New energy automobile power battery cooling liquid, preparation method and application

A technology for new energy vehicles and power batteries, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as electric shock hazards, and achieve the effects of low electrical conductivity and excellent metal anti-corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

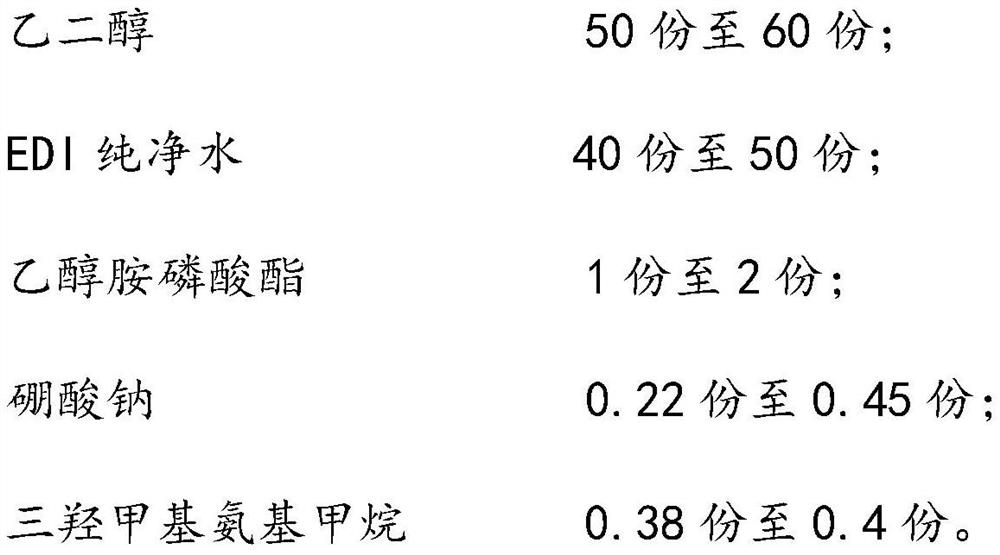

[0026] This embodiment discloses a new energy vehicle power battery coolant, which includes the following substances in parts by mass:

[0027]

[0028] Put the above raw materials into the reaction kettle according to the number of parts by mass; stir and mix for 30 to 90 minutes to fully dissolve and mix the components uniformly; pass the obtained mixed solution through a pressure pump through a mixed anion and cation exchange resin to obtain a new energy vehicle battery antifreeze cooling system liquid.

Embodiment 2

[0030] The main difference between this embodiment and embodiment 1 is as follows:

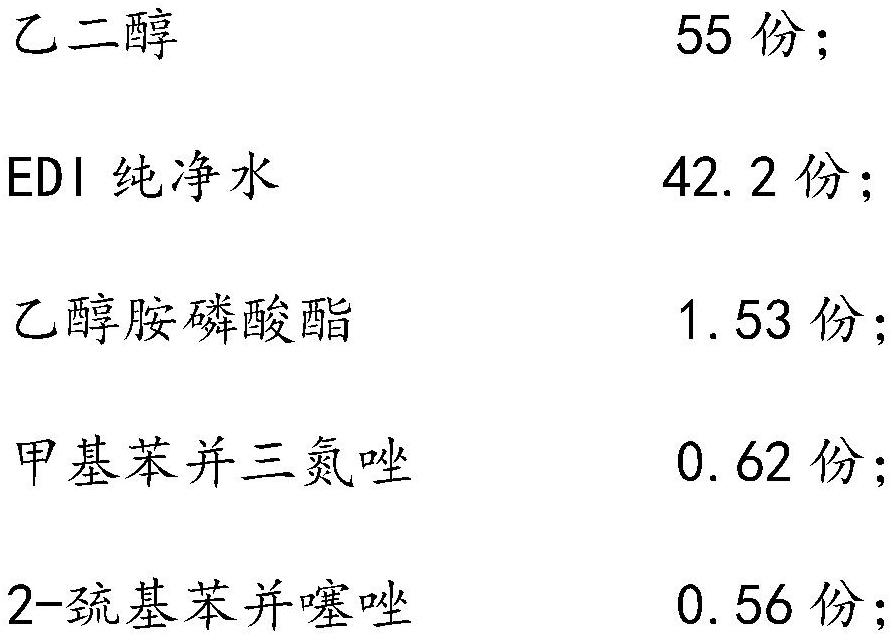

[0031] A new energy vehicle power battery coolant, comprising the following substances in parts by mass:

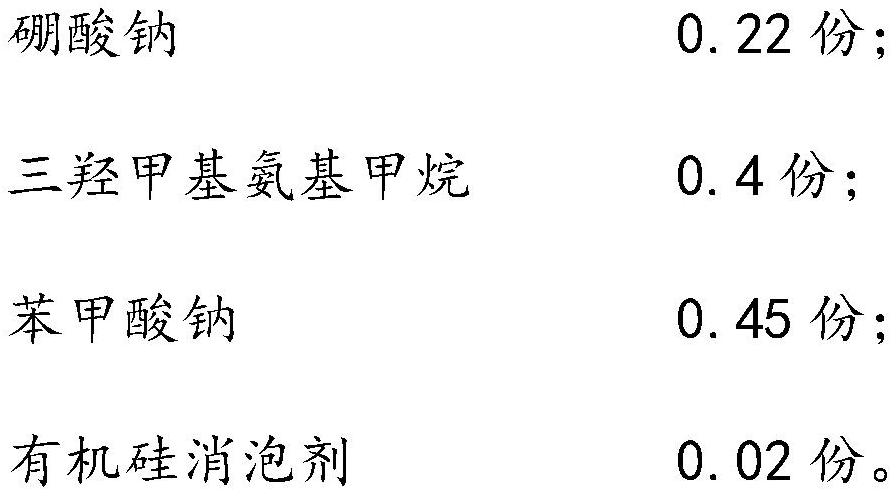

[0032]

[0033]

Embodiment 3

[0035] The main difference between this embodiment and embodiment 1 is as follows:

[0036] A new energy vehicle power battery coolant, comprising the following substances in parts by mass:

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com