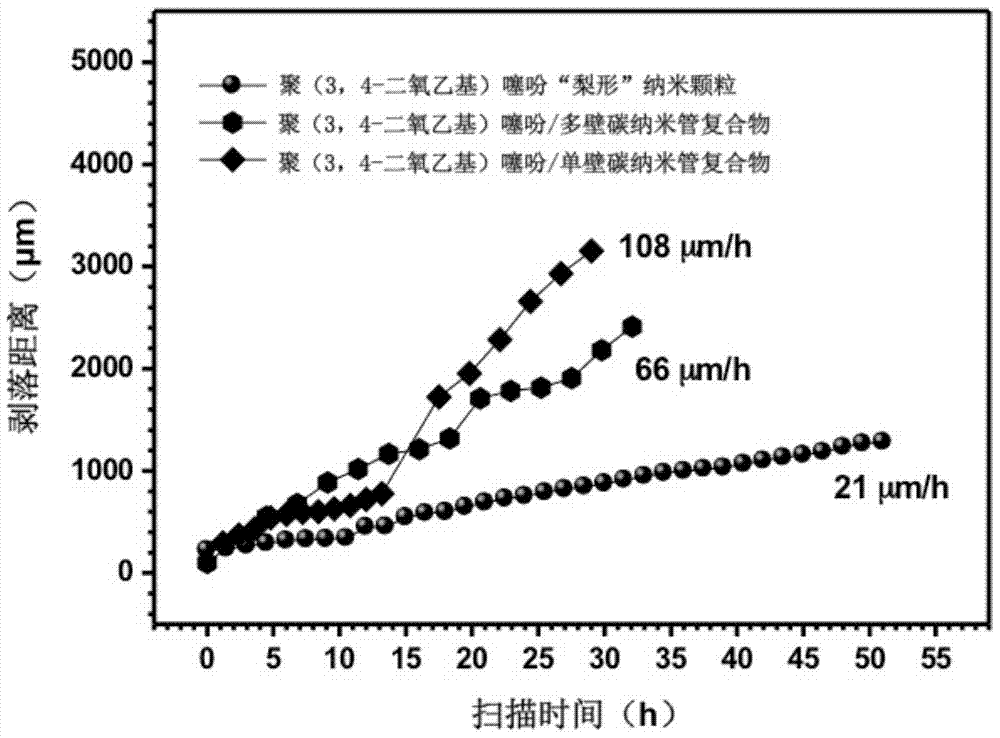

Embodiment 1

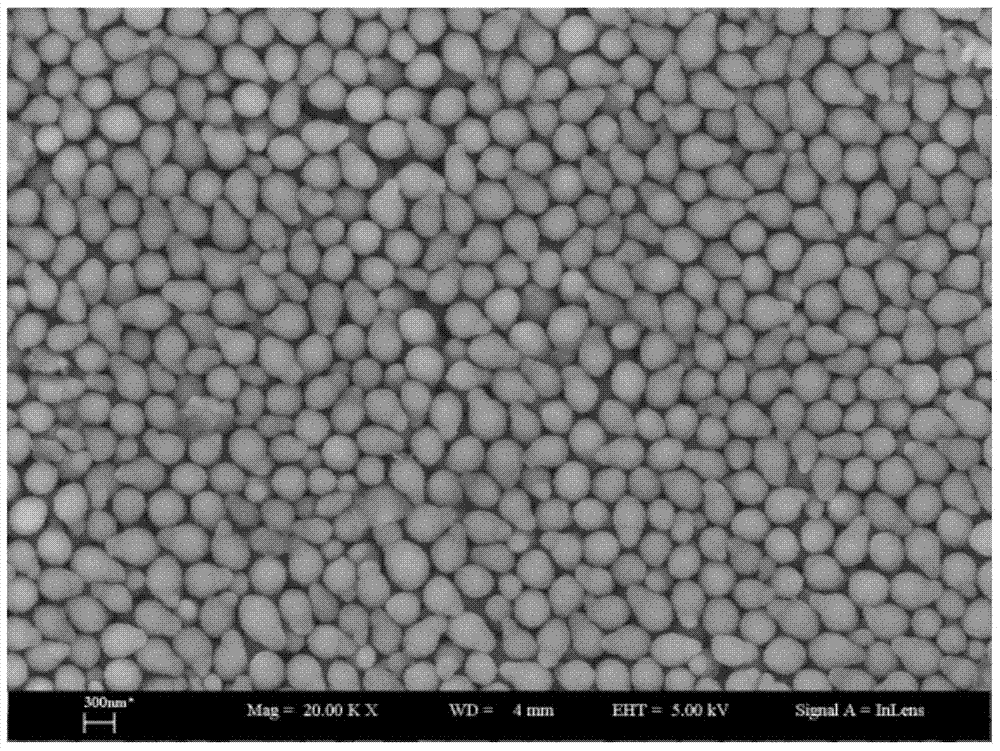

[0057] Preparation of "Pear Shaped" Nanoparticles of Poly(3,4-Dioxyethyl)thiophene:

[0058] 1) Dissolve polyvinylpyrrolidone in water and acetonitrile mixed solution with a volume ratio of 4:1, stir evenly, and prepare a water / acetonitrile mixed solution of polyvinylpyrrolidone with a concentration of 0.05mmol / L;

[0059] 2) Add 0.2mL monomeric (3,4-dioxyethyl)thiophene to the above solution, and sonicate for 0.5h to obtain a uniformly dispersed mixed solution;

[0060] 3) Add a certain volume of ammonium persulfate aqueous solution to the above solution, wherein the molar ratio of ammonium persulfate to monomer (3,4-dioxyethyl)thiophene (EDOT) is 2:1, forming a total volume of 100mL The polymerization system was continuously stirred, and the chemical polymerization reaction was carried out at room temperature for 48 hours to obtain a black mixed solution of "pear-shaped" nanoparticles containing poly(3,4-dioxyethyl)thiophene;

[0061] 4) Centrifuge the above black mixed sol...

Embodiment 2

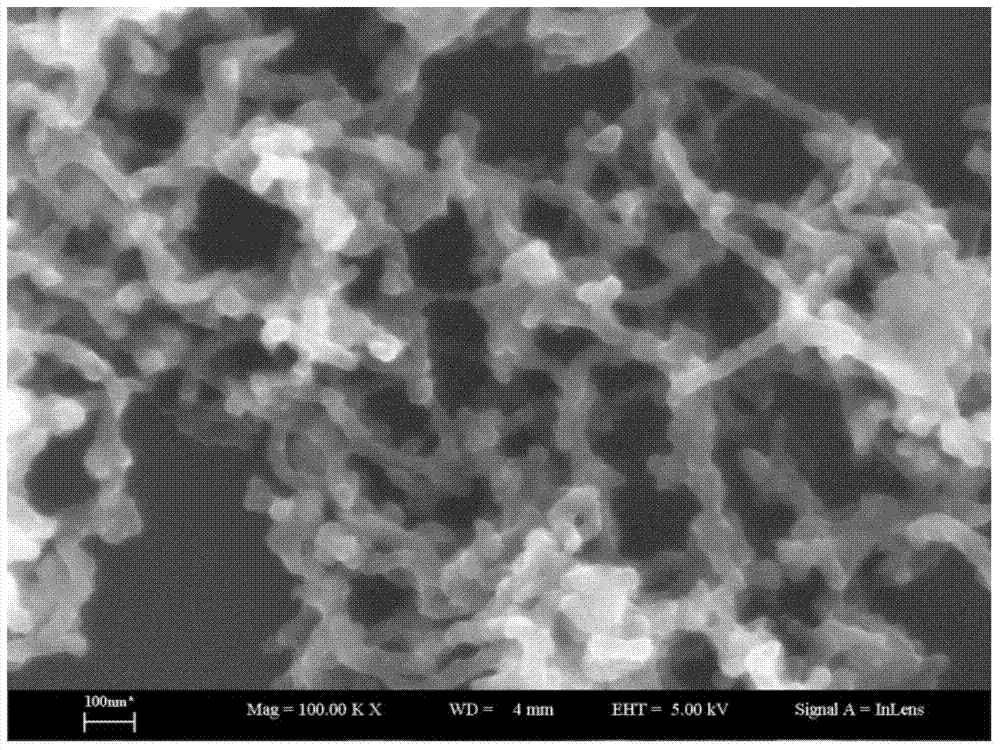

[0068] Preparation of composite nanofibers of poly(3,4-dioxyethyl)thiophene and multi-walled carbon nanotubes:

[0069] 1) Dissolve polyvinylpyrrolidone in water and acetonitrile mixed solution with a volume ratio of 4:1, and stir evenly to obtain a water / acetonitrile mixed solution of polyvinylpyrrolidone with a concentration of 1 mmol / L;

[0070] 2) adding 0.0162 g of multi-walled carbon nanotubes to the above solution, and ultrasonically dispersing for 1 hour to obtain a suspension containing multi-walled carbon nanotubes;

[0071] 3) Add 0.32 mL monomer (3,4-dioxyethyl) thiophene to the above solution, and sonicate for 2 hours to obtain a uniformly dispersed mixed solution;

[0072] 4) Add a certain volume of ammonium persulfate aqueous solution to the above solution, wherein the molar ratio of ammonium persulfate to monomer EDOT is 2:1 to form a polymerization system with a total volume of 100mL, keep stirring, and carry out chemical polymerization reaction at room temper...

Embodiment 3

[0080] Preparation of composite nanofibers of poly(3,4-dioxyethyl)thiophene and single-walled carbon nanotubes:

[0081] 1) Dissolve polyvinylpyrrolidone in water and acetonitrile mixed solution with a volume ratio of 4:1, and stir evenly to obtain a water / acetonitrile mixed solution of polyvinylpyrrolidone with a concentration of 1 mmol / L;

[0082] 2) Add 0.0162 g of single-walled carbon nanotubes to the above solution, and ultrasonically disperse for 1 hour to obtain a suspension containing multi-walled carbon nanotubes;

[0083] 3) Add 0.32 mL monomer (3,4-dioxyethyl) thiophene to the above solution, and sonicate for 2 hours to obtain a uniformly dispersed mixed solution;

[0084]4) Add a certain volume of ammonium persulfate aqueous solution to the above solution, wherein the molar ratio of ammonium persulfate to monomer EDOT is 2:1 to form a polymerization system with a total volume of 100mL, keep stirring, and carry out chemical polymerization reaction at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com