Lubricating oil composition and use thereof

a technology of lubricating oil and composition, applied in the field of lubricating oil composition, can solve the problems of adverse effects of after-treatment devices of internal combustion engines and fuel combustion engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

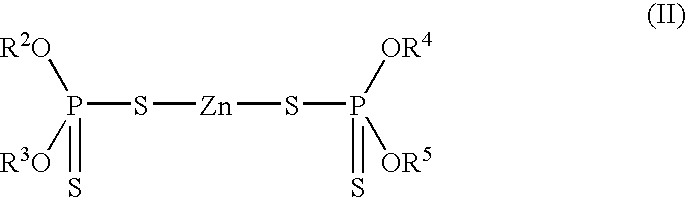

Method used

Image

Examples

example 1 and example 2

[0071] An SAE 10W-30 lubricating oil composition (Example 1) and an SAE 15W-40 lubricating oil composition (Example 2) as described in Table 1 were prepared containing formulation containing a compounds a) to f).

[0072] The lubricating oil composition of Example 1 and Example 2 had a sulfated ash content, a phosphorus content and a sulfur content of as provided in Table 1 above.

[0073] The lubricating oil compositions were tested as described above and the results are shown in Table 2.

TABLE 2Example 1Example 2Oxidation Induction Time (@ 210° C.)13 min.14 min.

[0074] As can be seen from Table 2, the lubricating oil composition has good oxidation stability for an engine oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com