Polyurea-based grease additive composition

A technology of polyurea-based grease and composition, applied in the field of grease, can solve the problems such as the lack of in-depth discussion on the extreme pressure and anti-wear performance of grease, and the lack of in-depth discussion, and achieve the effect of good high temperature performance and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

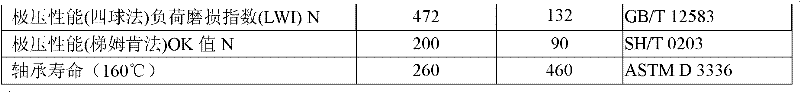

Embodiment 1

[0031] Composition (I) comprises:

[0032] The mass fraction is 0.2% sulfurized isobutylene; extreme pressure agent

[0033] The mass fraction is 0.2% dialkyl dithiophosphate; extreme pressure agent

[0034] The mass fraction is 0.1% dialkyl dithiocarbamate; extreme pressure agent

[0035] The mass fraction is 0.2% triphenyl thiophosphate; antiwear agent

[0036] The mass fraction is 0.3% borated fatty acid ester; antiwear agent

[0037] Parts by mass are 0.5% fatty acid amide; rust inhibitor

[0038] The mass fraction is 0.5% dinonyldiphenylamine. antioxidant

[0039] The mass fraction is 0.5% polymethyl methacrylate. Tackifier

[0040] 3.2% by mass of MDI is added to 46.3% by mass of autoclave oil, heated to 60°C, and simultaneously 1.6% by mass of octylamine and 1.2% by mass of aniline are added to the mass fraction of Heat 18.5% oil to 90°C, keep the temperature constant for 1 hour, continue heating to 120°C, hold the constant temperature for 1 hour, continue to r...

Embodiment 2

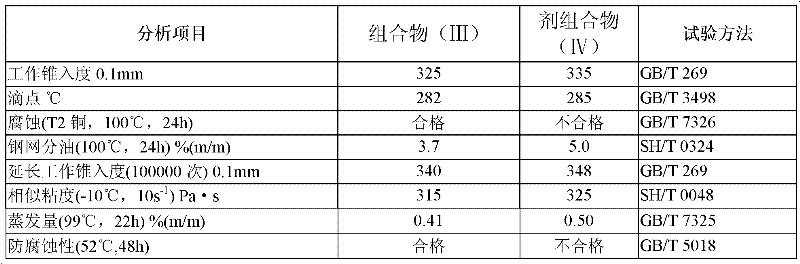

[0058] Composition (III) includes:

[0059] The mass fraction is 1.2% sulfurized isobutylene; extreme pressure agent

[0060] The mass fraction is 1.2% dialkyl dithiophosphate; extreme pressure agent

[0061] The mass fraction is 0.6% dialkyl dithiocarbamate; extreme pressure agent

[0062] Parts by mass are 3% succinimide; rust inhibitor

[0063] Parts by mass are 1.5% borated fatty acid ester; antiwear agent

[0064] The mass fraction is 3% dinonyldiphenylamine. antioxidant

[0065] The mass fraction is 3% polyisobutylene. Tackifier

[0066] 6.4% by mass of MDI is added to 40.5% by mass of autoclave oil, heated to 60°C, while 3.2% by mass of dodecylamine and 2.4% by mass of aniline are added to the mass fraction The parts are 18.7% in oil and heated to 90°C, constant temperature for 1 hour, continue to heat to 130°C, constant temperature for 1 hour, continue to heat up the material to 170°C, constant temperature for 10 minutes (the new type of grease composition is fur...

Embodiment 3

[0084] Composition (V) comprises:

[0085] The mass fraction is 0.6% sulfurized isobutylene; extreme pressure agent

[0086] The mass fraction is 0.6% dialkyl dithiophosphate; extreme pressure agent

[0087] The mass fraction is 0.3% dialkyl dithiocarbamate; extreme pressure agent

[0088] Parts by mass are 1.5% fatty acid amide; rust inhibitor

[0089] Parts by mass are 1.5% triphenyl thiophosphate; antiwear agent

[0090] The mass fraction is 1.5% dinonyl diphenylamine; Antioxidant

[0091] Parts by mass are 1.5% polymethyl methacrylate; tackifier

[0092] The mass fraction is 1.5% polyisobutylene. Tackifier

[0093] 3.2% by mass of MDI was added to 38.5% by mass of autoclave oil, heated to 70°C, while 1.6% by mass of dodecylamine and 1.2% by mass of aniline were added to the mass fraction Parts are 20.7% in oil heated to 90 ° C, constant temperature for 1 hour, continue to heat to 125 ° C, constant temperature for 2 hours, continue to heat up the material to 180 ° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com