A new energy vehicle power battery coolant and preparation method thereof

A new energy vehicle, power battery technology, applied in the direction of secondary batteries, chemical instruments and methods, circuits, etc., can solve the problem of high conductivity and achieve the effect of low conductivity and excellent metal anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

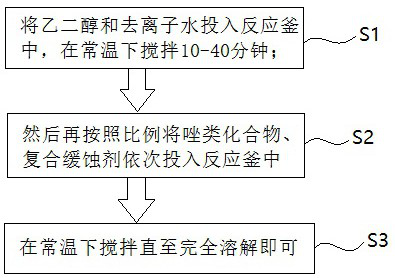

[0029] Below in conjunction with accompanying drawing, the present invention is further described:

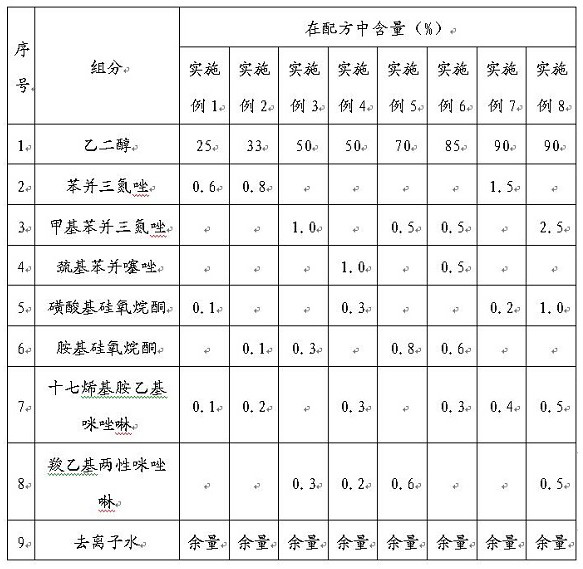

[0030] The invention provides a new energy vehicle power battery cooling liquid, which is prepared by mixing and stirring according to the following component proportions:

[0031] Components: Weight Percent:

[0032] Ethylene glycol 25%-95%;

[0033] azoles 0.5%-3%;

[0034] Composite corrosion inhibitor 0.2%-2%;

[0035] Deionized water balance;

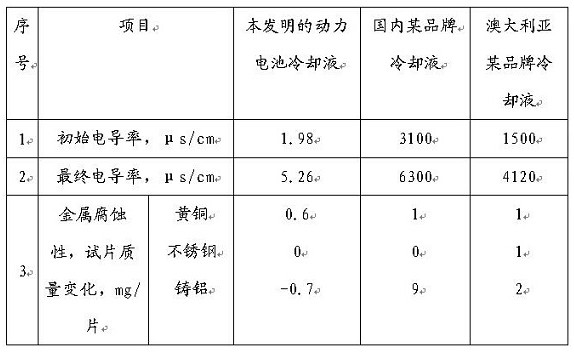

[0036] In the above scheme, the electrical conductivity of the cooling liquid does not exceed 20 μs / cm; the new energy vehicle power battery cooling liquid provided by the present invention is specially applied to the power battery cooling liquid of new energy vehicles, and the power battery cooling liquid does not contain inorganic salts, and the selected low The special composite corrosion inhibitor of electrical conductivity and azole compounds synergize, so that the power battery coolant has excellent antifreeze performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com