Patents

Literature

167 results about "Zinc dithiophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

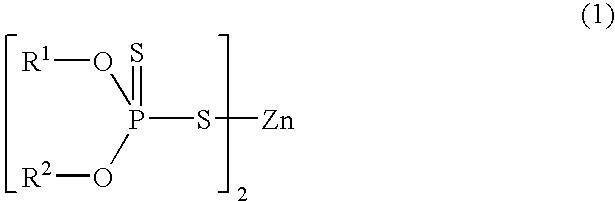

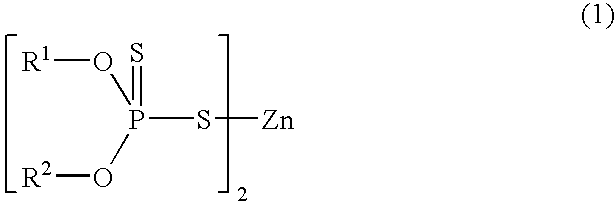

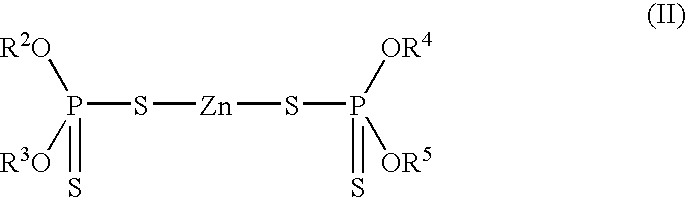

Zinc dialkyldithiophosphates (often referred to as ZDDP) are a family of coordination compounds developed in the 1940s that feature zinc bound to the anion of a dialkyldithiophosphoric acid (e.g., ammonium diethyl dithiophosphate). These uncharged compounds are not salts. They are soluble in nonpolar solvents, and the longer-chain derivatives easily dissolve in mineral and synthetic oils used as lubricants. They come under CAS number 68649-42-3. In aftermarket oil additives, the percentage of ZDDP ranges approximately between 2–15%. Zinc dithiophosphates have many names including ZDDP, ZnDTP, and ZDP.

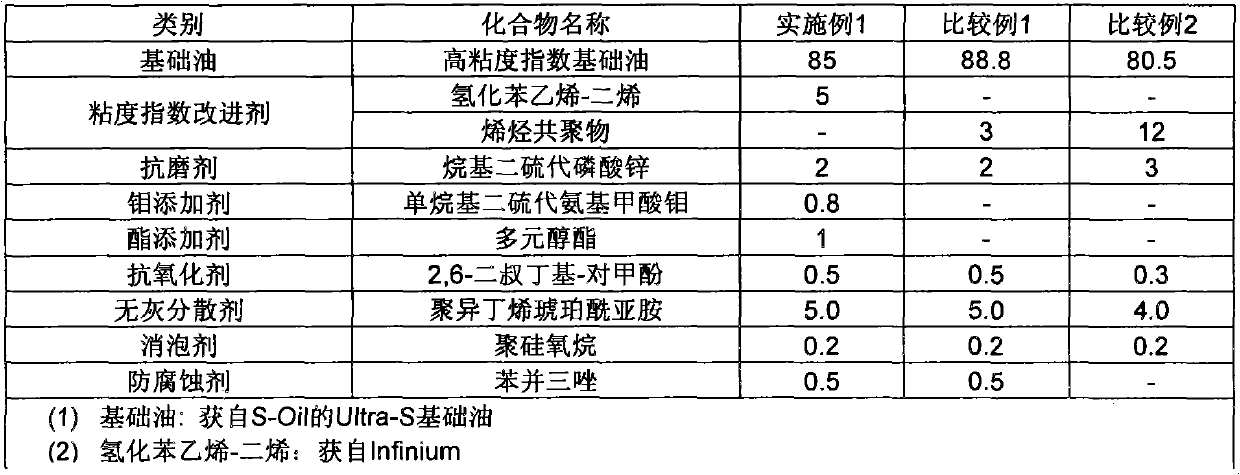

Low ash, low phosphorus and low sulfur engine oils for internal combustion engines

InactiveUS6730638B2Reduce friction and wearReduce frictionOrganic chemistryOrganic compound preparationCombustionSulfur

A lubricating composition for internal combustion engines especially useful with fuels having less than 350 ppm sulfur comprises a lubricating oil basestock, a boron containing ashless dispersant, a molybdenum containing friction reducing agent, a metal type detergent and zinc dithiophosphate.

Owner:EXXON RES & ENG CO

Lubricant and additive formulation

InactiveUS20030119682A1Improve the lubrication effectImprove engine performanceBiocideLiquid carbonaceous fuelsPolyolesterChemical composition

Owner:ASHLAND OIL INC +1

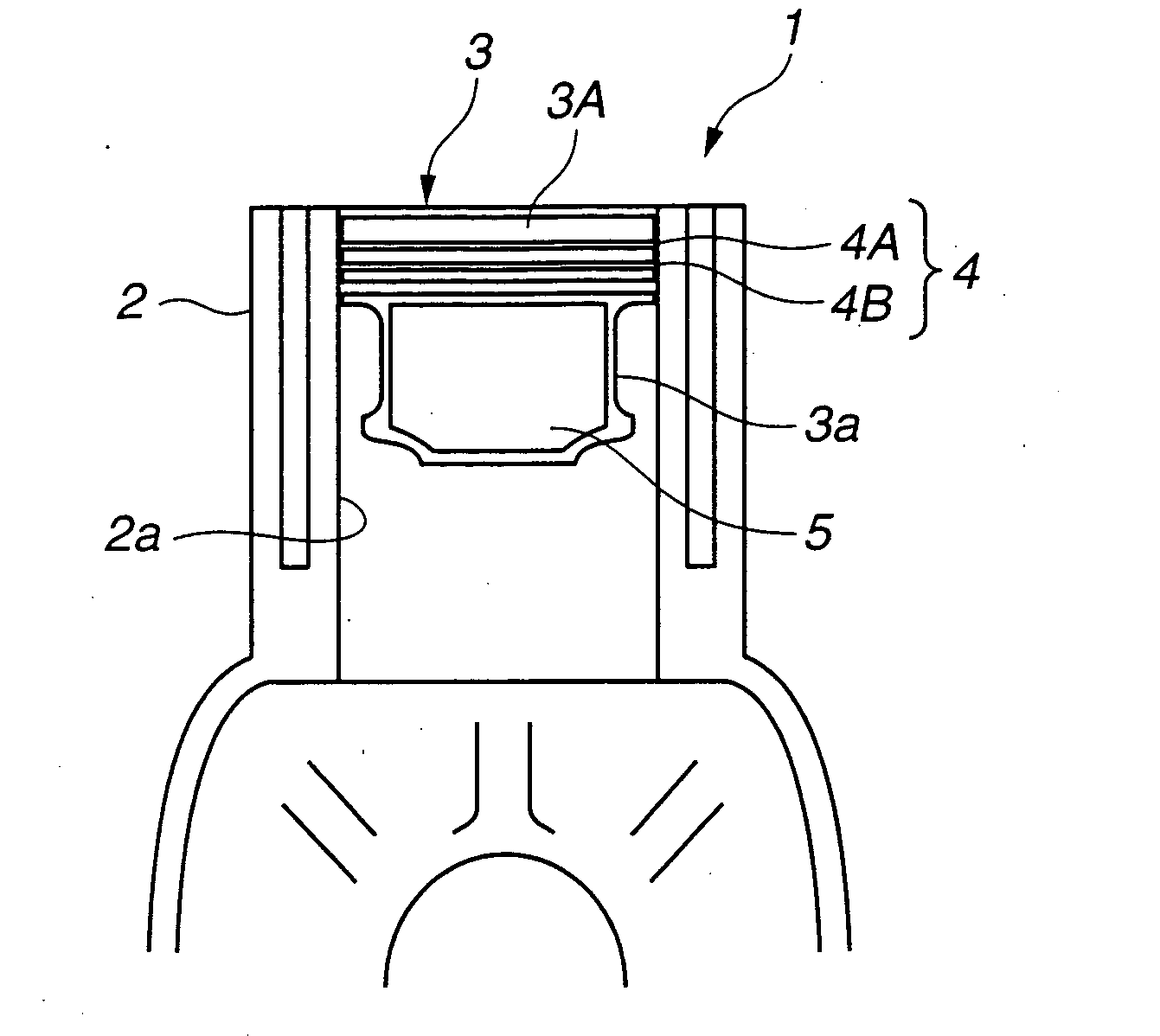

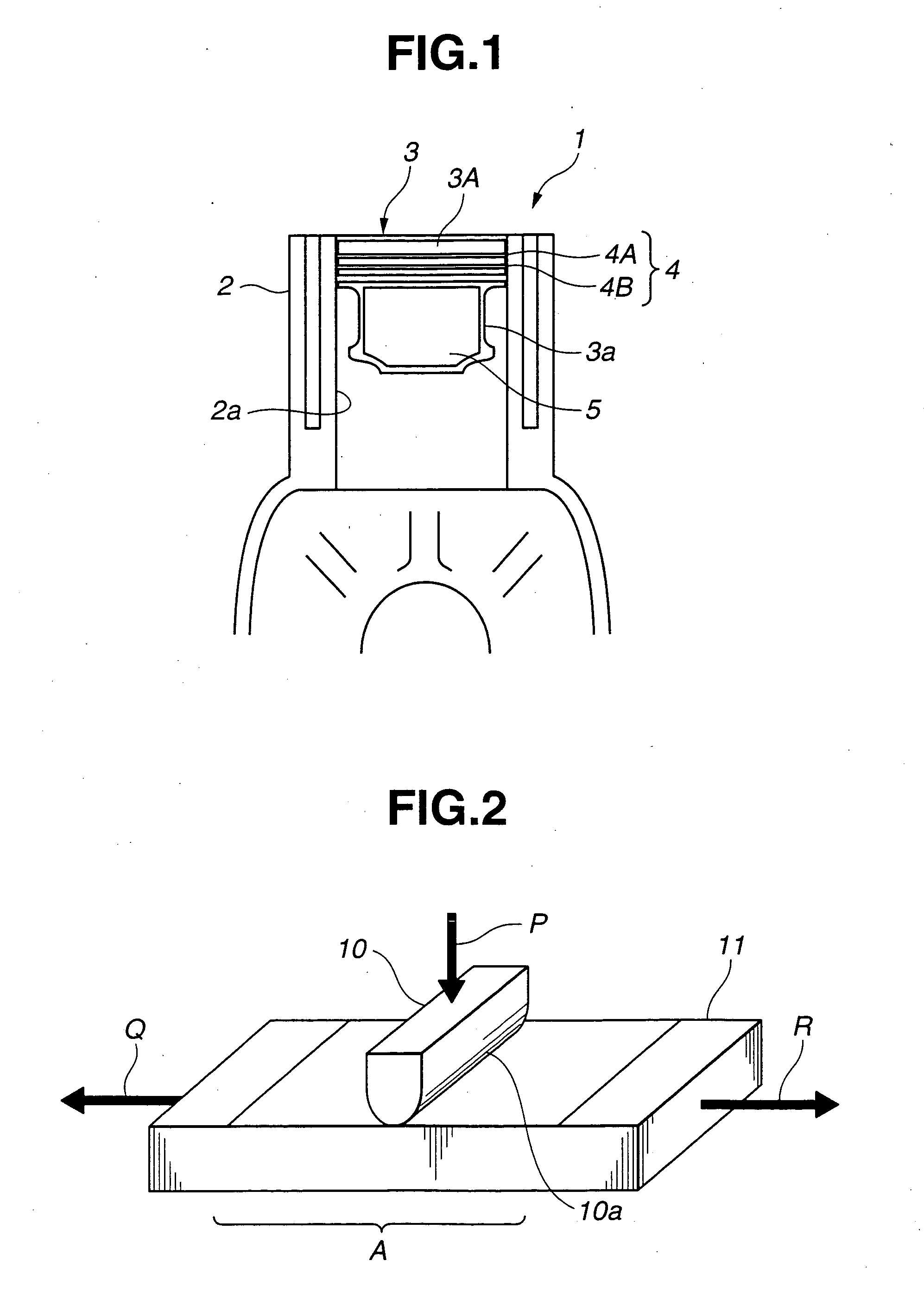

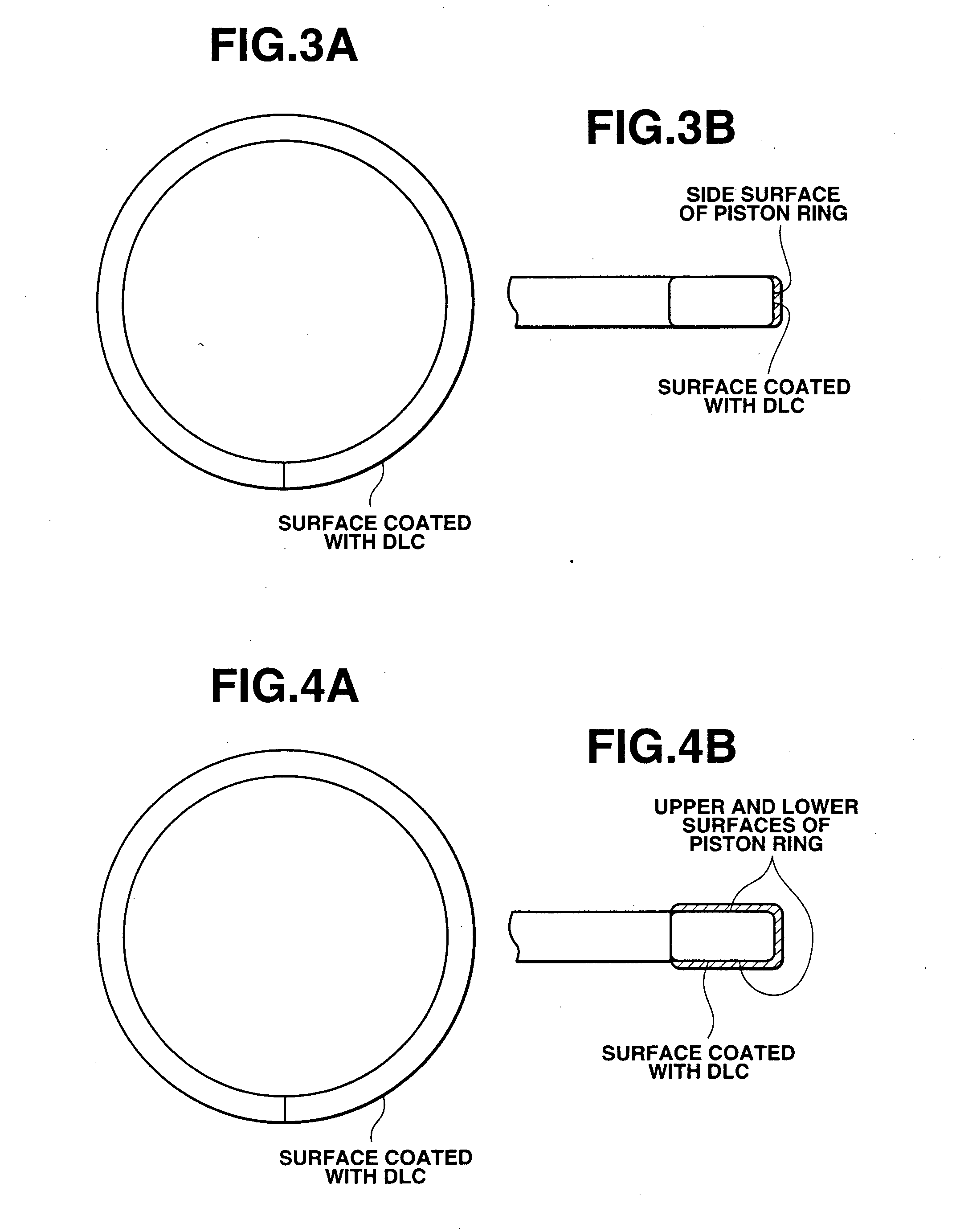

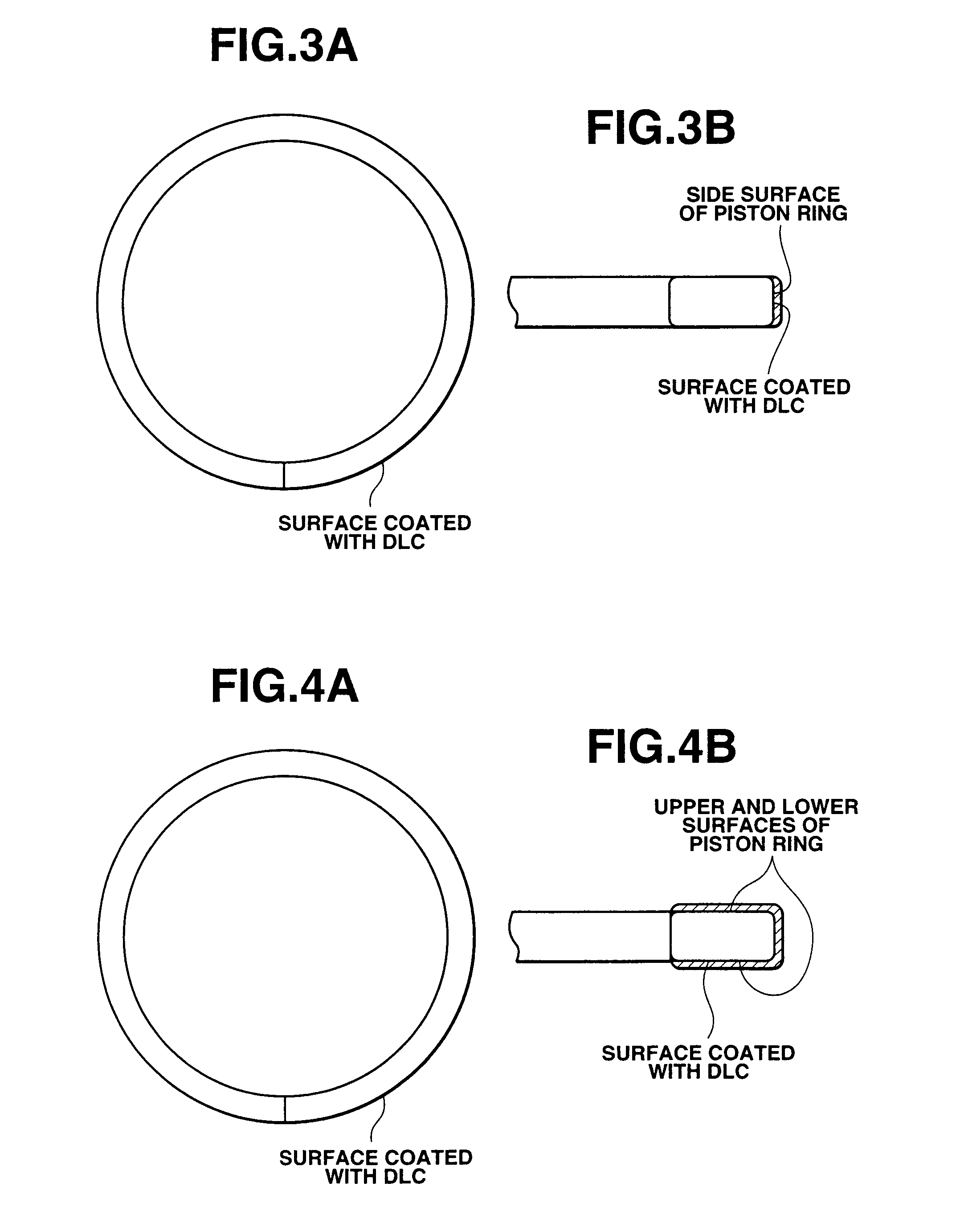

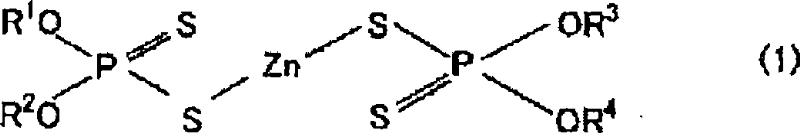

Piston for internal combustion engine

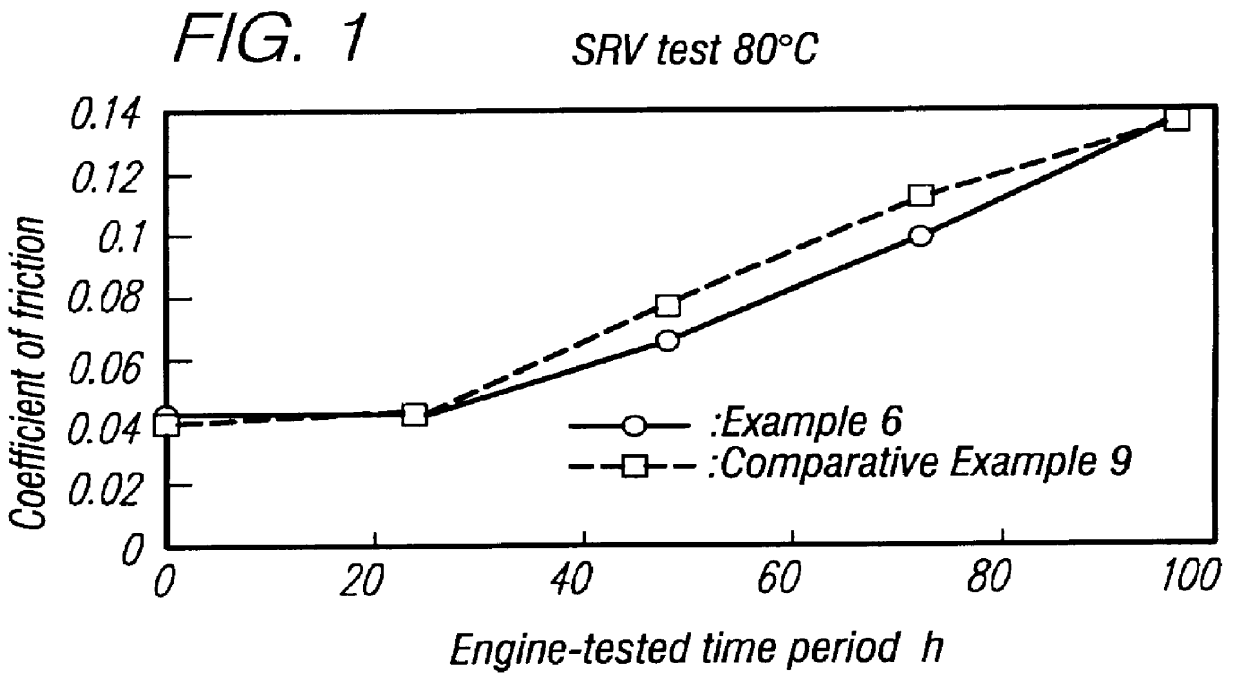

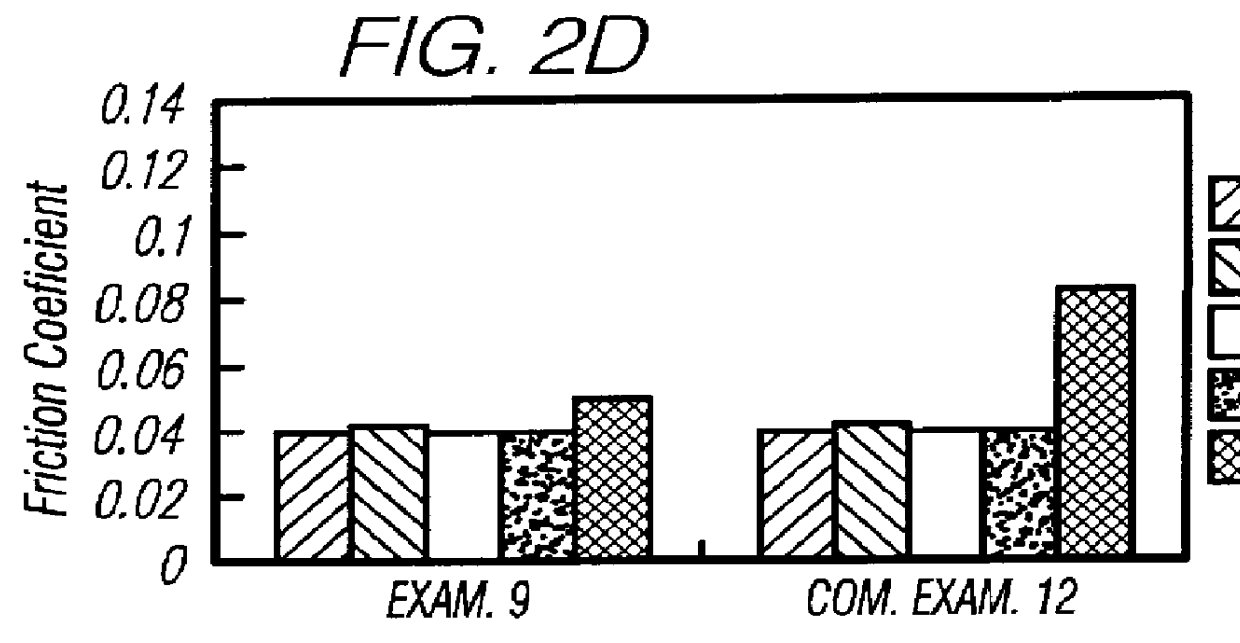

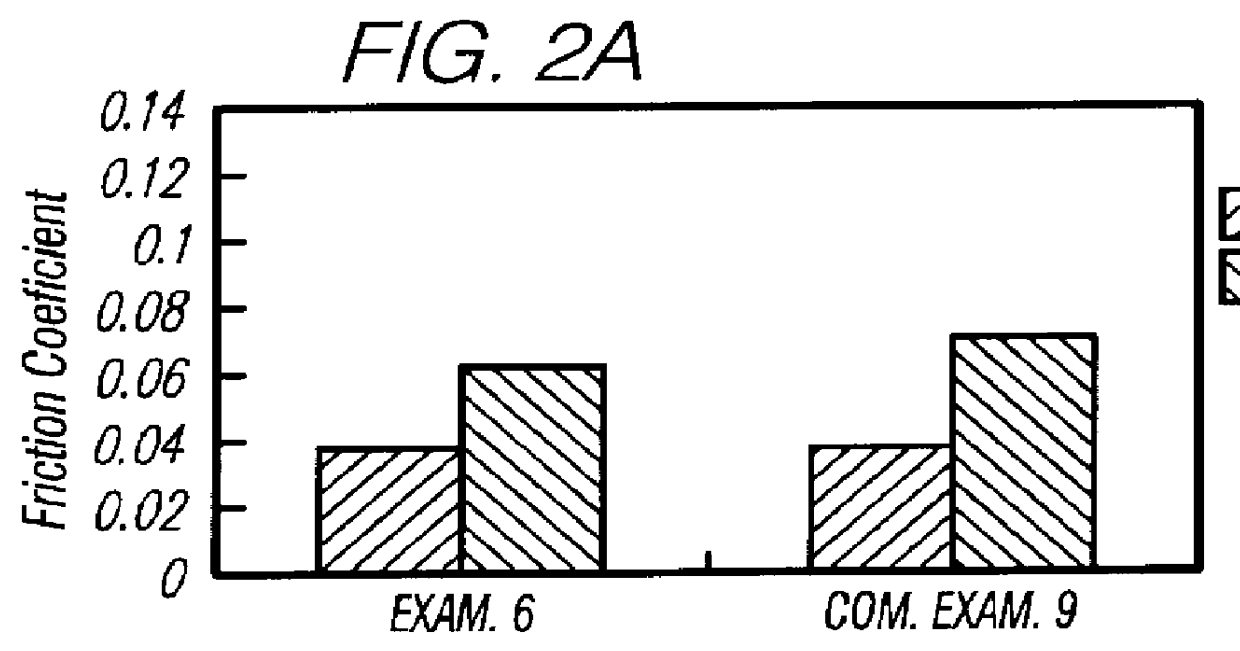

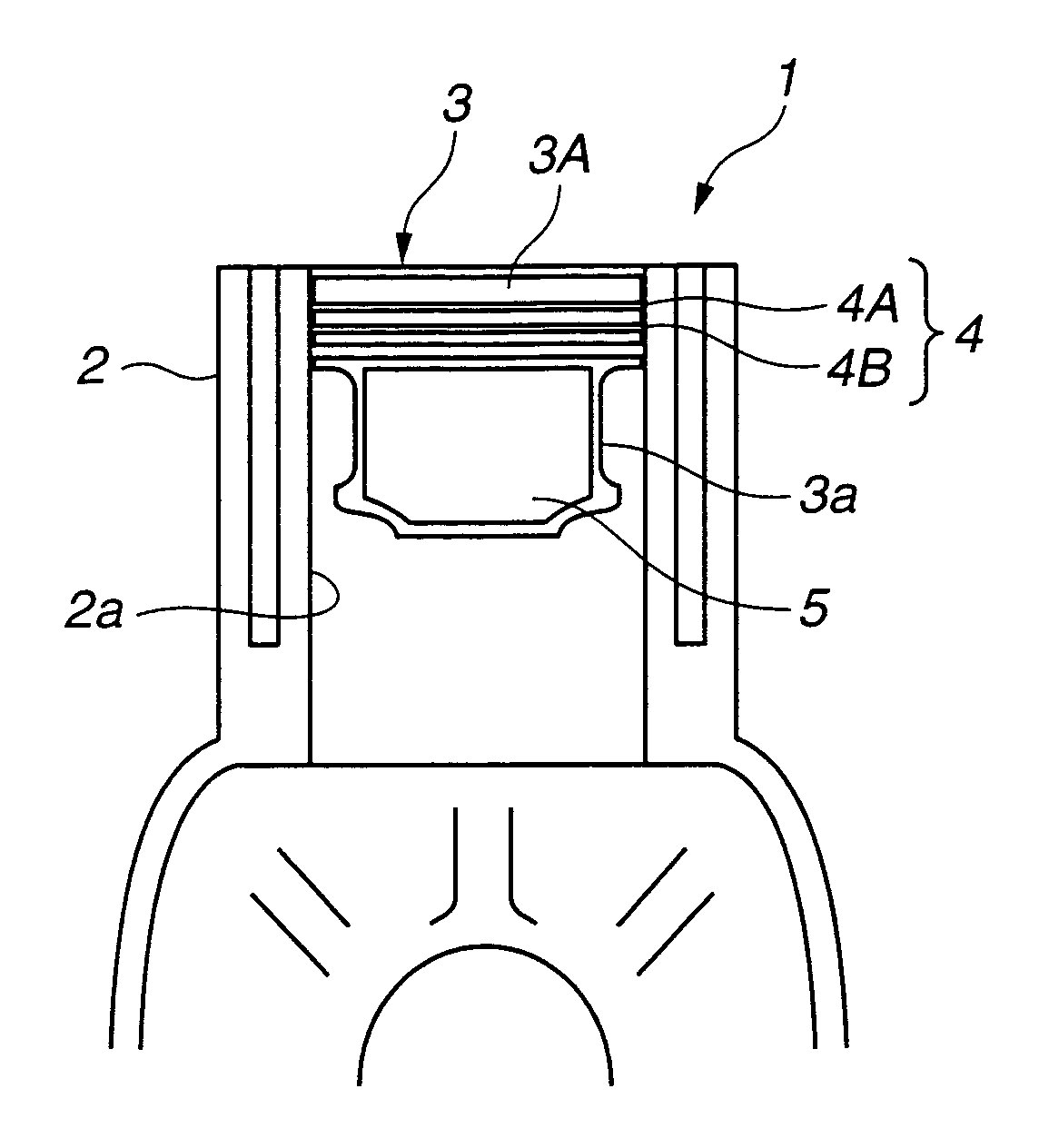

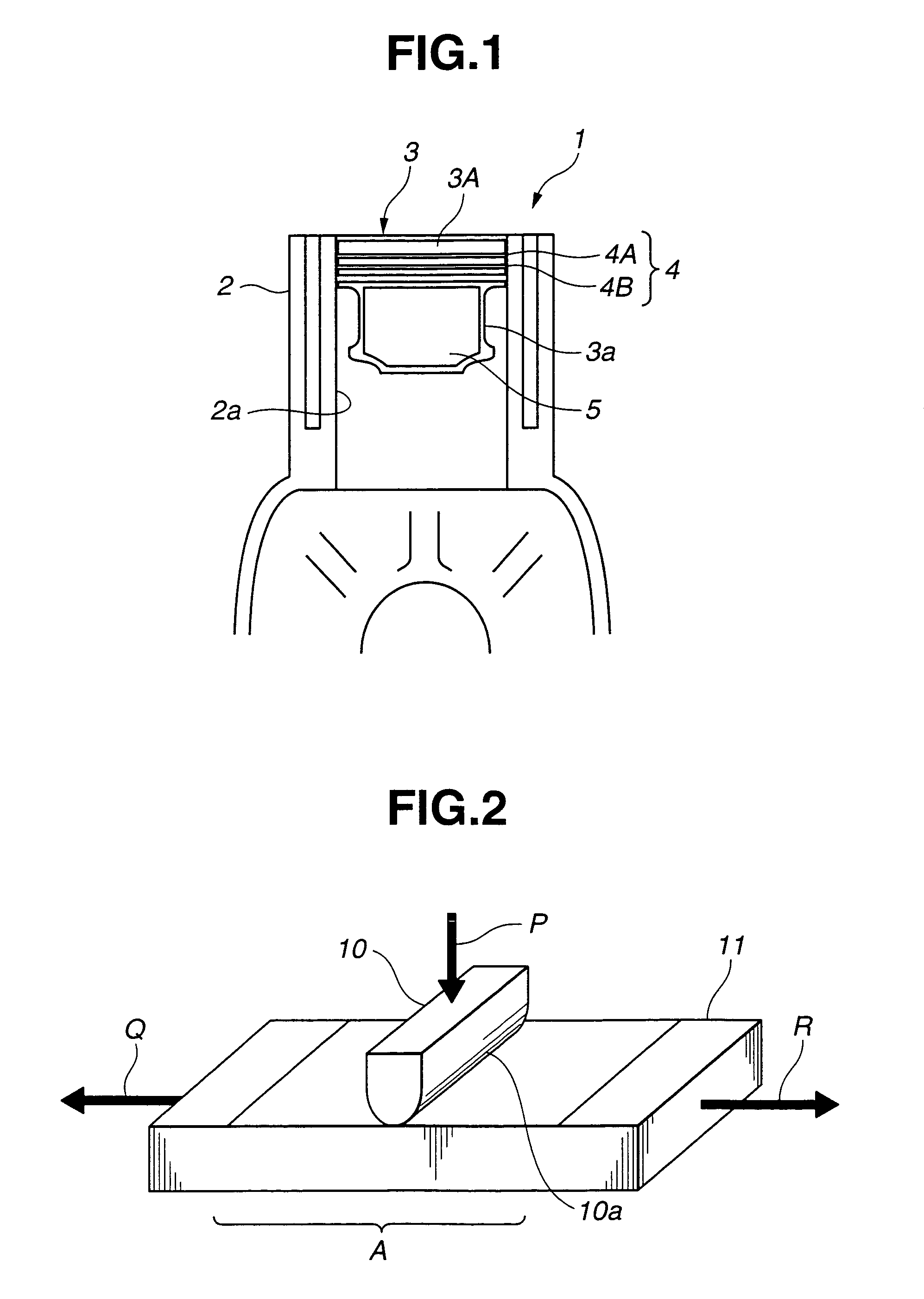

ActiveUS20050005892A1Excellent abrasion resistanceReduce coefficient of frictionCasingsPlungersPiston ringAliphatic amine

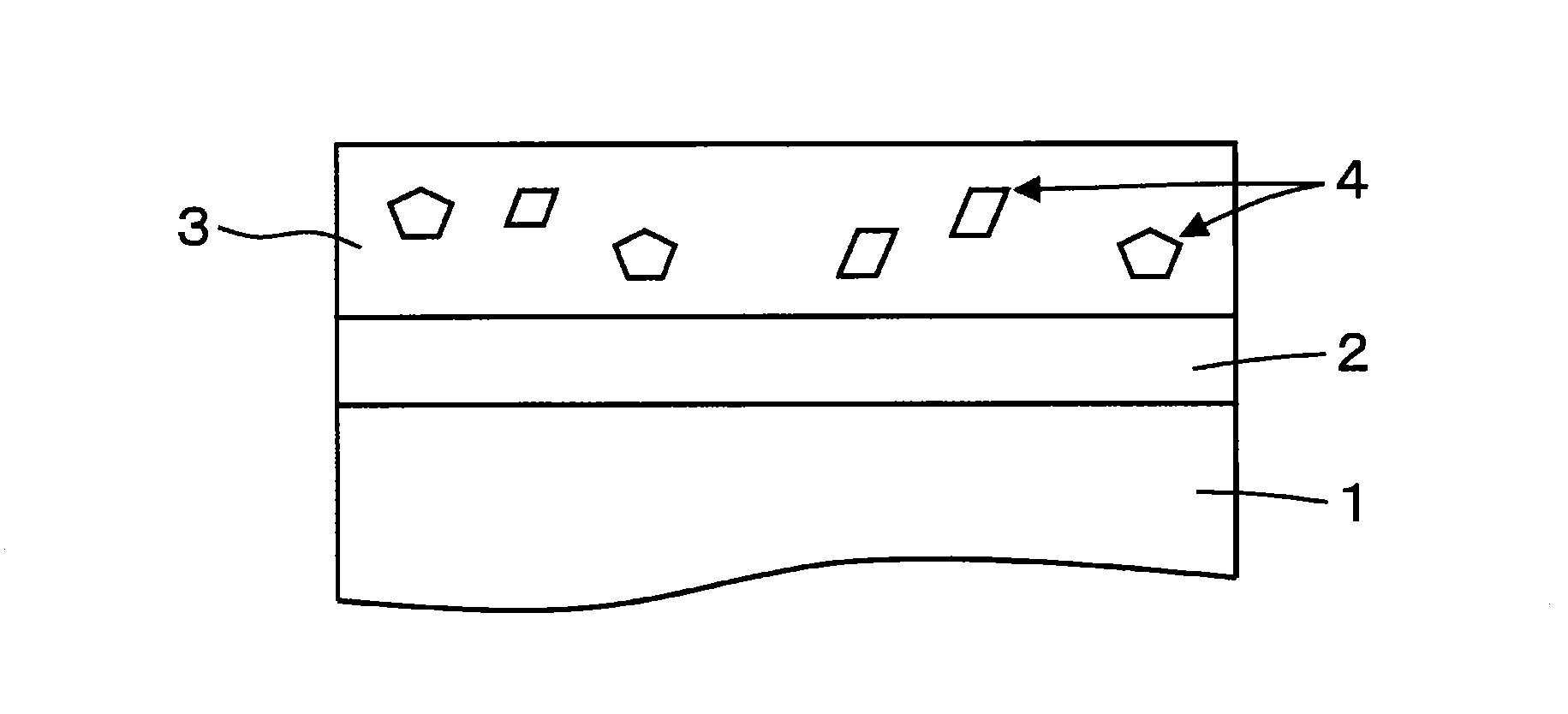

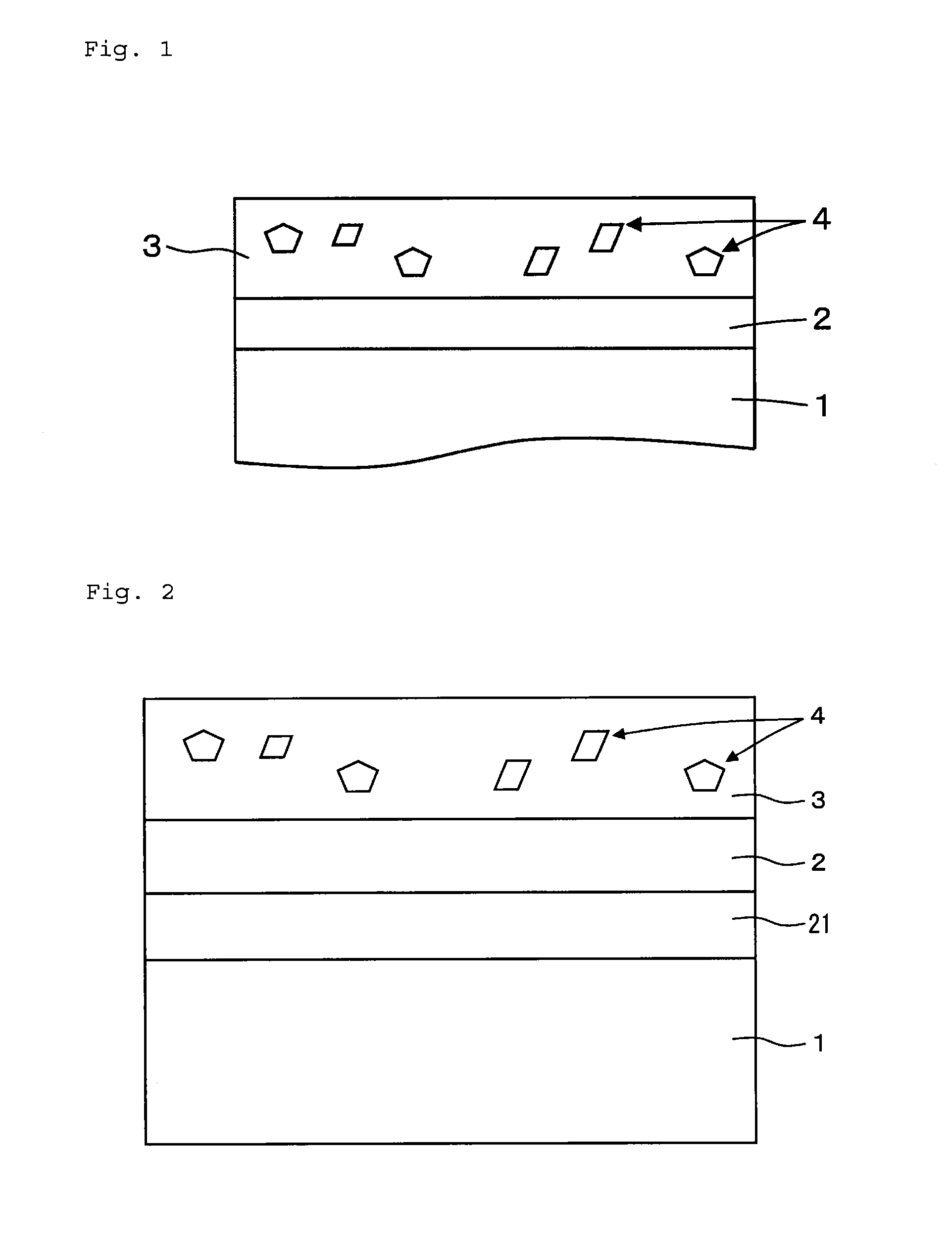

A piston for an internal combustion engine of an automotive vehicle. The piston has a piston ring and a piston skirt section each of which has a sliding section in slidable contact with a cylinder bore section of a cylinder block in presence of a lubricating oil. The cylinder bore section is formed of eutectic or hyper-eutectic aluminum alloy. Additionally, a hard carbon thin film is coated on the sliding section of the piston and contains hydrogen atom in an amount of not more than 1 atomic %. Here, the lubricating oil contains at least one selected from the group consisting of ashless fatty acid ester friction modifier, ashless aliphatic amine friction modifier, polybutenyl succinimide, derivative of polybutenyl succinimide, zinc dithiophosphate, and derivative of zinc dithiophosphate.

Owner:NISSAN MOTOR CO LTD

Lubricant Composition

InactiveUS20080020952A1Avoid corrosionExcellent in long drain performanceLiquid carbonaceous fuelsAdditivesCompound (substance)Metallic materials

The present invention provide a lubricant composition comprising a lubricant base oil, wherein said lubricant composition contains 0.08% by mass or less of zinc dithiophosphate or no zinc dithiophosphate as phosphorus amount for total amount of said lubricant composition, contacts metallic materials containing lead, and contains at least a kind of additive selected from a group consisting of following (A)˜(D): (A) organomolybdenum compounds (except molybdenum dithiophosphate); (B) borate ester and / or derivatives thereof; (C) organomolybdenum compounds, and borate ester and / or derivatives thereof; and (D) organomolybdenum compounds, and borated alkyl or alkenyl succinimide.

Owner:NIPPON OIL CORP

Lubricant additive formulation

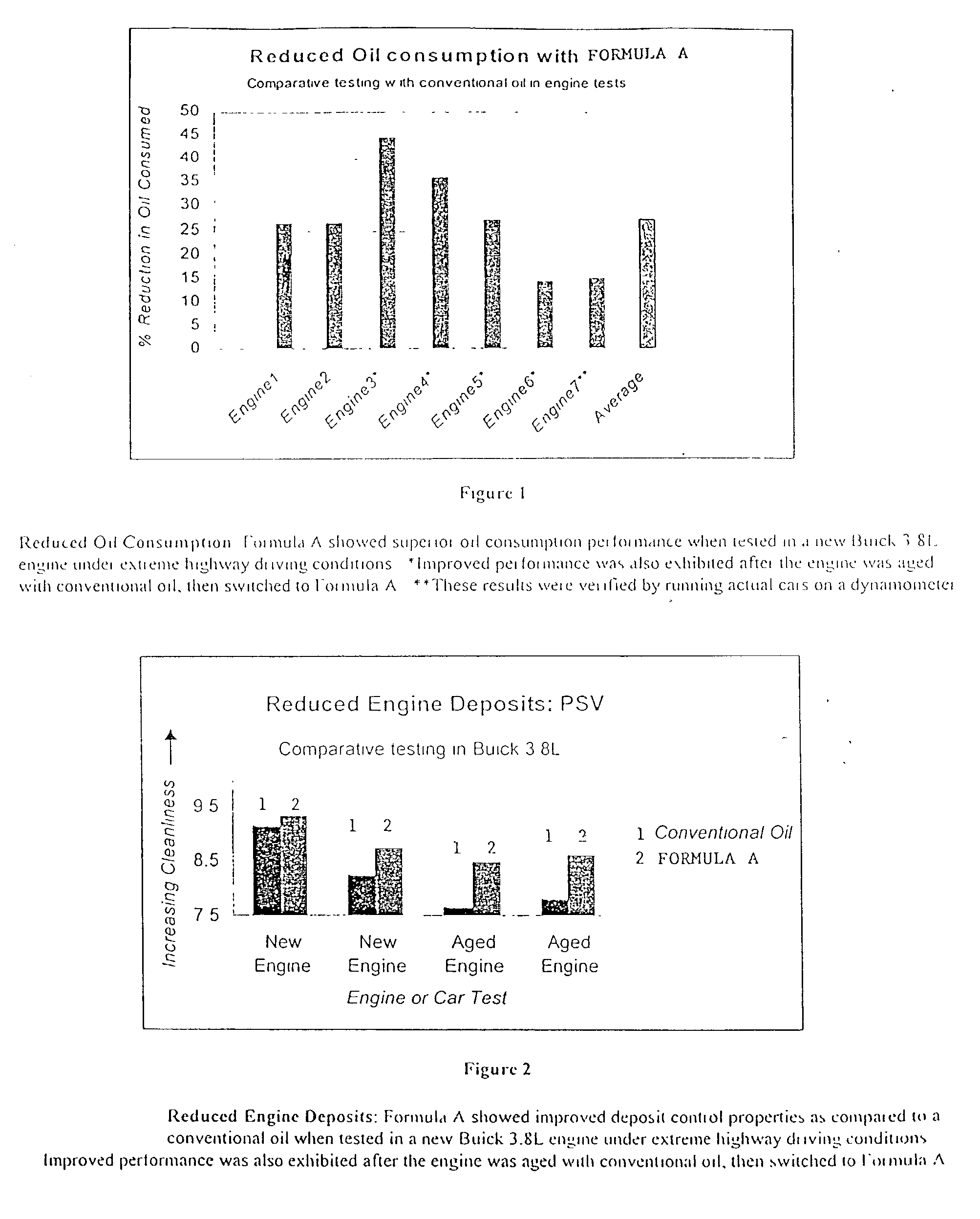

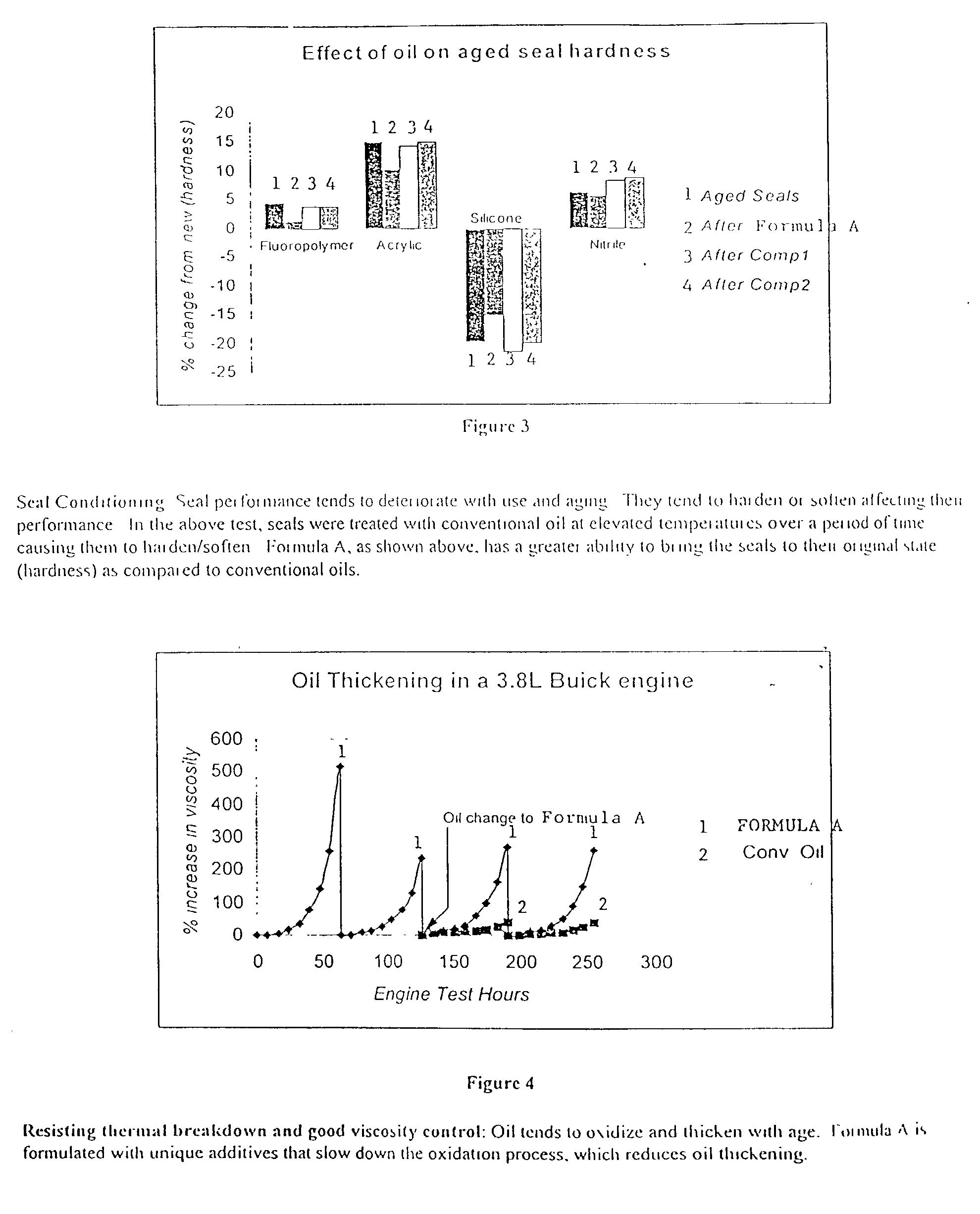

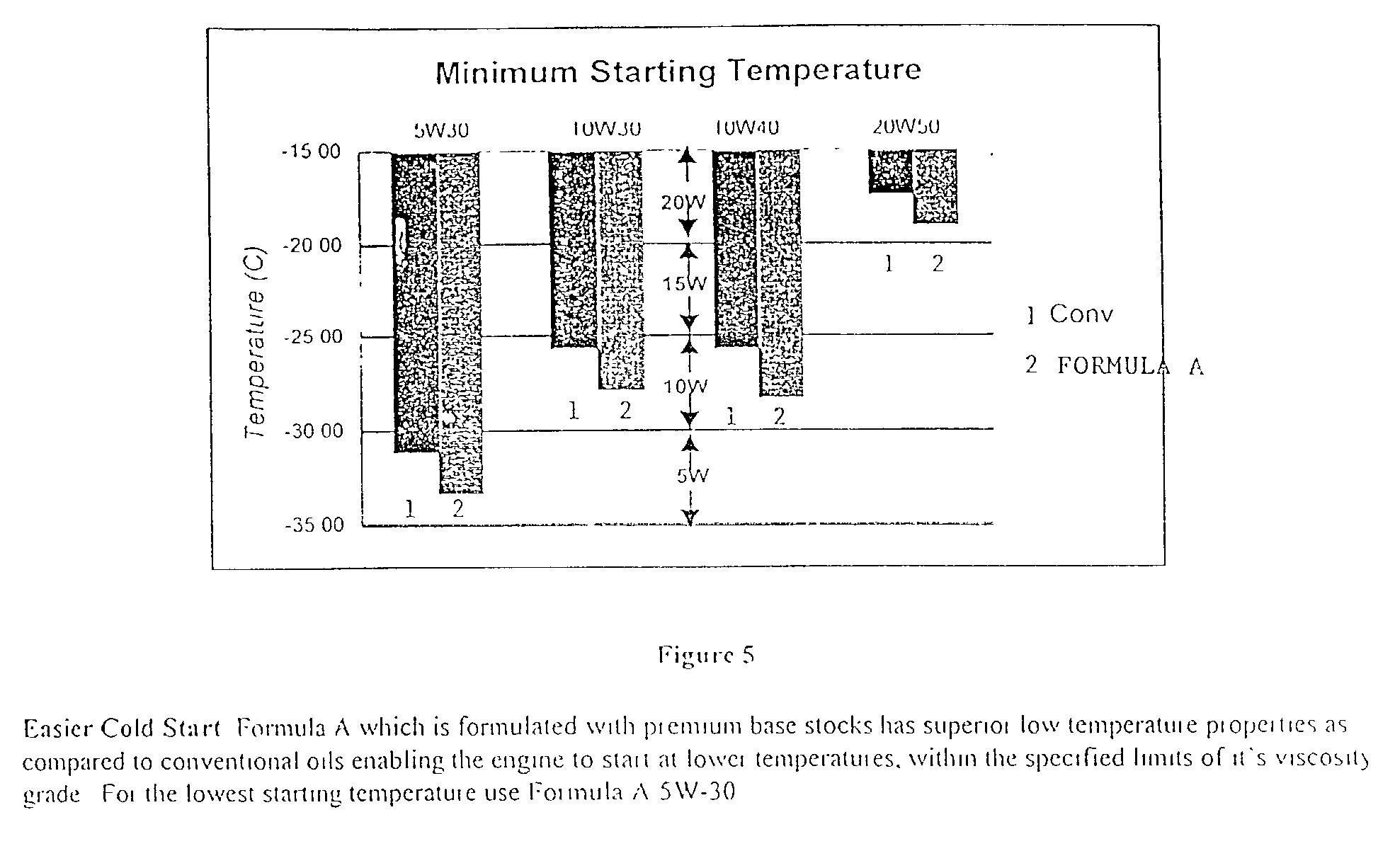

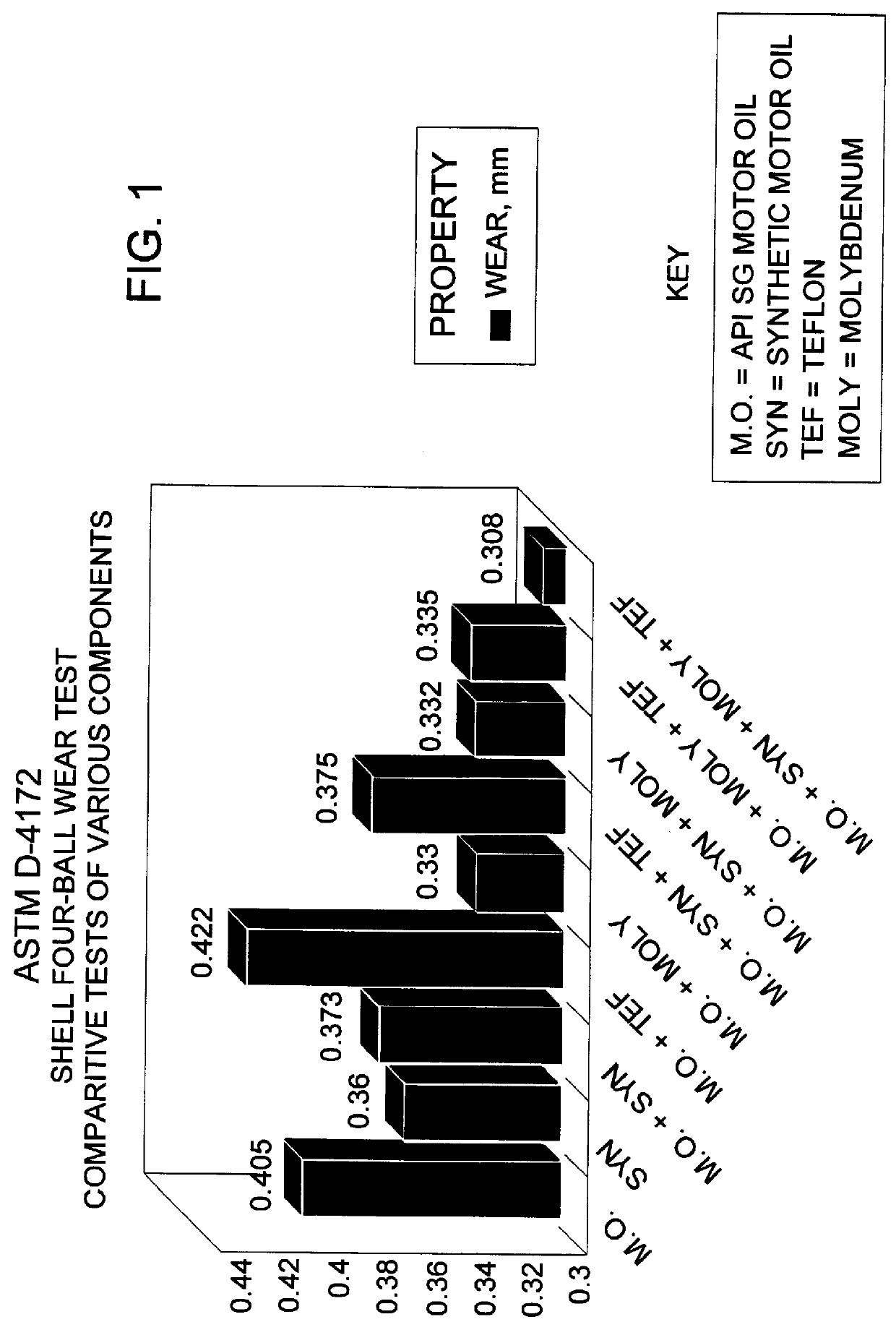

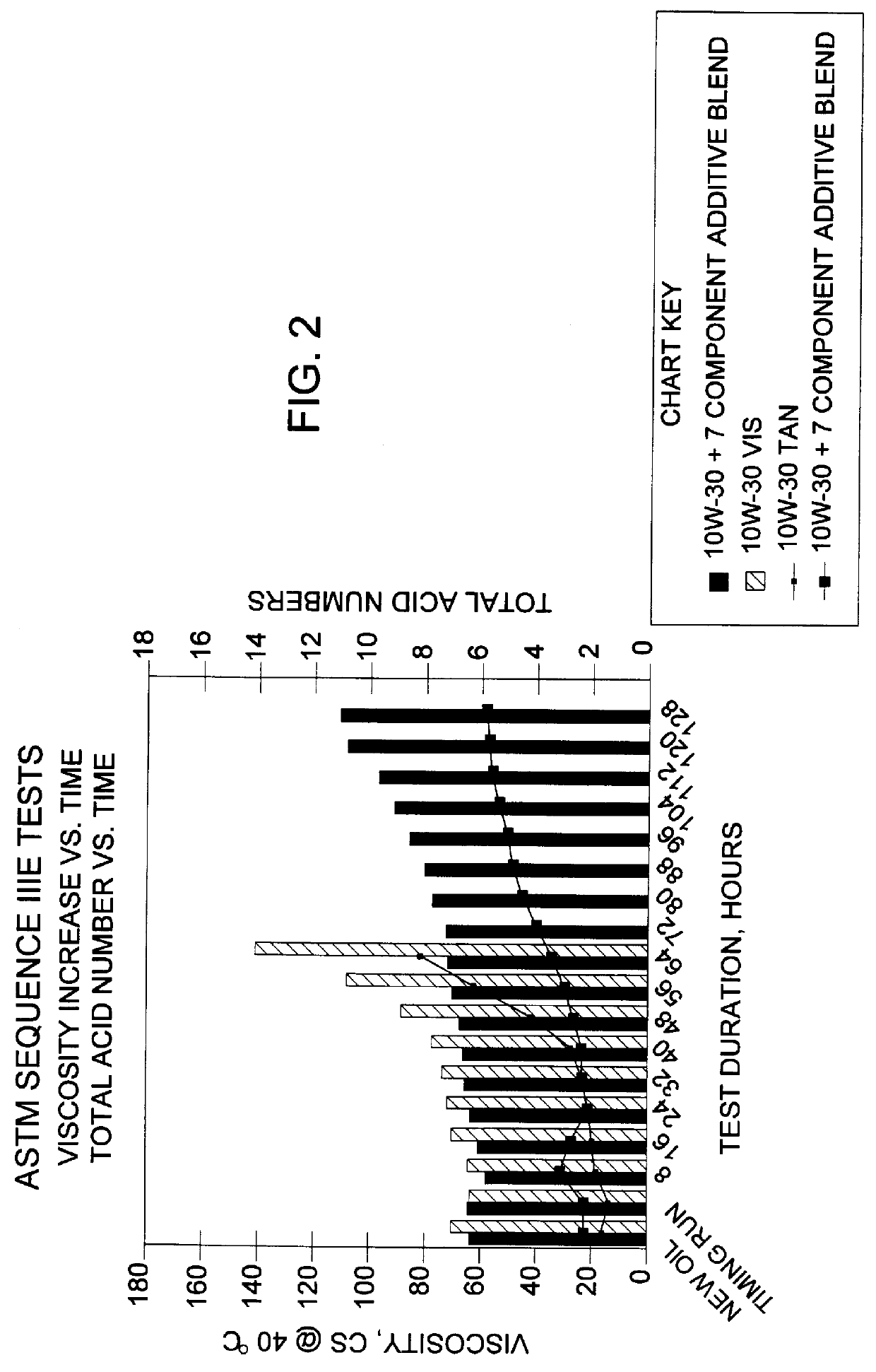

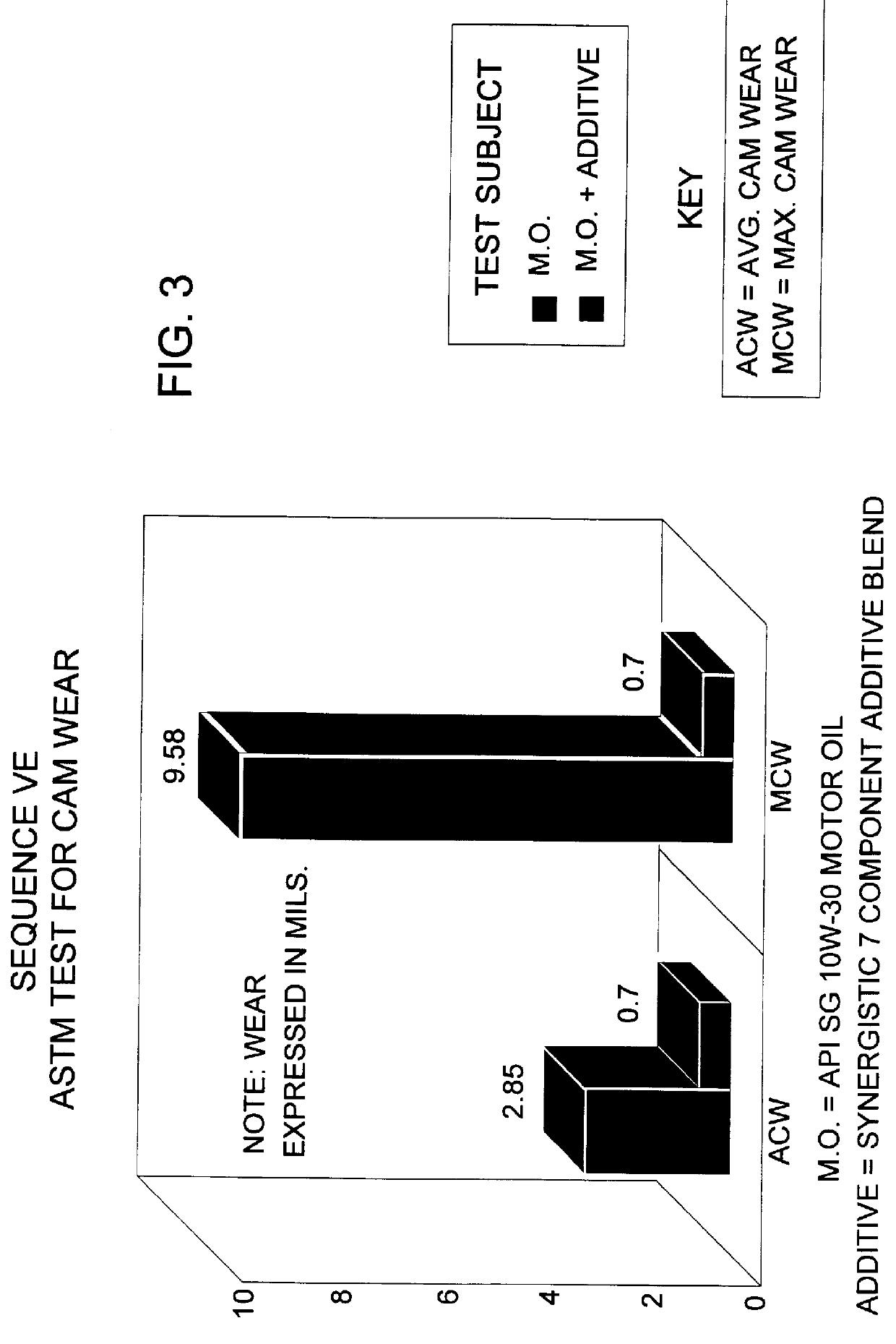

PCT No. PCT / US95 / 14186 Sec. 371 Date Aug. 27, 1997 Sec. 102(e) Date Aug. 27, 1997 PCT Filed Nov. 3, 1995 PCT Pub. No. WO96 / 15211 PCT Pub. Date May 23, 1996A lubricant additive formulation for addition to conventional motor oil to improve the lubricating properties of the engine oil and enhance the performance of the engine. The engine treatment oil additive comprises a synergistic blend of an oil soluble molybdenum additive, polyalphaolefin, ester such as a polyolester or diester, polytetrafluoroethylene, dispersant inhibitor containing zinc dithiophosphate, mineral oil base stock, viscosity index improvers, and borate ester used in combination with a conventional crankcase lubricant at about a 20 to about a 25% volume / percent. The improved performance of the engine additive in comparison with a conventional crankcase lubricants is attributable to the effect of optimizing the design parameters for each of the individual chemical constituents and combining the chemical constituents according to the present invention to obtain surprisingly good results including improved wear, oxidation resistance, viscosity stability, engine cleanliness, fuel economy, cold starting, and inhibition of acid formation.

Owner:VALVOLINE LICENSING & INTPROP LLC

Low ash, low phosphorus and low sulfur engine oils for internal combustion engines

InactiveUS20030158048A1Reduce friction and wearLow sulfurOrganic chemistryOrganic compound preparationCombustionSulfur

A lubricating composition for internal combustion engines especially useful with fuels having less than 350 ppm sulfur comprises a lubricating oil basestock, a boron containing ashless dispersant, a molybdenum containing friction reducing agent, a metal type detergent and zinc dithiophosphate.

Owner:EXXON RES & ENG CO

Lubricant compositions

InactiveUS20020119896A1Improve abilitiesSuppress increase of viscosityOrganic chemistryOrganic compound preparationViscosity indexZinc dithiophosphate

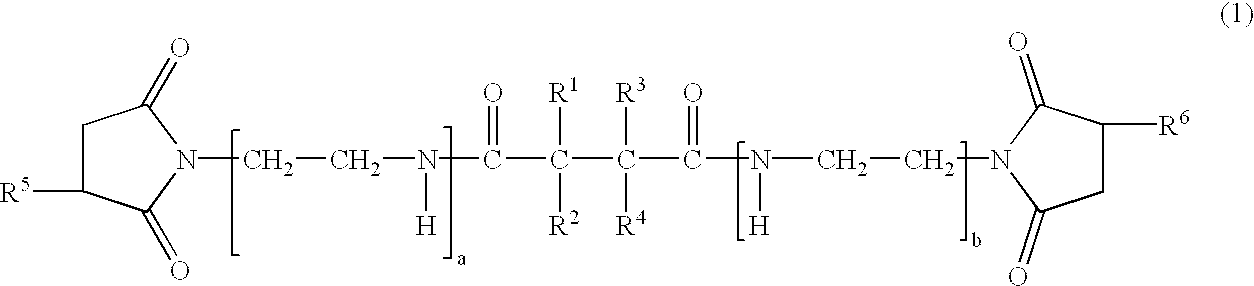

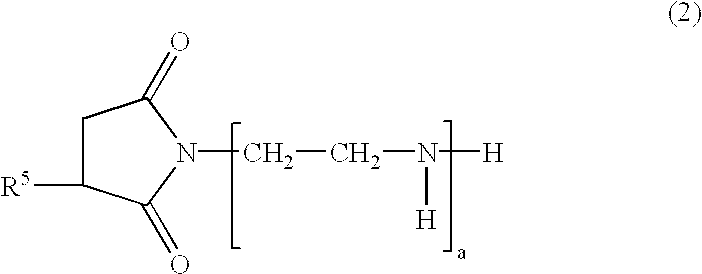

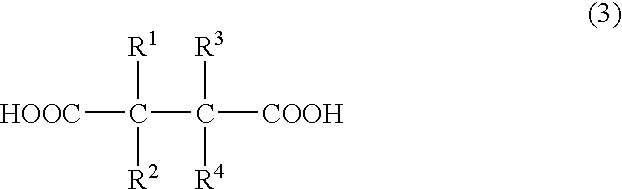

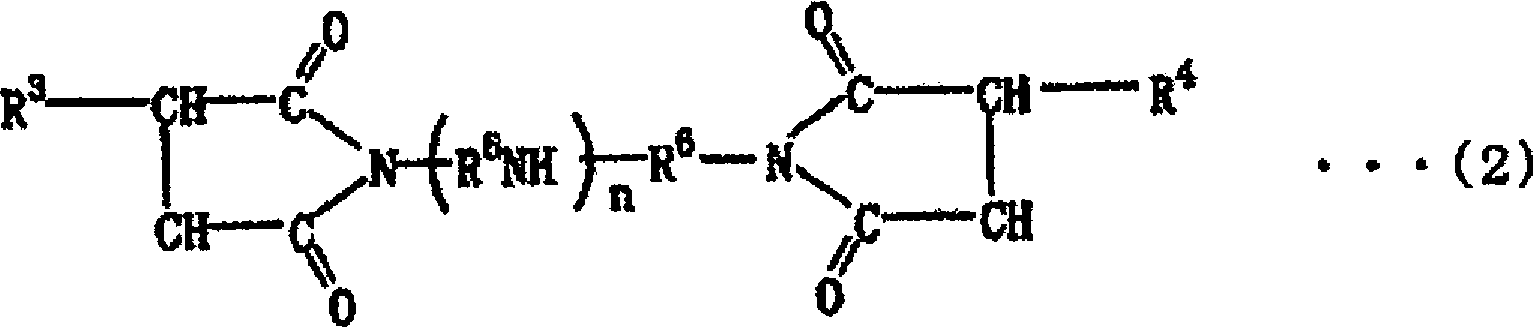

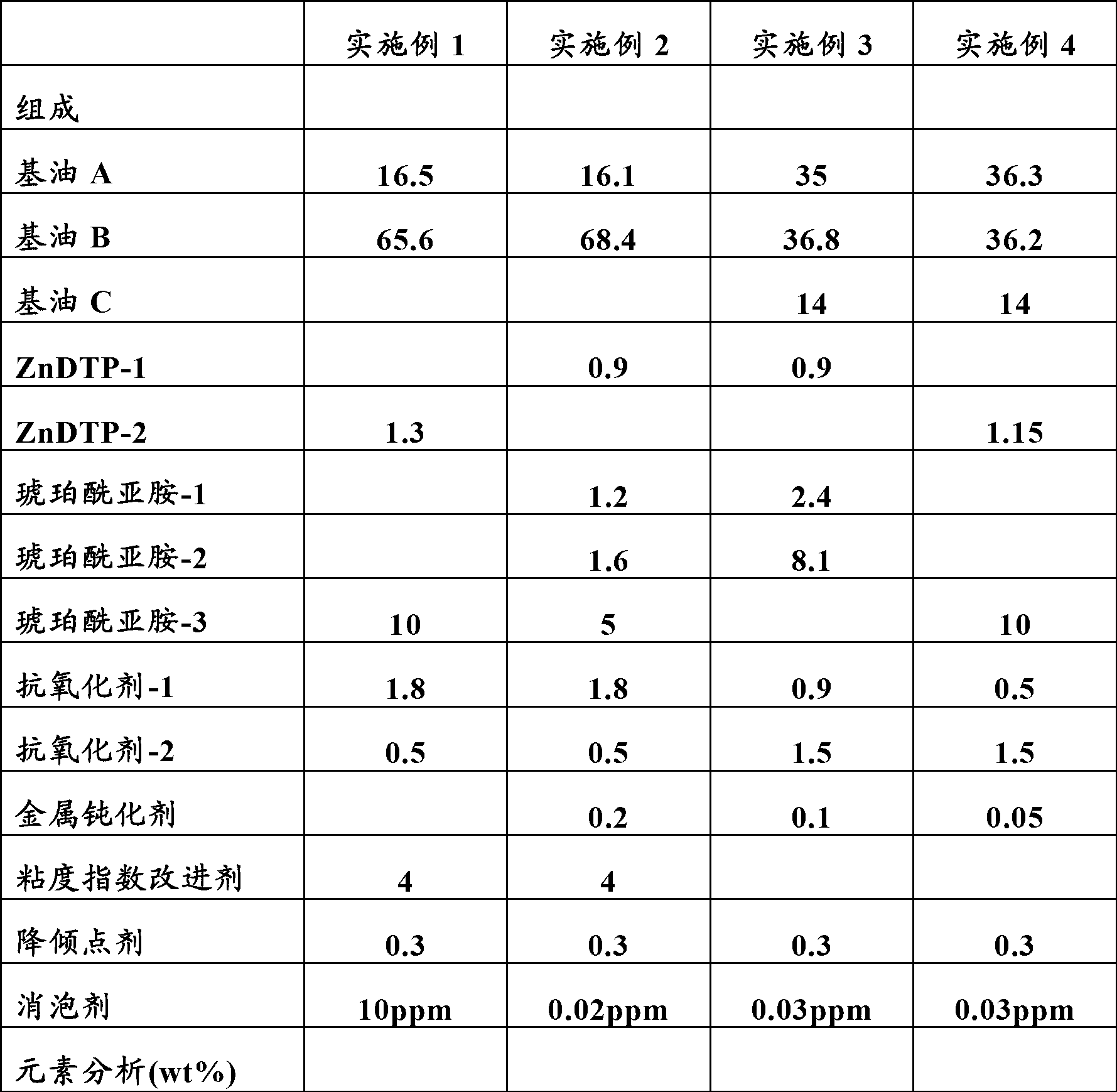

Lubricant compositions comprise a lubricant base oil, and (A) a mono substituted amide type bissuccinimide in an amount from 0.5 to 20 percent by mass, (B) zinc dithiophosphate in an amount from 0.05 to 0.3 percent by mass of phosphorus, and (C) a metal-based detergent in an amount form 0.5 to 4.0 percent by mass of sulfated ash, based on the total mass of the composition. Lubricant compositions preferably further comprises (D) a dispersant type viscosity index improver in an amount from 0.1 to 20 percent by mass, based on the total mass of the composition.

Owner:NIPPON MITSUBISHI OIL CORP

Lubricant compositions

InactiveUS6569819B2Reduce fluid resistanceImprove the lubrication effectOrganic chemistryOrganic compound preparationSulfateViscosity index

Lubricant compositions comprise a lubricant base oil, and (A) a mono substituted amide type bissuccinimide in an amount from 0.5 to 20 percent by mass, (B) zinc dithiophosphate in an amount from 0.05 to 0.3 percent by mass of phosphorus, and (C) a metal-based detergent in an amount form 0.5 to 4.0 percent by mass of sulfated ash, based on the total mass of the composition. Lubricant compositions preferably further comprises (D) a dispersant type viscosity index improver in an amount from 0.1 to 20 percent by mass, based on the total mass of the composition.

Owner:NIPPON MITSUBISHI OIL CORP

Engine oil composition

An engine oil composition is composed of: (1) at least one oil selected from the group consisting of a mineral oil and a synthetic lubricant as a base oil; (2) a molybdenum dithiocarbamate in an amount of 50 to 2000 ppm by weight when calculated as molybdenum (Mo), relative to the total weight of the engine oil composition; (3) zinc dithiophosphate in an amount of 0.01 to 0.2 wt % when calculated as phosphorus (P), relative to the total amount of the engine oil composition; and (4) an ashless organic polysulfide compound in an amount of 0.01 to 0.4 wt % when calculated as sulfur (S), relative to the total amount of the engine oil composition.

Owner:JAPAN ENERGY CORP +1

Piston for internal combustion engine

ActiveUS7406940B2Increase resistanceReduce coefficient of frictionCasingsPlungersHydrogen atomPiston ring

A piston for an internal combustion engine of an automotive vehicle. The piston has a piston ring and a piston skirt section each of which has a sliding section in slidable contact with a cylinder bore section of a cylinder block in presence of a lubricating oil. The cylinder bore section is formed of eutectic or hyper-eutectic aluminum alloy. Additionally, a hard carbon thin film is coated on the sliding section of the piston and contains hydrogen atom in an amount of not more than 1 atomic %. Here, the lubricating oil contains at least one selected from the group consisting of ashless fatty acid ester friction modifier, ashless aliphatic amine friction modifier, polybutenyl succinimide, derivative of polybutenyl succinimide, zinc dithiophosphate, and derivative of zinc dithiophosphate.

Owner:NISSAN MOTOR CO LTD

Lubricating oil composition

InactiveCN101044228AAvoid corrosionInhibition lossAdditivesChemical compositionDithiophosphoric acid

A lubricating oil composition which comprises a lube base oil and optionally contains zinc dithiophosphate in an amount of 0.08% by mass or below in terms of phosphorus based on the total amount of the composition and which is to be brought into contact with lead-containing metal materials, containing at least one additive selected from the group consisting of the following (A) to (D): (A) an organomolybdenum compound (except molybdenum dithio- phosphate), (B) a boric ester and / or a derivative thereof, (C) an organomolybdenum compound and a boric ester and / or a derivative thereof, and (D) an organomolybdenum compound and a boric acid-modified alkyl- or alkenylsuccinimide.

Owner:NIPPON OIL CO LTD

Lubricating oil composition and use thereof

InactiveUS20060281642A1Liquid carbonaceous fuelsGroup 6/16 element organic compoundsAlkaline earth metalAntioxidant

A lubricating oil composition having a sulfur content of from 0.3 to 0.5 wt. %, a phosphorus content of from 0.10 to 0.13 wt. % and a sulfated ash content of from 0.1 to 1.1 wt. %, based on the total weight of the lubricating oil composition is provided. The lubricating oil composition contains at least one Group II mineral base oil; at least one alkali and / or alkaline earth metal alkyl salicylate; an ashless dispersant; at least one zinc didithiophosphate; and at least one aminic ashless antioxidant and at least one phenolic ashless antioxidant.

Owner:SHELL OIL CO

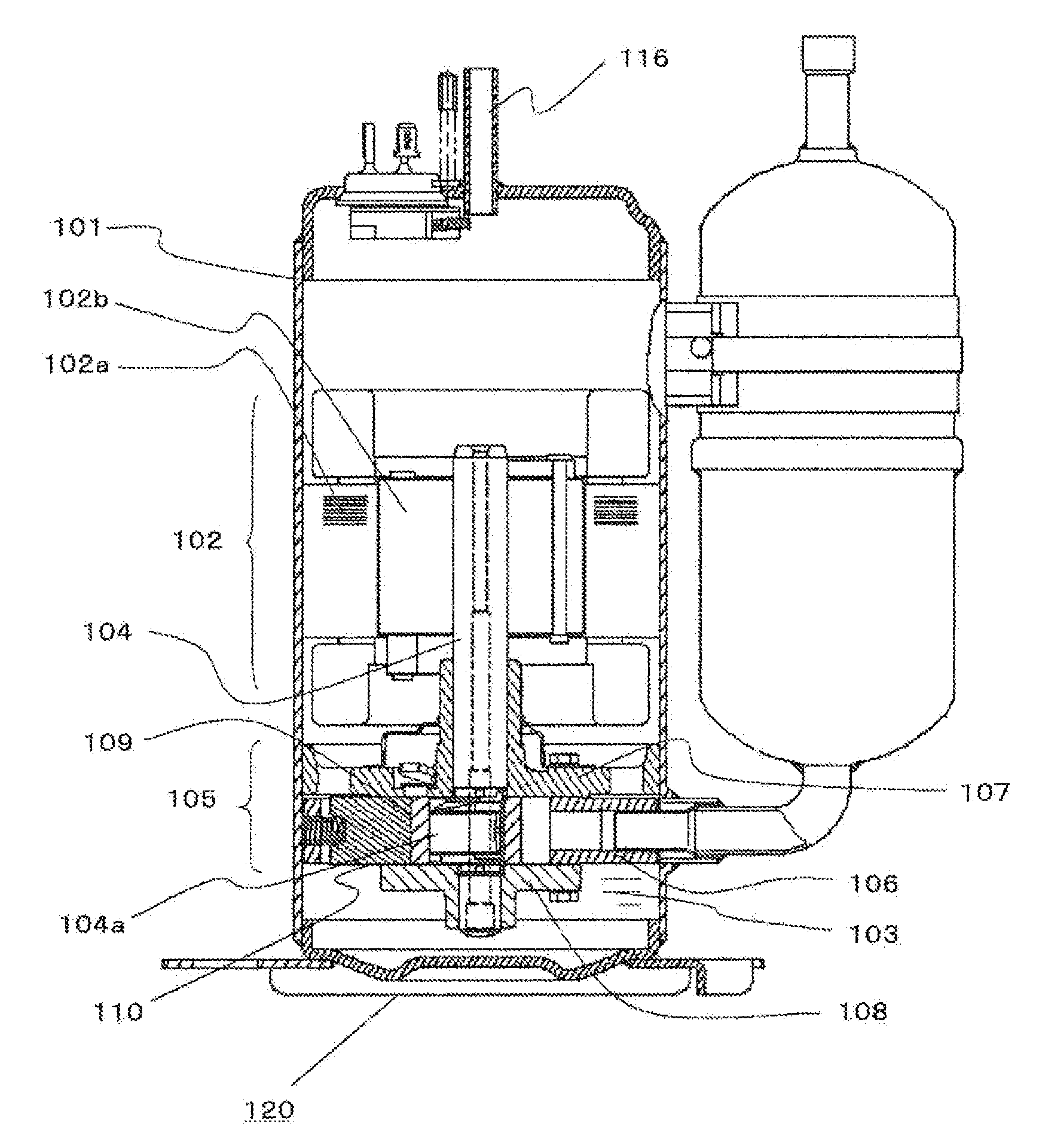

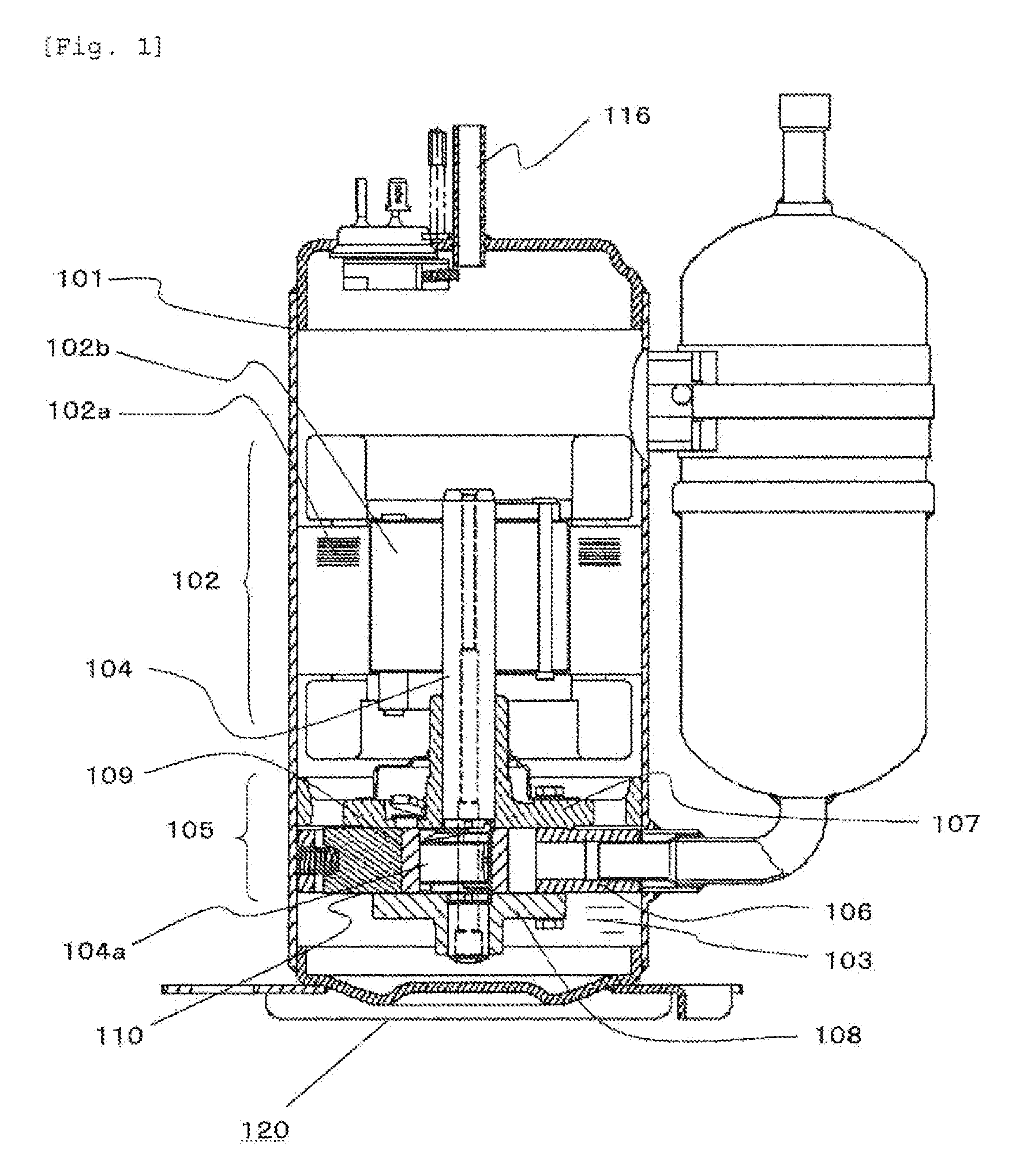

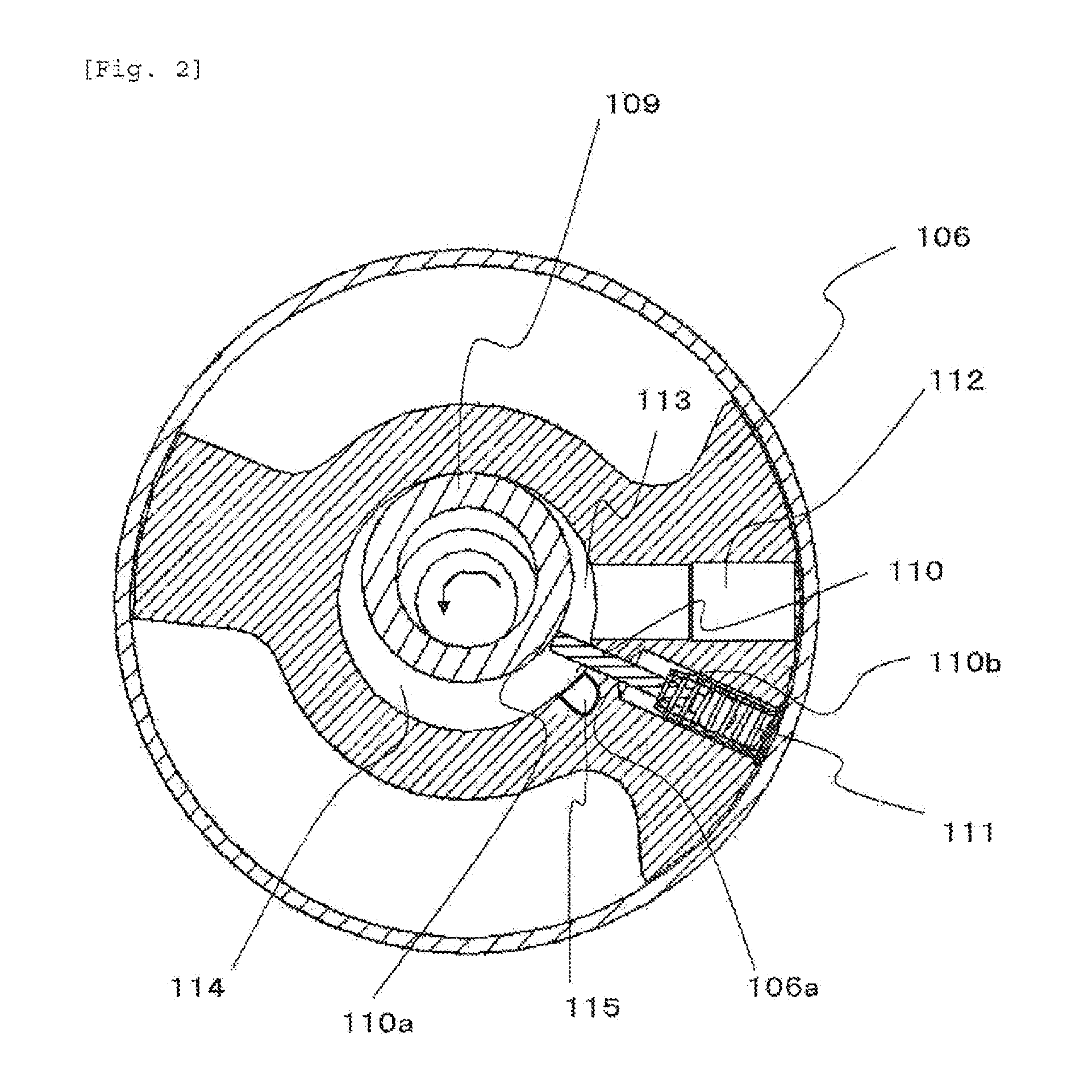

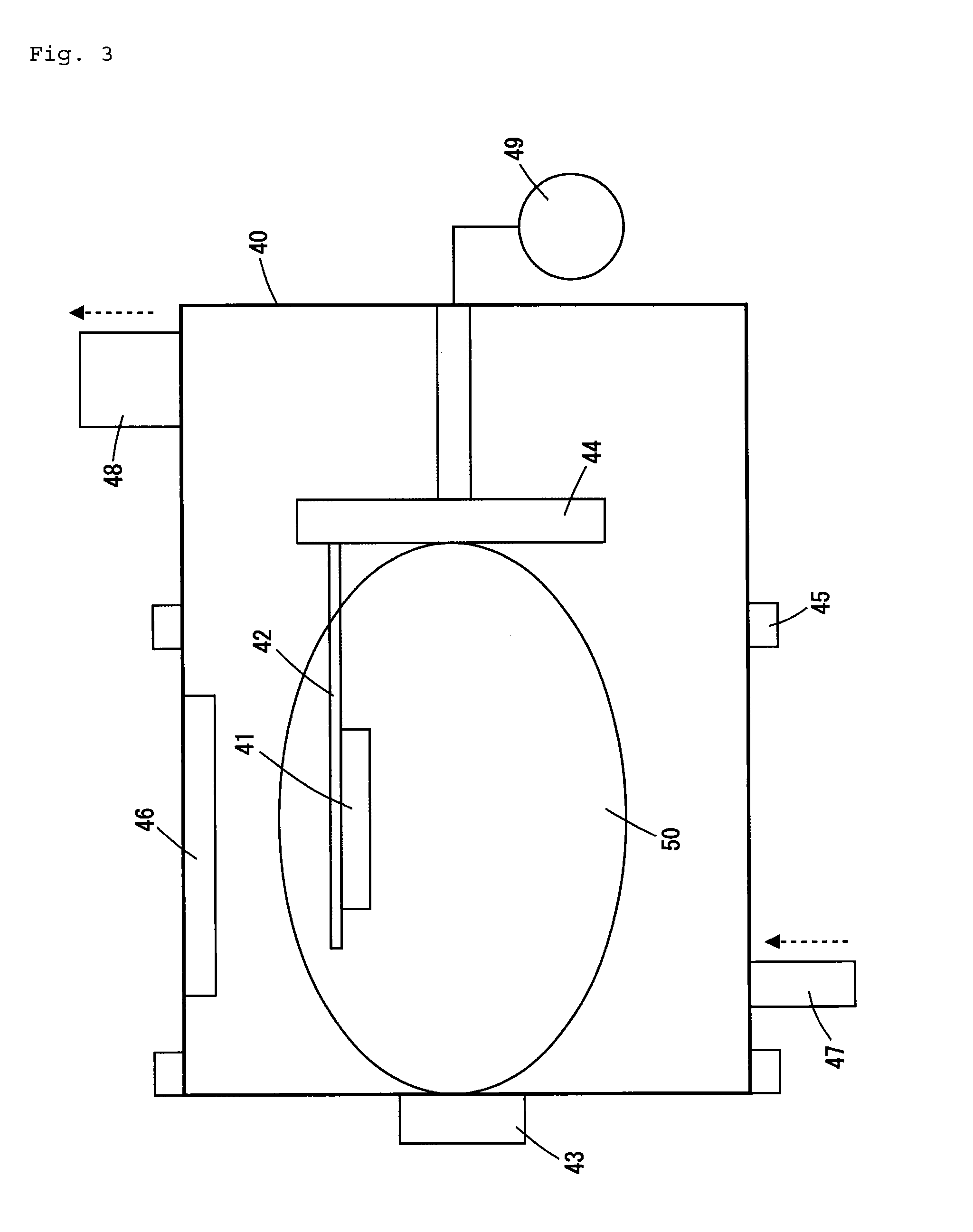

Compressor and refrigeration cycle device using same

ActiveUS20130098101A1Slow down the rate of deteriorationSecuring long-term reliabilityCompressorCompression machines with non-reversible cycleDecompositionDouble bond

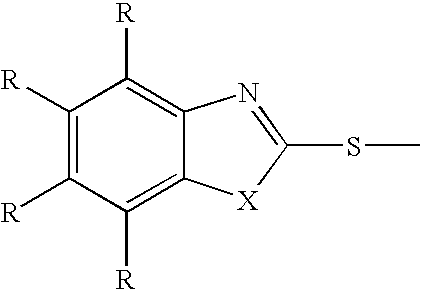

According to a compressor and a refrigeration cycle device using same of the present invention, a refrigerant and refrigeration oil 103 are sealed in an container 101, the refrigerant is a hydrofluoroolefin having double bond of carbon in its composition or a mixture of hydrofluoroolefin as a base component and hydrofluorocarbon having no double bond, and at least one of benzotriazole, dialkyl dithiophosphoric acid zinc, dialkyl selenium, metal phenate, and organic nitrogen compound is included in the refrigeration oil 103, and it is an object to suppress the decomposition and polymerization of refrigeration oil and a refrigerant, and to secure reliability of the compressor and the refrigeration cycle device.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

High-lubricating rolling oil composition and application thereof

ActiveCN106318568AImprove the lubrication effectMeet lubrication needsLubricant compositionPhosphateButylated hydroxytoluene

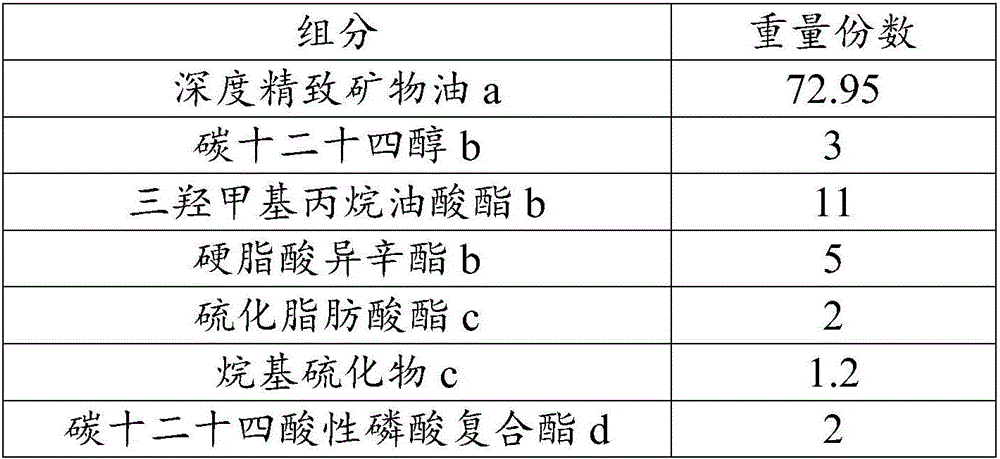

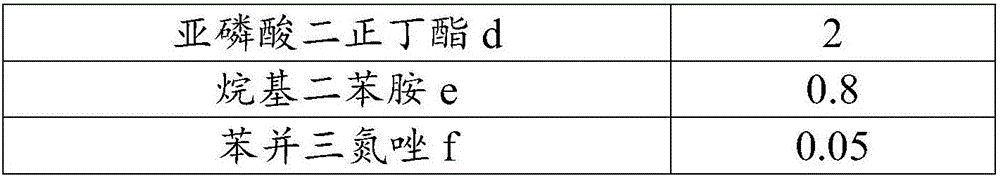

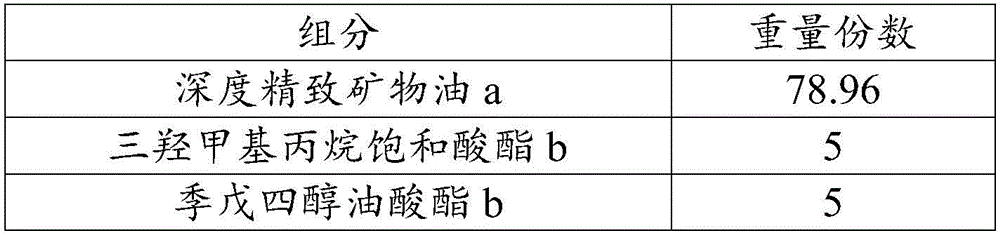

The invention relates to a high-lubricating rolling oil composition and application thereof. The composition is prepared from 40-90 parts of highly refined mineral oil, 10-30 parts of carbon dodecanol tetradecyl alcohol, isotridecyl alcohol, n-octanol, pentaerythritol oleate, trimethylolpropane trioleate, diisooctyl phthalate, 2-ethylhexyl palmitate, isooctyl stearate, methyl palmitate or butyl stearate, 1-5 parts of ZDTP, octadecyl zinc dithiophosphate, sulfurized olefin, sulfide aliphatic acid ester, sulfurized animal oil, alkyl sulfide or sulfur phosphorus molybdenum, 0.5-5 parts of amine thiophosphate, isooctyl acidic phosphate octadecylamine, tricresyl phosphate, tributyl phosphate, dibutyl phosphate and carbon-12 to carbon-14 acid phosphate compound ester, 0.1-5 parts of 2,6-butylated hydroxytoluene, N-phenyl naphthylamine, thioether phenol or alkyl diphenylamine and 0.01-2 parts of 1H-benzotriazole, thiadiazole derivative and benzotriazole.

Owner:CHINA PETROLEUM & CHEM CORP

Antirust agent containing modified vermiculite powder

The invention discloses an antirust agent containing modified vermiculite powder. The antirust agent containing modified vermiculite powder is prepared from the following raw materials by weight: 80-100 parts of castor oil, 5-8 parts of barium petroleum sulfonate, 1-3 parts of ferrocene, 0.8-1.0 part of polyisobutene, 0.5-1.0 part of bitertanol, 1-2 parts of ammonium benzoate, 5-8 parts of fatty acid amide, 8-10 parts of aluminium stearate, 0.8-1.2 parts of 2-aminoethyl heptadecenyl imidazoline, 1-2 parts of decylamine, 1-3 parts of zinc alkyl dithiophosphate, 5-8 parts of sodium citrate, 8-10 parts of phosphoric acid, 2-4 parts of sodium dodecyl benzene sulfonate, 2-3 parts of polyethylene glycol, 5-6 parts of a film-forming resin, 3-5 parts of lanolin, 3-5 parts of 1,3-glutaric acid morpholine and 5-8 parts of modified vermiculite powder. By adding the modified vermiculite powder and adjusting the formula, the antirust agent having a very good gas phase antirust effect is prepared. The antirust agent provided by the invention has excellent antirust performance and is convenient for use; and the production process is simple.

Owner:辽宁宝瑞科技有限公司

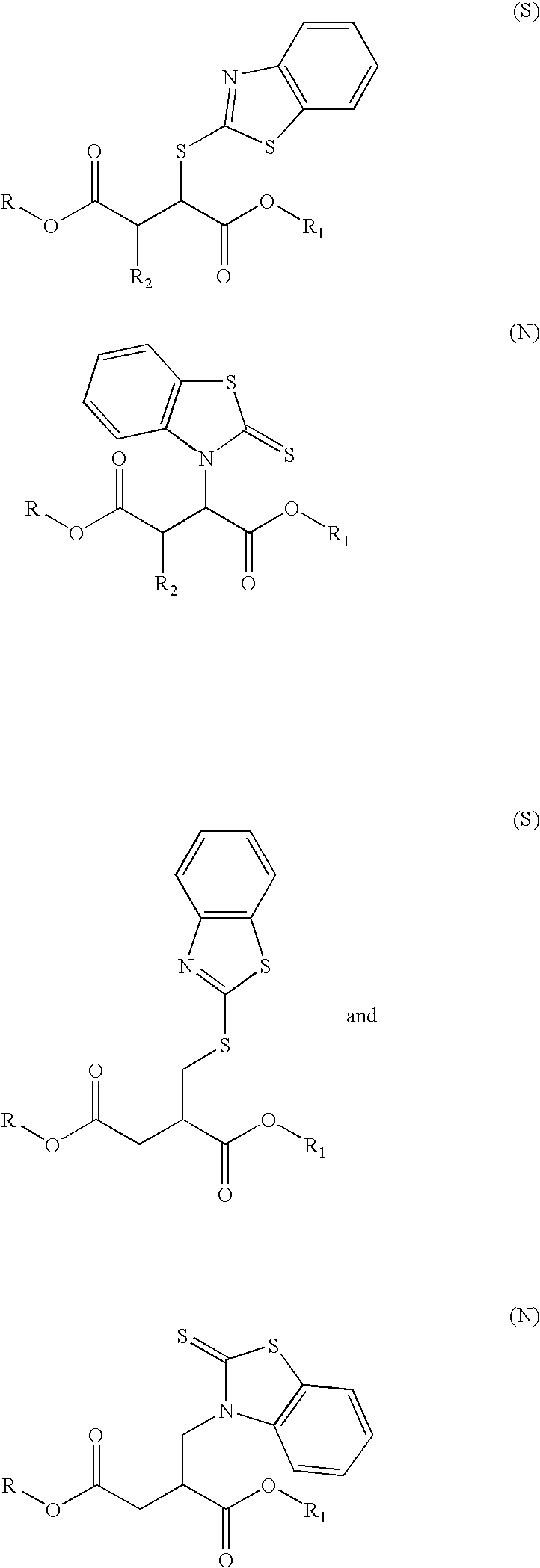

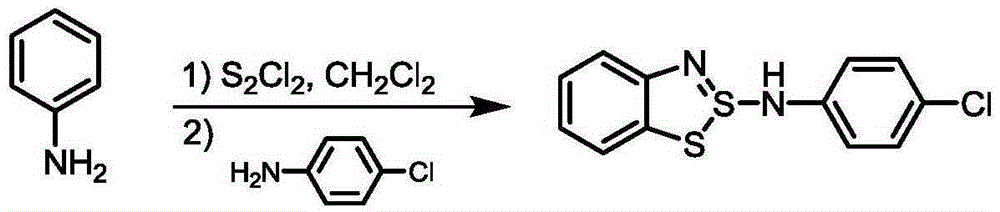

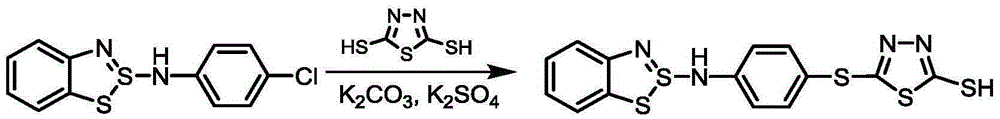

Lubricant and fuel compositions containing 2-(S(N)-mercaptobenzothiazole)succinic and methylene succinate esters

ActiveUS20060089271A1Lower performance requirementsReduce the amount requiredOrganic chemistryLiquid carbonaceous fuelsZincMercaptobenzothiazole

Disclosed herein is composition comprising: (A) a lubricant or a hydrocarbon fuel; (B) at least one additive that is a 2-(S(N)-mercaptobenzothiazole)succinic or methylene succinate esters of a structure defined herein; and optionally {circle around (C)}) at least one zinc dihydrocarbyldithiophosphate.

Owner:CHEMTURA CORP

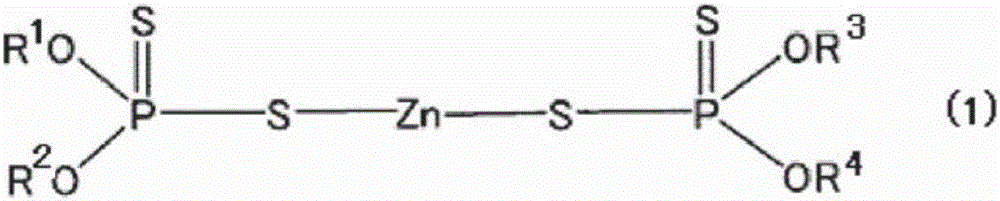

Tread rubber composition and pneumatic tire

Owner:SUMITOMO RUBBER IND LTD

Additive composition for ep greases with excellent antiwear and corrosion properties

A lubricant composition is provided as follows:At least 90% of a base grease;(a) a thiadiazole poly(ether)glycol complex in an amount which provides about 1500 to 3500 ppm sulfur;(b) molybdenum dihydrocarbyldithiophosphate in amount which provides about 77 to 450 ppm molybdenum; and(c) zinc dihydrocarbyldithiophosphate in an amount which provides about 600 to 1000 ppm zinc. An additive composition for grease, consisting of components (a), (b) and (c), is also provided.

Owner:VANDERBILT CHEM LLC

Rubber composition for treads and pneumatic tire

ActiveCN106574078AImprove puncture resistanceImprove wet grip performanceSpecial tyresPolymer scienceButadiene-styrene rubber

The present invention provides: a rubber composition for treads, which contains a diene rubber as a rubber component and is capable of achieving a good balance among wet grip performance, wear resistance and blowout resistance on dry roads; and a pneumatic tire having a tread which is produced using this rubber composition for treads. The present invention is a rubber composition for treads, which contains: a diene rubber containing a styrene butadiene rubber; zinc dithiophosphate; an inorganic filler which is composed of at least one substance selected from the group consisting of compounds represented by the formula described below, magnesium sulfate and silicon carbide, and which has a BET value of 5-120 m<2> / g and a linseed oil absorption of 30-80 ml / 100 g; and sulfur. Relative to 100 parts by mass of the diene rubber, the content of the zinc dithiophosphate is 0.2-15 parts by mass, the content of the inorganic filler is 1-70 parts by mass, and the content of zinc oxide is less than 2.5 parts by mass. In the formula of mM.xSiOy.zH2O, M represents at least one metal selected from the group consisting of Al, Mg, Ti, Ca and Zr, or an oxide or hydroxide of the metal; m represents an integer of 1-5; x represents an integer of 0-10; y represents an integer of 2-5; and z represents an integer of 0-10.

Owner:SUMITOMO RUBBER IND LTD

Alcohol-based foundry coating with abrasive resistance and fabrication method thereof

InactiveCN104014724AImprove wear resistanceGood suspensionFoundry mouldsFoundry coresFoundrySodium Bentonite

The invention discloses an alcohol-based foundry coating with abrasive resistance. The alcohol-based foundry coating is characterized by being prepared from the following raw materials in parts by weight: 1.2-3.4 parts of yellow dextrin, 0.4-0.7 part of magnesium chloride, 1-2 parts of lithium bentonite, 45-60 parts of kaoline, 30-40 parts of zirconite, 2-3 parts of sodium carboxymethylcellulose, 0.2-0.4 part of zinc dithiophosphate, 0.6-1.2 parts of triphenyl phosphite, 0.7-1.3 parts of white emulsion, 9-13 parts of shell, 3-5 parts of phenolic resin, 2-4 parts of hexamine, 45-60 parts of ethanol and 3-6 parts of assistant. The coating prepared by the method has the characteristics of being good in abrasive resistance, good in suspension property, good in surface smoothness, free of sediment, free of agglomeration, good in mobility, strong in anti-burn property, good in stability and good in application prospect.

Owner:佛山市顺德区采和装饰材料有限公司

Lubricating oil composition for internal combustion engine

ActiveUS20110021393A1Improve fuel saving effectSolve the lack of wear resistanceAdditivesAlkaline earth metalAntioxidant

The present invention provides a lubricating oil composition for internal combustion engine exhibiting excellent fuel-saving performance for a long period of time.The lubricating oil composition for internal combustion engine is characterized by containing a base oil having a kinematic viscosity as measured at 100° C. of 2 to 10 mm2 / s, an aromatic content (% CA) of 3 or less, and a sulfur content of 300 ppm by mass or less, and the following additives: (1) an alkaline earth metal salicylate-based detergent in an amount of 0.3 to 1.5 mass % as reduced to sulfated ash; (2) a zinc dihydrocarbyldithiophosphate in an amount of 0.03 to 0.10 mass % as reduced to phosphorus; (3) a succinimide-based ashless dispersant having a molecular weight of 500 to 4,000, and an alkenyl group or an alkyl group in an amount of 0.05 to 0.20 mass % as reduced to nitrogen; (4) a phenol-based ashless antioxidant in an amount of 0.05 to 3.0 mass %; (5) an amine-based ashless antioxidant in an amount of 0.05 to 3.0 mass %; (6) a molybdenum dithiocarbamate-based friction modifier in an amount of 0.01 to 0.15 mass % as reduced to molybdenum; and optionally, (7) a viscosity index improver in an amount of 0.01 to 8 mass % as resin amount, the unit mass % being based on the total amount of the composition.

Owner:IDEMITSU KOSAN CO LTD

Lubricating oil composition

ActiveUS20090131291A1Less in evaporation lossImprove the lubrication effectAdditivesMeth-Chemical composition

The present invention provides a lubricating oil composition which is less in evaporation loss even having a low viscosity and excellent in lubricating properties such as low-temperature viscosity characteristics and anti-seizure properties and in oxidation stability, suitable for use in engines, automatic transmissions, manual transmissions, final reduction gear units, and continuously variable transmissions. The lubricating oil composition comprises (A) a lubricating base oil and (B) a poly(meth)acrylate additive in such an amount that the kinematic viscosity at 100° C. of the composition (Vc) is from 3 to 15 mm2 / s, the viscosity index of the composition is from 95 to 200, and the ratio of the kinematic viscosity at 100° C. of (A) the lubricating base oil (Vb) to (Vc) (=Vb / Vc) is 0.60 or greater, further, (C) a metallic detergent, (D) an ashless dispersant and (E) zinc dithiophosphate, each in a specific amount.

Owner:NIPPON OIL CORP

Ship lubricant oil

The invention discloses a liquid composition of accessory ship diesel lubricate, which is characterized by the following: adopting middle basic oil as main component; mating fitful high-alkaline value calcium naphthenate, disuccinimide, dioctyl dithio-zinc phosphate, middle-alkaline alkyl calcium salicylate, high-grade lipoamide, polyoxypropylene polyoxyethylene block-typed polyether and silicon oil; allocating the system oil through scientific method.

Owner:彭美东

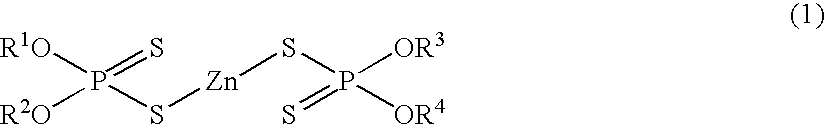

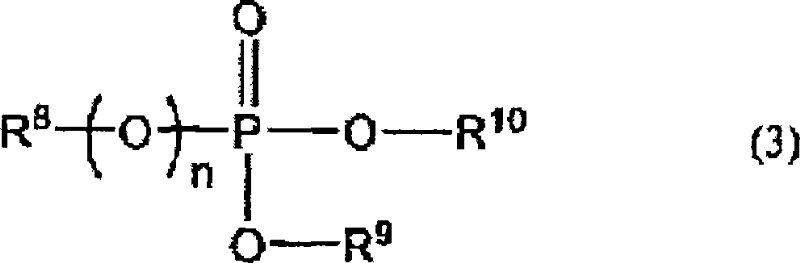

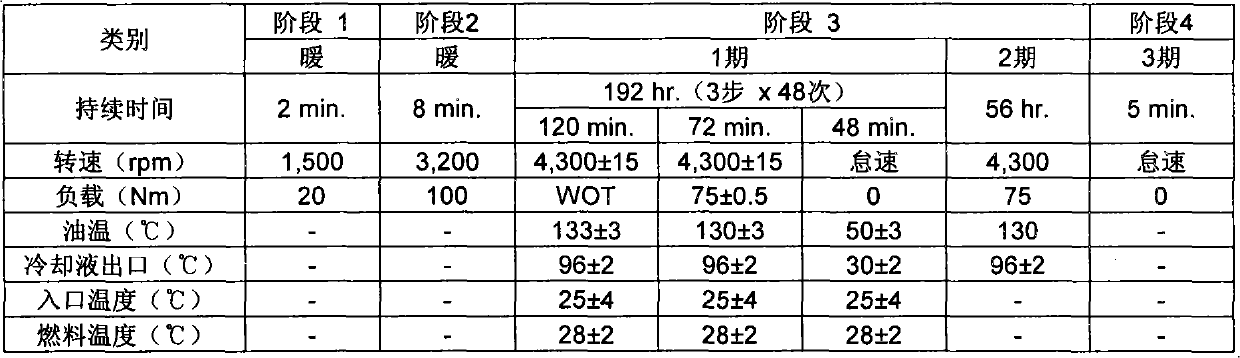

Diesel engine lubricating oil composition, preparation method, and application thereof

ActiveCN106753701AExcellent antioxidantImprove wear resistanceOrganic chemistryAdditivesSulfonateChemical composition

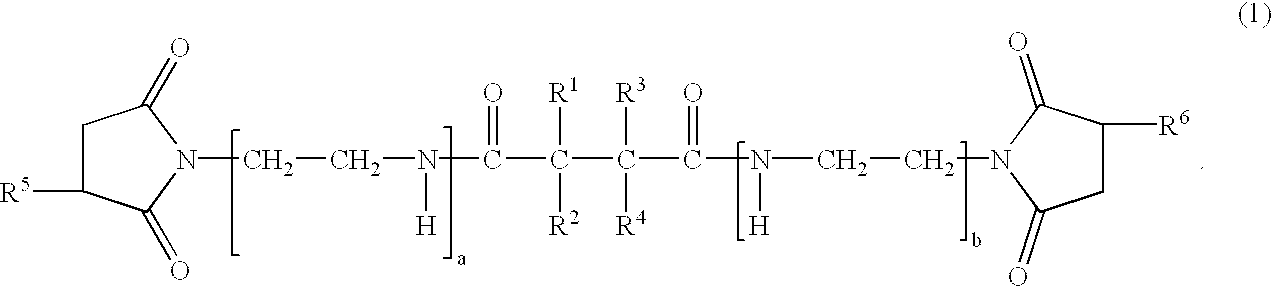

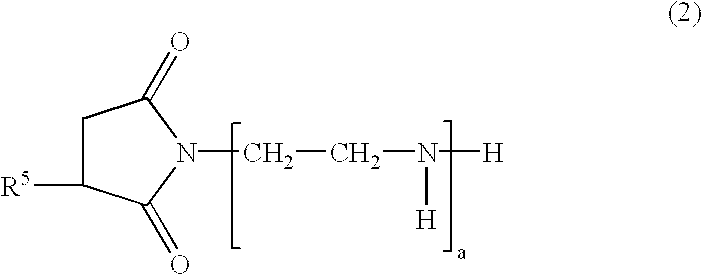

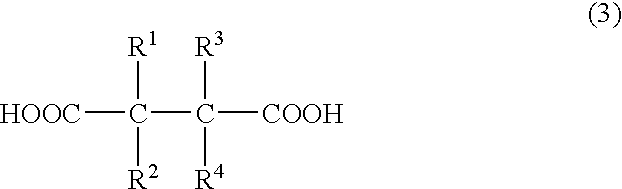

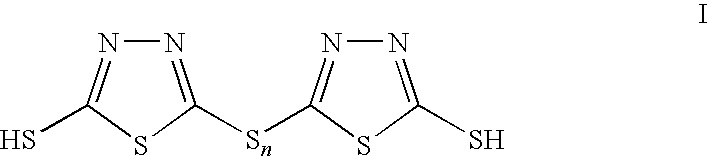

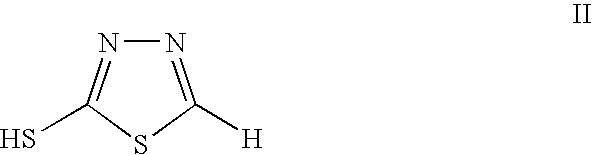

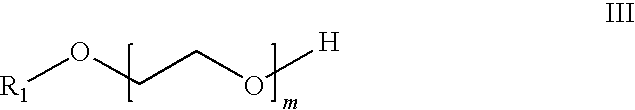

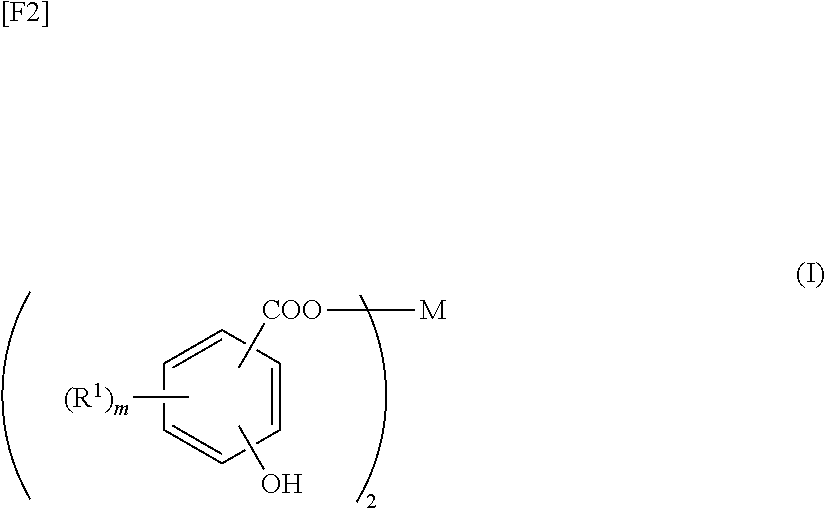

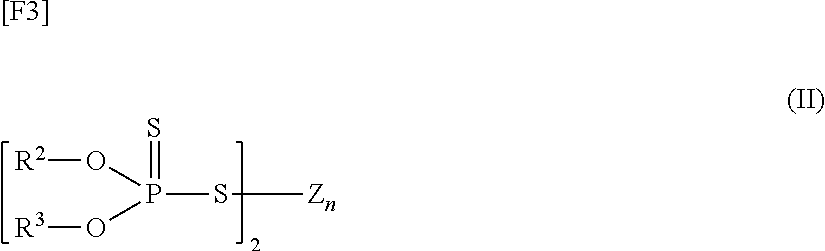

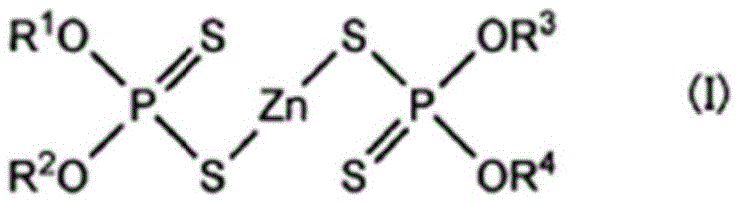

The invention provides a diesel engine lubricating oil composition, a preparation method, and an application thereof. The diesel engine lubricating oil composition includes: A) a multi-functional additive, which is represented as the formula (I); B) a boron-containing anti-oxygen-type polyisobutylene succinimide ash-free dispersant; C) at least one high-molecular-weight polyisobutylene succinimide ash-free dispersant; D) a sulfonate and / or a sulfurized alkylphenol salt; E) at least one dialkyl zinc dithiophosphate; F) an amine-type antioxidant and / or a phenolic ester antioxidant; and G) the balanced being lubricating basic oil. The lubricating oil composition is not higher than 0.09% in content of phosphorus and is not higher than 1% in sulfate ash content, has excellent anti-oxidizing, anti-wear and high-temperature cleaning performances, and can satisfy the demand of high-performance diesel engine lubricating oil at CH-4 and CI-4 grades.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alcohol-based foundry coating of light burned dolomite and fabrication method thereof

InactiveCN104014721AExpand the scope of useHigh temperature resistantFoundry mouldsFoundry coresFoundryPhosphoric acid

The invention discloses an alcohol-based foundry coating of light burned dolomite. The alcohol-based foundry coating is characterized by being prepared from the following raw materials in parts by weight: 0.4-0.7 part of phosphoric acid, 1.2-3.5 parts of polystyrene foam ball, 2.1-3.2 parts of light burned dolomite, 40-55 parts of graphite, 55-60 parts of chromite, 1-2 parts of attapulgite clay, 0.2-0.4 part of zinc dithiophosphate, 0.1-0.3 part of cocamidopropyl betaine, 2-4 parts of glass fiber, 11-14 parts of water hyacinth, 1-4 parts of phenolic resin, 2-3 parts of hexamine, 40-50 parts of ethanol and 3-6 parts of assistant. The water hyacinth is added to the raw materials after being processed at high temperature, the comprehensive utilization range of the water hyacinth is expanded, the cost is reduced, and the coating prepared by the method has the advantages of high temperature resistance, good fire resistance, caking property, coating property, excellent suspension property, easiness of smearing, good sand burning resistant effect and the like.

Owner:杨菊霞

Diesel engine lubricating oil composition for large-bore two-stroke cross-head diesel engines

ActiveUS20070149421A1Improve high temperature wear resistanceImprove thermal stabilityAdditivesTotal Base NumberChemical composition

A lubricating oil composition comprising a base oil of lubricating viscosity having a kinematic viscosity of 22 to 300 mm2 / s at 40° C. and dissolved or dispersed therein the following additives in the following amounts based on a total amount of the lubricating oil composition: (1) an overbased sulfurized alkylphenol calcium salt detergent in an amount of 0.1 to 1.6 wt. % in terms of calcium content, (2) an overbased calcium alkylbenzenesulfonate detergent in an amount of 0.6 to 2.1 wt. % in terms of calcium content, (3) a nitrogen-containing ashless dispersant in an amount of 0.005 to 0.1 wt. % in terms of nitrogen content, and (4) a zinc dihydrocarbyldithiophosphate in an amount of 0.01 to 0.1 wt. % in terms of phosphorus content, wherein the weight ratio of the overbased sulfurized alkylphenol calcium salt detergent to the overbased calcium alkylbenzenesulfonate detergent is in the range of 10:90 to 40:60 in terms of calcium content and wherein the lubricating oil composition has a total base number of 30 to 60 mg·KOH / g.

Owner:CHEVRON JAPAN

Lubricating oil composition, and sliding mechanism using lubricating oil composition

ActiveUS20150036962A1Reduce coefficient of frictionExcellent low frictionShaftsBearing componentsSulfonateAlkaline earth metal

Disclosed is a lubricating oil composition for low-friction sliding materials, which is used in a sliding mechanism where a DLC film containing hydrogen in an amount of from 5 atom % to 50 atom % is formed on at least one sliding surface.The lubricating oil composition contains, in the lubricant base oil therein and based on the total amount of the composition, (A) an organic zinc dithiophosphate in an amount of from 0.005% by mass to 0.12% by mass in terms of the phosphorus concentration therein, (B) an amide-based friction-reducing agent in an amount of from 0.05% by mass to 5.0% by mass, and (C) an alkaline earth metal salicylate-based detergent and / or an alkaline earth metal sulfonate-based detergent in an amount of from 0.05% by mass to 0.5% by mass in terms of the alkaline earth metal concentration therein.

Owner:IDEMITSU KOSAN CO LTD

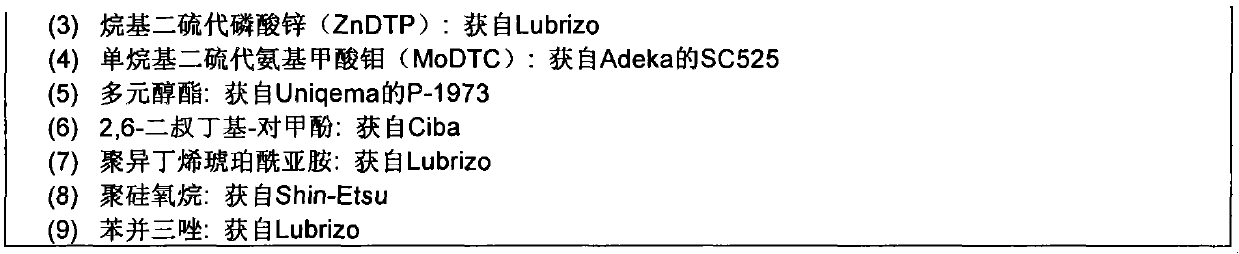

Long-life gasoline engine oil composition

The present invention provides a long-life gasoline engine oil composition, which contains a hydrogenated styrene-diene compound, zinc alkyldithiophosphate, monoalkyl molybdenum dithiocarbamate, polyol ester, a hindered phenol antioxidant, and a base oil. With this composition, vehicle fuel efficiency can be improved, oxidation stability can be increased, and the life span of engine oil can be extended.

Owner:HYUNDAI MOTOR CO LTD +2

Lubricating oil composition for diesel engines

Lubricating oil composition for use in diesel engines which comprises, in the base oil, not more than 0.3% by mass of sulphated ash, from 0.01 to 0.2% by mass of nitrogen in succinimides, from 0.05 to 0.12% by mass of zinc in zinc dithiophosphates, from 0.02 to 0.3% by mass of nitrogen in amine-based anti-oxidants, and from 0.01 to 0.08% by mass of boron, which further has a total value of [(zinc amount in zinc dithiophosphates) x (nitrogen amount in succinimides)] and [(zinc amount in zinc dithiophosphates) x (nitrogen amount in amine-based anti-oxidants) ] as regards the aforementioned of from 0.015 to 0.06, and which does not contain salicylate, phenate or sulphonate metallic detergents. The intention is to obtain a lubricating oil composition for use in diesel engines which does not contain a metallic detergent yet maintains excellent engine (piston) detergency while preventing DPF clogging, and which reduces valve-train wear.

Owner:壳牌润滑油日本株式会社

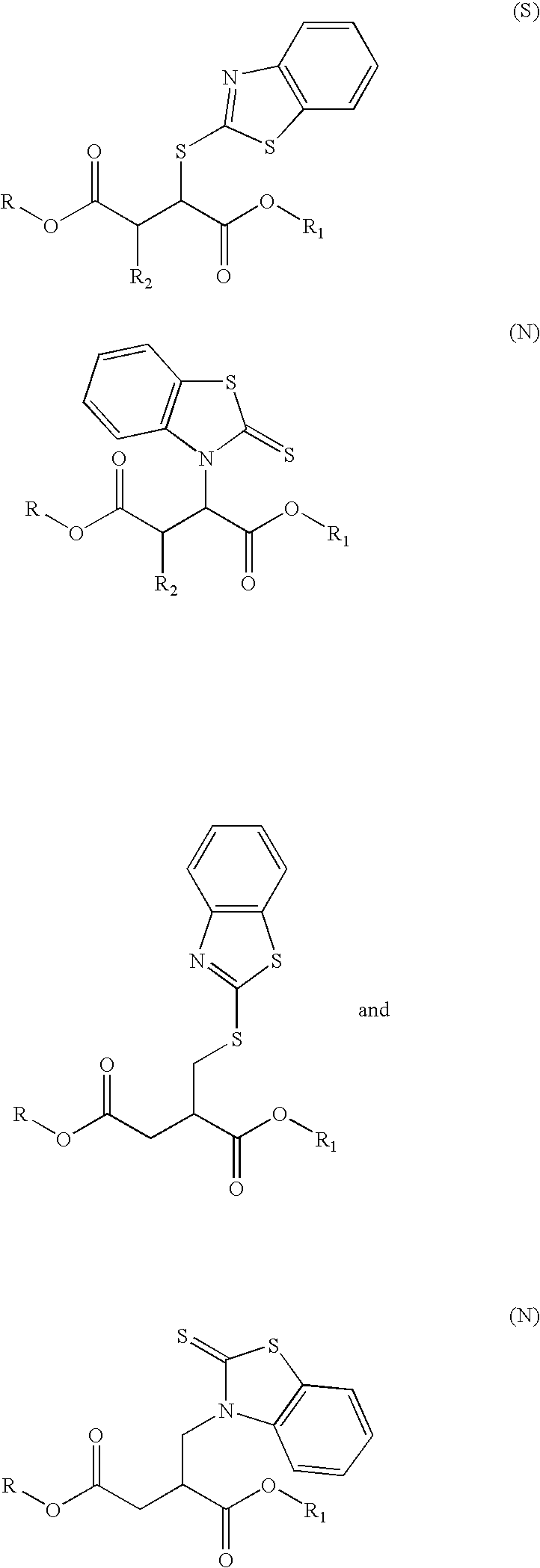

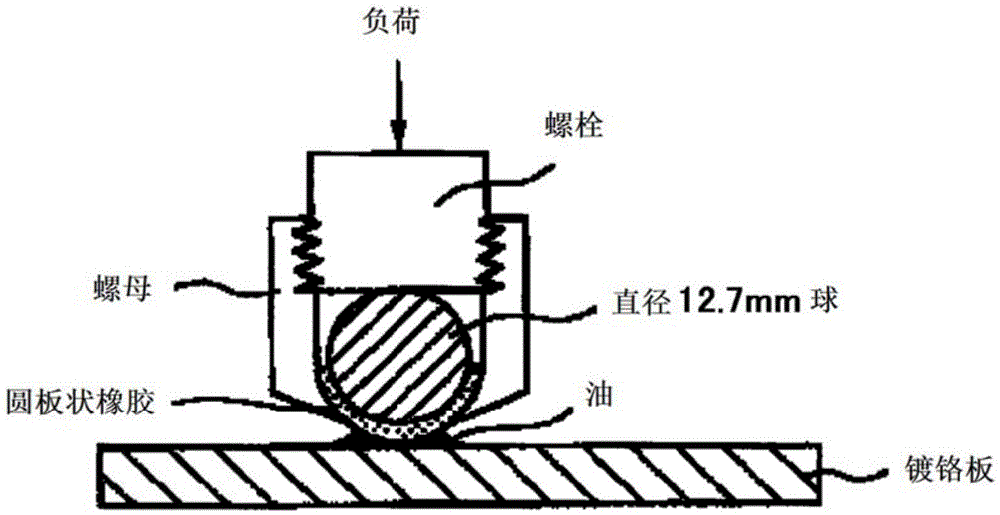

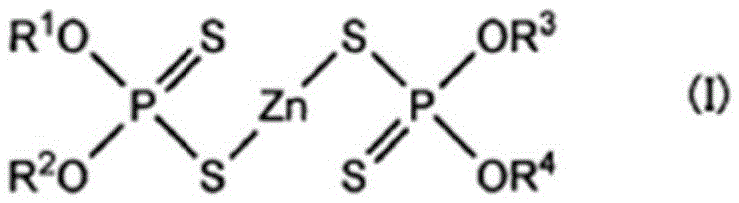

Lubricating oil composition for shock absorber and friction reduction method for shock absorber

ActiveCN105473694AReduce coefficient of frictionWithout compromising ride comfortAdditivesBase-materialsFriction reductionChemical composition

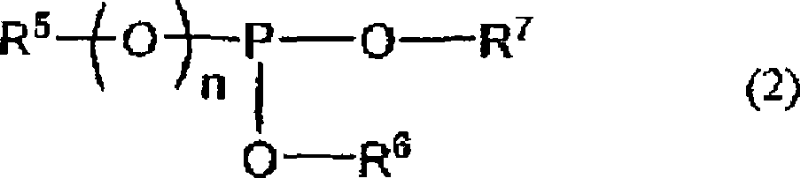

Provided is a lubricating oil composition for shock absorbers, having excellent thermal stability and capable of reducing the friction coefficient for rubber. The lubricating oil composition for shock absorbers is characterized by comprising: (A) a mineral oil and / or a base oil comprising a synthetic oil; (B) a zinc dithiophosphate indicated in general formula (I); (C) a fatty acid amide; and (D) a polyhydric alcohol ester. (In the formula, R1-R4 each independently indicate one type selected from a C6-20 linear, branched, or annular alkyl group and a C6-20 linear, branched, or annular alkenyl group.)

Owner:IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com