Patents

Literature

463 results about "Thiophosphoric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thiophosphoric acid is a chemical compound. Structurally, it is the acid derived from phosphoric acid with one extra sulfur atom, although it cannot be prepared from phosphoric acid. It is a colorless compound that is rarely isolated in pure form, but rather as a solution. The structure of the compound has not been reported, but two tautomers are reasonable: SP(OH)₃ and OP(OH)₂SH.

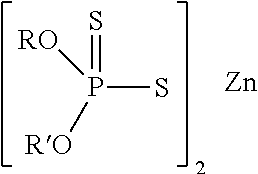

Premium wear resistant lubricant

A premium synthetic lubricant having antiwear properties comprises a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one antiwear additive. The antiwear additive is preferably at least one of a metal phosphate, a metal dialkyldithiophosphate, a metal dithiophosphate a metal thiocarbamate, a metal dithiocarbamate, an ethoxylated amine dialkyldithiophosphate and an ethoxylated amine dithiobenzoate. Metal dialkyldithiophosphates are preferred, particularly zincdialkyldithiophosphate (ZDDP). The base stock is derived from a waxy, Fischer-Tropsch synthesized hydrocarbon feed fraction comprising hydrocarbons having an initial boiling point in the range of about 650-750 DEG F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The lubricant may also contain hydrocarbonaceous and synthetic base stock material in admxture with the Fischer-Tropsch derived base stock.

Owner:EXXON RES & ENG CO

Preparation of phosphorothioate and boranophosphate oligomers

InactiveUS6160109AHigh diastereomeric excessLow costSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsOligomerDiastereomer

Owner:MCGILL UNIV +1

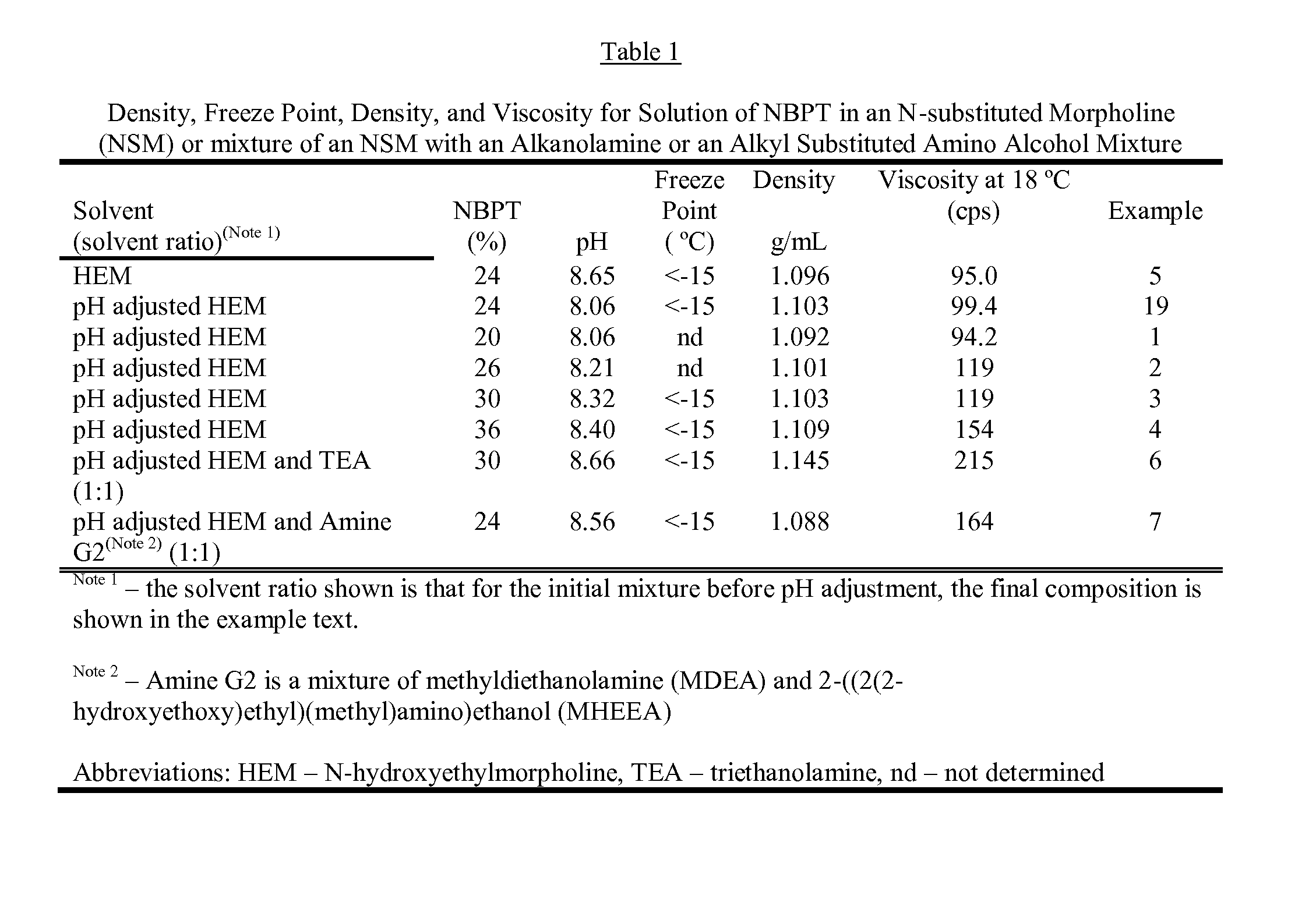

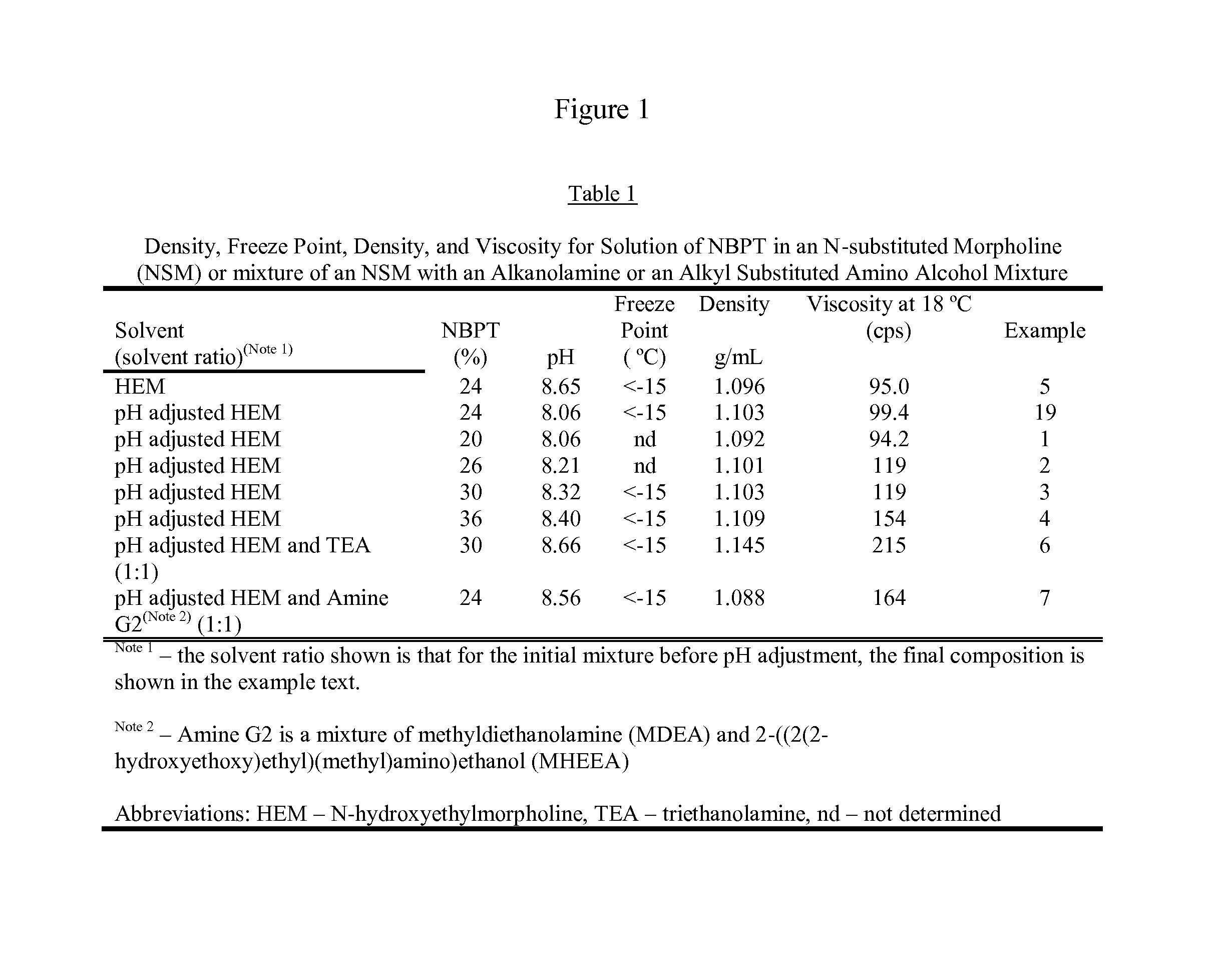

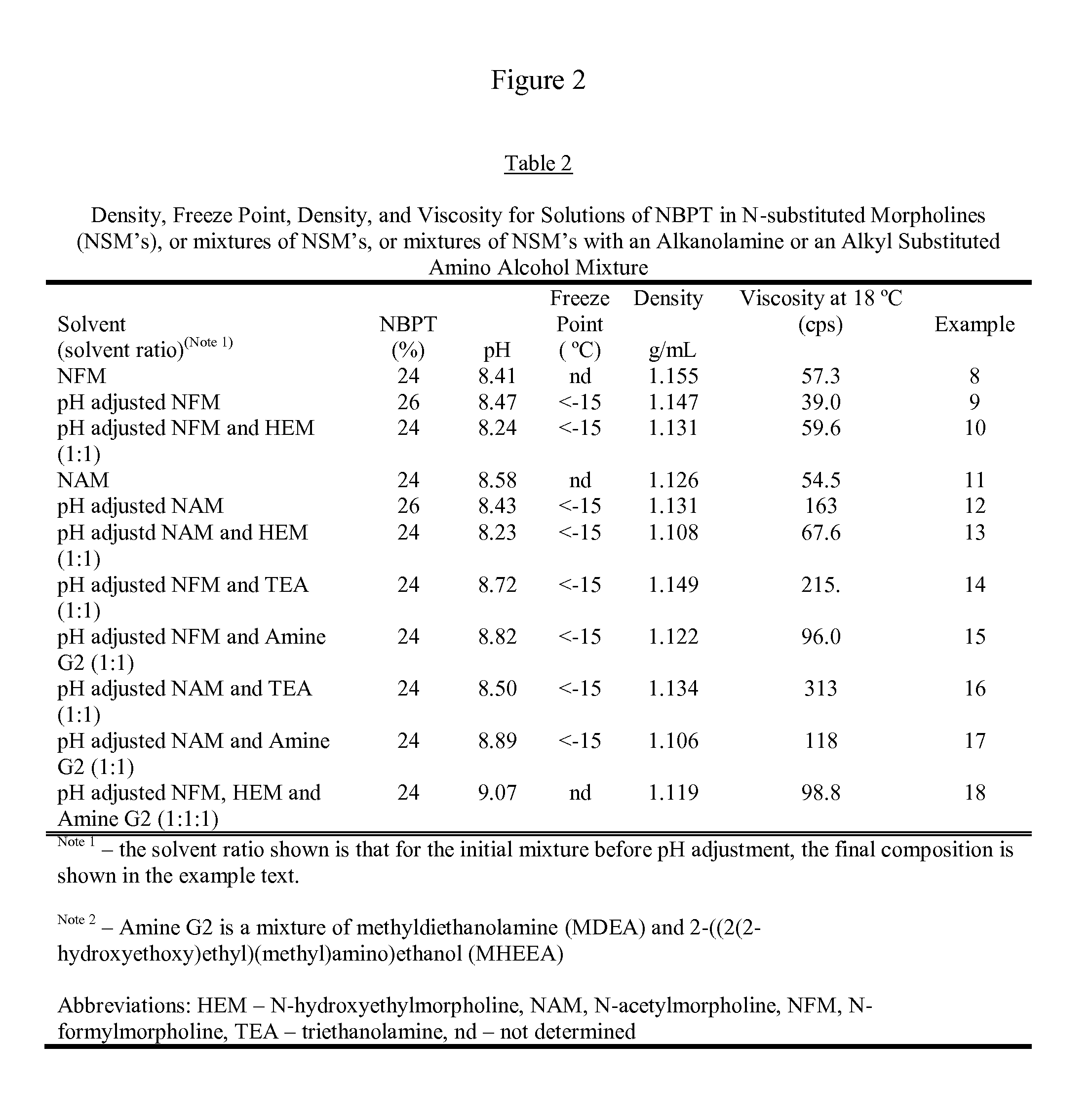

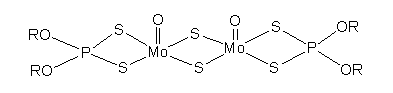

NBPT solutions for preparing urease inhibited urea fertilizers prepared from N-substituted morpholines

InactiveUS8888886B1Improve propertiesReduce concentrationBiocideOther chemical processesFertilizerUrine

Solutions are prepared by dissolving N-(n-butyl)-thiophosphoric triamide (NBPT) in one or more N-substituted morpholines and mixtures thereof. The solutions may be used in urea fertilizers to reduce nitrogen volatilization, or to reduce the odor of animal waste or urine. Methods of preparing urea fertilizers and the resultant products are also described.

Owner:WHITEHURST ASSOCS

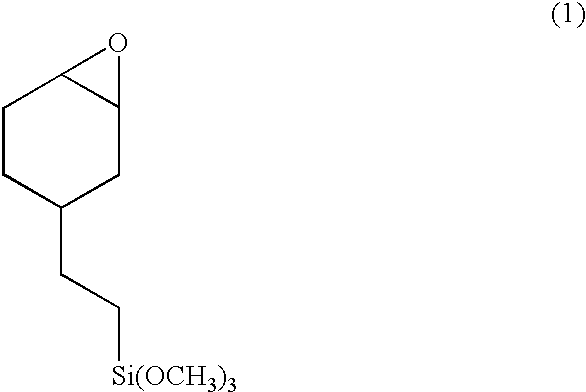

Chromium-free self-lubricating passivation solution and preparation method thereof

InactiveCN103290401AReduce coefficient of frictionImprove the lubrication effectMetallic material coating processesSilanesFirming agent

The invention discloses a chromium-free self-lubricating passivation solution and a preparation method thereof. The chromium-free self-lubricating passivation solution is formed by compounding the following compositions in percentage by weight: 8%-12% of water-borne epoxy resin, 0.5%-1% of curing agent, 10%-15% of silane coupling agent, 0.5%-1% of inorganic component, 2%-4% of solid lubricant, 1%-2% of friction modifier, 0.5%-1% of anti-wear agent, 0.5%-1% of anti-sinking agent, and 60%-75% of diluting agent. The inorganic component is one or a combination of Ce(NO3)3 and sodium molybdate, the solid lubricant is one or a combination of two or more of polytetrafluoroethylene, polyethylene wax, polyethylene, molybdenum disulfide and graphite, the friction modifier is self-synthesized molybdenum dialkyldithiophosphate, the anti-wear agent is one or a combination of nanosilicon dioxide and nano aluminum oxide, the anti-sinking agent is attapulgite, and the diluting agent is a mixture of water and ethanol. A plate product coated with passivation solution has the advantages of being pollution-free, low-friction, anti-oxidized, anti-wear and extreme pressure-resistant, corrosion-resistant, finger-resistant, having good mechanical performance and the like, and the passivation solution can be directly coated on the surfaces of a zinc-plated plate and parts of certain mechanical equipment for use.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

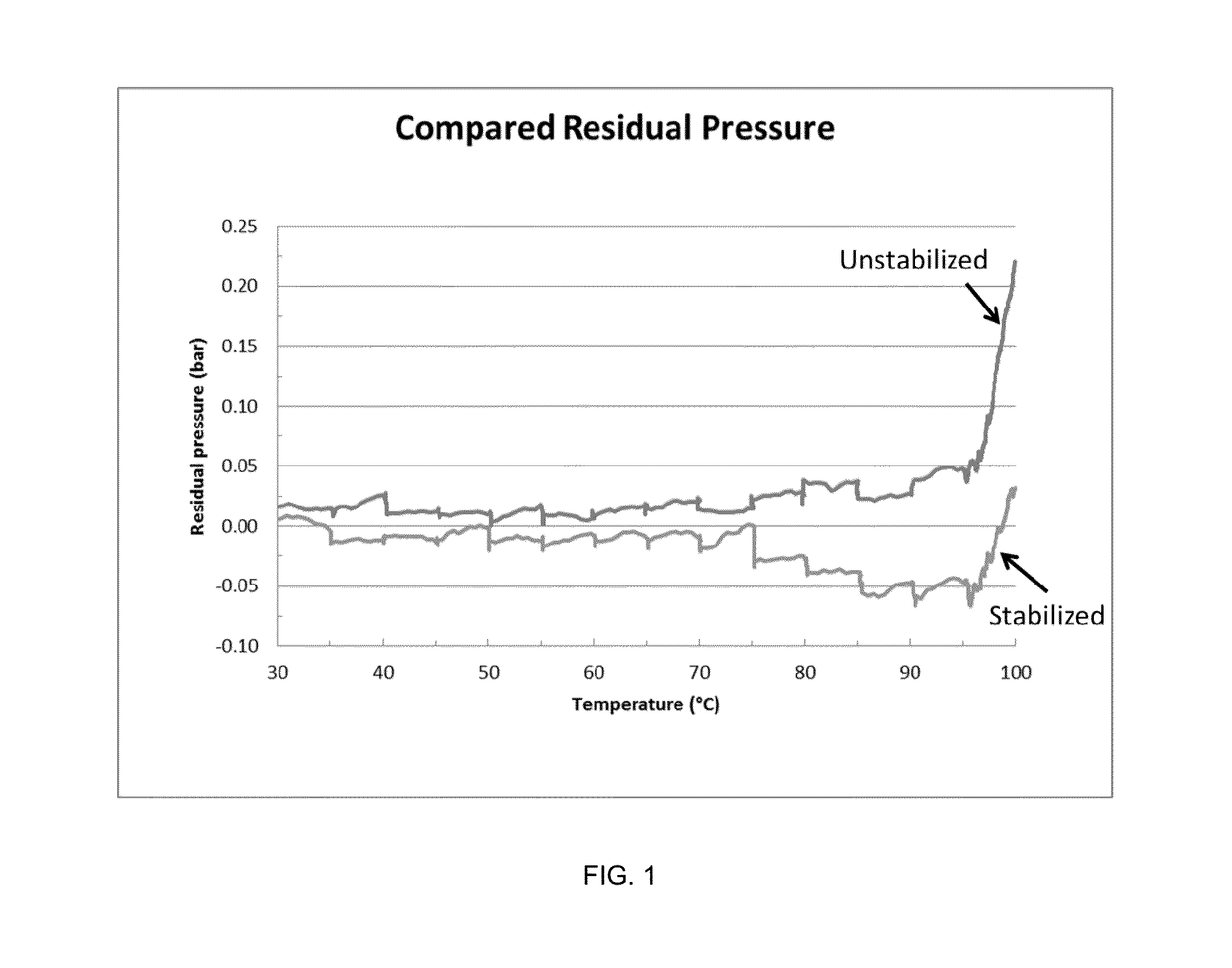

Phosphorus-containing stabilizers for fluoroolefins

ActiveUS20100301259A1Improve stabilityAvoid instabilityHeat-exchange elementsSolventAir conditioning

The present disclosure relates to compositions comprising at least one fluoroolefin and an effective amount of a stabilizer comprising at least one phosphorus-containing compound selected from the group consisting of thiophosphates, butylated triphenylphosphorothionates, and organophosphates. The stabilized compositions may be useful in cooling apparatus, such as refrigeration, air-conditioning, chillers and heat pumps, as well as in applications as foam blowing agents, solvents, aerosol propellants, fire extinguishants, and sterilants.

Owner:THE CHEMOURS CO FC LLC

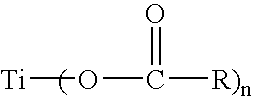

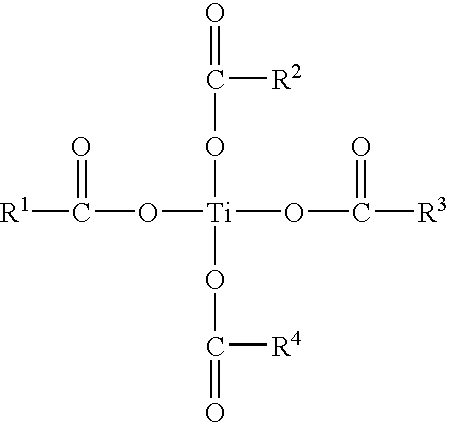

Titanium-containing lubricating oil composition

ActiveUS20070132274A1Improve fuel economyImprove wear characteristicsVehicle seatsWindowsTitanium metalPhysical chemistry

A lubricating oil composition comprising a) an oil of lubricating viscosity having a viscosity index of at least about 95; b) at least one calcium detergent; c) at least one oil soluble titanium compound; d) at least one friction modifier; and e) at least one metal dihydrocarbyldithiophosphate compound. The composition has a Noack volatility of about 15 wt. % or less, and contains from about 0.05 to about 0.6 wt. % calcium from the calcium detergent, titanium metal in an amount of at least about 10 ppm up to about 1500 ppm titanium from the titanium compound, and phosphorus from the metal dihydrocarbyldithiophosphate compound in an amount up to about 0.1 wt. %.

Owner:AFTON CHEMICAL

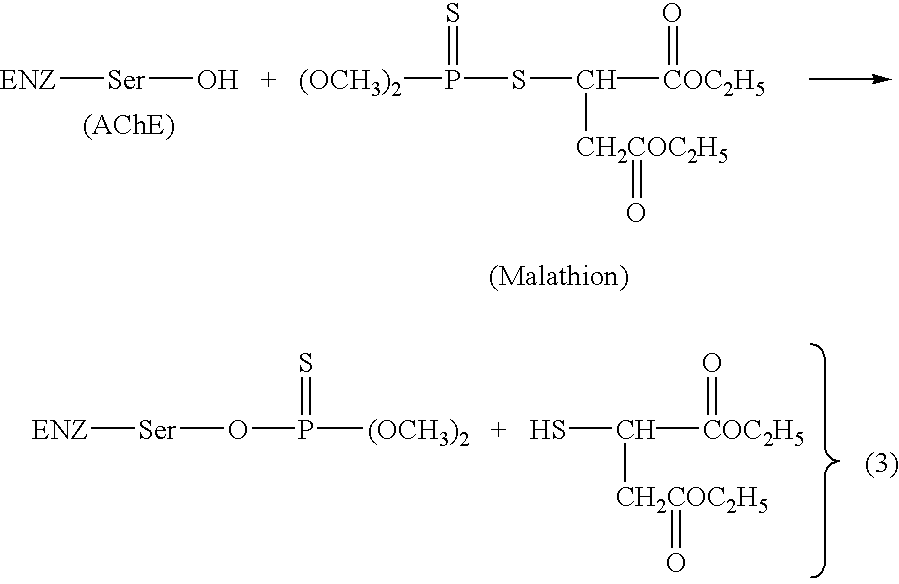

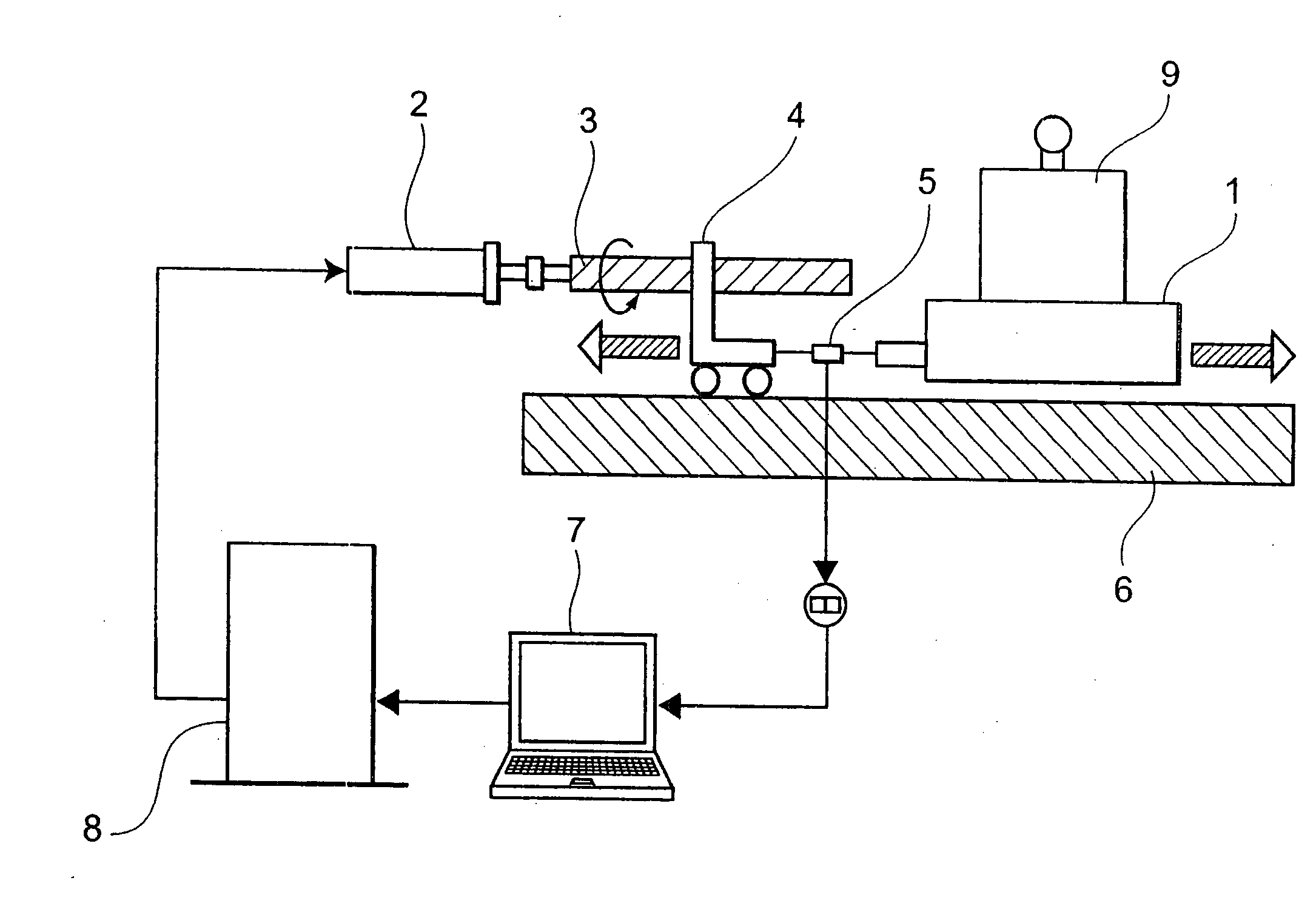

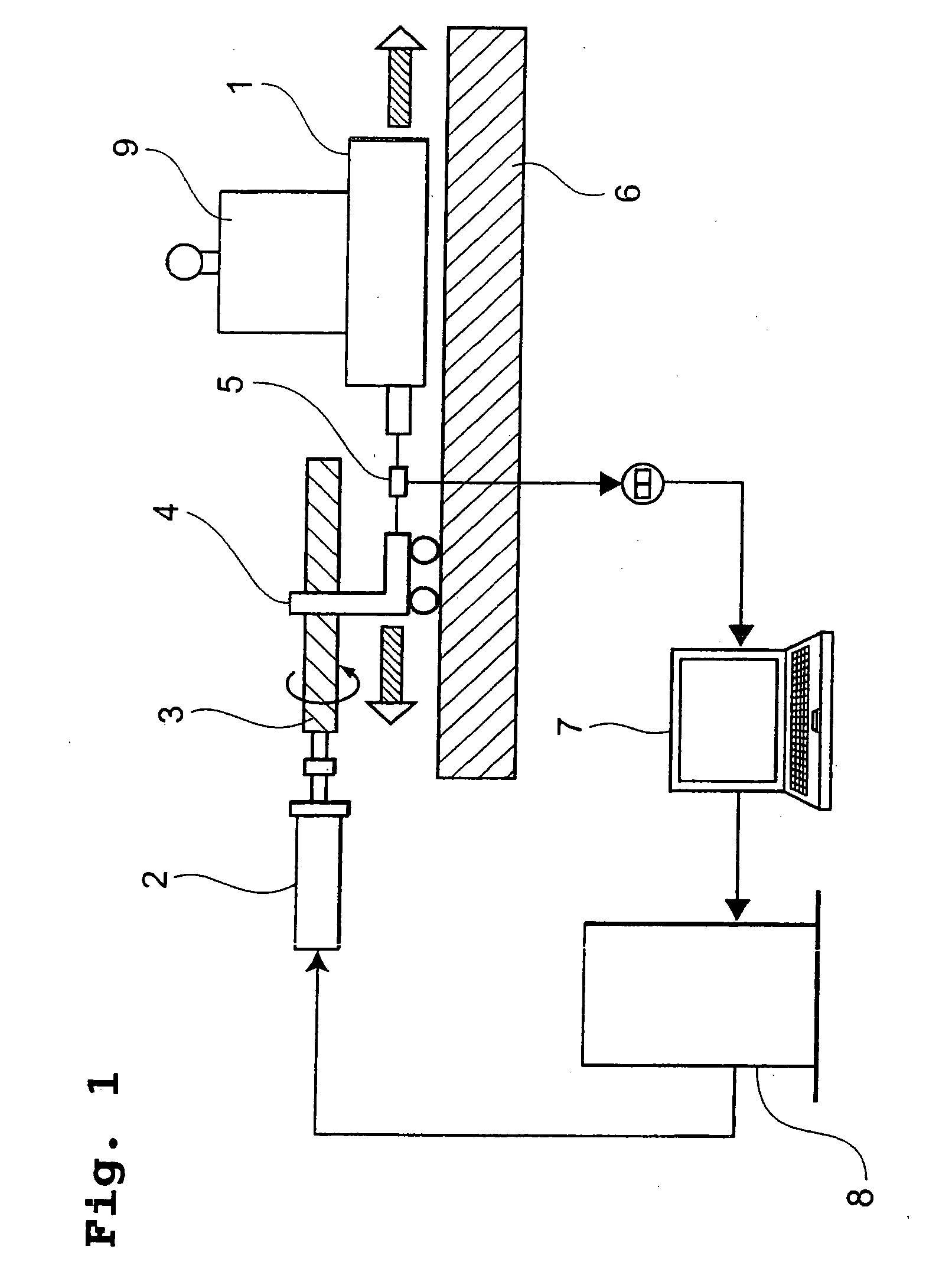

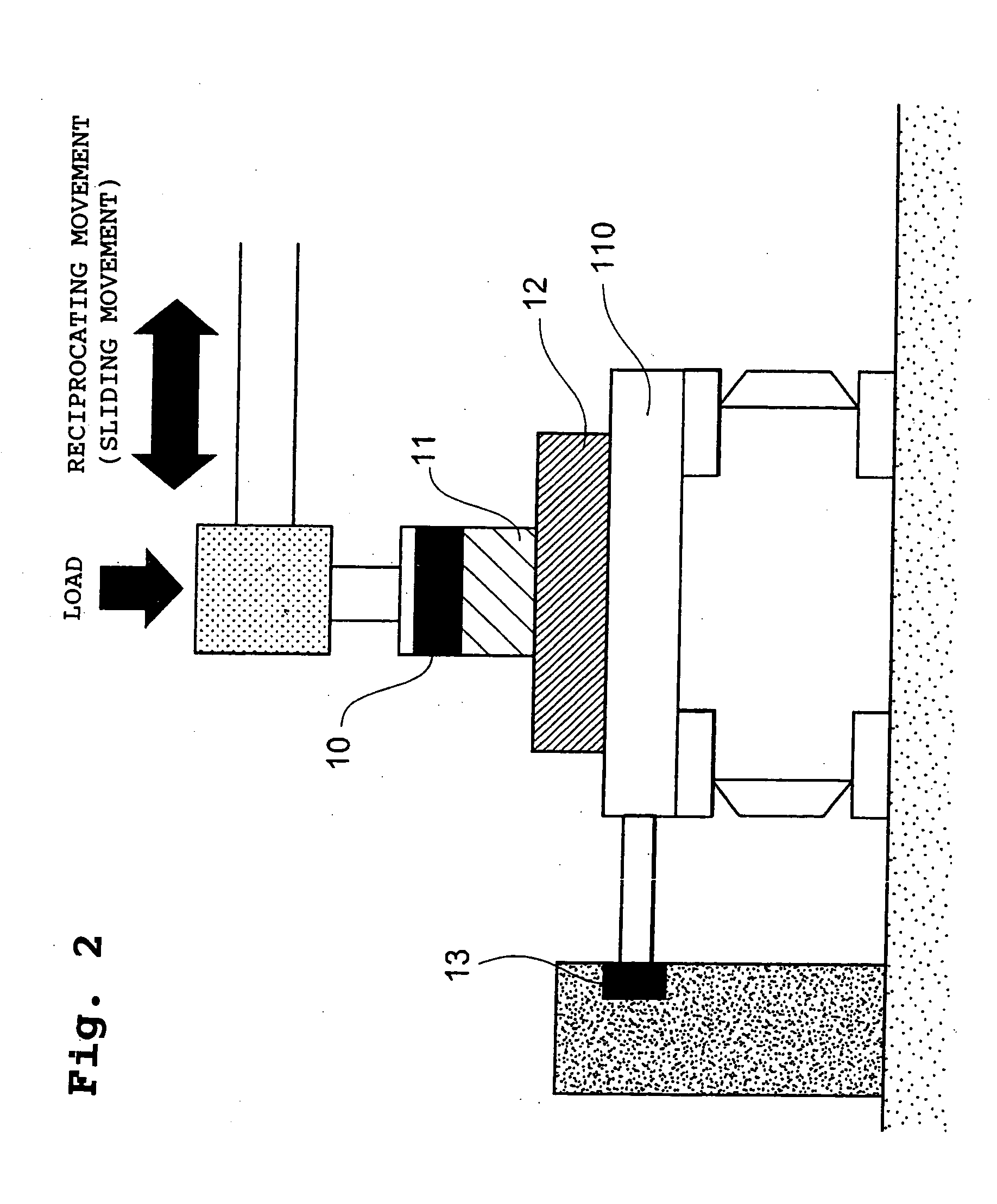

Sensors with variable response behavior

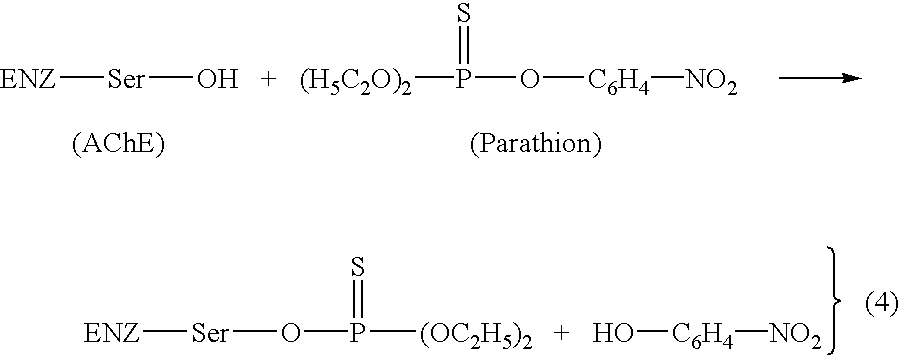

InactiveUS20030062263A1Few false alarmStrong specificityImmobilised enzymesBioreactor/fermenter combinationsChemical agentThiophosphate

A sensor and method for detecting biological and chemical agents comprising metal interdigitized electrodes coated with hybrid polymer-based conducting film and an instrument for applying electrical voltage to the electrodes and registering the change in electrical current. The hybrid film also comprises indicator biomolecules encapsulated within the film or attached to it. The bioindicator molecules preferably comprise enzyme acetylcholinesterase. When these indicator biomolecules come in a contact with a pathogen, chemical and / or morphological changes occur in the film and electrical current flowing through the electrodes is modulated. The pathogen comprise inhibitors of enzymes, preferably organophosphates, thiophosphates or phosphonates. The change in current indicates the presence of a biological and chemical agent and is registered.

Owner:HRL LAB

Lubricative Composition for Industrial Machinery and Equipment

InactiveUS20080058235A1Excellent in sludge resistance and extreme pressure propertyMaintain good propertiesGroup 5/15 element organic compoundsAdditivesViscosity indexCarboxylic acid

A lubricative composition for industrial machinery and equipment which comprises a base oil selected from among mineral oils, fats and oils, synthetic oils and mixture of two or more of them, and at least one additive selected from among the following components (A) to (D): component (A): (A-1) a phosphorus-containing carboxylic acid and / or (A-2) a thiophosphoric ester, component (B): a dispersant viscosity index improver, component (C): (C-1) a specific amidocarboxylic acid compound and / or (C-2) a specific carboxylic acid compound, and component (D): an ester oiliness improver. The composition is favorable as a lubricating oil composition and useful as a gear oil composition, a lubricating oil composition for paper machines or a lubricating oil composition for slide guides, a hydraulic oil, or the like.

Owner:NIPPON OIL CORP

Process for producing copper nanoparticles

ActiveUS20060053972A1Improve stabilityGood dispersionMaterial nanotechnologyTransportation and packagingHydrazine compoundReducing agent

The present invention provides a process for producing copper nanoparticles, comprising steps of: a) reacting an aqueous solution containing a reductant with an aqueous solution of a copper salt while stirring for 1-8 min, wherein the reductant being one or more selected from a group consisting of hydrazine hydrate, sodium borohydride and sodium hypophosphite; b) adding an apolar organic solution containing the extracting agent and continuing the stirring for 0.5-1.5 hrs, said extracting agent being one or more selected from the group consisting of alkyl dithiocarbonic acid and salts thereof, O,O′-dialkyl dithiophosphoric acid and salts thereof, and dialkylamino dithioformic acid and salts and said apolar organic solution being one selected from the group consisting of benzene, toluene and straight or branched alkanes having 6-12 carbon atoms, wherein the alkyl having 6-20 carbon atoms; and c) post-treating the reaction product to obtain copper nanoparticles.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Lubricant composition for diesel engine

ActiveCN102690707AImprove antioxidant capacityImprove high temperature wear resistanceAdditivesAntioxidantDiesel engine

The invention relates to a lubricant composition for a diesel engine. The lubricant composition for a diesel engine contains less than or equal to 0.09% by mass of phosphorus, less than or equal to 0.4% by mass of sulfur and less than or equal to 1.0% by mass of sulfate ash. The lubricant composition for a diesel engine comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a boronized polyisobutylene succinimide dispersant, C) a mixture of magnesium sulfate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyldithiophosphate, E) one or more ashless friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition for a diesel engine has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a diesel engine, and has excellent piston cleanliness, wear resistance and a viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inhibiting corrosion caused by aqueous aldehyde solutions

Aldehydes useful as H2S sulfide scavengers may be corrosive to some metals such as steel, iron and aluminum, but the corrosive effect of the aldehydes may be mitigated by employing a corrosion inhibitor selected from the group consisting of a di-basic soluble phosphate salt, a tri-basic soluble phosphate salt, a phosphate ester, a thiophosphate ester, a thioamine, and combinations thereof.

Owner:BAKER HUGHES INC

Lubricating oil composition and use thereof

InactiveUS20060281642A1Liquid carbonaceous fuelsGroup 6/16 element organic compoundsAlkaline earth metalAntioxidant

A lubricating oil composition having a sulfur content of from 0.3 to 0.5 wt. %, a phosphorus content of from 0.10 to 0.13 wt. % and a sulfated ash content of from 0.1 to 1.1 wt. %, based on the total weight of the lubricating oil composition is provided. The lubricating oil composition contains at least one Group II mineral base oil; at least one alkali and / or alkaline earth metal alkyl salicylate; an ashless dispersant; at least one zinc didithiophosphate; and at least one aminic ashless antioxidant and at least one phenolic ashless antioxidant.

Owner:SHELL OIL CO

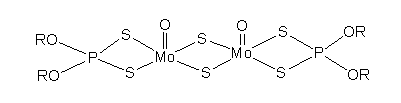

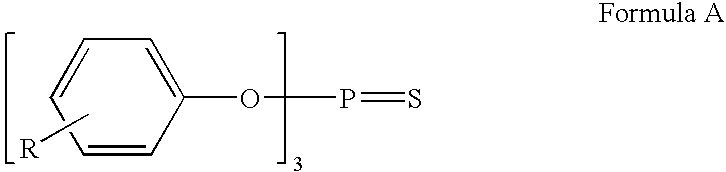

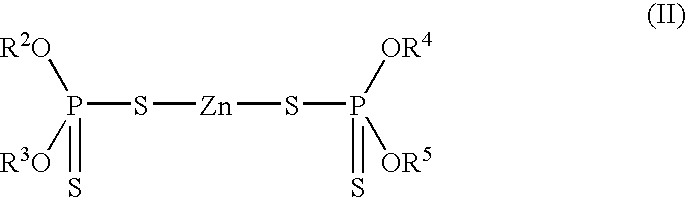

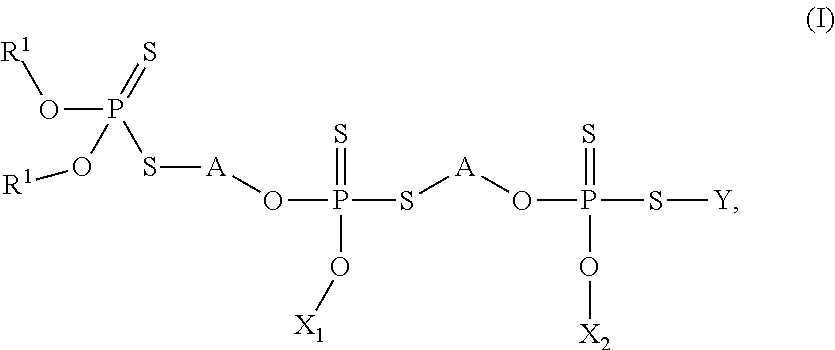

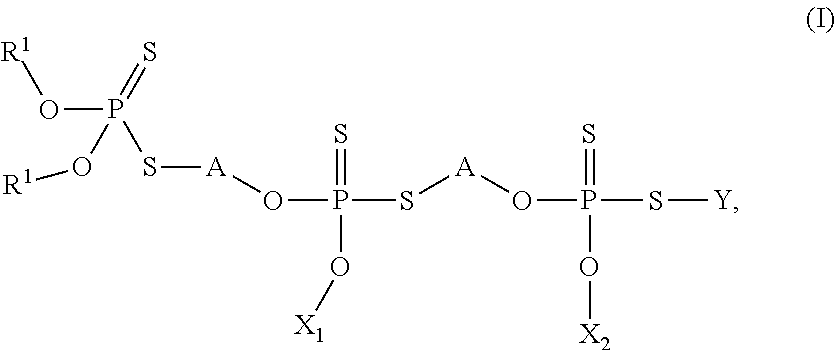

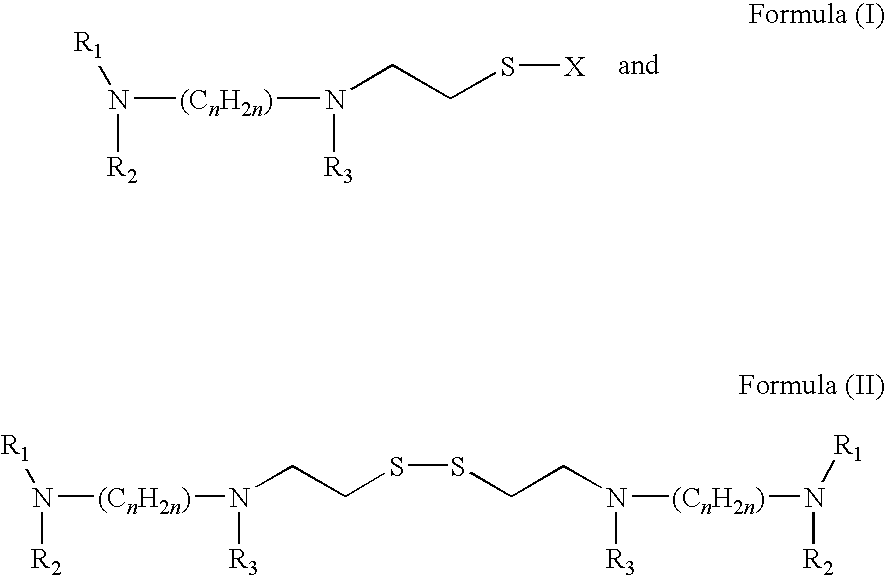

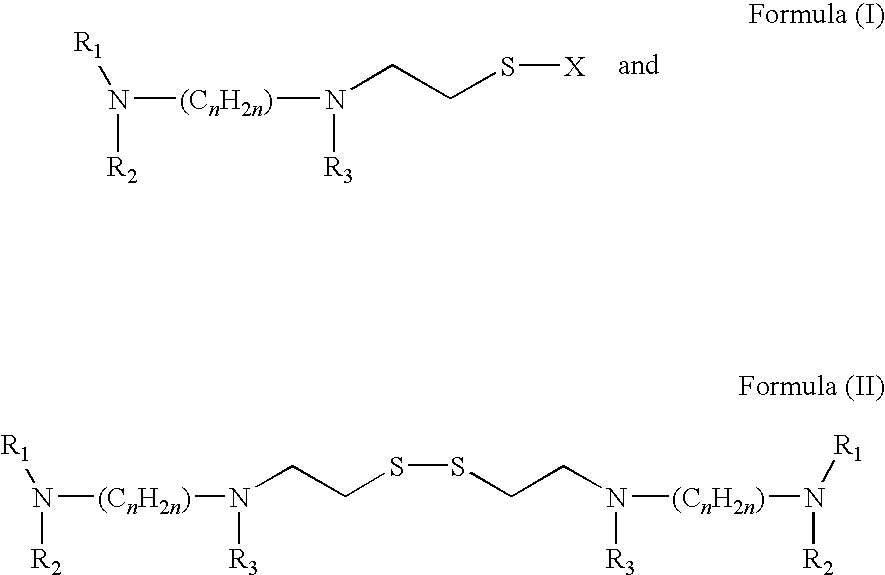

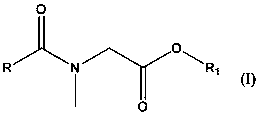

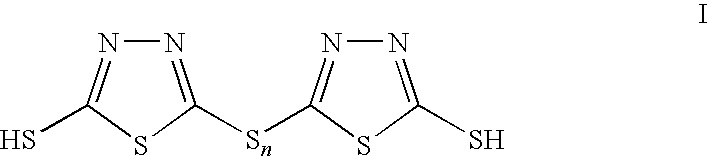

Thiophosphates and thiophosphate derivatives as lubricant additives

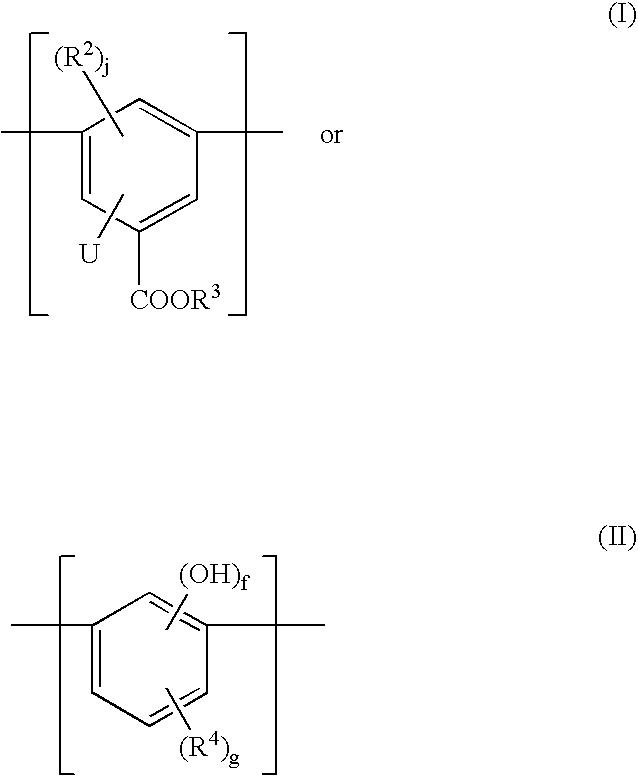

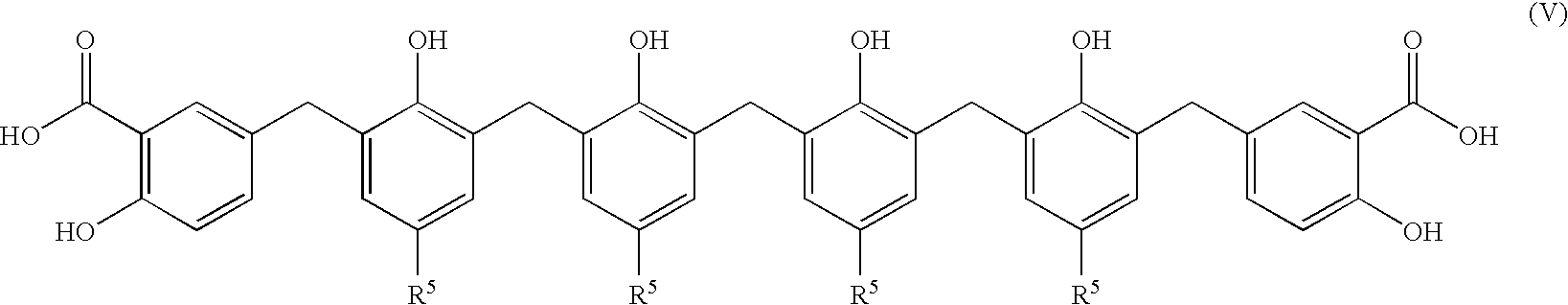

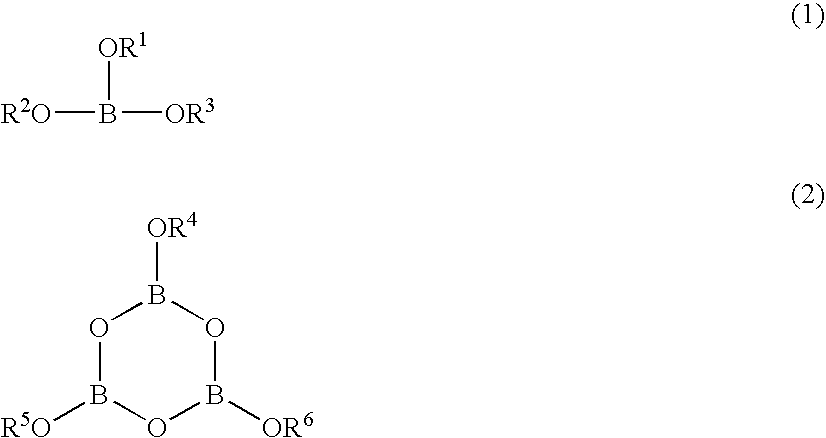

The present invention provides thiophosphates and thiophosphate derivatives useful as antiwear additive components, lubricant additive compositions and lubricant compositions each comprising such compounds, and methods for making and using the same. In one aspect, the invention relates to a compound of formula (I):or a tribologically acceptable salt thereof.

Owner:AFTON CHEMICAL

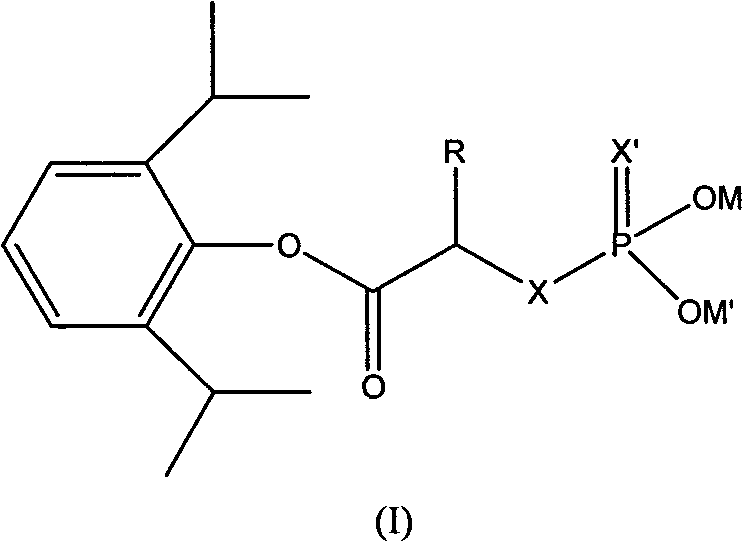

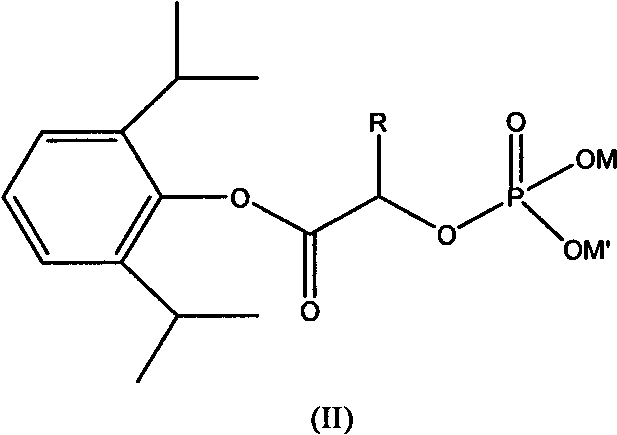

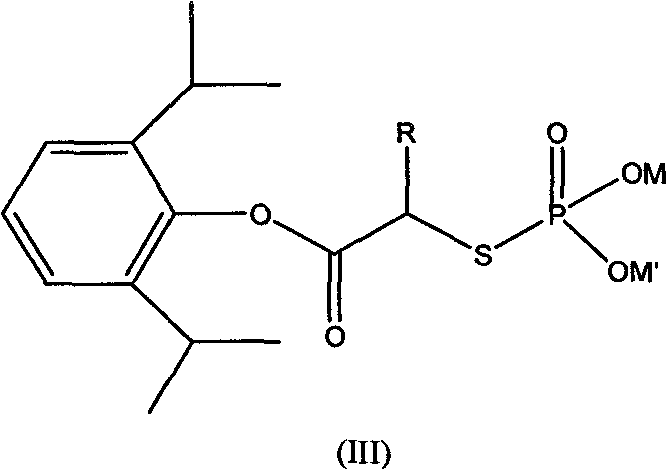

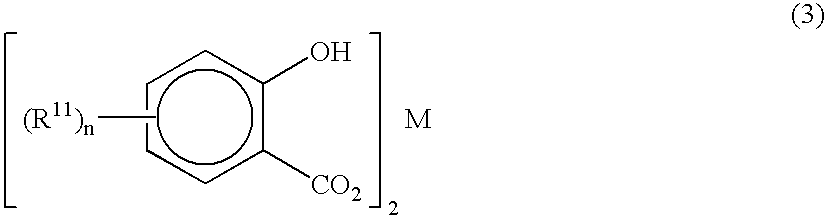

Phosphoryl carboxylic acid propofol ester derivative and preparation method thereof

ActiveCN101633671AImprove bioavailabilityGood water solubilityOrganic active ingredientsAnaestheticsO-Phosphoric AcidPhosphate

The invention relates to a phosphoryl carboxylic acid propofol ester derivative which has the general formula (I). The method comprises the following steps: propofol reacts with 2-halogenated carboxylic acid and a derivative thereof by alkali to obtain corresponding ester and then the product reacts with phosphoric acid or thiophosphoric acid and the derivative thereof by dissolvent to obtain a water-soluble product or the propofol reacts with a 2-halogenated carboxylic acid phosphate ester derivative by the alkali to obtain the corresponding ester and then the ester is catalyzed, hydrogenated and salified to obtain the water-soluble product (I). The preparation method has mild reaction condition, high yield, simple operation and industrialized prospect, and a prepared oral preparation has the characteristics of high bioavailability, rapid absorption, high stability, and the like; and auxiliary materials with safety defects, such as a surface active agent, and the like can not be added into the prepared injection, thereby improving the stability of the preparation, reducing or removing injection pain, increasing the compliance of patients, overcoming the defects of propofol emulsion and having the advantage of obvious effect. The invention has the structural general formula (I).

Owner:HANGZHOU ADAMERCK PHARMLABS INC

Solvent systems for dicyandiamide and/or alkyl thiophosphoric triamide and use in agricultural applications

ActiveUS20160107947A1Reduce conversionAvoid failureAgriculture gas emission reductionAmmonium nitrate fertilisersLiquid mediumOrganic solvent

An inhibitor composition contains dicyandiamide as a nitrification inhibitor, alkyl thiophosphoric triamide as a urease inhibitor, or a combination thereof, dissolved in a liquid medium comprising an organic solvent selected from, among others, one or more polar aprotic solvents, including one or more organophosphates, amine solvents, heterocyclic alcohol solvents, and mixtures thereof, is useful in making fertilizer compositions and in a method of fertilizing target plants.

Owner:RHODIA OPERATIONS SAS

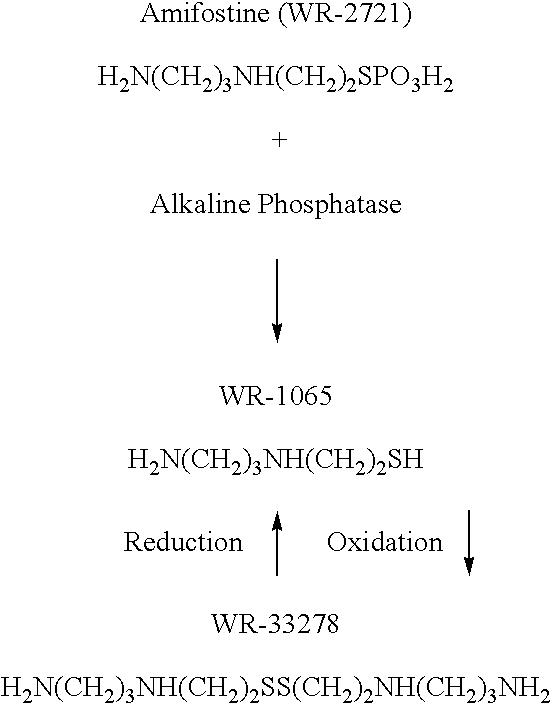

Organic thiophosphate antiretroviral agents

InactiveUS20090239817A1Reducing and preventing effectPromote repairBiocideSulfur/selenium/tellurium active ingredientsImmunodeficiency virusAmifostine

A method for the prevention or treatment of human immunodeficiency virus infection by administering an effective amount of amifostine, phosphonol, or similar compound to an individual in need is provided.

Owner:US DEPT OF HEALTH & HUMAN SERVICES +1

Premium wear resistant lubricant

Owner:EXXON RES & ENG CO

Special slow control/release compound fertilizer for eggplant and preparation method thereof

ActiveCN103524221AIncrease productionPromote flowering and fruitingAgriculture gas emission reductionFertilizer mixturesNitrification inhibitorsRapeseed

The invention provides a special slow control / release fertilizer for an eggplant. The fertilizer is characterized by comprising, in terms of mass percent, 0.05% to 0.08% of n-butyl triamine thiophosphate, 0.05 to 0.08% of hydroquinone and 0.24 to 0.28% of dicyandiamide. According to the invention, the special slow control / release fertilizer is prepared by combining macro-element, medium-element and trace-element fertilizers like nitrogen, phosphorus, potassium, calcium, magnesium, molybdenum, boron, zinc and iron with organic fertilizers like high-quality decomposed rapeseed dregs, chicken manure and grass carbon, adding a urease inhibitor and a nitrification inhibitor and carrying out mixing; the special slow control / release fertilizer has a slow release effect in soil, is rich in a variety of nutrient elements needed in growth of the eggplant, can meet demands of the eggplant for nutrients in different growth and development phases for a long time and effectively improves output of the eggplant.

Owner:SOUTHWEST UNIVERSITY

Process for preparing N-(hydrocarbyl) phosphoric or thiophosphoric triamides

The invention provides a process for preparing N-(hydrocarbyl)phosphoric or thiophosphoric triamides with substantially improved yields and purity. Two equivalents of hydrocarbylamine are used in the reaction with phosphoryl or thiophosphoryl chloride and then with ammonia in an aromatic solvent. The invention further relates to N-(hydrocarbyl)phosphopric or thiophosphoric triamides having the purity of at least 98% wherein R is a hydrocarbyl group and X is O or S.(RNH)(NH2)2P=X (I).

Owner:AGRA GROUP AS

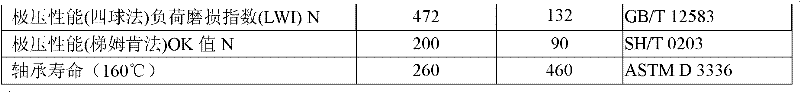

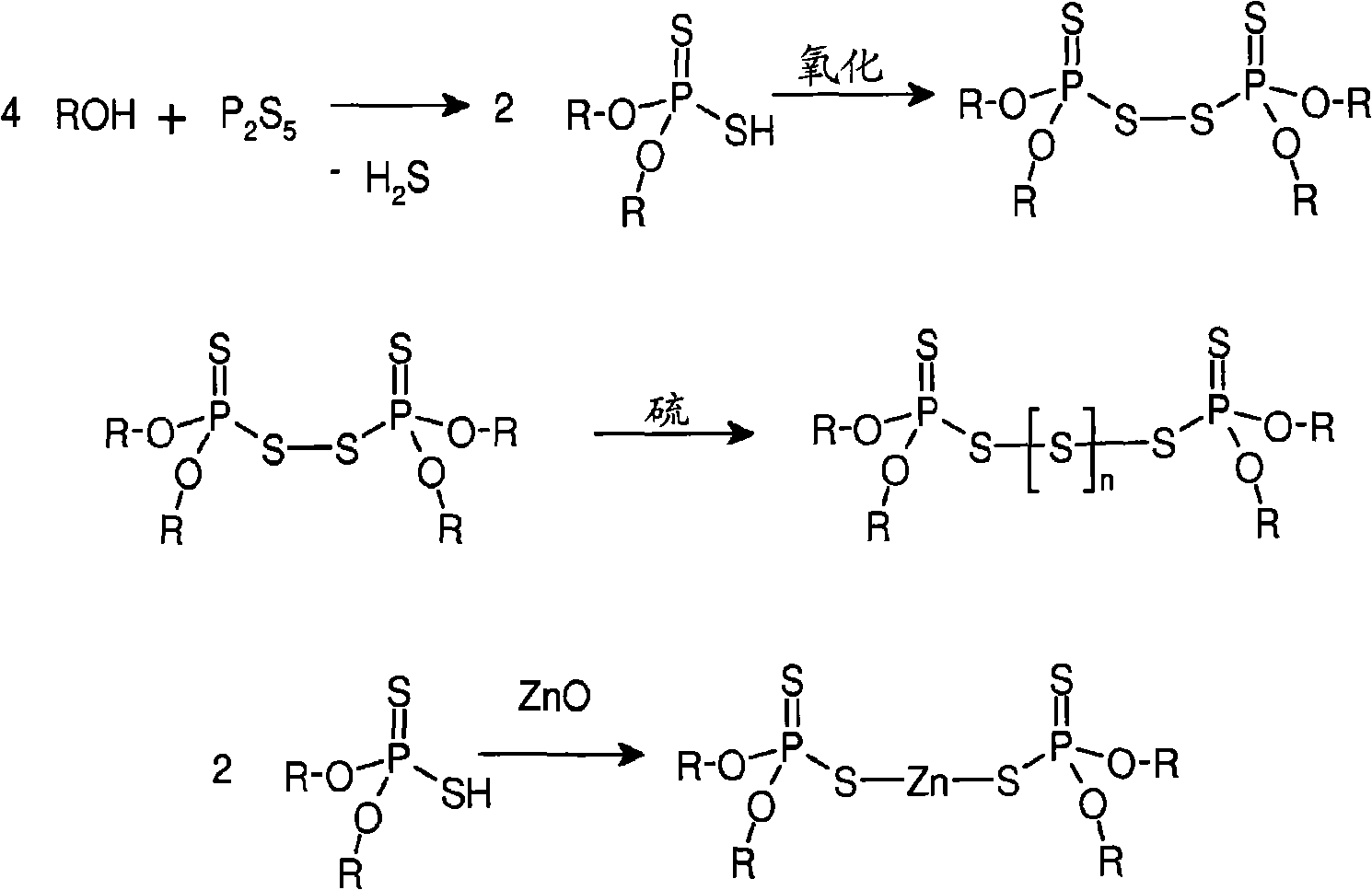

Polyurea-based grease additive composition

InactiveCN102504921AGood high temperature performanceImprove water resistanceLubricant compositionAntioxidantPolymethyl methacrylate

The invention relates to a polyurea-based grease additive composition. Components and percentage content of the polyurea-based grease additive composition are that: base oil is mineral oil and synthetic oil or blending oil of the mineral oil and the synthetic oil, and the content of the base oil is from 71% to 91.5%; a thickening agent is composed of a common reactant of isocyanate, fatty amine and alicyclic amine, and the content of the thickening agent is from 6% to 12%; an antioxidant uses amine antioxidants, and the total content of the antioxidant is from 0.5% to 3%; an extreme-pressure agent uses a mixture of sulfurized isobutylene, dialkyl group dithiophosphate and dialkyl group dithiocarbamic acid, and the total content of the extreme-pressure agent is from 0.5% to 5%; the content of an antirusting agent is from 0.5% to 3%; an antiwear agent is triphenyl thiophosphate and thiophosphoric acid ester or a mixture of the triphenyl thiophosphate and the thiophosphoric acid ester, and the total content of the antiwear agent is from 0.5% to 3%; and tackifier is polyisobutene and polymethyl methacrylate or a mixture of the polyisobutene and the polymethyl methacrylate, and the total content of the tackifier is from 0.5% to 3%. Due to the fact that appropriate raw material proportion is selected and used, grease has good high-temperature performance, a dropping point is higher than 260 DEG C, and the polyurea-based grease additive composition has a good water-resisting property, high and low temperature resistance and extreme pressure anti-wear performance, and can be applied to lubrication of each key running part of a continuous casing machine.

Owner:CHINA PETROLEUM & CHEM CORP

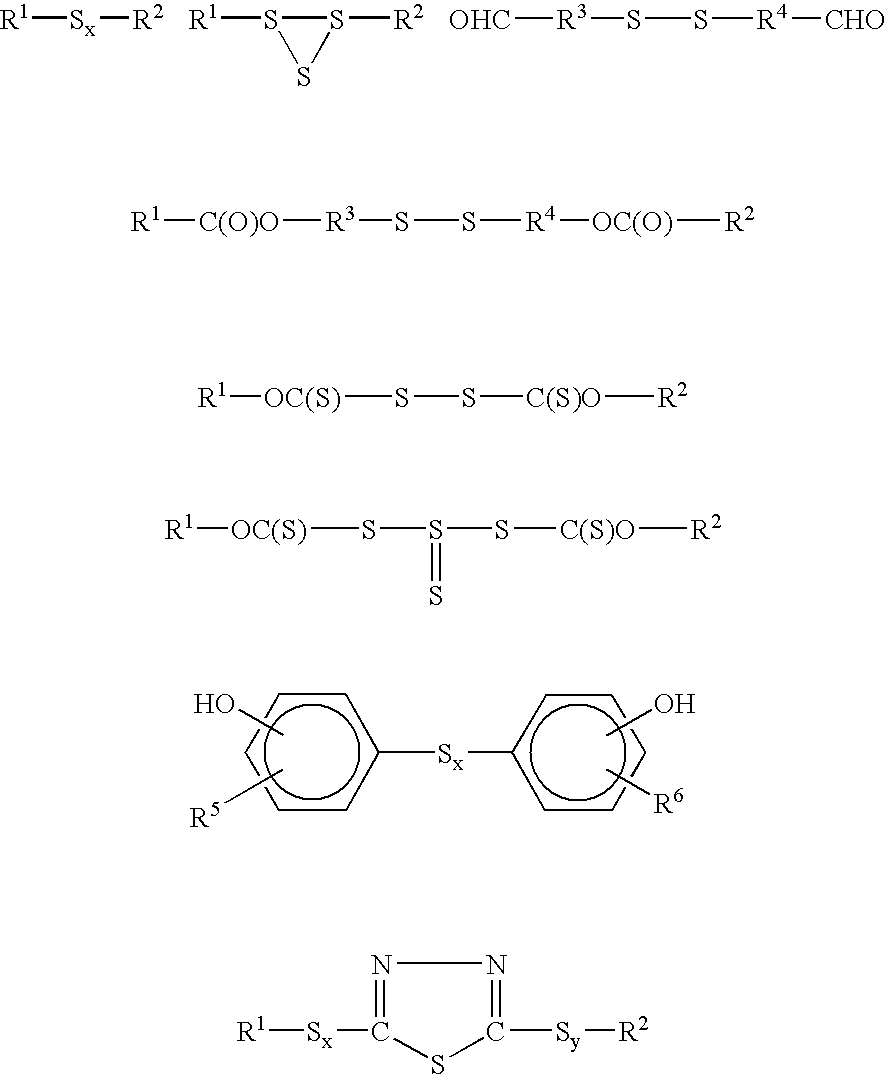

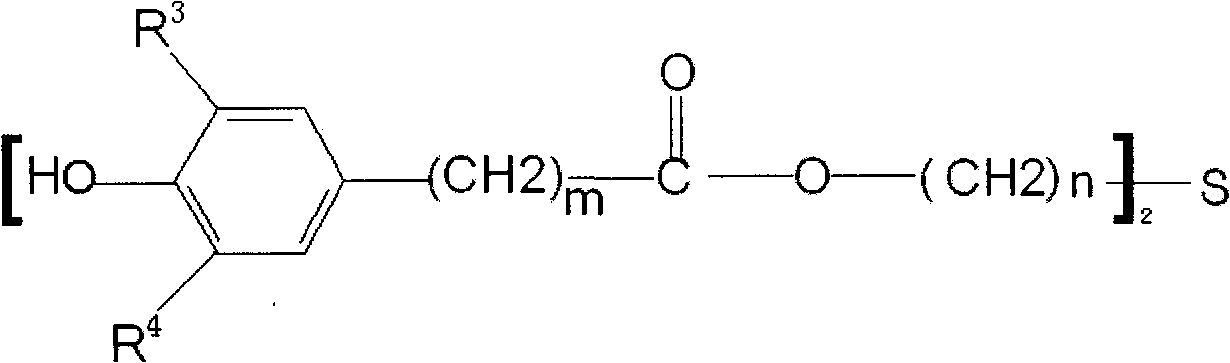

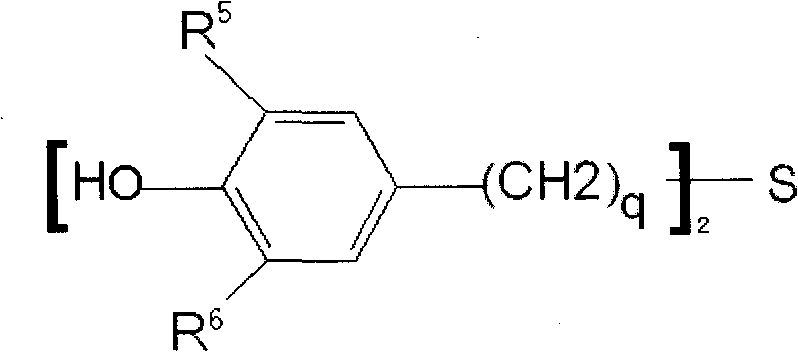

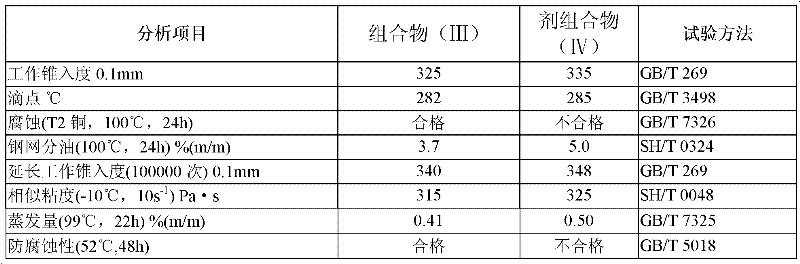

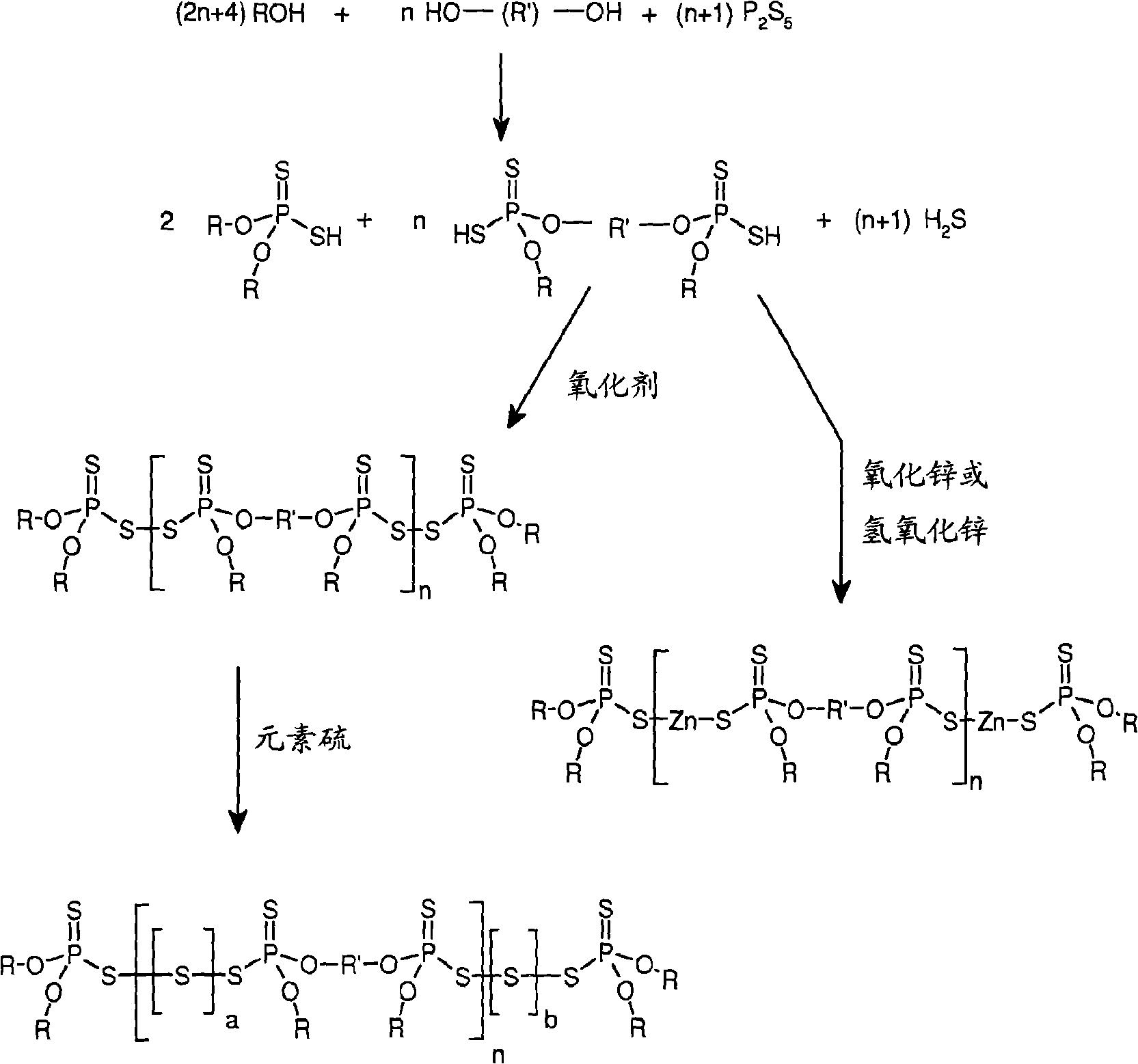

Dithiophosphate composition and utility in rubber

The present invention relates to oligomeric or polymer dithiophosphate di- or poly- sulfides and their utility in rubbers. Another aspect of the invention is a method for making oligomeric or polymeric dithiophosphates by reacting phosphorous pentasulfide with a di- or polyol and a mono alcohol to produce a dithiophosphoric acid, and then oxidizing the dithiophosphoric acid with an oxidizing agent to produce an oligomeric or polymeric dithiophosphate.

Owner:VANDERBILT CHEM LLC

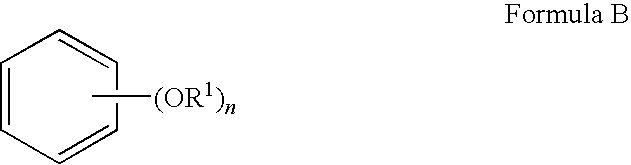

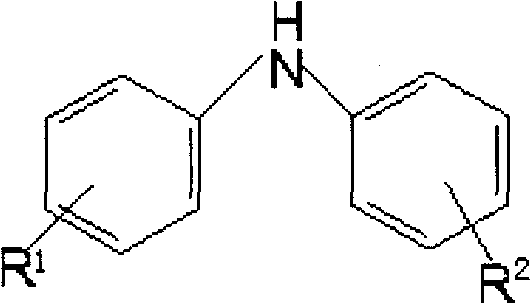

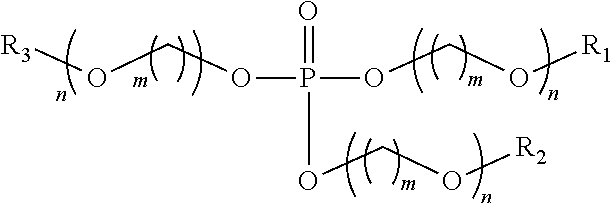

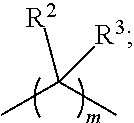

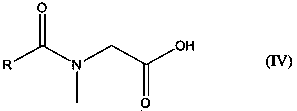

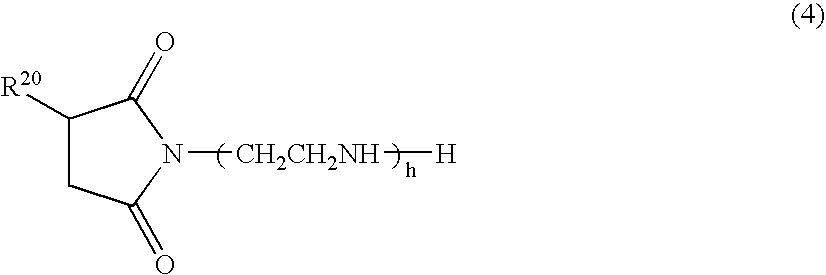

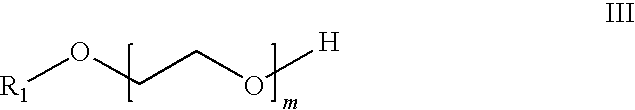

Additive compositions with a friction modifier and a metal dialkyl dithio phosphate salt

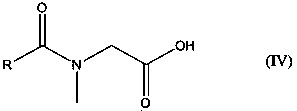

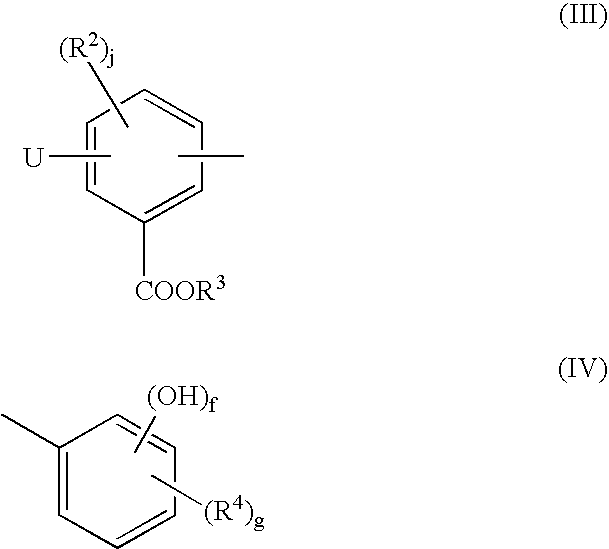

A lubricating composition comprising a major amount of base oil and a minor amount of an additive package, wherein the additive package comprises: (A) a friction modifier component selected from: (a) one or more a reaction products of an alcohol with a compound of the formula IV: (see formula IV); and (b) one or more compounds of the Formulae II-III: (see formula II) (see formula III) wherein wherein R is a linear or branched, saturated, unsaturated, or partially saturated hydrocarbyl having about 8 to about 22 carbon atoms; R2 and R3 are independently selected from hydrogen, C1-C18 hydrocarbyl groups, and C1-C18 hydrocarbyl groups containing one or more heteroatoms; and X is an alkali metal, alkaline earth metal, or ammonium cation and n is the valence of cation X; and (B) at least one metal dialkyl dithio phosphate salt.

Owner:AFTON CHEMICAL

Lubricating composition substantially free of ZDDP

InactiveUS20050148477A1Improved engine cleanlinessReduce wearOrganic chemistryLiquid carbonaceous fuelsFriction modifierAnti oxidant

The present invention provides a composition comprising: (a) a metal salixarate; (b) at least one additive selected from the group consisting of (1) an antioxidant; (2) a friction modifier; (3) a dispersant; (4) a viscosity modifier; (5) a dispersant viscosity modifier; and (6) an antiwear agent other than a metal hydrocarbyl dithiophosphate; and (c) an oil of lubricating viscosity, wherein the composition contains 400 ppm or less of phosphorus derived from a metal hydrocarbyl dithiophosphate. The invention further provides a process for preparing the composition and its use.

Owner:THE LUBRIZOL CORP

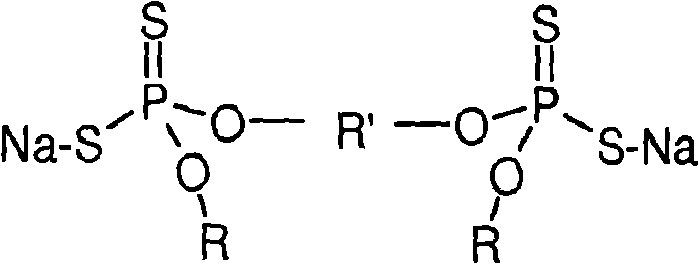

Trihydrate 3-amino propyl amine ethyl phosphorothioic acid high purity stable crystal and preparation thereof

ActiveCN101412732AImprove stabilityLittle side effectsGroup 5/15 element organic compoundsAntinoxious agentsHydrobromideProtic solvent

The invention relates to the field of chemosynthesis, a trihydrate 3-aminopropyl amine ethyl thiophosphoric acid(amifostine)stable crystal and a preparation method thereof. The method comprises the following steps: step one, according to the molar ratio of between 1.01 to 1.0 and 1.2 to 1.0, N-(2-bromethyl)-1,3-propane diamine bi-hydrobromide and sodium thiophosphate are dissolved in water, are added with a polar aprotic solvent as an accelerant and react at a temperature of between 10 and 40 DEG C; after reaction, the mixture is directly cooled to precipitate a coarse product of trihydrate amifostine; step two, the coarse product of the trihydrate amifostine obtained in the step one is subjected to primary recrystallization and purification, is dissolved in the water and is precipitated out through methanol to obtain anhydrous amifostine; and step three, the anhydrous amifostine obtained in the step two is subjected to secondary recrystallization and purification, is dissolved in the water and is decolored through active carbon; and the trihydrate amifostine crystal is precipitated out through ethanol. The purity of the crystal is more than or equal to 99.5 percent; the content of mercaptan is less than or equal to 0.1 percent; the content of other relevant substances is less than or equal to 0.1 percent; and a product is stable and is suitable for scale production.

Owner:MERRO PHARMA +1

High-temperature-resistant and wear-resistant lubricating oil for drilling fluid and preparation method of lubricating oil

InactiveCN104087269AImprove the lubrication effectImprove high temperature resistanceDrilling compositionPhosphoric Acid EstersEthyleneglycol monobutyl ether

The invention relates to high-temperature-resistant and wear-resistant lubricating oil for a drilling fluid. The lubricating oil is prepared from the following raw materials in parts by mass: 30-48 parts of palm oil, 11-14 parts of sulfurized isobutylene, 5-8 parts of fatty alcohol-polyoxyethylene ether, 6-9 parts of nano graphite powder, 4-9 parts of zinc dialkyl dithiophosphate, 8-12 parts of molybdenum oxygen dialkyldithiophosphate, 1-3 parts of 3, 4, 5-trimethoxyl cinnamic acid, 10-14 parts of lauric acid monoethanolamide phosphate, 16-19 parts of glycerine, 10-13 parts of ethylene glycol monobutyl ether and 20-30 parts of pentaerythritol. By reasonably compounding the palm oil and other additives, the lubricating performance, high-temperature resistance and wear resistance of the lubricating oil are effectively improved. Meanwhile, 3, 4, 5-trimethoxyl cinnamic acid and lauric acid monoethanolamide phosphate are added, so that the high-temperature resistance, the wear resistance and the antirust time of the lubricating oil are effectively improved under the joint effect of 3, 4, 5-trimethoxyl cinnamic acid, lauric acid monoethanolamide phosphate and other components, and the friction coefficient is greatly lowered.

Owner:青岛蓬勃石油技术服务有限公司

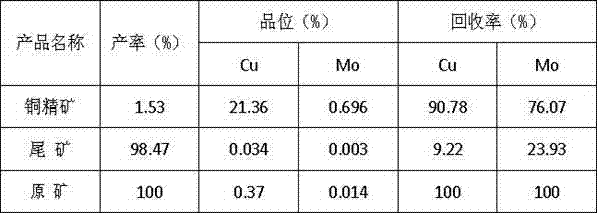

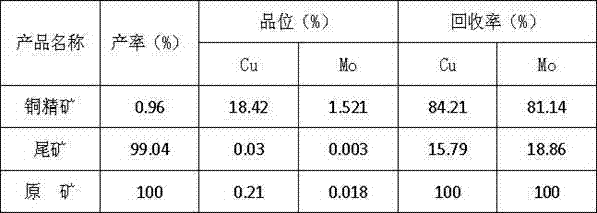

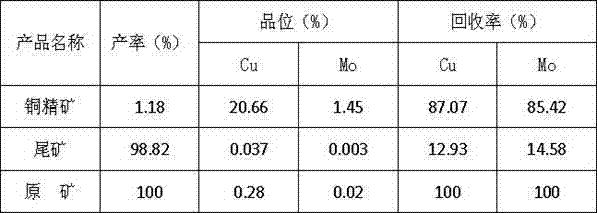

Composite collecting agent for bulk floatation of copper sulfide molybdenum ores

The invention discloses a composite collecting agent for bulk floatation of copper sulfide molybdenum ores. The collecting agent is a stable oily product which is formed by mixing 50%-70% of thiocarbamic acid ester, 2%-10% of thiophosphoric acid ester, 10%-30% of mixed non-polar hydrocarbon oil and 10%-20% of terpene alcohol. The collecting agent has the advantages that the thiocarbamic acid ester has the selective chelation on the exposing active points, such as copper and molybdenum, on the surfaces of minerals, the thiophosphoric acid ester has the selective adsorption function on the copper-containing minerals, the non-polar hydrocarbon oil can be adsorbed on the surface of the copper sulfide molybdenum ores through the Van der Waals force, and the terpene alcohol is a solution medium and has good air bubble property, so under the synergistic effect of the thiocarbamic acid ester, the thiophosphoric acid ester, the mixed non-polar hydrocarbon oil and the terpene alcohol, a good ore selection index can be obtained, and the agent mechanism is simplified; the collecting agent is used at the ore slurry temperature of 5-35 DEG C, and the usage amount is between 80-160g / t according to the change of the contents of usable minerals in the ores.

Owner:KUNMING METALLURGY INST

Lubricating oil composition for internal combustion engine

ActiveUS20050245402A1Improve performanceImprove antioxidant capacityCam-followersBearing componentsAnti oxidantPetroleum engineering

The present invention provides a lubricating oil composition for an internal combustion engine which is very good in base number retention property, detergency at high temperature and valve train anti-wear property and does not substantially contain phosphorus- and / or sulfur-containing anti-wear agent. The composition comprises a lubricant base oil comprising a mineral oil and / or a synthetic oil, (A) 0.001 to 0.5% by mass of an ester of a boric acid in terms of boron element therein and (B) 0.01 to 5% by mass of an ashless antioxidant, wherein said composition contains substantially no metal salts of dithiophosphoric acid and has a sulfur content of 0.2% by mass or less, each percentage being based on a total mass of the composition.

Owner:NIPPON OIL CORP

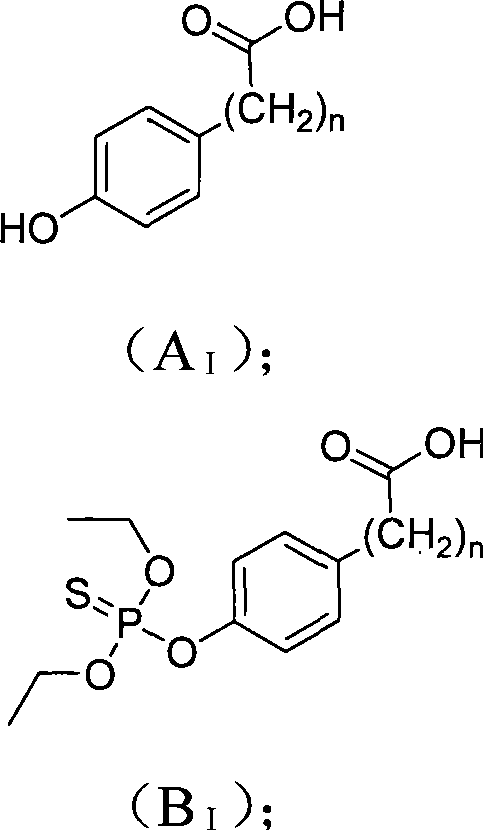

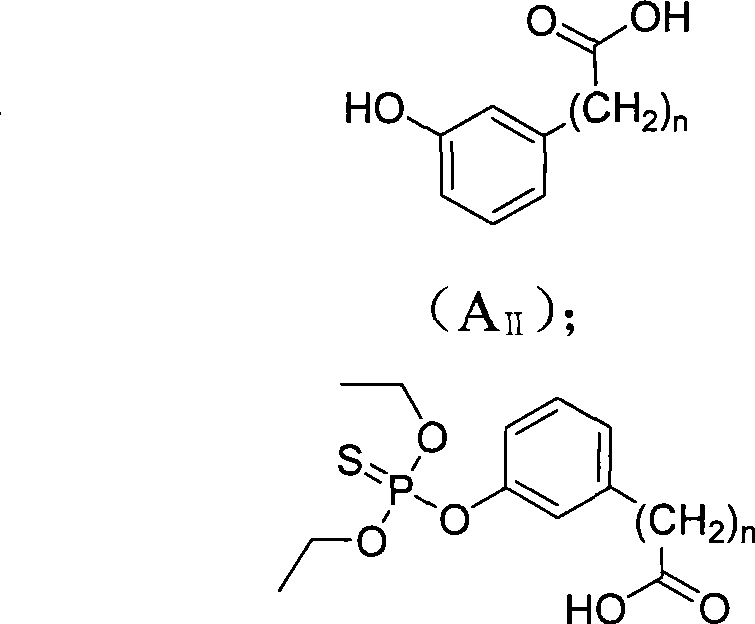

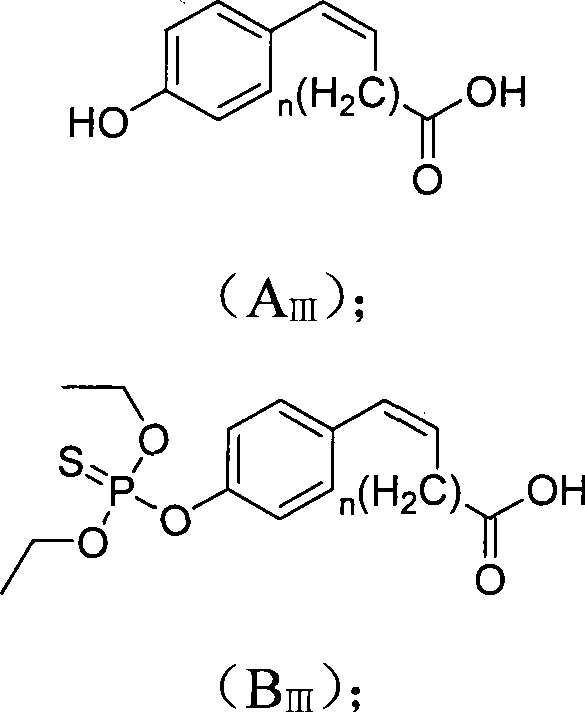

Diethoxy thiophosphate organophosphorus pesticide hapten and preparation thereof

ActiveCN101475587AProduce high potencyStrong specificityGroup 5/15 element organic compoundsMaterial analysisPhosphoric Acid EstersCarboxyl radical

The invention discloses a diethoxy phosphorothioate organic phosphorus pesticide haptens and a method for preparing the same. The haptens are products of nucleophilic substitution of diethylthiophosphoryl chloride and phenol derivates with a carboxyl or an amine acid. The invention provides a series of haptens aiming at a common structure of the organic pesticides of diethoxy phosphorothioate. The haptens are similar to the counterparts of organic pesticides having a common structure of the diethoxy phosphorothioate in terms of molecular structure, stereochemistry and electron distribution, wherein phenol derivative arms which have carboxyls and vary in length are introduced onto the oxygen atoms of the diethoxy phosphoramide to be bound with carrier proteins. The haptens and the metod lay a technical foundation for the preparation of antibodies of diethoxy phosphorothioate organic phosphorus pesticides and the development of quickly testing products.

Owner:SOUTH CHINA AGRI UNIV

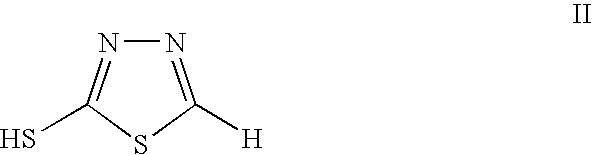

Additive composition for ep greases with excellent antiwear and corrosion properties

A lubricant composition is provided as follows:At least 90% of a base grease;(a) a thiadiazole poly(ether)glycol complex in an amount which provides about 1500 to 3500 ppm sulfur;(b) molybdenum dihydrocarbyldithiophosphate in amount which provides about 77 to 450 ppm molybdenum; and(c) zinc dihydrocarbyldithiophosphate in an amount which provides about 600 to 1000 ppm zinc. An additive composition for grease, consisting of components (a), (b) and (c), is also provided.

Owner:VANDERBILT CHEM LLC

Lubricating oil compositions

InactiveUS20150344812A1Reduce and inhibit corrosionAvoid corrosionLiquid carbonaceous fuelsAdditivesChemical compositionDithiophosphoric acid

A lubricating oil composition having a sulphated ash content of less than or equal to 1.2 mass % as determined by ASTM D874 and a phosphorous content of less than or equal to 0.12 mass % as determined by ASTM D5185, which lubricating oil composition comprises or is made by admixing: an oil of lubricating viscosity, in a major amount; an oil-soluble or oil-dispersible polymeric friction modifier as an additive in an effective minor amount; and, an oil-soluble or oil-dispersible dihydrocarbyl dithiophosphate metal salt as an additive in an effective minor amount.

Owner:INFINEUM INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com