Cold work refrigerator oil additive

A technology of refrigeration machine oil and additives, applied in the direction of additives, petroleum industry, lubricating compositions, etc., which can solve the problems of reduced operating efficiency, increased energy consumption, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a kind of preparation method of refrigerating machine oil additive, comprises the following steps:

[0026] Step 1: Add the antioxidant to the aromatic hydrocarbon diluent at 50-60°C, stir for 20-25 minutes until uniform, and obtain intermediate product 1;

[0027] Step 2: Add the extreme pressure and anti-wear agent to the above-mentioned intermediate product 1 at 50-70°C, stir for 20-25 minutes until uniform, and obtain intermediate product 2;

[0028] Step 3: adding the metal deactivator to the above-mentioned intermediate product 2 at 50-70°C, and stirring for 20-25 minutes to obtain the intermediate product 3;

[0029] Step 4: Add the defoamer to the intermediate product 3 at 40-60° C., and stir for 40-45 minutes until uniform to obtain the refrigerating machine oil additive.

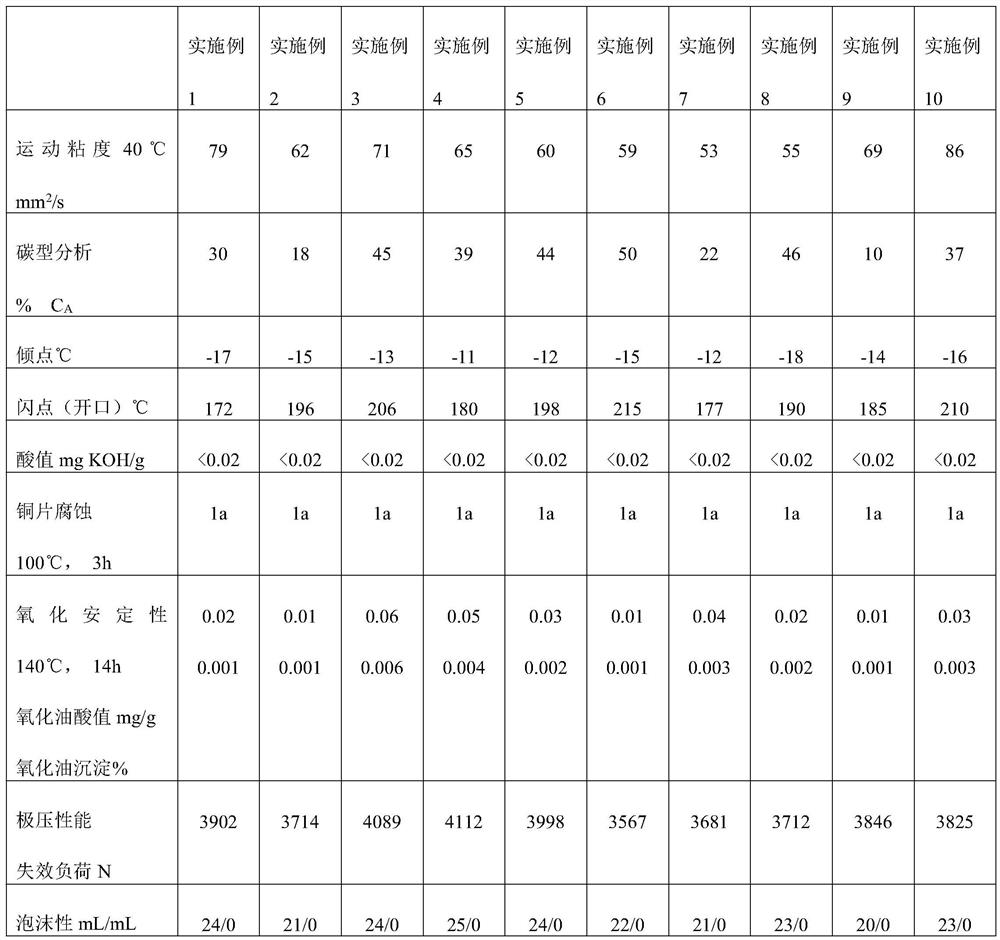

[0030] In order to verify the performance of the refrigerating machine oil additive of the present invention, the present invention has gone through mult...

Embodiment 1

[0032] The refrigerating machine oil additive includes the following raw materials in parts by weight: 32 parts of aromatic diluent, 11.6 parts of antioxidant, 7 parts of extreme pressure antiwear agent, 1.8 parts of metal deactivator, and 0.135 parts of defoamer.

Embodiment 2

[0034] The refrigerating machine oil additive includes the following raw materials in parts by weight: 34 parts of aromatic diluent, 11 parts of antioxidant, 6.8 parts of extreme pressure antiwear agent, 2 parts of metal deactivator, and 0.13 part of defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com