Low-carbon environment-friendly anticorrosive paint and preparation method thereof

An anti-corrosion coating, low-carbon and environmentally friendly technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as poor anti-corrosion performance, unsatisfactory weather resistance and corrosion resistance, and high organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

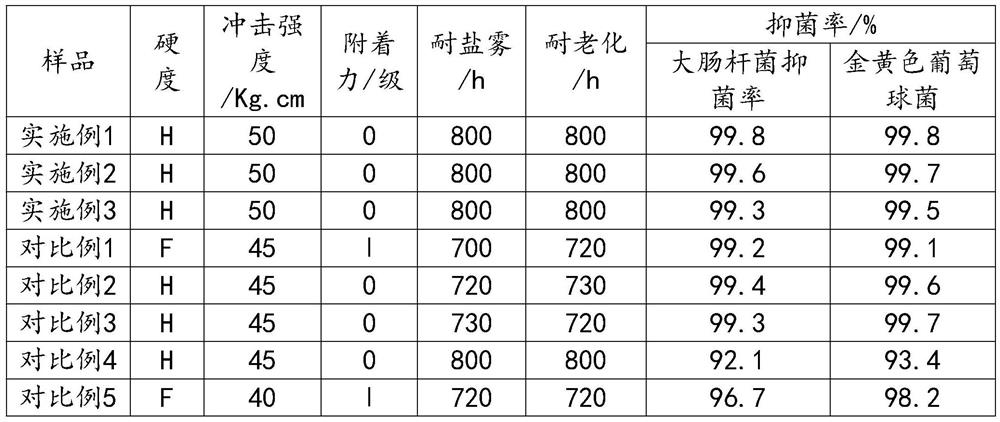

Examples

Embodiment 1

[0033] A kind of low-carbon environment-friendly anticorrosion coating, comprises the raw material of following weight part: Composite powder 25 parts, organosilicon modified polypropylene resin 15 parts, inorganic filler 0.5 part, organic solvent 1 part, deionized water 35 parts, modified concave-convex 10 parts of stick clay, 0.5 parts of compound antibacterial agent;

[0034] The preparation method of this low-carbon environmental protection anticorrosion paint is:

[0035] The first step is to weigh the composite powder, silicone modified polypropylene resin, inorganic filler, organic solvent, deionized water, modified attapulgite and composite antibacterial agent according to the proportioning requirements, and set aside;

[0036] In the second step, the composite powder, modified attapulgite and composite antibacterial agent are sequentially added into the mixing tank, and stirred at room temperature at a speed of 500r / min for 30min to obtain a mixture;

[0037] The third...

Embodiment 2

[0053] A kind of low-carbon environmental protection anticorrosion coating, comprises the raw material of following parts by weight: 40 parts of composite powders, 25 parts of organosilicon modified polypropylene resins, 1 part of inorganic fillers, 2 parts of organic solvents, 40 parts of deionized water, modified embossed 13 parts of stick clay, 0.8 parts of compound antibacterial agent;

[0054] The preparation method of this low-carbon environmental protection anticorrosion paint is:

[0055] The first step is to weigh the composite powder, silicone modified polypropylene resin, inorganic filler, organic solvent, deionized water, modified attapulgite and composite antibacterial agent according to the proportioning requirements, and set aside;

[0056] In the second step, the composite powder, modified attapulgite and composite antibacterial agent are sequentially added into the mixing tank, and stirred at room temperature at a speed of 1000r / min for 40min to obtain a mixtu...

Embodiment 3

[0073] A low-carbon environment-friendly anti-corrosion coating, comprising the following raw materials in parts by weight: 55 parts of composite powder, 30 parts of organosilicon-modified polypropylene resin, 2 parts of inorganic filler, 3 parts of organic solvent, 45 parts of deionized water, modified concave-convex 15 parts of stick clay, 1 part of compound antibacterial agent;

[0074] The preparation method of this low-carbon environmental protection anticorrosion paint is:

[0075] The first step is to weigh the composite powder, silicone modified polypropylene resin, inorganic filler, organic solvent, deionized water, modified attapulgite and composite antibacterial agent according to the proportioning requirements, and set aside;

[0076] In the second step, the composite powder, modified attapulgite and composite antibacterial agent are sequentially added into the stirring tank, and stirred at room temperature at a speed of 1500r / min for 60min to obtain a mixture;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com